1. Introduction

The sustainability of irrigated agriculture in the semi-arid Mediterranean region is threatening by overexploitation of natural resources, and changes in agricultural land use. Agriculture is the dominant water consumer in the region accounting for 81% of total water use; it is particularly vulnerable to climate conditions due to its dependence, for most of the year, on adequate quantities of good-quality water [

1,

2]. The diet of people who have lived in the Mediterranean is high in vegetables and fruits and is considered by UNESCO as an "Intangible Cultural Heritage of Humanity" with multiple sustainable benefits. Tomato (

Solanum lycopersicum L.) and cucumber (

Cucumis sativus L.) are among the most popular consumable vegetables that are produced all year round in greenhouses and open fields.

Greenhouses have increased productivity with reduced inputs, including water and fertilisers. Lower indoor wind speeds and solar radiation values decreased evapotranspiration by 20 to 40%. For a field-grown tomato in Egypt, the ratio of product yield to water use increased from 3 kg m−3 to 17 kg m−3 in an unheated greenhouse and reached

45 kg m

−3 in a soilless growing system [

3]. Accordingly, the ratio of the total value of production to the total crop irrigation water supply in cucumber crops was estimated at 30.5€ m

−3 and 4.7€ m

−3, respectively, for a greenhouse and an outdoor crop in Cyprus [

4]. Recently, closed recirculation soilless based systems have gained increasing interest as an environmentally friendly cultivation technique. It is relevant that the water use of tomato plants in an open soilless based system in Spain was estimated at 28.8 L Kg

−1, as opposed to 14.06 L Kg

−1 for a closed recirculating system in the Netherlands [

5].

Greenhouses in the Mediterranean are often concentrated in relatively small agricultural areas often associated with environmental pollution-related problems (e.g., eutrophication). To cope with nitrate contamination of aquifers, Mediterranean countries in the EU (e.g., Greece, Spain, Italy, Cyprus) adopted nitrates directive 91/676/EEC complemented within the water framework directive 2000/60/EC. The Common EU Agricultural Policy (CAP) also promotes sustainable food production with climate-friendly practices and methods. Better water management could reduce fertiliser’s use and the use of energy for pumping water from deep wells in dry regions [

6]. Furthermore, under Eastern Mediterranean conditions, high energy consumption for greenhouse cooling and irrigation processes is needed. That has to do also with the significant amount of good-quality water, which is needed to be evaporated within the greenhouse air to alleviate the high radiation load [

7].

The United Nations 2030 Agenda for the sustainable development and zero-pollution ambition complementing by 2050 a climate-neutrality goal is supporting adaptation to climate change and promoting circular economy. On the other hand, the use of non-conventional water resources for irrigation, such as treated wastewater (TWW), has gained acceptance as an economic and viable alternative that could replace water and nutrient requirements of crops, simultaneously releasing equal quantities of potable water for other uses (i.e., domestic) [

8]. Indicatively, the European Union (EU) have recently adopted the EU 2020/74 regulation on the minimum requirements for water reuse, aiming at promoting TWW reuse in agriculture and ensuring environmental protection, human and animal health and simultaneously supporting adaptation to climate change and promoting circular economy. Strict quality criteria for TWW reuse and precautionary agricultural practices have been also set by international organisations (WHO, [

9]) and adopted by several countries worldwide, while other countries are following their own regulations (i.e., Israel, United States, China). Currently, TWW is reused for the irrigation or fertigation of high-value crops including tomato and cucumber [

10,

11].

Considering the above facts and the United Nations agenda for adaptation to climate change and sustainable development promoting circular economy and zero-pollution, we acknowledge that greenhouse cultivation in the Mediterranean region faces unique challenges. The objective of this work was to make a better understanding of various aspects of irrigation and fertigation management of fruiting crops such as tomatoes and cucumbers widely grown in Mediterranean greenhouses towards nutrients and water resources sustainability.

2. Irrigation Scheduling

Rational and efficient irrigation practices need to be addressed by growers from the perspective of regional water resources sustainability. Pressurised irrigation systems and proper irrigation scheduling, can save water and labour with higher returns on investment. Today, irrigation based on preset time intervals (i.e., time clock scheduling) with an automatic irrigation controller unit and solenoid valves (i.e., electric on-off valve) is among the most common irrigation methods. However, a mismatch between water supply and transpiration (i.e., water needs) often occurs. A better method of increasing water application efficiency is to apply water several times during a cycle with a minimum amount of water and fertilisers instead of just one application by the end of the drying cycle (i.e., pulse time clock scheduling). Nevertheless, crop water stress cannot be completely avoided, even in the case where automatic irrigation controllers are used [

12]. The concept of a closed-loop feedback irrigation control system is central to the water application efficiency with the use of simple sensors for climate, soil or substrate monitoring (such as the tensiometers, pyranometers) [

13]. Neto et al. [

14] proposed a real-time feedback irrigation control system for a tomato crop based on maintained drainage electrical conductivity (EC) under preset limits (3 ± 0.8 dS m

−1). Recent developments in the field have led to commercialise irrigation scheduling based on greenhouse air vapour pressure deficit (VPD) values [

15]. Automatically monitoring plants’ actual responses to changes in water (i.e., sap-flow, stem micro-variations, leaf temperature) on a 24-h basis is an important component in greenhouse irrigation [

16,

17]. Precision agricultural irrigation systems such as microcontrollers, programmable logic controllers and crop/sensor interfaces, programmed to control specific tasks that are characterised by sequential evolution [

18]. In light of recent events in precision agriculture systems, the application of the Internet of Things (IoT), considered challenges in terms of productivity, food security and sustainability by connecting people with things [

19]. Relatively, Zamora-Izquierdo et al. [

20] showed that savings between 30–80% in water and nutrient consumption could be obtained for a soilless tomato crop based on edge and cloud computing of a precision agriculture management platform. Similarly, Katsoulas et al. [

21] developed a web-based irrigation scheduling algorithm considering greenhouse climatic conditions, substrate water content and water balance for scheduling irrigation.

The method for estimating crop evapotranspiration (i.e., crop water needs) based on Class-A evaporation pan and local crop coefficient values (Kc values) adopted and widely used due to its simplicity in many regions.

Table 1 shows, the monthly and yearly evapotranspiration requirements for tomato and cucumber soil-based grown crops in Cyprus as estimated for different greenhouse types and outdoor crops [

22]. These are average site-specific values and subsequently, they will vary depending on the region, cultural practices and crops cultivars. For example, in another Mediterranean climatic region (Almería, Spain) for a tomato autumn-spring growing cycle a value of 557 mm was reported [

23].

However, a significant amount of water for the operation of active cooling systems in greenhouses should also be considered, as many times exceeds the water consumed by the plant [

24]. For example, in a spring-summer cucumber crop under Mediterranean climatic conditions, the measured daily water evaporation through a wetted pad was between 2.1 and 2.9 L per m

−2 of greenhouse floor area [

7]. In another case, a forced-air ventilation system raised evaporation between 3.2 and 10.1 L per m

−2 of the greenhouse floor [

25].

Much consideration has been given in evapotranspiration models for the accurate irrigation, simulation and management of the greenhouse climate based on greenhouse climatic data. The Penman–Monteith (P–M) equation model (Equation (1)), one of the most commonly used evapotranspiration models, was generated by combining the energy balance with the mass transfer theory (Equations (2) and (3)) [

26].

where

λ, latent heat of vaporisation (J kg

−1);

ΕT, evapotranspiration rate (kg m

−2 s

−1);

∆, slope of the saturation vapour pressure curve at temperature (kPa °C

−1);

γ, psychrometric constant (kPa °C

−1);

Rn, Net radiation intercepted by the crop (W m

−2);

ρ, Air density (kg m

−3);

Cp, Specific heat at constant pressure (J kg

−1 °C

−1);

Di, air vapour pressure deficit (kPa);

gc, crop stomatal conductances (m s

−1);

ga, crop aerodynamic conductance (m s

−1);

gt, total canopy conductance to water vapour transfer (m s

−1);

HC, is the sensible heat exchanged between the canopy and the air (W m

−2).

However, the accuracy of the P–M model pertains to variables that are not easily estimated such as the crop aerodynamic and stomatal conductances which are side and crop-specific. Recently, Nikolaou et al. [

26], estimated cucumber resistances (resistance is the inverse of stomatal conductance) in different greenhouse climatic treatments (

Table 2). The authors’ reported for the first time on resistances calculation based on equations of canopy-to-air temperature (

Tc −

Ta) difference for an open field derived from the literature. The canopy and aerodynamic resistance were also parameterised based on a short time interval measurement (i.e., ten minutes basis) of leaf temperature and climatic variables using (Equation (4)), by rewriting the energy balance equation (Equation (2)) and combining Equations (5)–(7).

where

es, saturation vapor pressure at

Tc (kPa);

ea, actual vapor pressure (kPa); (

es − ea), Saturation vapor pressure deficit (kPa);

rcp, is the canopy resistance (s m

−1);

rap, is the aerodynamic resistance of a non-stressed crop (s m

−1), other equation parameters are the same as above.

As expected, aerodynamic and crop resistance values were affected by the greenhouse climate control equipment, cropping period and growth. To overcome the complexity of resistance calculations, several authors’ [

27,

28,

29,

30] used the following simplified form of the P-M equation transpiration model, according to Baille et al. [

31].

where

LAI, leaf area index (m

2 leaf m

−2 ground);

A, value of equation parameters (dimensionless);

B, value of equation parameters (W m

−2 kPa

−1).

However, even in the latter case, the simplified equation model must firstly be calibrated, as

A and

B equation coefficients respond differently under prevailing environmental conditions (

Table 3).

Considering that leaf temperature to be a very good indicator of a plant water status, a modification of the simplified P–M evapotranspiration model proposed by Nikolaou et al. [

26] based on real-time leaf temperature sensors’ feedback data. The proposed model (Equation (9)) does not use as inputs the data required for solar radiation or complex VPD calculations. The model validated within different environmental conditions and growth periods of a year than those calibrated with good results and therefore it could be used, in Mediterranean greenhouses, in a model-based irrigation decision support system:

where

T, leaf temperature (°C); other equation parameters are the same as above.

Several researchers attempted to evaluate the impact of water stress on different crops aiming at optimising water application, stimulate plant growth and/or production. For example, Nuruddin et al. [

34] showed that the timing of the water stress in tomato plants was much more important rather than the magnitude of the stress. In another case, Hooshmand et al. [

35], did not find any differences in crop formation prior to the fruiting stage, despite different irrigation applications. However, Schröder and Lieth [

36] suggested that slight water stress between transplanting and flowering promote the first and second trusses of tomatoes. After the fruiting stage, partial root-zone drying in 85% of the water requirement significantly increased the water use efficiency (WUE) in a hydroponic tomato crop [

37]. For soil-based greenhouse cucumber, deficit irrigation at 80% of crop evapotranspiration in certain crop stages positively affected crop water productivity (WP) [

38].

Wang and Xing [

39] evaluated the effects of different fertigation and irrigation regimes on a soil-based tomato concluding that WUE, yield and quality were more sensitive to changes in irrigation regimes than to changes in fertilisers. Furthermore, the most significant variable that has an influence on tomato productivity, in low and medium technology greenhouses in Spain, was the total irrigation water supply and the length of the growing cycle rather than the greenhouse technology [

40]. Indeed, the frequency and the amount of irrigation varies with substrate water holding capacity and rooting volume. In rockwool slabs, where the rooting volume is very restricted, slabs may be watered five to six times per hour or up to 30 times per day under Mediterranean summer conditions. Harmanto et al. [

41] have demonstrated that higher water savings of up to 25% could be obtained in a greenhouse drip irrigation system compared to outdoors tomatoes. In a soilless-based grown system increasing the irrigation interval (same daily amount applies) resulted in lower drainage emissions’ outflow for a cucumber crop. In line, Rodriguez-Ortega et al. [

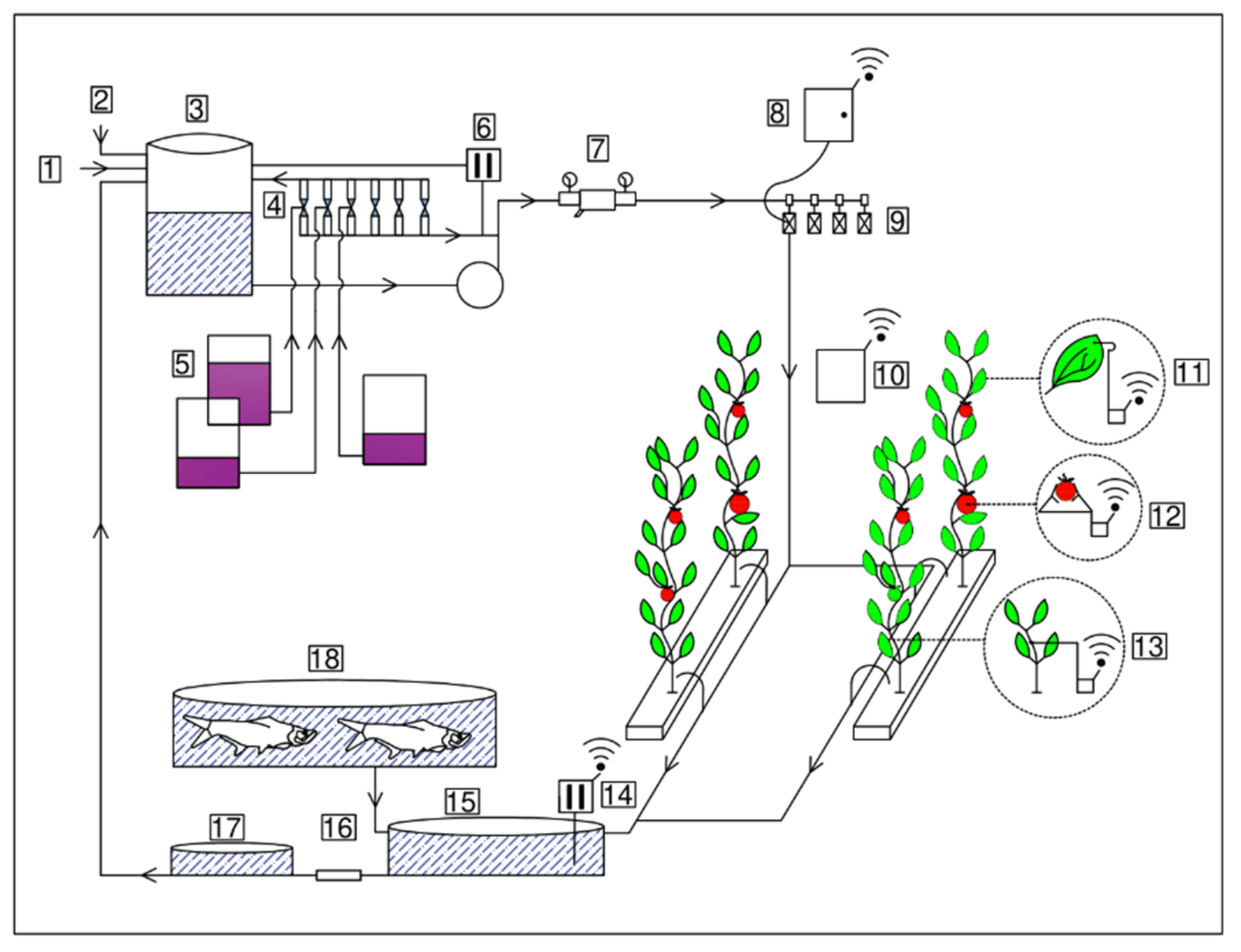

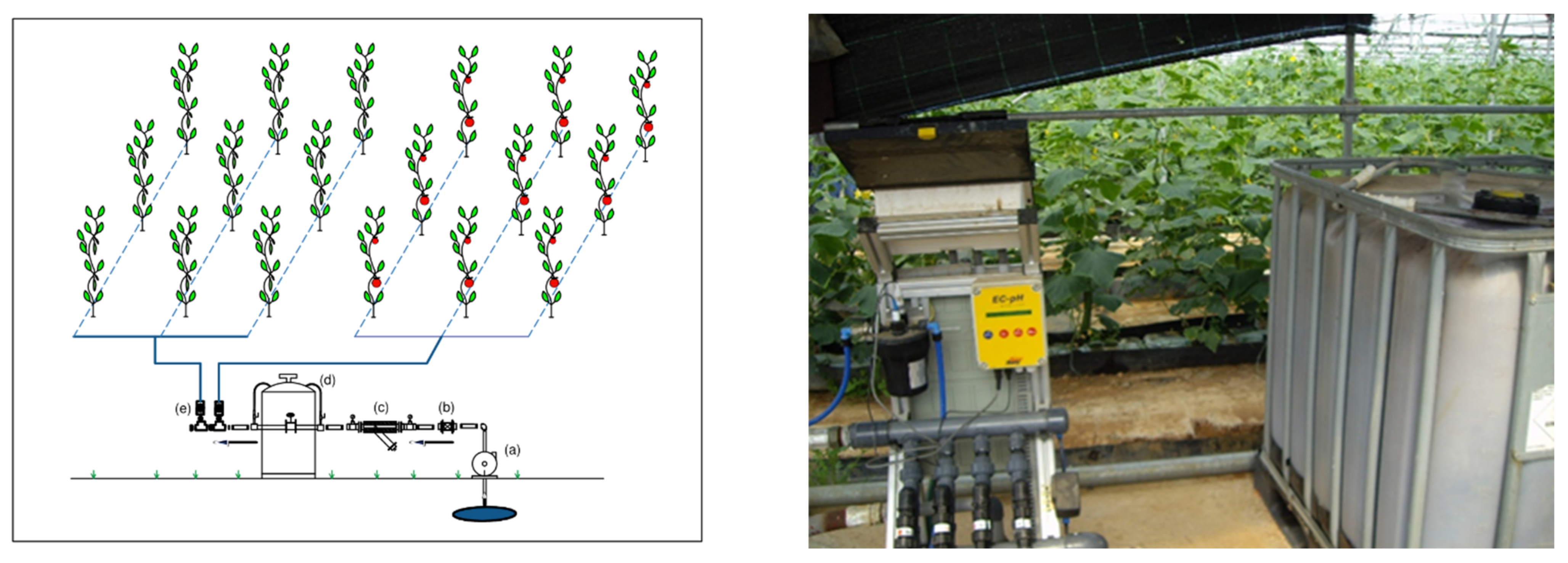

18] also recommended a higher irrigation frequency with fewer amounts of water for the optimal irrigation management of tomatoes cultivated in a soilless perlite grown system. Open-drain soilless systems (

Figure 1) may in addition reuse drainage in a second soil greenhouse or open field crop achieving a reduction in emissions to the water of up to 50% [

42]. Whichever irrigation system is used inside the greenhouse it must meet the daily fluctuation of water needs. The use of data acquisition systems and modelling in high-tech greenhouses will increase the water and fertilisers supply.

Table 4 shows WUE values of cucumber and tomato crops in different locations and growing conditions.

3. Water Quality

Water quality is an important factor in irrigation management. The most common water quality-related problems are related to water salinity, specific ions toxicity and the infiltration rate, while other miscellaneous constraints include the corrosion of irrigation equipment [

44]. Particularly, one of the most important aspects of low-quality saline water is the accumulation of salts in the rhizosphere and the restriction of plant growth, especially in arid and semi-arid regions worldwide. Soil salinity is estimated by electrical conductivity (EC) measurements, which corresponds to the osmotic potential outside the roots [

45]. It is well known that salinity reduces plant growth and there are differences in tolerance to salinity among different species and between cultivars [

46].

Table 5, presents the assessing permissible levels for tomato and cucumber crops’ water and soil extract electrical conductivity (EC

w, water salinity; EC

e, soil extract salinity) without yield reduction and the percentage of yield reduction per unit increase in salinity based on Food and Agricultural Organization-FAO [

44].

From

Table 5, one can be observed that EC

e is expected to be about 1.5 higher than the EC

w considering a 15–20% leaching fraction and a percentage of 40-30-20-10% of water use from the upper to the lower root zone. However, in greenhouses the salt concentrations in the soil many times increased in much higher values. It is common, after the end of the cropping period EC

e values of up to 15 to 18 dS m

−1 (unpublished data, Cyprus Department of Agriculture). This is mainly because of the excess application of fertilisers, the minimum leaching, and the use of low irrigation water quality. Tomato and cucumber are classified as moderately sensitive crops, in relation to water salt content and the toxicity of specific ions. Cucumber is classified as moderately sensitive to boron concentration in the irrigation water (maximum concentration 2.0 mg L

−1) and tomato as a moderate tolerant with an upper threshold limit at 4.0 mg L

−1. Maximum permissible concentrations of chlorides for tomato and cucumber without yield losses estimated at 875 (mg L

−1) [

44]. Local climatic and soil conditions should be taken into account when evaluating salinity and boron tolerance toxicity. For example, plants in gypsiferous soils may tolerance about 2 dS m

−1 higher EC

e compared with soil containing a low CaCO

3 content indicated in

Table 5. For instance, Phogat et al. [

47] suggested that annual gypsum application at a rate of 1.7 t. ha

−1 together with a leaching fraction of at least 20% was adequate for managing this soil salinity and sodicity hazard. The calculated soil salinity threshold values for yield decline were 1.73 dS m

−1 for EC

e and 2.52 dSm

−1 [

48]. Controversially, in soilless tomato crops, water with electrical conductivity up to 4.0 dS m

−1 positively affected photosynthetic rate, crop growth [

49] and fruit taste quality characteristics. Recommended EC, Na and Cl upper limits for open drain systems been at 1.0 dS m

−1, 3.0 and 2.8–3.0 mmol L

−1. In semi-closed or closed systems, those values should be lower than 0.5 dS m

−1, 1.5 and 1.5 mmol L

−1.

4. Alternative Water Resources

Alternative water resources (i.e., desalination, captured condensate, brackish, seawater as a complementary irrigation source) have been tested in an attempt to develop new water resources for greenhouse horticulture. Treated wastewater (TWW) reuse may have a lower environmental impact than other alternative water supplies and may offer a range of economic, environmental and social benefits.

The main concern in using TWW arises from the potential pathogenic and toxic pollution of agricultural produce. However, major technological advances have been made with respect to producing safe treated wastewater TWW (i.e., membrane bioreactors, advanced oxidation processes, disinfection), while also several comprehensive guidelines and criteria have been set and implemented to ensure both environmental sustainability and public health from potential negative effects of TWW reuse [

50,

51]. All regulations and criteria proactively incorporate extensive risk management schemes for the production of TWW of specific quality required for a particular need. Therefore, high-quality TWW (tertiary treated and disinfected) is now considered suitable for the irrigation of all crops that are consumed raw, given that some specific requirements are satisfied (irrigation method).

Several studies have investigated the impacts of TWW reuse for the irrigation of several crops, including vegetables, on the uptake and bioaccumulation of potentially toxic elements in the edible parts of such plants, as well as on the microbial contamination of these tissues. Results revealed that high-quality tertiary treated effluent can be safely reused for the irrigation of vegetable crops either grown in an open field or under protected agriculture, including tomatoes [

52,

53,

54], cucumber [

55] and other vegetables [

56,

57,

58].

The efficiency and advantages, as well as potential drawbacks, regarding the use of TWW for the fertigation and irrigation of tomato and cucumber plants under greenhouse conditions are closely related to the quality of TWW used; i.e., the source of sewage, the treatment process applied, the physicochemical properties and the microbial load of TWW used [

10]. Bar-Tal et al. [

59] reviewed the practices that simultaneously optimise the water and nutrient use efficiency in fertigation and irrigation with TWW under both open field and greenhouse cultivation, by presenting the Israeli experience (where TWW irrigation is a common practice), highlighting that the characteristics and composition of TWW are governing its potential use and benefits. Risks and challenges concerning TWW use are fouling of pipes and clogging of emitters and salinity development due to high salt concentrations in TWW compared with freshwater, whereas benefits concern the possible contribution of TWW components to availability of nutrients, especially N, P, K and micronutrients [

59]. Recently, the effects of using municipal solid waste-derived compost as a soil amendment (5, 10, 20, 40%), fertigation and/or TWW irrigation on yield, plant physiology and fruit quality of tomato plants (

Solanum lycopersicum L.) grown in pots under greenhouse conditions, were evaluated [

60]. TWW irrigation supported the mineral status of the growing media, while also increasing the biomass (≥20%) of plants, even though it did not affect the yield. Though, the combination of high compost ratios and TWW irrigation negatively affected stomatal conductance, leaf photosynthesis, chlorophyll fluorescence and internal CO

2 concentration. Fruit ascorbic acid, acidity, total soluble solids, firmness, and total phenolics were increased with TWW irrigation, but marketability did not. Also, lower levels of bacteria such as the Escherichia coli and total coliform were counted on fruit from TWW-irrigated plants compared with control, highlighting that TWW could be safely used for the irrigation of tomatoes in the greenhouse, following safety aspects [

60]. Moreover, the effects of oxyfertigation (enrichment of the nutrient solution used with oxygen) of tomato crops grown on rockwool slabs and irrigated with TWW under Mediterranean greenhouse conditions, were assessed [

61]. Results showed that TWW can be safely reused for the irrigation of tomatoes as such since oxyfertigation did not affect any of the irrigation and fertigation parameters evaluated, nor the aboveground biomass production rate and the quality and marketability of fruits. As far as cucumber cultivation is concerned, Pilatakis et al. [

62] evaluated the impacts of direct application of primary and secondary TWW on plant growth and development in hydroponically grown cucumber. Both TWW sources applied resulted in increased yield, despite the fact that plant biomass, root length, leaf chlorophyll levels and total fruit number were not modulated among treatments. TWW irrigation resulted in disease spread in roots and fruits (by cross-contamination), thus further exploitation is necessary for microbial load reduction when TWW is applied.

Advances in analytical techniques over the last couple of decades revealed the presence of various contaminants of emerging concern (CEC) in TWW applied for irrigation, as the applied wastewater treatment technologies fail to completely remove such contaminants from the final treated effluent. CEC may include pharmaceuticals and personal care products (PPCPs), antibiotic-resistant bacteria (ARB) and resistance genes (ARGs), among others. The fate of these contaminants in the environment (i.e., soil, ground/surface waters, plants/crops) in the framework of TWW reuse applications is still under intensive investigation [

22,

63]. By exposing tomato plants grown in silica sand in pots under greenhouse conditions to three widely prescribed pharmaceuticals (10 μg L

−1) (diclofenac, DCF; sulfamethoxazole, SMX; trimethoprim, TMP) through the irrigation solution, Christou et al. [

64] showed that plants can uptake and accumulate SMX and TMP in their fruits. Moreover, carbohydrate and soluble solids (total sugars, sucrose, glucose, fructose) content were significantly impacted by all studied pharmaceutical active compounds PhACs applied, while the plant productivity was unaffected.

Worth noting is the fact that the studied pharmaceuticals exerted, at least to some extent, significant impacts on the abundance of transcripts related to the biosynthesis and catabolism of sucrose. The extent of uptake of CEC by tomato and cucumber plants is largely dependent on environmental factors (i.e., soil environment, pH, organic matter content, clay content, climatic conditions such as temperature and humidity), plant physiology factors (i.e., the lipid content of roots) and plant species and genotype [

64,

65]. To this effect, Goldstein et al. [

66] reported that the concentration of CECe in tomato fruit were much lower compared to that in the cucumber fruit exposed to CECe through the nutrient solution. This was attributed because the functions and physiological responses of cucumber fruits were similar to those of leaves (water transpiration, direct fixation of atmospheric CO

2) [

67]. In addition, integrated modelling approaches have been lately developed aiming to predict the extent of pharmaceuticals’ uptake by crop species, taking into account several factors governing CEC uptake, like soil properties, plant species and physiology, climatic conditions, etc. [

68,

69].

Another major challenge regarding TWW reuse in agriculture is that it may lead to the increase in the exposure of livestock and humans to ARB and ARGs, as ARGs can spread among soil and plant-associated bacteria, a fact that may have serious human health implications [

70,

71]. The uptake and bioaccumulation of antibiotics by TWW irrigated plants (or plants grown in soils amended with manure or biosolids) may lead to antibiotics-mediated selective pressure in plant endophytes. Importantly, the composition of the endophytic microbiome and its associated resistome appears to be linked to the corresponding soil microbiome and resistome [

72]. The microbiome and its associated resistome of tomato plants grown in fields and irrigated with TWW or control water (in areas not affected by TWW irrigation or other major human activities) were recently examined. Results revealed that agricultural practices, such as soil amendment and fertilisation were the main drivers of ARGs loads on fruits, rather than TWW irrigation [

73,

74]. Therefore, whether or not TWW irrigation and fertigation represent a significant risk of exposure to ARBs, ARGs, and pathogens for the consumers is still a matter of discussion [

71,

75].

6. Conclusions

The semi-arid Mediterranean region has been classified as a global climate change hot spot, already witnessing the impacts of climate change, including a significant decrease in precipitation and an increase in mean air temperatures values. The overexploitation of groundwater resources has resulted in the lowering of water level, seawater intrusion and groundwater quality deterioration. In fact, crop yield is significantly affected by the quality of groundwater, therefore, it has been of great economic and environmental concern. The scarcity of water greatly affects the sustainability of irrigated agricultural crops. Rural areas are expected to experience major impacts of climate change on water availability and supply, infrastructure and agricultural incomes, reduced agricultural production and increase food insecurity with socio-economic consequences, such as increasing poverty and migration.

Recognising the critical role of water, this review article draws attention to the challenges that greenhouse growers in arid and semi-arid areas in the Mediterranean facing related to water and nutrient supply for tomato and cucumber crops. Indeed, for several countries within the EU (such as Spain, Italy, Greece), the water policy has been driven to a large extend by the EU legislation, which provides the framework for comprehensively addressing water protection and for achieving good status for inland surface waters, coastal waters and groundwater. Various management plans were developed and adopted to strengthen aquatic ecosystems and promote the resilience of the environment to climate change, therefore manage inputs (i.e., water and fertilisers) in a more acceptable manner.

More recently, in many cases, technological improvements in irrigation and water-saving practices have been adopted by growers. However, the adoption is relatively low because growers do not benefit directly from water-saving and these systems are of high cost. The lack of a precise internal control of the climate in protected cropping systems and the insufficient water and nutrients supply, increased biotic and abiotic stresses and negatively affected yield. As a consequence, water and nutrients are depleted and potentially lead to groundwater contamination. For this reason, factors controlling the crop water uptake should be properly considered for proper irrigation scheduling as discussed in this paper. However, farmers’ education and training under local conditions are one of the crucial pre-conditions for the sustainable implementation of many of these options.

This review article is a timely contribution as it cuts across the water and fertiliser sectors and summarises the highest level of knowledge on water and fertilisers management in relation to variations in environmental conditions and the challenges we face that can help in sustainably strengthening food security.