Evaluation of the Storage Characteristics in Maintaining the Overall Quality of Whole and Fresh-Cut Romaine Lettuce during MA Storage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Materials

2.2. Packaging Materials and Storage Conditions

2.3. Atmosphere Analysis and Sensory Qualities

2.4. Statistical Analysis

3. Results and Discussion

3.1. Respiration Rate and Ethylene Production Rate

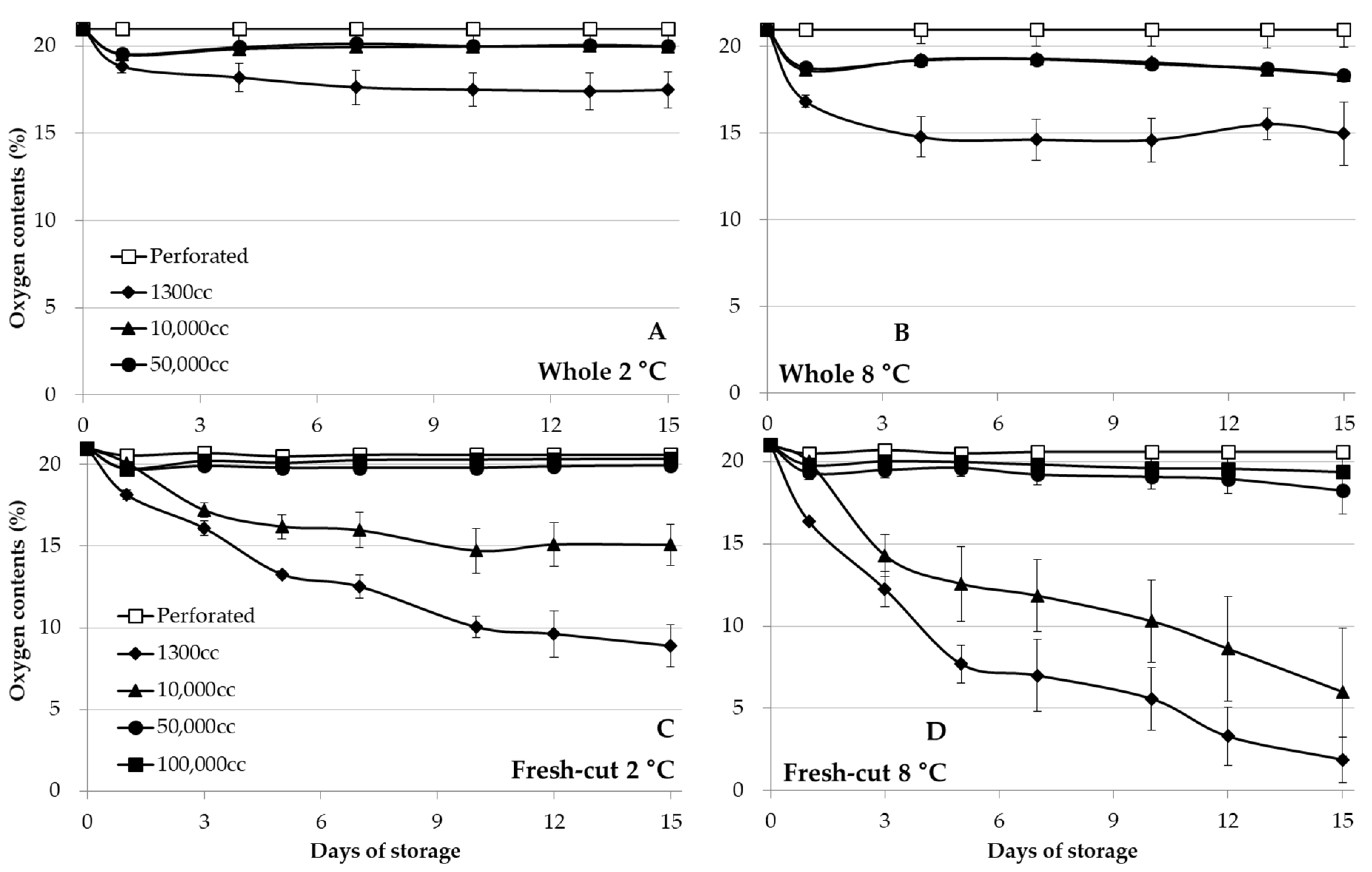

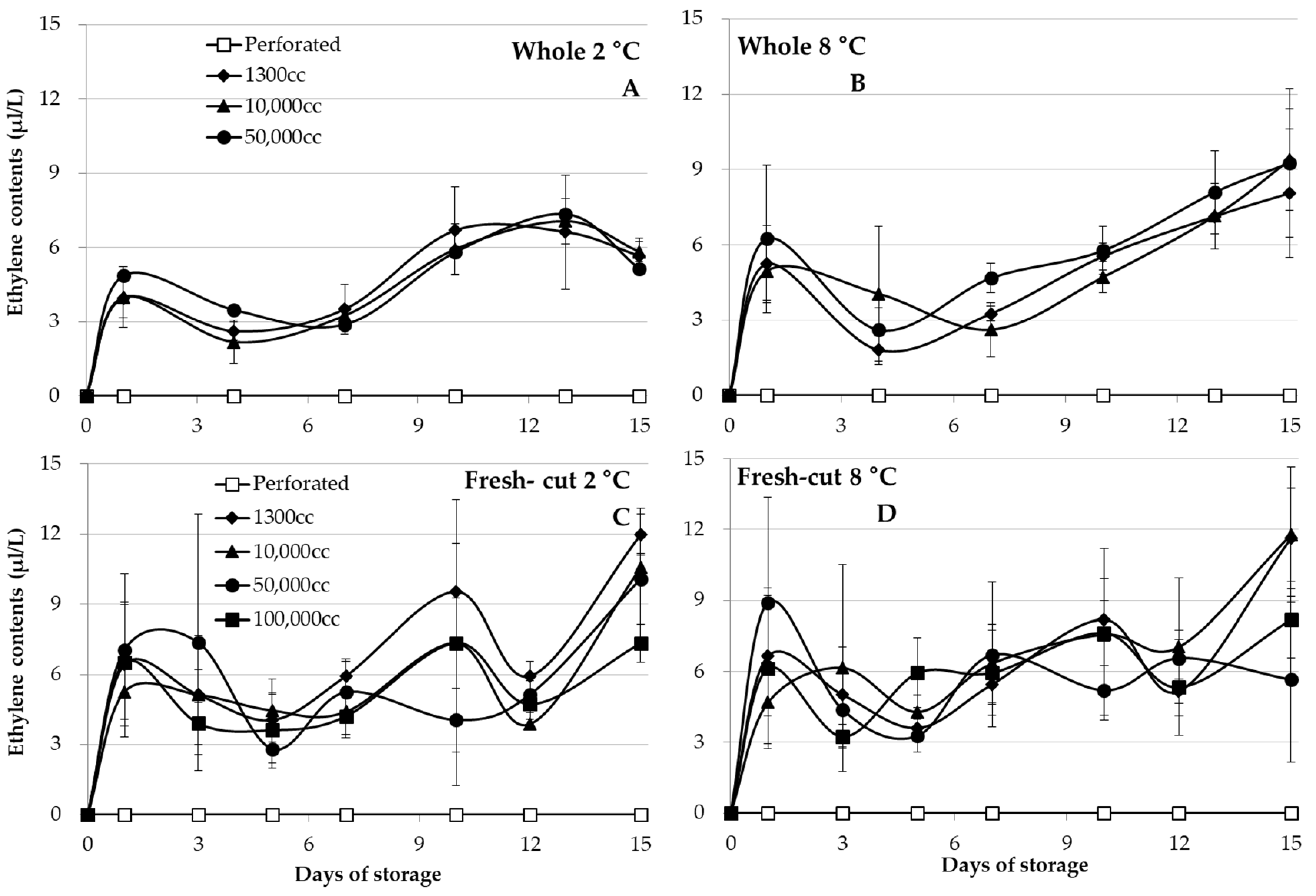

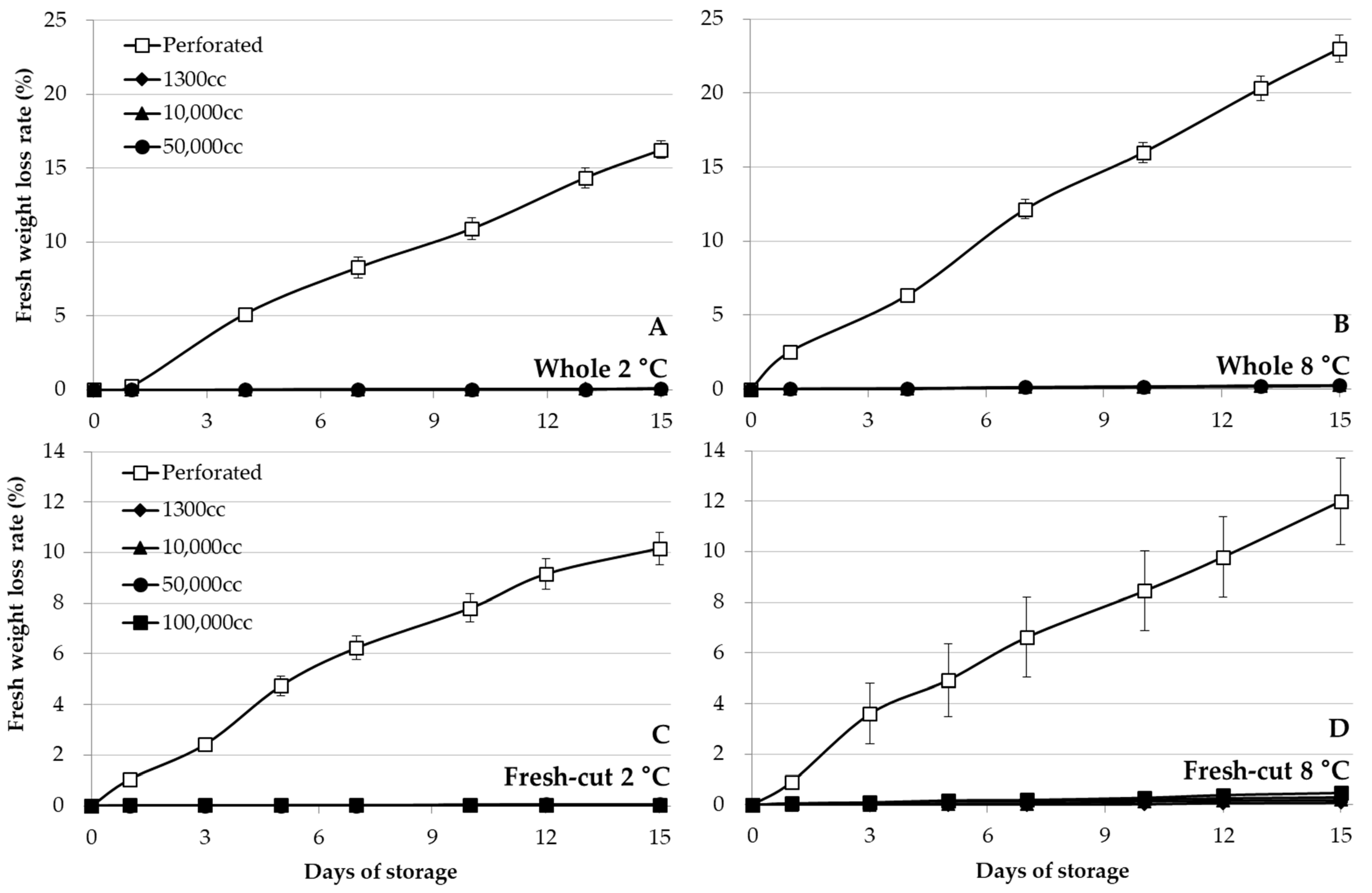

3.2. Atmosphere Analysis

3.3. Biochemical Traits and Sensory Qualities

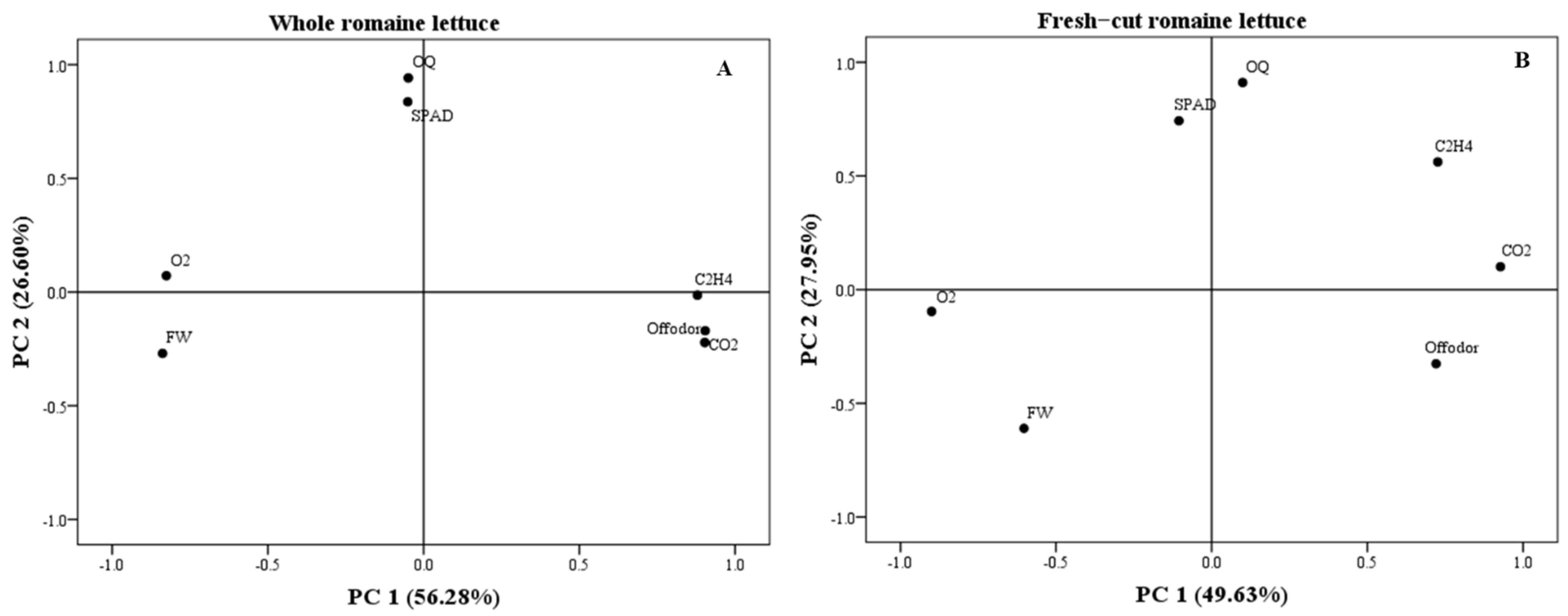

3.4. Pearson’s Correlation and Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hodges, D.M.; Toivonen, P.M.A. Quality of fresh-cut fruits and vegetables as affected by exposure to abiotic stress. Postharvest Biol. Technol. 2007, 48, 155–162. [Google Scholar] [CrossRef]

- Oh, S.Y.; Yu, Y.G.; Lee, G.J. Economical management of summer season harvest on cut rose (Rosa hyrida L.). Korean J. Hortic. Sci. Technol. 2009, 27, 130. [Google Scholar]

- Bae, J.M.; Lee, D.U.; Jeong, M.C.; Choi, J.H. Change of quality characteristics in fresh-cut ‘Romaine’ lettuce by heat treatment. Korean J. Food Preserv. 2016, 23, 27–33. [Google Scholar] [CrossRef]

- Danilo, L.; Cocetta, G.P.; Ferrante, A. Optimization of LED lighting and quality evaluation of romaine lettuce grown in an innovative indoor cultivation system. Sustainability 2019, 11, 841. [Google Scholar] [CrossRef] [Green Version]

- Saini, R.K.; Shang, X.M.; Ko, E.Y.; Choi, J.H.; Keum, Y.S. Stability of carotenoids and tocopherols in ready-to-eat baby-leaf lettuce and salad rocket during low-temperature storage. Int. J. Food Sci. Nutr. 2016, 67, 489–495. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.S.; Chung, D.S.; Choi, J.W.; Jo, M.A.; Lee, Y.S.; Chun, C.H. Effects of storage temperature and packaging treatment on the quality of leaf lettuce. Korean J. Food Preserv. 2006, 13, 8–12. [Google Scholar]

- Chang, M.S.; Kim, J.H.; Lee, J.S.; Park, M.H.; Chang, E.H.; Hong, Y.P. Comparison of the shelf-life of commercial salad lettuces based on packaging types. Korean J. Food Preserv. 2020, 27, 255–260. [Google Scholar] [CrossRef]

- Chisari, M.; Todaro, A.; Barbagallo, R.N.; Spagna, G. Salinity effects on enzymatic browning and antioxidant capacity of fresh-cut baby romaine lettuce (Lactuca sativa L. cv. Duende). Food Chem. 2010, 119, 1502–1506. [Google Scholar] [CrossRef]

- Luna, M.C.; Tudela, J.A.; Tomás-Barberán, F.A.; Gil, M.I. Modified atmosphere (MA) prevents browning of fresh-cut romaine lettuce through multi-target effects related to phenolic metabolism. Postharvest Biol. Technol. 2016, 119, 84–93. [Google Scholar] [CrossRef]

- Manolopoulou, H.; Lambrinos, G.R.; Chatzis, E.; Xanthopoulos, G.; Aravantinos, E. Efffect of temperature and modified atmosphere packaging on storage quality of fresh-cut Romaine lettuce. J. Food Quality 2010, 33, 317–336. [Google Scholar] [CrossRef]

- Lee, J.S.; Lee, H.E.; Lee, Y.S.; Chun, C.H. Effect of packaging methods on the quality of leaf lettuce. Korean J. Food Preserv. 2008, 15, 630–634. [Google Scholar]

- Kim, J.Y.; Han, S.J.; Wang, L.X.; Choi, I.L.; Kang, H.M. Comparison of post-harvest character and storability at several temperature for Lactuca indica L. baby and adult leaves. Prot. Hortic. Plant Fact. 2019, 28, 172–177. [Google Scholar] [CrossRef]

- Artes, F.; Conesa, M.A.; Hernandez, S.; Gil, M.I. Keeping quality of fresh-cut tomato. Postharvest Biol. Technol. 1999, 17, 153–162. [Google Scholar] [CrossRef]

- Mudau, A.R.; Soundy, P.; Araya, H.T.; Mudau, F.N. Influence of modified atmosphere packaging on postharvest quality of baby spinach (Spinacia oleracea L.) Leaves. Hortscience 2018, 53, 224–230. [Google Scholar] [CrossRef]

- Mastrandrea, L.; Amodio, M.L.; Pati, S.; Colelli, G. Effect of modified atmosphere packaging and temperature abuse on flavor related volatile compounds of rocket leaves (Diplotaxis tenuifolia L.). J. Food Sci Technol. 2017, 54, 2433–2442. [Google Scholar] [CrossRef]

- Boerzhijin, S.; Makino, Y.; Hirai, M.Y.; Sotome, I. Yoshimura, M. Effect of perforation-mediated modified atmosphere packaging on the quality and bioactive compounds of soft kale (Brassica oleracea L. convar. acephala (DC) Alef. var. sabellica L.) during storage. Food Packag. Shelf Life 2020, 23, 100427. [Google Scholar] [CrossRef]

- Park, W.S.; Kim, H.J.; Chung, H.J.; Chun, M.S.; Kim, S.T.; Seo, S.Y.; Lim, S.H.; Jeong, Y.H.; Chun, J.W.; An, S.K.; et al. Changes in carotenoid and anthocyanin contents, as well as antioxidant activity during storage of lettuce. J. Korean Soc. Food Sci. Nutr. 2015, 44, 1325–1332. [Google Scholar] [CrossRef]

- Tudela, J.A.; Hernández, N.; Pérez-Vicente, A.; Gil, M.I. Growing season climates affect quality of fresh-cut lettuce. Postharvest Biol. Technol. 2017, 123, 60–68. [Google Scholar] [CrossRef]

- Choi, I.L.; Lee, Y.B.; Kim, I.S.; Kang, H.M. A comparison of the storability in MA storage and the quality of paprika fruit among cultivars. J. Bio-Environ. Control 2012, 21, 252–260. [Google Scholar]

- Lee, J.H.; Oh, S.I.; Lee, J.S.; Lee, A.K. Change in quality of cut hydrangea flowers as affected by storage period and temperature. Korea J. Hortic. Sci. Technol. 2019, 37, 256–263. [Google Scholar] [CrossRef]

- In, B.C.; Kim, J.G.; Nimikeatkai, H.; Lee, J.S. Effects of harvest seasons on quality and microbial population of fresh-cut iceberg lettuce. J. Bio-Environ. Control 2010, 19, 343–350. [Google Scholar]

- Wang, L.X.; Choi, I.L.; Kang, H.M. Correlations among quality characteristics of green asparagus affected by the application methods of elevated CO2 combined with MA packaging. Horticulturae 2020, 6, 103. [Google Scholar] [CrossRef]

- Cantwell, M.; Suslow, T. Lettuce, Crisphead: Recommendations for Maintaining Postharvest Quality. 2002. Available online: http://ucanr.edu/sites/Postharvest_Technology_Center_/Commodity_Resources/Fact_Sheets/Datastores/Vegetables_English/?uid=19&ds=799 (accessed on 18 January 2014).

- Kays, J.S.; Paull, E.R. Postharvest Biology; Exon Press: Athens, GA, USA, 2004. [Google Scholar]

- Kader, A.A. Postharvest Technology of Horticultural Crops, 3rd ed.; University of California, Agriculture and Natural Resources: Davis, CA, USA, 2002. [Google Scholar]

- Fan, X.; Mattheis, J.P. Reduction of ethylene-induced physiological disorders of carrots and iceberg lettuce by 1-methylcyclopropene. Hortscience 2000, 35, 1312–1314. [Google Scholar] [CrossRef]

- Irtiza, S.A.B.; Wani, A.B.; Khan, F.A.; Murtaza, I.; Wani, M.Y. Physiological and biochemical interactions for extending the shelf life of fruits and vegetables: A review. Int. J. Chem. Stud. 2019, 7, 2153–2166. [Google Scholar]

- Islam, M.Z.; Lee, Y.T.; Mele, M.A.; Choi, I.L.; Jang, D.C.; Ko, Y.W.; Kim, Y.D.; Kang, H.M. Effect of modified atmosphere packaging on quality and shelf life of baby leaf lettuce. Qual. Assur. Saf. Crop. Foods 2019, 11, 749–756. [Google Scholar] [CrossRef]

- Kim, J.G.; Luo, Y.G.; Saftner, R.A.; Gross, K.C. Delayed modified atmosphere packaging of fresh-cut romaine lettuce: Effects on quality maintenance and shelf-life. J. Am. Soc. Hortic. Sci. 2005, 130, 116–123. [Google Scholar] [CrossRef] [Green Version]

- Aharoni, N.; Reuveni, A.; Dvir, O. Modified atmospheres in film packages delay senescence and decay of fresh herbs. Acta Hortic. 1989, 258, 255–262. [Google Scholar] [CrossRef]

- Gorny, J.R.; Kader, A.A. Low oxygen and elevated carbon dioxide atmospheres inhibit ethylene biosynthesis in preclimacteric and climacteric apple fruit. J. Am. Soc. Hortic. Sci. 1997, 122, 542–546. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Zhang, X.; Li, L.; Aghdam, M.S.; Wei, X.; Liu, J.; Xu, Y.; Luo, Z. Elevated CO2 delayed the chlorophyll degradation and anthocyanin accumulation in postharvest strawberry fruit. Food Chem. 2019, 285, 163–170. [Google Scholar] [CrossRef]

- Yoon, H.S.; Choi, I.L.; Bark, J.P.; Kang, H.M. Effects of 1-MCP and MA storage treatments for long-term storage of asparagus spears. Prot. Hortic. Plant Fact. 2016, 25, 118–122. [Google Scholar] [CrossRef]

- Miceli, A.; Vetrano, F.; Sabatino, L.; D’Anna, F.; Moncada, A. Influence of preharvest gibberellic acid treatments on postharvest quality of minimally processed leaf lettuce and rocket. Horticulturae 2019, 5, 63. [Google Scholar] [CrossRef] [Green Version]

| Respiration Rate (CO2 mL·kg−1·h−1) | Ethylene Production Rate (C2H4 μL·kg−1·h−1) | |

|---|---|---|

| Whole | 29.5 ± 3.2 z | 0.011 ± 0.002 |

| Fresh Cut | 35.3 ± 6.7 | 0.015 ± 0.003 |

| t = −1.948 | t = −3.100 | |

| p = 0.087 y | p = 0.015 |

| Overall Quality | Off-Odor | Chlorophyll (SPAD) | ||||

|---|---|---|---|---|---|---|

| 2 °C | 8 °C | 2 °C | 8 °C | 2 °C | 8 °C | |

| Initial | 5.0 ± 0.0 a | 5.0 ± 0.0 a | 1.0 ± 0.0 c | 1.0 ± 0.0 c | 50.2 ± 1.4 a | 50.2 ± 1.4 a |

| Perforated | 2.5 ± 0.0 c | 1.4 ± 0.1 c | 1.0 ± 0.0 c | 1.0 ± 0.0 c | 50.1 ± 0.7 a | 43.4 ± 1.8 b |

| 1300 cc | 2.9 ± 0.1 b | 1.5 ± 0.3 c | 2.8 ± 0.2 a | 4.1 ± 0.1 a | 46.3 ± 2.2 a | 44.8 ± 1.9 b |

| 10,000 cc | 3.0 ± 0.2 b | 2.2 ± 0.2 b | 1.9 ± 0.1 b | 2.9 ± 0.2 b | 50.9 ± 3.4 a | 47.3 ± 1.9 ab |

| 50,000 cc | 2.9 ± 0.2 b | 2.1 ± 0.3 b | 1.9 ± 0.3 b | 2.8 ± 0.1 b | 50.1 ± 2.7 a | 42.2 ± 3.7 b |

| Overall Quality | Off-Odor | Chlorophyll (SPAD) | ||||

|---|---|---|---|---|---|---|

| 2 °C | 8 °C | 2 °C | 8 °C | 2 °C | 8 °C | |

| Initial | 5.0 ± 0.0 a | 5.0 ± 0.0 a | 1.0 ± 0.0 a | 1.0 ± 0.0 c | 50.2 ± 1.4 a | 50.2 ± 1.4 a |

| Perforated | 1.8 ± 0.3 c | 1.3 ± 0.3 e | 1.0 ± 0.0 a | 1.0 ± 0.0 c | 39.8 ± 2.5 b | 30.6 ± 3.1 d |

| 1300 cc | 2.7 ± 0.3 b | 1.9 ± 0.4 c | 1.0 ± 0.1 a | 3.3 ± 0.1 a | 43.7 ± 3.1 ab | 39.6 ± 2.7 b |

| 10,000 cc | 2.6 ± 0.2 b | 1.8 ± 0.3 cd | 1.5 ± 0.2 a | 2.9 ± 0.1 b | 39.1 ± 3.0 b | 37.8 ± 2.0 bc |

| 50,000 cc | 2.6 ± 0.2 b | 2.2 ± 0.6 b | 1.1 ± 0.1 a | 2.9 ± 0.1 b | 44.2 ± 1.5 ab | 41.4 ± 2.1 b |

| 100,000 cc | 2.5 ± 0.4 b | 1.5 ± 0.4 de | 1.3 ± 0.2 a | 2.8 ± 0.1 b | 44.3 ± 2.4 ab | 33.2 ± 2.0 bc |

| Fresh Weight Loss Rate | Oxygen Content | Carbon Dioxide Content | Ethylene Content | Chlorophyll | Off -Odor | ||

|---|---|---|---|---|---|---|---|

| Whole | 2 °C | −0.785 ** | −0.550 * | 0.586 ** | 0.710 ** | 0.299 | 0.522 * |

| 8 °C | −0.452 * | −0.093 | 0.145 | 0.400 | 0.190 | 0.060 | |

| Fresh Cut | 2 °C | −0.777 ** | −0.422 | 0.448 * | 0.725 ** | 0.375 | −0.094 |

| 8 °C | −0.548 * | −0.319 | 0.287 | 0.435 | 0.842 ** | 0.454 * |

| Variables | Whole | Fresh Cut | ||

|---|---|---|---|---|

| PC1 | PC2 | PC1 | PC2 | |

| FW | −0.863 | −0.391 | −0.696 | −0.602 |

| O2 | −0.838 | 0.114 | −0.845 | −0.027 |

| CO2 | 0.926 | −0.131 | 0.901 | −0.001 |

| C2H4 | 0.858 | 0.142 | 0.783 | 0.394 |

| SPAD | −0.052 | 0.833 | −0.077 | 0.827 |

| OQ | −0.001 | 0.948 | 0.056 | 0.927 |

| Off-Odor | 0.946 | −0.262 | 0.808 | −0.292 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, I.-L.; Lee, J.-H.; Choi, D.-H.; Wang, L.-X.; Kang, H.-M. Evaluation of the Storage Characteristics in Maintaining the Overall Quality of Whole and Fresh-Cut Romaine Lettuce during MA Storage. Horticulturae 2021, 7, 461. https://doi.org/10.3390/horticulturae7110461

Choi I-L, Lee J-H, Choi D-H, Wang L-X, Kang H-M. Evaluation of the Storage Characteristics in Maintaining the Overall Quality of Whole and Fresh-Cut Romaine Lettuce during MA Storage. Horticulturae. 2021; 7(11):461. https://doi.org/10.3390/horticulturae7110461

Chicago/Turabian StyleChoi, In-Lee, Joo-Hwan Lee, Dam-Hee Choi, Li-Xia Wang, and Ho-Min Kang. 2021. "Evaluation of the Storage Characteristics in Maintaining the Overall Quality of Whole and Fresh-Cut Romaine Lettuce during MA Storage" Horticulturae 7, no. 11: 461. https://doi.org/10.3390/horticulturae7110461

APA StyleChoi, I.-L., Lee, J.-H., Choi, D.-H., Wang, L.-X., & Kang, H.-M. (2021). Evaluation of the Storage Characteristics in Maintaining the Overall Quality of Whole and Fresh-Cut Romaine Lettuce during MA Storage. Horticulturae, 7(11), 461. https://doi.org/10.3390/horticulturae7110461