Research on the Promotion of Sludge Anaerobic Fermentation with Sodium Citrate under Low Concentrations of Polyaluminum Chloride

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sludge and Reagents

2.2. Experimental Design

2.3. Sludge Extraction

2.4. Analysis Method

3. Results and Discussion

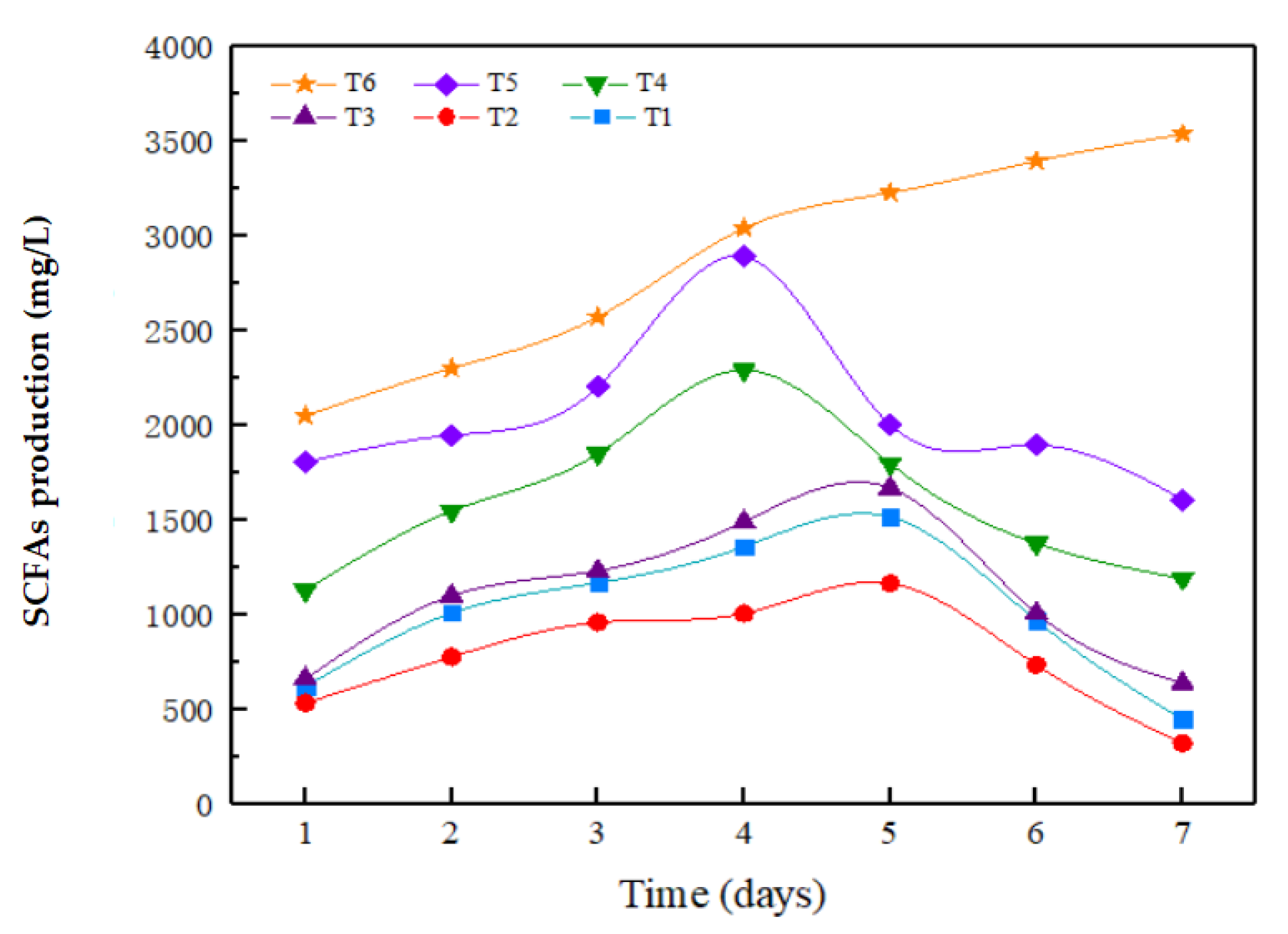

3.1. Effects of SC on SCFAs Produced in Sludge Anaerobic Fermentation

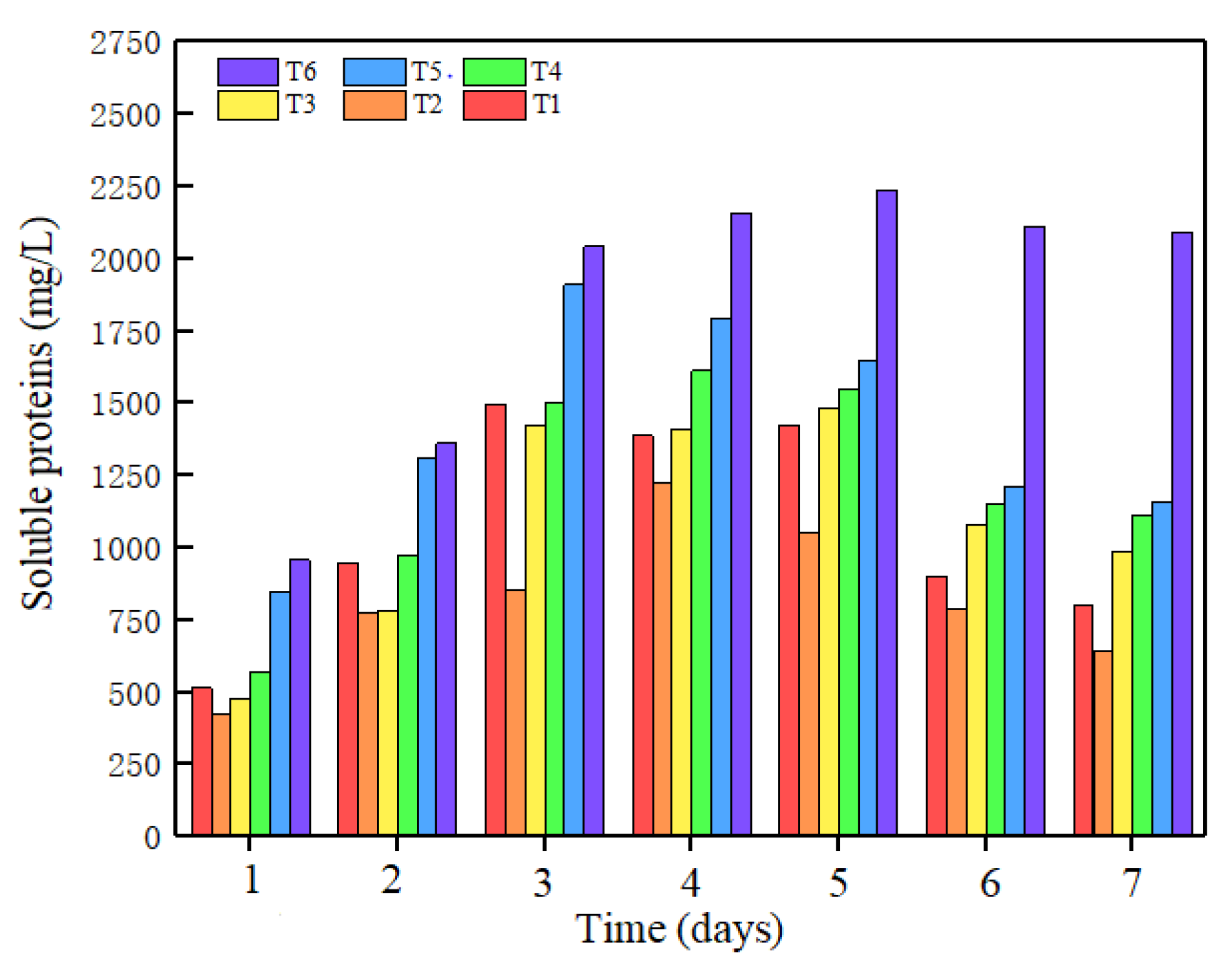

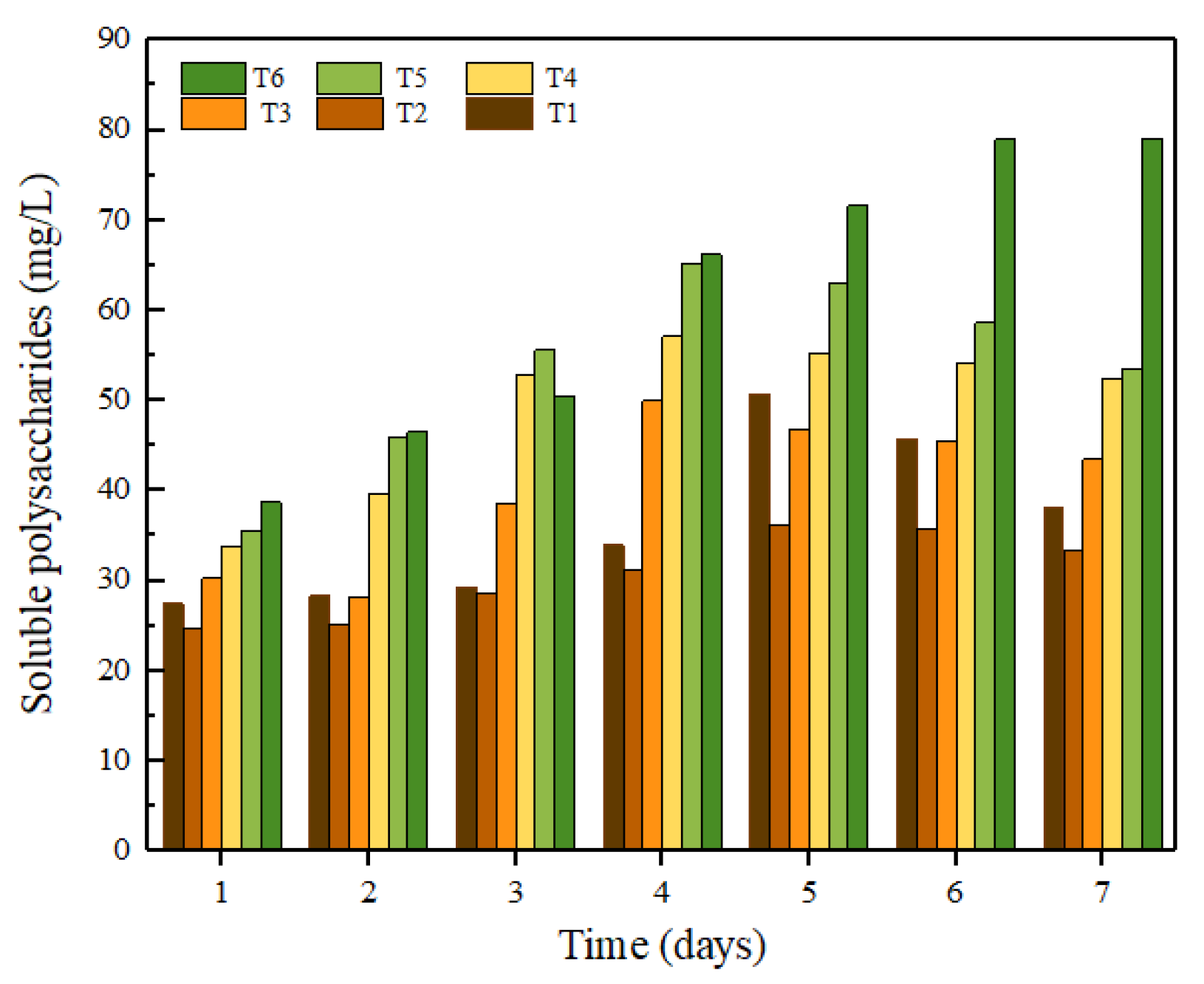

3.2. Effects of SC on Sludge Dissolution in Sludge Anaerobic Fermentation

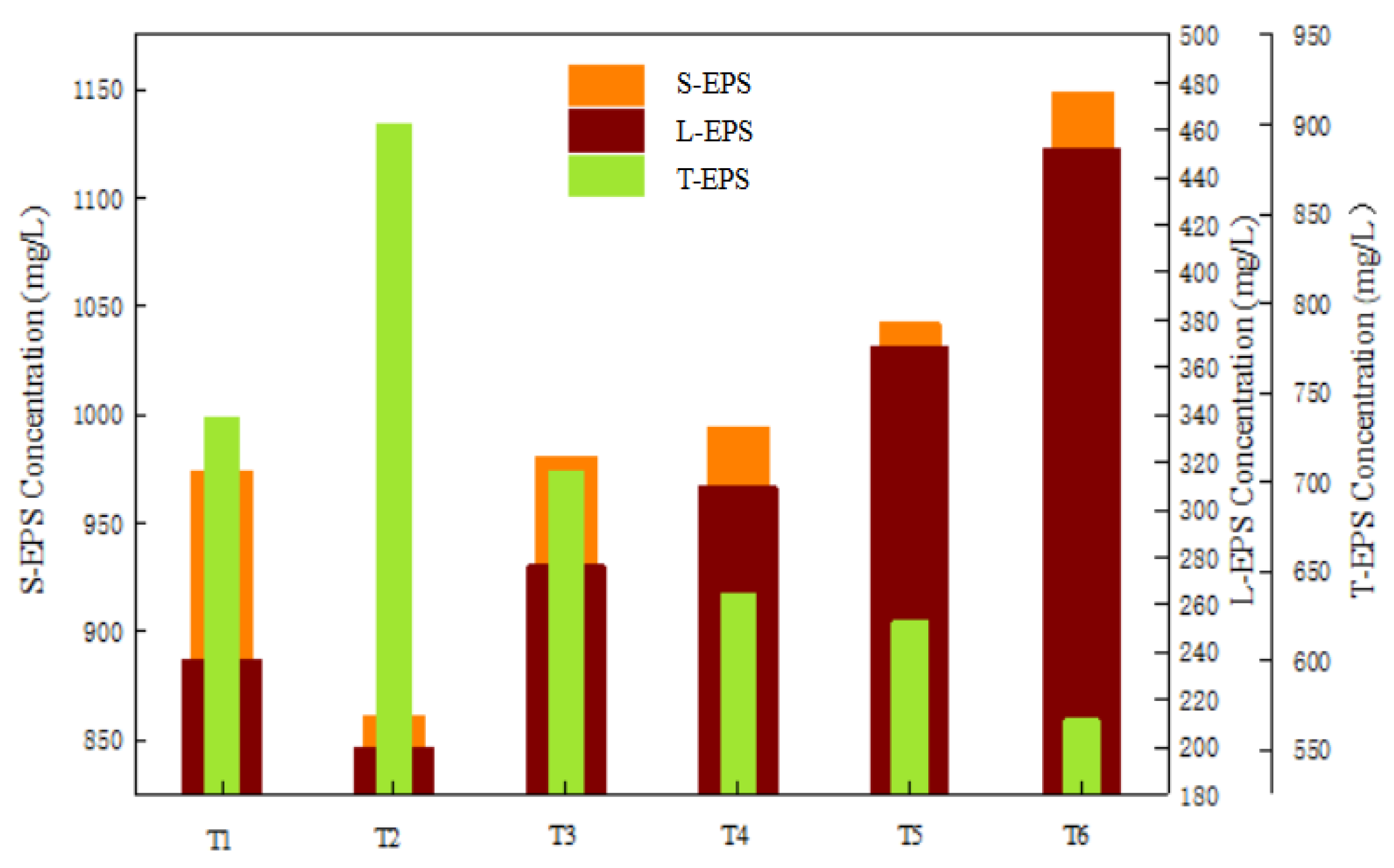

3.3. Effect of SC on the Structure of Sludge Floc

3.3.1. Effect of SC on the Appearance of Sludge

3.3.2. Effect of SC on EPS Distribution

3.4. Effect of SC on Key Enzyme Activities

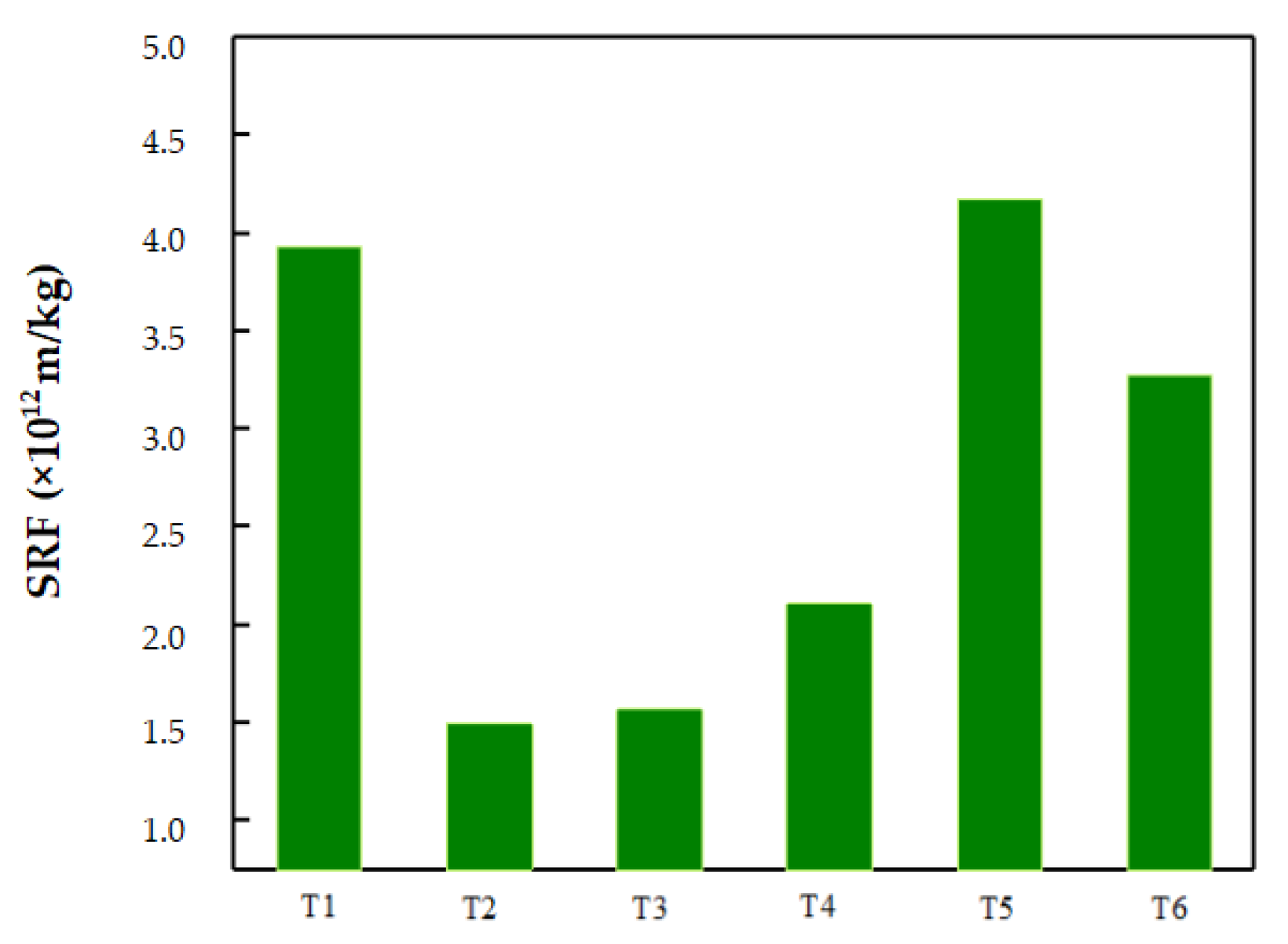

3.5. Effect of SC on Sludge Dewatering Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Wu, L.; Huang, J.; Qu, Y.; Pan, Y.; Liu, L.; Zhu, H. Recovering short-chain fatty acids from waste sludge via biocarriers and microfiltration enhanced anaerobic fermentation. Resour. Conserv. Recycl. 2022, 182, 106342. [Google Scholar] [CrossRef]

- Liu, X.; Du, M.; Yang, J.; Wu, Y.; Xu, Q.; Wang, D.; Yang, Q.; Yang, G.; Li, X. Sulfite serving as a pretreatment method for alkaline fermentation to enhance short-chain fatty acid production from waste activated sludge. Chem. Eng. J. 2020, 385, 123991. [Google Scholar] [CrossRef]

- Tsui, T.H.; Van Loosdrecht, M.C.; Dai, Y.; Tong, Y.W. Machine learning and circular bioeconomy: Building new resource efficiency from diverse waste streams. Bioresour. Technol. 2023, 369, 128445. [Google Scholar] [CrossRef] [PubMed]

- Tsui, T.H.; Zhang, L.; Zhang, J.; Dai, Y.; Tong, Y.W. Engineering interface between bioenergy recovery and biogas desulfurization: Sustainability interplays of biochar application. Renew. Sustain. Energy Rev. 2022, 157, 112053. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y. The effect of propionic acid accumulation on methane production in dry mesophilic anaerobic fermentation. IOP Conf. Ser. Earth Environ. Sci. 2021, 675, 012208. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, Y.; Wang, D.; Li, H.; Wang, Q.; Liu, Y.; Chen, Y. Understanding the mechanisms of how poly aluminium chloride inhibits short-chain fatty acids production from anaerobic fermentation of waste activated sludge. Chem. Eng. J. 2018, 334, 1351–1360. [Google Scholar] [CrossRef]

- Zhu, P.; Li, X.; Feng, J.; Zhang, R.; Bai, H.; Bu, D.; Dan, Z.; Li, W.; Lu, X. Short-Chain Fatty Acids Production from Anaerobic Fermentation of Sewage Sludge: The Effect of Higher Levels Polyaluminium Chloride. Int. J. Environ. Res. Public Health 2022, 19, 2806. [Google Scholar] [CrossRef]

- Park, C.; Muller, C.D.; Abu-Orf, M.M.; Novak, J.T. The effect of wastewater cations on activated sludge characteristics: Effects of aluminum and iron in floc. Water Environ. Res. 2006, 78, 31–40. [Google Scholar] [CrossRef]

- Ebenezer, A.V.; Kaliappan, S.; Adish Kumar, S.; Yeom, I.T.; Banu, J.R. Influence of deflocculation on microwave disintegration and anaerobic biodegradability of waste activated sludge. Bioresour. Technol. 2015, 185, 194–201. [Google Scholar] [CrossRef]

- Park, C.; Novak, J.T. Characterization of activated sludge exocellular polymersusing several cation associated extraction methods. Water Res. 2007, 41, 1679–1688. [Google Scholar] [CrossRef]

- Wawrzynczyk, J.E.; Szewczyka, O.; Norrlöw, E.; Dey, S. Application of enzymes, sodium tripolyphosphate and cation exchange resin for the release of extracellular polymeric substances from sewage sludge characterisation of the extracted polysaccharides/glycoconjugates by a panel of lectins. J. Biotechnol. 2007, 130, 274–281. [Google Scholar] [CrossRef] [PubMed]

- Xie, B.X.; Luo, K.; Yang, Q.; Mo, C.R.; Li, X.M.; Yu, J. Influence of complexing agents on enzymatic hydrolysis of sludge during anaerobic digestion. Acta Sci. Circumstantiae 2011, 31, 1699–1705. [Google Scholar]

- Brown, M.J.; Lester, J.N. Metal removal in activated sludge: The role of bacterial extracellular polymers. Water Res. 1979, 13, 817–837. [Google Scholar] [CrossRef]

- Feng, L.; Chen, Y.; Zheng, X. Enhancement of Waste Activated Sludge Protein Conversion and Volatile Fatty Acids Accumulation during Waste Activated Sludge Anaerobic Fermentation by Carbohydrate Substrate Addition: The Effect of pH. Environ. Sci. Technol. 2009, 43, 4373–4380. [Google Scholar] [CrossRef] [PubMed]

- Yu, G.; He, P.; Shao, L.; He, P. Stratification structure of sludge flocs with implications to dewaterability. Environ. Sci. Technol. 2008, 42, 7944–7949. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, X.; Wang, D.; Wu, Y.; Wang, Q.; Liu, Y.; Li, X.; An, H.; Zhao, J.; Chen, F.; et al. Free ammonia-based pretreatment enhances phosphorus release and recovery from waste activated sludge. Chemosphere 2018, 213, 276–284. [Google Scholar] [CrossRef]

- Duan, X.; Wang, X.; Xie, J.; Feng, L.Y.; Yan, Y.Y.; Zhou, Q. Effect of nonylphenol on volatile fatty acids accumulation during anaerobic fermentation of waste activated sludge. Water Res. 2016, 105, 209–217. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Z.; He, X.; Zheng, L.; Cheng, S.; Li, Z. Diminished inhibitory impact of ZnO nanoparticles on anaerobic fermentation by the presence of TiO2 nanoparticles: Phenomenon and mechanism. Sci. Total Environ. 2019, 647, 313–322. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, K.; Su, Y.; Zheng, X.; Wang, Q. Continuous bioproduction of short-chain fatty acids from sludge enhanced by the combined use of surfactant and alkaline pH. Bioresour. Technol. 2013, 140, 97–102. [Google Scholar] [CrossRef]

- Pang, L.; Ni, J.; Tang, X. Fast characterization of soluble organic intermediates and integrity of microbial cells in the process of alkaline anaerobic fermentation of waste activated sludge. Biochem. Eng. J. 2014, 86, 49–56. [Google Scholar] [CrossRef]

- Huang, X.; Shen, C.; Liu, J.; Lu, L. Improved volatile fatty acid production during waste activated sludge anaerobic fermentation by different bio-surfactants. Chem. Eng. J. 2015, 264, 280–290. [Google Scholar] [CrossRef]

- Duan, Y.; Zhou, A.; Wen, K.; Liu, Z.; Liu, W.; Wang, A. Upgrading VFAs bioproduction from waste activated sludge via co-fermentation with soy sauce residue. Front. Environ. Sci. Eng. 2018, 1, 53–62. [Google Scholar] [CrossRef]

- Lu, H.W.; Dai, R.H.; Liu, Y.; Song, A.N.; Lv, L.H. The influence factors and research progress in Anaerobic hydrolysis/acidification of sludge. Chem. Bull. 2012, 75, 489–495. [Google Scholar]

- Tyagi, V.K.; Lo, S.L.; Rajpal, A. Chemically coupled microwave and ultrasonic pre-hydrolysis of pulp and paper mill waste-activated sludge: Effect on sludge solubilisation and anaerobic digestion. Environ. Sci. Pollut. Res. 2014, 21, 6205–6217. [Google Scholar] [CrossRef]

- Park, C.; Abu-Orf, M.M.; Novak, J.T. Analysis of floc stucture and predicting sludge digestibility using different cation-associated EPS extraction methods. Proc. Water Environ. Fed. 2004, 8, 21–37. [Google Scholar] [CrossRef]

- Xin, X.; He, J.; Li, L.; Qiu, W. Enzymes catalyzing pre-hydrolysis facilitated the anaerobic fermentation of waste activated sludge with acidogenic and microbiological perspectives. Bioresour. Technol. 2018, 250, 69–78. [Google Scholar] [CrossRef]

- Wolski, P.; Zawieja, I. Hybrid conditioning before anaerobic digestion for the improvement of sewage sludge dewatering. Desalin. Water Treat. 2014, 52, 3725–3731. [Google Scholar] [CrossRef]

- Yuan, H.Y.; Yang, Y.P.; Wang, Y.N.; Wang, T.; Du, Y.M. Effects of Different Oxidation Agents on Sludge Dewatering and Hydrolysis Performance. Environ. Sci. Technol. 2017, 40, 33–37. [Google Scholar]

| Parameters | Sludge |

|---|---|

| pH | 6.9 ± 0.1 |

| Total solids (TS) | 25,100 ± 370 mg/L |

| Volatile solids (VS) | 16,800 ± 210 mg/L |

| Total chemical oxygen demand (TCOD) | 19,800 ± 450 mg/L |

| Soluble chemical oxygen demand (SCOD) | 165 ± 10 mg/L |

| Total protein | 9740 ±330 mg/L |

| Total polysaccharide | 2200 ± 120 mg/L |

| Anaerobic Bottles | PAC (mg/g TS) | SC (mg/g TS) |

|---|---|---|

| T1 | 0 | 0 |

| T2 | 70 | 0 |

| T3 | 70 | 35 |

| T4 | 70 | 70 |

| T5 | 70 | 140 |

| T6 | 0 | 70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, P.; Wang, Y.; Bai, H.; Feng, J.; Zhang, R.; Bu, D.; Dan, Z.; Li, W.; Lu, X. Research on the Promotion of Sludge Anaerobic Fermentation with Sodium Citrate under Low Concentrations of Polyaluminum Chloride. Fermentation 2023, 9, 776. https://doi.org/10.3390/fermentation9080776

Zhu P, Wang Y, Bai H, Feng J, Zhang R, Bu D, Dan Z, Li W, Lu X. Research on the Promotion of Sludge Anaerobic Fermentation with Sodium Citrate under Low Concentrations of Polyaluminum Chloride. Fermentation. 2023; 9(8):776. https://doi.org/10.3390/fermentation9080776

Chicago/Turabian StyleZhu, Puli, Yilin Wang, Hui Bai, Jing Feng, Rui Zhang, Duo Bu, Zeng Dan, Wei Li, and Xuebin Lu. 2023. "Research on the Promotion of Sludge Anaerobic Fermentation with Sodium Citrate under Low Concentrations of Polyaluminum Chloride" Fermentation 9, no. 8: 776. https://doi.org/10.3390/fermentation9080776

APA StyleZhu, P., Wang, Y., Bai, H., Feng, J., Zhang, R., Bu, D., Dan, Z., Li, W., & Lu, X. (2023). Research on the Promotion of Sludge Anaerobic Fermentation with Sodium Citrate under Low Concentrations of Polyaluminum Chloride. Fermentation, 9(8), 776. https://doi.org/10.3390/fermentation9080776