Underexplored Potential of Lactic Acid Bacteria Associated with Artisanal Cheese Making in Brazil: Challenges and Opportunities

Abstract

1. Introduction

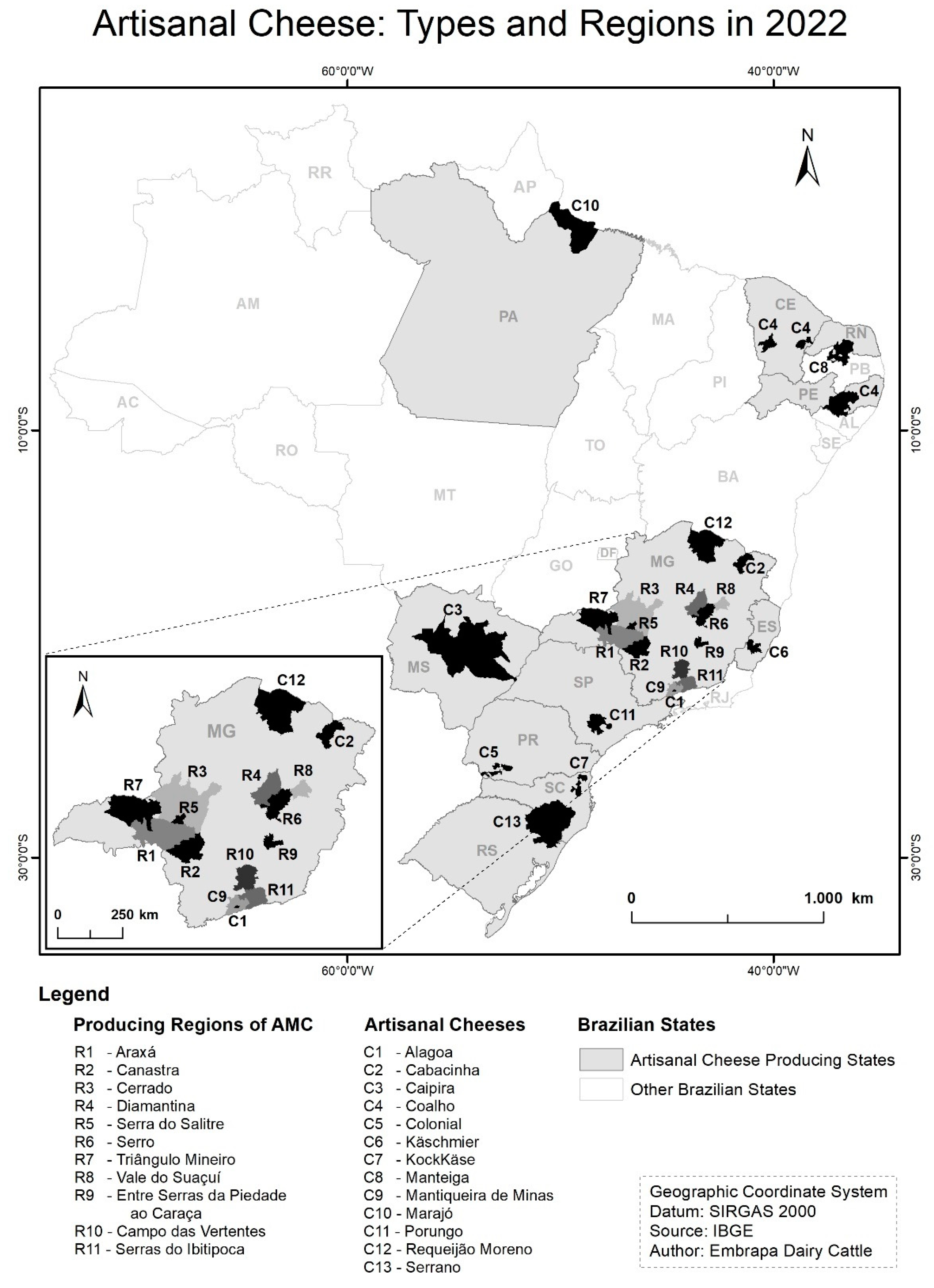

2. Brazilian Artisanal Cheeses (BAC)

3. LAB and Food Industry

4. LAB Isolated from BAC

5. Biotechnological Potential of LAB Isolated from BAC

5.1. Bacteriocin Production

5.2. Acidification Capacity

5.3. Probiotic Potential

5.4. Exopolysaccharide (EPS) Production

5.5. Diacetyl Production

5.6. Proteolytic and Lipolytic Activities

5.7. β-Galactosidase Activity

6. Underexplored Biopotential and Opportunities for LAB from BAC

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferchichi, M.; Sebei, K.; Boukerb, A.M.; Karray-Bouraoui, N.; Chevalier, S.; Feuilloley, M.G.J.; Connil, N.; Zommiti, M. Enterococcus spp.: Is It a Bad Choice for a Good Use—A Conundrum to Solve? Microorganisms 2021, 9, 2222. [Google Scholar] [CrossRef] [PubMed]

- Gopal, P.K. Bacteria, Beneficial: Probiotic Lactic Acid Bacteria: An Overview, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 4, ISBN 9780128187661. [Google Scholar]

- Lindner, J.D.D.; Pereira, G.V.M.; Miotto, M. Culturas microbianas para aplicação em alimentos fermentados. In Microbiologia de Alimentos Fermentados, 1st ed.; Blucher: São Paulo, Brazil, 2022; Volume 1, pp. 137–162. ISBN 9786555061321. [Google Scholar]

- Lima, T.T.M.; Hosken, B.O.; Venturim, B.C.; Lopes, I.L.; Martin, J.G.P. Traditional Brazilian fermented foods: Cultural and technological aspects. J. Ethn. Foods 2022, 9, 35. [Google Scholar] [CrossRef]

- Cavicchioli, V.Q.; Camargo, A.C.; Todorov, S.D.; Nero, L.A. Novel bacteriocinogenic Enterococcus hirae and Pediococcus pentosaceus strains with antilisterial activity isolated from Brazilian artisanal cheese. J. Dairy Sci. 2017, 100, 2526–2535. [Google Scholar] [CrossRef]

- Fidan, H.; Esatbeyoglu, T.; Simat, V.; Trif, M.; Tabanelli, G.; Kostka, T.; Montanari, C.; Ibrahim, S.A.; Ozogul, F. Recent developments of lactic acid bacteria and their metabolites on foodborne pathogens and spoilage bacteria: Facts and gaps. Food Biosci. 2022, 47, 101741. [Google Scholar] [CrossRef]

- Prêmio Queijo Brasil. Resultado V Prêmio Queijo Brasil. 2021. Available online: http://www.premioqueijobrasil.com.br (accessed on 15 July 2022).

- Mondial du Fromage. Concours International Produits. 2021. Available online: https://www.mondialdufromage.com/concours-produits.php/ (accessed on 12 August 2022).

- Dores, M.T.; Nobrega, J.E.; Ferreira, C.L.L.F. Room temperature aging to guarantee microbiological safety of brazilian artisan Canastra cheese. Food Sci. Technol. 2013, 33, 180–185. [Google Scholar] [CrossRef]

- Martins, J.M.; Galinari, É.; Pimentel-Filho, N.J.; Ribeiro, J.I.; Furtado, M.M.; Ferreira, C.L.L. Determining the minimum ripening time of artisanal Minas cheese, a traditional Brazilian cheese. Braz. J. Microbiol. 2015, 46, 219–230. [Google Scholar] [CrossRef]

- Margalho, L.P.; Kamimura, B.A.; Brexó, R.P.; Alvarenga, V.O.; Cebeci, A.S.; Janssen, P.W.M.; Dijkstra, A.; Starrenburg, M.J.C.; Sheombarsing, R.S.; Cruz, A.G.; et al. High throughput screening of technological and biopreservation traits of a large set of wild lactic acid bacteria from Brazilian artisanal cheeses. Food Microbiol. 2021, 100, 103872. [Google Scholar] [CrossRef]

- Kamimura, B.A.; Filippis, F.; Sant’Anna, A.S.; Ercolini, D. Large-scale mapping of microbial diversity in artisanal Brazilian cheeses. Food Microbiol. 2019, 80, 40–49. [Google Scholar] [CrossRef] [PubMed]

- Domingos-Lopes, M.F.P.; Santon, C.; Ross, P.R.; Dapkevicius, M.L.E.; Silva, C.G.C. Genetic diversity, safety and technological characterization of lactic acid bacteria isolated from artisanal Pico cheese. Food Microbiol. 2017, 63, 178–190. [Google Scholar] [CrossRef]

- Margalho, L.P.; Schalkwijk, S.; Bachmann, H.; Sant’Anna, A.S. Enterococcus spp. in Brazilian artisanal cheeses: Occurrence and assessment of phenotypic and safety properties of a large set of strains through the use of high throughput tools combined with multivariate statistics. Food Control 2020, 118, 107425. [Google Scholar] [CrossRef]

- Carneiro, J.O.; Chaves, A.C.S.D.; Stephan, M.P.; Boari, C.A.; Koblitz, M.G.B. Artisan minas cheese of Serro: Proteolysis during ripening. Heliyon 2020, 6, e04446. [Google Scholar] [CrossRef]

- Monteiro, R.P.; Matta, V.M. Queijo Minas Artesanal: Valorizando a Agroindústria Familiar. 2018. Available online: https://ainfo.cnptia.embrapa.br/digital/bitstream/item/199625/1/Livro-Queijo-Minas-Artesanal-Ainfo.pdf (accessed on 19 August 2022).

- Roldan, B.B.; Revillion, J.P.P. Convenções de qualidade em queijos artesanais no Brasil, Espanha e Itália. Rev. Inst. Laticínios Cândido Tostes 2019, 74, 108–122. [Google Scholar] [CrossRef]

- Instituto Mineiro de Agropecuária (IMA). Ordinance n° 2016. November 26th. Identifies the Serras da Ibitipoca Region as Producer of Minas Artesanal Cheese and Revokes IMA Ordinance No. 1834, of 4 July 2018. 2020. Available online: http://www.ima.mg.gov.br/institucional/portarias#ano-2020 (accessed on 10 May 2021).

- Instituto Mineiro de Agropecuária (IMA). Ordinance n° 2.141, of 19 April 2022. Identifies the Entre Serras da Piedade ao Caraça Region as Producer of Minas Artisanal Cheese. Available online: http://ima.mg.gov.br/index.php?preview=1&option=com_dropfiles&format=&task=frontfile.download&catid=1829&id=19230&Itemid=1000000000000 (accessed on 10 May 2021).

- Instituto do Patrimônio Histórico e Artístico Nacional (IPHAN). Certidão do Registro do Modo Artesanal de Fazer Queijo de Minas, nas Regiões do Serro e nas Serras da Canastra e do Salitre. 2008. Available online: http://portal.iphan.gov.br/uploads/ckfinder/arquivos/Certid%C3%A3o%20(Modo%20artesanal%20de%20fazer%20Queijo%20de%20Minas).pdf (accessed on 11 October 2022).

- Giannini, A. Queijos Brasileiros Conquistam 57 Medalhas em Concurso Mundial na França. 2021. Available online: https://veja.abril.com.br/gastronomia/queijos-brasileiros-conquistam-57-medalhas-em-concurso-mundial-na-franca/ (accessed on 3 September 2022).

- Pires, M.F.A. Queijo Artesanal Ganha Status, Internet e o Mundo. In Anuário do Leite 2019; Texto Comunicação Corporativa: São Paulo, Brazil, 2019; Available online: https://www.infoteca.cnptia.embrapa.br/handle/doc/1109959 (accessed on 5 September 2022).

- Abdel-Rahman, M.L.; Sonomoto, K. Opportunities to overcome the current limitations and challenges for efficient microbial production of optically pure lactic acid. J. Biotechnol. 2016, 236, 176–192. [Google Scholar] [CrossRef] [PubMed]

- König, H.; Unden, G.; Fröhlich , J. Lactic acid bacteria. In Biology of Microorganisms on Grapes, in Must and in Wine; Spring: Berlin, Germany, 2017; pp. 3–41. [Google Scholar] [CrossRef]

- Liu, W.; Pang, H.; Zhang, H.; Cai, Y. Biodiversity of lactic acid bacteria. In Lactic Acid Bacteria: Fundamentals and Practice; Springer: Dordrecht, The Netherlands, 2014; ISBN 978-94-017-8840-3. [Google Scholar]

- Settanni, L.; Moschetti, G. Non-starter lactic acid bacteria used to improve cheese quality and provide health benefits. Food Microbiol. 2010, 27, 691–697. [Google Scholar] [CrossRef]

- Widyastuti, Y.; Rohmatussolihat, Y.; Febrisiantosa, A. The role of lactic acid bacteria in milk fermentation. Food Nutr. Sci. 2014, 5, 435–442. [Google Scholar] [CrossRef]

- Diana, M.; Tres, A.; Quílez, J.; Llombart, M.; Rafecas, M. Spanish cheese screening and selection of lactic acid bacteria with high gamma-aminobutyric acid production. LWT-Food Sci. Technol. 2014, 56, 351–355. [Google Scholar] [CrossRef]

- Ruiz-Moyano, S.; Santos, M.T.P.G.; Galván, A.I.; Merchán, A.V.; González, E.; Córdoba, M.G.; Benito, M.J. Screening of autochthonous lactic acid bacteria strains from artisanal soft cheese: Probiotic characteristics and prebiotic metabolism. LWT-Food Sci. Technol. 2019, 114, 108388. [Google Scholar] [CrossRef]

- O’Connor, P.M.; Kuniyoshi, T.M.; Oliveira, R.P.S.; Hill, C.; Ross, R.P.; Cotter, P.D. Antimicrobials for food and feed; a bacteriocin perspective. Curr.Opin. Biotechnol. 2020, 61, 160–167. [Google Scholar] [CrossRef]

- Mayo, B.; Rodríguez, J.; Vázquez, L.; Flórez, A.B. Microbial Interactions within the Cheese Ecosystem and Their Application to Improve Quality and Safety. Foods 2021, 10, 602. [Google Scholar] [CrossRef]

- Meng, Z.; Zhang, L.; Xin, L.; Lin, K.; Yi, H.; Han, X. Technological characterization of Lactobacillus in semihard artisanal goat cheeses from different Mediterranean areas for potential use as nonstarter lactic acid bacteria. J. Dairy Sci. 2018, 101, 2887–2896. [Google Scholar] [CrossRef]

- Chawda, P.J.; Shi, J.; Xue, S.; Quek, S.Y. Co-encapsulation of bioactives for food applications. Food Qual. Saf. 2017, 1, 302–309. [Google Scholar] [CrossRef]

- Pupa, P.; Apiwatsiri, P.; Sirichokchatchawan, W.; Pirarat, N.; Muangsin, N.; Shah, A.A.; Prapasarakul, N. The efficacy of three double-microencapsulation methods for preservation of probiotic bacteria. Sci. Rep. 2021, 11, 13753. [Google Scholar] [CrossRef] [PubMed]

- Contessa, C.R.; Souza, N.B.; Gonçalo, G.B.; Moura, C.M.; Rosa, G.S.; Moraes, C.C. Development of active packaging based on agar-agar incorporated with bacteriocin of Lactobacillus sakei. Biomolecules 2021, 11, 1869. [Google Scholar] [CrossRef]

- Pellegrino, M.S.; Frola, I.D.; Natanael, B.; Gobelli, D.; Nader-Macias, M.E.F.; Bogni, C.I. In vitro characterization of lactic acid bacteria isolated from bovine milk as potential probiotic strains to prevent bovine mastitis. Probiotics Antimicrob. Proteins 2019, 11, 74–84. [Google Scholar] [CrossRef] [PubMed]

- Vanniyasingam, J.; Kapilan, R.; Vasantharuba, S. Isolation and characterization of potential probiotic lactic acid bacteria isolated from cow milk and milk products. J. Agric. Sci. 2019, 13, 32–43. [Google Scholar] [CrossRef]

- Djadouni, F.; Kihal, M. Antimicrobial activity of lactic acid bacteria and the spectrum of their biopeptides against spoiling germs in foods. Braz. Arch. Biol. Technol. 2012, 55, 435–444. [Google Scholar] [CrossRef]

- Margalho, L.P.; Feliciano, M.D.E.; Silva, C.E.; Abreu, J.S.; Piran, M.V.F.; Sant’Anna, A.S. Brazilian artisanal cheeses are rich and diverse sources of nonstarter lactic acid bacteria regarding technological, biopreservative, and safety properties—Insights through multivariate analysis. J. Dairy Sci. 2020, 103, 7908–7926. [Google Scholar] [CrossRef]

- Castro, R.D.; Oliveira, L.G.; Sant’Anna, F.M.; Luiz, L.M.P.; Sandes, S.H.C.; Silva, C.I.F.; Silva, A.M.; Nunes, A.C.; Penna, C.F.A.M.; Souza, M.R. Lactic acid microbiota identification in water, raw milk, endogenous starter culture, and fresh Minas artisanal cheese from the Campo das Vertentes region of Brazil during the dry and rainy seasons. J. Dairy Sci. 2016, 99, 6086–6096. [Google Scholar] [CrossRef]

- Matera, J.; Luna, A.S.; Batista, D.B.; Pimentel, T.C.; Moraes, J.; Kamimura, B.A.; Ferreira, M.V.S.; Silva, H.L.A.; Mathias, S.P.; Esmerino, E.A.; et al. Brazilian cheeses: A survey covering physicochemical characteristics, mineral content, fatty acid profile and volatile compounds. Food Res. Int. 2018, 108, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, M.G.; Lapointe, G. Invited review: Starter lactic acid bacteria survival in cheese: New perspectives on cheese microbiology. J. Dairy Sci. 2020, 103, 10963–10985. [Google Scholar] [CrossRef]

- Campagnollo, F.B.; Margalho, L.P.; Kamimura, B.A.; Feliciano, M.D.; Freire, L.; Lopes, L.S.; Alvarenga, V.O.; Cadavez, V.A.P.; Gonzales-Barron, U.; Schaffner, D.W.; et al. Selection of indigenous lactic acid bacteria presenting anti-listerial activity, and their role in reducing the maturation period and assuring the safety of traditional Brazilian cheeses. Food Microbiol. 2018, 73, 288–297. [Google Scholar] [CrossRef]

- Perin, L.M.; Sardaro, M.L.S.; Nero, L.A.; Neviani, E.; Gatti, M. Bacterial ecology of artisanal Minas cheeses assessed by culture-dependent and -independent methods. Food Microbiol. 2017, 65, 160–169. [Google Scholar] [CrossRef] [PubMed]

- Bruno, L.M.; Marcó, M.B.; Capra, M.L.; Carvalho, J.D.G.; Meinardi, C.; Quiberoni, A. Wild Lactobacillus strains: Technological characterisation and design of Coalho cheese lactic culture. Int. J. Dairy Technol. 2017, 70, 572–582. [Google Scholar] [CrossRef]

- Medeiros, N.C.; Abrantes, M.R.; Medeiros, J.M.S.; Campêlo, M.C.S.; Rebouças, M.O.; Costa, M.G.A.; Silva, J.B.A. Quality of milk used in informal artisanal production of coalho and butter cheeses. Semin. Ciências Agrárias 2017, 38, 1955–1962. [Google Scholar] [CrossRef]

- Lima, C.P.; Dias, G.M.P.; Soares, M.T.C.V.; Bruno, L.M.; Porto, A.L.F. Queijo coalho como fonte de bactérias ácido láticas probióticas. Res. Soc. Dev. 2020, 9, e266984958. [Google Scholar] [CrossRef]

- Kothe, C.I.; Mohellibi, N.; Renault, P. Revealing the microbial heritage of traditional Brazilian cheeses through metagenomics. Food Res. Int. 2022, 157, 111265. [Google Scholar] [CrossRef]

- Figueiredo, E.L.; Andrade, N.J.; Pires, A.C.S.; Peña, W.E.L.; Figueiredo, H.M. Caracterização do potencial tecnológico e identificação genética de bactérias ácido láticas isoladas de queijo do marajó, tipo creme, de leite de búfala. Rev. Bras. Prod. Agroind. 2016, 18, 293–303. [Google Scholar] [CrossRef]

- Almeida, T.T.; Andretta, M.; Ferreira, L.R.; Carvalho, A.F.; Nero, L.A. The complex microbiota of artisanal cheeses interferes in the performance of enumeration protocols for lactic acid bacteria and staphylococci. Int. Dairy J. 2020, 109, 104791. [Google Scholar] [CrossRef]

- Camargo, A.C.; Costa, E.A.; Fusieger, A.; Freitas, R.; Nero, L.A.; de Carvalho, A.F. Microbial shifts through the ripening of the “Entre Serras” Minas artisanal cheese monitored by high-throughput sequencing. Food Res. Int. 2020, 139, 109803. [Google Scholar] [CrossRef] [PubMed]

- Lima, C.D.L.C.; Lima, L.A.; Cerqueira, M.M.O.P.; Ferreira, E.G.; Rosa, C.A. Bactérias do ácido lático e leveduras associadas com o queijo de minas artesanal produzido na região da Serra do Salitre, Minas Gerais. Arq. Bras. Med. Vet. Zootec. 2009, 61, 266–272. [Google Scholar] [CrossRef]

- Luiz, L.M.P.; Castro, R.D.; Sandes, S.H.C.; Silva, J.G.; Oliveira, L.G.; Sales, G.A.; Nunes, A.C.; Souza, M.R. Aislamiento e identificación de las bacterias ácido-lácticas del queso brasileño Minas artesanal. CYTA—J. Food 2017, 15, 125–128. [Google Scholar] [CrossRef]

- Resende, M.F.S.; Costa, H.H.S.; Andrade, E.H.P.; Acúrcio, L.B.; Drummond, A.F.; Cunha, A.F.; Nunes, A.C.; Moreira, J.L.S.; Penna, C.F.A.M.; Souza, M.R. Queijo de minas artesanal da Serra da Canastra: Influência da altitude das queijarias nas populações de bactérias ácido lácticas. Arq. Bras. Med. Vet. Zootec. 2011, 63, 1567–1573. [Google Scholar] [CrossRef]

- Sant’Anna, F.M.; Wetzels, S.U.; Cicco, S.H.S.; Figueiredo, R.C.; Sales, G.A.; Figueiredo, N.C.; Nunes, C.A.; Schmitz-Esser, S.; Mann, E.; Wagner, M.; et al. Microbial shifts in Minas artisanal cheeses from the Serra do Salitre region of Minas Gerais, Brazil throughout ripening time. Food Microbiol. 2019, 82, 349–362. [Google Scholar] [CrossRef] [PubMed]

- Delamare, A.P.L.; Andrade, C.C.P.; Mandelli, F.; Almeida, R.C.; Echeverrigaray, S. Microbiological, physico-chemical and sensorial characteristics of Serrano, an artisanal Brazilian cheese. Food Nutr. Sci. 2012, 3, 1068–1075. [Google Scholar] [CrossRef]

- Rosa, T.D.; Wassermann, G.E.; Souza, C.F.V.; Caron, D.; Carlini, C.R.; Ayub, M.A.Z. Microbiological and physicochemical characteristics and aminopeptidase activities during ripening of Serrano cheese. Int. J. Dairy Technol. 2008, 61, 70–79. [Google Scholar] [CrossRef]

- Souza, C.F.V.; Rosa, T.D.; Ayub, M.A.Z. Changes in the microbiological and physicochemical characteristics of Serrano cheese during manufacture and ripening. Braz. J. Microbiol. 2003, 34, 260–266. [Google Scholar] [CrossRef]

- Zheng, J.; Wittouck, S.; Salvetti, E.; Franz, C.M.A.P.; Harris, H.M.B.; Mattarelli, P.; O’toole, P.W.; Pot, B.; Vandamme, P.; Walter, J.; et al. A Taxonomic Note on the Genus Lactobacillus: Description of 23 Novel Genera, Emended Description of the Genus Lactobacillus Beijerinck 1901, and Union of Lactobacillaceae and Leuconostocaceae. Int. J. Syst. Evol. Microbiol. 2020, 70, 2782–2858. [Google Scholar] [CrossRef]

- Powell, I.B.; Broome, M.C.; Limsowtin, G.K.Y. Cheese: Starter Cultures: General Aspects. In Encyclopedia of Dairy Sciences, 2nd ed.; Academic Press: Cambridge, MA, USA, 2011; pp. 552–558. [Google Scholar] [CrossRef]

- Broadbent, J.R.; Budinich, M.F.; Steele, J.L. Cheese: Non-Starter lactic acid bacteria. In Encyclopedia of Dairy Sciences, 2nd ed.; Academic Press: Cambridge, MA, USA, 2011; pp. 639–644. [Google Scholar] [CrossRef]

- Blaya, J.; Barzideh, Z.; LaPointe, G. Symposium review: Interaction of starter cultures and nonstarter lactic acid bacteria in the cheese environment. J. Dairy Sci. 2018, 101, 3611–3629. [Google Scholar] [CrossRef] [PubMed]

- Gobbetti, M.; Di Cagno, R.; Calasso, M.; Neviani, E.; Fox, P.F.; De Angelis, M. Drivers that establish and assembly the lactic acid bacteria biota in cheeses. Trends Food Sci. Technol. 2018, 78, 244–254. [Google Scholar] [CrossRef]

- Campagnollo, F.B.U.; Gonzales-Barron, V.A.; Pilão, C.A.S.; Sant’Ana, D.W.S. Quantitative risk assessment of Listeria monocytogenes in traditional Minas cheeses: The cases of artisanal semi-hard and fresh soft cheeses. Food Control 2018, 92, 370–379. [Google Scholar] [CrossRef]

- Melini, F.; Melini, V.; Luziatelli, F.; Ruzzi, M. Raw and heat-treated milk: From public health risks to nutritional quality. Beverages 2017, 3, 54. [Google Scholar] [CrossRef]

- Bortolomedi, B.M.; Paglarini, C.S.; Brod, F.C.A. Bioactive compounds in kombucha: A review of substrate effect and fermentation conditions. Food Chem. 2022, 385, 132719. [Google Scholar] [CrossRef] [PubMed]

- Kocabaş, D.S.; Lyne, J.; Ustunol, Z. Hydrolytic enzymes in the dairy industry: Applications, market and future perspectives. Trends in Food Sci. Technol. 2022, 119, 467–475. [Google Scholar] [CrossRef]

- Ağagündüz, D.; Şahin, T.Ö.; Ayten, Ş.; Yılmaz, B.; Güneşliol, B.E.; Russo, P.; Spano, G.; Özogul, F. Lactic acid bacteria as pro-technological, bioprotective and health-promoting cultures in the dairy food industry. Food Biosci. 2022, 47, 101617. [Google Scholar] [CrossRef]

- Sanlibaba, P.; Çakmak, G.A. Exopolyssacharide production by lactic acid bacteria. App. Microbiol. 2016, 2, 1000115. [Google Scholar] [CrossRef]

- Martins, M.C.F. Diversidade de bactérias láticas e identificação molecular de Lactococcus isolados de ambientes lácteos e não lácteos. Ph.D. Thesis, Universidade Federal de Viçosa, Viçosa, Brasil, 2018. [Google Scholar]

- Teixeira, C.G.; Fusieger, A.; Martins, E.; Freitas, R.; Vakarelova, M.; Nero, L.A.; de Carvalho, A.F. Biodiversity and technological features of Weissella isolates obtained from Brazilian artisanal cheese-producing regions. LWT-Food Sci. Technol. 2021, 147, 111474. [Google Scholar] [CrossRef]

- Margalho, L.P.; Jorge, G.P.; Noleto, D.A.P.; Silva, C.E.; Abreu, J.S.; Piran, M.V.F.; Brocchi, M.; Sant’Anna, A.S. Biopreservation and probiotic potential of a large set of lactic acid bacteria isolated from Brazilian artisanal cheeses: From screening to in product approach. Microbiol. Res. 2021, 242, 126622. [Google Scholar] [CrossRef]

- Brito, L.P.; Silva, E.C.; Calaça, P.R.A.; Medeiros, R.S.; Soares, M.T.C.V.; Porto, A. Bactérias ácido láticas isoladas de queijo de Coalho do nordeste brasileiro na produção de laticínios: Uma triagem para aplicação tecnológica. Res. Soc. Dev. 2020, 9, e5249108457. [Google Scholar] [CrossRef]

- Dias, G.M.P.; Silva, A.B.; Granja, N.M.C.; Silva, T.N.; Lima, G.V.M.; Cavalcanti, M.T.H.; Porto, A.L.F. Can Coalho cheese lactic microbiota be used in dairy fermentation to reduce foodborne pathogens? Sci. Plena 2019, 15, 1–9. [Google Scholar] [CrossRef]

- Mareze, J.; Ramos-Pereira, J.; Santos, J.A.; Beloti, V.; López-Díaz, T.M. Identification and characterisation of lactobacilli isolated from an artisanal cheese with antifungal and antibacterial activity against cheese spoilage and mycotoxigenic Penicillium spp. Int. Dairy J. 2022, 130, 105367. [Google Scholar] [CrossRef]

- Acurcio, L.B.; Sandes, S.H.C.; Bastos, R.W.; Sant’Anna, F.M.; Pedroso, S.H.S.P.; Reis, D.C.; Nunes, Á.C.; Cassali, G.D.; Souza, M.R.; Nicoli, J.R. Milk fermented by Lactobacillus species from Brazilian artisanal cheese protect germ-free-mice against Salmonella Typhimurium infections. Beneficial Microbes 2017, 8, 579–588. [Google Scholar] [CrossRef]

- Andrade, C.R.G.; Souza, M.R.; Penna, C.F.A.M.; Acurcio, L.B.; Sant’Anna, F.M.; Castro, R.D.; Oliveira, D.L.S. Propriedades probióticas in vitro de Lactobacillus spp. isolados de queijos minas artesanais da Serra da Canastra—MG. Arq. Bras. Med. Vet. Zootec. 2014, 66, 1592–1600. [Google Scholar] [CrossRef]

- Brumano, E.C.C. Impacto do tipo de fermento endógeno na qualidade e tempo de maturação de queijo Minas artesanal produzido em propriedades cadastradas pelo IMA (Instituto Mineiro de Agropecuária) na região do Serro—MG. Ph.D. Thesis, Universidade Federal de Viçosa, Viçosa, Brasil, 2016. [Google Scholar]

- Costa, H.H.S.; Souza, M.R.; Acúrcio, L.B.; Cunha, A.F.; Resende, M.F.S.; Nunes, Á.C. Potencial probiótico in vitro de bactérias ácido-láticas isoladas de queijo-de-minas artesanal da Serra da Canastra, MG. Arq. Bras. Med. Vet. Zootec. 2013, 65, 1858–1866. [Google Scholar] [CrossRef]

- Sant’Anna, F.M.; Acúrcio, L.B.; Alvim, L.B.; Castro, R.D.; Oliveira, L.G.; Silva, A.M.; Nunes, A.C.; Nicoli, J.R.; Souza, M.R. Assessment of the probiotic potential of lactic acid bacteria isolated from Minas artisanal cheese produced in the Campo das Vertentes region, Brazil. Int. J. Dairy Technol. 2017, 70, 592–601. [Google Scholar] [CrossRef]

- Todorov, S.D.; Holzapfel, W.; Nero, L.A. Safety evaluation and bacteriocinogenic potential of Pediococcus acidilactici strains isolated from artisanal cheeses. LWT-Food Sci. Technol. 2020, 139, 110550. [Google Scholar] [CrossRef]

- Tulini, F.L.; Winkelströter, L.K.; Martinis, E.C.P. Identification and evaluation of the probiotic potential of Lactobacillus paraplantarum FT259, a bacteriocinogenic strain isolated from Brazilian semi-hard artisanal cheese. Anaerobe 2013, 22, 57–63. [Google Scholar] [CrossRef]

- Valente, G.L.C.; Acúrcio, L.B.; Freitas, L.P.V.; Nicoli, J.R.; Silva, A.M.; Souza, M.R.; Penna, C.F.A.M. Short communication: In vitro and in vivo probiotic potential of Lactobacillus plantarum B7 and Lactobacillus rhamnosus D1 isolated from Minas artisanal cheese. J. Dairy Sci. 2019, 102, 5957–5961. [Google Scholar] [CrossRef]

- Gontijo, M.T.P.; Silva, J.S.; Vidigal, M.P.; Martin, J.G.P. Phylogenetic distribution of the bacteriocin repertoire of lactic acid bacteria species associated with artisanal cheese. Food Res. Int. 2020, 128, 108783. [Google Scholar] [CrossRef] [PubMed]

- Perez, R.H.; Zendo, T.; Sonomoto, K. Circular and leaderless bacteriocins: Biosynthesis, mode of action, applications and prospects. Front. Microbiol. 2018, 9, 2085. [Google Scholar] [CrossRef]

- Silva, C.C.G.; Silva, S.P.M.; Ribeiro, S.C. Application of bacteriocins and protective cultures in dairy food preservation. Front. Microbiol. 2018, 9, 594. [Google Scholar] [CrossRef]

- Mills, S.; Serrano, L.; Griffin, C.; O’Connor, P.M.; Schaad, G.; Bruining, C.; Hills, C.; Ross, R.; Meijer, W.C. Inhibitory activity of Lactiplantibacillus plantarum subsp. plantarum LMG P-26358 against Listeria innocua when used as an adjunct starter in the manufacture of cheese. Microb. Cell Fact. 2011, 10, S7. [Google Scholar] [CrossRef]

- Ogaki, M.B.; Furlaneto, M.C.; Maia, L.F. Revisão: Aspectos gerais das bacteriocinas. Braz. J. Food Technol. 2015, 18, 267–276. [Google Scholar] [CrossRef]

- Balciunas, E.M.; Martinez, F.A.C.; Todorov, S.D.; Franco, B.D.G.M.; Converti, A.; Oliveira, R.P.S. Novel biotechnological applications of bacteriocins: A review. Food Control 2013, 32, 134–142. [Google Scholar] [CrossRef]

- Coelho, M.C.; Silva, C.C.G.; Ribeiro, S.C.; Dapkevicius, M.L.N.E.; Rosa, H.J.D. Control of Listeria monocytogenes in fresh cheese using protective lactic acid bacteria. Int. J. Food Microbiol. 2014, 191, 53–59. [Google Scholar] [CrossRef] [PubMed]

- Montel, M.C.; Buchin, S.; Mallet, A.; Delbes-Paus, C.; Vuitton, D.A.; Desmasures, N.; Berthier, F. Traditional cheeses: Rich and diverse microbiota with associated benefits. Int. J. Food Microbiol. 2014, 177, 136–154. [Google Scholar] [CrossRef]

- Galvéz, A.; Abriquel, H.; López, R.L.; Omar, N.B. Bacteriocin-based strategies for food biopreservation. Int. J. Food Microbiol. 2007, 120, 51–70. [Google Scholar] [CrossRef]

- Heredia-Castro, P.Y.; Hérnández-Mendoza, A.; González-Córdova, A.; Vallejo-Cordoba, B. Bacteriocinas de bacterias ácido lácticas: Mecanismos de acción y actividad antimicrobiana contra patógenos en quesos. Interciencia 2017, 42, 340–346. Available online: https://www.redalyc.org/journal/339/33951621002/html/ (accessed on 21 May 2021).

- Yang, S.C.; Lin, C.H.; Sung, C.T.; Fang, J.Y. Antibacterial activities of bacteriocins: Application in foods and pharmaceuticals. Front. Microbiol. 2014, 5, 241. [Google Scholar] [CrossRef]

- Ahmad, V.; Khan, M.S.; Jamal, Q.M.S.; Alzohairy, M.A.; Karaawi, M.A.A.; Siddiqui, M.U. Antimicrobial potential of bacteriocins: In therapy, agriculture and food preservation. Int. J. Antimicrob. Agents 2017, 49, 1–11. [Google Scholar] [CrossRef]

- Godoy-Santos, F.; Pinto, M.S.; Barbosa, A.A.T.; Brito, M.A.V.P.; Mantovani, H.C. Efficacy of a ruminal bacteriocin against pure and mixed cultures of bovine mastitis pathogens. Indian J. Microbiol. 2019, 59, 304–312. [Google Scholar] [CrossRef] [PubMed]

- Ibarra-Sánchez, L.A.; El-Haddad, N.; Mahmoud, D.; Miller, M.J.; Karam, L. Invited review: Advances in nisin use for preservation of dairy products. J. Dairy Sci. 2020, 103, 2041–2052. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Cortés, C.; Suarez, H.; Buitrago, G.; Nero, L.A.; Todorov, S.D. Characterization of bacteriocins produced by strains of Pediococcus pentosaceus isolated from Minas cheese. Ann. Microbiol. 2018, 68, 383–398. [Google Scholar] [CrossRef]

- Nespolo, C.R.; Brandelli, A. Production of bacteriocin-like substances by lactic acid bacteria isolated from regional ovine cheese. Braz. J. Microbiol. 2010, 41, 1009–1018. [Google Scholar] [CrossRef] [PubMed]

- Winkelströter, L.K.; Tulini, F.L.; De Martinis, E.C.P. Identification of the bacteriocin produced by cheese isolate Lactobacillus paraplantarum FT259 and its potential influence on Listeria monocytogenes biofilm formation. LWT-Food Sci. Technol. 2015, 64, 586–592. [Google Scholar] [CrossRef]

- Pegoraro, K.; Sereno, M.J.; Cavicchioli, V.Q.; Viana, C.; Nero, L.A.; Bersot, L.S. Bacteriocinogenic potential of lactic acid bacteria isolated from artisanal colonial type—Cheese. Arch. Vet. Sci. 2020, 25. [Google Scholar] [CrossRef]

- Paula, J.C.J.; Carvalho, A.F.; Furtado, M.M. Princípios básicos de fabricação de queijo: Do histórico à salga. Rev. Inst. Latícinios Cândido Tostes 2009, 64, 19–25. Available online: https://www.revistadoilct.com.br/rilct/article/view/76/82 (accessed on 17 May 2021).

- Pontarolo, G.H.; Melo, F.D.; Martini, C.L.; Wildemann, P.; Alessio, D.R.M.; Sfaciotte, R.; Neto, A.T.; Vaz, E.K.; Ferraz, S.M. Quality and safety of artisan cheese produced in the serrana region of Santa Catarina. Semina Ciências Agrárias 2017, 38, 739–747. [Google Scholar] [CrossRef]

- Martin, J.G.P.; Lindner, J.D. Alimentos fermentados: Passado, presente e futuro. In Microbiologia de Alimentos Fermentados, 1st ed.; Blucher: São Paulo, Brazil, 2022; Volume 1, pp. 29–62. ISBN 9786555061321. [Google Scholar]

- Souza, J.V.; Dias, F.S. Protective, technological, and functional properties of select autochthonous lactic acid bacteria from goat dairy products. Curr. Opin. Food Sci. 2017, 13, 1–9. [Google Scholar] [CrossRef]

- Food and agriculture organization of united nations (FAO); World health organization (WHO). Evaluation of health and nutritional properties of probiotics in food including powder milk with live lactic acid bacteria. In Probiotics in Food; FAO: Rome, Italy, 2001; ISSN 0254-4725. [Google Scholar]

- Davani-Davari, D.; Negahdaripour, M.; Karimzadeh, I.; Seifan, M.; Mohkam, M.; Masoumi, S.J.; Berenjian, A.; Ghasemi, Y. Prebiotics: Definition, Types, Sources, Mechanisms, and Clinical Applications. Foods 2019, 8, 92. [Google Scholar] [CrossRef]

- Ferreira, C.L.L.F.; Carvalho, M.M.; Píccolo, M.P. Alimentos probióticos. In Microbiologia de Alimentos Fermentados, 1st ed.; Blucher: São Paulo, Brazil, 2022; Volume 1, pp. 163–221. ISBN 9786555061321. [Google Scholar]

- Caggianiello, G.; Kleerebezem, M.; Spano, G. Exopolysaccharides produced by lactic acid bacteria: From health-promoting benefits to stress tolerance mechanisms. Appl. Microbiol. Biotechnol. 2016, 100, 3877–3886. [Google Scholar] [CrossRef]

- Marco, M.L.; Sanders, M.E.; Gänzle, M.; Arrieta, M.C.; Cotter, P.D.; De Vuyst, L.; Hill, C.; Holzapfel, W.; Leeber, S.; Merenstein, D.; et al. The International Scientific Association for Probiotics and Prebiotics (ISAPP) consensus statement on fermented foods. Nat. Rev. Gastroenterol. Hepatol. 2021, 18, 196–208. [Google Scholar] [CrossRef]

- Li, J.; Feng, S.; Yu, L.; Zhao, J.; Tian, F.; Chen, W.; Zhai, Q. Capsular polysaccharides of probiotics and their immunomodulatory roles. Food Sci. Hum. Wellness 2022, 11, 1111–1120. [Google Scholar] [CrossRef]

- Marquez, A.; Andrada, E.; Russo, M.; Bolondi, M.L.; Fabersani, E.; Medina, R.; Gauffin-Cano, P. Characterization of autochthonous lactobacilli from goat dairy products with probiotic potential for metabolic diseases. Heliyon 2022, 8, e10462. [Google Scholar] [CrossRef]

- Mohd-Zubri, N.S.; Ramasamy, K.; Abdul-Rahman, N.Z. Characterization and potential oral probiotic properties of Lactobacillus plantarum FT 12 and Lactobacillus brevis FT 6 isolated from Malaysian fermented food. Arch Oral Biol. 2022, 143, 105515. [Google Scholar] [CrossRef]

- Evivie, S.E.; Huo, G.C.; Igene, J.O.; Bian, X. Some current applications, limitations and future perspectives of lactic acid bacteria as probiotics. Food Nutr. Res. 2017, 61, 1318034. [Google Scholar] [CrossRef] [PubMed]

- Tarique, M.; Abdalla, A.; Masad, R.; Al-Sbiei, A.; Kizhakkayil, J.; Osaili, T.; Olaimat, A.; Liu, S.-Q.; Fernandez-Cabezudo, M.; Ramadi, B.; et al. Potential probiotics and postbiotic characteristics including immunomodulatory effects of lactic acid bacteria isolated from traditional yogurt-like products. LWT-Food Sci. Technol. 2022, 159, 113207. [Google Scholar] [CrossRef]

- Agostini, C.; Eckert, C.; Vincenzi, A.; Machado, B.L.; Jordon, B.C.; Kipper, J.P.; Dullius, A.; Dullius, C.H.; Lehn, D.N.; Sperotto, R.A.; et al. Characterization of technological and probiotic properties of indigenous Lactobacillus spp. from south Brazil. 3 Biotech. 2018, 8, 451. [Google Scholar] [CrossRef]

- Borges, L.; Bastos, R.; Sandes, S.; Guimarães, A.C.C.; Alves, A.G.; Reis, D.C.; Wuyts, S.; Nunes, A.C.; Cassali, G.; Lebeer, S.; et al. Protective effects of milk fermented by Lactiplantibacillus plantarum subsp. plantarum B7 from Brazilian artisanal cheese on a Salmonella enterica serovar Typhimurium infection in BALB/c mice. J. Funct. Foods 2017, 33, 436–445. [Google Scholar] [CrossRef]

- Chourasia, R.; Abedin, M.M.; Phukon, L.C.; Sahoo, D.; Singh, S.P.; Rai, A.K. Biotechnological approaches for the production of designer cheese with improved functionality. Compr. Rev. Food Sci. Food Saf. 2021, 20, 960–979. [Google Scholar] [CrossRef] [PubMed]

- Chambers, E.S.; Preston, T.; Frost, G.; Morrison, D.J. Role of gut microbiota-generated short-chain fatty acids in metabolic and cardiovascular health. Curr. Nutr. Rep. 2018, 7, 198–206. [Google Scholar] [CrossRef]

- Behare, P.V.; Singh, R.; Kumar, M.; Prajapati, J.B.; Singh, R.P. Exopolysaccharides of lactic acid bacteria: A review. J. Food Sci. Technol. 2009, 46, 1–11. Available online: https://www.researchgate.net/publication/261474901 (accessed on 10 May 2021).

- Zhou, Y.; Cui, Y.; Qu, X. Exopolysaccharides of lactic acid bacteria: Structure, bioactivity and associations: A review. Carbohydr. Polym. 2019, 207, 317–332. [Google Scholar] [CrossRef] [PubMed]

- Angmo, K.; Kumari, A.; Savitri; Bhalla, T.C. Probiotic characterisation of lactic acid bacteria isolated from fermented foods and beverage of Ladakh. LWT-Food Sci. Technol. 2016, 66, 428–435. [Google Scholar] [CrossRef]

- Breyer, G.M.; Arechavaleta, N.N.; Siqueira, F.M.; Motta, A.S. Characterization of lactic acid bacteria in raw buffalo milk: A screening for novel probiotic candidates and their transcriptional response to acid stress. Probiotics Antimicro. Proteins 2021, 13, 468–483. [Google Scholar] [CrossRef]

- Kumari, A.; Angmo, K.; Monika; Bhalla, T.C. Probiotic attributes of indigenous Lactobacillus spp. isolated from traditional fermented foods and beverages of north-western Himalayas using in vitro screening and principal component analysis. J. Food Sci. Technol. 2016, 53, 2463–2475. [Google Scholar] [CrossRef]

- Lynch, K.M.; Zanini, E.; Coffey, A.; Arendt, E.K. Lactic acid bacteria exopolysaccharides in foods and beverages: Isolation, properties, characterization and health benefits. Annu Rev. Food Sci. Technol. 2018, 9, 155–176. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Ren, H.; Liu, L.; Ma, L.; Li, M.; Bi, W. Impact of using exopolysaccharides (EPS)- Producing strain on qualities of half-fat cheddar cheese on qualities of half-fat cheddar cheese. Int. J. Food Prop. 2015, 18, 1546–1559. [Google Scholar] [CrossRef]

- Badel, S.; Bernardi, T.; Michaud, P. New perspectives for Lactobacilli exopolysaccharides. Biotechnol. Adv. 2011, 29, 54–66. [Google Scholar] [CrossRef]

- Das, D.; Baruah, R.; Goyal, A. A food additive with prebiotic properties of an α-d-glucan from Lactobacillus plantarum DM5. Int. J. Biol. Macromol. 2014, 69, 20–26. [Google Scholar] [CrossRef] [PubMed]

- Antonio, M.B.; Borelli, B.M. A importância de bactérias láticas na segurança e qualidade dos queijos Minas artesanais. Rev. Inst. Laticínios Cândido Tostes 2020, 75, 204–221. [Google Scholar] [CrossRef]

- Bintsis, T. Lactic acid bacteria as starter cultures: An update in their metabolism and genetics. AIMS Microbiol. 2018, 4, 665–684. [Google Scholar] [CrossRef]

- Hernandez-Valdes, J.A.; Solopova, A.; Kuipers, O.P. Development of Lactococcus lactis Biosensors for Detection of Diacetyl. Front. Microbiol. 2020, 11, 1032. (accessed on 1 September 2021). [Google Scholar] [CrossRef] [PubMed]

- Kamarinou, C.S.; Papadopoulou, O.S.; Doulgeraki, A.I.; Tassou, C.C.; Galanis, A.; Chorianopoulos, N.G.; Argyri, A.A. Mapping the key technological and functional characteristics of indigenous lactic acid bacteria isolated from greek traditional dairy products. Microorganisms 2022, 10, 246. [Google Scholar] [CrossRef] [PubMed]

- Kieliszek, M.; Pobiega, K.; Piwowarek, K.; Kot, A.M. Characteristics of the Proteolytic Enzymes Produced by Lactic Acid Bacteria. Molecules 2021, 26, 1858. [Google Scholar] [CrossRef]

- Bachmann, H.P.; Fröhlich-Wyder, M.T.; Jakob, E.; Roth, E.; Wechsler, D.; Beuvier, E.; Buchin, S. Cheese: Raw milk cheeses. In Encyclopedia of Dairy Sciences, 2nd ed.; Academic Press: Cambridge, MA, USA, 2011; pp. 652–660. [Google Scholar] [CrossRef]

- Coolbear, T.; Weimer, B.; Wilkinson, M.G. Lactic acid bacteria: Lactic acid bacteria in flavor development. In Encyclopedia of Dairy Sciences, 2nd ed.; Academic Press: Cambridge, MA, USA, 2011; pp. 160–165. [Google Scholar] [CrossRef]

- Biscola, V.; Choiset, Y.; Rabesona, H.; Chobert, J.-M.; Haertlé, T.; Franco, B.D.G.M. Brazilian artisanal ripened cheeses as sources of proteolytic lactic acid bacteria capable of reducing cow milk allergy. J. Appl. Microbiol. 2018, 125, 564–574. [Google Scholar] [CrossRef]

- Barbosa, N.E.A.; Ferreira, N.C.J.; Vieira, T.L.E.; Brito, A.P.S.O.; Garcia, H.C.R. Intolerância à lactose: Revisão sistemática. Para Res. Med. J. 2020, 4, e33. [Google Scholar] [CrossRef]

- Silvério, S.C.; Macedo, E.A.; Teixeira, J.A.; Rodrigues, L.R. New β- galactosidase producers with potential for prebiotic synthesis. Bioresour. Technol. 2018, 250, 131–139. [Google Scholar] [CrossRef]

- Saqib, S.; Akram, A.; Halim, S.A.; Tassaduq, R. Sources of β-galactosidase and its applications in food industry. Biotechnol 2017, 7, 79. [Google Scholar] [CrossRef]

- Souza, B.M.S.; Borgonovi, T.F.; Casarotti, S.N.; Todorov, S.D.; Penna, A.L.B. Lactobacillus casei and Lactobacillus fermentum Strains Isolated from Mozzarella Cheese: Probiotic Potential, Safety, Acidifying Kinetic Parameters and Viability under Gastrointestinal Tract Conditions. Probiotics Antimicrob. Proteins 2019, 11, 382–396. [Google Scholar] [CrossRef] [PubMed]

- Paula, A.T.; Jeronymo-Ceneviva, A.B.; Silva, L.F.; Todorov, S.D.; Franco, B.D.G.M.; Penna, A.L.B. Leuconostoc Mesenteroides SJRP55: A Potential Probiotic Strain Isolated from Brazilian Water Buffalo Mozzarella Cheese. Ann. Microbiol. 2015, 65, 899–910. [Google Scholar] [CrossRef]

- Confederação Nacional da Indústria (CNI). Mercado de Insumos e Matérias Primas. 2021. Available online: https://static.portaldaindustria.com.br/portaldaindustria/noticias/media/filer_public/58/3b/583b1a48-b74e-4c31-8600-9dbad69f802f/sondagem_especial_-_insumos_e_materias-primas.pdf (accessed on 22 August 2022).

| BAC | LAB * | References |

|---|---|---|

| Caipira | Enterococcus sp., E. faecium, E. durans, E. faecalis, E. hermanniensis, Lactococcus, Lb. plantarum subsp. plantarum, Lb. paracasei subsp. paracasei, Lb. casei. | [12,39] |

| Coalho | Enterococcus sp., E. faecium, E. casseliflavus, E. durans, E. faecalis, E. gallinarum, E. italicus, E. hermanniensis, Lactobacillus sp., Lb. acidophilus, Lb. curvatus, Lb. fermentum, Lb. paracasei subsp. paracasei, Lb. plantarum subsp. plantarum, Lb. rhamnosus , Lactococcus sp., Lc. lactis, Lc. lactis subsp. lactis, Lc. garvieae, Leuconostoc sp., Lc. mesenteroides subsp. mesenteroides, Streptococcus sp., S. infantarius, subsp. infantarius, S. lutetiensis, S. macedonicus, S. waiu, Weisella sp., W. paramesenteroides | [12,39,45,46,47] |

| Colonial | E. faecium, E. durans, E. faecalis,, E. hermanniensis, Lactococcus sp., Lc. lactis, Lc. piscium, Lc. raffinolactis group, Lactobacillus sp., Lb. brevis, Lb. casei-paracasei, Leuconostoc sp., S. equinus-lutetiensis, S. parauberis, S. porcorum/sanguinis | [12,39,48] |

| Manteiga | E. faecium, E. durans, E. faecalis, E. hermanniensis, Lactobacillus sp., Lactococcus sp., Leuconostoc sp., Streptococcus sp | [12,39] |

| Marajó | E. durans, E. faecium, E. faecalis, E. gilvus, E. hermanniensis, Lactobacillus sp., Lactococcus sp., Leuconostoc sp., Streptococcus sp | [12,39,49] |

| Artisanal Minas | Enterococcus spp., E. durans, E. faecalis, E. faecium, E. gilvus, E. hermanniensis, E. raffinosus, E. rivorum, Lactobacillus sp., Lb. casei, Lb. paracasei subsp. paracasei, Lb. plantarum subsp. plantarum, Lb. paraplantarum, Lb. rhamnosus, Lb. hilgardii, Lb. brevis, Lb. buchneri subsp. buchneri, Lb. parabuchneri, Lb. acidipiscis, Lactococcus spp., Lc. lactis, Lc. garvieae, Leuconostoc sp., Ln. mesenteroides, Pediococcus sp., P. acidilactici, Streptococcus sp., S. agalactiae, S. macedonicus, S. porcorum/sanguinis, S. thermophilus, S. infantarius, W. paramesenteroides | [39,40,44,48,50,51,52,53,54,55] |

| Serrano | Enterococcus sp., E. faecium, E. durans, E. faecalis, E. hermanniensis. Lactobacillus sp., Lb. casei, Lb. plantarum subsp. plantarum, Lb. paracasei subsp. paracasei, Lb. rhamnosus, Lb. acidophilus, Lb. curvatus, Lb. fermentum, Lactococcus sp., Lc. lactis, Lc. piscium, Lc. raffinolactis, Leuconostoc sp., Ln. mesenteroides, Streptococcus sp., S. equinus-lutetiensis-infantarius, S. parauberis, S. porcorum/sanguinis. | [39,56,57,58] |

| BAC | Biotechnological Potential | References |

|---|---|---|

| Marajó | Antimicrobial activity against L. monocytogenes, St. aureus and Es. coli, lipolytic activity, proteolytic activity, acidification capacity, diacetyl production | [11,14,49,70,71] |

| Manteiga | Antimicrobial activity against L. monocytogenes and St. aureus, lipolytic activity, proteolytic activity, acidification capacity, diacetyl production, probiotic potential | [11,14,39,72] |

| Coalho | Antimicrobial activity against Listeria sp., B. cereus, B. subtilis, E. faecalis, St. aureus, Es. coli, K. pneumoniae and P. aeruginosa, lipolytic activity, proteolytic activity, acidification capacity, probiotic potential, β-galactosidase synthesis | [11,14,39,47,72,73,74] |

| Serrano | Antimicrobial activity against L. monocytogenes, St.aureus, Es. coli, S. enterica and Penicillium, lipolytic activity, proteolytic activity, acidification capacity, diacetyl production, probiotic potential | [11,14,39,72,75] |

| Caipira | Antimicrobial activity against L. monocytogenes and St.aureus, lipolytic activity, proteolytic activity, acidification capacity, diacetyl production, probiotic potential | [11,14,39,72] |

| AMC | Antimicrobial activity against Listeria sp., Enterococcus sp., St. aureus, S. Typhimurium and S. Enteritidis, lipolytic activity, proteolytic activity, acidification capacity, diacetyl production, probiotic potential, EPS production | [11,14,39,43,72,76,77,78,79,80,81,82,83] |

| Colonial | Antimicrobial activity against L. monocytogenes and St. aureus, lipolytic activity, proteolytic activity, acidification capacity, diacetyl production, probiotic potential | [11,14,39,72] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hosken, B.d.O.; Melo Pereira, G.V.; Lima, T.T.M.; Ribeiro, J.B.; Magalhães Júnior, W.C.P.d.; Martin, J.G.P. Underexplored Potential of Lactic Acid Bacteria Associated with Artisanal Cheese Making in Brazil: Challenges and Opportunities. Fermentation 2023, 9, 409. https://doi.org/10.3390/fermentation9050409

Hosken BdO, Melo Pereira GV, Lima TTM, Ribeiro JB, Magalhães Júnior WCPd, Martin JGP. Underexplored Potential of Lactic Acid Bacteria Associated with Artisanal Cheese Making in Brazil: Challenges and Opportunities. Fermentation. 2023; 9(5):409. https://doi.org/10.3390/fermentation9050409

Chicago/Turabian StyleHosken, Bianca de Oliveira, Gilberto Vinícius Melo Pereira, Thamylles Thuany Mayrink Lima, João Batista Ribeiro, Walter Coelho Pereira de Magalhães Júnior, and José Guilherme Prado Martin. 2023. "Underexplored Potential of Lactic Acid Bacteria Associated with Artisanal Cheese Making in Brazil: Challenges and Opportunities" Fermentation 9, no. 5: 409. https://doi.org/10.3390/fermentation9050409

APA StyleHosken, B. d. O., Melo Pereira, G. V., Lima, T. T. M., Ribeiro, J. B., Magalhães Júnior, W. C. P. d., & Martin, J. G. P. (2023). Underexplored Potential of Lactic Acid Bacteria Associated with Artisanal Cheese Making in Brazil: Challenges and Opportunities. Fermentation, 9(5), 409. https://doi.org/10.3390/fermentation9050409