Abstract

Bifidobacteria, a major bacterial group, have several beneficial impacts on health, such as enhancing the intestinal flora by limiting the colonization of pathogenic microorganisms and stimulating the immune system. As a result, bifidobacteria have been extensively included in various food products. In this study, Bifidobacterium breve TISTR 2130 was microencapsulated using an emulsion technique with sodium alginate and calcium lactate in green soybean milk as wall materials. This study found that microbeads prepared with 2.0% (w/v) sodium alginate and 2.0% (w/v) calcium lactate had the highest microencapsulation efficiency (MEE) of 99.8% ± 0.07%. In addition, the viability of microencapsulated B. breve TISTR 2130 and free cells was evaluated following a simulated gastrointestinal treatment. Microencapsulated B. breve TISTR 2130 showed higher cell viability than free cells under the simulated gastrointestinal conditions. The viability reduction of free cells dropped substantially to zero after 1 h of incubation in simulated gastrointestinal juice (SIJ), while the viable cell count of microencapsulated B. breve TISTR 2130 remained greater than 5 log CFU/mL and the survival rate was greater than 64% at the end of the sequential digestion. During refrigerated storage of green soybean yogurt (GSY) fortified with microencapsulated B. breve, the viability of B. breve TISTR 2130, syneresis, and acidity decreased, while the pH and viscosity increased. Microencapsulated B. breve TISTR 2130 has the potential to be used as a probiotic fortification in GSY since the viability remained above the recommended minimal limit of 6 log CFU/mL for 10 days during refrigerated storage. The present study demonstrated that the optimized microencapsulated B. breve TISTR 2130 sodium alginate matrix could survive the human gastrointestinal tract to provide health benefits and the possibility of incorporation into functional foods.

1. Introduction

Green soybean (Glycine max L.) milk is a great source of natural antioxidant phytochemicals (procyanidins, quercetin, glycitein, daidzein, genistin, and linalool) that protect against reactive oxygen species. The most abundant phytochemicals in green soybean milk are procyanidins (3.27 ± 0.01 mg/100 g), which are responsible for the mechanisms underlying the development of several severe disorders [1]. Procyanidins have been discovered to have anticancer [2], anti-infectious, anti-inflammatory, cardioprotective, antimicrobial, antiviral, antimutagenic, wound healing, antihyperglycemic, and anti-allergic properties [3].

Yogurt is one of the most widely consumed fermented foods and has acquired considerable market acceptance as a functional food. Consumption of yogurt reduces the risk of type 2 diabetes, improves insulin resistance, lowers circulating levels of glucose and triglycerides, and prevents osteoporosis, high blood pressure, and obesity. Yogurt containing adequate amounts of viable probiotic microorganisms has increased health benefits for the host [4]. These types of bacteria enhance the gut microbial population as carriers of probiotics, which regulate intestinal infections, reduce serum cholesterol levels and lactose intolerance, and lower the risk of developing cancer. The most prevalent and promising probiotic bacterial species are lactic acid bacteria, including lactobacilli and bifidobacteria [5]. However, it is very important that probiotic strains retain their viability and functional activity to confer the above-mentioned benefits on the host. Reports regarding the survival and viability of probiotics indicated that the viability of probiotic bacteria is frequently low in yogurt, producing lower quantities than the daily recommended intake [6]. Yogurt prepared from cow’s milk is popular in both developing and industrialized countries. Despite this, alternatives such as plant-based yogurt are desired by people with lactose intolerance or an allergy to cow’s milk protein, as well as vegetarians. These reasons promote the demand for soy-based yogurt products containing probiotics in adequate amounts to confer a health benefit on the host [7].

To be beneficial for the host, probiotic bacteria in foods must survive gastrointestinal transit and reach the small intestine in sufficient quantities. Therefore, foods incorporating probiotic bacteria should contain a minimum of 6–7 log colony-forming units per milliliter (log CFU/mL) in order to maintain a substantial proportion to reach the large intestine and confer health benefits on the host. It is predicted that a potentially successful probiotic strain would possess a variety of additional desirable qualities, and these properties would influence commercial feasibility [8]. Since the viability and activity of probiotics are required at the site of action, they must be able to tolerate the host’s natural barriers in the gastrointestinal tract (GIT).

The bacteria of the genus Bifidobacterium are Gram-positive, anaerobic, and typical residents of the human colon. By preventing the colonization of dangerous bacteria, the intestinal flora is improved, protein digestion is enhanced, and the immune system is stimulated. Thus, bifidobacteria have been extensively added to food products [9]. Although these microorganisms have probiotic properties and provide health benefits to consumers, the food industry faces a technological challenge in incorporating and ensuring the survival of these bacteria in commercial products. The viability of bifidobacteria is affected by several factors, including acidity, pH value, storage temperature, and oxygen concentration. Therefore, several Bifidobacterium strains included in fermented food products lose their viability during storage and in the digestive tract of humans. Thus, microencapsulation is a promising alternative for the protection of probiotics, as it confers enhanced viability to the strains and increases the effectiveness of probiotic activity. Furthermore, stabilizing probiotics with a carrier could increase the survivability of these microorganisms in products, both during processing and GIT transition, in which they can resist severe gastric and intestinal conditions (such as acid, bile, and enzymes) and attach to the gut epithelium [10].

The effect of microencapsulating probiotics in hydrocolloid beads on their viability in food products and during GIT transit has been investigated. The most common material for encapsulating active compounds is sodium alginate, which contains a biocompatible and non-toxic matrix and is extremely flexible [11]. It is the most common polysaccharide used to encapsulate lactic acid bacteria due to its simplicity of handling, low cost, and capacity to boost bacterial viability under extreme conditions [12]. Therefore, calcium alginate gels have been widely employed in a variety of biotechnology disciplines, including the functional food, pharmaceutical, and medical industries. Alginate beads have been found to promote the survival of probiotics by up to 80–95%. Encapsulation of Lactobacillus rhamnosus in alginate increased survivability at pH 2.0 up to 48 h, whereas free cells were entirely eliminated [13]. In a similar manner, the mortality rate of B. longum immobilized in alginate decreased proportionally with increasing alginate concentrations (2–4% w/v) and bead size. Moreover, bifidobacteria encapsulated in microcapsules show a much lower decline in population when exposed to a simulated gastric environment and bile solution [10]. Petraitytė and Šipailienė [14] reported that calcium lactate has no toxic effect on encapsulated probiotics, showing an improvement in the encapsulation efficiency of L. plantarum.

There are few studies about the viability of bifidobacterial in soy-based yogurt production, and there is no published information about the production of green soybean yogurt (GSY) containing encapsulated B. breve. The viability of probiotics in GSY could be reduced during storage, and gastrointestinal tract conditions could result in the death of B. breve. The purpose of this study was to investigate the effect of various concentrations of coating materials on the efficacy and survival of alginate-encapsulated B. breve TISTR 2130. In addition, this study aimed to improve the survivability of the probiotic B. breve TISTR 2130 in gastrointestinal tract conditions. The quality changes in green soybean yogurt containing B. breve were also assessed during refrigerated storage.

2. Materials and Methods

2.1. Microbial Strains and Reactivation of Probiotic Culture

B. breve TISTR 2130 and L. delbrueckii subsp. bulgaricus TISTR 2290 freeze-dried cultures were acquired directly from the Thailand Institute of Scientific and Technological Research (TISTR). Powdered B. breve TISTR 2130 was cultivated in 5 mL of lactobacilli MRS broth (Difco, Detroit, United States) supplemented with 0.05% (w/v) cysteine-hydrochloride (mMRS) under anaerobic conditions at 37 °C for 24 h to allow bacterial growth. After 24 h, the bacteria were isolated using the streak plate technique. A single loop of bacterial cell culture was streaked on a lactobacilli MRS agar medium. The Petri dish containing the cell culture was then incubated at 37 °C for 48 h under anaerobic conditions to permit the formation of a single colony [10]. The B. breve TISTR 2130 culture in a glycerol stock with approximately 6 log CFU/mL of cell viability was stored at −20 °C until use [9]. L. delbrueckii subsp. bulgaricus TISTR 2290 and Streptococcus thermophilus TISTR 2289 were grown on deMan Rogosa Sharpe (MRS) agar (Himedia Ltd., Bombay, India) at 45 °C for 24 h under anaerobic conditions [15]. The inoculated media were cultivated at the same temperature for 16 h in an effort to stimulate the growth of probiotic bacteria. The glycerol stock cultures of L. delbrueckii subsp. bulgaricus TISTR 2290 and S. thermophilus TISTR 2289 were stored at −20 °C until further usage [16].

2.2. Preparation of Cell Culture

The culture of B. breve TISTR 2130 was transferred from a glycerol stock to a sterile 100-mL Duran bottle containing 25 mL Lactobacilli MRS broth and incubated under anaerobic conditions for 48 h at 37 °C. After adding 75 mL of lactobacilli MRS broth to the cell culture, it was further incubated for 24 h at 37 °C. The collected cells were then centrifuged at 4800 rpm (Nüve NF400R, Ankara City, Turkey) for 10 min at 4 °C. The supernatant was removed after centrifugation, and the pellets were washed twice with a 0.85% sodium chloride solution. The pellets were resuspended in 50 mL of a 0.85% sodium chloride solution. The final cell culture was stored at 4 °C before encapsulation.

Sterile 10-mL portions of MRS broth (Sigma Chemical Co., St. Louis, MO, USA) were inoculated with 1% of each strain (L. delbrueckii subsp. bulgaricus TISTR 2290 and S. thermophilus TISTR 2289) and incubated at 45 °C for 24 h. After incubation, the probiotic bacteria were collected by centrifugation at 4800 rpm (Dinamica, UK) for 10 min at 4 °C, washed twice with a 0.85% sodium chloride solution, and then separated. The cell pellets were then transferred to sterile green soy milk at a concentration of 1% (v/v). The number of cells at the beginning of fermentation for L. delbrueckii subsp. bulgaricus TISTR 2290 and S. thermophilus TISTR 2289 were around 4 log CFU/mL and 6 log CFU/mL, respectively [17].

2.3. Green Soybean Milk Preparation

Whole green soybeans (Glycine max L.) were obtained from Lanna Agro Industry Co., Ltd. (LACO, Chiang Mai, Thailand). Green soybean seeds (GSSs) were separated from their pods and rinsed with tap water. The seeds (500 g) were further ground and mixed in 1500 mL of heated distilled water at 87–90 °C using the medium speed of a blending machine (HR2602, Philips, Ningbo, China) until homogeneous (approximately 5 min). The mixture was filtered using a muslin cloth to obtain green soybean milk. Duran bottles containing green soybean milk were autoclaved at 121 °C for 15 min and thereafter held at 5 °C until use.

2.4. Microencapsulation of B. breve TISTR 2130

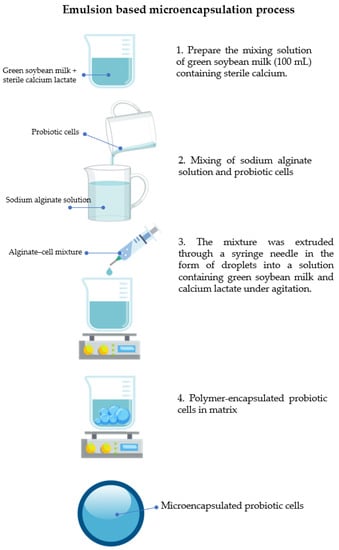

B. breve TISTR 2130 cells were encapsulated in a sodium alginate matrix, as described by Nawong et al. [15]. Green soybean milk, sodium alginate solutions (1.5%, 2.0%, and 2.5%), and calcium lactate solutions (1.0% and 2.0%) were prepared, autoclaved at 121 °C for 15 min, and then cooled to 38–40 °C. Cell pellets from 50 mL of cell suspension and 50 mL of sodium alginate solution were transferred into a 50 mL centrifuge tube, and the content was vortexed until homogeneous. Green soybean milk (100 mL) containing sterile calcium lactate was placed in a 500 mL beaker, to which the alginate–cell mixture was added dropwise through an 18G needle (Figure 1). The height of the drop was 10 cm while stirring magnetically at 500 rpm at room temperature (22–23 °C). The encapsulated probiotic bacteria were separated and washed with a 0.85% (w/v) sodium chloride solution. The beads were harvested by filtering them through No. 4 filter paper, transferring them to a sterile Petri dish, and then storing them in a 10 °C refrigerator. In the microcapsules, the cell concentration was approximately 8 log CFU/g.

Figure 1.

Diagrammatic representation of the emulsion-based microencapsulation process.

Microencapsulation efficiency (MEE) refers to the assessment of cell viability and entrapment efficacy during the encapsulation process [10]. EE was determined using Equation (1), where N represents the number of cells released from the beads and N0 represents the number of free cells.

2.5. Survival of Free and Microencapsulated Probiotics during Exposure to Gastrointestinal Conditions

Preparation of Simulated Gastric Juice (SGJ) and Simulated Intestinal Juice (SIJ)

Simulated gastric juice (SGJ) was produced freshly according to the procedure outlined by Nawong et al. [15]. The SGJ was produced by mixing 0.3 g of pepsin (Sigma-Aldrich Ltd., Steinheim, Germany) with 0.2% (w/w) NaCl. The volume was adjusted to 1000 mL. After adjusting the pH to 2.0, the solution was sterilized.

Simulated intestinal juice (SIJ) was freshly prepared according to the approach by Huang and Adams [18] by adding 8 g of pancreatin (Sigma-Aldrich Ltd., Steinheim, Germany) and 36 g of bile salts (Fisher Scientific Ltd., Kandel, Germany) into a 0.02 M phosphate buffer. The volume was adjusted to 1000 mL, and the solution was sterilized after the pH was adjusted to 7.4.

2.5.1. Survival of Free and Microencapsulated Probiotic Bacteria during Exposure to SGJ

An amount of 25 g of free and microencapsulated probiotic bacteria was added to 225 mL of SGJ that had been heated to 37 °C. The sample was then mixed, sealed with Parafilm, and incubated at 37 °C for 30, 60, and 120 min. MRS agar was used to determine the survival of probiotic bacteria.

2.5.2. Survival of Free and Microencapsulated Probiotic Bacteria during Sequential Exposure to Simulated Gastrointestinal Juice

An amount of 25 g of free and microencapsulated probiotic bacteria was added to 225 mL of SGJ that had been heated to 37 °C. The sample was then mixed, covered with Parafilm, and incubated at 37 °C for 60 min. Then, 25 mL of SIJ that had been heated to 37 °C was added, and the pH was changed to 7.4. The volume of the mixture was adjusted to 500 mL with phosphate buffer. The mixtures were then sealed with Parafilm and incubated at 37 °C for 60, 120, 180, and 240 min. MRS agar was used to determine the survival of probiotic bacteria.

2.5.3. Determination of Microbial Viability

The microencapsulated probiotic bacteria were released from the microcapsules according to the approach provided by Nawong et al. [15]. Briefly, microcapsules (1 g) were resuspended in sterile 55 mM sodium citrate (Loba Ltd., Mumbai, India), the pH was adjusted to 7.4, and the mixture was shaken at 250 rpm for 15 min. MRS agar was used to incubate the probiotic bacteria at 37 °C for 48 h under anaerobic conditions. The viable cell count for the beads and free cells was expressed as log colony-forming units per millimeter (log CFU/mL) [19].

2.6. The Morphology of Microencapsulated Probiotic Bacteria and Free Cells during Sequential Exposure to Simulated Gastrointestinal Conditions

The samples were obtained via an in vitro simulation of a gastrointestinal condition test. Microencapsulated probiotic bacteria were released by sodium citrate as described in the sub-section “Survival rate calculation of viable probiotic bacteria”, and then the cell pellet was separated via centrifugation at 5000 rpm for 5 min before resuspending it in 0.85% (w/v) NaCl. After centrifuging the cell suspensions, they were fixed with 2.5% (w/v) glutaraldehyde (Loba Ltd., Mumbai, India) at 4 °C for 1 h. A buffer was used to wash the samples three times for 15 min. The samples were then post-fixed with 1% (v/v) osmium tetroxide (Sigma-Aldrich Ltd., Steinheim, Germany) for 1 h and rinsed three times with distilled water for 15 min. The samples were dehydrated in ethanol solutions at concentrations of 30%, 50%, 70%, and, finally, 99.8% (v/v) (RCI Labscan, Chiang Mai, Thailand). The samples were dried using a Critical Point Dryer (Polaron CPD 7501, Quorum Technologies Ltd., East Sussex, UK). The dried cells were placed on gold-coated aluminum stubs and observed using a scanning electron microscope, JSM-IT300 (JEOL Ltd., Peabody, MA, USA), at 15 kV. Sample images were acquired at 10,000× magnification [20].

2.7. Preparation of Green Soybean Yogurt

Batches of yogurt were prepared in sterilized glass bottles, each containing 500 mL of sterile green soybean milk. The starter cultures in 1% (v/v) of sterile green soybean milk contained 6 log CFU/mL of S. thermophilus TISTR 2289 and 4 log CFU/mL of L. delbrueckii subsp. bulgaricus TISTR 2290. The incubation was carried out at 37 °C for 24 h to produce green soybean yogurt (GSY). Encapsulated B. breve TISTR 2130 was then transferred to GSY at a concentration of 1% (w/w). After that, treated yogurt samples were blended for 15 min using a hand blender (Taylor Ltd., Rockton, IL, USA). Both control (without encapsulated probiotic bacteria) and treated GSY samples were then packed in 100 g plastic cups. GSY samples were refrigerated at 4 °C to stop the fermentation process. The samples were collected aseptically at regular intervals of 0, 5, 10, 15, and 20 days for microbiological (as previously described in Section 2.5), chemical (pH value and total lactic acid), and physical (syneresis, viscosity, and color) analysis.

2.7.1. pH Value

The pH values of the samples were determined using a pH meter (Thermo Scientific Orion 3 Star, Thermo Electron Corporation, Beverly, MA, USA) with ROSS Ultra pH/ATC Triode (8157 BNUMD) electrodes from the same manufacturer.

2.7.2. Total Lactic Acid

The fermentation-produced lactic acid was titrated against a 0.1 N sodium hydroxide standard solution (factor = 1). Equation (2) was used to calculate titratable acidity (TA):

2.7.3. Syneresis

Syneresis was measured using the method described by Mei et al. [21] with slight modifications. Twenty grams of each collected GSY sample was placed in a funnel lined with No. 1 Whatman filter paper, and the volume of the obtained liquid was recorded. Syneresis was calculated using Equation (3):

2.7.4. Apparent Viscosity

The apparent viscosity of the stirred GSY samples was measured using a Brookfield viscometer (Brookfield Viscometer, DVII, USA) at 5 °C. Measurements were performed with the No. 4 spindle at a rotational speed of 80 RPM. The results were reported as centipoises after 30 s of rotation in the samples [22].

2.7.5. Color Measurement

Color measurements were taken at 5 °C using a Labscan XE Spectrophotometer (Hunterlab, Reston, CA, USA). Before the measurement, GSY samples (50 mL) at 5 °C were agitated and deposited in an aluminum cylinder (55 mm outside diameter) with an optically smooth surface, and the sensor was installed directly on top of the cylinder to eliminate ambient light noise. A standard plate (L0 = 93.37, a0 = −0.91, and b0 = 0.19) was used to calibrate the measurement. These analyses were repeated three times.

2.8. Statistical Analysis

Each experiment was performed in triplicate (n = 3). SPSS (version 16.0, SPSS Inc., Chicago, IL, USA) was used for statistical analysis. The data were reported as the mean ± standard deviation (SD). A Tukey’s post hoc test was used to compare the group means at the 5% significance level.

3. Results and Discussion

3.1. Effect of Different Concentrations of Sodium Alginate and Calcium Lactate on Bead Size and Microencapsulation Efficiency of Microencapsulated B. breve TISTR 2130

Based on the effectiveness of microencapsulation and bead size, the concentrations of sodium alginate and calcium lactate were optimized in this study to provide an appropriate hardening solution for microbeads. As shown in Table 1, increasing the sodium alginate concentration from 1.5% to 2.0% improved the microencapsulation efficiency. Moreover, there was no further increase in MEE when the sodium alginate concentration exceeded 2.0%. The encapsulated B. breve TISTR 2130 exhibited the greatest MEE (99.8% ± 0.07%) when 2.0% (w/v) sodium alginate and 2.0% (w/v) calcium lactate were used in the microencapsulation. A similar result was reported by Rappai et al. [23], who stated that the microencapsulation efficiency of Pediococcus pentosaceus DM101 increased when the concentration of sodium alginate increased from 0.5% to 2.0% (w/v). The characteristic structure of alginate, which is a linear copolymer of 1,4-linked β-D-mannuronic acid and α-L-guluronic acid in which homopolymeric stretches of guluronic acid residues cooperatively bind calcium ions to form a three-dimensional gel structure, also known as the egg-box model, is related to the formation of calcium alginate gels [24].

Table 1.

Cell viabilities, microencapsulation efficiencies, and particle sizes of different concentration levels of sodium alginate and calcium lactate B. breve TISTR 2130 microcapsules.

The results obtained here showed that the uniformity and spherical shape of the alginate beads at a concentration of 1.5% (w/v) were unsatisfactory due to the low viscosity and, consequently (Figure 2), the smaller number of binding sites for Ca2+ ions (cross-linkage) [25]. However, the beads were too viscous to be extruded via the 18G needle containing 2.5% (w/v) alginate. Thus, the concentration of 2.0% (w/v) alginate provided optimal conditions for encapsulation. Alginate is a superior probiotic carrier that improves the survival rate of probiotics. Alginate alone, on the other hand, has reportedly been shown to have significant drawbacks when used to encapsulate probiotics. In comparison to microcapsules with a coating, some studies indicate that alginate microbeads protect probiotics during storage but not when the pH is low (such as in gastrointestinal fluids). Hansen et al. [26] discovered that the porosity of alginate gel changes with the concentration of H+ and increases with the presence of certain bacteria, therefore limiting the protection of probiotics. Additionally, Razavi et al. [27] revealed that the high porosity of alginate microbeads resulted in limitations such as the rapid release of loaded molecules, ineffective probiotic encapsulation, fast degradation in an acidic environment, and inefficient transport of probiotics to the intestine [28]. Hence, the technique of cross-linking between sodium alginate and calcium lactate during microencapsulation is required to minimize the aforementioned disadvantages.

Figure 2.

Shape and morphology of encapsulated B. breve TISTR 2130 (T1-T6) with different concentrations of sodium alginate and calcium lactate (T1: 1.5 and 1.0% w/v; T2: 1.5 and 2.0% w/v; T3: 2.0 and 1.0% w/v; T4: 2.0, and 2.0% w/v, T5: 2.5 and 1.0% w/v; T6: 2.5 and 2.0% w/v, respectively).

In this study, 2.0% (w/v) calcium lactate produced a higher MEE than 1.0% (w/v) calcium lactate. This result is supported by the findings of Chean et al. [29], who found that the MEE of Lactiplantibacillus plantarum 299v microencapsulation increased with increasing calcium chloride concentrations from 0.5% to 2.0%. (77.16% to 92.88%). This result is also supported by Petraitytė and Šipailienė [14], who investigated the effects of several cross-linking agents, including calcium chloride, calcium lactate, and strontium chloride, on the MEE of L. plantarum encapsulation. Calcium lactate produced capsules with the highest MEE (more than 92%), whereas an extremely low MEE of 52.5% ± 2.9% was observed when calcium chloride was used as the cross-linking agent. Hence, calcium lactate is necessary for the formation of an insoluble gel during the hardening process. The data on cell viability in Table 1 indicate that the growth of lactic acid bacteria was greater in the material with a high concentration of calcium lactate. In this regard, various researchers have noted that calcium provides a protective coating to the bacterial cell wall, thereby increasing their survival. Yadav et al. [30] stated that calcium lactate has the capacity to retain approximately 30% moisture content. Due to this property, calcium lactate, which is deemed a GRAS (Generally Recognized as Safe) entity, has obviously helped to protect lactic acid bacteria cells and maintain their cell-bound water, causing less damage to surface proteins, the cell wall and the cell membrane, as well as the functional integrity.

The diameter of the beads increased significantly (p ≤ 0.05) when the sodium alginate concentration increased from 1.5% (w/v) to 2.5% (w/v), as shown in Table 1. However, the size of the beads decreased when the concentration of calcium lactate increased from 1.0% to 2.0% (w/v). This agrees with the findings of Jeong et al. [24], who demonstrated that the diameter of the calcium alginate beads grew with increasing concentrations of sodium alginate (1.2–3.6% w/v) and decreased with increasing calcium lactate concentrations. The study of Klokk and Melvik [31], in which the gel network was contracted by diffusing calcium ions into the sodium alginate droplets in the reactor, can be used to explain these findings. As 2.0% (w/v) sodium alginate and 2.0% (w/v) calcium lactate provided the highest levels of cell viability and MEE, these concentrations were selected and maintained for further analysis.

3.2. Viability of Free Cells and Encapsulated B. breve TISTR 2130 under Simulated Gastrointestinal Conditions

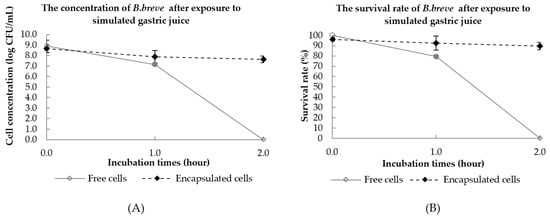

The definition of sequential digestion is the continual incubation of bacteria in the digestive environment. When exposed to unfavorable conditions, such as oxygen, heat, and the presence of pepsin and bile salt in the gastrointestinal system, probiotic bacteria tend to lose viability [32]. One of the primary functions of probiotic microencapsulation is to ensure their survival and high viability (≥7 log CFU/mL) during the gastrointestinal transition [33]. The viability of encapsulated B. breve TISTR 2130 and free cells in a simulated gastric environment (pH 2.0 for 2 h) was investigated, as shown in Figure 3.

Figure 3.

Total viable cell count (log CFU/mL) (A) and survival rates (%) (B) of free and encapsulated B. breve TISTR 2130 in simulated gastric juice (pH 2.0) during incubation at 37 °C for 2 h (n = 3, bars indicate the standard deviation).

After 1 h of incubation in SGJ solution, the viability of both free cells and microencapsulated B. breve TISTR 2130 decreased significantly (p < 0.05), as shown in Figure 3. The viability of microencapsulated cells decreased by 7.07% from 8.49 ± 0.26 log CFU/mL to 7.89 ± 0.59 log CFU/mL after 1 h and further decreased to 7.63 ± 0.31 log CFU/mL after 2 h of incubation. However, the survival rate (%) of free cells was lower than that of encapsulated B. breve TISTR 2130 after 1 h of incubation in SGJ solution. In addition, the viability of free cells was not detected after 2 h of incubation. According to the result of Lai et al. [10], the viable cell count of encapsulated B. lactis Bi-07 cells decreased significantly (p < 0.05) after 1 and 2 h of incubation, but free cells demonstrated a greater rate of reduction as compared to the encapsulated B. lactis Bi-07 after 1 h of incubation in SGJ solution. Gandomi et al. [34] reported comparable results, with free cells exhibiting a more drastic decrease following incubation in SGJ solution than encapsulated probiotics. As the majority of probiotic cells are sensitive to low-pH environments, this reduction was anticipated. This is confirmed by Gunzburg et al. [35], who noted that the lack of protection for free cells exposed to an acidic environment might result in a significant loss of cell viability. Overall, only microencapsulated B. breve TISTR 2130 was able to survive for 2 h in acidic gastric conditions with a viable cell count of greater than 7 log CFU/mL.

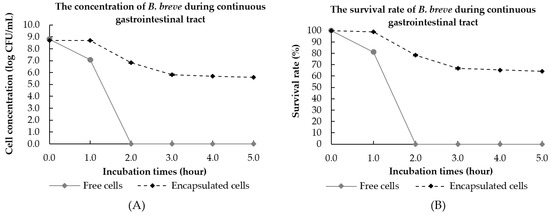

Probiotics that are effective must be able to tolerate both very acidic gastric conditions and strongly alkaline intestinal environments. Probiotics must pass through the small intestine, which contains a high concentration of bile salt, before reaching the large intestine. The presence of bile salts in the small intestine may limit the growth of probiotics. Consequently, the wall material in the probiotic microencapsulation is a crucial criterion for ensuring adequate protection for probiotics [36]. After 2 h in SGJ, the beads were transferred to an SIJ solution and incubated for another 3 h. The total number of viable cells and survival rates of free and encapsulated B. breve TISTR 2130 when exposed to SIJ for 3 h are shown in Figure 4.

Figure 4.

Total viable cell counts (log CFU/mL) (A) and survival rates (%) (B) of free and encapsulated B. breve TISTR 2130 during sequential exposure to simulated gastrointestinal juice (pH 7.5) for 5 h (n = 3, bars indicate the standard deviation).

With increasing incubation time, the number of viable B. breve TISTR 2130 decreased. When exposed to SGJ for 1 h, the survival rate (%) of microencapsulated B. breve TISTR 2130 (98.9% ± 0.06%) was significantly (p < 0.05) greater than that of free B. breve TISTR 2130 (81.2% ± 0.69%). As shown in Figure 4, the viability of free B. breve TISTR 2130 significantly (p < 0.05) decreased from 8.80 log CFU/mL to 7.07 log CFU/mL after 1 h of incubation in gastric juice. It was observed that the number of free probiotic cells dropped substantially to zero after 1 h of incubation in SIJ, while the encapsulated probiotic bacteria were found to be alive at the end of the sequential digestion. The findings of this research could be supported by Lai et al. [37], who proposed that bile salts might have a cytotoxic effect on probiotic cell membranes, leading to cell death. The reduction in the viability of free B. lactis cells in SIJ demonstrated that the probiotics are sensitive to alkaline conditions and bile salt.

Although the viability of encapsulated B. breve TISTR 2130 was lowered during SGJ and SIJ treatments, the observed reductions were substantially less than those of free cells. Moreover, after exposure to SIJ for 2 h, the viable cell counts of encapsulated B. breve TISTR 2130 remained greater than 6 log CFU/mL. This may be because alginate is stable in low-pH conditions but swells in mildly basic conditions [34]. Due to the stability in low-pH solutions of alginate shown in our current research, alginate microspheres can be employed to protect B. breve TISTR 2130 from the acidity of gastric juice. This result is also supported by Kowalska et al. [38], who reported that alginate microcapsules significantly improved the survival of Bifidobacterium bacteria. Their obtained results confirmed that alginate microspheres cross-linked with calcium ions provided superior protection for bacterial cells throughout transit through the digestive tract. There was a reduction of only 1.75 log CFU/mL of viable cells encapsulated with alginate, which had been cross-linked with calcium ions. Upon exposure of alginate microcapsules to simulated digestive fluids, the number of viable bacterial cells ranged from 7.35 to 7.57 log CFU/mL, which was significantly greater than the number of free cells.

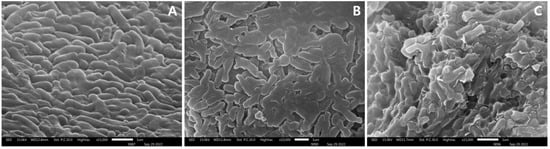

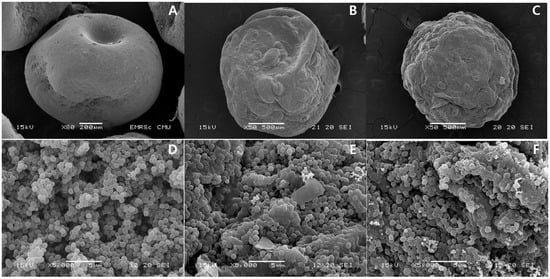

3.3. Particle Morphology

The scanning electron micrographs showed morphological changes in the cell surface of B. breve TISTR 2130 without exposure to the simulated gastrointestinal conditions (Figure 5A), after exposure to SGJ for 1 h (Figure 5B), and after exposure to SGJ/SIJ for 4 h (Figure 5C). Untreated samples showed a normal morphological structure. There were a number of wrinkled and shrunken structures on the cell surface of free B. breve TISTR 2130 during sequential exposure to simulated gastrointestinal conditions (Figure 5B,C).

Figure 5.

Scanning electron microscopy showing morphological changes in B. breve TISTR 2130 free cells without exposure to the simulated gastrointestinal conditions (A), after exposure to SGJ for 1 h (B), and after sequential exposure to SGJ for 1 h and SIJ for 4 h at 37 °C under anaerobic conditions (C).

The scanning electron micrographs revealed morphological changes in the microcapsules loaded with B. breve TISTR 2130 under sequential exposure to gastrointestinal juices (Figure 6). Untreated microcapsules exhibited a rather smooth and spherical appearance (Figure 6A). Nonetheless, drastic changes in the surface and shape of the microcapsules were detected during the course of the assay. After 1 h of incubation at pH 2 in gastric juice, the surface of the microcapsules clearly seemed to be damaged, and the presence of dimples was also observed (Figure 6B). After being exposed to the SGJ/SIJ, the microcapsules demonstrated a shrunken and empty appearance (Figure 6C). Several microcapsules had surface ruptures during these incubation periods. At the end of the sequential exposure to gastrointestinal fluids, a large amount of microcapsule debris was verified with the viability reduction of B. breve TISTR 2130. The current study found that microencapsulation might considerably protect probiotic bacteria during exposure to gastrointestinal conditions.

Figure 6.

Morphological changes in the microcapsules loaded with B. breve TISTR 2130 without exposure to the simulated gastrointestinal conditions (A,D), after exposure to SGJ for 1 h (B,E), and after sequential exposure to SGJ for 1 h and SIJ for 4 h at 37 °C under anaerobic conditions (C,F).

Free probiotic cells showed the greatest loss during exposure to gastrointestinal conditions. This is consistent with the findings of Ribeiro et al. [39], who discovered that yogurt with microencapsulated L. acidophilus was more resistant to simulated gastrointestinal fluids than yogurt containing free L. acidophilus. In addition, Matias et al. [40] demonstrated that ice cream containing free L. acidophilus LA-5 exhibited physiological changes when stress was induced in the gastrointestinal tract (in vitro assay). Furthermore, Nawong et al. [15] found that encapsulated probiotics using maltodextrin and gelatin as wall materials, which had been cross-linked with transglutaminase, significantly improved the survivability of Lactobacillus spp. following exposure to SGJ and SIJ for 4 h at 37 °C. Sengsaengthong and Oonsivilai [41] suggested that the low pH in SGJ may enhance the extracellular H+ concentration. An external pH level close to 2.0 could inhibit enzymes in several types of bacteria. In addition, bacteria maintain their H+ level by utilizing energy (ATP) to actively remove protons via backward ATPase. This results in the loss of an energy source (ATP) for bacterial cells, thereby inhibiting nutrient metabolism and ultimately leading to cell death. According to Zhu et al. [42], bile salt could be hazardous to probiotic bacteria, and many probiotic bacteria have bile salt hydrolases to minimize bile salt [43].

However, microencapsulation improved the survival of B. breve TISTR 2130 after exposure to SGJ and sequential exposure to SIJ. This research clearly showed that the wall materials prevented probiotic bacteria from interacting with a low pH environment, enzymes, and bile salts because of the position of the probiotic bacteria inside the microcapsules, the buffering effect of the sodium alginate matrix, and resistance to pepsin by the actions of TGase enzymes. Microencapsulated probiotics in SIJ significantly decreased because this low pH medium destroyed the structure of the microcapsules, which were composed of units of β-d mannuronic acid and α-l-guluronic acid from alginate chains. Therefore, sodium alginate structure precipitate as an insoluble alginic acid [44].

In the present work, the viability of free cells was lost after 2 h of incubation in SIJ solution, while encapsulated B. breve TISTR 2130 was able to survive in simulated gastrointestinal juice for 5 h with a viable cell count greater than 5 log CFU/mL. In addition, the total number of viable probiotic bacteria in the microcapsules after sequential exposure to SGJ for 2 h and SIJ for 3 h (6.83 ± 0.05 log CFU/mL) remained within the range outlined in the International Dairy Federation guidelines.

3.4. Quality Changes in Green Soybean Yogurt (GSY) during Refrigerated Storage

The prepared green soybean yogurt (GSY) was stored at a refrigerated temperature (4 °C), followed by analyses after 0, 5, 10, 15, and 20 days. According to the results in Table 2, the viability of encapsulated B. breve TISTR 2130 significantly decreased (p < 0.05) during storage. However, the encapsulation could maintain the viability of bacterial cells greater than 6 log CFU/mL in GSY after 10 days of storage. These results are in accordance with Prasanna and Charalampopoulos [45], who discovered that encapsulating B. longum subsp. increased bacterial cell viability in goat milk during storage. Hansen et al. [26] also found that the viability of free B. longum cells in milk was much lower than that of encapsulated bacterial cells during storage at 4 °C for 16 days. This could be a result of the denser surface morphology of alginate-dairy microcapsules, which helps protect the encapsulated cells from harmful external conditions. Alginate-based microcapsules provided superior protection to the probiotics throughout refrigerated storage. This research demonstrated that encapsulating B. breve TISTR 2130 in sodium alginate microcapsules improved bacterial cell viability in the yogurt during 20 days of storage at 4 °C. Consequently, it may be feasible to promote the growth of bifidobacteria in fermented GSY products by microencapsulating them with sodium alginate/green soybean milk.

Table 2.

Effects of storage time on quality changes in green soybean yogurt (GSY).

The pH value of GSY was initially 4.36 ± 0.04, and the total lactic acid concentration was 0.113% ± 0.001%. The storage period significantly (p < 0.05) affected the pH value and total lactic acid of GSY. The lowest value (4.36) was obtained at the beginning of the storage period, while the highest value (4.58) was obtained at the end. As shown in Table 2, the increase in the pH of the sample during the storage period was related to the reduction in the total lactic acid. During the fermentation process, microorganisms can cause a decrease in pH through sugar consumption and the production of organic acids. However, by finishing up the sugar resources, the microorganisms consume the proteins in the environment, resulting in an increase in pH. Shahbandari et al. [46] stated that relatively high pH values and low acidity are caused by the low amount of lactose in initial soy milk. Ghorbani et al. [47] also observed that the pH value of soymilk yogurt products slightly increased during 28 days of storage at 4 °C. One possible explanation for these pH values during storage might be the idea that the pH increase or decrease is mostly associated with the activity of the yogurt starters rather than the probiotics. In probiotic yogurt, probiotics may promote the growth of starters, whereas soymilk matrices may inhibit the growth of starters. Shahbandari et al. [46] also showed that L. bulgaricus and S. thermophilus produced more acid (1.67%) and a lower pH (3.9) in cow milk yogurt than the acid (1–1.19%) and pH (4–4.2) in soy yogurt.

Syneresis is considered a highly essential physical test for determining yogurt quality and is related to the instability of the yogurt gel network and the impossibility of trapping the serum phase in its gel network [22]. Syneresis in yogurt occurs due to compression of the three-dimensional structure of the protein network, which results in a decrease in protein binding power and the exit of water from the yogurt. In the present study of GSY samples (Table 2), the syneresis of the yogurt samples decreased significantly during storage. The highest syneresis (91.0% ± 1.41%) was detected at the beginning of storage, whereas the lowest (91.0% ± 1.41%) was detected on day 20. These results are in line with those reported by Ghorbani et al. [47], who found a significant decrease in the syneresis of soy yogurt containing B. lactis B-12 during 21-day refrigerated storage at 4 °C (p < 0.01). This decrease may be attributed to the lack of marked effect on pH values and lactic acid contents during storage. Hence, there was no set surface of the gel structure of soy protein hydrophobic links and spontaneous separation for GSY. In addition, refrigerated storage provided sufficient time for the rearrangement of the yogurt gel structure and an increase in water activity, resulting in decreased syneresis and increased viscosity.

The viscosity of the GSY increased up to the 20th day of storage, which was 28% higher than that on the 1st day of storage. This increase in viscosity during storage may be due to changes in protein-protein binding in a three-dimensional protein network of yogurt and their rearrangement [48]. In addition, the interactions between soy protein and starch can increase the viscosity of the product. The longer samples are stored, the more interactions dry matter molecules have with each other and also with water, which finally increases the number of dry matter molecules and the viscosity of samples. According to Abu-Jdayil and Mohameed [49], the formation of the gel structure during storage contributed to an increase in the apparent viscosity of concentrated yogurt. Celik et al. [50] reported that the viscosity of fruit-flavored yogurt (by adding cornelian cherry paste and sugar at different ratios) increased rapidly up to day 7, and then increased gradually up to day 14 of storage.

A comparison of the colorimetric parameters of stirred soy yogurt is shown in Table 2. The results show significant differences among the L, a*, and b* parameters during the 20-day storage period (p < 0.05). The L* (lightness) values of GSY were significantly lower (p < 0.05) than those from the first day of storage. The brightness of GSY samples was significantly affected by storage duration. A decrease in yogurt brightness was observed as the storage time increased to 20 days. Similar results were reported by Achouri et al. [51] concerning the influence of storage on the color of soymilk. With an increase in the storage time and color intensity, the color of stored soymilk changed from a creamy yellow to a brownish hue. The brightness of soymilk is related to the particle size of both fat globules and proteins, which affects its light reflectance and scattering ability [52].

According to Table 2, all of the evaluated samples had negative values for the a* parameter of GSY (change in color in the range from green to red) in the range from −3.12 to −2.26. A significantly (p < 0.05) reduced proportion of green color (a*) during storage was found in the yogurt samples stored at 4 °C. However, all the tested yogurt samples had positive values for the b* parameter (change in color in the range from blue to yellow) in the range from 2.38 to 4.05. Based on the present study, the lightness (L*), redness (a*), and yellowness (b*) values decreased with time. These changes were noted by an increase in darkness or brown color. Increases in darkness may have occurred due to Maillard browning during storage. Furthermore, lutein (the major carotenoid) in green soybean, when found at high levels, can potentially alter the color of green soymilk that has undergone an enzymatic browning reaction. The lutein content of beans has been observed to differ depending on variables such as their stage of maturation [51].

In order to have any beneficial effect on humans, the viable cell count should exceed 6 log CFU/mL to supply a sufficient “daily dose”. It is worth mentioning that a standard requiring a minimum of 6–7 log CFU/mL of L. acidophilus or bifidobacteria in fermented milk products has been introduced by several food organizations worldwide (IDF, 2003). The present research showed that a 10-day storage period at refrigerator temperature maintained bacterial cell viability over 6 log CFU/mL, which is satisfactory for the production of high-quality GSY.

4. Conclusions

Microencapsulation of B. breve TISTR 2130 in 2.0% (w/v) sodium alginate and 2.0% (w/v) calcium lactate beads was successfully optimized, with the highest MEE. The optimized encapsulated B. breve TISTR 2130 was efficient in protecting the probiotics from simulated gastrointestinal fluids and displayed higher cell viability than free cells. The amount of viable probiotic bacteria in GSY after 10 days of storage was greater than the minimum recommendation of the International Dairy Federation (6 log CFU/mL). These encapsulation results prove this microencapsulation method to be a viable alternative, substantially maintaining the stability of B. breve TISTR 2130 in both the passage through the gastrointestinal tract and during refrigerated storage. Moreover, encapsulated B. breve can also be applied to other probiotic bacteria and food products that have the potential to be incorporated into functional foods for balancing the microflora in the digestive tract of humans and conferring health benefits on the host.

Author Contributions

J.K. and K.N. designed the study; J.K., K.N. and P.T. performed the experiments and collected and analyzed the data; J.K. and N.S. wrote the initial draft of the manuscript; N.L., C.T., P.R., S.T. and R.N. revised the manuscript; J.K., N.S. and P.R. wrote the final version of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Faculty of Agro-Industry and partially supported by the Cluster of Agro Bio-Circular-Green Industry (Agro BCG), Chiang Mai University.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available on request from the corresponding author.

Acknowledgments

The authors gratefully acknowledge Lanna Agro Industry Co., Ltd., for the supply of green soybeans for this project. The authors would like to thank Chiang Mai University (CMU) and the Bioprocess Research Cluster (BRC) for their in-kind assistance.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leksawasdi, N.; Taesuwan, S.; Prommajak, T.; Techapun, C.; Khonchaisri, R.; Sittilop, N.; Halee, A.; Jantanasakulwong, K.; Phongthai, S.; Nunta, R.; et al. Ultrasonic extraction of bioactive compounds from green soybean pods and application in green soybean milk antioxidants fortification. Foods 2022, 11, 588. [Google Scholar] [CrossRef]

- Li-Chan, E.C.Y. Bioactive peptides and protein hydrolysates: Research trends and challenges for application as nutraceuticals and functional food ingredients. Curr. Opin. Food Sci. 2015, 1, 28–37. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, Y.; Luo, X.; Duan, Y. Protective effect of procyanidins extracted from the lotus seedpod on immune function injury induced by extremely low frequency electromagnetic field. Biomed. Pharmacother. 2016, 82, 364–372. [Google Scholar] [CrossRef] [PubMed]

- Soni, R.; Jain, N.K.; Shah, V.; Soni, J.; Suthar, D.; Gohel, P. Development of probiotic yogurt: Effect of strain combination on nutritional, rheological, organoleptic and probiotic properties. J. Food Sci. Technol. 2020, 57, 2038–2050. [Google Scholar] [CrossRef] [PubMed]

- Linares, D.M.; Gómez, C.; Renes, E.; Fresno, J.M.; Tornadijo, M.E.; Ross, R.P.; Stanton, C. Lactic acid bacteria and Bifidobacteria with potential to design natural biofunctional health-promoting dairy foods. Front. Microbiol. 2017, 8, 846. [Google Scholar] [CrossRef] [PubMed]

- Afzaal, M.; Zahoor, T.; Sadiq, F.A.; Ahmad, F.; Khan, Q.F.; Yasmeen, A.; Imran, M.; Sakandar, H.A. Effect of encapsulation on the viability of probiotics in yoghurt. Prog. Nutr. 2018, 20, 44–52. [Google Scholar]

- Sethi, S.; Tyagi, S.K.; Anurag, R.K. Plant-based milk alternatives an emerging segment of functional beverages: A review. J. Food Sci. Technol. 2016, 53, 3408. [Google Scholar] [CrossRef]

- Ranadheera, C.S.; Vidanarachchi, J.K.; Rocha, R.S.; Cruz, A.G.; Ajlouni, S. Probiotic delivery through fermentation: Dairy vs. non-dairy beverages. Fermentation 2017, 3, 67. [Google Scholar] [CrossRef]

- Holkem, A.T.; Raddatz, G.C.; Nunes, G.L.; Cichoski, A.J.; Jacob-Lopes, E.; Ferreira Grosso, C.R.; de Menezes, C.R. Development and characterization of alginate microcapsules containing Bifidobacterium BB-12 produced by emulsification/internal gelation followed by freeze drying. LWT—Food Sci. Technol. 2016, 71, 302–308. [Google Scholar] [CrossRef]

- Lai, P.Y.; How, Y.H.; Pui, L.P. Microencapsulation of Bifidobacterium lactis Bi-07 with galactooligosaccharides using co-extrusion technique. J. Microbiol. Biotechnol. Food Sci. 2022, 11, e2416. [Google Scholar] [CrossRef]

- Goh, C.H.; Heng, P.W.S.; Chan, L.W. Alginates as a useful natural polymer for microencapsulation and therapeutic applications. Carbohydr. Polym. 2012, 88, 1–12. [Google Scholar] [CrossRef]

- Burgain, J.; Gaiani, C.; Linder, M.; Scher, J. Encapsulation of probiotic living cells: From laboratory scale to industrial applications. J. Food Eng. 2011, 104, 467–483. [Google Scholar] [CrossRef]

- Goderska, K.; Zybala, M.; Czarnecki, Z. Characterisation of microencapsulated Lactobacillus rhamnosus LR7 strain. Pol. J. Food Nutr. Sci. 2003, 53, 21–24. [Google Scholar]

- Petraitytė, S.; Šipailienė, A. Enhancing encapsulation efficiency of alginate capsules containing lactic acid bacteria by using different divalent cross-linkers sources. LWT 2019, 110, 307–315. [Google Scholar] [CrossRef]

- Nawong, S.; Oonsivilai, R.; Boonkerd, N.; Truelstrup Hansen, L. Entrapment in food-grade transglutaminase cross-linked gelatin-maltodextrin microspheres protects Lactobacillus spp. during exposure to simulated gastro-intestinal juices. Food Res. Int. 2016, 85, 191–199. [Google Scholar] [CrossRef] [PubMed]

- Bujalance, C.; Jiménez-Valera, M.; Moreno, E.; Ruiz-Bravo, A. A selective differential medium for Lactobacillus plantarum. J. Microbiol. Methods 2006, 66, 572–575. [Google Scholar] [CrossRef] [PubMed]

- Horáčková, Š.; Mühlhansová, A.; Sluková, M.; Schulzová, V.; Plocková, M. Fermentation of soymilk by yoghurt and bifidobacteria strains. Czech J. Food Sci. 2015, 33, 313–319. [Google Scholar] [CrossRef]

- Huang, Y.; Adams, M.C. In vitro assessment of the upper gastrointestinal tolerance of potential probiotic dairy propionibacteria. Int. J. Food Microbiol. 2004, 91, 253–260. [Google Scholar] [CrossRef] [PubMed]

- IDF. Yogurt enumeration of characteristic microorganisms colony-count technique at 37 degree C. Food Microbiol. 2003, 117, 1–11. [Google Scholar]

- Czerwińska-Główka, D.; Krukiewicz, K. Guidelines for a morphometric analysis of prokaryotic and eukaryotic cells by scanning electron microscopy. Cells. 2021, 10, 3304. [Google Scholar] [CrossRef] [PubMed]

- Mei, J.; Feng, F.; Li, Y. Effective of different homogeneous methods on physicochemical, textural and sensory characteristics of soybean (Glycine max L.) yogurt. CyTA—J. Food. 2016, 15, 21–26. [Google Scholar]

- Izadi, Z.; Nasirpour, A.; Garoosi, G.A.; Tamjidi, F. Rheological and physical properties of yogurt enriched with phytosterol during storage. J. Food Sci. Technol. 2015, 52, 5341–5346. [Google Scholar] [CrossRef] [PubMed]

- Rappai, J.; Beena, A.K.; James, L.; Aparna, S. V Process standardization for alginate encapsulation of potentially probiotic Pediococcus pentosaceus DM101. J. Vet. Anim. Sci 2021, 52, 196–199. [Google Scholar] [CrossRef]

- Jeong, C.; Kim, S.; Lee, C.; Cho, S.; Kim, S.B. Changes in the physical properties of calcium alginate gel beads under a wide range of gelation temperature conditions. Foods 2020, 9, 180. [Google Scholar] [CrossRef]

- Coelho-Rocha, N.D.; De Castro, C.P.; De Jesus, L.C.L.; Leclercq, S.Y.; De Cicco Sandes, S.H.; Nunes, A.C.; Azevedo, V.; Drumond, M.M.; Mancha-Agresti, P. Microencapsulation of lactic acid bacteria improves the gastrointestinal delivery and in situ expression of recombinant fluorescent protein. Front. Microbiol. 2018, 9, 2398. [Google Scholar] [CrossRef] [PubMed]

- Hansen, L.T.; Allan-Wojtas, P.M.; Jin, Y.L.; Paulson, A.T. Survival of Ca-alginate microencapsulated Bifidobacterium spp. in milk and simulated gastrointestinal conditions. Food Microbiol. 2002, 19, 35–45. [Google Scholar] [CrossRef]

- Razavi, S.; Janfaza, S.; Tasnim, N.; Gibson, D.L.; Hoorfar, M. Microencapsulating polymers for probiotics delivery systems: Preparation, characterization, and applications. Food Hydrocoll. 2021, 120, 106882. [Google Scholar] [CrossRef]

- Wang, X.; Gao, S.; Yun, S.; Zhang, M.; Peng, L.; Li, Y.; Zhou, Y. Microencapsulating alginate-based polymers for probiotics delivery systems and their application. Pharmaceuticals 2022, 15, 644. [Google Scholar] [CrossRef] [PubMed]

- Xian Chean, S.; Ying Hoh, P.; Hsuan How, Y.; Lin Nyam, K.; Phing Pui, L. Microencapsulation of Lactiplantibacillus plantarum with inulin and evaluation of survival in simulated gastrointestinal conditions and roselle juice. Braz. J. Food Technol. 2021, 24, 1–13. [Google Scholar] [CrossRef]

- Yadav, A.K.; Chaudhari, A.B.; Kothari, R.M. Cost-effective fermentative production of calcium lactate using BISS (below Indian standard sugar) and Spirulina hydrolysate. Indian J. Biotechnol. 2009, 8, 418–424. [Google Scholar]

- Klokk, T.I.; Melvik, J.E. Controlling the size of alginate gel beads by use of a high electrostatic potential. J. Microencapsul. 2002, 19, 415–424. [Google Scholar] [CrossRef]

- Giraffa, G.; Mattarelli, P.; Taverniti, V.; Wendel, U. Assessing viability and stress tolerance of probiotics-a review. Front. Microbiol. 2021, 12, 818468. [Google Scholar]

- Nazzaro, F.; Fratianni, F.; Coppola, R.; Sada, A.; Orlando, P. Fermentative ability of alginate-prebiotic encapsulated Lactobacillus acidophilus and survival under simulated gastrointestinal conditions. J. Funct. Foods 2009, 1, 319–323. [Google Scholar] [CrossRef]

- Gandomi, H.; Abbaszadeh, S.; Misaghi, A.; Bokaie, S.; Noori, N. Effect of chitosan-alginate encapsulation with inulin on survival of Lactobacillus rhamnosus GG during apple juice storage and under simulated gastrointestinal conditions. LWT—Food Sci. Technol. 2016, 69, 365–371. [Google Scholar] [CrossRef]

- Gunzburg, W.H.; Aung, M.M.; Toa, P.; Ng, S.; Read, E.; Tan, W.J.; Brandtner, E.M.; Dangerfield, J.; Salmons, B. Efficient protection of microorganisms for delivery to the intestinal tract by cellulose sulphate encapsulation. Microb. Cell Fact. 2020, 19, 216. [Google Scholar] [CrossRef]

- Ayyash, M.M.; Abdalla, A.K.; AlKalbani, N.S.; Baig, M.A.; Turner, M.S.; Liu, S.Q.; Shah, N.P. Invited review: Characterization of new probiotics from dairy and nondairy products—Insights into acid tolerance, bile metabolism and tolerance, and adhesion capability. J. Dairy Sci. 2021, 104, 8363–8379. [Google Scholar] [CrossRef] [PubMed]

- Lai, J.T.; Lai, K.W.; Zhu, L.Y.; Nyam, K.L.; Pui, L.P. Microencapsulation of Lactobacillus plantarum 299v and its storage in kuini juice. Malays. J. Microbiol. 2020, 16, 235–244. [Google Scholar]

- Kowalska, E.; Ziarno, M.; Ekielski, A.; Żelaziński, T. Materials used for the microencapsulation of probiotic bacteria in the food industry. Molecules 2022, 27, 3321. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, M.C.E.; Chaves, K.S.; Gebara, C.; Infante, F.N.S.; Grosso, C.R.F.; Gigante, M.L. Effect of microencapsulation of Lactobacillus acidophilus LA-5 on physicochemical, sensory and microbiological characteristics of stirred probiotic yoghurt. Food Res. Int. 2014, 66, 424–431. [Google Scholar] [CrossRef]

- Matias, N.S.; Padilha, M.; Bedani, R.; Saad, S.M.I. In vitro gastrointestinal resistance of Lactobacillus acidophilus La-5 and Bifidobacterium animalis Bb-12 in soy and/or milk-based synbiotic apple ice creams. Int. J. Food Microbiol. 2016, 234, 83–93. [Google Scholar] [CrossRef]

- Sengsaengthong, S.; Oonsivilai, R. Effect of microencapsulation of Lactobacillus sp. 21C2-10 isolated from cassava pulp on physicochemical, sensorial and microbiological characteristics of ice cream. Int. Food Res. J. 2019, 26, 585–594. [Google Scholar]

- Zhu, H.; Hart, C.A.; Sales, D.; Roberts, N.B. Bacterial killing in gastric juice-effect of pH and pepsin on Escherichia coli and Helicobacter pylori. J. Med. Microbiol. 2006, 55, 1265–1270. [Google Scholar] [CrossRef] [PubMed]

- Bustos, A.Y.; Font de Valdez, G.; Fadda, S.; Taranto, M.P. New insights into bacterial bile resistance mechanisms: The role of bile salt hydrolase and its impact on human health. Food Res. Int. 2018, 112, 250–262. [Google Scholar] [CrossRef] [PubMed]

- Choukaife, H.; Doolaanea, A.A.; Alfatama, M. Alginate nanoformulation: Influence of process and selected variables. Pharmaceuticals 2020, 13, 335. [Google Scholar] [CrossRef]

- Prasanna, P.H.P.; Charalampopoulos, D. Encapsulation of Bifidobacterium longum in alginate-dairy matrices and survival in simulated gastrointestinal conditions, refrigeration, cow milk and goat milk. Food Biosci. 2018, 21, 72–79. [Google Scholar] [CrossRef]

- Shahbandari, J.; Golkar, A.; Taghavi, S.M.; Amiri, A. Effect of storage period on physicochemical, textural, microbial and sensory characteristics of stirred soy yogurt. Int. J. Farming Allied Sci. 2016, 5, 476–484. [Google Scholar]

- Ghorbani, M.; Mofaredi, B.; Bashiriyan, S. Study of the relationship between intellectual capital management and organizational innovation in the banks. African J. Bus. Manag. 2012, 6, 5208–5217. [Google Scholar]

- Yekta, M.; Ansari, S. Jujube mucilage as a potential stabilizer in stirred yogurt: Improvements in the physiochemical, rheological, and sensorial properties. Food Sci. Nutr. 2019, 7, 3709–3721. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mohameed, H. Experimental and modelling studies of the flow properties of concentrated yogurt as affected by the storage time. J. Food Eng. 2002, 52, 359–365. [Google Scholar] [CrossRef]

- Celik, S.; Bakrc, I.; Şat, I.G. Physicochemical and organoleptic properties of yogurt with cornelian cherry paste. Int. J. Food Prop. 2006, 9, 401–408. [Google Scholar] [CrossRef]

- Achouri, A.; Boye, J.I.; Zamani, Y. Soybean variety and storage effects on soymilk flavour and quality. Int. J. Food Sci. Technol. 2008, 43, 82–90. [Google Scholar] [CrossRef]

- Chanamai, R.; McClements, D.J. Prediction of emulsion color from droplet characteristics: Dilute monodisperse oil-in-water emulsions. Food Hydrocoll. 2001, 15, 83–91. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).