Adaptation of Ancient Techniques to Recreate ‘Wines’ and ‘Beverages’ Using Withered Grapes of Muscat of Alexandria

Abstract

:1. Introduction

2. Materials and Methods

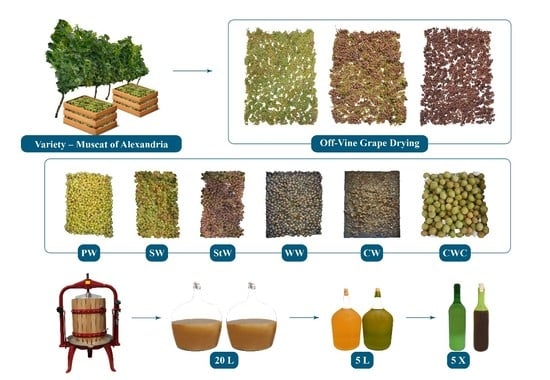

2.1. Sample Collection and Dehydration Process

2.2. Grape Processing

2.3. Fermentation

2.4. Physicochemical Analysis

2.5. Quantitative Determination of Mineral Content

2.6. Statistical Analysis

3. Results and Discussion

3.1. Grape Ripening and Dehydration

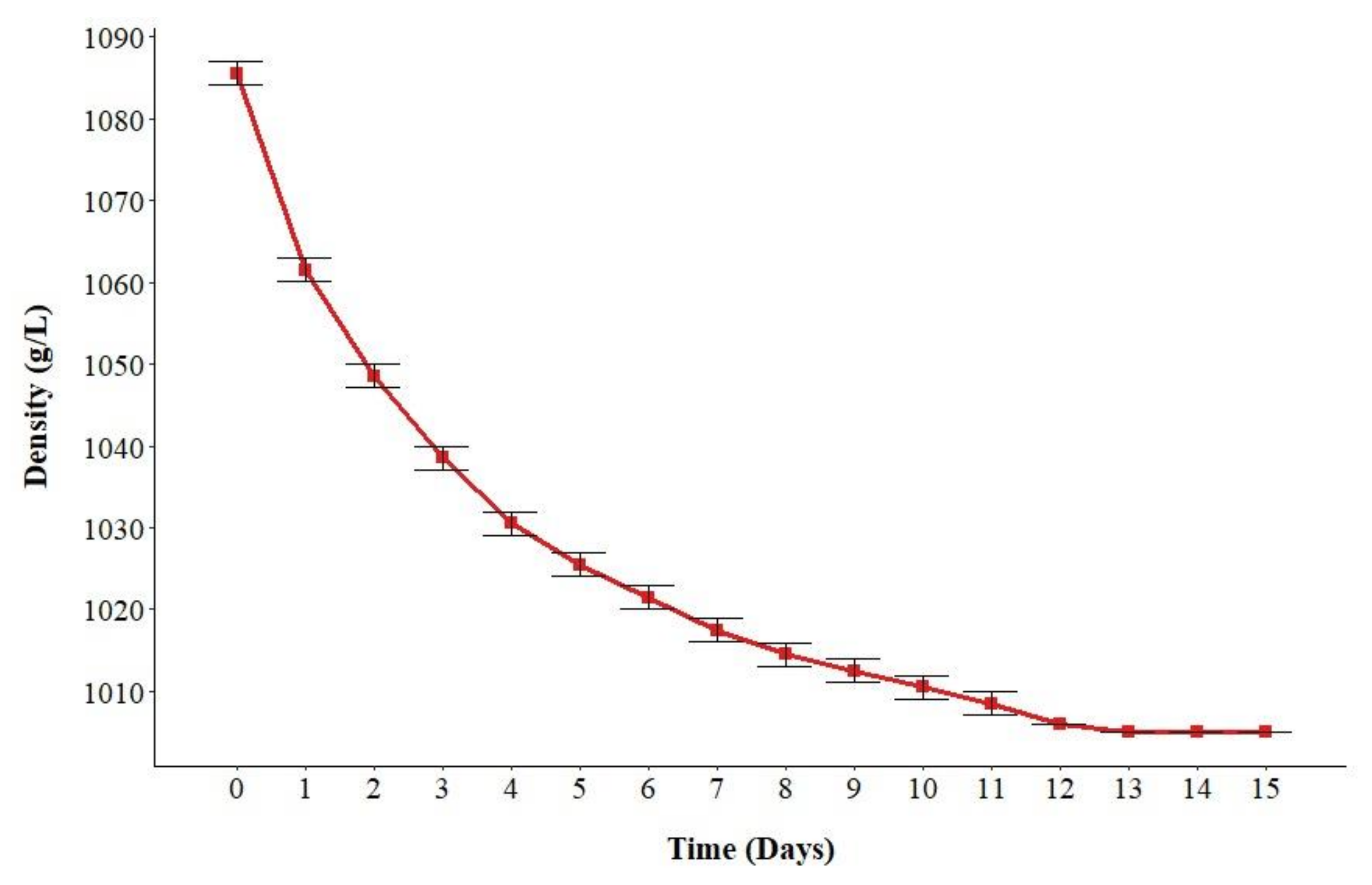

3.2. Fermentation Kinetics

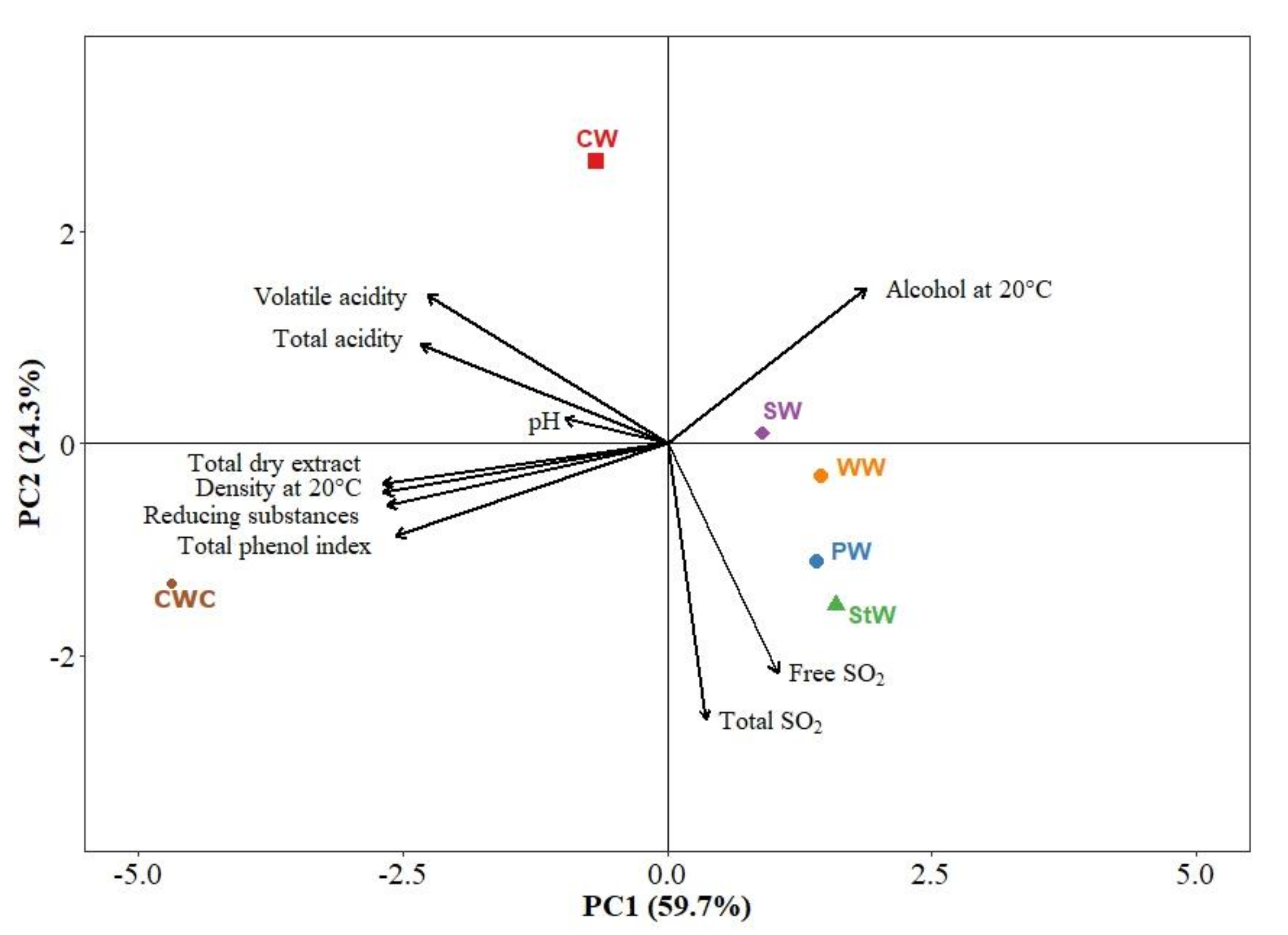

3.3. Physicochemical Analysis

3.4. Mineral Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- McGovern, P.E. Ancient Wine: The Search for the Origins of Viniculture; Princeton Science Library: Princeton, NJ, USA; Princeton University Press: Oxford, UK, 2019. [Google Scholar]

- Tchernia, A.; Brun, J.-P. Le Vin Romain Antique; Glénat Editions: Grenoble, France, 1999. [Google Scholar]

- Dodd, E.K. Roman and Late Antique Wine Production in the Eastern Mediterranean: A Comparative Archaeological Study at Antiochia Ad Cragum (Turkey) and Delos (Greece); Archaeopress Roman Archaeology 63; Archaeopress Publishing Ltd.: Oxford, UK, 2020. [Google Scholar]

- Mencarelli, F.; Tonutti, P. Sweet, Reinforced and Fortified Wines: Grape Biochemistry, Technology and Vinification; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Scienza, A. Italian Passito Wines. In Sweet, Reinforced and Fortified Wines: Grape Biochemistry, Technology and Vinification; Mencarelli, F., Tonutti, P., Eds.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2013; pp. 215–250. [Google Scholar] [CrossRef]

- Scalzini, G.; Giacosa, S.; Río Segade, S.; Paissoni, M.A.; Rolle, L. Effect of Withering Process on the Evolution of Phenolic Acids in Winegrapes: A Systematic Review. Trends Food Sci. Technol. 2021, 116, 545–558. [Google Scholar] [CrossRef]

- Torchio, F.; Urcan, D.E.; Lin, L.; Gerbi, V.; Giacosa, S.; Río Segade, S.; Pop, N.; Lambri, M.; Rolle, L. Influence of Different Withering Conditions on Phenolic Composition of Avanà, Chatus and Nebbiolo Grapes for the Production of ‘Reinforced’ Wines. Food Chem. 2016, 194, 247–256. [Google Scholar] [CrossRef]

- Thurmond, D.L. From Vines to Wines in Classical Rome: A Handbook of Viticulture and Oenology in Rome and the Roman West; Brill: Leiden, The Netherlands, 2017. [Google Scholar]

- Robinson, J. The Oxford Companion to Wine, 4th ed.; Oxford University Press: Oxford, UK, 2015. [Google Scholar]

- Roth, P. Kosher Wine in Medieval Provence and Languedoc—Production and Commerce. Revue des Études Juives 2019, 178, 59–78. [Google Scholar] [CrossRef]

- Counihan, C.M. Around the Tuscan Table: Food, Family, and Gender in Twentieth Century Florence; Routledge: New York, NY, USA, 2004; p. 74. [Google Scholar]

- European Commission. Council Regulation (EC) No. 1493/1999 of 17 May 1999 on the Common Organisation of the Market in Wine. Off. J. Eur. Union 1999, 179, 1–84. Available online: https://eur-lex.europa.eu/eli/reg/1999/1493/oj (accessed on 30 December 2021).

- Corona, O.; Planeta, D.; Bambina, P.; Giacosa, S.; Paissoni, M.A.; Squadrito, M.; Torchio, F.; Segade, S.R.; Cinquanta, L.; Gerbi, V.; et al. Influence of Different Dehydration Levels on Volatile Profiles, Phenolic Contents and Skin Hardness of Alkaline Pre-Treated Grapes Cv Muscat of Alexandria (Vitis vinifera L.). Foods 2020, 9, 666. [Google Scholar] [CrossRef] [PubMed]

- Columella. On Agriculture, Volume III: Books 10–12. On Trees; Loeb Classical Library No. 408; Forster, E.S.; Heffner, E.H., Translators; Harvard University Press: Cambridge, MA, USA, 1955. [Google Scholar]

- Pliny. Natural History, Volume IV: Books 12–16; Loeb Classical Library No. 370; Rackham, H., Translator; Harvard University Press: Cambridge, MA, USA, 1945. [Google Scholar]

- Feier, I.; Migała, A.; Pietruszka, M.; Jackowski, M. Roman Wine in Barbaricum: Preliminary Studies on Ancient Wine Recreation. Heritage 2019, 2, 331–338. [Google Scholar] [CrossRef] [Green Version]

- Dozier, C.A.; Tsai, G.E. Experimental Recreation of 16th Century Wine: Palynological and Enological Characteristics. Archaeol. Food Foodways 2022, 1, 16–33. [Google Scholar] [CrossRef]

- Harutyunyan, M.; Malfeito-Ferreira, M. Historical and Heritage Sustainability for the Revival of Ancient Wine-Making Techniques and Wine Styles. Beverages 2022, 8, 10. [Google Scholar] [CrossRef]

- De Almeida Costa, A.I.; Marano-Marcolini, C.; Malfeito-Ferreira, M.; Loureiro, V. Historical Wines of Portugal: The Classification, Consumer Associations and Marketing Implications. Foods 2021, 10, 979. [Google Scholar] [CrossRef]

- Komar, P. De gustibus disputandum est—‘Fame’ or Ordinary Wines? In Eastern Wines on Western Tables: Consumption, Trade and Economy in Ancient Italy; Komar, P., Ed.; Brill: Leiden, The Netherlands, 2021; Volume 435, pp. 76–127. [Google Scholar]

- European Commission. Commission Regulation (EEC) No. 2676/90 of 17 September 1990 Determining Community Methods for the Analysis of Wines. Off. J. Eur. Union 1990, 272, 1–192. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:31990R2676 (accessed on 30 December 2021).

- OIV (International Organisation of Vine and Wine). Alcoholic strength by volume (Resolution Oeno 377/2009), Method OIV-MA-AS312-01B; Compendium of International Methods of Wine and Must Analysis; Organisation Internationale de la Vigne et du Vin: Paris, France, 2009; Available online: https://www.oiv.int/public/medias/2490/oiv-ma-as312-01b.pdf (accessed on 30 December 2021).

- Ribéreau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. Handbook of Enology: The Chemistry of Wine Stabilization and Treatments, 3rd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2021; Volume 2. [Google Scholar]

- OIV (International Organisation of Vine and Wine). Reducing Substances (Resolution Oeno 377/2009), Method OIV-MA-AS311-01A; Compendium of International Methods of Wine and Must Analysis; Organisation Internationale de la Vigne et du Vin: Paris, France, 2009; Available online: https://www.oiv.int/public/medias/2481/oiv-ma-as311-01a.pdf (accessed on 20 December 2021).

- OIV (International Organisation of Vine and Wine). Analysis of Mineral Elements in Wines Using ICP-AES (Inductively Coupled Plasma/Atomic Emission Spectrometry) (Resolution Oeno 478/2013), Method OIV-MA-AS322-13; Compendium of International Methods of Wine and Must Analysis; Organisation Internationale de la Vigne et du Vin: Paris, France, 2013; Available online: https://www.oiv.int/public/medias/2575/oiv-ma-as322-13-en.pdf (accessed on 20 December 2021).

- Lê, S.; Josse, J.; Husson, F. FactoMineR: An R Package for Multivariate Analysis. J. Stat. Softw. 2008, 25, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Tronchoni, J.; Gonzalez, R.; Guindal, A.M.; Calleja, E.; Morales, P. Exploring the Suitability of Saccharomyces Cerevisiae Strains for Winemaking under Aerobic Conditions. Food Microbiol. 2022, 101, 103893. [Google Scholar] [CrossRef]

- Morales, M.L.; Fierro-Risco, J.; Ríos-Reina, R.; Ubeda, C.; Paneque, P. Influence of Saccharomyces Cerevisiae and Lachancea Thermotolerans Co-Inoculation on Volatile Profile in Fermentations of a Must with a High Sugar Content. Food Chem. 2019, 276, 427–435. [Google Scholar] [CrossRef] [PubMed]

- Andorrà, I.; Martín, L.; Nart, E.; Puxeu, M.; Hidalgo, C.; Ferrer-Gallego, R. Effect of Grape Juice Composition and Nutrient Supplementation on the Production of Sulfur Dioxide and Carboxylic Compounds by Saccharomyces Cerevisiae. Aust. J. Grape Wine Res. 2018, 24, 260–266. [Google Scholar] [CrossRef]

- Rantsiou, K.; Dolci, P.; Giacosa, S.; Torchio, F.; Tofalo, R.; Torriani, S.; Suzzi, G.; Rolle, L.; Cocolin, L. Candida zemplinina can Reduce Acetic Acid Produced by Saccharomyces cerevisiae in Sweet Wine Fermentations. Appl. Environ. Microbiol. 2012, 78, 1987–1994. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, X.; Torija, M.-J.; Mas, A.; Beltran, G.; Navarro, Y. Effect of a Multistarter Yeast Inoculum on Ethanol Reduction and Population Dynamics in Wine Fermentation. Foods 2021, 10, 623. [Google Scholar] [CrossRef]

- Henderson, C.M.; Lozada-Contreras, M.; Jiranek, V.; Longo, M.L.; Block, D.E. Ethanol Production and Maximum Cell Growth Are Highly Correlated with Membrane Lipid Composition during Fermentation as Determined by Lipidomic Analysis of 22 Saccharomyces cerevisiae Strains. Appl. Environ. Microbiol. 2013, 79, 91–104. [Google Scholar] [CrossRef] [Green Version]

- Rolle, L.; Giordano, M.; Giacosa, S.; Vincenzi, S.; Río Segade, S.; Torchio, F.; Perrone, B.; Gerbi, V. CIEL*a*b* Parameters of White Dehydrated Grapes as Quality Markers According to Chemical Composition, Volatile Profile and Mechanical Properties. Anal. Chim. Acta 2012, 732, 105–113. [Google Scholar] [CrossRef] [PubMed]

- OIV (International Organisation of Vine and Wine). ANNEX: Maximum Acceptable Limits; International Code of Oenological Practices; Organisation Internationale de la Vigne et du Vin: Paris, France, 2021; Available online: https://www.oiv.int/public/medias/3741/e-code-annex-maximum-acceptable-limits.pdf (accessed on 20 December 2021).

- Skendi, A.; Papageorgiou, M.; Stefanou, S. Preliminary Study of Microelements, Phenolics as Well as Antioxidant Activity in Local, Homemade Wines from North-East Greece. Foods 2020, 9, 1607. [Google Scholar] [CrossRef]

- Soto Vázquez, E.; Rio Segade, S.; Fernández Gomez, E. Incidence of the Winemaking Technique on Metal Content and Phenolic Composition of Red Wines. Int. J. Food Prop. 2013, 16, 622–633. [Google Scholar] [CrossRef]

- Shimizu, H.; Akamatsu, F.; Kamada, A.; Koyama, K.; Iwashita, K.; Goto-Yamamoto, N. Variation in the Mineral Composition of Wine Produced Using Different Winemaking Techniques. Int. J. Food Prop. 2020, 130, 166–172. [Google Scholar] [CrossRef] [PubMed]

| Wine Products | Code | Withered Grapes (kg) | Description |

|---|---|---|---|

| Obtained from | PW | 20.0 | Free-run juice from grape trodden by foot (prototropum) |

| withered grapes | SW | 33.8 | Juice from rehydration of grapes with 15 L saltwater (15 g/L NaCl) |

| StW | 22.6 | Juice from rehydration of grapes with 5 L of one-year-old white wine a | |

| WW | 22.6 | Juice from rehydration of destemmed grapes with 5 L of one-year-old white wine | |

| CW | 33.8 | Juice of destemmed grapes after pressing | |

| CWC | - | CW wine added of grape juice boiled down to one-third (sapa) | |

| CW21 b | 270 | Juice of destemmed grapes after pressing | |

| CW21L | - | Wine resulting from the gross juice lees by settling for 24 h under room temperature | |

| Piquettes from grape pomaces c | PSW | 24.5 | Pomace from SW wine plus 15 L of tartaric acid solution |

| PStW | 34.2 | Pomace from StW wine plus 20 L of tartaric acid solution | |

| PWW | 23.0 | Pomace from WW wine plus 15 L of tartaric acid solution | |

| PCW | 17.8 | Pomace from CW wine plus 20 L of tartaric acid solution |

| Phase | Date | Weight of 100 Berries (g) | Weight Loss (%) | Volume of Juice (mL) | Juice Yield (mL/g) | Brix (°Brix) | pH | Total Acidity (g/L Tartaric Acid) |

|---|---|---|---|---|---|---|---|---|

| Ripening | 3 August | 447.6 | - | 204 | 0.46 | 17.3 | 2.86 | 7.7 |

| 10 August | 426.6 | - | 222 | 0.52 | 19.4 | 3.18 | 5.7 | |

| 17 August | 401.8 | - | 238 | 0.59 | 18.9 | 3.21 | 5.3 | |

| 24 August | 495.0 | - | 250 | 0.51 | 20.1 | 3.38 | 5.0 | |

| 31 August | 520.0 | - | 216 | 0.41 | 21.4 | 3.44 | 4.5 | |

| Dehydration | 4 September | 570.6 | 0 | 278 | 0.49 | 24.7 | 3.95 | 4.1 |

| 7 September | 438.8 | 23.1 | 133 | 0.30 | 29.4 | 3.87 | 4.9 | |

| 8 September | 469.7 | 17.7 | 138 | 0.29 | 29.7 | 3.91 | 3.9 | |

| 10 September | 385.0 | 32.5 | 128 | 0.33 | 27.9 | 3.75 | 4.5 |

| Wine | Alcohol at 20 °C (%, v/v) | Reducing Substances (g/L) | Total Acidity (g/L Tartaric Acid) | Volatile Acidity (g/L Acetic Acid) | pH | Total SO2 a (mg/L) | Free SO2 (mg/L) | Total SO2 (mg/L) | Density at 20 °C (g/L) | Total Dry Extract (g/L) | Total Phenol Index |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PW b | 15.0 | 0.8 | 5.1 | 0.21 | 3.90 | 28 | 43 | 138 | 989.8 | 27.9 | 7.2 |

| SW c | 14.8 ± 0.1 | 2.6 ± 0.4 | 4.7 ± 0.0 | 0.50 ± 0.01 | 3.85 ± 0.02 | 20 ± 0 | 19 ± 1 | 125 ± 0 | 994.2 ± 0.0 | 38.8 ± 0.0 | 7.7 ± 0.0 |

| StW c | 14.8 ± 0.0 | 0.7 ± 0.1 | 5.3 ± 0.1 | 0.32 ± 0.01 | 3.59 ± 0.03 | 33 ± 0 | 41 ± 0 | 157 ± 2 | 990.0 ± 0.0 | 27.9 ± 0.0 | 8.8 ± 0.0 |

| WW c | 17.0 ± 0.0 | 6.1 ± 0.0 | 4.7 ± 0.3 | 0.39 ± 0.02 | 3.95 ± 0.01 | 40 ± 0 | 30 ± 0 | 148 ± 4 | 990.4 ± 0.0 | 35.2 ± 0.0 | 8.6 ± 0.0 |

| CW c | 16.3 ± 0.1 | 17.9 ± 1.1 | 7.7 ± 0.3 | 2.26 ± 0.06 | 3.82 ± 0.01 | 13 ± 0 | 14 ± 1 | 72 ± 5 | 1000.2 ± 0.0 | 58.5 ± 0.0 | 8.7 ± 0.0 |

| CWC c | 12.6 ± 0.3 | 125.8 ± 1.8 | 8.0 ± 0.1 | 2.15 ± 0.06 | 3.94 ± 0.01 | - | 26 ± 1 | 144 ± 2 | 1048.0 ± 0.0 | 172.7 ± 0.8 | 40.2 ± 0.0 |

| CW21 c | 17.6 ± 0.3 | 36.0 ± 0.2 | 5.1 ± 0.1 | 1.16 ± 0.10 | 4.36 ± 0.03 | - | 12 ± 1 | 55 ± 6 | 1.0 ± 0.0 | 68.0 ± 0.5 | 12.0 ± 0.7 |

| CW21L b | 18.9 | 18.1 | 5.3 | 0.83 | 4.24 | - | 14 | 36 | 1.0 | 50.7 | 12.4 |

| Sample | Alcohol at 20 °C (%, v/v) | Reducing Substances (g/L) | Total Acidity (g/L Tartaric Acid) | Volatile Acidity (g/L Acetic Acid) | pH | Free SO2 (mg/L) | Total SO2 (mg/L) |

|---|---|---|---|---|---|---|---|

| PSW | 14.1 | 1.4 | 4.95 | 0.74 | 3.87 | 43 | 170 |

| PWW | 16.0 | 1.0 | 4.35 | 0.62 | 3.97 | 48 | 160 |

| PStW | 10.2 | 0.1 | 4.50 | 0.45 | 3.75 | 48 | 160 |

| PCW | 11.5 | 0.9 | 5.70 | 0.75 | 3.62 | 66 | 158 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harutyunyan, M.; Viana, R.; Granja-Soares, J.; Martins, M.; Ribeiro, H.; Malfeito-Ferreira, M. Adaptation of Ancient Techniques to Recreate ‘Wines’ and ‘Beverages’ Using Withered Grapes of Muscat of Alexandria. Fermentation 2022, 8, 85. https://doi.org/10.3390/fermentation8020085

Harutyunyan M, Viana R, Granja-Soares J, Martins M, Ribeiro H, Malfeito-Ferreira M. Adaptation of Ancient Techniques to Recreate ‘Wines’ and ‘Beverages’ Using Withered Grapes of Muscat of Alexandria. Fermentation. 2022; 8(2):85. https://doi.org/10.3390/fermentation8020085

Chicago/Turabian StyleHarutyunyan, Mkrtich, Renato Viana, Joana Granja-Soares, Miguel Martins, Henrique Ribeiro, and Manuel Malfeito-Ferreira. 2022. "Adaptation of Ancient Techniques to Recreate ‘Wines’ and ‘Beverages’ Using Withered Grapes of Muscat of Alexandria" Fermentation 8, no. 2: 85. https://doi.org/10.3390/fermentation8020085

APA StyleHarutyunyan, M., Viana, R., Granja-Soares, J., Martins, M., Ribeiro, H., & Malfeito-Ferreira, M. (2022). Adaptation of Ancient Techniques to Recreate ‘Wines’ and ‘Beverages’ Using Withered Grapes of Muscat of Alexandria. Fermentation, 8(2), 85. https://doi.org/10.3390/fermentation8020085