Immobilization of Saccharomyces cerevisiae on Apple Pieces to Produce Cider

Abstract

1. Introduction

2. Materials and Methods

2.1. Yeasts

- S. cerevisiae W13, isolated from Uva di Troia (Laboratory of Predictive Microbiology, Department of the Science of Agriculture, Food, and Environment (SAFE), University of Foggia, Foggia, Italy) and able to remove ochratoxin A [12];

- S. cerevisiae strain 17, isolated from Altamura bread DPA (Denomination of Protected Origin) sourdough (collection of the Laboratory of Predictive Microbiology) [16];

- S. cerevisiae var. boulardii ATCC MYA-796 (American Type Culture Collection).

2.2. Immobilization on Apple Pieces

2.3. Fermentation of Apple Juice

- (1)

- Experiment (A). Yeast was immobilized on apple pieces, and the carriers were immediately used for apple juice fermentation;

- (2)

- Experiment (B). Yeast was immobilized on apple pieces and then stored at 4 °C for 7 days. After the storage, the pieces were used for juice fermentation.

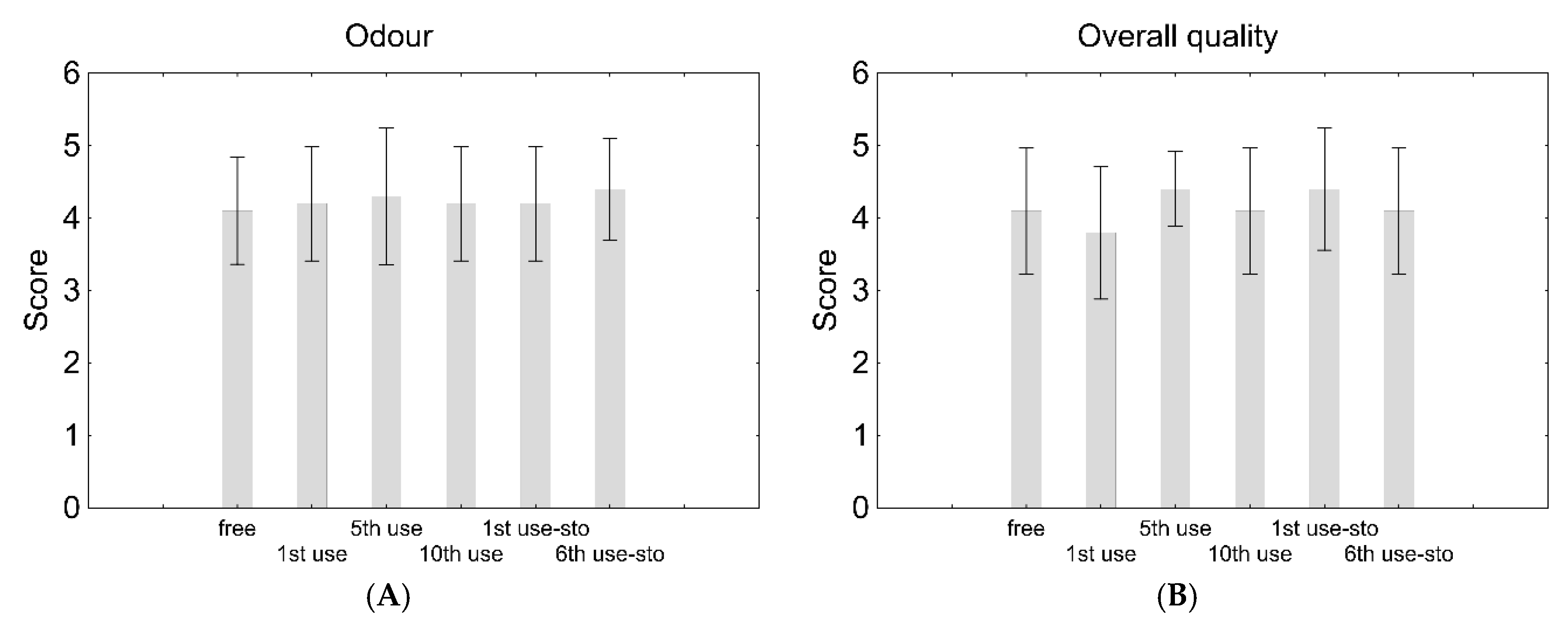

2.4. Sensory Analyses

2.5. Statistical Analyses

3. Results

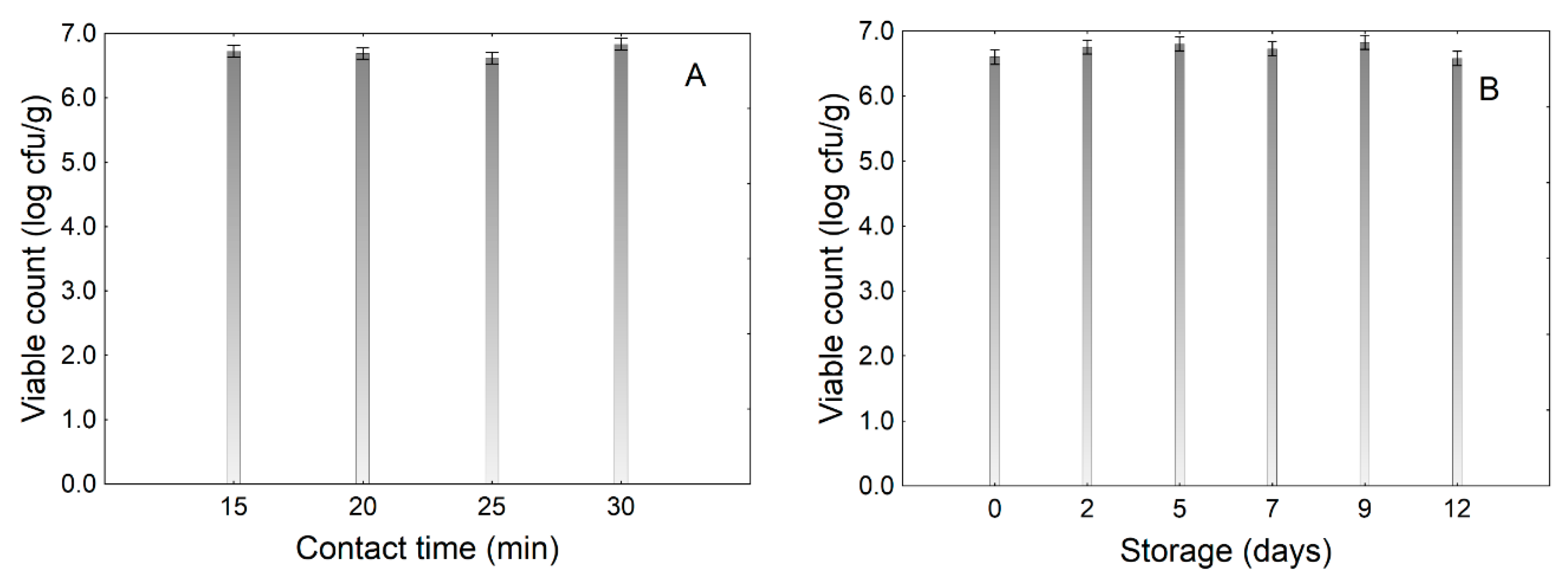

3.1. Immobilization of Yeasts on Apple Pieces

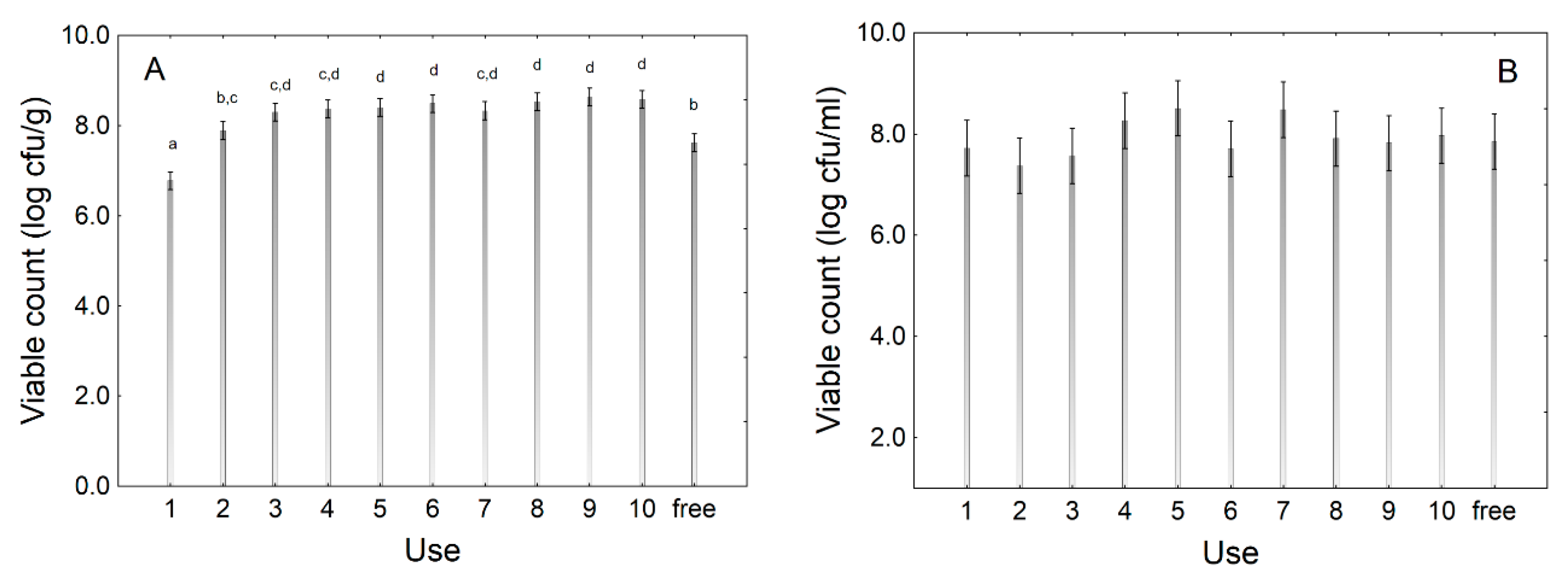

3.2. Cider Production

4. Discussion

- (a)

- Surface with functional properties, favoring yeast adhesion;

- (b)

- Easy to handle and/or regenerate;

- (c)

- High and retained cell viability and operational stability;

- (d)

- Catalytic activity not affected;

- (e)

- Cost-effective.

Author Contributions

Funding

Conflicts of Interest

References

- Kourkoutas, Y.; Bekatorou, A.; Banat, I.M.; Marchant, R.; Koutinas, A.A. Immobilization technologies and support materials suitable in alcohol beverages production: A review. Food Microbiol. 2004, 21, 377–397. [Google Scholar] [CrossRef]

- Nedović, V.; Obradović, B.; Leskošek-Čukalović, I.; Trifunović, O.; Pešić, R.; Bugarski, B. Electrostatic generation of alginate microbeads loaded with brewing yeast. Process Biochem. 2001, 37, 17–22. [Google Scholar] [CrossRef]

- Gallo, M.; Bevilacqua, A.; Speranza, B.; Sinigaglia, M.; Corbo, M.R. Alginate beads and apple pieces as carriers for Saccharomyces cerevisiae var. boulardii, as representative of yeast functional starter cultures. Int. J. Food Sci. Technol. 2014, 49, 2092–2100. [Google Scholar] [CrossRef]

- Kourkoutas, Y.; Kanellaki, M.; Koutinas, A.A. Apple pieces as immobilization support of various microorganisms. LWT-Food Sci. Technol. 2006, 39, 980–986. [Google Scholar] [CrossRef]

- Moreno-García, J.; García-Martinez, T.; Mauricio, J.C.; Moreno, J. Yeast immobilization systems for alcoholic wine fermentations: Actual trends and future perspectives. Front. Microbiol. 2018, 9, 241. [Google Scholar] [CrossRef]

- Arevallo-Villena, M.; Briones-Perez, A.; Corbo, M.R.; Sinigaglia, M.; Bevilacqua, A. Biotechnological application of yeasts in food science. Starter cultures, probiotic, and enzyme production. J. Appl. Microbiol. 2017, 123, 1360–1372. [Google Scholar] [CrossRef] [PubMed]

- Graff, S.; Hussain, S.; Chaumeil, J.C.; Charrueau, C. Increased intestinal delivery of viable Saccharomyces boulardii by encapsulation in microspheres. Pharm. Res. 2008, 25, 1290–1296. [Google Scholar] [CrossRef] [PubMed]

- Ciccarelli, S.; Stolfi, I.; Caramia, G. Management strategies and treatment of neonatal and pediatric gastroenteritis. Infect. Drug Resist. 2013, 6, 133–161. [Google Scholar] [PubMed]

- Serce, O.; Benzer, D.; Gursoy, T.; Karatekin, G.; Ovali, F. Efficacy of Saccharomyces boulardii on necrotizing enterocolitis or sepsis in very low birth weight: A randomized controlled trial. Early Hum. Dev. 2013, 89, 1033–1036. [Google Scholar] [CrossRef] [PubMed]

- Shan, L.S.; Hou, P.; Wang, Z.J.; Liu, F.R.; Chen, N.; Shu, L.H.; Zhang, H.; Han, X.H.; Han, X.X.; Shang, Y.X.; et al. Prevention and treatment of diarrhea with Saccharomyces boulardii in children with acute lower respiratory tract infections. Benef. Microbes 2013, 4, 329–334. [Google Scholar] [CrossRef]

- Bevilacqua, A.; Casanova, F.P.; Arace, E.; Augello, S.; Carfagna, R.; Cedola, A.; Delli Cari, S.; De Stefano, F.; Di Maggio, G.; Marinelli, V.; et al. A case-study on the selection of promising functional starter strains from grape yeasts: A report by student of Food Science and Technology degree, University of Foggia (Southern Italy). J. Food Res. 2012, 1, 44–54. [Google Scholar] [CrossRef][Green Version]

- Petruzzi, L.; Bevilacqua, A.; Baiano, A.; Beneduce, L.; Corbo, M.R.; Sinigaglia, M. Study of Saccharomyces cerevisiae W13 as a functional starter for the removal of ochratoxin A. Food Control 2014, 35, 373–377. [Google Scholar] [CrossRef]

- Petruzzi, L.; Bevilacqua, A.; Corbo, M.R.; Garofalo, C.; Baiano, A.; Sinigaglia, M. Selection of authochtonous Saccharomyces cerevisiae as strains as wine starters using a polyphasic approach and ochratoxin A removal. J. Food Prot. 2014, 77, 1168–1177. [Google Scholar] [CrossRef] [PubMed]

- Rosend, J.; Kuldjärv, R.; Rosenvald, S.; Paalme, T. The effects of apple variety, ripening stage, and yeast strain on the volatile composition of apple cider. Heliyon 2019, 5, 201953. [Google Scholar] [CrossRef]

- Laaksonen, O.; Kuldjärv, R.; Paalme, T.; Virkki, M.; Yang, B. Impact of apple cultivar, ripening stage, fermentation type and yeast strain on phenolic composition of apple ciders. Food Chem. 2017, 233, 29–37. [Google Scholar] [CrossRef] [PubMed]

- Perricone, M.; Bevilacqua, A.; Corbo, M.R.; Sinigaglia, M. Technological characterization and probiotic traits of yeasts isolated from Altamura sourdough to select promising microorganisms as functional starter cultures for cereal-based products. Food Microbiol. 2014, 38, 26–35. [Google Scholar] [CrossRef]

- Kopsahelis, N.; Panas, P.; Kourkoutas, Y.; Koutinas, A.A. Evaluation of the thermally dried immobilized cells of Lactobacillus delbrueckii subsp. bulgaricus on apple pieces as a potent starter culture. J. Agric. Food Chem. 2007, 55, 9829–9836. [Google Scholar] [CrossRef]

- Berbegal, C.; Spano, G.; Tristezza, M.; Griego, F.; Capozzi, V. Microbial resources and innovation in the wine production sector. S. Afr. J. Enol. Viticult. 2017, 38, 156–166. [Google Scholar] [CrossRef]

- Weinbreck, F.; Bodnar, I.R.; Marco, M.L. Can encapsulation lengthen the shelf-life of probiotic bacteria in dry products? Int. J. Food Microbiol. 2010, 136, 364–367. [Google Scholar] [CrossRef]

- Corbo, M.R.; Bevilacqua, A.; Gallo, M.; Speranza, B.; Sinigaglia, M. Immobilization and microencapsulation of Lactobacillus plantarum: Performances and in vivo applications. Innov. Food Sci. Emerg. Technol. 2013, 18, 196–201. [Google Scholar] [CrossRef]

- Nedović, V.; Gibson, B.; Mantzouridou, T.F.; Bugarski, B.; Djordjević, V.; Kalušević, A.; Paraskevopoulou, A.; Sandell, M.; Šmogrovičová, D.; Yilmaztekin, M. Aroma formation by immobilized yeast cells in fermentation processes. Yeast 2015, 32, 173–216. [Google Scholar] [CrossRef] [PubMed]

- Kourkoutas, Y.; Mc Erlean, C.; Kanellaki, M.; Hack, C.J.; Marchant, R.; Banat, I.M.; Koutinas, A.A. High-temperature wine making using the thermotolerant yeast strain Kluyveromyces marxianus IMB3. Appl. Biochem. Biotechnol. 2004, 112, 25–35. [Google Scholar] [CrossRef]

- Berbegal, C.; Polo, L.; García-Esparza, M.J.; Lizama, V.; Ferrer, S.; Pardo, I. Immobilisation of yeasts on oak chips for use in bottle-fermented sparkling wine. Food Microbiol. 2019, 78, 25–37. [Google Scholar] [CrossRef] [PubMed]

- Armani, M.; Morozova, K.; Scampicchio, M. Immobolization of Saccharomyces cerevisiae on nylon-6-nonofibrous membranes for grape juice fermentation. LWT-Food Sci. Technol. 2019, 110, 360–364. [Google Scholar] [CrossRef]

| Variables | SS | df | MS | p |

|---|---|---|---|---|

| Saccharomyces boulardii | ||||

| Contact time | 2.315 | 3 | 0.772 | >0.05 |

| Storage | 3.456 | 5 | 0.691 | >0.05 |

| Contact x storage | 0.564 | 15 | 0.038 | >0.05 |

| W13 | ||||

| Contact time | 3.257 | 3 | 1.085 | >0.05 |

| Storage | 4.445 | 5 | 0.889 | >0.05 |

| Contact x storage | 0.721 | 15 | 0.048 | >0.05 |

| 17 | ||||

| Contact time | 4.568 | 3 | 1.523 | >0.05 |

| Storage | 3.456 | 5 | 0.691 | >0.05 |

| Contact x storage | 0.935 | 15 | 0.062 | >0.05 |

| Use | Experiment A1 | Experiment B |

|---|---|---|

| 1 | 2.23 ± 1.08 | 3.09 ± 1.54 |

| 2 | 1.67 ± 0.51 | 4.75 ± 0.44 |

| 3 | 2.39 ± 0.58 | 3.79 ± 1.19 |

| 4 | 2.90 ± 1.76 | 3.52 ± 1.67 |

| 5 | 2.92 ± 1.52 | 2.08 ± 0.17 |

| 6 | 3.27 ± 0.35 | 2.03 ± 0.21 |

| 7 | 2.28 ± 0.50 | - |

| 8 | 2.25 ± 0.32 | - |

| 9 | 5.17 ± 2.72 | - |

| 10 | 6.93 ± 3.52 | - |

| Free | 3.10 ± 0.14 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Altieri, C.; Campaniello, D.; Speranza, B.; Sinigaglia, M.; Corbo, M.R.; Bevilacqua, A. Immobilization of Saccharomyces cerevisiae on Apple Pieces to Produce Cider. Fermentation 2019, 5, 74. https://doi.org/10.3390/fermentation5030074

Altieri C, Campaniello D, Speranza B, Sinigaglia M, Corbo MR, Bevilacqua A. Immobilization of Saccharomyces cerevisiae on Apple Pieces to Produce Cider. Fermentation. 2019; 5(3):74. https://doi.org/10.3390/fermentation5030074

Chicago/Turabian StyleAltieri, Clelia, Daniela Campaniello, Barbara Speranza, Milena Sinigaglia, Maria Rosaria Corbo, and Antonio Bevilacqua. 2019. "Immobilization of Saccharomyces cerevisiae on Apple Pieces to Produce Cider" Fermentation 5, no. 3: 74. https://doi.org/10.3390/fermentation5030074

APA StyleAltieri, C., Campaniello, D., Speranza, B., Sinigaglia, M., Corbo, M. R., & Bevilacqua, A. (2019). Immobilization of Saccharomyces cerevisiae on Apple Pieces to Produce Cider. Fermentation, 5(3), 74. https://doi.org/10.3390/fermentation5030074