Abstract

Maize (Zea mays) is one of the most cultivated crops in South Africa, serving as a staple food, stock feed, and a key element in several industrial applications. It contributes significantly to the growth of the South African agricultural economy. The cultivation of maize generates a large amount of agricultural waste, mainly in the form of maize stover (MS), which encapsulates leaves, stalks, cobs, and husks. Approximately 5.15 metric tons (Mt) yr−1 of MS are generated in South Africa. This corresponds to an energy potential of 94 PJ. There is immense potential to surpass the annual yield of MS by 126% up to about 11.66 Mt yr−1 through practices such as zero tillage and improved agricultural production systems. MS may pose a serious threat to the environment if not managed in a sustainable and eco-friendly manner. Valorization of MS into biogas presents an excellent opportunity to effectively control biomass waste while contributing to renewable energy production and mitigating dependence on depleting fossil fuels. However, MS continues to be overlooked as a sustainable bioenergy resource due to its lignocellulosic structure. This study explores the potential of converting MS into biogas for heat and power generation, addressing both energy needs and waste management in South Africa. The purpose is to provide knowledge that will inform researchers, innovators, industrialists, policy makers, investors, and other key stakeholders interested in renewable energy systems. Collaborative efforts among multiple stakeholders are vital to leverage biogas as a technology to promote socio-economic development in South Africa.

1. Introduction

Maize (Zea mays) is the most widely grown cereal crop in South Africa. South Africa is the hub of maize production in Africa, followed by Nigeria. An estimated 2.6 million ha of land is currently under maize cultivation in South Africa [1]. In 2023, about 16.4 million metric tons (Mt) of maize were harvested in South Africa [1]. Maize is a multipurpose crop vital for food security. In South Africa, it is cultivated as a source of food, animal feed, or raw material for the food and beverage industry [2]. The maize value chain generates significant amounts of crop residues, primarily in the form of maize stover (MS). MS consists of leaves, stalks, cobs, and husks [3,4]. South Africa produces around 5.15 Mt yr−1 of MS, with a projected increase in the foreseeable future [5]. MS is burnt, composted, mulched, or used as stock feed in South Africa. However, a large portion of MS residue often goes unused, imposing social, technical, and environmental problems. Proper waste disposal is essential to abate environmental pollution and promote socio-economic well-being. With an estimated energy potential of 17 MJ kg−1, processing MS can produce sustainable fuel products [6].

MS contains large amounts of organic matter. It is a rich resource of fermentable sugars amenable to anaerobic digestion (AD). AD presents a unique opportunity to recover energy from biomass while mitigating environmental concerns [7,8]. It is a biochemical process that produces biogas, a renewable energy resource. The primary components of biogas are methane (CH4) and carbon dioxide (CO2). In AD, organic matter is degraded synergistically using bacteria consortia in the absence of oxygen [8,9]. AD involves three major steps, namely hydrolysis, fermentation, and methanogenesis. Biogas is generated through the degradation of fermentation products during the methanogenic step [8,10]. MS is composed of a compact three-dimensional matrix of cellulose, hemicelluloses, and lignin. This structural complexity prolongs the residence period of MS in biodigesters [11,12,13]. Hydrolysis is the rate-limiting step, which dictates speed of the entire AD process. Despite these constraints, MS is a potent feedstock for biogas production. Studies have reported good theoretical biomethane potential (BMP) from MS in the range of 377.9 to 421.1 mL g−1 VS [14]. It is noteworthy that the real BMP of MS rarely exceeds the hypothetical CH4 values. This calls for an acceleration of the degradation of MS.

Pretreatment is a phenomenon that can promote the AD of recalcitrant organic compounds [15,16,17,18]. The underlying principle is to disintegrate the lignin structure and expose more fermentable sugars to microbial degradation [19]. Several pretreatment methods can enhance biogas production. These can be grouped into chemical, physical, biological, and hybrid technologies [20,21]. Altogether, biological pretreatment is more advantageous than other methods. It is an inexpensive and eco-friendly technology [15,22]. The authors envisage biogas as an alternative to chemical fuels. This is due to its renewable nature, improved greenhouse gas (GHG) emission savings, and the potential for multiple uses. Biogas can be used as a fuel for power generation and combined heat and power (CHP) systems [23,24]. Utilizing the nutrient-rich digestate by-product of AD as a biofertilizer is a sustainable way to improve the agricultural value chain in South Africa [25,26].

Currently, South Africa has installed approximately 700 biodigesters [27,28]. These biodigesters are mainly operating at the small-scale domestic level [25,27]. However, only 30 digester projects are commercialized in the country [8]. South Africa produces biogas at a technical capacity of 3 million Nm3 d−1. Prevalent feedstocks for various biogas plants include livestock manure, sugarcane bagasse, food waste, and wastewater [23]. The installed capacity is predicted at 50–70 MW [27]. This value can be surpassed by diversifying feedstock streams. This review is premised on the idea that MS can play a mammoth task in sustaining the energy industry, thereby alleviating poverty in South Africa. This can be attributed to its abundance, low cost, and recyclable nature. On the contrary, technical, economic, social, cultural, and market barriers have hampered the scalability of MS biogas technology. The gist of the article is that MS is a potential feedstock for biogas production in South Africa. The viewpoint is to provide informed decisions and attract stakeholders interested in biogas power generation to invest in novel feedstock streams.

2. Maize Stover Generation in South Africa

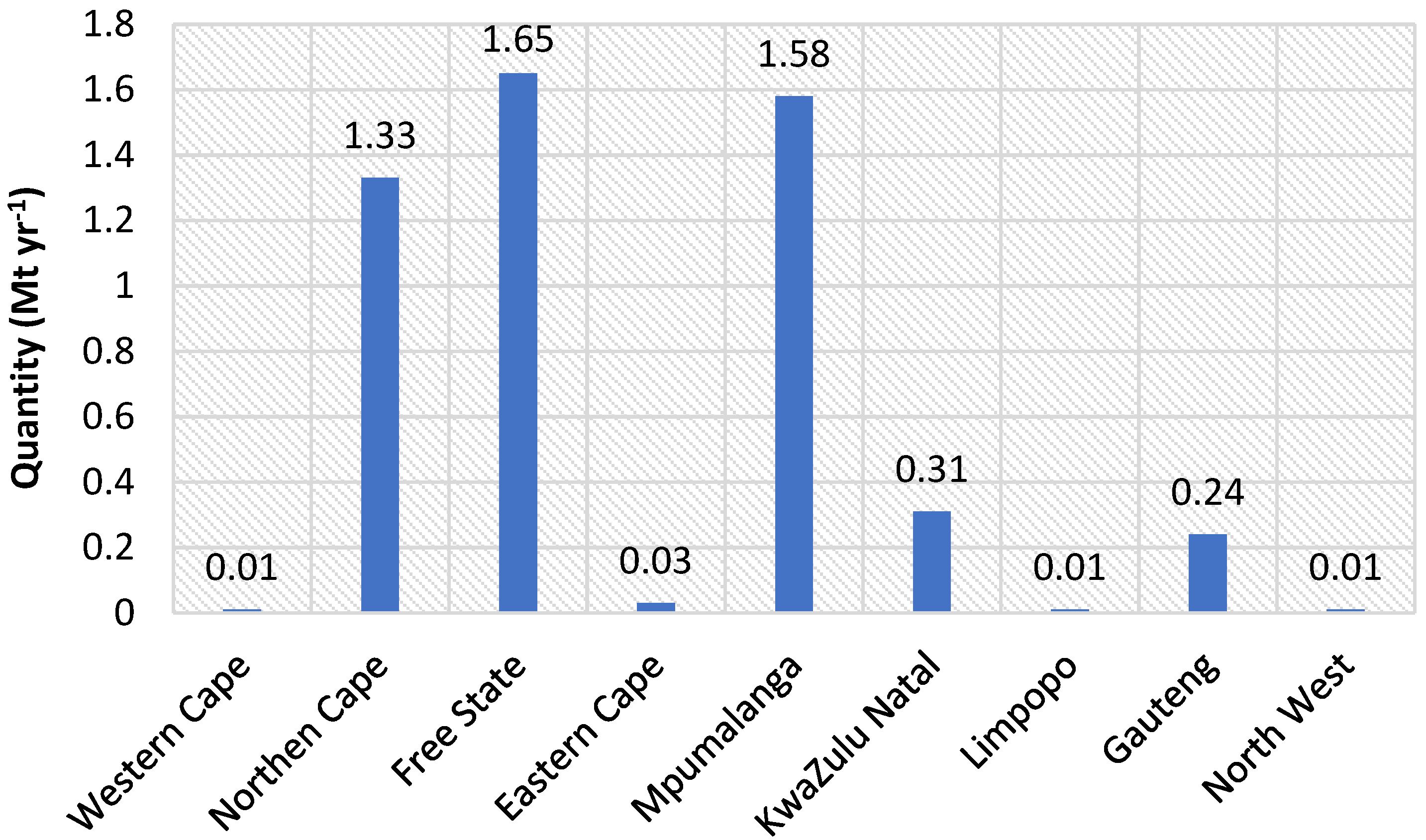

South Africa is popularly known for producing vast amounts of the maize grain. Reports have indicated that the country is the leading producer of maize in Africa. Approximately 16.4 million Mt yr−1 of maize is harvested from 2.6 million ha of land in South Africa [1]. Maize production generates large volumes of non-grain biomass residues. The residue-to-grain production ratio for the maize crop is 1:1 [27]. MS is the main by-product from harvesting and processing of the maize grain. The residue contains different fractions of stalks, husks, cobs, leaves, and other left-over residues in variable proportions [3,4]. MS covers around 47–50% of the total maize harvest on a dry-weight basis [3]. MS fractions were reported as 27.5% stalks, 8.2% cobs, 11.4% leaves, and 7.0% husks on a dry matter basis [29]. Mensah et al. [4] reported the percentage dry weight distribution for MS fractions of 9.4% for the cob and 44.3% for the combined husk, leaf, and stalk. Current aggregated data on the generation of MS in South Africa are not well-updated. However, Batidzirai et al. [5] reported that South Africa produced an average of 5.15 Mt yr−1 of MS between 1990 and 2011. Stover generation capacity is likely to outweigh this by 126% up to about 11.66 Mt yr−1 if agricultural practices and technologies are well-reformed [5]. The distribution of MS production by province in South Africa is shown in Figure 1. Around 89% of the stover comes from the Free State, Mpumalanga, and Northen Cape, the most significant maize producers in South Africa [5].

Figure 1.

Comparison of maize stover production among nine provinces in South Africa [5].

3. Chemical Composition of Maize Stover

MS is a highly lignocellulosic material. It mainly contains 40.7% cellulose, 31.1% hemicelluloses, 11.7% lignin, and other constituencies in small quantities [4]. Yang et al. [30] revealed that the cellulose, hemicellulose, and lignin content of MS is 41.16, 24.95, and 5.90%, respectively. Lignocellulose is the primary strengthening component in MS. Other constituents found in MS include crude protein, ash, and mineral elements. Mensah et al. [4] reported total solid (TS), moisture content, and ash values of 93.31, 6.69, and 5.05%, respectively. The volatile solid (VS) (81.73%), TS (97.00%), ash (15.27%), and moisture content (3.00%) were found in a study by Olugbemide et al. [31]. MS contains roughly 4.3% crude protein, 88.16% TS, and 79.67% [30]. Stover fat content differs from 0.48 to 3.10% while the dry matter content is around 75% [14].

MS is morphologically diverse in tissue, fiber, and chemical composition [3,32]. The cob comprises three types of tissues: the chaff, woody ring, and pith. The stalk comprises the rind, pith, and several mineral elements [3]. The chemical composition of stover may vary from one fraction to another (Table 1). This heterogeneity can be ascribed to variations in genetic factors, maturity, and biotic and abiotic conditions. Variability in the lignocellulosic content of MS directly influences biomethane production and other processes. Hence, it is necessary to ascertain the chemical composition of feedstocks before AD trials are conducted. Hemicelluloses and lignin are hard-to-digest compounds. Lignin cannot be digested by anaerobic microorganisms [3,12]. Pretreatment of MS improves the recovery of sugars and biogas during AD. The effectiveness of pretreatment is affected by the composition and type of stover fraction. For example, Aboagye et al. [33] compared the effect of alkali (2% w/v NaOH) and acid (2% w/v H2SO4) pretreatment on glucose yield from maize cobs, stalks, and leaves. The results revealed a higher glucose recovery from alkali-pretreated cobs and stalks than acid-pretreated fractions.

Table 1.

Lignocellulosic content of maize stover.

4. Maize Stover to Biogas

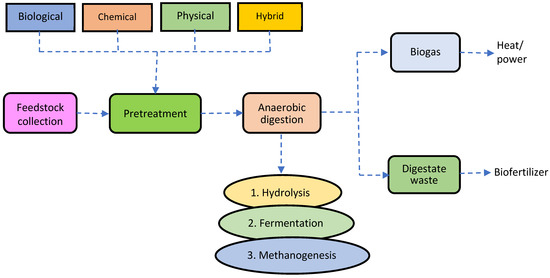

4.1. Biogas Value Chain

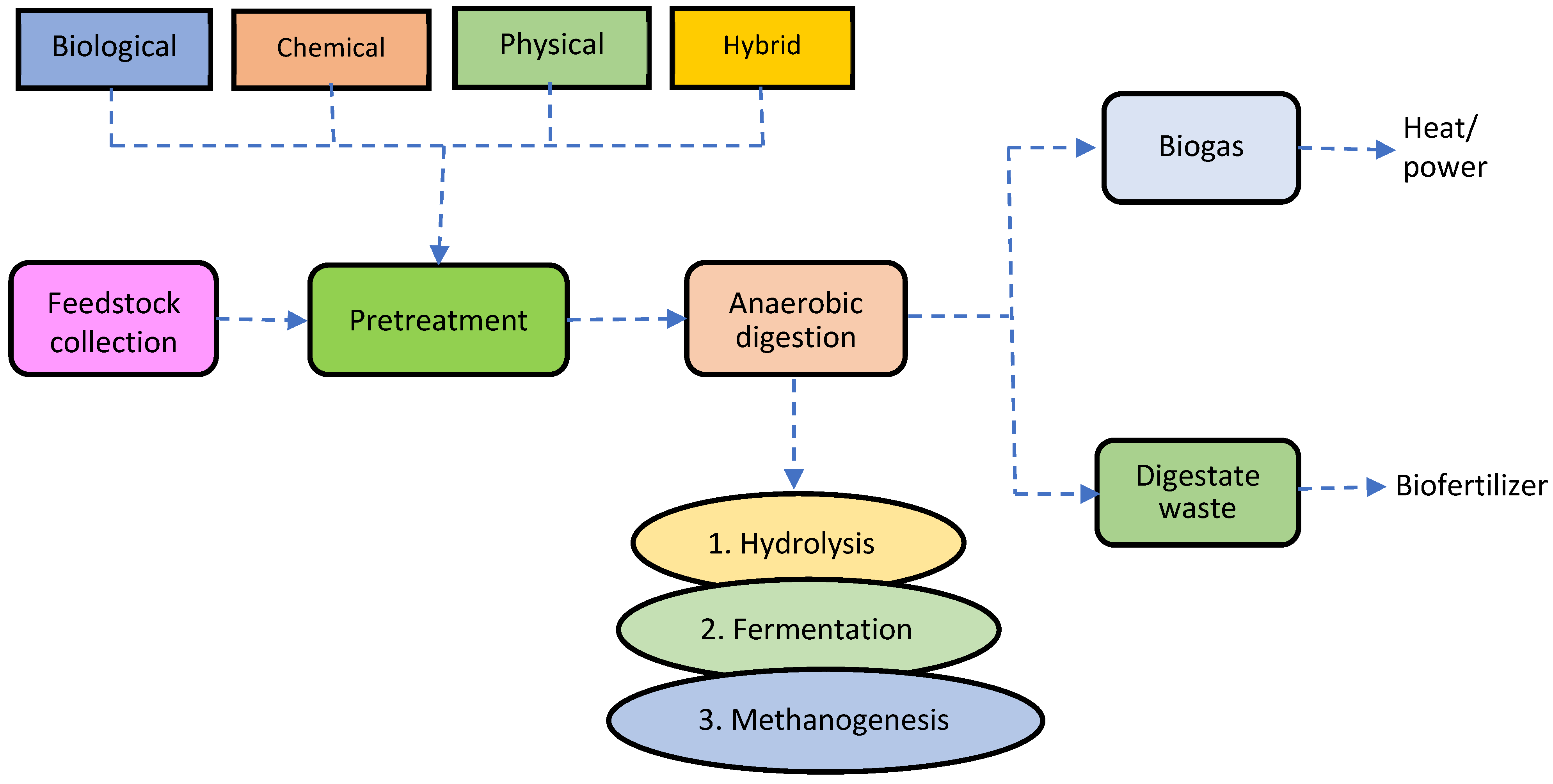

The MS biogas value chain comprises feedstock collection, pretreatment, AD, biogas utilization, and digestate slurry management. AD is the actual biogas production process. It involves using anaerobic bacteria to turn organic matter into biogas [35]. AD minimizes the volume, mass, and toxicity of the feedstock material [36]. The digestate slurry is a waste product of the AD process. The MS biogas value chain is summarized in Figure 2.

Figure 2.

Outline of biogas production from maize stover for heat and power generation.

4.1.1. Feedstock Collection

Feedstock collection is the first step in biogas production from MS residue. It involves harvesting and transporting the raw material to the biogas processing facility [37]. The choice of a feedstock collection method is a critical criterion for an efficient biogas production system. It is a function of grain harvest efficiency, grain loss rate, and soil contamination [37]. MS can be gathered manually for small-holder operations or using mechanized equipment such as harvesters and balers for large-scale production systems. Technologies like single-, two-, and multi-pass procedures are available to collect stover fractions from maize fields [3,37]. Maize kernels are harvested using a combine harvester and separated from cobs using the single-pass method. A pull-type collection wagon (e.g., the Vermeer Cob Harvester CCX770) is used to collect cobs after removing kernels [3,4]. An ideal approach to collect stover for biogas facilities is the two-pass method. Compared to other methods, the two-pass procedure is energy efficient, with a high rate (90%) of cob and husk harvest. More so, it does not affect harvest efficiency or the grain-loss rate, and soil contamination is limited [37,38]. Harvest cost is a crucial parameter to determine the feasibility of a stover harvest system. It includes labor, equipment ownership, and maintenance and fuel consumption. The cost per ha of harvested MS exhibits the following order: singe-pass < two-pass < multi-pass harvest system [39]. A multi-pass system requires huge capital investment in equipment [40]. In the first harvest of a two-pass method, a special header fitted with a chopper-windrower is deployed to cut husks, cobs, and leaves. The second pass involves baling the chopped stover into round or square bales [4]. Bales can be temporarily stored at a primary site or directly transported to the biogas plant. The biogas facility’s proximity to the field offers the best way to minimize transport costs [37].

4.1.2. Feedstock Pretreatment

MS is characterized by the high content of cellulosic matter that restricts its utility for AD. Lignin is highly resistant to AD due to its amorphous structure. This reduces the availability of fermentable sugars to microorganisms and degradative enzymes [12,16,19,41]. As a result, the AD of MS is very slow, leading to low biogas production. Many attempts have been made to overcome this drawback in order to increase the biogas yield of recalcitrant substances. Researchers have proposed feedstock pretreatment as a panacea to destroy the lignin seal and release more digestible sugars to AD [19]. Pretreatment methods are extensively presented in the extant literature. They fall into four major categories: chemical, physical, biological, and combined pretreatment. The merits and demerits of pretreatment methods are well-documented in scientific studies [15,16]. As shown in Table 2, each pretreatment method has its own advantages and disadvantages. Pretreatment methods such as steam explosion, dilute acid or alkali (ammonia (NH3), NaOH, Ca(OH)2, H2SO4, H2O2, etc.), microwave, ionizing radiation, and hydrothermal treatments have been extensively studied [35,42]. Steam explosion pretreatment of stover at 160 °C for 2 min produced 22% higher CH4 yield than the control [43]. Fang et al. [44] pretreated MS at 180, 200, and 220 °C for 20 d using a fluidized bed pyrolysis reactor. Results indicated a maximum biogas yield of 23 319 mL that was 10% higher than the non-treated counterpart. Ultrasound treatment of maize straw at 50 kHz and 250 W caused a 60.7% rise in CH4 production [45]. Zheng et al. [46] generated 73.4% higher CH4 than unpretreated conditions after exposure of MS to 2% NaOH at 20 °C for 72 h. However, the commercialization of physical and chemical pretreatment technologies has hit a brick wall. Their pitfalls include the need for specialized equipment, high capital, high energy, and the release of secondary pollutants [15,42].

Biological pretreatment (bacteria, fungi, enzymatic, etc.) is a promising alternate to saccharify cellulosic material and improve the overall digester performance. It is an environmentally benign method with low chemical and energy use [41,42,47]. In addition to fermentable sugars, biopretreatment can produce several beneficial products including biochemicals and biomaterials [41]. Pretreatment of MS for 2 d using crude ligninolytic enzymes from Phanerochaete chrysosporium and Coridus versicolor produced 323 mg g−1 of sugar. This concentration was 50.2% more than unpretreated conditions [47]. MS modified by Ceriporiopsis subvermispora for 5–90 d increased CH4 yield by 15.2%, reaching a peak of 235 mL g−1 VS [19]. Stover pretreatment for 3 d using a liquid digestate waste improved biogas and CH4 yield by 70.4 and 66.3%, respectively [42]. Makri et al. [48] investigated the effect of three different concentrations of rumen fluid flora (4, 6, and 12% w/v) on MS pretreatment to optimize biogas production. The highest cumulative biogas yield of 282.57 mL g−1 VS was attained after 28 d of digesting stover pretreated with 4% w/v rumen fluid microbiota. Enzymatic pretreatment of MS under optimal conditions of enzyme load (30 FPU g−1) and solid content (60 g L−1) enhanced cumulative biogas production by 36.9% after 24 h of AD [49]. Exposure of maize straw to complex microbial agents for 15 d enhanced biogas and CH4 yield by 33.1 and 75.6%, respectively. The pretreatment time decreased by 34.6% compared to control conditions [50]. It was established that pretreatment of MS with a coculture of bacteria and fungi can reduce the digestion time and promote CH4 production [34]. A compound microbial agent consisting of five bacterial strains (i.e., Bacillus cereus MA-02, B. subtilis A90, B. amyloliquefaciens JS-23, B. subtilis DS-10, and B. licheniformis MS-44) improved biogas and CH4 recovery by 56.6 and 82.6%, respectively, after pretreatment of MS for 20 d [41]. Full-scale adoption of biopretreatment has been deterred by extra costs incurred to prepare and continuously add biological agents [42]. Researchers are now concentrating on lowering this cost and improving the efficacy of biological pretreatment.

Combined pretreatment is expected to enhance sugar recovery and the overall AD efficiency [51]. It involves merging various pretreatment technologies to destroy lignin and hemicelluloses in stover residues. The most common pretreatment combinations are thermo-chemical processes [8]. Zhang et al. [51] optimized sugar recovery from MS using alkali-assisted extrusion pretreatment. Sugar yields of 86.8% glucose and 50.5% xylose were achieved that were 3.9- and 13.3-fold increased, respectively, compared to non-treated residues [51]. Pretreatment of MS at a temperature of 29.8–31.1 °C and pH of 7.05–7.84 produced cumulative biogas yield of 54.97 m3, which was higher that unpretreated conditions [52]. Although, combined pretreatment shows positive energetic balance, it has been associated with strict operational conditions like harsh temperatures and pressures. Furthermore, chemicals are used in many cases, which may discharge inhibitors and increase the operational cost [16].

Table 2.

Advantages and disadvantages of pretreatment techniques for maize stover [16,53].

Table 2.

Advantages and disadvantages of pretreatment techniques for maize stover [16,53].

| Pretreatment Method | Advantages | Disadvantages |

|---|---|---|

| Physical |

|

|

| Chemical |

|

|

| Biological |

|

|

| Combined |

|

|

4.1.3. Anaerobic Digestion

At this stage, pretreated stover is fed into anaerobic digesters where microbially-mediated digestion occurs. AD is a mature technology widely utilized to manage and convert waste into biomethane [12,19]. This technology has been practiced for a considerable period in South Africa. AD utilizes a broad spectrum of feedstocks such as livestock manure, crop waste, and energy crops [54]. MS is an abundant and sustainable feedstock for AD due to its high organic matter content. The TS content of MS has been reported to be above 15%. Hence, solid-state anaerobic digestion (SS-AD) is considered the best approach for treating feedstocks with high TS content [7]. Acclaimed attributes for SS-AD include high volumetric CH4 yield, minimized reactor volume, low energy input, limited material handling, and positive energetic balances [7]. AD is a complex process that consists of three main steps. These are hydrolysis, fermentation, and methanogenesis (Figure 2). AD is facilitated by different bacteria consortia under limited oxygen conditions. Complex organic molecules are degraded into simple monomer units during hydrolysis. Fermentation involves the breakdown of hydrolytic products to release alcohols, acetic acids, fatty acids, hydrogen, and CO2. Methanogenesis is the final step, where fermentation products are degraded into biogas [8,35]. Biogas is composed of 50–60% CH4, 30–40% CO2, and 2% trace gases [8].

AD of stover is affected by several environmental factors. Key factors include pH, chemical oxygen demand, volatile fatty acids (VFAs), NH3 concentration, micronutrient availability, and total alkalinity [7,12]. These variables are a function of operational parameters including the carbon to nitrogen (C/N) ratio, temperature, inoculum, substrate particle size, agitation, TS content, hydraulic retention time (HRT), and organic loading rate (OLR) [7]. Process parameters must be severely monitored and balanced for an efficient AD system. Table 3 outlines the optimal conditions for various process parameters affecting the AD of MS residues. pH is one of the most critical factors affecting methanogenesis. Too high or too low pH inhibits the growth and function of digester microorganisms. Methanogens operate at an optimal pH of 7.0–8.0 [55]. Modern digesters favor thermophilic temperatures around 37 °C to improve digestion rates [55]. A strong synergistic interaction exists between the temperature and pH of a bioreactor system. Methanogenic activities are suppressed by acidic pH conditions, thus lowering biogas production [56]. It is vital to maintain these parameters at an optimum level. A mixture of cow dung and water at a 1:1 ratio is the most preferred inoculum to halt the building up of acids in digesters [57]. While a C/N ratio in the range of 20 to 30 promotes synergism and nutrient balance in the digester [20]. Codigestion of MS with animal manure can balance the C/N ratio and ensure an adequate supply of nutrients [58].

Table 3.

Operational parameters that affect the anaerobic digestion of maize stover.

4.1.4. Biogas Utilization

Biogas is a renewable and sustainable energy resource that can help South Africa to address its energy demands and manage organic waste. MS can contribute around 135 million m3 to the South African biogas mix [27]. Stover biogas can be used for cooking, space heating, and electricity and power generation or upgraded to biomethane [23,24,27]. Using biogas for cooking can significantly improve rural livelihoods, alleviate deforestation pressures, and reduce indoor pollution caused by traditional biomass [65]. With a predicted power potential of 0.9 GW, electric power generation holds much of the market share for biogas in South Africa. Nevertheless, this potential is technically unrealistic, as it is constrained by feedstock availability and logistical and technological costs. Variation in feedstock types is a plausible approach that can improve the technical potential of biogas in South Africa [27]. Bioelectrification is the most widely known commercial use of biogas in South Africa. Electricity from biogas can be directly consumed or distributed into the public domain, either the municipal or national grid [25,27]. Biogas is transformed into electricity using a genset. This device consists of an engine or turbine and an electric generator. The efficiency of a genset in converting biogas to electricity typically falls in the range of 20 to 45% [65]. The rest of the energy is lost as heat [25]. A heat recovery system (CHP unit) can be connected to the genset to collect this heat in the form of hot water or steam. A CHP unit captures around 90% of the heat [65]. This energy can be utilized to heat digesters, water, and space. South Africa has limited space heating activities; hence, a few CHP units are installed in the country [25]. It is practical to use biogas for heating without electricity generation. In this scenario, the gas is directly fed into a boiler or burner for heat or steam production. The utility of this heat or steam varies from heating biogas plants to several industrial applications [25,65]. Food and chemical manufacturing industries in South Africa can utilize biogas as a source of thermal energy [65].

Biogas can substitute petroleum products as a transport fuel. However, applying biogas to power vehicles is not mature in South Africa. This is attributed to further upgrading biogas to high-grade CH4 [27]. Biogas contains impurities such as water (H2O), CO2, hydrogen sulfide, etc., that may destroy appliances [23]. These impurities must be separated from CH4 for biogas to match natural gas standards. Upgraded biogas can be either compressed or liquified to be used as a vehicular-grade fuel. Compressed or liquified gas is more straightforward to store and transport than raw biogas [23,27]. CH4 is a common source of household cooking energy and a precursor for chemical synthesis in industry [25]. Its utilization can lower the carbon footprint, contributing to South Africa’s climate change goals. The renewable energy directive (RED) has established the GHG emission savings as a sustainable strategy. The minimum threshold for GHG emission savings from biogas production is set at 70% as of 2021 onwards. It is expected to rise up to 80% in 2026 or afterwards [66]. GHG emission savings for electricity generated from stover biogas are poorly understood. These savings rarely exceed the minimum threshold level. For example, the GHG emission savings for MS biogas electricity were observed at 46–66% [66]. However, MS can be codigested with livestock manure to surpass the minimum threshold for sustainable GHG emission savings [66].

4.1.5. Digestate Waste Management

The decomposition of MS organic matter into biogas via AD generates digestate waste [67]. Digestate is a nutrient-rich slurry that cannot be converted into biogas. A typical 500 kW AD facility can produce more than 10,000 tons of digestate per annum [68]. Digestate is very diverse in composition, mainly affected by feedstock type and operational conditions. Stover digestate is endowed with cellulosic material (cellulose and lignin), water, and microorganisms [68]. It also contains various fertilizing elements such as nitrogen, phosphorous, potassium, and micronutrients. Micropollutants, especially cadmium, are also found in the digestate slurry [26,69]. If not properly treated, digestate waste can spread pathogens and diseases to the natural ecosystem [68]. This demands innovative disposal strategies conforming to South African regulations to minimize the environmental impact [25]. Valorizing digestate into organic fertilizer is a smart way of adding value while managing the digestate in a circular economy [26,69]. Digestate effluent is a high-grade fertilizer that can enhance soil health and close the nutrient loop in farming ecosystems [31]. It can be applied to soil in its solid or liquid form. Organic agriculture is a common practice in South Africa. Therefore, setting up biodigesters nearer to organic farms could provide a sustainable solution to meet fertilizer requirements [25]. However, uncontrolled application of digestate, whether acidic or alkaline, may adversely affect soil health and fertility [68]. It may alter the physicochemical properties of soil, for instance pH, thus impeding the accessibility of nutrients by plants. The unstable nutrient content of digestate can cause leaching of surplus nitrogen and its derivatives, posing detrimental effects on water resources and the climate [68].

Other authors have suggested digestate waste as a promising substrate for edible mushroom cultivation. For example, using stover digestate as an additive to wheat straw substrate resulted in 5.1% higher fruiting bodies of Pleurotus ostreatus than the control [70]. Wystalska and Kwarciak-Kozlowska [69] posited that stover digestate can be an excellent feedstock for biochar production. This is due to its high carbon content that falls within the range of 15 to 55%. High temperature pyrolysis, hydrothermal carbonization, and gasification are mature technologies to convert stover digestate into biochar [68]. Biochar can be utilized as a natural fertilizer and a biosorbent [69]. Contrarily, biochar may contain persistent secondary pollutants such as dioxins, chlorinated hydrocarbons, and polycyclic aromatic hydrocarbons [68].

4.2. Biomethane Potential of Maize Stover

BMP determines the maximum volume of CH4 that can be obtained from a biodegradable feedstock. It estimates the amount of organic matter in a feedstock that can be converted into CH4 [15]. A gamut of methods is well-established in the literature to estimate the BMP of organic feedstocks, including theoretical models and experimental approaches [15]. Many studies have reported on the BMP of various crop residues [8]. However, a few authors have concentrated on the biogas potential of MS residue. Mernado et al. [14] observed the BMP for different stover fractions ranging from 206.6 to 393.0 mL g−1 VS. Digesting stover at 37, 42, 47, and 55 °C for 20 d produced CH4 yields of 102.0, 141.7, 119.6, and 125.4 mL g−1 VS, respectively [71]. Schilling et al. [72], Rasopo et al. [73], and Tuyen et al. [74] found BMP values varying between 317.0 and 363.0 mL g−1 VS from MS waste. This article reports on BMP values and CH4 content in the range of 115.4–307.0 mL g−1 VS and 55.2–66.8%, respectively (Table 4). These values deviate significantly from theoretical predictions in the 377.9–421.1 mL g−1 VS range [14]. This can be ascribed to variations in chemical composition and the digestibility of the organic fraction [14]. Kamusoko et al. [75] reported that the CH4 yield of plant waste may differ depending on biomass quality, geographical location of the feedstock, and reactor conditions. Deploying state-of-the-art technologies (i.e., pretreatment, codigestion, bioaugmentation, and microbial community monitoring) can increase the BMP of MS residue [61]. For example, codigestion of MS with cattle manure generated 357.4 mL g−1 VS of CH4 and improved the VS conversion efficiency by 51.8% after 21 d of treatment at 55 °C [76]. Bioaugmentation of lab-scale bioreactors with cellulolytic bacteria consortia increased CH4 production of α-cellulose and MS by 22–24% [77].

Table 4.

Biomethane potential of maize stover fractions.

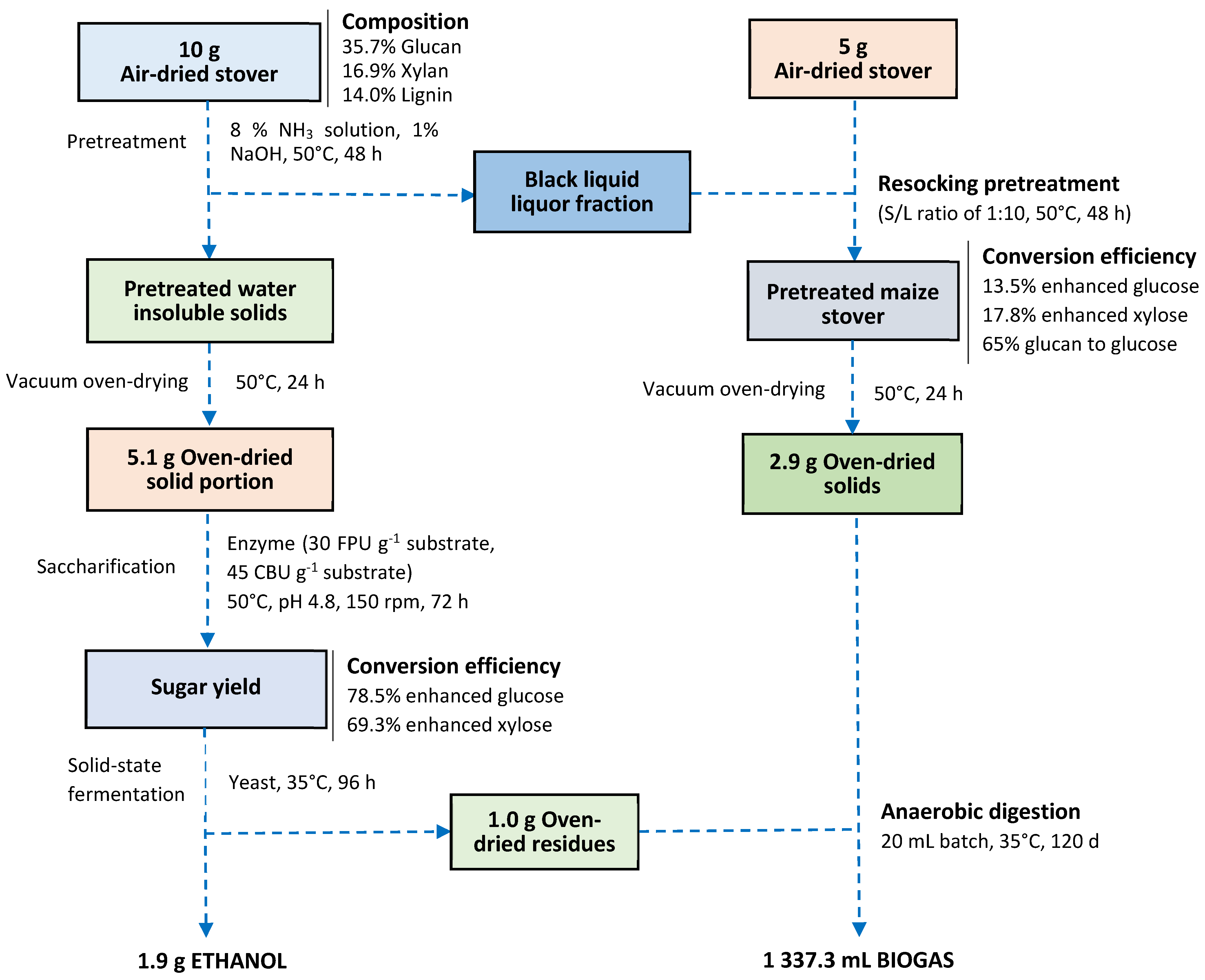

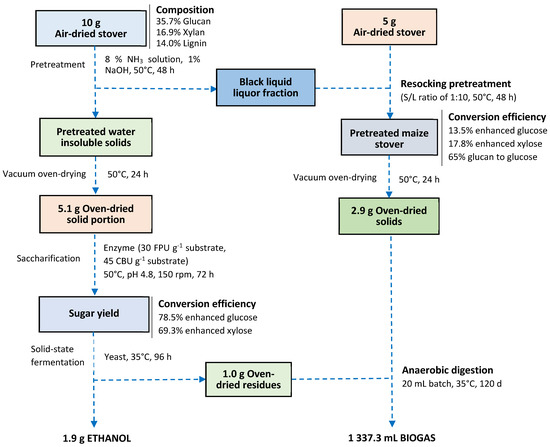

4.3. Biomass Balance

The biomass balance (BMB) concept is a fundamental tool for modeling, monitoring, and optimizing the efficiency of a biochemical process [82,83,84]. This approach utilizes biomaterials instead of fossil-derived feedstocks in its production system. BMB enables scientists to track how much raw material that enters the biological system is stored or converted into final products. The resultant products are referred to as BMB products [82]. The economic viability of biochemical platforms can be assessed using the BMB approach. As such, the BMB approach has become an integral part of the AD process. For example, Dolan et al. [85] proposed a BMB model to describe the flow of material and energy in AD of organic matter. It can be envisaged that the wet AD of 1 000 kg of organic matter can potentially produce 175 kg and 825 kg of biogas and digestate, respectively. Processing 175 kg of biogas through a CHP system results in the generation of 0.34 MWh of net electricity and 0.17 MWh of net heat. This demonstrates the efficiency of CHP unit in capturing both electrical and thermal energy from biogas. The CHP unit emits 1 206 kg of flue gas (molecular nitrogen (N2), CO2, H2O, and other pollutants) [83]. Substrate pretreatment can help to improve the efficacy of material flow and the theoretical yield of biomass in AD facilities. There is a paucity of information in the literature on BMB analysis of MS for AD systems. However, Zuo et al. [86] conducted a BMB analysis of alkali-pretreated MS for combined ethanolic fermentation and AD. About 10 g of MS was pretreated at 50 °C for 48 h by mixing with 1% NaOH and 8% NH3 solution in a solid-to-liquid (S/L) ratio of 1:10. Solid-state fermentation of pretreated biomass using Pichia stipitis produced an alcohol concentration of 36.1 g L−1. This concentration was equivalent to 63.3% of the maximum theoretical yield. Overall, the biorefinery process transformed 15 g of MS into 1.9 g of ethanol and 1 337.3 mL of biogas [86]. Material flow for the entire ethanol and biogas production process is shown in Figure 3.

Figure 3.

Biomass balance for the integrated ethanol and biogas production from maize stover [86].

5. Challenges and Future Prospects

The future of biogas holds much promise, prospecting opportunities for renewable energy, waste disposal, and economic empowerment in South Africa. Despite this inevitable potential, the technology is not widely accepted, especially in rural households [87,88]. Most rural households are prohibited by the herd size required to produce sufficient manure to generate biogas needed to power their domestic needs [87]. Based on this criterion, about 625,000 households in South Africa could potentially benefit from biogas technology [89]. Integrating MS into biogas production is a promising strategy to diversify feedstock streams in South Africa. However, the growth of biogas technology has faced some bottlenecks, including policy and regulation, technical barriers, funding, sustainability, socio-cultural issues, awareness, and education, amongst others [88,89,90,91,92,93]. These hurdles have hindered the widespread adoption of stover biogas in South Africa.

5.1. Technical Barriers

Feedstock availability is a significant technical issue that can impact the sustainability and applicability of biogas in South Africa [87,93]. Livestock waste alone may not fully fulfil the feedstock requirements for rural household digesters [93]. On the other hand, MS is affected by seasonal changes; hence, it is not always available as a feedstock for biogas production. This variation implies that MS cannot be an effective feedstock for developing an economically viable biogas production system. Strategies that permit the availability of feedstocks throughout the year should be implemented to ensure sustainability [94]. It is imperative to search for alternative feedstocks, such as animal manure, kitchen waste, etc., and investigate their feasibility for the codigestion with MS.

The resistance of MS to microbial degradation is another key technical barrier to stover biogas technology. This significantly hinders the AD efficiency, often leading to process failure [41]. As such, current bioreactor operations in South Africa cannot productively utilize MS residue as a feedstock for biogas production. Several pretreatment methods have been suggested to overcome this technological hurdle, but most struggle with scalability due to reduced efficiency, release of toxic by-products, and high operational costs. Future research should be tailored toward adopting suitable pretreatment technologies that will enhance the digestibility of MS. Low nitrogen content in MS can cause nutrient imbalances and affect synergism in biodigesters. Thus, the codigestion of MS with more biodegradable organic substances like animal manure should be prioritized to surmount this technical obstacle [8].

5.2. Funding

Infrastructural needs can be cited as a stumbling block for the maturation of MS biogas technology [88,93]. MS biogas technology is still being researched at the lab scale in South Africa. The government of South Africa took its first initiative to deal with waste biomass by establishing the Council for Scientific and Industrial Research’s Biorefinery Industry Development Facility in 2018. The mandate of this state-of-the-art biorefinery plant is to manage wood and saw mill waste while generating new processes and valuable products [94]. However, key drivers to support this technology transfer are not fully present in the country. This has been necessitated by limited funding for research and development (R&D) and a shortage of highly qualified technical expertise [87,91]. While there are no specific pilot studies reported on stover biogas in South Africa, the country does have an increasing interest in biogas technology. MS biogas facilities require colossal capital, operational, and maintenance costs, which may be problematic in rural settings [89]. Financial resources for R&D should be readily accessible to small-holder communities to support biogas research, technology development, and demonstration projects. Rural households must be sensitized about securing the available funding opportunities for technology transfer.

5.3. Socio-Cultural Issues

Many societal and cultural issues can significantly impact MS biogas dissemination in rural communities of South Africa [87,88,91,95]. Lack of public participation and consumer interest is the most prevalent socio-cultural barrier. Rural people have different cultural opinions regarding the adoption of stover biogas [91]. MS is often seen as a waste, and its use for biogas may be perceived as untraditional or unappealing. As a result, farmers may be hesitant to accept technologies or practices that deprive them of their social norms. Others may consider MS biogas production a low-status activity often associated with poor hygiene [95]. Gender roles are a critical development factor in most rural societies. Women are obliged to gather fuelwood and cook on open fires in rural areas. Hence, they are vulnerable to indoor pollution and severe respiratory diseases. Women may be exempted from decision-making processes or have limited exposure to resources and training for clean fuels [90]. Attention should be paid to implementing strategies and initiatives to safeguard the public, indigenous communities, and workers’ rights. There is a need to engage with local people to acquire knowledge of their needs, concerns, and cultural practices. To effectively adopt MS biogas, farmers, particularly women, need adequate training and resources to conscientize them and build their capacity to implement and maintain biogas technology. It is important to actively engage diverse voices and consider gender parity and multiple stakeholders to ensure inclusive and equitable decision-making processes.

5.4. Information and Market Barriers

Other authors have pointed the finger at information and market barriers to the low uptake of biogas as one of the primary fuels for cooking and heating in South Africa [87,91,96]. Awareness and education on biogas from cellulosic material are still limited in the public, government, and private domains. A number of rural households believe in biogas from livestock manure. This is not in agreement with sustainable feedstock production in South Africa. Educating farmers and other stakeholders on the availability of MS and its long-term benefits is pertinent to disseminating knowledge and promoting the wide-scale adoption of renewable energy resources. It is a fundamental part of developing markets for MS biogas and technologies that encourage its production and use. Establishing demo facilities in rural areas, followed by several campaigns and workshops, could promote biogas projects from lignocellulosic biomass [8]. This could help to widen the market base for MS biogas in South Africa. Biogas faces strenuous competition from traditional biomass (e.g., fuelwood and dung), which is more accessible to most rural areas [90]. More so, the price of biogas is often higher than natural gas, putting it at risk of being rejected in the market [91]. It is without doubt that MS biogas can compete in market with fossil gas and other smart energy technologies if the cost is moderately low. Generally, the market cost of advanced biomass fuel in South Africa is predicted at USD 0.066 kWh−1. This energy cost is relatively higher than coal (USD 0.023 kWh−1) and lower than solar PV (USD 0.068 kWh−1) and wind (USD 0.12 kWh−1) [97]. The lifespan of renewable energy technologies ranging from 20 to 40 yr is shorter than that of coal. South Africa could benefit from coal-fired plants for a period of 200 years [97].

5.5. Policy and Regulatory Barriers

MS biogas technology needs to be fully supported and enhanced by imposing stringent measures to implement the technology on a large-scale. South Africa has made significant strides in drafting strategies to promote waste management and smart energy technologies. Key strategies include waste reduction, waste prevention, waste as a resource, sustainable strategic partnerships, and environmentally sound socio-economic growth and development [98]. However, the lack of consistent renewable energy policies could be a barricade to stover biogas penetration in South Africa. The quality of products and services from stakeholders and suppliers should be governed by policy documentation [89]. To encourage adoption of stover biogas technology, policies such as subsidies, tax incentives, or regulatory frameworks that promote its use should be formulated. Supportive government policies could stimulate MS biogas advancement. The government should provide incentives such as tax credits or grants to attract investment in biogas projects. Recently, the South African government has proposed the incorporation of an Enhanced Renewable Energy Tax Incentive in section 12B of the Income Tax Act. This incentive will enable businesses and other stakeholders to withhold a 125% tax for all renewable energy assets, including those utilized for biogas [99]. Ensuring a favorable regulatory environment is a key milestone in attracting private investors and stakeholders interested in biogas technology. It is suggested that South Africa should develop a standalone waste-to-energy policy to address renewable energy policy gaps and match international best practices [98].

6. Conclusions

MS is one of the most abundant bioresources available on earth and has untapped energy potential. Valorization of MS into biogas offers an immense opportunity for South Africa to boost its renewable energy portfolio and contribute to sustainable development. Given that the energy potential of MS is 94 PJ, it could contribute to biogas resources for sustainable heat and power generation in South Africa. However, the scalability of MS biogas technology has been hampered by technical, economic, socio-cultural, and regulatory barriers. By overcoming these challenges, South Africa can effectively harness its agricultural waste, support rural development, and fulfill its sustainable energy goals. The MS biogas value chain needs to be safeguarded by vibrant government policies to ensure sustainability. Despite high organic matter content, MS is touted to be a hard-to-digest material. This trait limits its utility for biogas production through AD. The actual energy potential of stover has not yet reached its full potential, as predicted by theoretical models. Emerging research must concentrate on optimal conditions for AD and explore new technologies that promote the stover biogas value chain. The most critical aspect is to identify favorable pretreatment methods that can improve the hydrolysis and BMP of MS. It is important to demonstrate knowledge and understanding of advanced applications of MS biogas in real-world energy systems. South Africa’s biogas policy initiatives should focus on enhancing economic viability, conducting market research, increasing funding, providing incentives, and fostering community participation. One of the key drivers could be to locally develop a waste-to-energy policy in alignment with the global standards. A multi-stakeholder approach engaging the government, private sector, and communities is a prerequisite to recognize the full potential of this renewable energy venture.

Author Contributions

Conceptualization, R.K. and P.M.; writing—original draft preparation, R.K.; writing—review and editing, R.K. and P.M.; visualization, R.K.; supervision, P.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors are grateful to the Research Niche Area: Renewable Energy (Wind) of the Department of Research and Innovation (DRI) at the University of Fort Hare for its financial support.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AD | Anaerobic digestion |

| BMB | Biomass balance |

| BMP | Biomethane potential |

| CHP | Combined heat and power |

| C/N | Carbon to nitrogen |

| GHG | Greenhouse gas |

| HRT | Hydraulic retention time |

| MS | Maize stover |

| Mt | Metric tons |

| OLR | Organic loading rate |

| R&D | Research and development |

| RED | Renewable energy directive |

| SS-AD | Solid state anaerobic digestion |

| TS | Total solid |

| VFAs | Volatile fatty acids |

| VS | Volatile solid |

References

- Food and Agricultural Organization of the United Nations (FAO). FAOSTAT Statistical Database; FAO: Rome, Italy, 2024. [Google Scholar]

- Haarhoff, S.T.; Kotzé, T.N.; Swanepoel, P.A. A prospectus for sustainability of rainfed maize production systems in South Africa. Crop Sci. 2020, 60, 14–28. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Przybył, J.; Ratajczak, I.; Golinski, P.; Janczak, D.; Waskiewicz, A.; Szentner, K.; Wozniak, M. Chemical composition of maize stover fraction versus methane yield and energy value in fermentation process. Energy 2020, 198, 117258. [Google Scholar] [CrossRef]

- Mensah, M.B.; Jumpah, H.; Boadi, N.O.; Awudza, J.A.M. Assessment of quantities and composition of corn stover in Ghana and their conversion into bioethanol. Sci. Afr. 2021, 12, e00731. [Google Scholar] [CrossRef]

- Batidzirai, B.; Valk, M.; Wicke, B.; Junginger, M.; Daioglou, V.; Euler, W.; Faaij, A.P.C. Current and future technical, economic and environmental feasibility of maize and wheat residues supply for biomass energy application: Illustrated for South Africa. Biomass Bioenergy 2016, 92, 106–129. [Google Scholar] [CrossRef]

- Mdhluli, F.T.; Harding, K.G. Comparative life-cycle assessment of maize cobs, maize stover and wheat stalks for the production of electricity through gasification vs traditional coal power electricity in South Africa. Clean. Environ. Syst. 2021, 3, 100046. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Chen, C.; Liu, G.; He, Y.; Liu, X. Biogas production from codigestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions. Bioresour. Technol. 2013, 149, 406–412. [Google Scholar] [CrossRef]

- Kamusoko, R.; Mukumba, P. Potential of wheat straw for biogas production by anaerobic digestion in South Africa: A review. Energies 2024, 17, 4662. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, R.; Wang, B.; Zhang, S. Modeling and optimization of anaerobic digestion of corn stover on biogas production: Initial pH and carbon to nitrogen ratio. Energy Sources A Recovery Util. Environ. Eff. 2017, 39, 1497–1503. [Google Scholar] [CrossRef]

- Wagh, M.S.; Sowjanya, S.; Nath, P.C.; Chakraborty, A.; Amrit, R.; Mishra, B.; Mishra, A.K.; Mohanta, Y.K. Valorization of agro-industrial wastes: Circular bioeconomy and biorefinery process—A sustainable symphony. Process Saf. Environ. Prot. 2024, 183, 708–725. [Google Scholar] [CrossRef]

- Li, X.; Dang, F.; Zhang, Y.; Zou, D.; Yuan, H. Anaerobic digestion performance and mechanism of ammoniation pretreatment of corn stover. Bioresources 2015, 10, 5777–5790. [Google Scholar] [CrossRef]

- Croce, S.; Wei, Q.; D’Imporzano, G.; Dong, R.; Adani, F. Anaerobic digestion of straw and corn stover: The effect of biological process optimization and pre-treatment on total bio-methane yield and energy performance. Biotechnol. Adv. 2016, 34, 1289–1304. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Rodríguez, M.J.; Mushtaq, M.; Tian, L.; Jiménez-Rodríguez, A.; Rincón, B.; Gilroyed, B.H.; Borja, R. Evaluation and modelling of methane production from corn stover pretreated with various physicochemical techniques. Waste Manag. Res. 2022, 40, 698–705. [Google Scholar] [CrossRef] [PubMed]

- Menardo, S.; Airoldi, G.; Cacciatore, V.; Balsari, P. Potential biogas and methane yield of maize stover fractions and evaluation of some possible stover harvest chains. Biosyst. Eng. 2015, 129, 352–359. [Google Scholar] [CrossRef]

- Kamusoko, R.; Jingura, R.M.; Parawira, W.; Sanyika, W.T. Comparison of pretreatment methods that enhance biomethane production from crop residues—A review. Biofuel Res. J. 2019, 24, 1080–1089. [Google Scholar] [CrossRef]

- Khani, M.F.S.; Akbar, M.; Xu, Z.; Wang, H. A review on the role of pretreatment technologies in the hydrolysis of lignocellulosic biomass of corn stover. Biomass Bioenergy 2021, 155, 106276. [Google Scholar] [CrossRef]

- Dahunsi, S.O. Mechanical pretreatment of lignocelluloses for enhanced biogas production: Methane yield prediction from biomass structural components. Bioresour. Technol. 2019, 280, 18–26. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, X.; Li, Z.; Wang, X.; Sun, J. Effects of liquid digestate pretreatment on biogas production for anaerobic digestion of wheat straw. Bioresour. Technol. 2019, 280, 345–351. [Google Scholar] [CrossRef]

- Huang, W.B.; Wachemo, A.C.; Yuan, G.R.; Li, X. Modification of corn stover for improving biodegradability and anaerobic digestion performance by Ceriporiopsis subvermispora. Bioresour. Technol. 2019, 283, 76–85. [Google Scholar] [CrossRef]

- Jain, S.; Jain, S.; Wolf, I.T.; Lee, J.; Tong, Y.W. A comprehensive review on operating parameters and different pretreatment technologies for anaerobic digestion of municipal solid waste. Renew. Sustain. Energy Rev. 2015, 52, 142–154. [Google Scholar] [CrossRef]

- Munoz, C.; Hidalgo, C.; Zapata, M.; Jeison, D.; Riquelme, C.; Rivas, M. Use of cellulolytic marine bacteria for enzymatic pretreatment in microalgal biogas production. Appl. Environ. Microbiol. 2014, 80, 4199–4206. [Google Scholar] [CrossRef]

- Vasmara, C.; Cianchetta, S.; Marchetti, R.; Galletti, S. Biogas production from wheat straw pretreated with ligninolytic fungi and codigestion with pig slurry. Environ. Eng. Manag. J. 2015, 14, 1751–1760. [Google Scholar] [CrossRef]

- Shonhiwa, C.; Mapantsela, Y.; Makaka, G.; Mukumba, P.; Shambira, N. Biogas valorization to biomethane for commercialization in South Africa: A Review. Energies 2023, 16, 5272. [Google Scholar] [CrossRef]

- Sidahmed, S.H.; Shuichi, T.; Kavitha, M.S. New methodologies for the optimization of operational parameters of biogas power plants: A review. J. Renew. Energy Environ. 2024, 11, 9–27. [Google Scholar]

- Department Forestry, Fisheries and the Environment (DFFE). Biogas Guidebook for Small- to Medium-Scale Industrial Biogas Plants in South Africa; DFFE: Pretoria, South Africa, 2021; pp. 1–64. [Google Scholar]

- Angouria-Tsorochidou, E.; Seghetta, M.; Trémier, A.; Thomsen, M. Life cycle assessment of digestate post-treatment and utilization. Sci. Total Environ. 2022, 815, 152764. [Google Scholar] [CrossRef] [PubMed]

- Laks, R. The Potential for Electricity Generation from Biogas in South Africa: A Potential Study as Part of the BAPEPSA Project; ECN: Petten, The Netherlands, 2017; Volume 17, pp. 1–34. [Google Scholar]

- Mutungwazi, A.; Mukumba, P.; Makaka, G. Biogas digester types installed in South Africa: A review. Renew. Sustain. Energy. Rev. 2018, 81, 172–180. [Google Scholar] [CrossRef]

- Pordesimo, L.O.; Hame, B.R.; Sokhansanj, S.; Edens, W.C. Variation in corn stover composition and energy content with crop maturity. Biomass Bioenergy 2005, 28, 366–374. [Google Scholar] [CrossRef]

- Yang, L.; Moran, T.; Han, A. Comparison of operating methods in cartridge anaerobic digestion of corn stover. Bioenerg. Res. 2022, 15, 1225–1231. [Google Scholar] [CrossRef]

- Olugbemide, A.D.; Labunmi, L.; Ifijen, I.H.; Ogungbemide, D.I. Corn stover as substrate for biogas generation and precursor for biosilica production via anaerobic digestion. Tanz. J. Sci. 2020, 46, 807–816. [Google Scholar] [CrossRef]

- Li, Z.; Zhai, H.; Zhang, Y.; Yu, L. Cell morphology and chemical characteristics of corn stover fractions. Ind. Crops Prod. 2012, 37, 130–136. [Google Scholar] [CrossRef]

- Aboagye, D.; Banadda, N.; Kambugu, R.; Seay, J.; Kiggundu, N.; Zziwa, A.; Kabenge, I. Glucose recovery from different corn stover fractions using dilute acid and alkaline pretreatment techniques. J. Ecol. Environ. 2017, 41, 26. [Google Scholar] [CrossRef]

- Li, Y.; Hou, Z.; Shi, Q.; Cheng, Y.; Zhu, W. Methane production from different parts of corn stover via a simple co-culture of an anaerobic fungus and methanogen. Front. Bioeng. Biotechnol. 2020, 8, 314. [Google Scholar] [CrossRef] [PubMed]

- Kamusoko, R.; Mukumba, P. Pineapple waste biorefinery: An integrated system for production of biogas and marketable products in South Africa. Biomass 2025, 5, 17. [Google Scholar] [CrossRef]

- Roopnarain, A.; Adeleke, R. Current status, hurdles, and future prospects of biogas digestion technology in Africa. Renew. Sustain. Energy. Rev. 2017, 67, 1162–1179. [Google Scholar] [CrossRef]

- Viskovic, M.; Djatkov, D.; Martinov, M. Corn stover collection prior to biogas production—Evaluation of greenhouse gas emissions. J. Clean. Prod. 2018, 199, 383–390. [Google Scholar] [CrossRef]

- Shinners, K.J.; Bennett, R.G.; Hoffman, D.S. Single- and two-pass corn grain and stover harvesting. Trans. ASABE 2012, 55, 341–350. [Google Scholar] [CrossRef]

- Vadas, P.A.; Digman, M.F. Production costs of potential corn stover harvest and storage systems. Biomass Bioenergy 2013, 54, 133–139. [Google Scholar] [CrossRef]

- Hemmelgarn, A.B.; Lin, Y.; Wendt, L.M.; Hartely, D.S.; Digman, M.F. Techno-economic assessment of single-stream feedstock logistics supply chain for corn stover and grain. Biofuels Bioprod. Biorefin. 2023, 17, 437–448. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, Z.; Liu, J.; Zhang, S. Experimental study on biogas fermentation of corn stover pretreated with compound microbial agent. Energy 2024, 306, 132469. [Google Scholar] [CrossRef]

- Hu, Y.; Pang, Y.; Yuan, H.; Zou, D.; Liu, Y.; Zhu, B.; Chufo, W.A.; Jaffar, M.; Li, X. Promoting anaerobic biogasification of corn stover through biological pretreatment by liquid fraction of digestate (LFD). Bioresour. Technol. 2015, 175, 167–173. [Google Scholar] [CrossRef]

- Lizasoain, J.; Trulea, A.; Gittinger, J.; Kral, I.; Piringer, G.; Schedl, A.; Nilsen, P.J.; Potthast, A.; Gronauer, A.; Bauer, A. Corn stover for biogas production: Effect of steam explosion pretreatment on the gas yields and on the biodegradation kinetics of the primary structural compounds. Bioresour. Technol. 2017, 244, 949–956. [Google Scholar] [CrossRef]

- Fang, W.; Weisheng, N.; Andong, Z.; Weiming, Y. Enhanced anaerobic digestion of corn stover by thermo-chemical pretreatment. Int. J. Agric. Biol. Eng. 2015, 8, 84–90. [Google Scholar]

- Zou, S.; Wang, X.; Chen, Y.; Wan, H.; Feng, Y. Enhancement of biogas production in anaerobic codigestion by ultrasonic pretreatment. Energy Convers. Manag. 2016, 112, 226–235. [Google Scholar] [CrossRef]

- Zheng, M.; Li, X.; Li, L.; Yang, X.; He, Y. Enhancing anaerobic biogasification of maize stover through wet state NaOH pretreatment. Bioresour. Technol. 2009, 100, 5140–5145. [Google Scholar] [CrossRef]

- Wang, F.; Xie, H.; Chen, W.; Wang, E.; Du, F.; Song, A. Biological pretreatment of corn stover with ligninolytic enzyme for high efficient enzymatic hydrolysis. Bioresour. Technol. 2013, 144, 572–578. [Google Scholar] [CrossRef]

- Makri, A.; Ntougias, S.; Melidis, P. Enhancing anaerobic degradation of corn stover residues and biogas production via rumen microorganisms. Environ. Process. 2024, 11, 54. [Google Scholar] [CrossRef]

- Wang, S.; Li, F.; Wu, D.; Zhang, P.; Wang, H.; Tao, X.; Ye, J.; Nabi, M. Enzyme pretreatment enhancing biogas yield from corn stover: Feasibility, optimization, and mechanism analysis. J. Agric. Food Chem. 2018, 66, 10026–10032. [Google Scholar] [CrossRef]

- Zhong, W.; Zhang, Z.; Luo, Y.; Sun, S.; Qiao, W.; Xiao, M. Effect of biological pretreatments in enhancing corn straw biogas production. Bioresour. Technol. 2011, 102, 11177–11182. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Keshwani, D.R.; Xu, Y.; Hanna, M.A. Alkali combined extrusion pretreatment of corn stover to enhance enzyme saccharification. Ind. Crops Prod. 2012, 37, 352–357. [Google Scholar] [CrossRef]

- Adebowale, D.; Oziegbe, O.; Obafemi, Y.D.; Ahuekwe, E.F.; Oranusi, S.U. Biogas production from thermo–alkaline pretreated corn stover codigested with rumen content. In Bioenergy and Biochemical Processing Technologies. Green Energy and Technology; Ayeni, A.O., Sanni, S.E., Oranusi, S.U., Eds.; Springer: Cham, Switzerland, 2022; pp. 151–162. [Google Scholar]

- Karthikeyan, P.K.; Bandulasena, H.C.H.; Radu, T. A comparative analysis of pre-treatment technologies for enhanced biogas production from anaerobic digestion of lignocellulosic waste. Ind. Crops Prod. 2024, 215, 118591. [Google Scholar] [CrossRef]

- Erbetta, E.; Echarte, L.; Elizagaray, C.R.; Depetris, G.J.; Gabbanelli, N.; Echarte, M.M. Stover biogas potential of corn crops grown under contrasting water availability and nitrogen supply. Biomass Bioenergy 2021, 145, 105943. [Google Scholar] [CrossRef]

- Jingura, R.M.; Kamusoko, R. Technical options for valorization of jatropha press-cake: A review. Waste Biomass Valor. 2018, 9, 701–713. [Google Scholar] [CrossRef]

- Demichelis, F.; Tommasi, T.; Deorsola, F.A.; Marchisio, D.; Fino, D. Effect of inoculum origin and substrate-inoculum ratio to enhance the anaerobic digestion of organic fraction municipal solid waste (OFMSW). J. Clean. Prod. 2022, 351, 131539. [Google Scholar] [CrossRef]

- Chinwendu, D.; Sunkanmi, F.; Joshua, O.; Blessing, O. Investigating the synergistic effect of temperature and pH dynamics on biogas yield from lignocellulosic biomass codigested with cow dung. J. Adv. Microbiol. 2024, 24, 139–162. [Google Scholar] [CrossRef]

- Wang, B. Factors That Influence the Biochemical Methane Potential (BMP) Test: Steps Towards the Standardization of BMP Test. Ph.D. Thesis, Lund University, Lund, Sweden, 2016. [Google Scholar]

- Ge, X.; Xu, F.; Li, Y. Solid-state anaerobic digestion of lignocellulosic biomass: Recent progress and perspectives. Bioresour. Technol. 2016, 205, 239–249. [Google Scholar] [CrossRef]

- Shitophyta, L.M.; Budiyono; Fuadi, A.M. Solid-state anaerobic digestion of rice straw for biogas production. A review. Chemica 2016, 3, 17–23. [Google Scholar] [CrossRef][Green Version]

- Kamusoko, R.; Jingura, R.M.; Parawira, W.; Chikwambi, Z. Biogas: Microbiological research to enhance efficiency and regulation. In Handbook of Biofuels; Sahay, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 485–497. [Google Scholar]

- Mir, M.A.; Hussain, A.; Verma, C. Design considerations and operational performance of anaerobic digester: A review. Cogent Eng. 2016, 3, 1181696. [Google Scholar] [CrossRef]

- Siddique, M.N.I.; Wahid, Z.A. Achievements and perspectives of anaerobic codigestion: A review. J. Clean. Prod. 2018, 194, 359–371. [Google Scholar] [CrossRef]

- Teghammar, A. Biogas Production from Lignocelluloses: Pretreatment, Substrate Characterization, Codigestion and Economic Evaluation. Ph.D. Thesis, University of Boras, Boras, Sweden, 2013. [Google Scholar]

- Alengebawy, A.; Ran, Y.; Osman, A.I.; Jin, K.; Samer, M.; Ai, P. Anaerobic digestion of agricultural waste for biogas production and sustainable bioenergy recovery: A review. Environ. Chem. Lett. 2024, 22, 2641–2668. [Google Scholar] [CrossRef]

- Viskovic, M.; Djatkov, D.; Martinov, M. Greenhouse gas emission savings of electricity generated from biogas produced from corn stover. Biomass Convers. Biorefin. 2022, 12, 1459–1469. [Google Scholar] [CrossRef]

- Chojnacka, K.; Moustakas, K. Anaerobic digestate management for carbon neutrality and fertilizer use: A review of current practices and future opportunities. Biomass Bioenergy 2024, 180, 106991. [Google Scholar] [CrossRef]

- Guan, D.; Zhao, J.; Wang, Y.; Fu, Z.; Zhang, D.; Zhang, H.; Xie, J.; Sun, Y.; Zhu, J.; Wang, D. A critical review on sustainable management and resource utilization of digestate. Process Saf. Environ. Prot. 2024, 183, 339–354. [Google Scholar] [CrossRef]

- Wystalska, K.; Kwarciak-Kozłowska, A. Utilization of digestate from agricultural and food waste for the production of biochar used to remove methylene blue. Sustainability 2023, 15, 14723. [Google Scholar] [CrossRef]

- Zuffi, V.; Puliga, F.; Zambonelli, A.; Trincone, L.; Sanchez-Cortes, S.; Francioso, O. Sustainable management of anaerobic digestate: From biogas plant to full-scale cultivation of Pleurotus ostreatus. Agronomy 2023, 13, 950. [Google Scholar] [CrossRef]

- Liu, R.; Gong, H.; Xu, Y.; Cai, C.; Hua, Y.; Li, L.; Dai, L.; Dai, X. The transition temperature (42 °C) from mesophilic to thermophilic micro-organisms enhances biomethane potential of corn stover. Sci. Total Environ. 2021, 759, 143549. [Google Scholar] [CrossRef]

- Schilling, J.S.; Ai, J.; Blanchette, R.A.; Duncan, S.M.; Filley, T.R.; Tschirner, U.W. Lignocellulose modifications by brown rot fungi and their effects, as pretreatments, on cellulolysis. Bioresour. Technol. 2012, 116, 147–154. [Google Scholar] [CrossRef] [PubMed]

- Raposo, F.; De La Rubia, M.A.; Fernández-Cegrí, V.; Borja, R. Anaerobic digestion of solid organic substrates in batch mode: An overview relating to methane yields and experimental procedures. Renew. Sustain. Energy Rev. 2012, 16, 861–877. [Google Scholar] [CrossRef]

- Tuyen, D.V.; Phuong, H.N.; Cone, J.W.; Baars, J.J.P.; Sonnenberg, A.S.M.; Hendriks, W.H. Effect of fungal treatments of fibrous agricultural by-products on chemical composition and in vitro rumen fermentation and methane production. Bioresour. Technol. 2013, 129, 256–263. [Google Scholar] [CrossRef]

- Kamusoko, R.; Jingura, R.M.; Parawira, W.; Chikwambi, Z. Characterization of lignocellulosic crop residues for potential biogas production in Zimbabwe. Biofuels Bioprod. Biorefin. 2022, 16, 1165–1171. [Google Scholar] [CrossRef]

- Joseph, G.; Zhang, B.; Rahman, Q.M.; Wang, L.; Shahbazi, A. Two-stage thermophilic anaerobic co-digestion of corn stover and cattle manure to enhance biomethane production. J. Environ. Sci. Health A 2019, 54, 452–460. [Google Scholar] [CrossRef]

- Strang, O.; Ács, N.; Wirth, R.; Maróti, G.; Bagi, Z.; Rákhely, G.; Kovács, K.L. Bioaugmentation of the thermophilic anaerobic biodegradation of cellulose and corn stover. Anaerobe 2017, 46, 104–113. [Google Scholar] [CrossRef]

- Chen, G.; Zheng, Z.; Yang, S.; Fang, C.; Zou, X.; Luo, Y. Experimental codigestion of corn stalk and vermicompost to improve biogas production. Waste Manag. 2010, 30, 1834–1840. [Google Scholar] [CrossRef] [PubMed]

- Schroyen, M.; Vervaeren, H.; Vandepitte, H.; Hulle, S.W.H.V.; Raes, K. Effect of enzymatic pretreatment of various lignocellulosic substrates on production of phenolic compounds and biomethane potential. Bioresour. Technol. 2015, 192, 696–702. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Luo, K.; Zhang, Y.; Zheng, Z.; Cai, Y.; Wen, B.; Cui, Z.; Wang, X. Improving the methane yield of maize straw: Focus on the effects of pretreatment with fungi and their secreted enzymes combined with sodium hydroxide. Bioresour. Technol. 2018, 250, 204–213. [Google Scholar] [CrossRef]

- Menardo, S.; Airoldi, G.; Balsari, P. The effect of particle size and thermal pre-treatment on the methane yield of four agricultural by-products. Bioresour. Technol. 2012, 104, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Jeswani, H.K.; Krüger, C.; Kicherer, A.; Antony, F.; Azapagic, A. A methodology for integrating the biomass balance approach into life cycle assessment with an application in the chemicals sector. Sci. Total Environ. 2019, 687, 380–391. [Google Scholar] [CrossRef]

- Fujino, J.; Yamaji, K.; Yamamoto, H. Biomass-balance table for evaluating bioenergy resources. Appl. Energy 1999, 63, 75–89. [Google Scholar] [CrossRef]

- Moscoviz, R.; Jimenez, J. Improving anaerobic digestion mass balance calculations through stoichiometry and usual substrate characterization. Bioresour. Technol. 2021, 337, 125402. [Google Scholar] [CrossRef]

- Dolan, T.; Cook, M.B.; Angus, A.J. Financial appraisal of wet mesophilic AD technology as a renewable energy and waste management technology. Sci. Total Environ. 2011, 409, 2460–2466. [Google Scholar] [CrossRef]

- Zuo, Z.; Tian, S.; Chen, Z.; Li, J.; Yang, X. Soaking pretreatment of corn stover for bioethanol production followed by anaerobic digestion process. Appl. Biochem. Biotechnol. 2012, 167, 2088–2102. [Google Scholar] [CrossRef]

- Rasimphi, T.; Kilonzo, B.; Tinarwo, D.; Nyamukondiwa, P. Challenges, opportunities, and possible interventions in the biogas sector in rural areas of Limpopo, South Africa. Energy Strat. Rev. 2024, 56, 101562. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Decentralized Micro-Biodigester Systems for Rural South Africa; IEA Bioenergy: Task 36; IEA Bioenergy: Paris, France, 2021; pp. 1–32. [Google Scholar]

- Msibi, S.S.; Kornelius, G. Potential for domestic biogas as household energy supply in South Africa. J. Energy S. Afr. 2017, 28, 1–13. [Google Scholar] [CrossRef]

- Mittala, S.; Ahlgrena, E.O.; Shuklab, P.R. Barriers to biogas dissemination in India: A review. Energy Policy 2018, 112, 361–370. [Google Scholar] [CrossRef]

- Nevzorova, T.; Kutcherov, V. Barriers to the wider implementation of biogas as a source of energy: A state-of-the-art review. Energy Strat. Rev. 2019, 26, 100414. [Google Scholar] [CrossRef]

- Rasimphi, T.; Kilonzo, B.; Tjale, M.; Tinarwo, D.; Nyamukondiwa, P. Review of implementation of biogas technology in rural communities of South Africa. Cogent Soc. Sci. 2024, 10, 2419536. [Google Scholar] [CrossRef]

- Mukumba, P.; Makaka, G.; Mamphweli, S. Biogas technology in South Africa, problems, challenges and solutions. Int. J. Sustain. Energy Environ. Res. 2016, 5, 58–69. [Google Scholar] [CrossRef]

- Sekoai, P.T.; Chunilall, V.; Msele, K.; Buthelezi, L.; Johakimu, J.; Andrew, J.; Zungu, M.; Moloantoa, K.; Maningi, N.; Habimana, O.; et al. Biowaste biorefineries in South Africa: Current status, opportunities, and research and development needs. Renew. Sustain. Energy Rev. 2023, 188, 113870. [Google Scholar] [CrossRef]

- Dumont, K.B.; Hildebrandt, D.; Sempuga, B.C. The “yuck factor” of biogas technology: Naturalness concerns, social acceptance and community dynamics in South Africa. Energy Res. Soc. Sci. 2021, 71, 101846. [Google Scholar] [CrossRef]

- Nethengwe, N.S.; Uhunamure, S.E.; Tinarwo, D. Potentials of biogas as a source of renewable energy: A case study of South Africa. Int. J. Renew. Energy Res. 2018, 8, 1112–1123. [Google Scholar]

- Anekwe, I.M.S.; Akpasi, S.O.; Mkhize, M.M.; Zhou, H.; Moyo, R.T.; Gaza, L. Renewable energy investments in South Africa: Potentials and challenges for a sustainable transition—A review. Sci. Prog. 2024, 107, 368504241237347. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Review of Waste to Energy Policies in South Africa and International Comparisons; IEA Bioenergy: Task 36; IEA Bioenergy: Paris, France, 2023; pp. 1–32. [Google Scholar]

- Department of National Treasury. Frequently Asked Questions. Enhanced Renewable Energy Incentive for Businesses; Department of National Treasury: Pretoria, South Africa, 2023; pp. 1–4. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).