Abstract

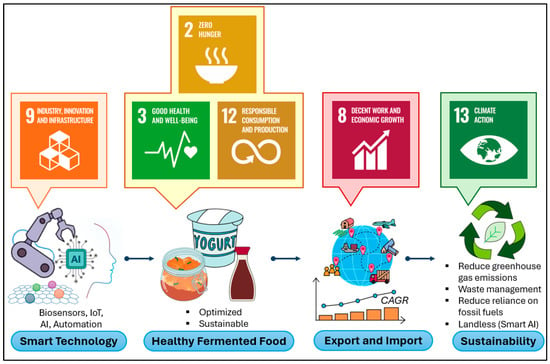

Traditional fermented foods are appreciated worldwide for their cultural significance and health-promoting properties. However, traditional fermentation production suffers from many obstacles such as microbial variability, varying quality, and lack of scalability. The implementation of smart fermentation technologies, including biosensors, the Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML), hold the key to the optimization of microbial process control, enhance product consistency, and improve production efficiency. This review summarizes modern developments in real-time microbial monitoring, IoT, AI, and ML tailored to traditional fermented foods. Despite significant technical advancements, challenges related to high costs, the absence of standardized frameworks, and access restrictions for small producers remain substantial limitations. This review proposed a future direction prioritizing modular, scalable solutions, open-source innovation, and environmental sustainability. In alignment with Sustainable Development Goal 9 (Industry, Innovation, and Infrastructure), smart fermentation technologies advance sustainable industry through innovation and serve as a critical bridge between traditional craftsmanship and Industry 4.0, fostering inclusive development while preserving microbial biodiversity and cultural heritage.

1. Introduction

1.1. Importance of Traditional Fermented Foods

Fermented foods have been integral to human diets and cultural identities throughout history in civilizations [1]. The fermentation process, a biochemical conversion through microbial enzymatic activity, began as a means of food preservation and of improving its nutritional and sensory quality [2]. Traditional fermented foods, including miso, kimchi, tempeh, yogurt, and traditional drinks, are now being cherished not only for their tasty flavors but also for their important health benefits, which are due to their nutritional characteristics [3].

One of the other remarkable advantages of fermented foods is their contribution to food security and preservation [4]. The production of organic acids, ethanol, carbon dioxide, and bacteriocins during fermentation prevents spoilage organisms and pathogenic bacteria from growing, being that fermented products are intrinsically more stable [5]. For instance, lactic acid bacteria (LAB), which are in yogurt, sauerkraut, and pickles, are also strong bio-preservatives, making the spaces inhospitable to bad microbes [6].

In addition to safety, the nutritional value of foods is improved by fermentation. Microbial activity can further enhance the bioavailability of minerals such as iron, zinc, and calcium through the degradation of antinutritional factors like phytates [7]. In addition, numerous fermented foods, particularly in traditional diets around the world, contain a wealth of probiotics that contain beneficial live bacteria that impart health benefits when consumed in sufficient quantities [8]. Frequent intake of probiotic fermented foods and direct evidence of beneficial effects of the regular intake of these foods include enhanced intestinal microbiota composition, digestive health improvement, inflammation reduction, and even mental health via the gut-brain axis [9].

In cultural terms, fermented foods are a repository of the biodiversity and ecological wisdom of specific places [10]. The microorganisms behind traditional fermentation are commonly those found in nature and have been selected by centuries of environmental adaptation and culinary tradition [1]. The natural mix of microbes, known as microbial terroir, gives fermented foods their unique flavors, which cannot be exactly copied using industrial methods [11]. Therefore, fermented foods are not just food; they are alive with their resistance to ‘culture’, civilizations, and biological monochromes [1]. In the current era of functional foods and natural products and increasing demand for “back-to-nature” health-promoting ingredients, the importance of traditional fermented foods and their intrinsic microbial communities is expected to increase even more.

1.2. Challenges in Traditional Fermentation (Microbial Inconsistency, Variable Quality)

Although traditional fermentations are highly valuable and offer several advantages, they encounter various challenges that limit their continuity and economic feasibility in the contemporary world of the food industry [12,13]. Microbiological variability, batch-to-batch product variation, safety issues, limitation in scale, and low eligibility are some of the main issues being faced [14,15,16].

Conventional fermentation traditionally uses natural or spontaneous inoculation to initiate fermentation, which is driven by environmental microflora [17]. Environmental factors, including ambient temperature, relative humidity, juiced composition, and microbial load, affect microbial succession in the course of juice fermentation [18]. Therefore, even small variations in the production environment, such as the average temperatures of the processing line or the types of raw material, can result in varying product quality, flavor profiles, and safety records. Microbial instability constitutes a dual risk, as it jeopardizes both the sensory stability of the product and raises concerns about food safety [19]. Lack of control over starter cultures may lead to unwanted organisms (e.g., spoilage or opportunistic pathogens) outcompeting in the population and resulting in potentially unsafe or spoiled products [20]. For example, aged vegetable fermentations, like kimchi or sauerkraut, may occasionally harbor Listeria monocytogenes or spoilage yeasts if environmental and sanitary conditions are inadequately managed [21].

Scaling up traditional fermentation techniques to an industrial level often amplifies existing challenges. In traditional practices, sensory evaluation and the experience of master fermenters play a key role in guiding the process. However, these methods are difficult to standardize for large production, especially at an industrial scale, and are not easily transferable to new generations of workers without significant time investment [22]. As the market for traditional fermented foods becomes more globalized, a conflict arises between maintaining traditional practices and integrating modern quality assurance methods [23].

In addition, for non-germinated food, it is a requirement of contemporary food safety regulations for traceability, reproducibility, and microbial documentation in the entire production process [24]. Such regulatory demands are, however, difficult to meet with traditional fermentation technologies where no standardized monitoring equipment is available [25,26]. One of the challenges traditional fermented products face in international markets is the trade restrictions imposed on imported items without documented microbial profiles and the lack of assurance that hygienic practices are maintained [25].

A growing challenge involves meeting consumer demands. Fermented foods have gained popularity, particularly among health-conscious consumers who like fermented foods for their probiotic content and other health benefits, and the desire to substantiate health claims has increased [25]. Conventional producers rarely have the capacity to verify probiotic strains and assess the concentrations of viable microbes or to scientifically validate the health-promising functions, rendering them less competitive against industrial entities that perform clinical trials and implement quality assurance measures such as legal certification [27,28,29].

The traditional fermentation is further challenged by environmental conditions caused by climate change. Oscillations of temperature and humidity, on the other hand, may modify microbial communities in unpredictable ways, with negative effects on product consistency and safety [30,31]. Such unpredictability is particularly important when it comes to delicate fermentation processes like koji fermentation for soy sauce and sake [32,33].

Consequently, while traditional fermentation represents a repository of culinary and microbiological variety, the continuation of these age-old processes in both domestic and industrial contexts hinges on addressing those issues. In this context, interventions are urgently required that honor the artisanal history of these techniques while integrating scientific rigor to ensure the safety, standardization, and scalability of these products. Smart fermentation approaches represent a potential way to link the gap and enable traditional food to succeed in a modern, globalized, safety-concern food environment.

1.3. Need for Smart Technologies in Fermentation

The application of intelligent technologies in fermentation is becoming an urgent necessity to ensure the relevance and competitiveness of traditional practices in the modern food landscape [34,35]. Smart fermentation systems that integrate real-time monitoring, machine learning (ML), biosensors, and automation offer effective solutions to longstanding challenges such as microbial variability, product inconsistency, and food safety risks [36]. Continuous, data-driven monitoring allows producers to optimize processes, improve quality, and minimize losses [37], while predictive models further enhance control and decision [38].

Moreover, the accessibility of affordable IoT devices and open platforms lowers barriers for small and artisanal producers to adopt digital fermentation tools [39]. Even artisanal producers can take advantage of smart tools with cloud-based dashboards, mobile apps, and friendly interfaces that do not require specialized expertise. However, implementing smart technologies must support and preserve the craftsmanship and microbial diversity that define traditional fermentation. Thoughtful integration will be key to enhancing resilience, authenticity, and global market access for traditional fermented foods [40].

The incorporation of smart fermentation technologies transcends simple modernity; it is essential for bolstering resilience, maintaining authenticity, and augmenting the worldwide competitiveness of traditional fermented foods. When applied wisely, these technologies allow traditional fermenters to utilize the precision and control provided by scientific breakthroughs while preserving the cultural importance and microbiological variety that characterize their legacy traditions.

2. Overview of Smart Fermentation Technologies

2.1. Definition and Scope of Smart Technologies

Smart technologies are defined by their autonomous and context-aware capabilities, facilitated by the integration of information and communication technologies [41], real-time data processing, and decentralized systems [42,43].

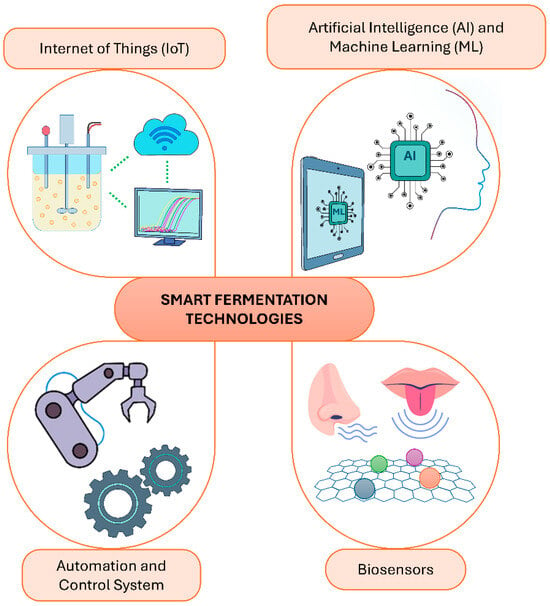

Besides that, smart technologies also denote systems and devices that integrate extensive computing, communication, and automation features to provide context-aware, adaptive, and autonomous functions [44]. These technologies are aligned with Industry 4.0, which is engineered to detect, analyze, and react to their surroundings, frequently employing the IoT, biosensors, AI, and ML as well as automation and control systems in fermentation (Figure 1). In the context of fermentation, smart technologies enable dynamic control over microbial processes, enhancing efficiency, consistency, and scalability in bioproduction.

Figure 1.

Smart fermentation technologies (Figure by author).

The global market for smart technologies, especially AI and ML, has undergone substantial expansion in the last 5 years, and the worldwide AI software industry is anticipated to attain $126 billion by 2025, reflecting a 270% gain in corporate use over the previous 4 years [45]. By 2025, AI is projected to facilitate 95% of customer contacts, with the industry expanding at an annual rate of around 54%, ultimately reaching a valuation of $22.6 billion [45]. This expansion is propelled by enhancements in computing capacity, augmented data availability, and extensive use across many industries.

SMART also denotes “self-monitoring, analysis, and reporting technology”, which employs AI, ML, and big data analysis to confer cognitive awareness to items previously regarded as inanimate [46]. Besides that, augmented adoption is an advanced iteration of the tangible physical world, realized by the integration of digital visual components, auditory aspects, or other sensory stimulation facilitated by technology [47,48]. Since the COVID-19 pandemic, the usage of smart technologies has evolved to combat the physical touch and interactions between humans and become the new normal [49]. The new normal encompasses disruptive and transformative digital advancements, which have created new living standards that vary from highly interconnected, interactive, and collaborative social structures to segregated, isolated, and decentralized social frameworks [50].

2.2. Key Technologies in Smart Fermentation

2.2.1. Internet of Things (IoT): Real-Time Sensors, Cloud-Based Data

The integration of the IoT into fermentation processes has revolutionized the way fermentation is monitored and controlled. By leveraging real-time sensors and cloud-based data management, IoT facilitates enhanced precision, efficiency, and scalability in fermentation operations. The IoT enables real-time oversight and regulation of fermentation processes through the integration of sensors with cloud computing platforms [51]. An embedded IoT system employing an ESP32 microcontroller has been created to monitor and manage temperature and turbidity in bioreactors, transferring data to cloud platforms for analysis and visualization [52]. This connection improves process control, allowing prompt interventions and optimization (Table 1).

Real-time sensors are essential for acquiring instantaneous data from fermentation operations [53]. These sensors identify minor fluctuations in ambient variables, offering immediate input for process modifications [54]. Cloud data platforms contribute the computing capacity required to analyze intricate datasets, facilitating predictive analytics and ML applications that may anticipate fermentation results and identify prospective problems pre-emptively [55].

The integration of IoT and cloud computing improves the efficiency and reliability of fermentation operations [39]. It facilitates remote oversight and management, diminishing the necessity for manual interventions and mitigating the danger of human mistakes [56]. Furthermore, the scalability of cloud-based data guarantees that the system can accommodate many production sizes, ranging from modest laboratory configurations to extensive industrial operations [57].

2.2.2. Biosensors and Electronic Noses/Tongues

Biosensors are defined as analytical instruments that detect analytes using a biological sensing element and physicochemical detector [58]. Biosensors, such as electronic noses (E-noses) and tongues (E- tongues), are essential in smart fermentation for real-time, high-resolution monitoring of biochemical parameters. Recent improvements encompass AI-driven biosensors that can identify chemicals, like glucose and amino acids, at picomolar concentrations, thereby enhancing bioprocess transparency and mitigating contamination hazards [59]. Moreover, ML-augmented biosensors have been utilized for food safety detection, providing greater sensitivity and precision [60].

Both E-noses and E-tongues are utilized as biosensors in fermentation. An E-nose is defined as a sensor array that replicates the human olfactory system to detect and distinguish volatile chemicals, whereas an E-tongue is a sensor that simulates human taste experience by analyzing liquid non-volatile chemicals [61,62]. Smart fermentation processes need the use of biosensors, E-tongues, and E-noses because they provide improved product verification, quality control, and monitoring (Table 1).

2.2.3. Artificial Intelligence and Machine Learning

AI comprises computer methods that allow robots to replicate human cognition, whereas ML, a subset of AI, utilizes algorithms that enhance performance based on various experiences [63,64]. Recent literature underscores the advancement of these technologies, focusing on the amalgamation of deep learning, reinforcement learning, and neural networks to improve decision-making processes across several domains (Table 1).

AI and ML have revolutionized fermentation process optimization, especially metabolic pathway prediction and dynamic parameter modification. These technologies increase biomanufacturing process control, yields, and costs [65].

The dynamic regulation of fermentation parameters is essential for sustaining optimum conditions during the bioprocess. Reinforcement learning (RL), a branch of machine learning (ML), has been utilized to create adaptive control techniques that modify process variables in real time [66]. The evolution of deep learning [28] approaches, specifically algorithms that integrate reinforcement learning (RL) with deep neural networks, known as deep reinforcement learning (DRL), has enhanced environmental sensing and allowed RL algorithms to make judgments with superior performance, flexibility, and time efficiency [67]. For instance, RL-based controllers have been developed to dynamically regulate enzyme expression, leading to substantial improvements in product titers while preserving robustness against system uncertainties [68].

AI and ML enable the forecasting and formulation of metabolic pathways through the analysis of intricate biological data [69]. Machine learning algorithms, such as those utilizing flux balance analysis (FBA), can forecast intracellular metabolic fluxes, facilitating the discovery of optimum genetic changes for improved product synthesis [70]. Besides that, hybrid physics-informed models amalgamate machine learning surrogates with FBA to streamline dynamic optimization problems in metabolic engineering [71]. In fungal bioprocesses, AI has been employed to enhance production yields and comprehend intricate bioprocess dynamics via soft sensors [72]. Furthermore, the integration of biosensors with ML methodologies has improved the efficacy of food safety detection systems, allowing real-time monitoring and prompt identification of pollutants [73] (Table 1).

2.2.4. Automation and Control Systems (Proportional-Integral-Derivative (PID) Control, Neural Networks)

Automation in fermentation employs control systems, including proportional-integral-derivative (PID) controllers and neural networks, to sustain ideal conditions. The amalgamation of IoT with PID control has been shown in bioreactor systems to proficiently manage temperature and turbidity [74]. Moreover, AI technologies have been employed to regulate microfluidic chips, improving the accuracy and efficacy of biosensing devices [75]. In the fermentation process, PID controllers are essential in industrial process control because of their simplicity and efficacy in handling linear systems (Table 1).

PID controllers have been efficiently utilized in fermentation to adjust essential parameters, including temperature and pH [76]. A study indicated that utilizing a PID logic controller for temperature regulation in batch ethanol fermentation resulted in enhanced cell proliferation and product yield relative to traditional approaches. Traditional PID controllers may encounter difficulties due to the nonlinear and dynamic characteristics of fermentation operations [77]. Researchers have investigated hybrid methodologies to tackle this issue. Integrating PID with fuzzy logic has demonstrated enhanced performance in regulating nonlinear chemical processes, providing superior flexibility to varying situations [77,78].

Table 1.

Applications of technologies in smart fermentation from previous studies.

Table 1.

Applications of technologies in smart fermentation from previous studies.

| Technologies | Applications | References |

|---|---|---|

| IoT (real-time sensors and cloud-based data) | Wine fermentation monitoring— Utilized real-time sensors to monitor temperature and sugar concentrations, relaying data to a cloud platform for analysis. This configuration facilitated real-time oversight and regulation, guaranteeing optimal fermentation conditions and product excellence. | [79,80] |

| Tea fermentation detector— An IoT-based methodology using CNNs and majority voting was presented to determine optimal tea fermentation stages. The method used a Raspberry Pi camera to take pictures of fermenting tea and ML algorithms to estimate its fermentation level. | [81,82] | |

| Beer fermentation control— Wireless sensor networks (WSNs) in beer fermentation provide real-time pH, density, and temperature monitoring. | [83,84] | |

| Sourdough fermentation—Gas sensor arrays that analyze exhaust gases and correlate them with pH and TTA levels. | [85] | |

| Biosensors, E-noses, and E-tongues | Detection of adulteration in fermented products— E-tongues to detect adulteration in whey protein powders and olive oil. | [86,87] |

| Monitoring fermentation process— Maintain authenticity, consistency and quality of food. | [29,88] | |

| AI an ML | Brewing industry— Energy consumption prediction and recipe optimization have been primarily handled by artificial neural networks (ANNs) and support vector machines (SVMs). | [89,90] |

| Biofuel production—Artificial neural networks (ANN) were used to forecast yields of bioethanol and biohydrogen to produce the optimum cellulosic biomass fermentation. | [91] | |

| Arabica coffee fermentation— ML improves the sensory attributes of coffee, augmenting the product’s value by creating varied sensory characteristics. | [92] | |

| Automation and control systems | Antibiotic production— Back-propagation neural network (BPNN) with adaptive genetic algorithm (AGA) enhanced nutrient delivery, resulting in elevated cell concentration and improved fermentation efficiency. | [93] |

| Ethanol production— The use of PID and fuzzy logic controllers for improved temperature and pH regulation has led to increased yields and enhanced process stability. | [76,94] | |

| Lactic acid fermentation— PID enhanced the management of process nonlinearities, resulting in greater product consistency. | [95] |

3. Microbial Process Control in Traditional Fermented Foods

3.1. Importance of Microbial Control in Fermentation

Fermented foods are part of many cultures, providing unique tastes and flavors and longer shelf lives [96]. Numerous fermented foods are classified as functional foods due to their incorporation of microbes, which improve the general health of consumers [93]. Fermentation is mainly mediated by a rich microbial community composed of bacteria, yeasts, and molds. Efficient control of microbial populations in order to guarantee the safety, quality, and stability of these foods is an indispensable requirement [97].

Lactic acid bacteria (LAB), such as Lactobacillus, Leuconostoc, and Pediococcus spp. are crucial organisms in many fermentation processes, such as kefir, yogurt, butter, and cheese, as they produce lactic acid, which lowers the pH of the food [98]. This creates an environment that helps prevent the growth of harmful bacteria and spoilage organisms while also enhancing the food’s shelf life and giving it a pleasantly tangy flavor [99]. Not only that, LAB also produce good bioactive compounds such as vitamins, antioxidant compounds, peptides, and gamma-aminobutyric acid during the fermentation process [100,101]. Yeasts such as Saccharomyces, Candida, and Zygosaccharomyces play a role in alcoholic fermentation, leading to the formation of ethanol, carbon dioxide, and several aromatic compounds, which are important for the complexity of the flavor [102]. Based on their ability to produce enzymes that degrade archive complex carbohydrates and proteins, filamentous fungi contribute to the fermentation of some foods as well, especially in the tradition of fermenting food in East Asia, such as Aspergillus spp., Rhizopus spp., and Mucor spp. [103].

The interaction of these microorganisms with their environment is complex and can significantly influence the result of the fermentation [104]. Factors such as temperature, acidity, oxygen, and salt concentration must all be manipulated to stimulate the growth of beneficial microbes while inhibiting undesirable ones [105]. These conditions are typically manipulated in traditional practice, such as back-slopping and inoculation with starter cultures, in order to obtain the expected results [106].

In summary, microbial control during fermentation is important to guarantee the safety, quality, and uniformity of traditional fermented foods. By understanding and managing the complex interactions among microorganisms and their environment, producers can harness the benefits of fermentation while minimizing risks [107].

3.2. Microbial Fermentation Instability and Its Impact on Product Quality

Microbial fermentation instability is an immense issue that has erupted in the food, pharmaceutical, and cosmetic sectors because it profoundly impacts product safety, longevity, and customer approval.

Firstly, spontaneous mutations and alterations in gene regulation throughout fermentation cycles are significant contributors to microbial instability. According to [108,109], prolonged fermentations of Lactobacillus plantarum induce genomic drift, impacting metabolite production and the repeatability of fermentation processes. In another study by [110], the effects of enriched pit mud were investigated, and the study discovered that Caproicibacterium lactatifermentan inoculation in Baiju fermentation resulted in enhanced synthesis of fatty acids and ethyl esters in the short term. However, prolonged usage led to a reduction in these chemicals’ compounds. Furthermore, heterologous gene expression in Saccharomyces cerevisiae for alcohol fermentation was studied, and a reduced yield was noted, attributed to plasmid loss and burden effects under batch settings [111].

Other than that, fluctuations in pH, temperature, oxygen concentration, and shear force over fermentation cycles also induce microbial stress and alter population dynamics. Based on the study by Beschkov and Angelov [112], fed-batch anaerobic fermentation demonstrated oxygen incursions resulted in the collapse of obligatory anaerobes and the buildup of volatile fatty acids. The excessive buildup of volatile fatty acids resulted in a pH reduction and significantly inhibited methanogenesis. Dual-species biofilms composed of L. monocytogenes and P. fluorescens of food fermentation exhibited structural shrinkage, decreased thickness, and uneven matrix distribution at low temperatures [113].

During fermentation, microbial consortia frequently encounter instability caused by competition or imbalances in cross-feeding. Also, accidental fermentation results are attributed to biotic variables such as variations in initial microbial composition and microbial abundance and instability in liquor fermentation [114]. In another application of microbial instability by Thomashoff [115], oxidative stress impairs cellular integrity and granule development in Bifidobacterium spp., resulting in diminished viability and functionality in yogurt. Instability in yogurt fermentation was associated with protein misfolding and impaired biofilm formation [115].

3.3. Microbial Process Optimization Using Smart Technologies

The traditional control of microbial fermentation has been based for a long time on empirical practices and craftsman’s knowledge [37]. The application of practices like back-slopping, ecological manipulation and substrate treatment underpin the management of microflora in several cultures. Although these practices have contributed to the processing of safe and palatable fermented products for centuries, these methods are generally less accurate, reproducible, and scalable [106]. Meanwhile, new smart technologies rely on data-driven, automated, and accurately precise strategies to control the microbial community and maximize fermentation efficiency [116]. The integration of digital tools, molecular biology, and process engineering is transforming the understanding, and exploitation, of microbial fermentation for traditional and industrial applications [13].

Real-time monitoring of fermentation systems is the cornerstone of this technological progression. These include the combination of biosensors, optical sensors, and IoT devices to achieve seamless monitoring of key fermentation parameters like temperature, pH, redox potential, dissolved oxygen, microbial biomass, and metabolite concentrations [41]. For instance, the optical density sensors continuously measure the growth of microbial culture in real time, and the potentiometric sensors monitor the change in pH values that reflects the metabolic intensity [117]. These sensor technologies allow high-resolution data measurement and minimize the reliance on manual sampling that is labor-intensive and has potential contamination and handling issues [118]. In less-controlled environments, or those where fermentation varies from time to time, such monitoring can be used to homogenize and stabilize product development without compromising its individuality.

Another significant progress was the automatic fermentation control by more advanced feedback systems [119]. With programmable logic controllers (PLCs) combined with intelligent software, these systems can facilitate the automatic alteration of process conditions to adapt to sensor data in real time [120]. For example, if the pH falls rapidly due to the overproduction of acid, the system can control temperature or aeration to reduce microbial action. Likewise, if microbial growth is delayed by oxygen limitation, controlled aeration can be introduced [121]. Automation such as fed-batch fermentation interventions helps guarantee that the best state of fermentation can be kept constant, which is highly desirable in large-scale or continuous fermentation setups [122]. The resulting improvements in process efficiency and product uniformity make these technologies attractive even to traditional producers seeking to expand.

Outside the realm of external control, advanced fermentation science now incorporates molecular-level monitoring using ‘omics’ technologies. The integration of metagenomics, transcriptomics, proteomics, and metabolomics has now shed light on microbial community structure and function [123]. Metagenomic sequencing presents the opportunity to assess both culturable and non-culturable microbes’ populations, providing an accurate assessment of the diversity and temporal dynamics of microbial communities in fermentation systems [124]. Transcriptomic and proteomic studies are a way of identifying which genes and proteins are expressed at different times during fermentation and can provide clues to metabolic and stress processes [125]. For instance, [126] employed metatranscriptomics to explore microbial interactions in traditional fermented products such as strong-flavor Baijiu production and revealed metabolic networks for the development of flavor and pathogen inhibition. This knowledge will enable better strain development and the rational design of fermentation processes.

AI and ML are also being adopted as fermentation technologies to process massive datasets obtained from sensors and omics platforms [127]. AI models, including neural networks and support vector machines, can learn from historical fermentation data to provide predictions and detection of anomalies and process recommendations for process adjustments [128]. In practice, these models are used to optimize medium composition, forecast the kinetics of microbial growth, and even predict the risk of contamination before it occurs [129]. Furthermore, predictive modeling enables the construction of “digital twins”—digital models of fermentation systems that can dial in different conditions to find the proper balance of variables without disturbing ongoing production [130]. These tools are a big step forward from mere static quality control toward dynamic, predictive process management.

Smart fermentation technologies would be refined by synthetic biology and precision fermentation [107]. Precision fermentation has already been commercialized in the production of recombinant proteins such as casein and whey, which are typically extracted from milk [131]. Companies like Perfect Day are using engineered microbes to create animal-free dairy ingredients that mimic the taste and nutrition of the real thing [132]. These applications provide extremely controlled microbial ecosystems, a condition that optimizes yield, quality, and economic resiliency, especially in the context of global food security and climate adaptability [133].

Smart technologies are indeed transforming the field of microbial fermentation, acting as a conduit between traditional knowledge and contemporary scientific rigor. From biosensors and computerized automation to AI-guided analytics and synthetic biology, these tools together increase the efficiency, safety, and repeatability of fermentations. Although challenges including cost, regulation, and adoption remain, the impacts these systems could have on innovation, scalability, and being green are possibly considerable. Going forward, the smart adoption of technology combined with the traditional creates a new layer of food-ready systems that are resilient, not to mention seen as a flagbearer of culinary heritage.

4. Advances in Real-Time Microbial Monitoring

Real-time monitoring of microbial populations is transforming traditional fermentations by delivering in situ or at-line feedback on complex consortia [53]. Advances in optical, spectroscopic, electrochemical, and molecular (‘omics’) sensors now enable continuous measurement of biomass, metabolites, and specific taxa across diverse solid–liquid matrices [134,135,136]. This section evaluates each technology, its operating principle, performance, and suitability for traditional foods, and outlines how IoT networks, ML-driven dashboards, and digital twins turn raw data into actionable control. Table 2 summarizes the key real-time monitoring methods.

Table 2.

Comparative landscape of real-time microbial monitoring tools applicable to traditional fermented foods. Note: The example applications are illustrative scenarios devised by the authors and are not directly drawn from the cited studies.

4.1. Sensor-Based Approaches for In-Process Microbial Detection

4.1.1. Optical Density (OD) Sensors

OD sensors work by sending visible or near-infrared light through the fermentation broth. As the light passes through, it gets scattered by the microorganisms present. The more cells there are, the more the light is scattered. By measuring how much light is scattered (or blocked), the sensor can quickly estimate the amount of biomass in the fermenter, usually within just a few seconds. Probes can sit directly in the tank or in a sidestream loop for continuous readings [145]. They reliably detect cell densities above ~105–106 CFU/mL (very dense cultures may need dilution), cost $1–5 k, and are at a technology readiness level (TRL) of around 9. OD sensors work well in clear liquid fermentations (e.g., kombucha, soy sauce) but lose accuracy in opaque or high-solid systems due to particle scattering and probe fouling [146,147].

4.1.2. Inline or At-Line Flow Cytometry (FCM)

Flow cytometry analyzes individual cells by passing a small liquid sample through laser beams and measuring light scatter and fluorescence. Automated systems can draw broth samples, stain cells with viability dyes (e.g., DAPI or propidium iodide), and count total versus live cells every few minutes [148]. This delivers detailed information on cell size, viability, and physiology down to a few cells per microliter—far more sensitive than turbidity sensors [149]. However, the equipment is complex and expensive, which limits its use compared to simpler in-tank probes [138]. In sidestream setups, a small portion of the fermenting liquid is diverted, filtered, and sent to the cytometer, preventing clogs in solids-rich batches but limiting the analysis to the liquid fraction (e.g., kimchi brine). Even so, FCM can still track mixed cultures, distinguishing yeast and bacteria by size and fluorescence [150].

4.1.3. Fluorescence Sensors

Fluorescence sensors detect natural or added fluorophores to gauge microbial activity in real time. For example, NADH—which accumulates in active cells—emits UV-excited fluorescence, so probes measuring NADH or tryptophan signals can track metabolic rate and biomass changes [147]. Unlike turbidity, fluorescence also reveals physiological shifts (e.g., increased NADH under low-oxygen conditions). Added dyes or genetically encoded reporters can further monitor intracellular pH or ATP levels in yeast during beer and wine fermentations [151]. Fluorescence sensors respond in under a second and can detect fluorophore levels down to picomolar concentrations, enabling the detection of early exponential-phase cultures (~104–105 cells/mL). Equipment ranges from basic LED/photodiode assemblies for a few thousand dollars to high-end spectrofluorometers. Many fluorescence monitoring systems (e.g., NADH probes) are at around TRL 8 and already in use in industrial bioreactors [147]. Natural autofluorescence, such as riboflavin in yogurt or polyphenols in kombucha, can indicate microbial activity, though background signals sometimes interfere [152].

4.1.4. Raman and Infrared (IR) Spectroscopy

IR spectroscopy uses molecular “fingerprints” to track fermentation chemistry [153]. Fiber-optic Raman probes detect laser-scattered peaks from cell walls, nucleic acids, or metabolites (≈106 cells/mL; seconds–minutes per scan) and can even distinguish some microbes by unique spectra, though complex matrices may mask signals [154]. In contrast, NIR/FTIR sensors measure absorbance bands of sugars, acids, and ethanol (≈0.1% w/v; <15 s) and perform well in cloudy or colored media [155]. Both methods are label-free, with IR offering faster, broader metabolite monitoring and Raman providing higher specificity at the cost of greater matrix sensitivity [156]. Raman systems are expensive, thus lowering their TRL. Despite non-invasive probes, opaque solids like spices or grains can scatter light and weaken the signal [157]. Nevertheless, Raman still delivers high specificity—even single-cell Raman microspectroscopy can detect individual bacteria in yogurt starter cultures [158].

4.1.5. Infrared Spectroscopy (NIR and FTIR)

NIR and FTIR measure the absorbance of molecular bonds to track sugars, acids, ethanol, and biomass during fermentation [155]. NIR, which can penetrate cloudy liquids, has been successfully applied to monitor yogurt fermentation in real time [146]. An aquaphotomics NIR sensor non-invasively tracks water–matrix interactions and lactic acid buildup in yogurt, correlating its signals with LAB growth and milk coagulation. IR spectra can be acquired in seconds, and chemometric models convert them into microbial or metabolite concentrations. FTIR detects lactic acid down to ~0.1% (≈107 CFU/mL LAB). Commercial NIR/MIR systems (TRL 9) are common in breweries and dairies, and fiber-optic IR probes have been used to monitor salt and acidity in kimchi and pickle brines throughout fermentation [159].

4.1.6. Electrochemical Biosensors

Electrochemical biosensors detect microbial activity by converting biochemical reactions into electrical signals (current, voltage, or impedance) [160]. Because they rely on electrical signals, they work well in opaque or solid ferments. For example, a potentiometric sensor coated with kefir microbes measures shifts in open-circuit potential as they produce organic acids and CO2, providing real-time feedback on fermentation progress without any optical components [139]. Enzyme- or aptamer-based electrochemical biosensors use immobilized recognition elements to detect specific targets, such as amperometric lactic acid sensors for LAB growth or impedance immunosensors for pathogen binding. They respond in seconds to minutes and, with signal amplification, can detect nanomolar metabolite levels or as few as ~102 cells/mL [161]. Electrode fouling by microbial films can cause drift as residues build up. To combat this, anti-fouling coatings, periodic polarity reversal, or microfluidic sampling chambers are used [162]. Their low power requirements and wireless IoT compatibility make electrochemical sensors ideal for small or off-grid setups.

4.1.7. E-Nose and E-Tongue

E-noses and E-tongues use sensor arrays to capture the overall aroma and taste of a ferment. An E-nose combines multiple gas sensors (e.g., metal oxide or polymer sensors) to detect VOC patterns in the headspace, and ML models interpret those patterns to track fermentation progress or spot off-odors. Likewise, an E-tongue uses an array of liquid-phase sensors (potentiometric or voltametric) to profile dissolved taste compounds (acid, salt, sweetness). Together, they have been applied to tasks like distinguishing kimchi origins by aroma, monitoring cheese ripening, and detecting spoilage in fish sauce [163].

Modern E-nose arrays can sense VOCs at parts-per-billion levels, catching off-odors (like sulfur compounds) before humans can. They deliver a full aroma profile in seconds to a few minutes. They are well-established for use in food quality control, though usually used on headspace samples rather than inline [164]. Some fermenters now pipe exhaust into E-nose units—for example, miso and natto producers use them to track aroma milestones and standardize flavor development [159]. E-tongues use arrays of liquid-phase sensors (potentiometric or voltametric) to detect taste compounds such as sour, sweet, salty, bitter, and umami in real time [165]. For instance, an eight-channel E-tongue tracked kimchi’s acidity, sweetness, and umami during aging, matching human panel scores and signaling optimal ripeness without manual tasting. Similar systems have been applied to kombucha and kefir to monitor acid and sugar levels via their characteristic electrochemical “flavor” fingerprints [166].

4.1.8. Microfluidic Impedance Cytometry

Microfluidic impedance cytometry uses a small chip with electrodes in a microchannel [167]. As cells flow through, each disrupts the electrical field, creating a pulse that is counted. This label-free method can process thousands of cells per second and works in cloudy or colored broths since it relies on electrical signals, not optics. It can detect down to ~102 cells/mL with results every few seconds [168]. While it is typically unable to tell live vs. dead cells or species without extra markers, it has been demonstrated to be feasible with a few tweaks (such as the use of neural networks) in the systems [168].

4.2. Rapid Molecular and Omics-Driven Monitoring Platforms

While sensor devices detect bulk properties or general indicators, molecular methods directly interrogate microbial identities and functions, often with high specificity. Recent advances in genomics and bioassays are enabling near real-time profiling of fermentation microbiota.

4.2.1. qPCR and Isothermal Amplification

These techniques bring genetic testing to the fermenter side. Portable qPCR units can quantify specific microbes, such as Tetragenococcus halophilus in soy sauce, in about an hour, helping operators adjust salt levels on the spot. LAMP (loop-mediated isothermal amplification) runs at a single temperature in roughly 30 min and yields a simple color or fluorescence readout, detecting pathogens like Staphylococcus in kimchi down to tens of DNA copies [169]. Modern lab-on-chip devices now integrate sample prep, amplification, and detection in a single cartridge, making on-site safety testing robust even in rural settings [170].

4.2.2. CRISPR-Based Diagnostics

CRISPR-based diagnostics use Cas enzymes (e.g., Cas12a or Cas13a) programmed with guide RNA to bind specific microbial DNA/RNA and trigger a fluorescent or colorimetric signal [171]. Platforms like SHERLOCK and DETECTR deliver results in 20–60 min with single-copy sensitivity, allowing on-site detection of pathogens (e.g., Listeria in cheese) or contaminants (wild yeast in beer) without plating. As assays become multiplexed and automated, they promise to act as rapid, genomic sentinels in traditional fermentations to verify that only the intended microbes are active [172].

4.2.3. Next-Generation Sequencing (NGS) and Omics

Portable nanopore sequencers, such as the MinION, now transmit DNA readings in real time, enabling the identification of a ferment’s microbial population within 1 to 2 h following a rapid extraction. Run costs are just a few hundred dollars, rendering “microbial fingerprint” analyses viable for artisanal producers throughout production. In addition to identifying the organisms present, metagenomic and metatranscriptomic investigations elucidate the active genes and pathways, such as those involved in amino acid synthesis related to flavor, providing predictive insights into the quality of the final product [144,173].

4.3. Data Integration, Visualization & Digital Twins

Connecting sensors, from OD probes to PCR devices, via IoT lets data flow continuously to a central dashboard for real-time oversight. In a smart fermenter, temperature, pH, microbial counts, and gas-production sensors wirelessly send readings (e.g., a kimchi producer using 30 Wi-Fi sensors over 4G) [174]. Local edge computers can preprocess data (filter noise, calculate trends) without relying on constant internet, making this approach practical even in remote fermentation sites [175]. ML models on the cloud then turn these inputs into actionable alerts and predictions [176]. A fermentation digital twin is a live virtual model of the process that mirrors real-time sensor data and predicts future behavior. For example, a kombucha twin uses inputs like tea concentration, pH, and microbial counts in kinetic and ML algorithms to forecast how the ferment will evolve—and it can alert operators if the actual data diverges from the prediction, effectively “seeing into the future” of the batch [177]. By integrating IoT and digital twins, operators move from passive monitoring to active control. Automated data logging creates traceable records for food safety certification (e.g., HACCP) and post-batch failure analysis [178]. Finally, user-friendly visualization closes the loop by making complex data actionable. Many artisanal fermenters are not engineers or data scientists; thus, interfaces often use simple metaphors (gauges, traffic-light signals, batch “health” scores) [179].

5. Machine Learning in Fermentation

5.1. Principles of Predictive Modeling

Machine learning (ML) is a subset of computer science that enables computer systems to learn from large datasets without explicit programming. The machine is able to extract knowledge from the data and develop a framework to make enhanced predictions and intelligent decisions [180]. This is achieved by using statistics and probability science to develop a predictive algorithm based on learned patterns from processing datasets and uncovering hidden links between them [181]. The ability of ML to discover relationships between variables is what sets it apart from traditional statistical methods, whose main goal is to make highly accurate predictions [182]. Using a performance metric that can be enhanced with experience over time, the capacity of an ML algorithm in executing specific jobs can be calculated [183].

A variety of ML algorithms have been developed to address different types of problems. They are classified into two categories which are supervised and unsupervised learning. In supervised learning, the algorithm develops an input–output relationship using a labeled dataset and makes predictions of outputs for undefined inputs [180]. Supervised learning algorithms can be used for predicting non-numeric values (classification algorithms) and predicting numeric values (regression algorithms) [184]. Common supervised models include artificial neural networks (ANNs), which are adept at capturing non-linear patterns, and support vector machines (SVMs), known for effectively separating data into classes. In contrast, unsupervised learning deals with unlabeled data, grouping it by underlying similarities to reveal previously unrecognized structures [185]. Techniques like clustering and dimensionality reduction are used to analyze and simplify complex datasets [180].

Currently, the food industry relies on human interaction to solve convoluted problems in food processing and optimize various process parameters, with the aim of achieving low energy consumption and high-quality products [186]. Fermentation is a traditional method for food preservation and for food quality modification and culinary enjoyment (due to the unique flavors, scents, and textures of fermented foods) [187]. However, fermentation processes are typically difficult to control due to many interrelated factors such as microbial communities, environmental conditions, and substrate composition. The rise of ML is proving to be particularly transformative in the production of fermented food. ML offers a data-driven approach for refining process parameters and process kinetics, which can result in minimal energy consumption and processing time, as well as to enhance the quality of fermented food products [188]. By meticulously analyzing a multitude of parameters, including temperature, pH, microbial composition, and nutrient levels, ML models can predict optimal conditions for fermentation, paving the way for more efficient and consistent production of traditional fermented foods.

5.2. Machine Learning Application in Traditional Fermented Foods

The application of machine learning in traditional fermented foods has been documented, but it remains an underexplored area. In this section, the application of different ML algorithms in the production of various traditional fermented foods is discussed. Table 3 presents different types of algorithms utilized for quality prediction, substrate determination, and classification of fermentation processes, as well as drawing a correlation between process parameters and sensory outcomes.

5.2.1. Artificial Neural Networks (ANNs)

Artificial neural networks (ANNs) are a computational simulation of the human brain, made up of numerous intricately linked artificial neurones, known as processing elements, that work together to solve a specific problem [189]. ANNs usually consist of an input layer, an output layer, and one or more hidden layers that allow the algorithm to process complex interactions between the input and output variables [190]. In fermented food production, ANNs have been proven to model and optimize complex processes such as fermentation conditions. For instance, the prediction of fermentation pH in cream cheese, an application that ultimately enables the forecast of fermentation end time and increases overall efficiency [191]. ANNs have also been used to optimize the fermentation time of cocoa beans, accurately determining the fermentation degree with a low misclassification rate [192]. In a lot of cases, ANNs have been applied to assess the quality of fermented food products, such as soy sauce and bread, by determining the liquid concentration and electrical resistance, respectively [193,194]. Classification represents a significant application of ANNs in traditional fermented foods, previously reported with beer and soy sauce [195,196].

5.2.2. Support Vector Machines (SVMs)

Support vector machines (SVMs) are powerful tools for classification and regression tasks. SVMs find the optimal boundary that best separates data points into different categories [197]. In the context of fermented foods, SVMs can be employed for the classification of fermented products based on their chemical composition or sensory attributes. [198] used SVMs to validate a group of chemical variables as a predictor to detect early problems in wine fermentation, while [199] were able to determine consumer preferences for yogurt based on their sensory attributes. In addition, SVMs were reported to predict the fermentation degree of black tea, which showcases the ability of this ML algorithm to optimize the quality of traditional fermented food parameters [200].

5.2.3. Decision Trees (DTs)

Decision trees (DTs) partition data into subsets based on the values of different features until a requirement is satisfied. This process creates a tree-like structure of decisions or splits, represented by a node each [201]. Every node in the tree defines a class name or a particular test that separates the examples based on the potential outcomes of the test [192]. DTs provide an interpretable way to understand the relationships between variables. They can be employed to determine critical factors that significantly affect the sensory properties of traditional fermented foods. For instance, DTs were employed to investigate the interplay between the average concentrations of organic compounds and sensory evaluation scores of Arabica coffee. Here, DTs revealed fructose concentration as the most important factor, with 92% accuracy [92]. In another study, DTs predicted the ultrafiltration concentration to maximize the yield of cream cheese [202].

5.2.4. Random Forest (RF)

Random forest (RF) combines multiple decision trees, each tree contributing to a single “vote” to the classification of an object. The object is classified according to the majority votes [192]. This collective approach is considered to be highly robust, as it incorporates variety between individual trees, which prevents overfitting and strengthens it against data imbalance [197]. In fermented food applications, RF can handle the complex interactions between various factors affecting the quality of fermented food products. For example, based on the storage date and temperature, pH, and packaging film type, RF was used in predicting TA, RSC, and TLAB count changes in kimchi [203]. In another study, the fermentation degree of cocoa beans was determined using RF based on their volatile profiles, which demonstrates the application of this ML algorithm for the optimization of fermentation time [192].

5.2.5. Extreme Gradient Boosting (XGB)

Extreme gradient boosting (XGB) utilizes a collection of classification and regression trees to improve loose function, regularization, and column sampling [204]. Not only was it demonstrated to be particularly effective in handling large datasets, but it can also be adjusted to sparse data due to its blocking technology [205]. In one study, XGB achieved a 90% accuracy in predicting the yield of SCOBY (a symbiotic consortium of bacteria and yeast) cellulose in kombucha, using concentrations of tea, sugar, SCOBY, and kombucha inoculum, initial pH, temperature, and duration of fermentation as input parameters [206]. The algorithm creates a weak classifier for every iteration of a process, which it then combines to create a powerful learner with a more precise prediction [207]. Another application of XGB in traditional fermented foods is mozzarella and cheddar cheese, where readily available input features such as chemical composition, storage time, and storage factors were collected from literature and used to predict the level of proteolysis [208]. Similarly, in an investigation with kimchi, the storage date and temperature, pH, and packaging film type were considered in predicting its quality [203]. These applications prove XGB to be a useful model not only to enhance the fermentation process but also to improve the long-term storage of traditional fermented foods.

Table 3.

Application of various machine learning algorithms/models on traditional fermented food.

Table 3.

Application of various machine learning algorithms/models on traditional fermented food.

| Algorithm/Model | Traditional Fermented Food | Functionality | Accuracy | References |

|---|---|---|---|---|

| ANNs | Cream cheese | Prediction of cream cheese fermentation pH | R2 > 99% | [191] |

| Cocoa beans | Determination of the fermentation degree of cocoa beans | Misclassification rate = 12.8% | [192] | |

| Beer | Classification of beers into the top, bottom, and spontaneous fermentation | R2 = 97% | [195] | |

| Soy sauce | Classification of soy sauce by fermentation and geographic region | Fermentation (R2 = 100%) Geographic region (R2 = 100%) | [196] | |

| Determination of soy sauce concentration | RMSE = 5.396 | [193] | ||

| Bread | Determination of the electrical properties of bread doughs during fermentation | MSE = 0.007 | [194] | |

| SVMs | Black tea | Prediction of fermentation degree of black tea based on electrical properties | R2 = 77% | [200] |

| Yogurt | Prediction of consumer preferences based on sensory attributes | Preferred (RMSE = 3.56 Disliked (RMSE = 3.30) | [199] | |

| Wine | Early detection of abnormal wine fermentation | R2 = 90% | [198] | |

| DTs | Arabica coffee | Analysis of the relationship between the average concentrations of organic compounds and sensory evaluation scores | R2 = 92% | [92] |

| Cream cheese | Prediction of the ultrafiltration concentration factor to maximize yield | R2 = 91% | [202] | |

| RF | Kimchi | Prediction of titratable acidity (TA) and reducing sugar content (RSC) changes, and total lactic acid bacteria (TLAB) growth | Overall R2 > 90% | [203] |

| Cocoa beans | Determination of the fermentation degree of cocoa beans | Misclassification rate = 9.4% | [192] | |

| XGB | Kimchi | Prediction of titratable acidity (TA) and reducing sugar content (RSC) changes, and total lactic acid bacteria (TLAB) growth | Overall R2 > 90% | [203] |

| Kombucha | Prediction of the yield of SCOBY (Symbiotic consortium of bacteria and yeast) | R2 = 90% | [206] | |

| Mozzarella and cheddar cheese | Prediction of the level of proteolysis (breakdown of protein) | Mozzarella (R2 = 92%) Cheddar (R2 = 97%) | [208] |

Note: ANNs: Artificial neural networks; SVMs: Support vector machines; DTs: Decision trees; RF: Random forest; XGB: Extreme gradient boosting; R2: Coefficient of determination; RMSE: Root mean squared error, MSE: Mean squared error.

6. Adaptive Control Systems in Fermentation Automation

The increasing demand for consistent quality in traditional fermented foods has driven an industrial shift from manual, experience-driven methods toward the use of more advanced bioprocess systems that are automated and data-driven [209]. These advances within the fermentation sector usually account for the upgrade and improvement of bioreactors of all types no matter their feeding strategies such as continuous-, batch-, or fed-batch bioreactors [210]. Upgrading and advancing systems by integrating biosensors, IoT-enabled data acquisition, ML algorithms, and adaptive control systems may contribute significantly to optimizing microbial process control, enhancing product consistency, and increasing scalability in both traditional and emerging fermentation industries [211].

Adaptive control is an area of advanced process automation that has emerged as a powerful tool to handle the complexities of microbial fermentation, especially in plants with dynamic environment (in which the traditional PID systems are inefficient) e.g., nonstationary plant parameters [212]. The ability of adaptive systems to alter internal parameters in response to real-time changes sets them apart from traditional controls, which makes them ideal for fermentation processes with nonlinear growth kinetics, fluctuating substrate concentrations, and microbial variability [213,214]. The theoretical underpinnings of adaptive control in fermentation are examined in this section, along with its potential to revolutionize small-scale enterprises and its present uses and constraints. According to the main argument of the review, adaptive control technologies are essential for bridging the gap between intelligent, Industry 4.0-compatible production systems and artisanal fermentation techniques.

6.1. Concept of Adaptive Control in Fermentation

Adaptive control systems are pivotal in modernizing traditional fermentation processes by addressing inherent challenges such as microbial instability and inconsistent product quality [215]. These systems dynamically adjust control parameters in real time to accommodate the nonlinear and time-varying nature of fermentation kinetics [216]. Adaptive control systems may be classified into three different categories, as stated by Ritonja, Goršek [214], which are as follows:

6.1.1. Gain Scheduling Control (GSC)

GSC serves as a transitional approach between conventional control systems and fully adaptive control strategies [217]. It is often adopted in nonlinear control applications largely due to its simplicity and transparency [218]. GSC operates by identifying measurable process variables—referred to as scheduling quantities—that closely correlate with the system’s dynamic behavior. These variables are then used to adjust the controller parameters in real time, ensuring that the control system adapts to changes in operating conditions without altering the underlying control structure [219].

6.1.2. Self-Tuning Control (STC)

STC is also known as indirect or explicit adaptive control, where three fundamental components are merged: identification of the controlled plant parameters, tuning of controller parameters, and implementation of the control law [220]. A STC system features two distinct information channels: the first is a conventional feedback loop that allows the controller output to respond to changes in the process output, while the second is a dedicated parameter adaptation channel. This second channel adjusts the controller’s parameters based on real-time estimation of the plant dynamics, thereby enhancing adaptability and performance [221].

6.1.3. Model Reference Adaptive Control (MRAC)

MRAC, often referred to as direct or implicit adaptive control, utilizes a predefined reference model to dictate the desired performance of the controlled system [222]. The actual system output is continuously compared to that of the reference model, and the resulting error is used to generate an adaptive control signal that drives the system response to closely follow the model behavior [223]. MRAC systems typically employ one of two configurations—parallel or series—and implement either signal synthesis adaptation or parameter adaptation strategies. The most commonly used setup is the parallel structure with signal synthesis adaptation [224].

Adaptive control systems may be applied in many different systems involving many different processes. One example is lactic acid fermentation systems, where it would effectively manage unknown kinetics without the need for state observers [225]. Within this example, Petre and Selişteanu [225] designed a strategy in which the consumption rates of two limiting substrates are taken as unknowns and summarized in two unknown and time-varying parameters, which are estimated by using an observer-based estimator which may be considered to be using a MRAC-styled system. Similarly, in milk fermentation, the MRAC system has also been employed to regulate stirring speed, ensuring optimal fermentation outcomes even in the absence of precise mathematical models, as reported by Ritonja, Goršek [214].

6.2. Benefits of Automation in Small-Scale Industries

Implementing adaptive control systems in small-scale fermentation industries offers numerous benefits, including improved product consistency, enhanced scalability, and reduced dependency on manual monitoring [226]. Automation facilitates real-time adjustments to process variables, thereby maintaining optimal fermentation conditions and ensuring consistent product quality [227]. This is particularly beneficial for traditional fermented foods, where variations in microbial activity can significantly impact the final product. Moreover, automation enables small-scale producers to scale up operations without compromising quality, bridging the gap between artisanal practices and industrial standards [36]. The integration of smart technologies such as IoT devices and biosensors further enhances monitoring capabilities, allowing for precise control over fermentation parameters [39]. Table 4 summarizes the key benefits of automation in small-scale fermentation industries.

A notable example is an undisclosed family-run winery that transitioned from manual Brix measurements to an automated system made by a German-based company, IFM Electronics, reported in their case study [228,229]. By implementing pressure sensors and real-time monitoring, the winery achieved higher wine quality through precise Brix value calculations and temperature monitoring. This automation led to more accurate measurements than traditional methods and allowed for real-time visualization of fermentation progress, enhancing efficiency and product consistency.

In Thailand, small-scale soy sauce manufacturers have adopted improved fermentation technologies via a consortium approach with scientists [230]. This collaboration introduced fiberglass tanks as bioreactors, replacing traditional earthenware containers, implemented cost-effective waste management systems as well as changed the methodologies used in the production of soy sauce. Such advancements have shortened processing times and improved product quality while maintaining the authenticity of the fermented products.

Table 4.

Benefits of automation in small-scale fermentation industries.

Table 4.

Benefits of automation in small-scale fermentation industries.

| Benefit | Description | References |

|---|---|---|

| Consistent Product Quality | Real-time adjustments lead to uniform fermentation outcomes across batches. | [225,231] |

| Improved Food Safety and Traceability | Digital logs from constant 24 h monitoring support hazard tracking and compliance with food safety standards. | [232] |

| Enhanced Scalability | Automation allows growth without compromising quality or requiring proportional labor increases via efficient workflow. | [231] |

| Resource and Energy Efficiency | Reduces waste and optimizes utility use via responsive control of energy-intensive processes such as feature selection and feature extraction. | [232] |

| Reduced Labor Demand | Minimizes need for continuous supervision, ideal for low-labor rural or family-owned operations. | [232] |

| Resilience in Tropical Climates | Adapts to unpredictable environmental conditions to prevent microbial imbalance or spoilage. | [232] |

| Lower Learning Curve | User-friendly interfaces and configurations facilitate new entrepreneurs in managing fermentation as well as gaining useful data in an instant. | [231,232] |

| Competitive Differentiation | Supports branding around technology, quality assurance, and eco-consciousness. | [233] |

These examples illustrate how small-scale industries can benefit from adaptive control systems, leading to improved product quality, operational efficiency, and scalability. The integration of smart technologies such as IoT devices and biosensors further enhances monitoring capabilities, allowing for precise control over fermentation parameters. This alignment with Industry 4.0 principles enables small-scale producers to bridge the gap between artisanal practices and industrial standards.

6.3. Industry Applications

Adaptive control systems have found applications across various fermentation industries, including dairy, beverage, and biofuel production. These industries implement smart fermentation systems that utilize ML and IoT in order to ramp up fermentation processes in a system called smart fermentation system [188].

In dairy fermentation, adaptive controllers have been successfully implemented to regulate pH and temperature, ensuring consistent yogurt and cheese quality [214]. In the beverage industry, adaptive control facilitates the production of consistent flavors in products like beer and wine by managing fermentation variables such as temperature and sugar concentration. Not limited to the production, within the beer industry, the sensory analysis and quality control could be done using AI technologies such as electric noses, which may forecast consumer acceptability [214] as well as the flavor profiles of beer based on volatile compounds within the beer [234]. These electric noses could be built with low cost with the utilization of various modern sensors, particularly the MQ series gas sensors, which are widely known for their affordability, ease of use, and ability to detect specific gases through changes in their internal resistance in the presence of target gases [235]. Each MQ sensor is calibrated for a specific type or range of gases: capable of detecting specific gases such as MQ3 (ethanol), MQ4 (methane), MQ7 (carbon monoxide), MQ8 (hydrogen), MQ135 (ammonia, alcohol, benzene), MQ136 (hydrogen sulfide), MQ137 (ammonia) and MQ138 (benzene, alcohol, ammonia) [234]. These sensors could be used to detect volatile compounds in beer which correlate to certain aromas which contribute to the whole taste experience of beer such as ethyl isovalerate for sweet apple, ethyl benzoate for cherry/ grape, linalool for citrus, and humulene for the scent of hops [236]. Other than the electric nose, industries such as the beer industry and other fermented food industries could opt to use bioinformatics and omics tools to further characterize the contents of products in terms of nutritional value as specific contents such as phenolics, antioxidants, and functional flavonoids as well as to gain understanding of these compounds and whether they could be increased to improve the quality of the products to a point they may be considered a nutraceutical or superfood.

7. Challenges in Smart Fermentation Adoption

The emergence of smart fermentation technologies offers a new dimension to food production with reduced wastage, higher precision, and sustainability. However, despite these benefits, there are a number of obstacles that are stopping more smallholder and artisanal producers from adopting the technology. These barriers represent economic, technical, regulatory, and operational barriers that in aggregate provide formidable barriers to entry for newer participants to adopt such sophisticated systems. The obstacles from cost to best practices and standards enforcement, as well as the dearth of technical knowhow, make adoption difficult procedures. Moreover, privacy, security, and environmental challenges further complicate the migration. This section addresses significant obstacles to the deployment of smart fermentation technologies, particularly those that smaller entities must surmount to remain competitive in an increasingly intricate landscape.

7.1. High Costs and Technological Barriers

One of the critical factors that hinders the commercialization of smart fermentation is related to the economic aspects of smart fermentation technology, such as its substantial development, operation, and huge expenditures. More advanced IoT devices, complex biosensors, and AI-driven analytics solutions regularly entail substantial initial investments that are unaffordable for several small and medium-sized manufacturers, artisanal enterprises, and developing countries [51]. The issue extends beyond mere acquisition expenses, encompassing continuous charges like software upgrades, cloud storage fees, system calibrations, cybersecurity support, and technical assistance, which culminate in persistent financial hardship.

Furthermore, the majority of these systems are intricate, necessitating extensive user training post-implementation and requiring highly skilled technical assistance, which incurs significant technological costs [42]. In low-resource contexts where financial margins are minute, these barriers restrict most implementers from consideration. However, the existing market offers available mainly focus on large companies in the industry, and smart fermentation kits or cloud services that are available and affordable are rare [39].

On top of this, there is insufficient venture capital or government backing put into smart fermentation to accelerate the transmission to small-scale producers [237]. Without deliberate strategies to lower these barriers through affordable, modular, and scalable solutions, smart fermentation risks becoming an exclusive technology accessible only to the well-resourced.

7.2. Standardization Issues

Despite the advanced technology in smart fermentation, it appears that the field of smart fermentation suffers from a striking lack of standardization. Sensors, data platforms, and AI engines are often proprietary, incompatible, and tailored to particular industrial ecosystems, thus limiting cross-communication and integration [238]. This complicates matters for manufacturers attempting to integrate smart technology because they are predominantly navigating without clear guidance to develop a coherent system.

The problem of non-standardized data extends into issues of reliability and reproducibility. Information produced using different approaches or sensors, or processed using different algorithms, cannot simply be compared or aggregated, therefore obstructing the possibilities for joint learning, benchmarking, and improving the quality of the ML models [144]. This lack of standardization stifles the collective intelligence that could arise from a globally networked smart fermentation community. In addition, proprietary standards lead to “vendor lock-in”, which obliges manufacturers to rely on specific suppliers over the long run, resulting in higher costs and lower innovation flexibility [239].

Apart from technical deficiencies, non-standardization brings a lot of regulatory obstacles. Food traceability policies, especially in export markets, now require digital transparency about production practices, microbial species, and processing technology and conditions [178]. This poses considerable difficulties for small and medium-sized companies, who frequently do not have the means to meet legal obligations without conforming to standardized metadata systems.

7.3. Accessibility for Small-Scale and Artisanal Producers

Accessibility remains a critical fault line in the smart fermentation revolution. Larger local-scale and industrial producers of alcohol often have the facilities, expertise, and financial resources needed to adopt digital technologies, while small-scale and artisanal producers frequently face a range of obstacles [240]. These factors include inaccessibility of stable internet and power, expensive hardware and software purchases, and lack of exposure to digital literacy training.

Most artisanal producers are situated in socialized knowledge systems which generationally evolved by oral tradition and which are not of standardized metrology that is characteristic of digital technologies [241]. In addition, the majority of smart fermentation platforms are developed in languages and have user interfaces that are directed at highly educated/technological natural consumers. Rural farmers often consider it difficult or not friendly to use, and thus, the accessibility gap is widened [39].

7.4. Limited Technical Expertise and Workforce Skills

There are various technical depths and complexities to be addressed in smart fermentation, where skills of microbiology, food science, data analytics, ML, and systems engineering are needed to be incorporated together. Nevertheless, the fermentation industry, in particular at the informal and SME level, experiences a pervasive deficiency of such skills [231].

Traditional fermenters possess substantial experienced knowledge and practical expertise, although they may lack digital proficiency. Conversely, when scientists or engineers transition to the food sector, their understanding of biological complexity, ecological dynamics, and the cultural processes of fermentation is often inadequate [239]. This knowledge mismatch results in ineffective communication, suboptimal system design, and insufficient utilization of intelligent systems.

Moreover, training programs often fail to bridge this gap effectively. Technical education often compartmentalizes disciplines rather than promoting integrated and interdisciplinary literacy [242]. Apart from the skills gap, there is also a shortage of accessible localized technical support structures. Engineers who could install and maintain biosensors, calibrate them, secure the system, and deal with cloud platforms are rarely found outside major urban centers [232]. Without a coordinated effort to upskill the fermentation workforce and establish decentralized technical support networks, the promise of smart fermentation will remain out of reach for many.

7.5. Cybersecurity and Data Privacy Concerns

IoT-connected devices, cloud services, and remote monitoring solutions and systems can be used in unauthorized manners, making the system vulnerable to data theft, process sabotage, or even intellectual property theft [42]. Exclusive formulations, microbial strain details, and fermentation data are considered valuable assets. One single breach would lead to a competitive disadvantage, a regulatory fine, or a well-exploitable culture. Even smart fermentation implementations used in SMEs and craft often have little or no cybersecurity procedures [243]. Emerging blockchain-based solutions for secure traceability offer potential, but they are complex, energy-intensive, and not yet accessible to small producers [178]. Therefore, cybersecurity and data privacy should not be seen as secondary concerns but rather as cornerstones of smart fermentation design, especially if the aim is to enhance rather than exploit artisanal and small producers.

7.6. Environmental and Sustainability Considerations

Smart fermentation solutions are not necessarily environmentally sound technology, even when positioned as a more efficient way to recycle and use renewable processes. Manufacturing of IoT sensors, microprocessors, and cloud servers is energy-intensive and uses ores of rare earth metals [244]. Additionally, the power needs to transmit data non-stop and analyze it with AI, expanding the carbon footprint of fermentation activity [245].