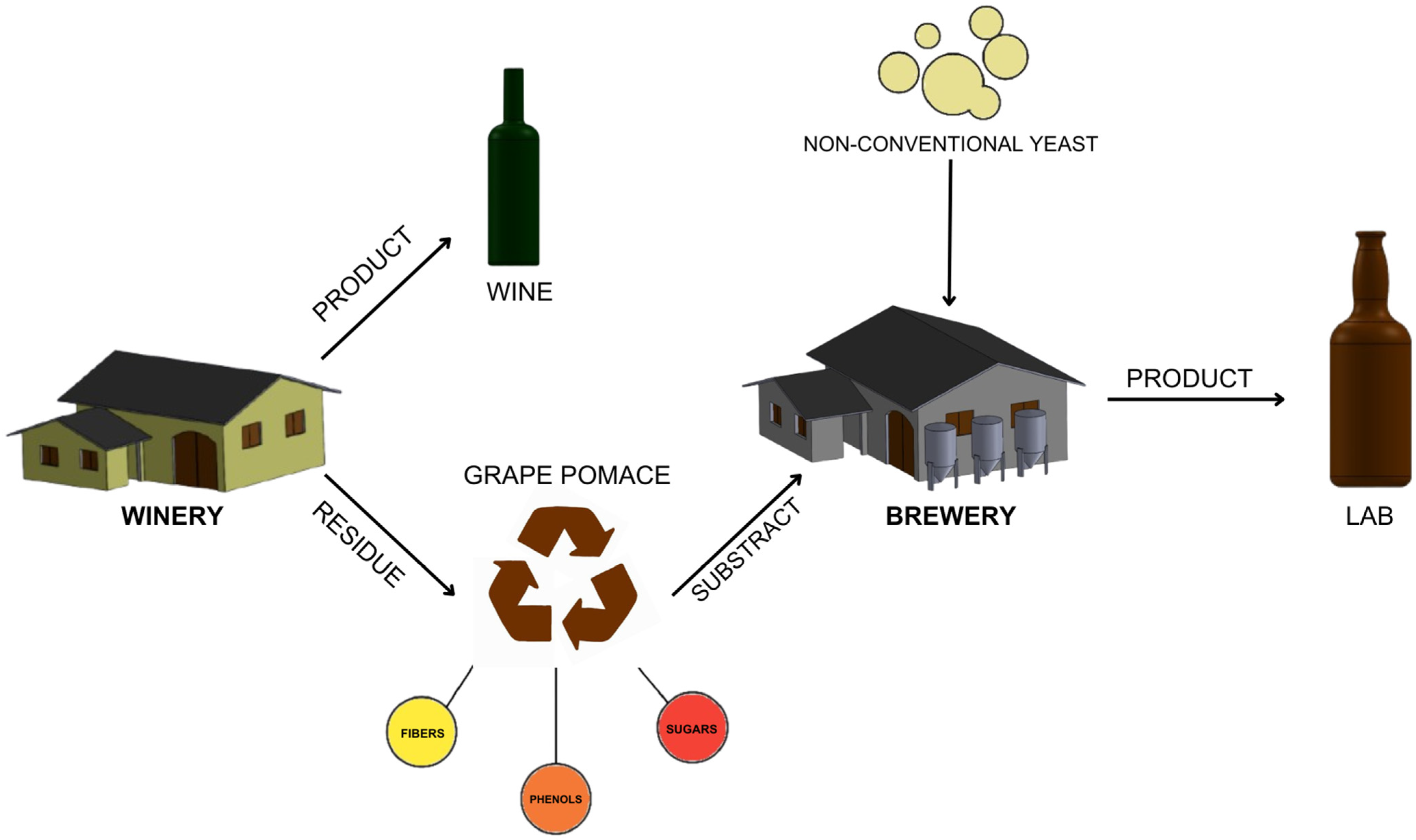

From Vineyard to Brewery: A Review of Grape Pomace Characterization and Its Potential Use to Produce Low-Alcohol Beverages

Abstract

1. Introduction

1.1. Grape Pomace Composition and Variability

- (a)

- Phenolic Compounds: Grape pomace is a rich source of phenolic compounds, including flavonoids, tannins, and anthocyanins. These compounds are predominantly found in skins and seeds, contributing to the pomace’s antioxidant properties. Red grape varieties, such as Cabernet Sauvignon and Merlot, tend to have higher phenolic concentrations than white varieties like Chardonnay or Sauvignon Blanc [8]. Polyphenols are the most studied group of bioactive compounds in grape pomace, primarily consisting of flavonoids (e.g., anthocyanins, flavan-3-ols, flavonols) and non-flavonoids (e.g., phenolic acids, stilbenes). These compounds are renowned for their antioxidant properties, which are critical in combating oxidative stress and reducing the risk of chronic diseases, including cardiovascular diseases, diabetes, and certain cancers [9]. The polyphenolic profile of grape pomace is influenced by grape variety, cultivation conditions, and vinification processes. For instance, red grape pomace is particularly rich in anthocyanins, which impart strong antioxidant and anti-inflammatory effects [10]. Incorporating these polyphenols into functional beverages, such as low-alcohol options, can enhance their health-promoting properties, while also improving sensory characteristics like color and astringency.

- (b)

- Dietary Fibers: Grape pomace is a valuable source of dietary fibers, which comprises both insoluble fractions (e.g., cellulose, hemicellulose, lignin) and soluble fractions (e.g., pectin, gums) [11]. Dietary fibers promote gut health by improving bowel regularity and serving as a substrate for beneficial gut microbiota, leading to the production of short-chain fatty acids (SCFAs) that support intestinal and metabolic health [12]. These fibers, found in the skins and stems, contribute to its potential as a functional food ingredient [11]. Moreover, fiber-enriched diets are associated with lower cholesterol levels, improved glycemic control, and reduced risks of obesity and type 2 diabetes [13]. The addition of grape pomace to low-alcohol beverages may offer a novel strategy to increase dietary fiber intake while leveraging its other nutritional benefits.

- (c)

- (d)

- Proteins and Minerals: Although grape pomace is not as well studied for its micronutrient content as for its polyphenols and fibers, it contains several vitamins (e.g., vitamin C, vitamin E, and B-complex vitamins) and minerals (e.g., potassium, calcium, magnesium). These nutrients contribute to the overall antioxidant activity and metabolic functions in the body [16]. Grape pomace contains tiny amounts of proteins and essential minerals such as potassium, calcium, and magnesium, which further enhance its nutritional value [17], making it an interesting source of nutrition for microorganisms. Vitamin C, for instance, works synergistically with polyphenols to enhance antioxidant capacity, while vitamin E’s lipid-soluble nature protects cell membranes from oxidative damage. Minerals like potassium are vital for maintaining electrolyte balance and cardiovascular health [13].

1.2. Differences Among Grape Varieties

| Constituent | Quantity (Dry Weight) | Application in Fermentation Processes | References |

|---|---|---|---|

| Phenolic Compounds | 50–70 g/kg | Antioxidants in fermented foods, substrate for enzyme production in fermentation. | [2,8] |

| Fibers | 35–60% | Prebiotics in kombucha and kefir fermentation, support for immobilization of fermentative cells. | [11] |

| Residual Sugars | 5–10% | Substrate for ethanol, lactic acid, and other metabolite production in microbial fermentations. | [15,17] |

| Minerals | 5–10% | Nutritional supplement in fermentation media to enhance microbial growth. | [17] |

| Proteins | 10–15% | Nitrogen source in alcoholic fermentation and amino acid production by microorganisms. | [17,24] |

2. Low-Alcohol and Alcohol-Free Beverages

2.1. Grape Pomace as a Functional Ingredient

2.2. Low-Alcohol Wine

2.3. Low-Alcohol Spirits

2.4. Global Consumption and Market Trends

3. Low-Alcohol Beer: Production and Use of Grape Pomace

4. Challenges in the Application of Grape Pomace Extract (GPE) in Fermentation Processes

5. Using Non-Conventional Yeasts for Fermented Beverages with Grape Pomace

6. Enhancing Grape Pomace Extract (GPE) Nutritional Value Through Fermentation

7. Sustainability and Waste Valorization

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- OIV General Principles of Sustainable Vitiviniculture-Environmental-Social-Economic and Cultural Aspects | OIV”. s.d. Acedido a 27 de dezembro de 2024. Available online: https://www.oiv.int/node/3207#_Toc149297691 (accessed on 20 December 2024).

- Karastergiou, A.; Gancel, A.-L.; Jourdes, M.; Teissedre, P.-L. Valorization of Grape Pomace: A Review of Phenolic Composition, Bioactivity, and Therapeutic Potential. Antioxidants 2024, 13, 1131. [Google Scholar] [CrossRef] [PubMed]

- Sinrod, A.J.; Shah, I.M.; Surek, E.; Barile, D. Uncovering the promising role of grape pomace as a modulator of the gut microbiome: An in-depth review. Heliyon 2023, 9, e20499. [Google Scholar] [CrossRef]

- de Mello, L.M.R.; Machado, C.A.E. Vitivinicultura Brasileira: Panorama 2021. Bento Gonçalves: Embrapa Uva e Vinho, 2022. 17p. (Embrapa Uva e Vinho. Comunicado Técnico, 226). Available online: https://ainfo.cnptia.embrapa.br/digital/bitstream/doc/1149674/1/Com-Tec-226.pdf (accessed on 29 December 2024).

- Mello, L.M.R.d.; Machado, C.A.E. Vitivinicultura Brasileira: Panorama 2020. 2021. Available online: http://www.infoteca.cnptia.embrapa.br/handle/doc/1135990 (accessed on 20 December 2024).

- Kokkinomagoulos, E.; Kandylis, P. Grape Pomace, an Undervalued by-Product: Industrial Reutilization within a Circular Economy Vision. Rev. Environ. Sci. Bio/Technol. 2023, 22, 739–773. [Google Scholar] [CrossRef]

- Beres, C.; Costa, G.N.S.; Cabezudo, I.; da Silva-James, N.K.; Teles, A.S.C.; Cruz, A.P.G.; Mellinger-Silva, C.; Tonon, R.V.; Cabral, L.M.C.; Freitas, S.P. Towards integral utilization of grape pomace from winemaking process: A review. Waste Manag. 2017, 68, 581–594. [Google Scholar] [CrossRef] [PubMed]

- Xia, E.-Q.; Deng, G.-F.; Guo, Y.-J.; Li, H.-B. Biological Activities of Polyphenols from Grapes. Int. J. Mol. Sci. 2010, 11, 622–646. [Google Scholar] [CrossRef] [PubMed]

- Almanza-Oliveros, A.; Bautista-Hernández, I.; Castro-López, C.; Aguilar-Zárate, P.; Meza-Carranco, Z.; Rojas, R.; Michel, M.R.; Martínez-Ávila, G.C.G. Grape Pomace—Advances in Its Bioactivity, Health Benefits, and Food Applications. Foods 2024, 13, 580. [Google Scholar] [CrossRef] [PubMed]

- Rockenbach, I.I.; Rodrigues, E.; Gonzaga, L.V.; Caliari, V.; Genovese, M.I.; de Souza Schmidt Gonçalves, A.E.; Fett, R. Phenolic compounds content and antioxidant activity in pomace from selected red grapes (Vitis vinifera L. and Vitis labrusca L.) widely produced in Brazil. Food Chem. 2011, 127, 174–189. [Google Scholar] [CrossRef]

- Wang, C.; You, Y.; Huang, W.; Zhan, J. The high-value and sustainable utilization of grape pomace: A review. Food Chem. X 2024, 24, 101845. [Google Scholar] [CrossRef] [PubMed]

- Kurćubić, V.S.; Stanišić, N.; Stajić, S.B.; Dmitrić, M.; Živković, S.; Kurćubić, L.V.; Živković, V.; Jakovljević, V.; Mašković, P.Z.; Mašković, J. Valorizing Grape Pomace: A Review of Applications, Nutritional Benefits, and Potential in Functional Food Development. Foods 2024, 13, 4169. [Google Scholar] [CrossRef]

- Slavin, J. Fiber and prebiotics: Mechanisms and health benefits. Nutrients 2013, 5, 1417–1435. [Google Scholar] [CrossRef]

- García-Lomillo, J.; González-SanJosé, M.L.; Del Pino-García, R.; Rivero-Pérez, M.D.; Muñiz-Rodríguez, P. Antioxidant and Antimicrobial Properties of Wine Byproducts and Their Potential Uses in the Food Industry. J. Agric. Food Chem. 2014, 62, 12595–12602. [Google Scholar] [CrossRef] [PubMed]

- Barakat, N.; Bouajila, J.; Beaufort, S.; Rizk, Z.; Taillandier, P.; El Rayess, Y. Development of a New Kombucha from Grape Pomace: The Impact of Fermentation Conditions on Composition and Biological Activities. Beverages 2024, 10, 29. [Google Scholar] [CrossRef]

- Tseng, A.; Zhao, Y. Wine grape pomace as antioxidant dietary fibre for enhancing nutritional value and improving storability of yogurt and salad dressing. Food Chem. 2013, 138, 356–365. [Google Scholar] [CrossRef] [PubMed]

- Muhlack, R.A.; Potumarthi, R.; Jeffery, D.W. Sustainable wineries through waste valorisation: A review of grape marc utilisation for value-added products. Waste Manag. 2018, 72, 99–118. [Google Scholar] [CrossRef] [PubMed]

- Milinčić, D.D.; Jelić, A.S.S.; Lević, S.M.; Stanisavljević, N.S.; Milošević, T.; Pavlović, V.B.; Gašić, U.M.; Obradović, N.S.; Nedović, V.A.; Pešić, M.B. Craft Beer Produced by Immobilized Yeast Cells with the Addition of Grape Pomace Seed Powder: Physico-Chemical Characterization and Antioxidant Properties. Foods 2024, 13, 2801. [Google Scholar] [CrossRef]

- Sousa, E.C.; Uchôa-Thomaz, A.M.A.; Carioca, J.O.B.; de Morais, S.M.; de Lima, A.; Martins, C.G.; Alexandrino, C.D.; Ferreira, P.A.T.; Rodrigues, A.L.M.; Rodrigues, S.P.; et al. Chemical composition and bioactive compounds of grape pomace (Vitis vinifera L.), Benitaka variety, grown in the semiarid region of Northeast Brazil. Food Sci. Technol. 2014, 34, 135–142. [Google Scholar] [CrossRef]

- Lopes, J.d.C.; Madureira, J.; Margaça, F.M.A.; Verde, S.C. Grape Pomace: A Review of Its Bioactive Phenolic Compounds, Health Benefits, and Applications. Molecules 2025, 30, 362. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, R.P.; Sousa, A.M.; Gando-Ferreira, L.M.; Quina, M.J. Grape Pomace as a Natural Source of Phenolic Compounds: Solvent Screening and Extraction Optimization. Molecules 2023, 28, 2715. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Han, Y.; Tian, X.; Sajid, M.; Mehmood, S.; Wang, H.; Li, H. Phenolic Composition of Grape Pomace and Its Metabolism. Crit. Rev. Food Sci. Nutr. 2024, 64, 4865–4881. [Google Scholar] [CrossRef] [PubMed]

- Jakabová, S.; Fikselová, M.; Mendelová, A.; Ševčík, M.; Jakab, I.; Aláčová, Z.; Kolačkovská, J.; Ivanova-Petropulos, V. Chemical Composition of White Wines Produced from Different Grape Varieties and Wine Regions in Slovakia. Appl. Sci. 2021, 11, 11059. [Google Scholar] [CrossRef]

- Ramírez, R.; Delgado, J.; Rocha-Pimienta, J.; Valdés, M.E.; Martín-Mateos, M.J.; Ayuso-Yuste, M.C. Preservation of White Wine Pomace by High Hydrostatic Pressure. Heliyon 2023, 9, e21199. [Google Scholar] [CrossRef] [PubMed]

- Likar, M.; Vogel-Mikuš, K.; Potisek, M.; Hančević, K.; Radić, T.; Nečemer, M.; Regvar, M. Importance of Soil and Vineyard Management in the Determination of Grapevine Mineral Composition. Sci. Total. Environ. 2015, 505, 724–731. [Google Scholar] [CrossRef] [PubMed]

- Ikusika, O.O.; Akinmoladun, O.F.; Mpendulo, C.T. Enhancement of the Nutritional Composition and Antioxidant Activities of Fruit Pomaces and Agro-Industrial Byproducts through Solid-State Fermentation for Livestock Nutrition: A Review. Fermentation 2024, 10, 227. [Google Scholar] [CrossRef]

- Krasteva, D.; Ivanov, Y.; Chengolova, Z.; Godjevargova, T. Antimicrobial Potential, Antioxidant Activity, and Phenolic Content of Grape Seed Extracts from Four Grape Varieties. Microorganisms 2023, 11, 395. [Google Scholar] [CrossRef] [PubMed]

- Mewa-Ngongang, M.; du Plessis, H.W.; Ntwampe, S.K.O.; Chidi, B.S.; Hutchinson, U.F.; Mekuto, L.; Jolly, N.P. Grape Pomace Extracts as Fermentation Medium for the Production of Potential Biopreservation Compounds. Foods 2019, 8, 51. [Google Scholar] [CrossRef] [PubMed]

- Nutt, D.J.; Tyacke, R.J.; Spriggs, M.; Jacoby, V.; Borthwick, A.D.; Belelli, D. Functional Alternatives to Alcohol. Nutrients 2022, 14, 3761. [Google Scholar] [CrossRef]

- Blanco, C.A.; Andrés-Iglesias, C.; Montero, O. Low-alcohol Beers: Flavor Compounds, Defects, and Improvement Strategies. Crit. Rev. Food Sci. Nutr. 2016, 56, 1379–1388. [Google Scholar] [CrossRef] [PubMed]

- Anderson, P.; Kokole, D.; Llopis, E.J. Production, Consumption, and Potential Public Health Impact of Low- and No-Alcohol Products: Results of a Scoping Review. Nutrients 2021, 13, 3153. [Google Scholar] [CrossRef] [PubMed]

- Betancur, M.I.; Motoki, K.; Spence, C.; Velasco, C. Factors influencing the choice of beer: A review. Food Res. Int. 2020, 137, 109367. [Google Scholar] [CrossRef] [PubMed]

- Sam, F.E.; Ma, T.-Z.; Salifu, R.; Wang, J.; Jiang, Y.-M.; Zhang, B.; Han, S.-Y. Techniques for Dealcoholization of Wines: Their Impact on Wine Phenolic Composition, Volatile Composition, and Sensory Characteristics. Foods 2021, 10, 2498. [Google Scholar] [CrossRef]

- Okaru, A.O.; Lachenmeier, D.W. Defining No and Low (NoLo) Alcohol Products. Nutrients 2022, 14, 3873. [Google Scholar] [CrossRef] [PubMed]

- The Science Behind Non-Alcoholic Beer and Wine Production. 2022. SevenFifty Daily. 25 de Julho de 2022. Available online: https://daily.sevenfifty.com/the-science-behind-non-alcoholic-beer-and-wine-production/ (accessed on 18 January 2025).

- Steensels, J.; Snoek, T.; Meersman, E.; Nicolino, M.P.; Voordeckers, K.; Verstrepen, K.J. Improving Industrial Yeast Strains: Exploiting Natural and Artificial Diversity. FEMS Microbiol. Rev. 2014, 38, 947–995. [Google Scholar] [CrossRef] [PubMed]

- Brányik, T.; Silva, D.P.; Baszczyňski, M.; Lehnert, R.; e Silva, J.B.A. A Review of Methods of Low Alcohol and Alcohol-Free Beer Production. J. Food Eng. 2012, 108, 493–506. [Google Scholar] [CrossRef]

- Campanella, D.; Rizzello, C.G.; Fasciano, C.; Gambacorta, G.; Pinto, D.; Marzani, B.; Scarano, N.; De Angelis, M.; Gobbetti, M. Exploitation of grape marc as functional substrate for lactic acid bacteria and bifidobacteria growth and enhanced antioxidant activity. Food Microbiol. 2017, 65, 25–35. [Google Scholar] [CrossRef] [PubMed]

- Lorusso, A.; Marconi, O.; Ferretti, G.; D’Archivio, A.A.; Ruggeri, S.; Cappelli, A.; Perretti, G. Exploiting Non-Conventional Yeasts for Low-Alcohol Beer Production. Microorganisms 2023, 11, 316. [Google Scholar] [CrossRef] [PubMed]

- Cassani, L.; Gomez-Zavaglia, A.; Simal-Gandara, J.; Munekata, P.E.S.; Miralles, B.; Lorenzo, J.M. Fruit and vegetable by-products as functional ingredients: Characterization, technological properties, and applications in the food industry. J. Adv. Res. 2020, 24, 58. [Google Scholar] [CrossRef]

- Escarpment Laboratories. Approaches to Non-Alcoholic Beer Fermentation. Available online: https://escarpmentlabs.com/en-us/blogs/resources/approaches-to-non-alcoholic-beer-fermentation (accessed on 18 January 2025).

- Rehm, J.; Lachenmeier, D.W.; Llopis, E.J.; Imtiaz, S.; Anderson, P. Evidence of Reducing Ethanol Content in Beverages to Reduce Harmful Use of Alcohol. Lancet Gastroenterol. Hepatol. 2016, 1, 78–83. [Google Scholar] [CrossRef]

- Silva, P. Low-Alcohol and Nonalcoholic Wines: From Production to Cardiovascular Health, along with Their Economic Effects. Beverages 2024, 10, 49. [Google Scholar] [CrossRef]

- Ways to Stop Wine Fermentation [Ultimate Guide]. 2020. 19 de Abril de 2020. Available online: https://wineturtle.com/how-to-stop-fermentation-in-winemaking/ (accessed on 18 January 2025).

- Salanță, L.C.; Coldea, T.E.; Ignat, M.V.; Pop, C.R.; Tofană, M.; Mudura, E.; Borșa, A.; Pasqualone, A.; Zhao, H. Non-Alcoholic and Craft Beer Production and Challenges. Processes 2020, 8, 1382. [Google Scholar] [CrossRef]

- Jackowski, M.; Trusek, A. Non-Alcoholic Beer Production—An Overview. PJCT 2018, 20, 32–38. [Google Scholar] [CrossRef]

- Liguori, L.; Russo, P.; Albanese, D.; Di Matteo, M. Production of Low-Alcohol Beverages: Current Status and Perspectives. In Food Processing for Increased Quality and Consumption; Elsevier: Amsterdam, The Netherlands, 2018; pp. 347–382. [Google Scholar]

- Schmitt, M.; Freund, M.; Schuessler, C.; Rauhut, D.; Brezina, S. Strategies for the sensorial optimization of alcohol-free wines. Editado por P. Roca. BIO Web Conf. 2023, 56, 02007. [Google Scholar] [CrossRef]

- Mangindaan, D.; Khoiruddin, K.; Wenten, I. Beverage Dealcoholization Processes: Past, Present, and Future. Trends Food Sci. Technol. 2018, 71, 36–45. [Google Scholar] [CrossRef]

- WHO. A Public Health Perspective on Zero- and Low-Alcohol Beverages. Brief 10, 2023, 1st ed.; World Health Organization: Geneva, Switzerland, 2023. [Google Scholar]

- Longo, R.; Blackman, J.W.; Antalick, G.; Torley, P.J.; Rogiers, S.Y.; Schmidtke, L.M. Harvesting and Blending Options for Lower Alcohol Wines: A Sensory and Chemical Investigation. J. Sci. Food Agric. 2018, 98, 33–42. [Google Scholar] [CrossRef] [PubMed]

- Liguori, L.; Albanese, D.; Crescitelli, A.; Di Matteo, M.; Russo, P. Impact of Dealcoholization on Quality Properties in White Wine at Various Alcohol Content Levels. J. Food Sci. Technol. 2019, 56, 3707–3720. [Google Scholar] [CrossRef]

- Top Global Consumer Trends 2025|Euromonitor”. s.d. Euromonitor International. Available online: https://go.euromonitor.com/white-paper-2025-global-consumer-trends.html (accessed on 27 December 2024).

- Gabur, G.-D.; Teodosiu, C.; Fighir, D.; Cotea, V.V.; Gabur, I. From Waste to Value in Circular Economy: Valorizing Grape Pomace Waste through Vermicomposting. Agriculture 2024, 14, 1529. [Google Scholar] [CrossRef]

- Mellor, D.D.; Hanna-Khalil, B.; Carson, R. A Review of the Potential Health Benefits of Low Alcohol and Alcohol-Free Beer: Effects of Ingredients and Craft Brewing Processes on Potentially Bioactive Metabolites. Beverages 2020, 6, 25. [Google Scholar] [CrossRef]

- Global Non-Alcoholic and Low-Alcohol Beer Share”. s.d. Statista. Available online: https://www.statista.com/statistics/1251485/volume-share-non-low-alcohol-beer-global/ (accessed on 27 December 2024).

- Luz, B.R.T.; da Silva, C.N.; Hercos, G.d.F.d.L.; Ribeiro, B.D.; Egea, M.B.; Lemes, A.C. Innovative Craft Beers Added with Purple Grape Pomace: Exploring Technological, Sensory, and Bioactive Characteristics. Beverages 2024, 10, 80. [Google Scholar] [CrossRef]

- Silva, F.A.; Borges, G.d.S.C.; Lima, M.d.S.; Queiroga, R.d.C.R.D.E.; Pintado, M.M.E.; Vasconcelos, M.A.d.S. Integral use of Isabel grapes to elaborate new products with nutritional value and functional potential. Braz. J. Food Technol. 2021, 24, e2020041. [Google Scholar] [CrossRef]

- Caponio, G.R.; Minervini, F.; Tamma, G.; Gambacorta, G.; De Angelis, M. Promising Application of Grape Pomace and Its Agri-Food Valorization: Source of Bioactive Molecules with Beneficial Effects. Sustainability 2023, 15, 9075. [Google Scholar] [CrossRef]

- Leni, G.; Romanini, E.; Bertuzzi, T.; Abate, A.; Bresciani, L.; Lambri, M.; Dall’asta, M.; Gabrielli, M. Italian Grape Ale Beers Obtained with Malvasia di Candia Aromatica Grape Variety: Evolution of Phenolic Compounds during Fermentation. Foods 2023, 12, 1196. [Google Scholar] [CrossRef] [PubMed]

- Fiori, L.; de Faveri, D.; Casazza, A.A.; Perego, P. Grape By-Products: Extraction of Polyphenolic Compounds Using Supercritical CO2 and Liquid Organic Solvent—A Preliminary Investigation Subproductos de La Uva: Extracción de Compuestos Polifenólicos Usando CO2 Supercrítico y Disolventes Orgánicos Líquidos—Una Investigación Preliminar. CyTA—J. Food 2009, 7, 163–171. [Google Scholar] [CrossRef]

- Pires, E.J.; Teixeira, J.A.; Brányik, T.; Vicente, A.A. Yeast: The Soul of Beer’s Aroma—A Review of Flavour-Active Esters and Higher Alcohols Produced by the Brewing Yeast. Appl. Microbiol. Biotechnol. 2014, 98, 1937–1949. [Google Scholar] [CrossRef]

- Eduardo, P.; Brányik, T. An Overview of the Brewing Process. In Biochemistry of Beer Fermentation; Springer International Publishing: Cham, Switzerland, 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Radonjić, S.; Maraš, V.; Raičević, J.; Košmerl, T. Wine or Beer? Comparison, Changes and Improvement of Polyphenolic Compounds during Technological Phases. Molecules 2020, 25, 4960. [Google Scholar] [CrossRef] [PubMed]

- Bilanishvili, N.; Gulua, L. Influence of Winemaking By-Products on the Phenolic Activity of Beer. Brew. Sci. 2024, 77, 50–56. [Google Scholar] [CrossRef]

- Fillaudeau, L.; Blanpain-Avet, P.; Daufin, G. Water, Wastewater and Waste Management in Brewing Industries. J. Clean. Prod. 2006, 14, 463–471. [Google Scholar] [CrossRef]

- Maicas, S.; Mateo, J.J. The Life of Saccharomyces and Non-Saccharomyces Yeasts in Drinking Wine. Microorganisms 2023, 11, 1178. [Google Scholar] [CrossRef]

- Patra, A.; Abdullah, S.; Pradhan, R.C. Review on the extraction of bioactive compounds and characterization of fruit industry by-products. Bioresour. Bioprocess. 2022, 9, 14. [Google Scholar] [CrossRef]

- Ferrer-Gallego, R.; Silva, P. The Wine Industry By-Products: Applications for Food Industry and Health Benefits. Antioxidants 2022, 11, 2025. [Google Scholar] [CrossRef] [PubMed]

- Redha, A.A.; Kodikara, C.; Cozzolino, D. Does Encapsulation Improve the Bioavailability of Polyphenols in Humans? A Concise Review Based on In Vivo Human Studies. Nutrients 2024, 16, 3625. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Gaete, C.; Avendaño-Godoy, J.; Escobar-Avello, D.; Campos-Requena, V.H.; Rogel-Castillo, C.; Estevinho, L.M.; Martorell, M.; Sharifi-Rad, J.; Calina, D. Revolutionizing fruit juice: Exploring encapsulation techniques for bioactive compounds and their impact on nutrition, flavour and shelf life. Food Prod. Process. Nutr. 2024, 6, 8. [Google Scholar] [CrossRef]

- Yang, F.; Chen, C.; Ni, D.; Yang, Y.; Tian, J.; Li, Y.; Chen, S.; Ye, X.; Wang, L. Effects of Fermentation on Bioactivity and the Composition of Polyphenols Contained in Polyphenol-Rich Foods: A Review. Foods 2023, 12, 3315. [Google Scholar] [CrossRef]

- Li, B.; Liu, N.; Zhao, X. Response Mechanisms of Saccharomyces cerevisiae to the Stress Factors Present in Lignocellulose Hydrolysate and Strategies for Constructing Robust Strains. Biotechnol. Biofuels Bioprod. 2022, 15, 28. [Google Scholar] [CrossRef]

- Gu, H.; Zhu, Y.; Peng, Y.; Liang, X.; Liu, X.; Shao, L.; Xu, Y.; Xu, Z.; Liu, R.; Li, J. Physiological Mechanism of Improved Tolerance of Saccharomyces cerevisiae to Lignin-Derived Phenolic Acids in Lignocellulosic Ethanol Fermentation by Short-Term Adaptation. Biotechnol. Biofuels 2019, 12, 268. [Google Scholar] [CrossRef] [PubMed]

- Barreto, S.M.; da Silva, A.B.; Dutra, M.D.; Bastos, D.C.; Carvalho, A.J.; Viana, A.C.; Narain, N.; dos Santos Lima, M. Effect of commercial yeasts (Saccharomyces cerevisiae) on fermentation metabolites, phenolic compounds, and bioaccessibility of Brazilian fermented oranges. Food Chem. 2023, 408, 135121. [Google Scholar] [CrossRef]

- Watanabe, D.; Hashimoto, W. Adaptation of Yeast Saccharomyces cerevisiae to Grape-Skin Environment. Sci. Rep. 2023, 13, 9279. [Google Scholar] [CrossRef]

- Freire, J.M.; Barroso, A.R.; de Assis, A.A.; Texeira, B.H.; Braga, J.H.G.; Oliveira, D.A.; Braga, M.A.; Marcussi, S. Enzymes modulation by dried grape pomace from the manufacture of wines and juices. Braz. J. Pharm. Sci. 2020, 56, e18467. [Google Scholar] [CrossRef]

- Korkie, L.; Janse, B.; Viljoen-Bloom, M. Utilising Grape Pomace for Ethanol Production. S. Afr. J. Enol. Vitic. 2017, 23, 31–36. [Google Scholar] [CrossRef][Green Version]

- Siddiqui, S.A.; Erol, Z.; Rugji, J.; Taşçı, F.; Kahraman, H.A.; Toppi, V.; Musa, L.; Di Giacinto, G.; Bahmid, N.A.; Mehdizadeh, M.; et al. An Overview of Fermentation in the Food Industry—Looking Back from a New Perspective. Bioresour. Bioprocess. 2023, 10, 85. [Google Scholar] [CrossRef] [PubMed]

- Kalli, E.; Lappa, I.; Bouchagier, P.; Tarantilis, P.A.; Skotti, E. Novel Application and Industrial Exploitation of Winery By-Products. Bioresour. Bioprocess. 2018, 5, 46. [Google Scholar] [CrossRef]

- Bordiga, M.; Travaglia, F.; Locatelli, M. Valorisation of Grape Pomace: An Approach That Is Increasingly Reaching Its Maturity—A Review. Int. J. Food Sci. Technol. 2019, 54, 933–942. [Google Scholar] [CrossRef]

- Wang, L.; Li, B.; Su, R.-R.; Wang, S.-P.; Xia, Z.-Y.; Xie, C.-Y.; Tang, Y.-Q. Screening Novel Genes by a Comprehensive Strategy to Construct Multiple Stress-Tolerant Industrial Saccharomyces cerevisiae with Prominent Bioethanol Production. Biotechnol. Biofuels Bioprod. 2022, 15, 11. [Google Scholar] [CrossRef]

- Gibson, B.; Geertman, J.-M.A.; Hittinger, C.T.; Krogerus, K.; Libkind, D.; Louis, E.J.; Magalhães, F.; Sampaio, J.P. New Yeasts—New Brews: Modern Approaches to Brewing Yeast Design and Development. FEMS Yeast Res. 2017, 17, fox038. [Google Scholar] [CrossRef]

- Salvadó, Z.; Arroyo-López, F.N.; Guillamón, J.M.; Salazar, G.; Querol, A.; Barrio, E. Temperature Adaptation Markedly Determines Evolution within the Genus Saccharomyces. Appl. Environ. Microbiol. 2011, 77, 2292–2302. [Google Scholar] [CrossRef]

- Jolly, N.P.; Varela, C.; Pretorius, I.S. Not Your Ordinary Yeast: Non-Saccharomyces Yeasts in Wine Production Uncovered. FEMS Yeast Res. 2014, 14, 215–237. [Google Scholar] [CrossRef]

- Pal, P.; Singh, A.K.; Srivastava, R.K.; Rathore, S.S.; Sahoo, U.K.; Subudhi, S.; Sarangi, P.K.; Prus, P. Circular Bioeconomy in Action: Transforming Food Wastes into Renewable Food Resources. Foods 2024, 13, 3007. [Google Scholar] [CrossRef]

- Haniffadli, A.; Ban, Y.; Rahmat, E.; Kang, C.H.; Kang, Y. Unforeseen Current and Future Benefits of Uncommon Yeast: The Metschnikowia Genus. Appl. Microbiol. Biotechnol. 2024, 108, 534. [Google Scholar] [CrossRef]

- Francois, J.M.; Alkim, C.; Morin, N. Engineering Microbial Pathways for Production of Bio-Based Chemicals from Lignocellulosic Sugars: Current Status and Perspectives. Biotechnol. Biofuels 2020, 13, 118. [Google Scholar] [CrossRef]

- Bilal, M.; Ji, L.; Xu, Y.; Xu, S.; Lin, Y.; Iqbal, H.M.N.; Cheng, H. Bioprospecting Kluyveromyces marxianus as a Robust Host for Industrial Biotechnology. Front. Bioeng. Biotechnol. 2022, 10, 851768. [Google Scholar] [CrossRef]

- Bely, M.; Stoeckle, P.; Masneuf-Pomarède, I.; Dubourdieu, D. Impact of Mixed Torulaspora delbrueckii–Saccharomyces cerevisiae Culture on High-Sugar Fermentation. Int. J. Food Microbiol. 2008, 122, 312–320. [Google Scholar] [CrossRef]

- Vicente, J.; Calderón, F.; Santos, A.; Marquina, D.; Benito, S. High Potential of Pichia kluyveri and Other Pichia Species in Wine Technology. Int. J. Mol. Sci. 2021, 22, 1196. [Google Scholar] [CrossRef]

- Méndez-Zamora, A.; Gutiérrez-Avendaño, D.O.; Arellano-Plaza, M.; González, F.J.D.l.T.; Barrera-Martínez, I.; Mathis, A.G.; Casas-Godoy, L. The Non-Saccharomyces Yeast Pichia kluyveri for the Production of Aromatic Volatile Compounds in Alcoholic Fermentation. FEMS Yeast Res. 2021, 20, foaa067. [Google Scholar] [CrossRef]

- Fracassetti, D.; Bottelli, P.; Corona, O.; Foschino, R.; Vigentini, I. Innovative Alcoholic Drinks Obtained by Co-Fermenting Grape Must and Fruit Juice. Metabolites 2019, 9, 86. [Google Scholar] [CrossRef]

- Ciani, M.; Morales, P.; Comitini, F.; Tronchoni, J.; Canonico, L.; Curiel, J.A.; Oro, L.; Rodrigues, A.J.; Gonzalez, R. Non-conventional Yeast Species for Lowering Ethanol Content of Wines. Front. Microbiol. 2016, 7, 642. [Google Scholar] [CrossRef]

- Nevoigt, E. Progress in Metabolic Engineering of Saccharomyces Cerevisiae. Microbiol. Mol. Biol. Rev. 2008, 72, 379–412. [Google Scholar] [CrossRef]

- Vasaki, M.; Sithan, M.; Ravindran, G.; Paramasivan, B.; Ekambaram, G.; Karri, R.R. Biodiesel production from lignocellulosic biomass using Yarrowia lipolytica. Energy Convers. Manag. X 2022, 13, 100167. [Google Scholar] [CrossRef]

- Mammadova, S.M.; Fataliyev, H.K.; Gadimova, N.S.; Aliyeva, G.R.; TAGIYEV, A.T.; Baloglanova, K.V. Production of functional products using grape processing residuals. Food Sci. Technol. 2020, 40 (Suppl. S2), 422–428. [Google Scholar] [CrossRef]

- Cueva, C.; Gil-Sánchez, I.; Moreno-Arribas, M.V.; Bartolomé, B. Interactions between Wine Polyphenols and Gut Microbiota. In Wine Safety, Consumer Preference, and Human Health; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Machado, T.O.; Portugal, I.; Kodel, H.d.A.; Droppa-Almeida, D.; Lima, M.D.S.; Fathi, F.; Oliveira, M.B.P.; de Albuquerque-Júnior, R.L.; Dariva, C.; Souto, E.B. Therapeutic potential of grape pomace extracts: A review of scientific evidence. Food Biosci. 2024, 60, 104210. [Google Scholar] [CrossRef]

- Ahmed, A.I.; Abou-Taleb, K.A.A.; Abd-Elhalim, B.T. Characterization and Application of Tannase and Gallic Acid Produced by Co-Fungi of Aspergillus niger and Trichoderma viride Utilizing Agro-Residues Substrates. Sci. Rep. 2023, 13, 16755. [Google Scholar] [CrossRef]

- Govindarajan, R.; Revathi, S.; Rameshkumar, N.; Krishnan, M.; Kayalvizhi, N. Microbial Tannase: Current Perspectives and Biotechnological Advances. Biocatal. Agric. Biotechnol. 2016, 6, 168–175. [Google Scholar] [CrossRef]

- Tamang, J.P.; Shin, D.-H.; Jung, S.-J.; Chae, S.-W. Functional Properties of Microorganisms in Fermented Foods. Front. Microbiol. 2016, 7, 578. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, D.; Zhang, J.; Shen, J.; Cao, J.; Gu, H.; Cui, M.; He, L.; Chen, G.; Liu, S.; et al. Improving Soluble Phenolic Profile and Antioxidant Activity of Grape Pomace Seeds through Fungal Solid-State Fermentation. Foods 2024, 13, 1158. [Google Scholar] [CrossRef]

- Sarıtaş, S.; Portocarrero, A.C.M.; López, J.M.M.; Lombardo, M.; Koch, W.; Raposo, A.; El-Seedi, H.R.; Alves, J.L.d.B.; Esatbeyoglu, T.; Karav, S.; et al. The Impact of Fermentation on the Antioxidant Activity of Food Products. Molecules 2024, 29, 3941. [Google Scholar] [CrossRef]

- Petrosillo, I.; Aretano, R.; Zurlini, G. Socioecological Systems. In Encyclopedia of Ecology; Elsevier: Amsterdam, The Netherlands, 2015; pp. 419–425. [Google Scholar] [CrossRef]

- Ilyas, T.; Chowdhary, P.; Chaurasia, D.; Gnansounou, E.; Pandey, A.; Chaturvedi, P. Sustainable Green Processing of Grape Pomace for the Production of Value-Added Products: An Overview. Environ. Technol. Innov. 2021, 23, 101592. [Google Scholar] [CrossRef]

- Yu, J.; Ahmedna, M. Functional Components of Grape Pomace: Their Composition, Biological Properties and Potential Applications. Int. J. Food Sci. Technol. 2013, 48, 221–237. [Google Scholar] [CrossRef]

- Perra, M.; Bacchetta, G.; Muntoni, A.; De Gioannis, G.; Castangia, I.; Rajha, H.N.; Manca, M.L.; Manconi, M. An outlook on modern and sustainable approaches to the management of grape pomace by integrating green processes, biotechnologies and advanced biomedical approaches. J. Funct. Foods 2022, 98, 105276. [Google Scholar] [CrossRef]

- Rinaldi, S.; Bonamente, E.; Scrucca, F.; Merico, M.C.; Asdrubali, F.; Cotana, F. Water and Carbon Footprint of Wine: Methodology Review and Application to a Case Study. Sustainability 2016, 8, 621. [Google Scholar] [CrossRef]

- Nirmal, N.P.; Khanashyam, A.C.; Mundanat, A.S.; Shah, K.; Babu, K.S.; Thorakkattu, P.; Al-Asmari, F.; Pandiselvam, R. Valorization of Fruit Waste for Bioactive Compounds and Their Applications in the Food Industry. Foods 2023, 12, 556. [Google Scholar] [CrossRef]

- Laca, A.; Gancedo, S.; Laca, A.; Díaz, M. Assessment of the environmental impacts associated with vineyards and winemaking. A case study in mountain areas. Environ. Sci. Pollut. Res. 2021, 28, 1204–1223. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Telini, B.d.P.; Villa, L.C.; Vainstein, M.H.; Lopes, F.C. From Vineyard to Brewery: A Review of Grape Pomace Characterization and Its Potential Use to Produce Low-Alcohol Beverages. Fermentation 2025, 11, 57. https://doi.org/10.3390/fermentation11020057

Telini BdP, Villa LC, Vainstein MH, Lopes FC. From Vineyard to Brewery: A Review of Grape Pomace Characterization and Its Potential Use to Produce Low-Alcohol Beverages. Fermentation. 2025; 11(2):57. https://doi.org/10.3390/fermentation11020057

Chicago/Turabian StyleTelini, Bianca de Paula, Lorenza Corti Villa, Marilene Henning Vainstein, and Fernanda Cortez Lopes. 2025. "From Vineyard to Brewery: A Review of Grape Pomace Characterization and Its Potential Use to Produce Low-Alcohol Beverages" Fermentation 11, no. 2: 57. https://doi.org/10.3390/fermentation11020057

APA StyleTelini, B. d. P., Villa, L. C., Vainstein, M. H., & Lopes, F. C. (2025). From Vineyard to Brewery: A Review of Grape Pomace Characterization and Its Potential Use to Produce Low-Alcohol Beverages. Fermentation, 11(2), 57. https://doi.org/10.3390/fermentation11020057