Wind tunnel measurements performed at full scale on a ground vehicle show interest in shape modifications of the undertray. Applied on a reduced scale model (model scale of 1:7), the same relative geometrical variations of an air dam lead to the same drag reduction values. Therefore, this study is focused on an aerodynamic optimization process performed at reduced scales on a ground vehicle mockup.

2.1. Wind Tunnel and Mockup Description

Large flow detachments observed in the rear wake of a Sport Utility Vehicles (SUV) lead to drag values that are much higher than those observed with other vehicle shapes. These flow detachments can be reduced either with rear spoiler inclinations or with underbody shape improvements. Therefore, a modular vehicle mockup provides the testing availability of different geometrical combinations.

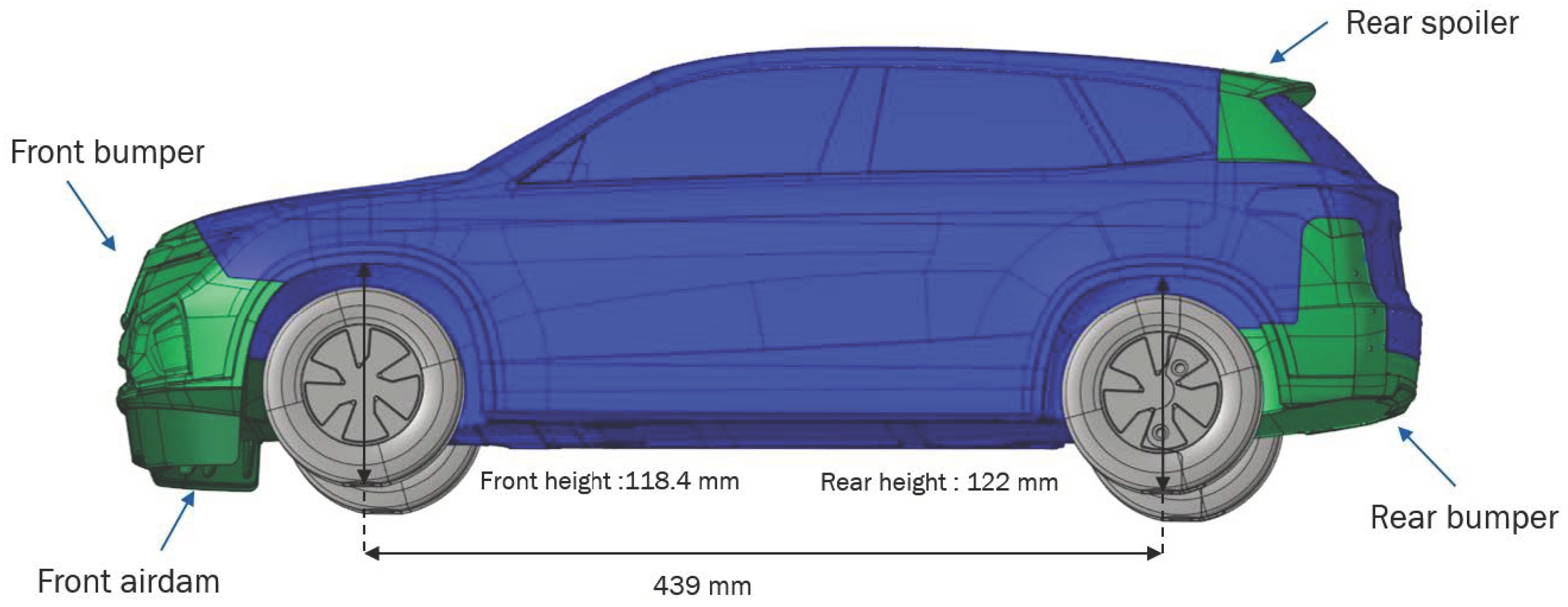

Figure 1 shows the different modules that can be changed in green. The height of the underfloor can also be modified until reaching the lowest drag value. Front and rear height values are provided for this purpose in the figure below, leading to a drag coefficient Cd of 0.36 for this baseline configuration.

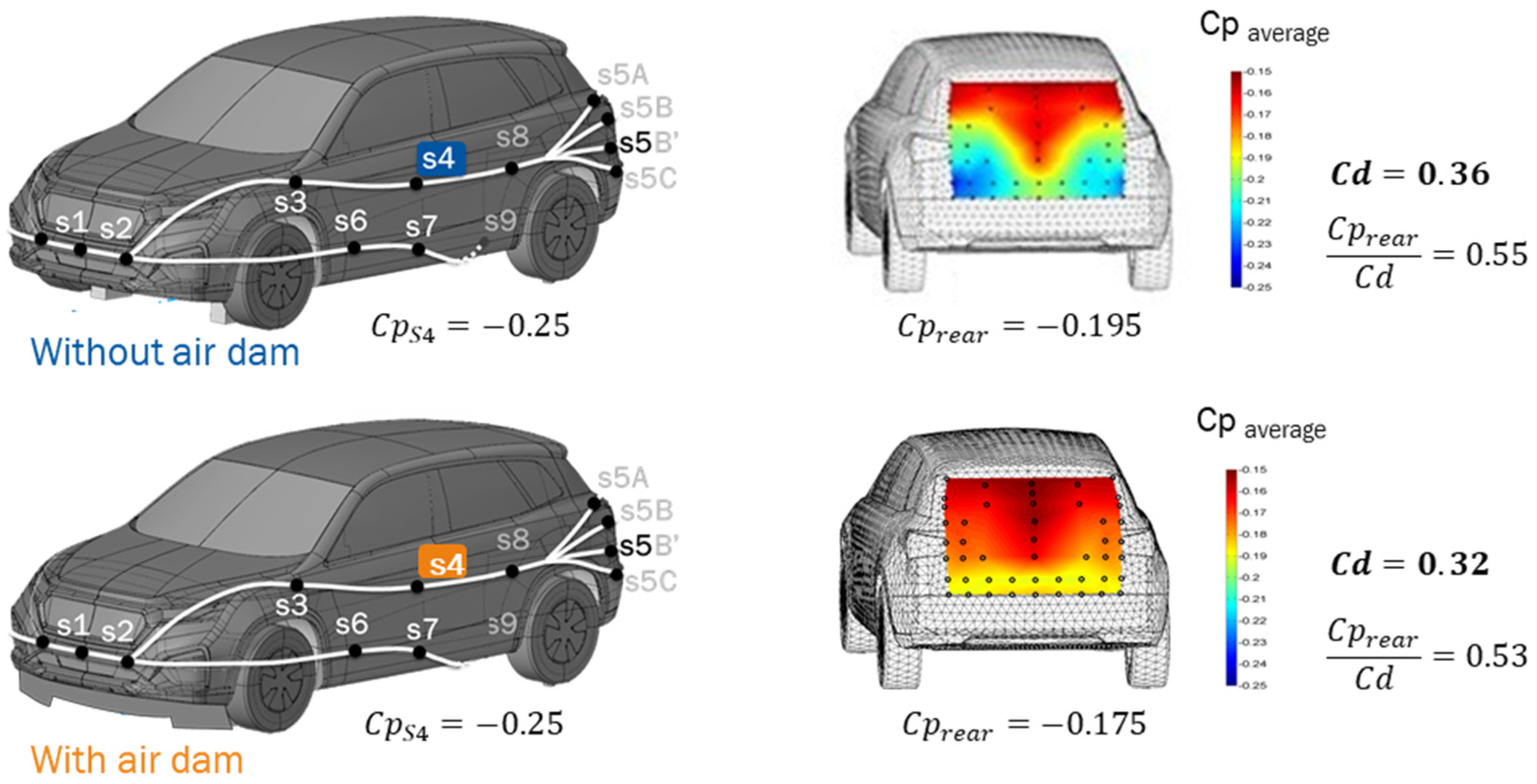

In addition to measurements performed with an aerodynamic balance, 48 pressure sensors mounted at the rear of the mockup enabled the quantification of aerodynamic contributions of the slant window, the tailgate and the rear bumper surfaces. According to the reference pressure taken at the Pitot tube, localized at a height of 1034 mm above the floor and at 630 mm ahead the front bumper (

Figure 2), pressure measurements on these three rear surfaces lead to a partial Cd ratio between 55% and 53% with or without an air dam (

Figure 3). Therefore, the optimization objective seems to be applicable either on the total Cd or on the rear wall pressure.

Thanks to an experimental design-of-experiment method, it has been found that a specific air dam geometry enables a decrease in drag force by 9%, leading to a Cd value of 0.32 and keeping the rear pressure force ratios at a level of 53% (

Figure 3). This optimized configuration is now used with the baseline configuration in order to check the grid convergence of the numerical model before performing the optimization process.

Rear pressure and drag coefficients are defined as follows:

where

N denotes the number of rear sensors equal to 48,

denotes the pressure measured at sensor

n,

denotes the static pressure measure at the Pitot tube location,

denotes the velocity measured from dynamic pressure at the Pitot tube equal to 30 m/s and A is the projected frontal area of the mockup equal to 0.06 m

2 for a model scale of 1:7. In addition to the rear pressure sensors, several pressure taps have been introduced on both sides of the mockup in order to capture possible asymmetries of the flow. Pressure measurements were conducted at sensor 4 on the left side in the front door (

Figure 3) but also on the opposite side [

13], and they both provide equivalent values of

without any yaw angle.

2.2. Grid Convergence for Lattice Boltzmann Numerical Model

In a lattice Boltzmann method (LBM), velocity and pressure come from the collision equation [

15,

16]. The time iteration number must be high enough in order to reach the periodic state checked at the reference Pitot tube location. The time step must be in concordance with the cell size in order to capture the convection phenomena respecting the Courant number condition and the inertial slope of the power density spectrum at some specific points situated in turbulent regions behind detachment zones. A Smagorinsky turbulence model is used in the core region of the fluid and a wall model enables the computation of friction velocity in the three first layers in order to match to the non-dimensional velocity profile in the core region.

Generally, simulation time for this reduced scale model is set at 2.5 s, and the number of iterations is set at 15,000 for a mesh size of 400 million hexahedron cells or voxels. This numerical model definition enables frequency analysis between 2 Hz and 2500 Hz but needs two and a half days of computation. Therefore, we decrease the simulation time to 1.35 s and the number of iterations to 4000 in order to limit computation time to 4 h for a mesh of 50 million voxels. The cell size in the wall region must also be able to capture the wall friction in the wall model. In this paper, we compare the velocity profiles obtained with the standard fine mesh of 400 million voxels generally used for computations and a coarse mesh of 50 million voxels (

Table 1) defined for this optimization study to hotwire measurements at three sensor locations (

Figure 4).

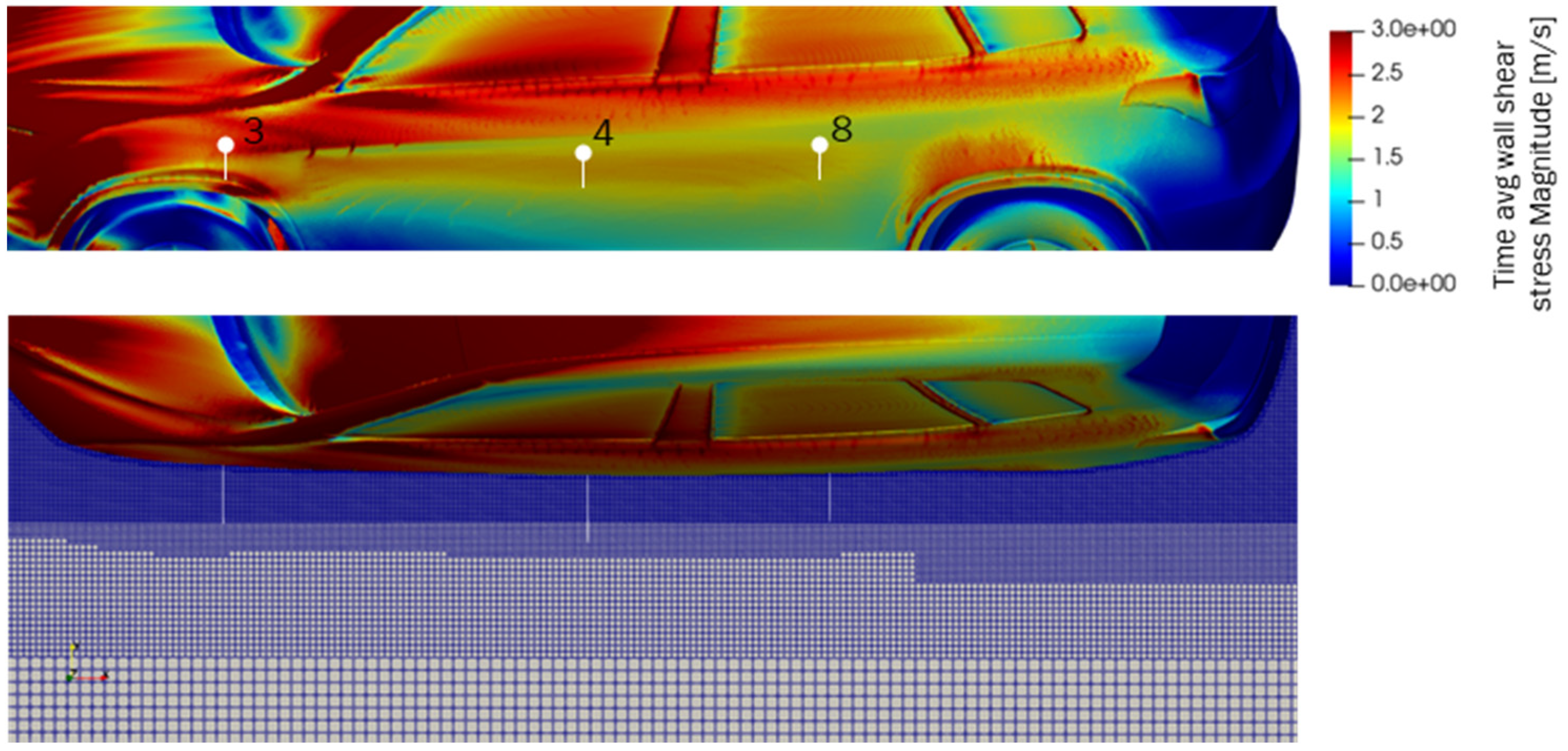

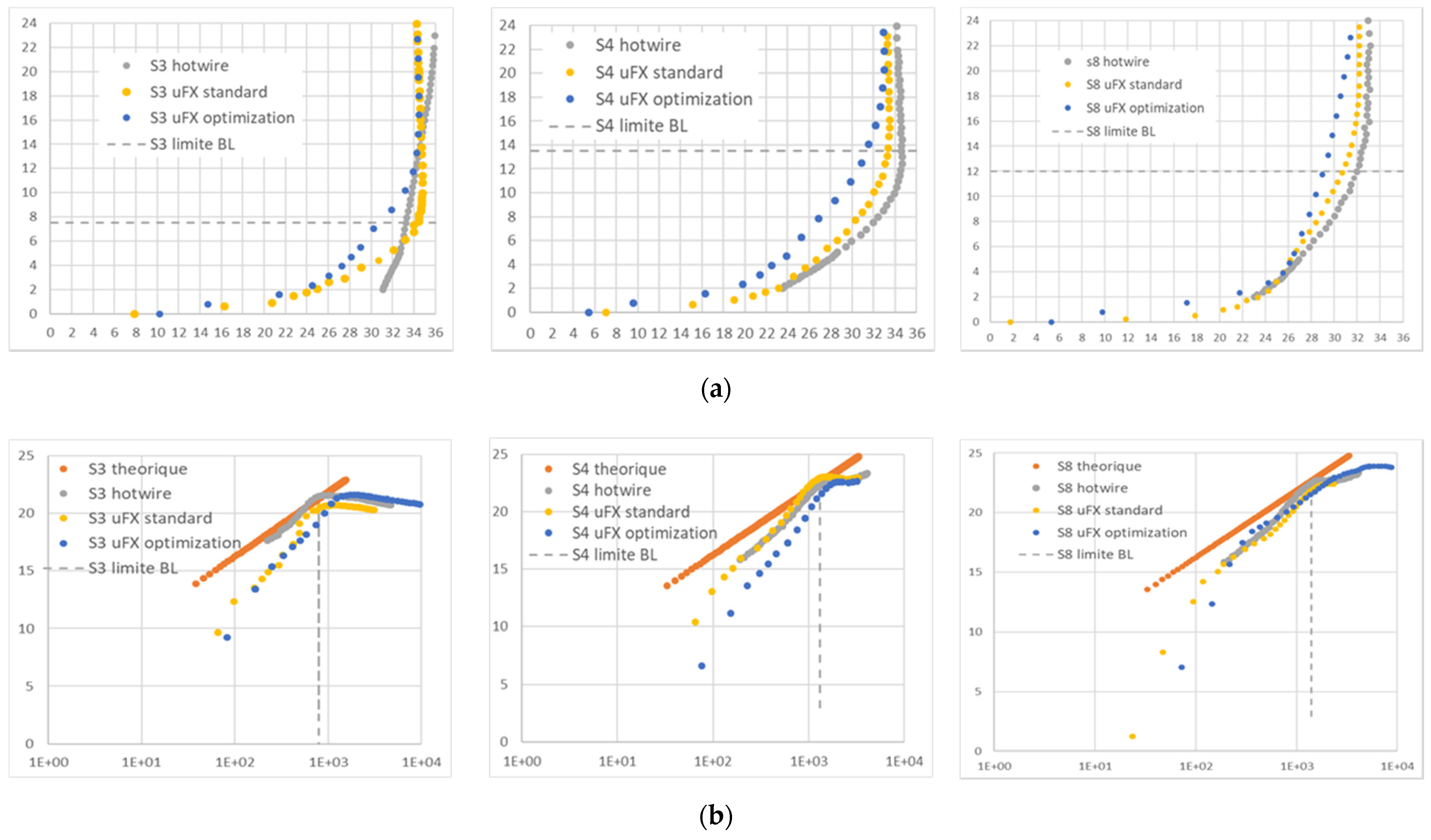

Velocity profiles have been measured thanks to a hotwire system for the baseline configuration, with a step of 0.2 mm starting at 2 mm from the wall. We can notice in

Figure 5a that experimental profiles for sensors 4 and 8 (in grey) are very close to the numerical velocity profiles (in yellow) obtained with the reference fine mesh of 400 million voxels (see bottom view of

Figure 4). This high number of voxels is due to the size of the five first layers close to the wall, equal to 0.4 mm (see

Table 1). Friction velocity

U* computed with the fine mesh is equal to 1.7 m/s on sensor 4 and 8 (see top view of

Figure 4) and used for reference in order to calculate the non-dimensional velocity profiles

U+ such as the following.

Thickness of the boundary layers is estimated at the end of the logarithmic law, which must be parallel to the analytic law (in orange in

Figure 5b), and it is defined as follows.

This method enables the ability to find a boundary layer thickness between 12 mm and 14 mm for sensor 4 and 8 (

Figure 5a) and avoids questions about velocity acceleration due to the blocking ratio.

Even if the resulting velocity profiles (in blue) on

Figure 5a show differences with velocity profiles of the refined mesh (in yellow), slopes in the three first layers lead to the same friction velocity. Differences were observed to be increased at sensor 3 where acceleration of the flow along the fender seems difficult to capture either with coarse or fine mesh. It is, therefore, important to check if the pressure fields in the detachment regions are well computed, especially with coarse mesh in the rear end of the mockup.

The same velocity profiles have been realized on this baseline configuration with a coarse mesh in order to check if CFD computations are precise enough to create a database in a reasonable time. Voxels measuring 50 million are used in this mesh, with cell sizes of 0.8 mm in the six first layers close to the wall (

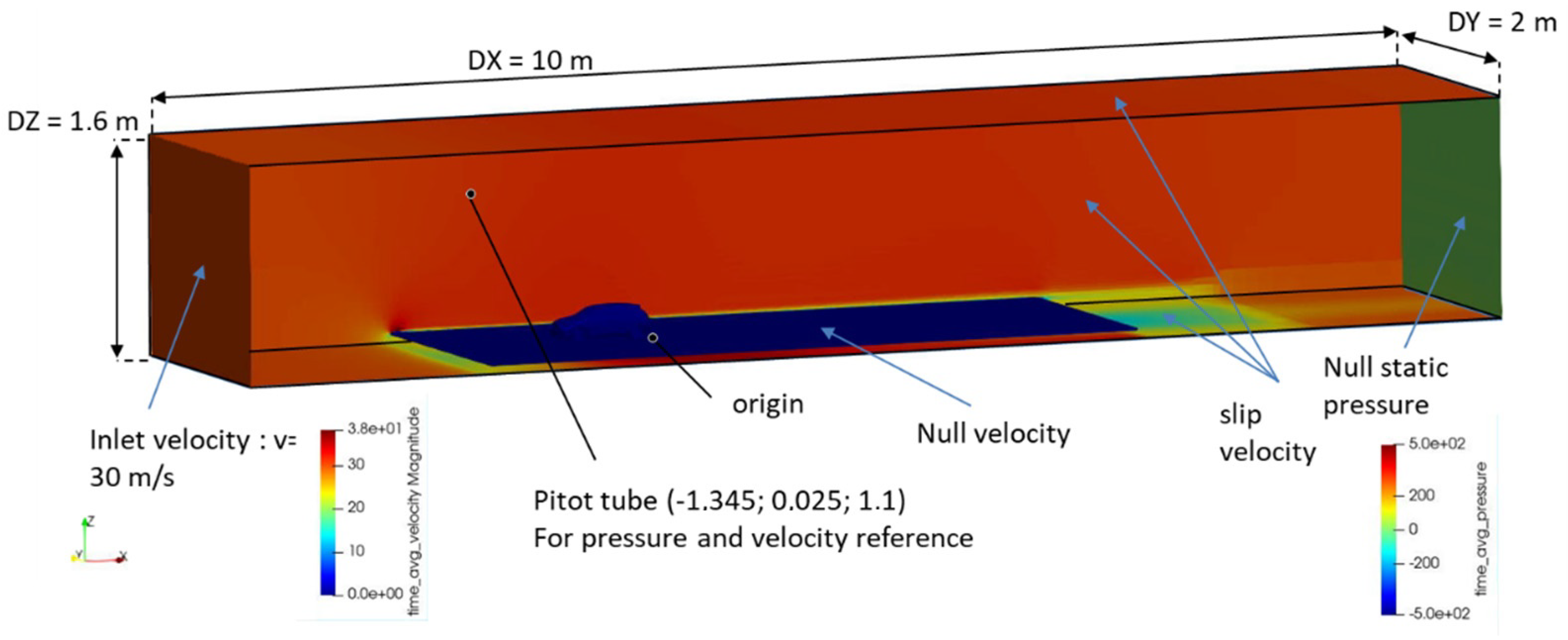

Table 1). Slip boundary conditions are imposed on the wall of the wind tunnel, and zero velocity conditions are applied on the floor, the wheels and the surfaces of the mockup (

Figure 6). An inlet velocity of 30 m/s leads to a velocity at the Pitot tube of 30.6 m/s corresponding to a blocking rate of 1.8%. A zero relative static pressure condition is defined at the outlet. Pressure and drag coefficients are normalized with pressure and velocity magnitudes, measured at the Pitot tube.

According to

Figure 7, we obtain a numerical Cd value for this smaller mesh of 0.36 for the baseline and 0.332 for the optimized configurations with pressure map and velocity measurements both averaged on the last 1000 iterations. As a remainder, experimental Cd value is equal to 0.36 in baseline and 0.32 with airdam. These numerical results are in concordance with wind tunnel measurements (see

Figure 3).

When taking into account the pressure sensor locations (left side of

Figure 7), the rear pressure coefficient versus drag coefficient

of the computed baseline configuration is equal to 58%, close to the ratio of 55% found in experiments (

Figure 3). When using the slant and tailgate surfaces, this pressure ratio is equal to 30%. This difference of rear pressure ratio found between rear pressure sensors and rear partial surfaces is due to a higher density of the pressure sensors in the region of low-pressure values, especially in the rear bumper region.

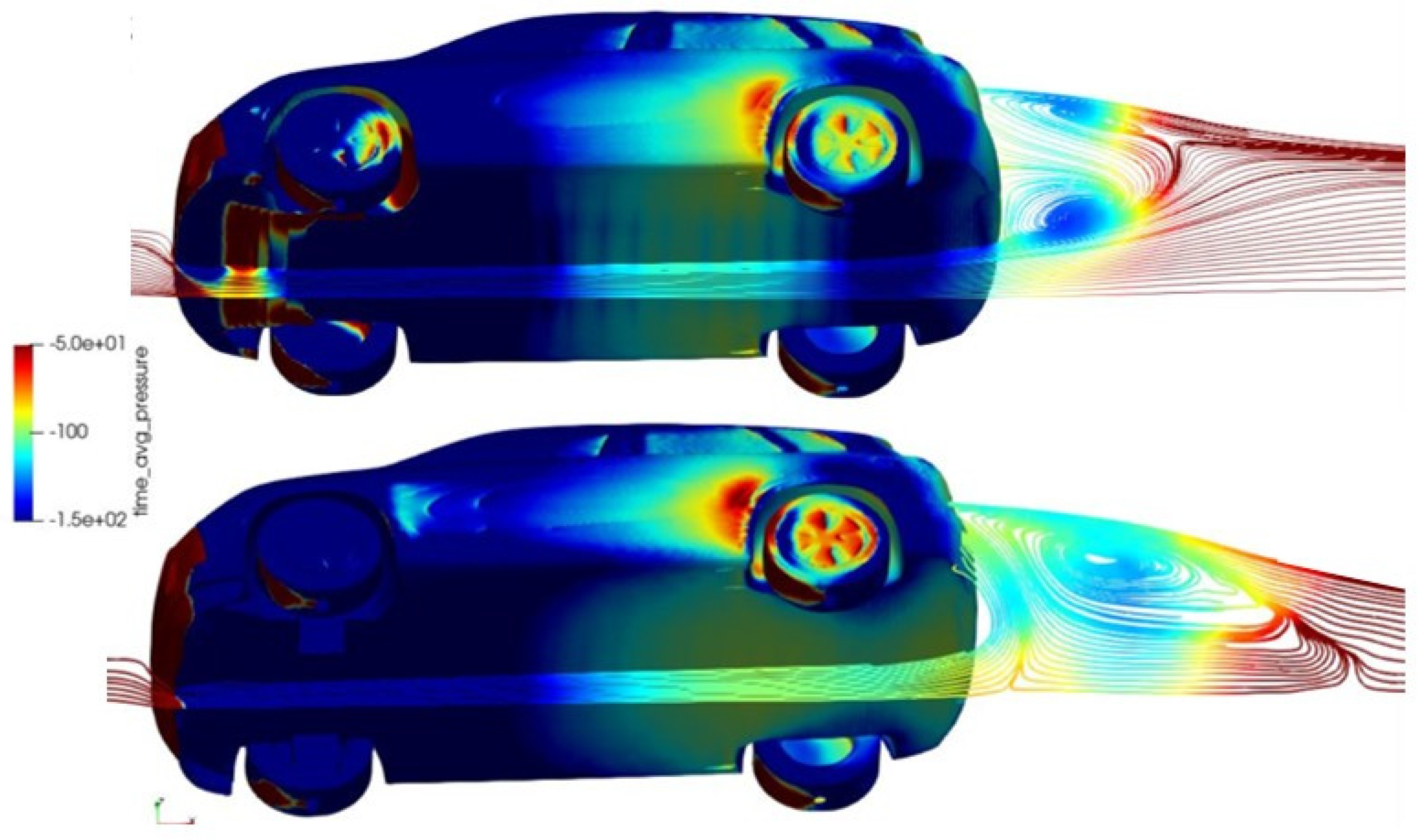

In relation with wall pressure map of

Figure 7, streamlines in the symmetry plane in the longitudinal direction show influence of the air dam on wake structure (

Figure 8). Without the air dam, airflow in the underfloor creates a recirculation behind the rear bumper. With the reference air dam, this bottom recirculation disappears, increasing the size of the remaining recirculation, which pushed itself downward. Pressure in the wake increases, leading to drag force reduction in the tailgate. However, this benefit is balanced by an increase in pressure on the front air dam. Nevertheless, numerical Cd reduction is equal to 8% compared to an experimental gain of 9%.

Thanks to the numerical model’s definition, computation takes 4 h on a DGX-1 machine working with 8 GPU Tesla cards of 32 GByte of RAM per card for a numerical model of 50 million voxels. Depending on the number of free variables, this solver time per variant leads to a total computation time of one month in order to build up the database for the surrogate by running the design-of-experiments.

2.3. Shape Optimisation Process

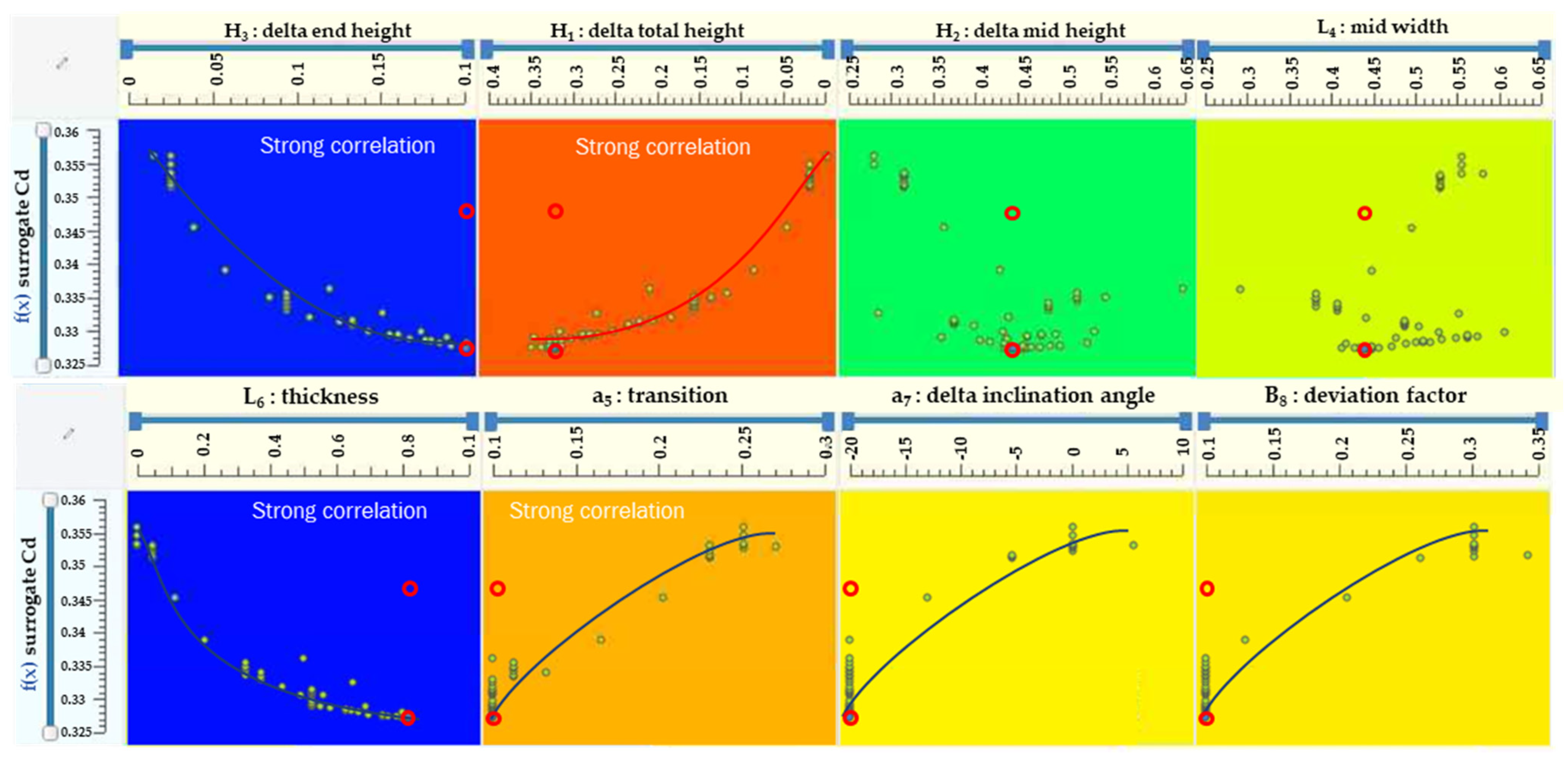

According to the optimized configuration described above, there is an air dam geometry decreasing drag forces by 8% (

Figure 6). However, the absolute total height of this geometry limits its integration below the front bumper due to the style issues and the reliability of the system. A design exploration of the geometric parameters must help delivering a less intrusive shape with similar aerodynamic performance.

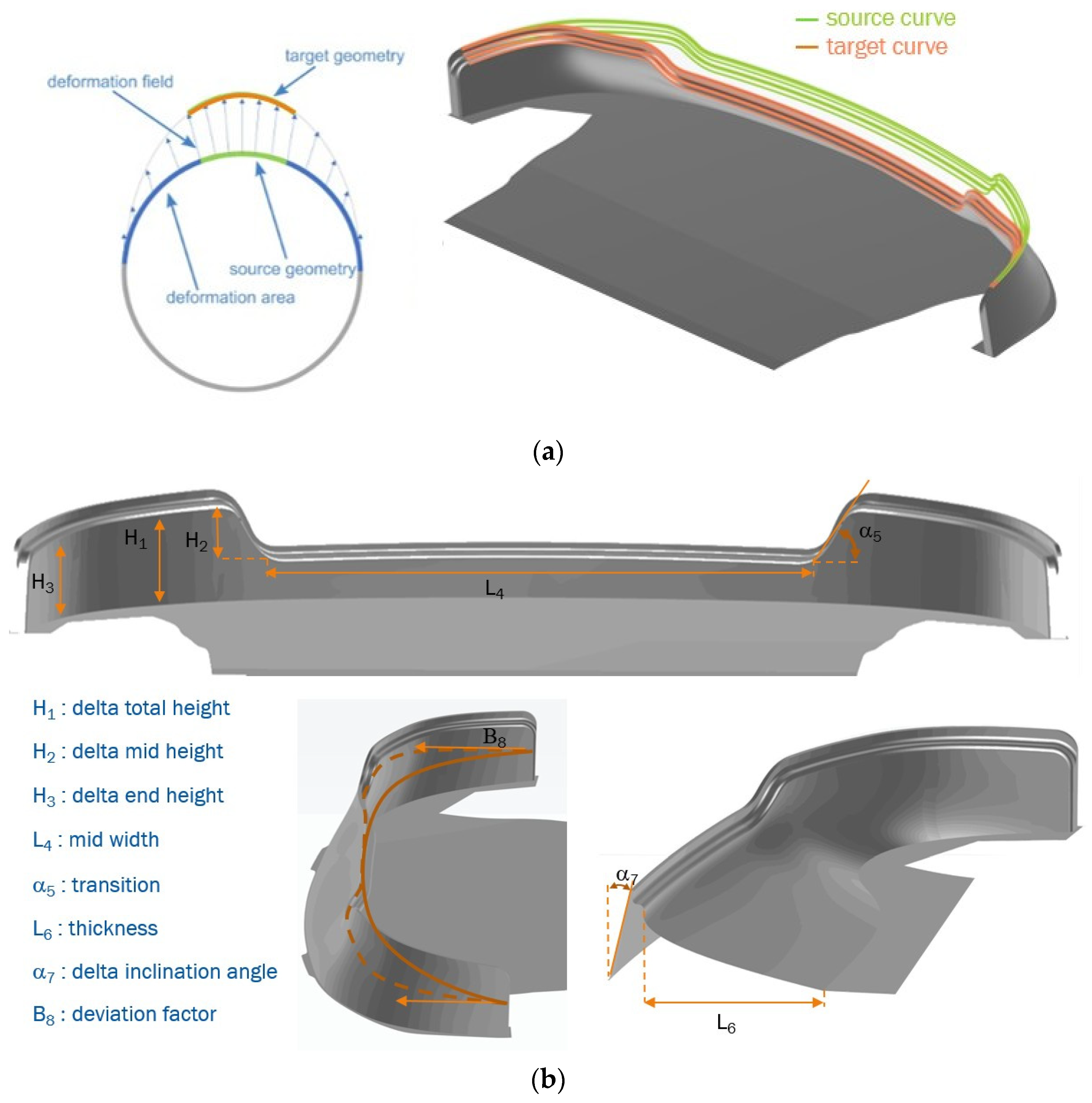

Starting from the most efficient air dam geometry, Radial Basis Functions (RBFs) are applied on the source curves in order to deform the shape until reaching the target curves. Target curves, defined as NURBS, are morphed with their control points, according to geometric parameters such as the total height of the air dam and the height and the width of the central section.

Figure 9a shows a description of the deformation process, and

Figure 9b presents the eight geometric parameters retained to morph the shape of the air dam.

The new air dam geometry is exported in the STL format and joined to the static STL file of the numerical model. The volume hexahedral mesh, performed in the closed volume limited by the shell mesh, enables the computation of a new aerodynamic solution thanks to the lattice Boltzmann method with the cell size definition selected from the grid convergence study.

There are different methods for building response surfaces (surrogates) used to search a minimum number of objective functions. The Latin Hypercube technique is often used, but Sobol sequence is preferred as this global sensitivity analysis method based on variance decomposition enables adapting sampling during design space exploration. The precision of the resulting surrogate model can be increased thanks to additional sampling, dealing with extended geometric parameter ranges [

17].

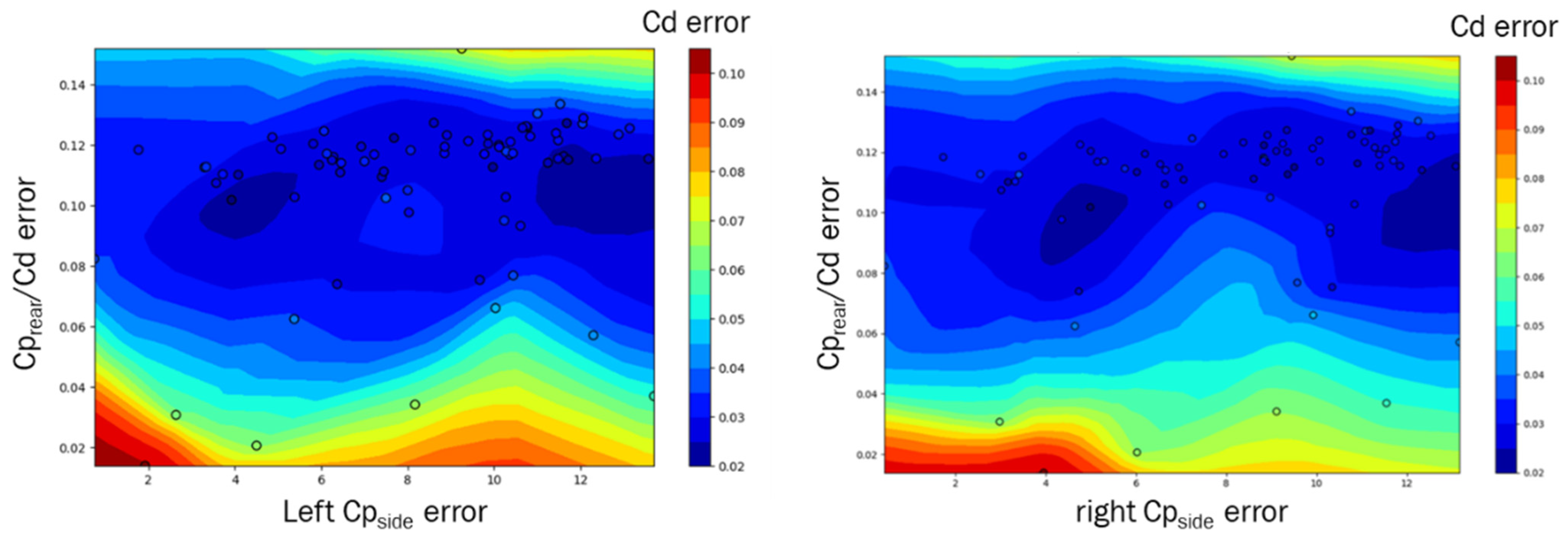

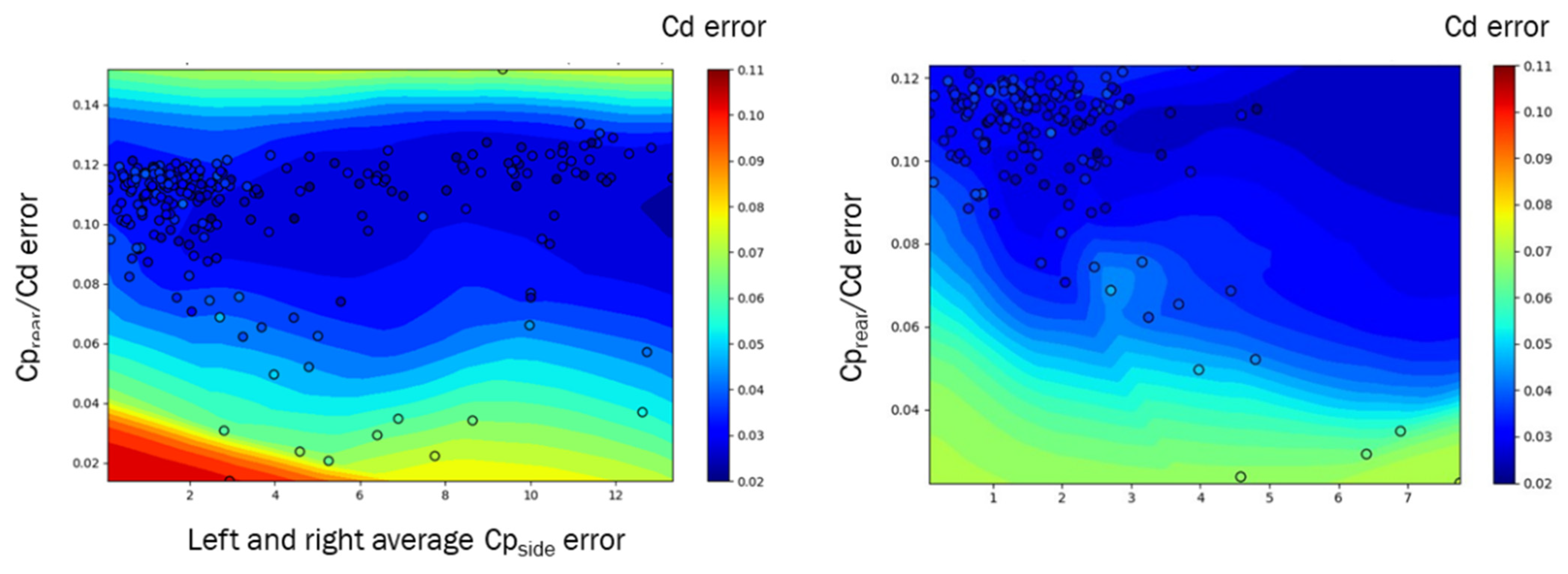

As mentioned in the Introduction, response variables have been chosen in order to explore numerical solutions close to the experimental results. The objective is the drag value and constraints dealing with pressure sensor values on the side and at the rear of the mockup. Sampling results must show the response surface of the minimum drag value in the range of pressure constraints.

Figure 10 illustrates the process with objectives and constraints definition. An error of Cd corresponds to the difference between a computed Cd value and the objective value of 0.32. An error of 0.02 corresponds then to a Cd of 0.34. Therefore, an error on Cp

side4 of 4 will correspond to a value of −0.21 and an error on

of 0.1 corresponds to a value of 0.25. Results of the Sobol sequence are presented in the next section.

Surrogate models are often built from the available design space database, either with artificial neural networks or with a Kriging model. This model, also called a Gaussian process, enables the prediction of the objective of function

f(

x) depending on the range of the geometric variable vector dataset

thanks to the following relation:

with

being the vector of design variables of dimension

n,

(

) is the vector of trend basis functions,

is a vector containing the generalized least squares estimates of the trend basis function coefficients,

(

) is the correlation vector of terms between

x and the data points,

is the correlation matrix for all of the data points,

is the vector of response values and

is the matrix containing the trend basis functions evaluated at all data points. Correlation vector

(

) and matrix

are computed using a Gaussian correlation function depending on a vector of correlation parameters of dimension

n,

= {θ

1, …, θ

n}

T using a Maximum Likelihood Estimation (MLE) procedure involving the Likelihood join probability function p(y|θ). Therefore, the Kriging model allows an approximation of predictors and their uncertainty through the mean square error (MSE). The Kriging model defined and used in this paper has been introduced in Dakota, an optimization algorithm available from the Sandia National laboratory [

18] and implemented in CAESES©.

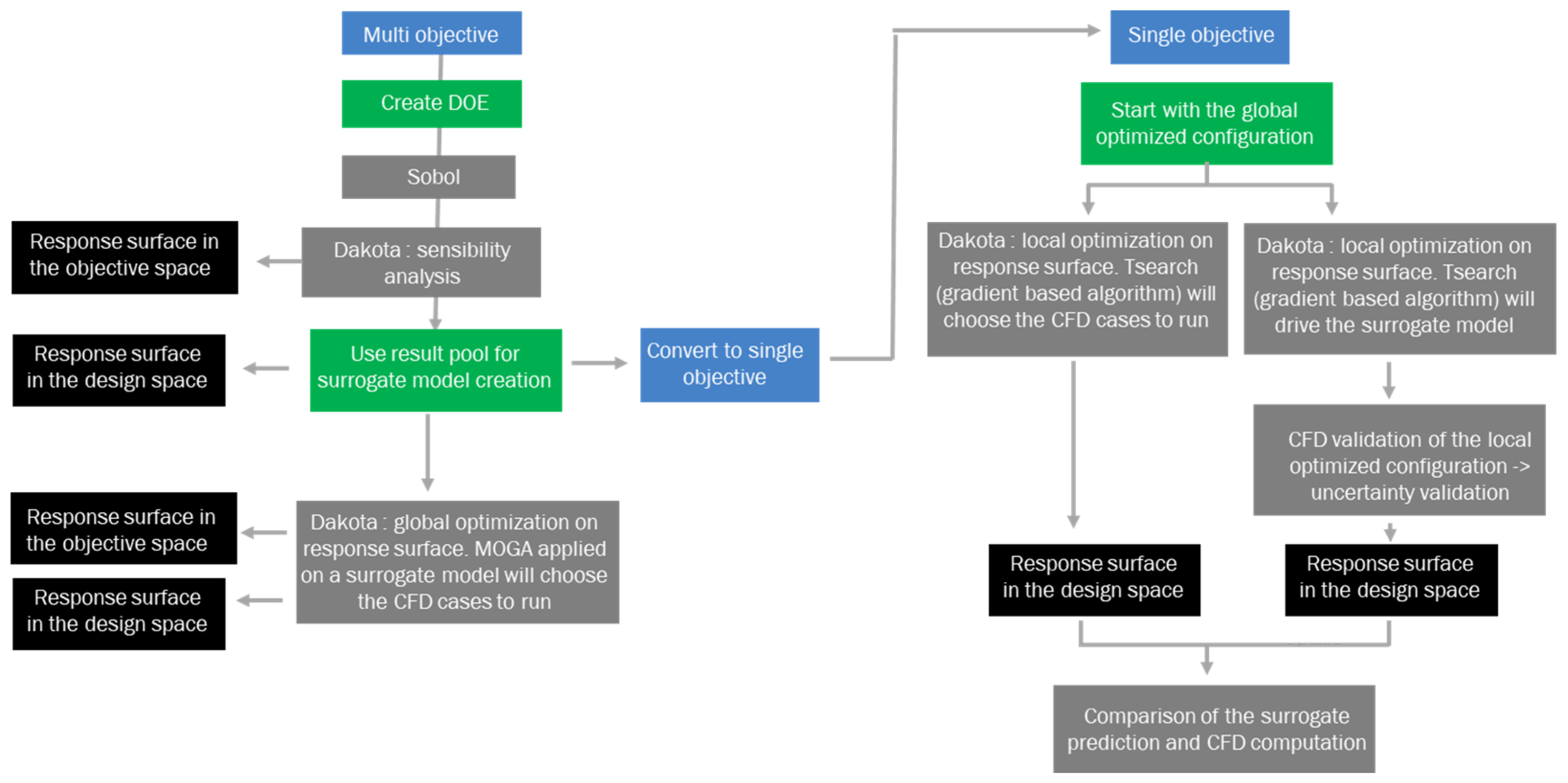

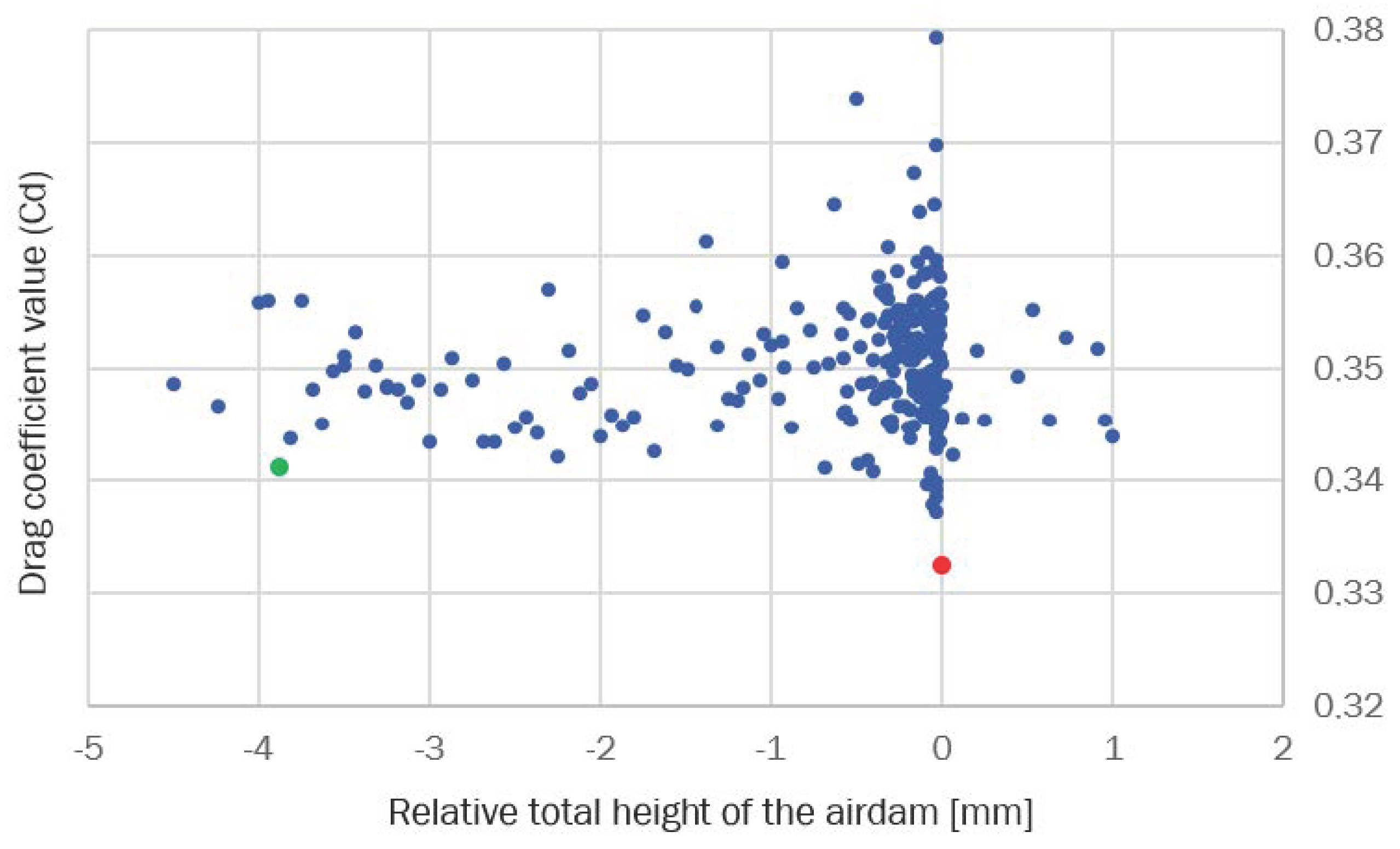

This CFD optimization study deals with drag coefficient reduction with pressure constraints. Therefore, we need to solve a multi-objective problem in order to find the global minimum of the individual objective functions defined thanks to each Kriging model: with m corresponding to the number of objectives. As CFD simulations can lead to different minimums according to flow topology change, a multi-objective genetic algorithm (MOGA) seems to be the most appropriate in order to find the global minimum in the objective space. This genetic algorithm uses a two-point crossover technique, starting from 50 random design points. The result is a population of the 10 best “parent” (elitist strategy) plus 40 new “children”. The MOGA optimization process is finished after either 150 generations or 2000 function evaluations. We will then be able to select the minimum drag objective value in the response surface that is associated with pressure objective values.

Due to pressure constraints, the minimum value of the drag coefficient may be decreased, performing a single-objective optimization in the design space. This second optimization process can involve a genetic algorithm on the single function of the Kriging model or a gradient search (Tsearch algorithm) applied on the surrogated model and verified with CFD computations. A gradient search on the surrogate model could help in understanding the relation between design variables and drag values. Then, CFD computations performed at specific points enables the verification of whether the resulting CFD-computed Cd values are close to the Kriging model’s prediction. In cases where CFD results are far from the Kriging prediction, a gradient search can be performed using CFD computations directly without surrogate models.

Figure 11 presents these different possibilities.