Magneto-Bioconvection Flow of Williamson Nanofluid over an Inclined Plate with Gyrotactic Microorganisms and Entropy Generation

Abstract

1. Introduction

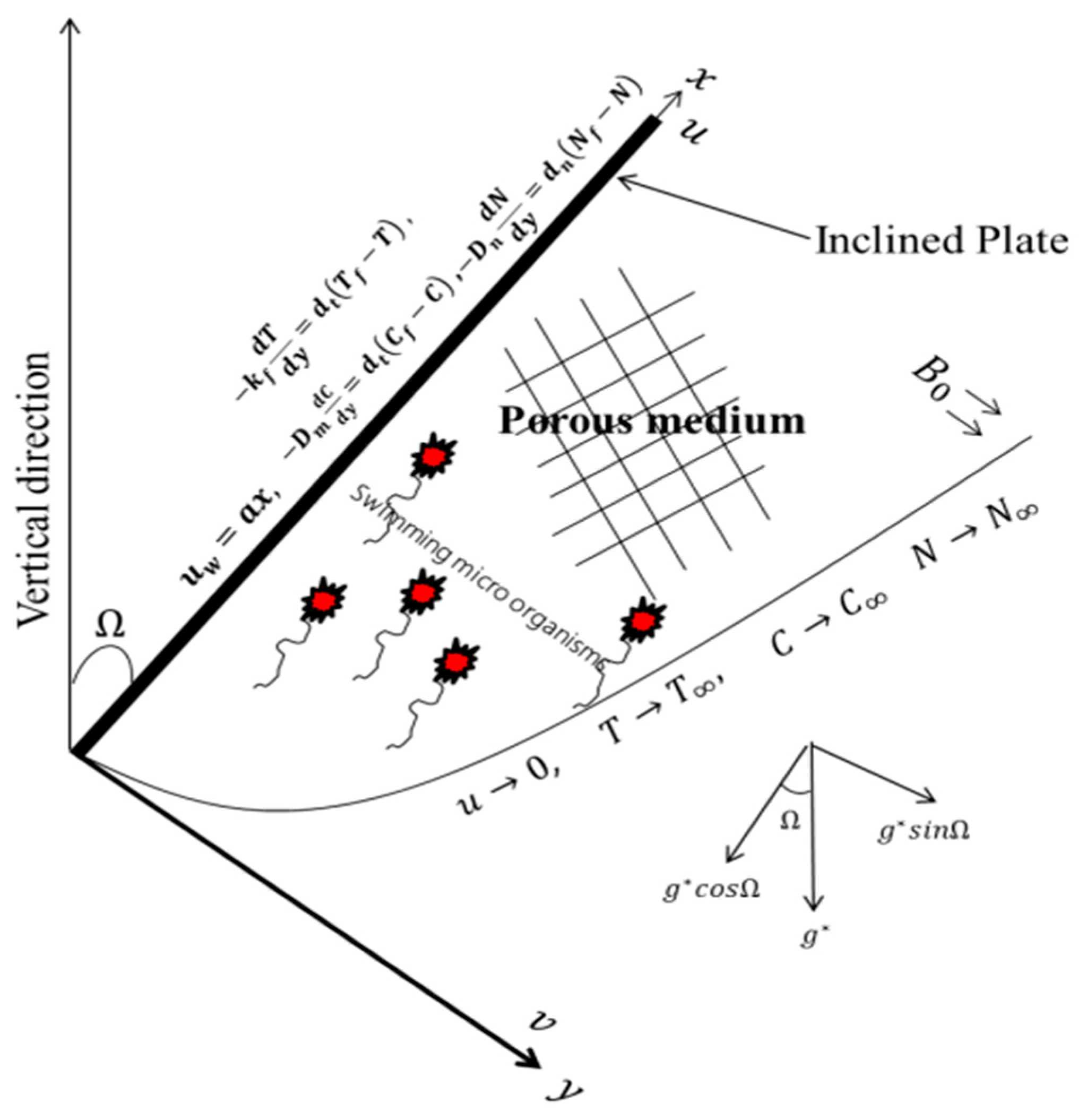

2. Problem Formulation

3. Entropy Generation

4. Numerical Solution

5. Results and Discussion

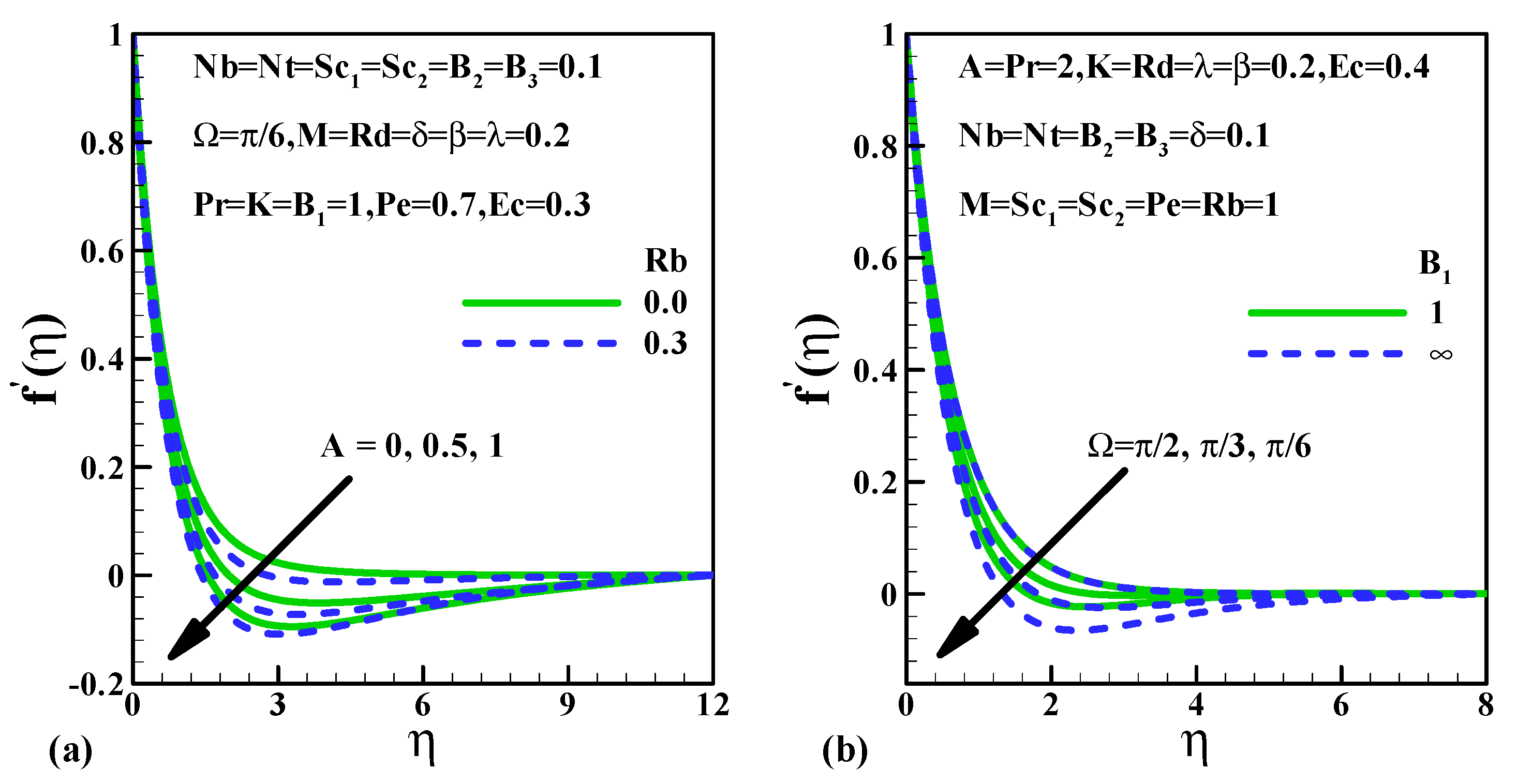

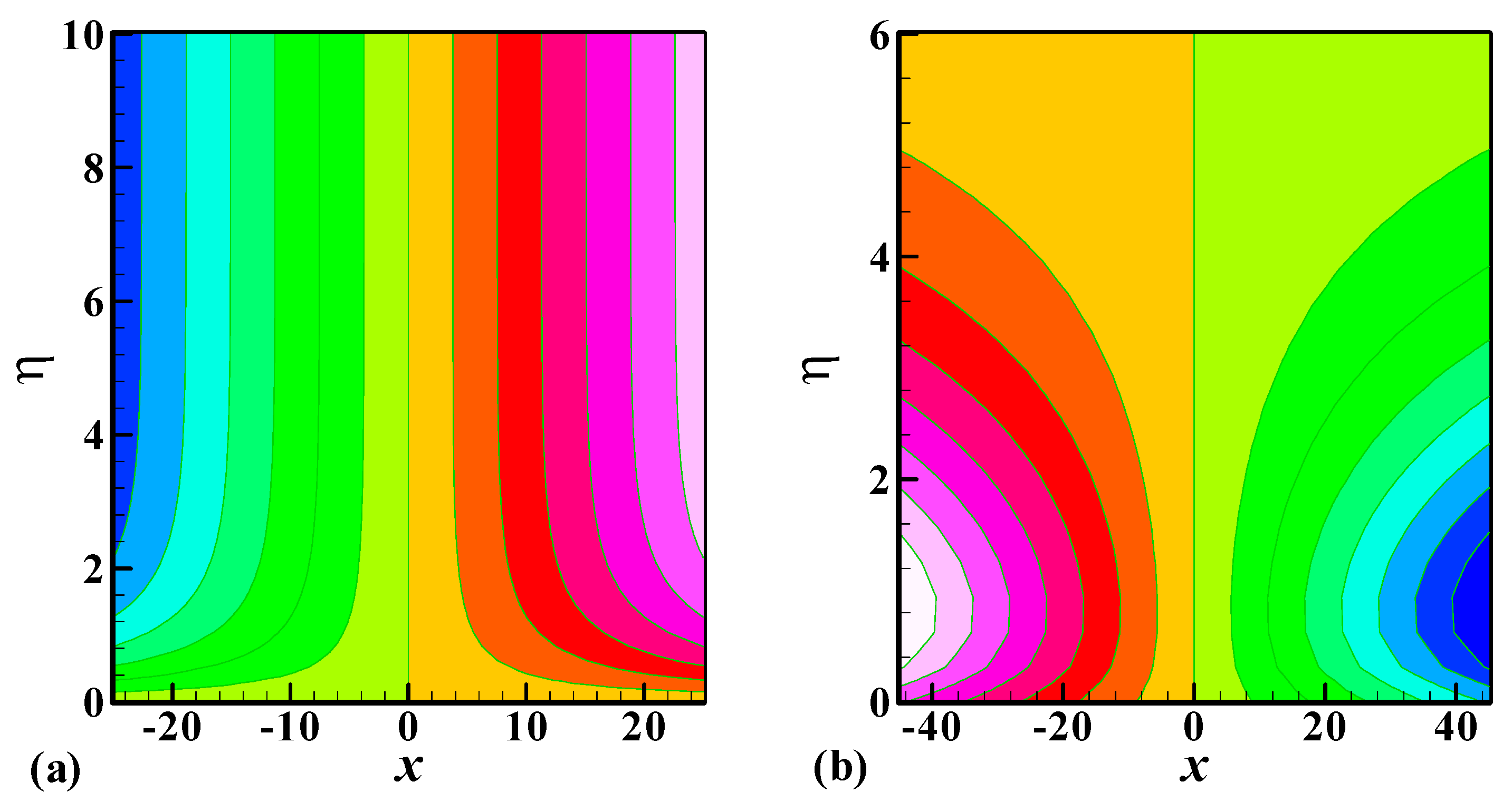

5.1. Flow Characteristics

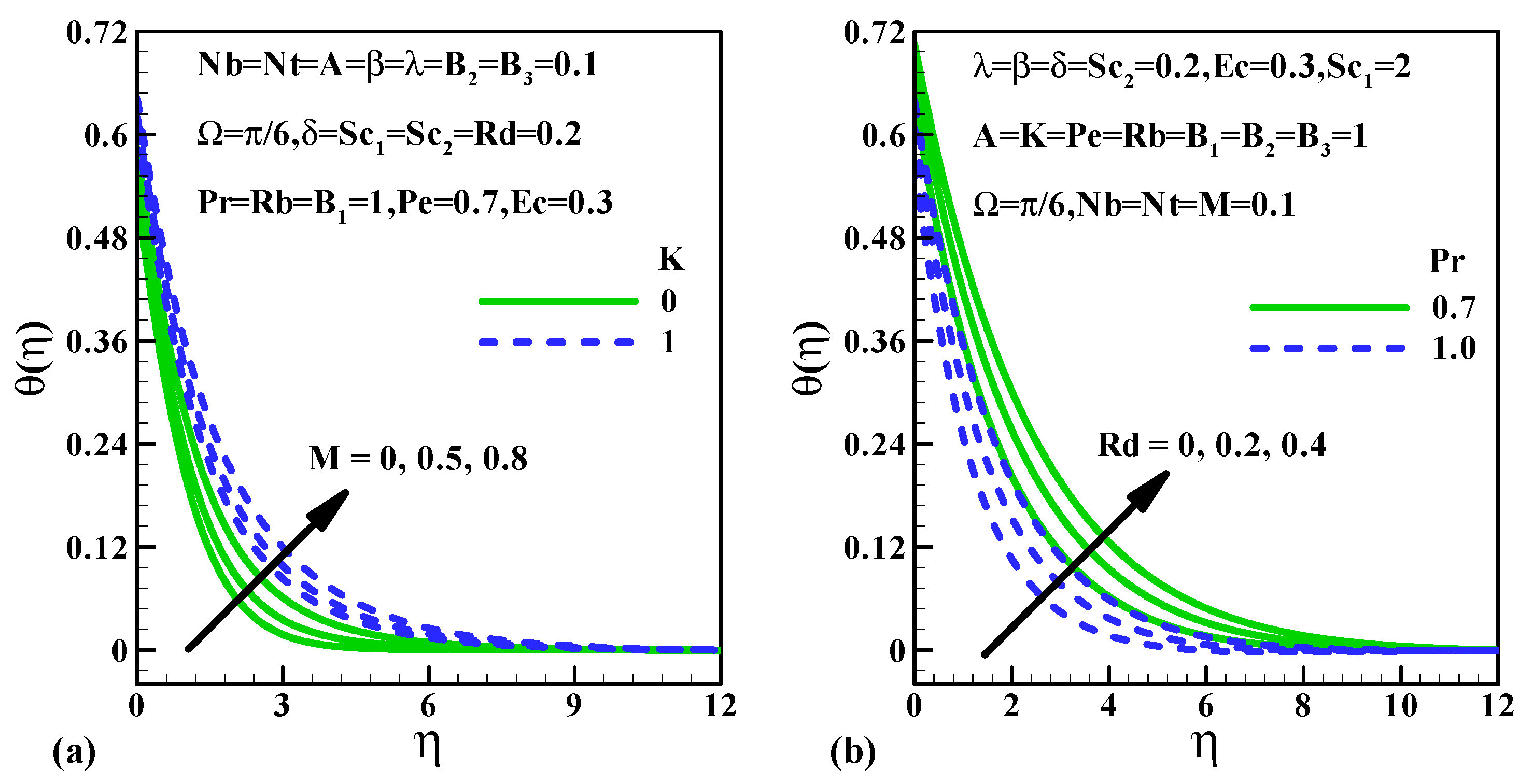

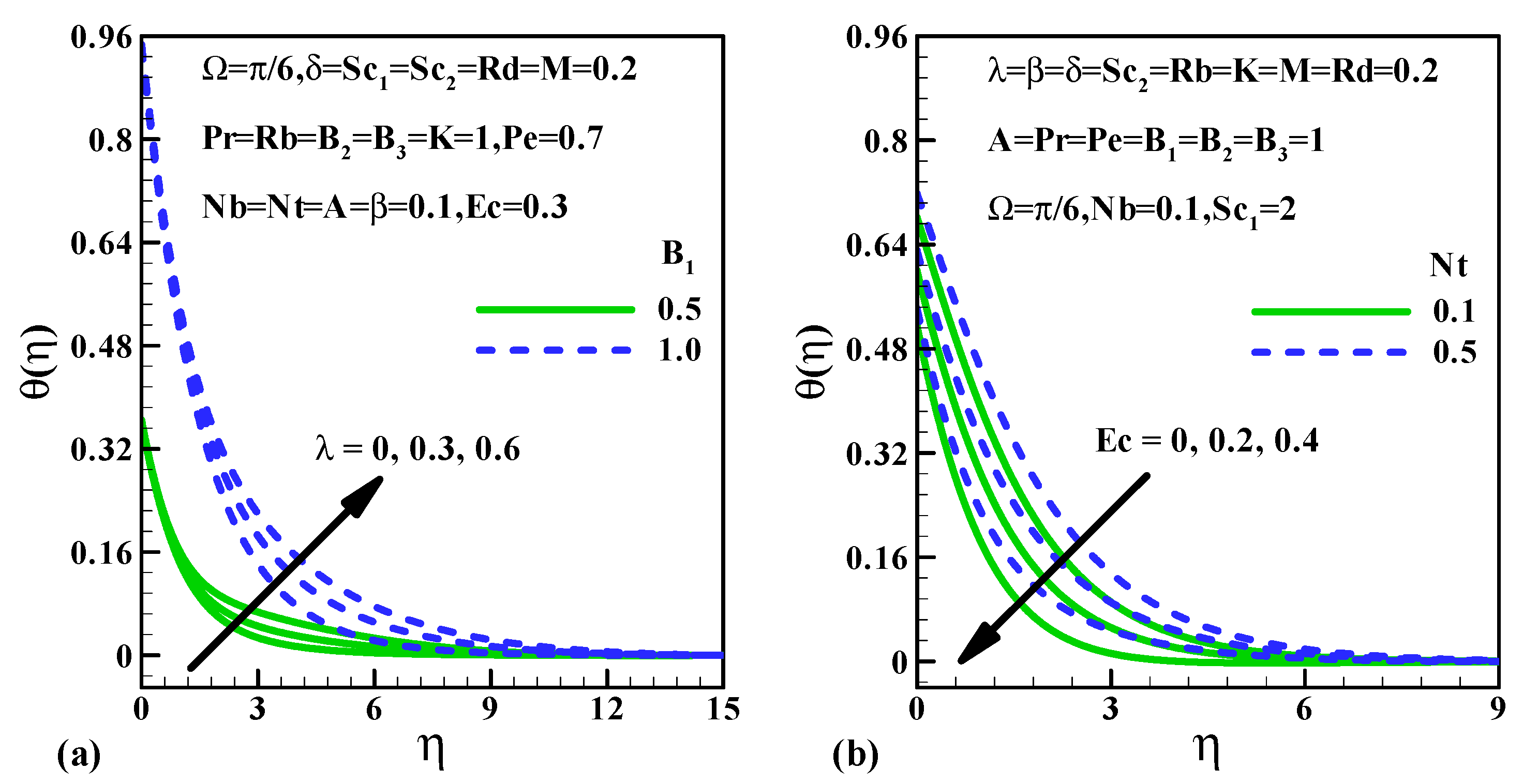

5.2. Heat Transfer Characteristics

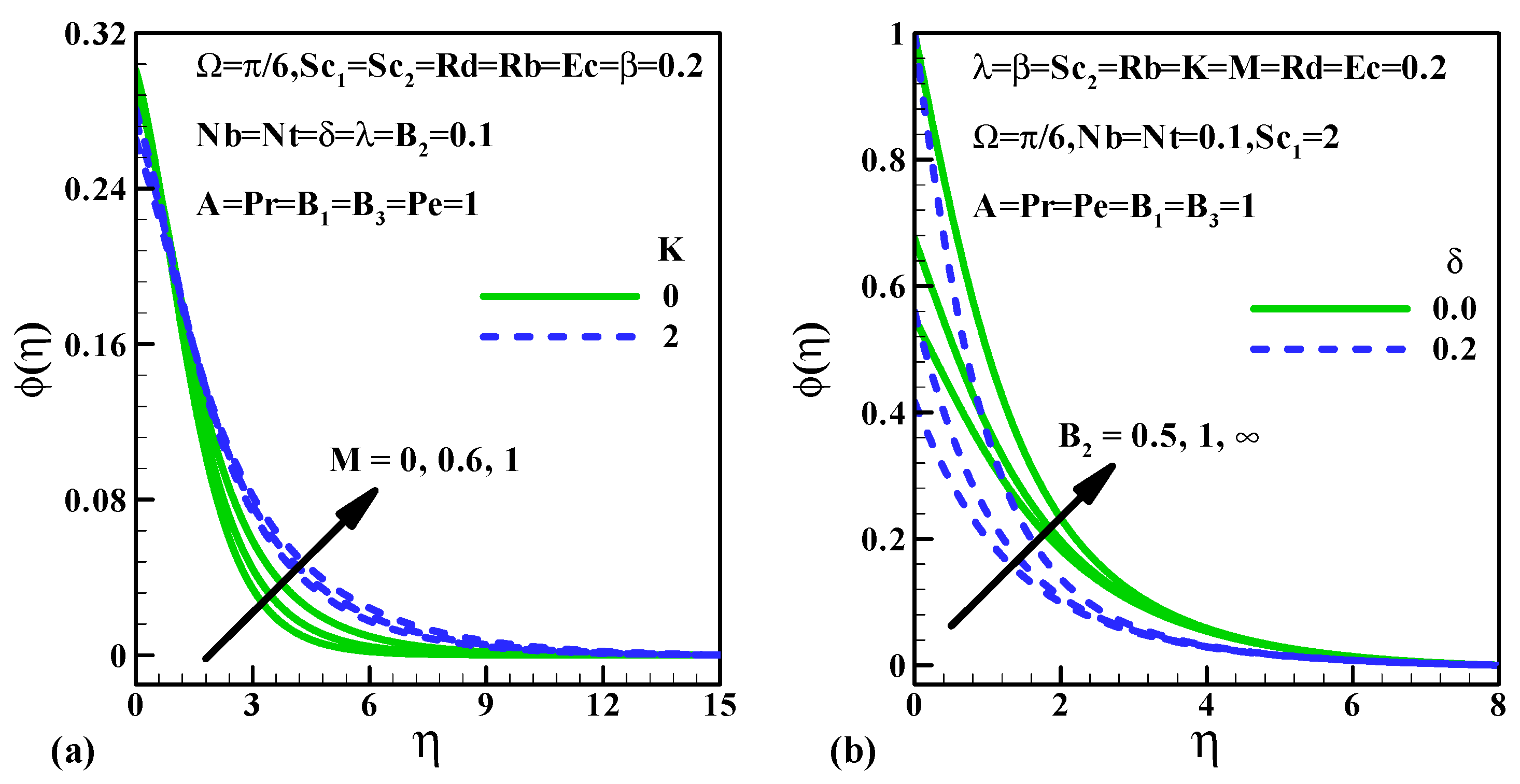

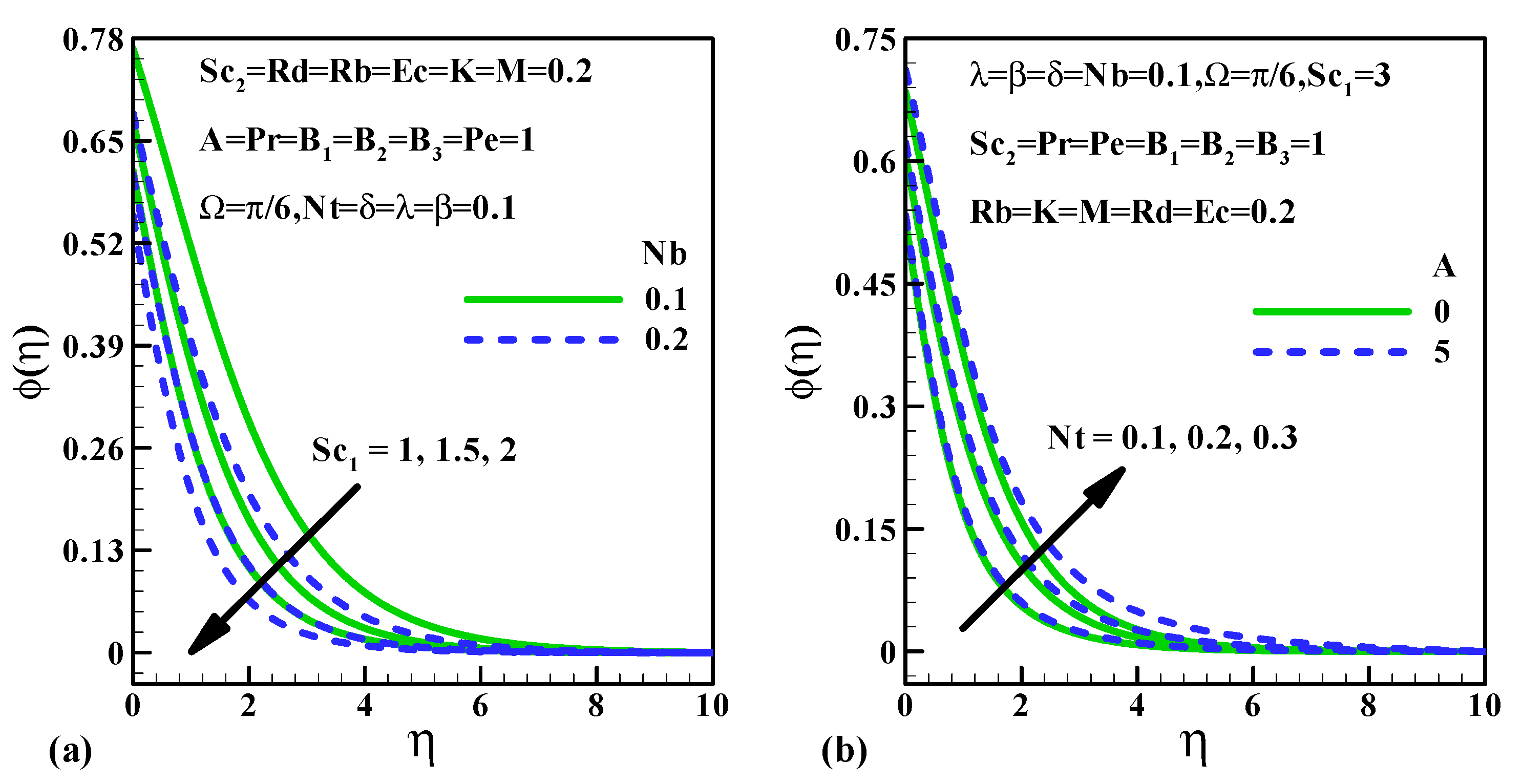

5.3. Mass Transfer Characteristics

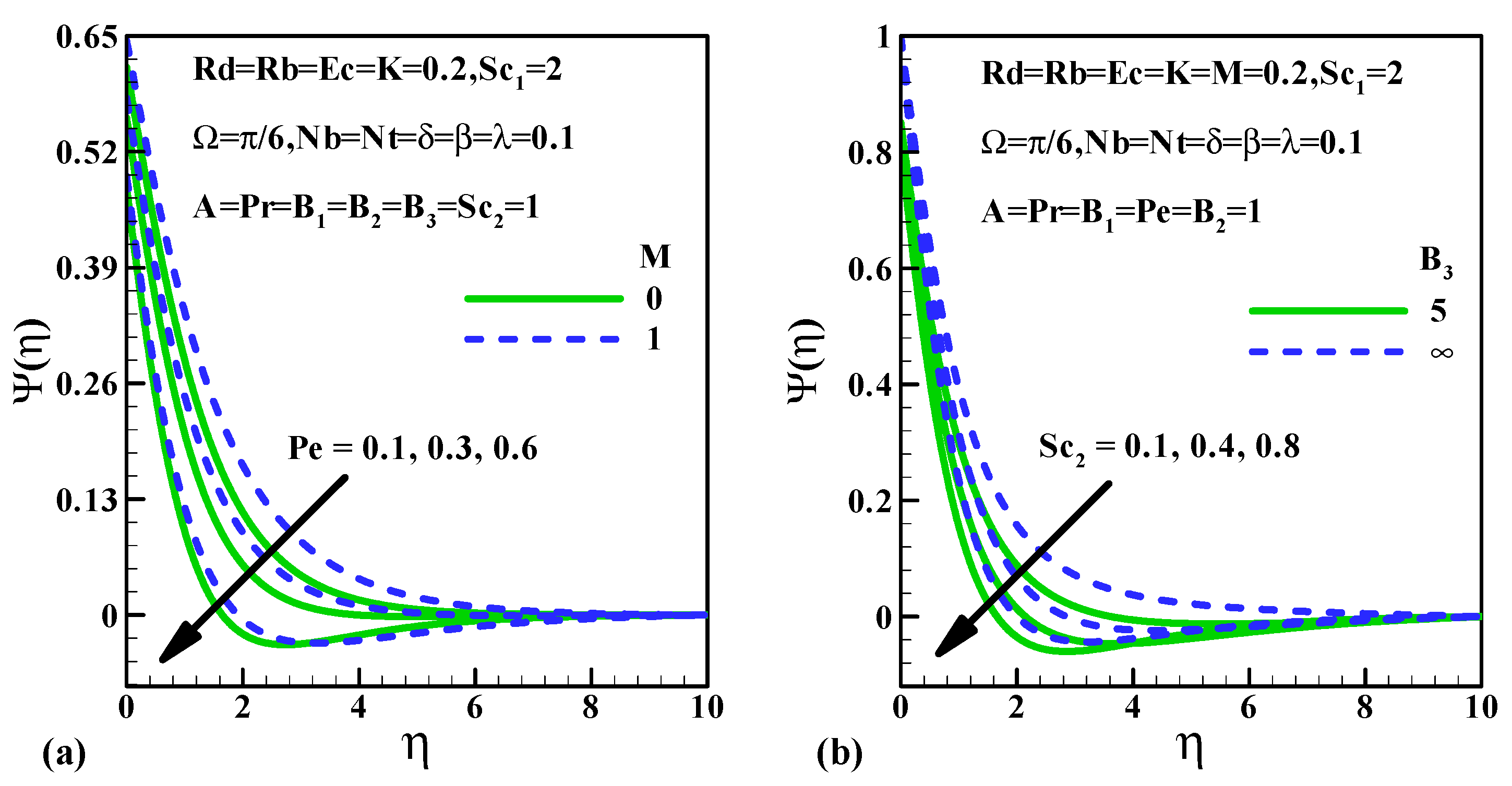

5.4. Microorganism Density Characteristics

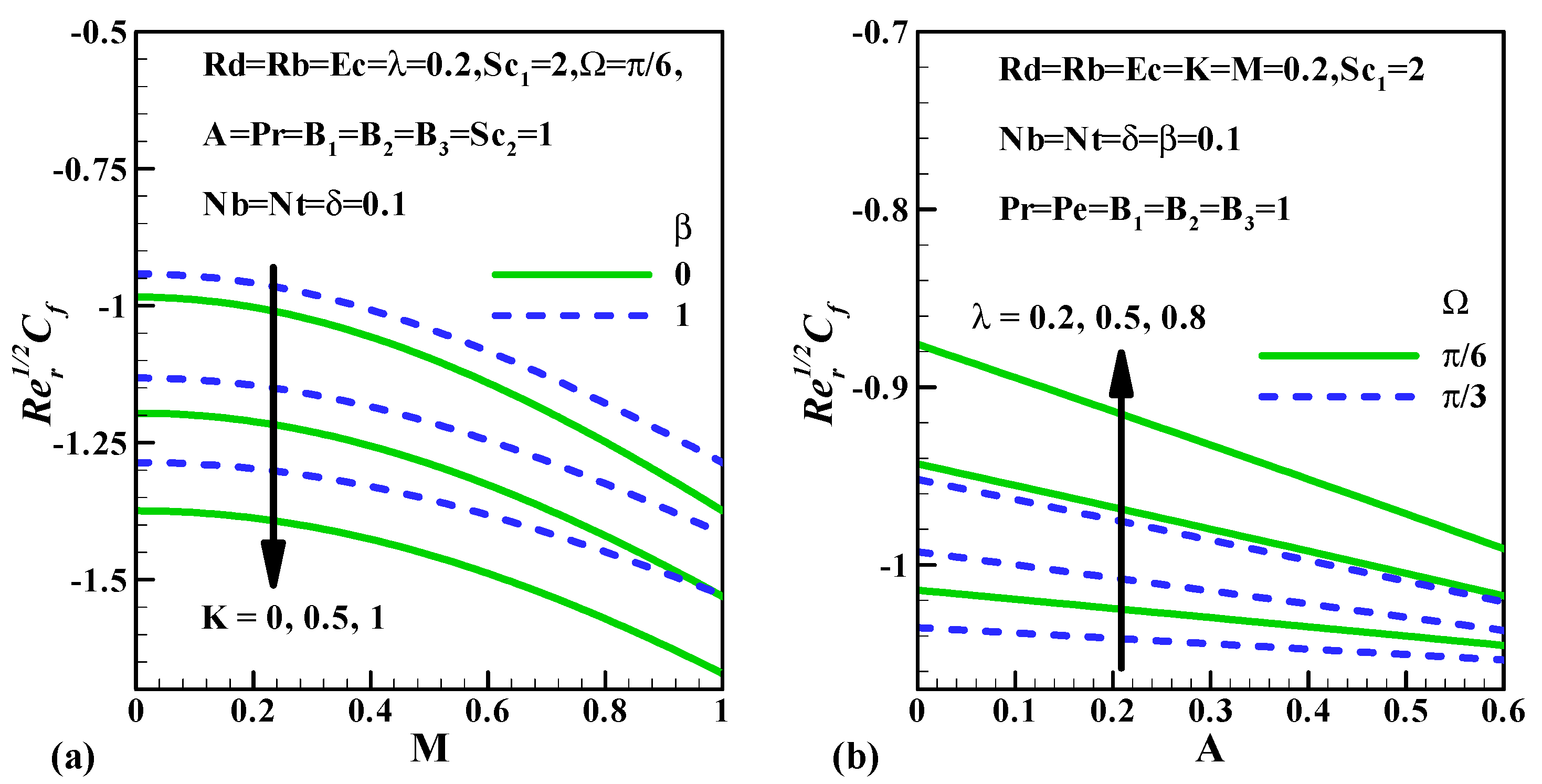

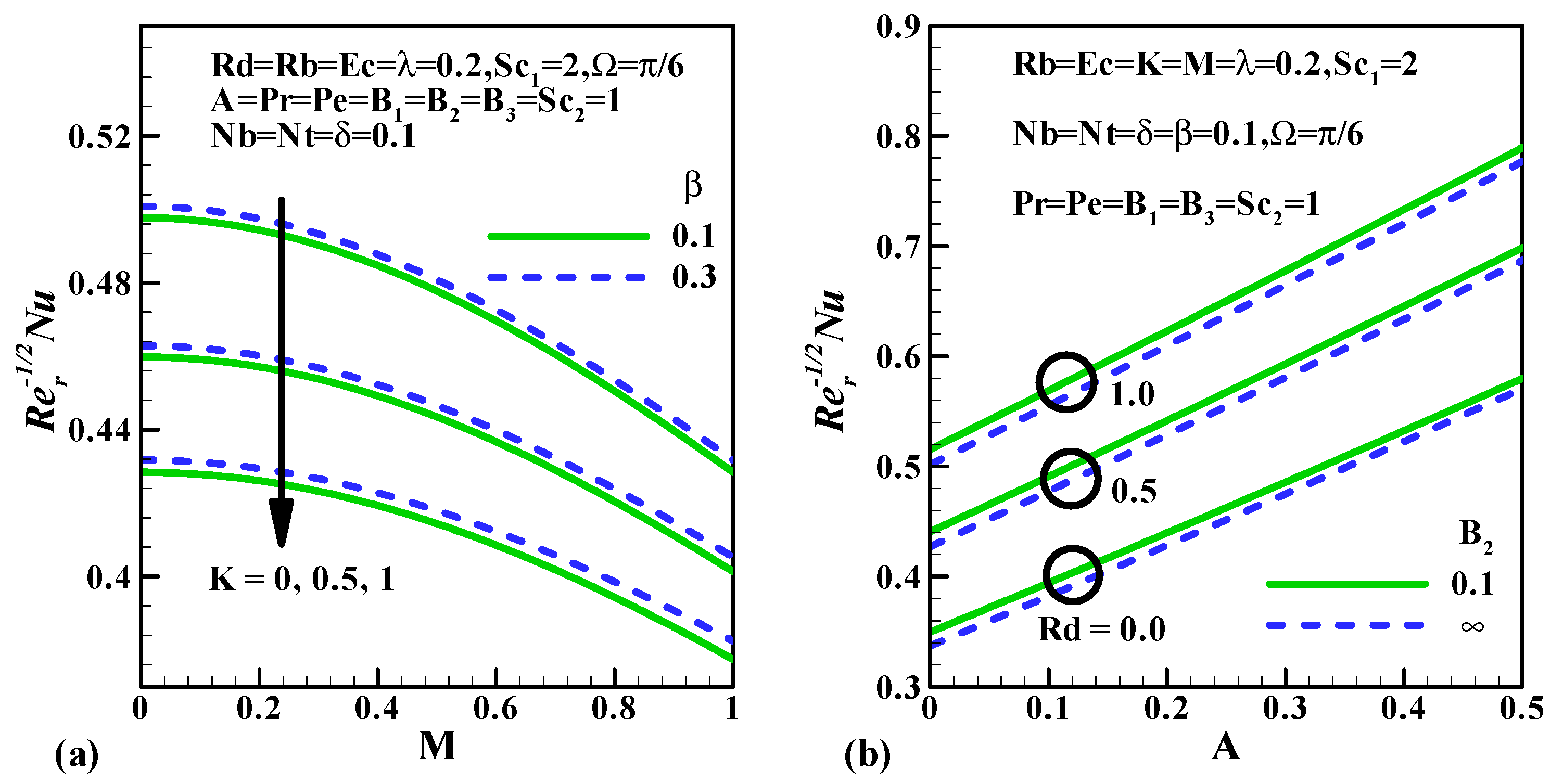

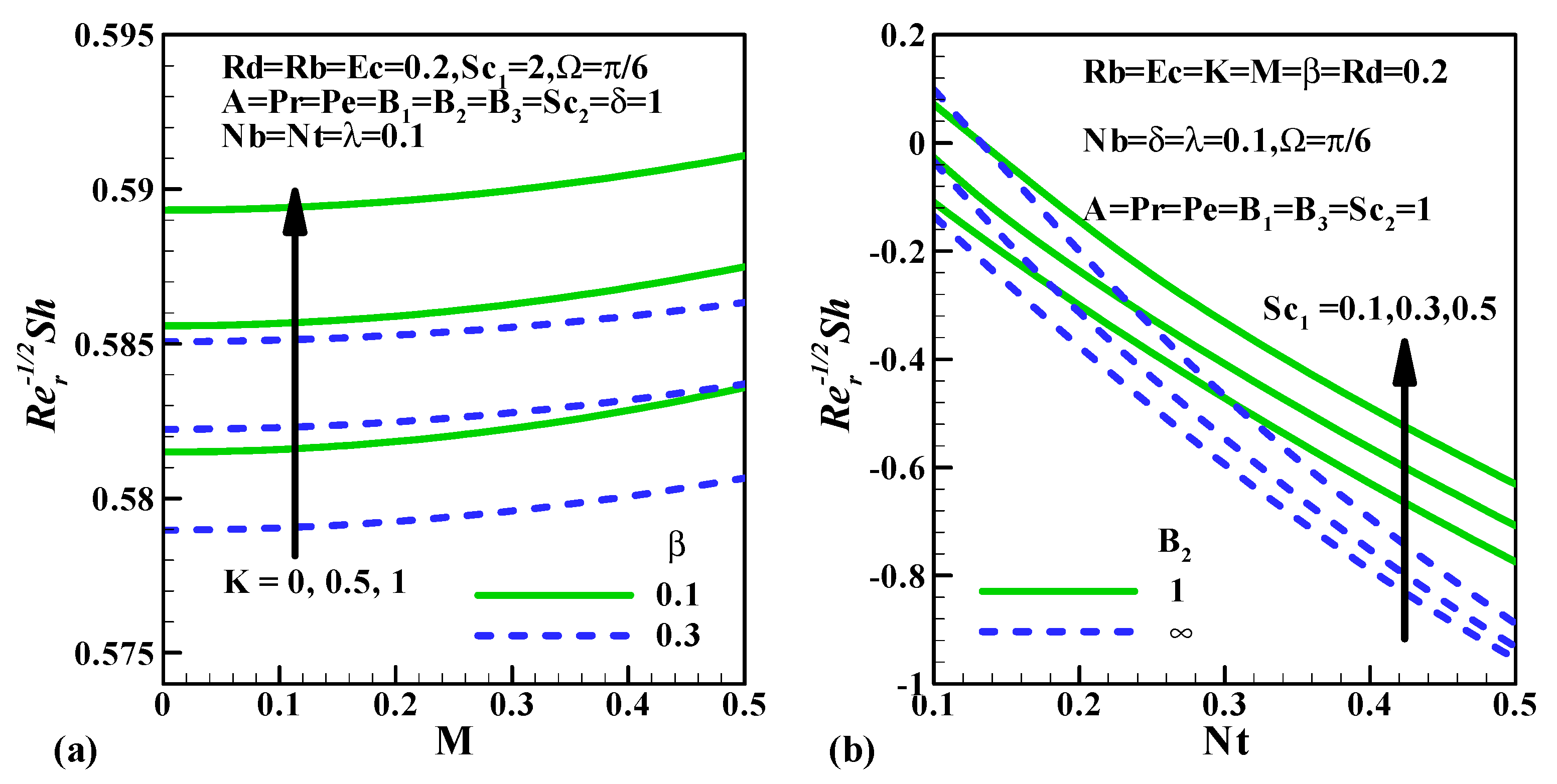

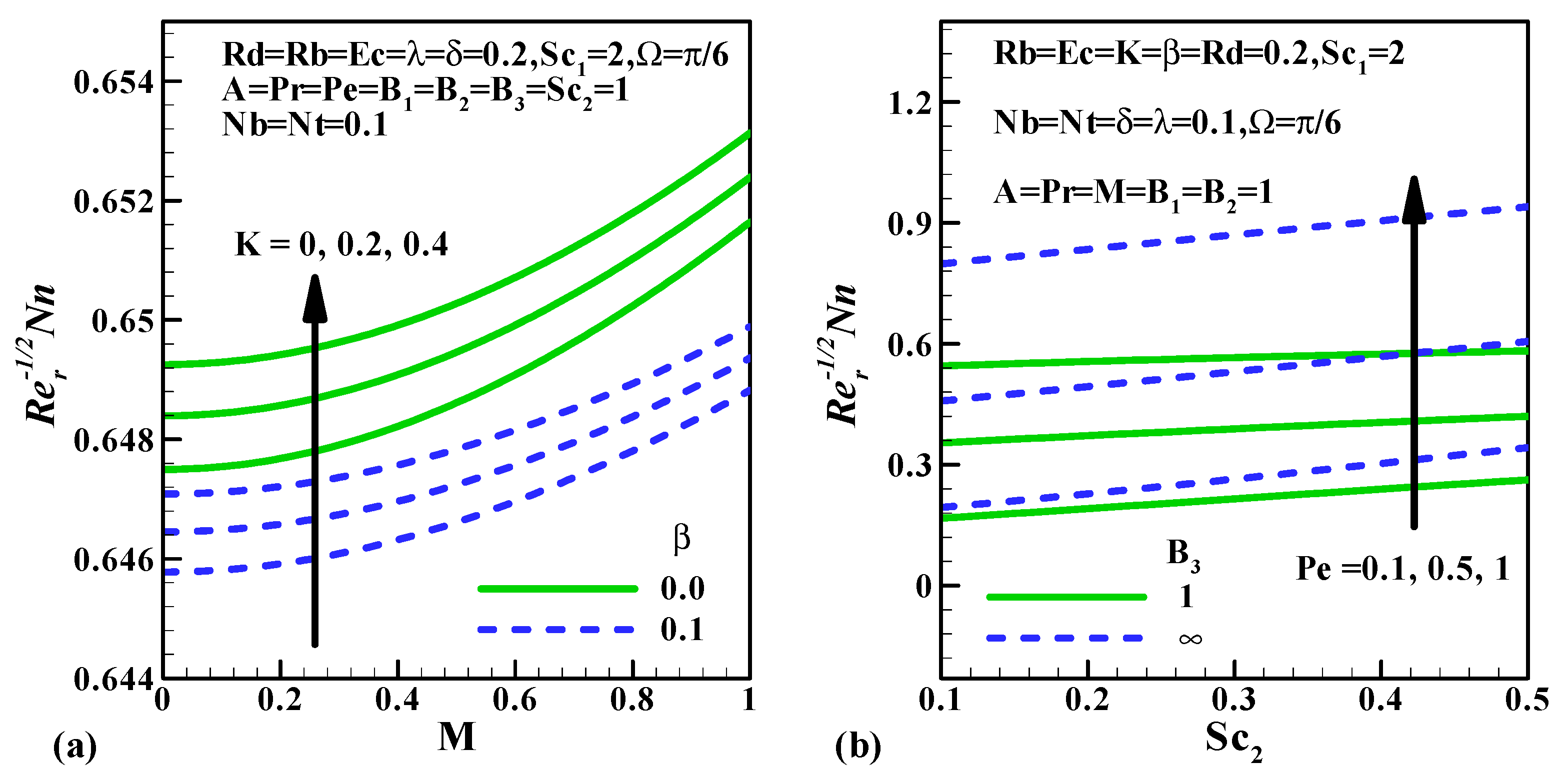

5.5. Skin Friction Coefficient, Nusselt Number, Sherwood Number and the Density Number of the Motile Microorganisms

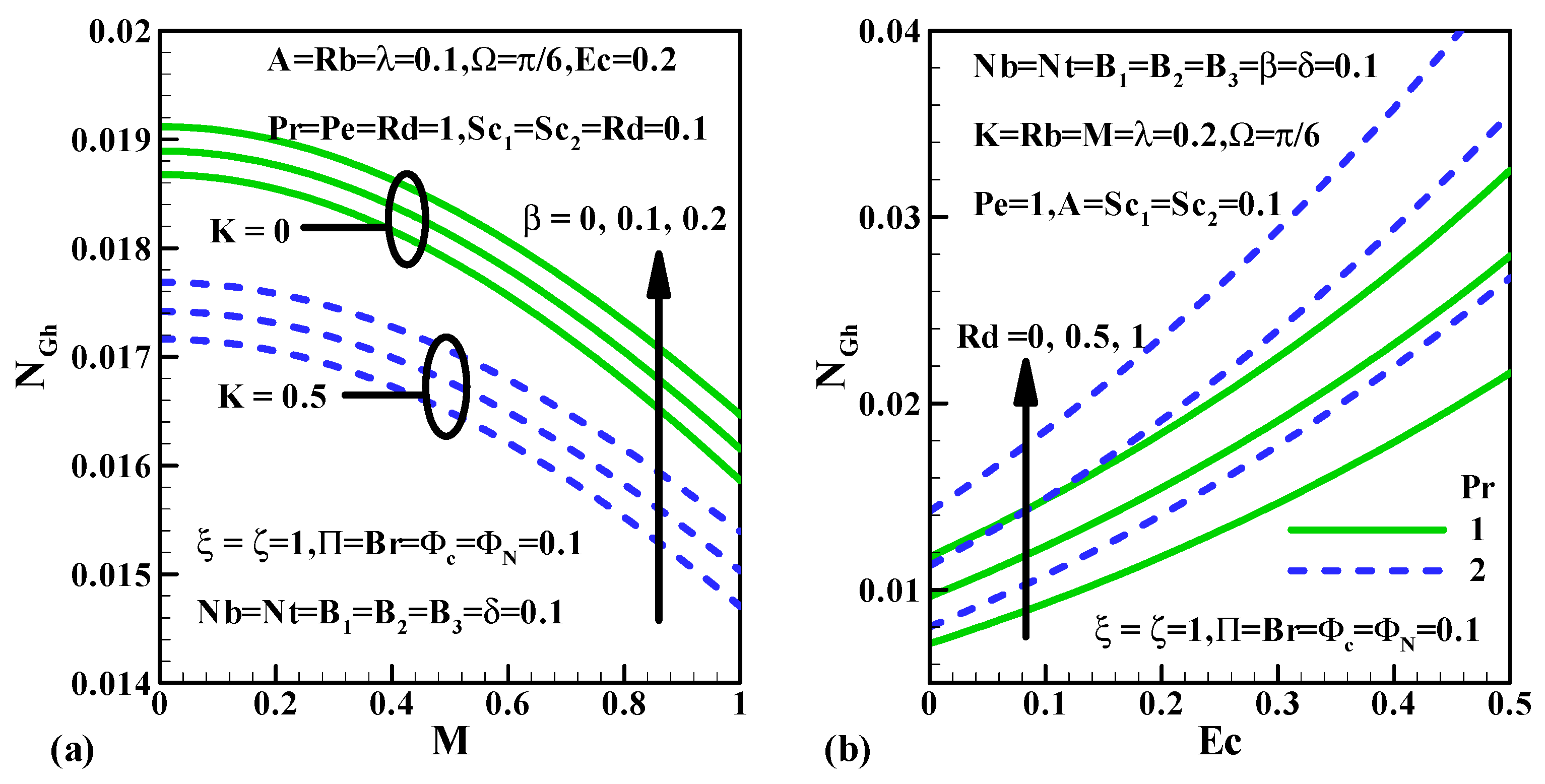

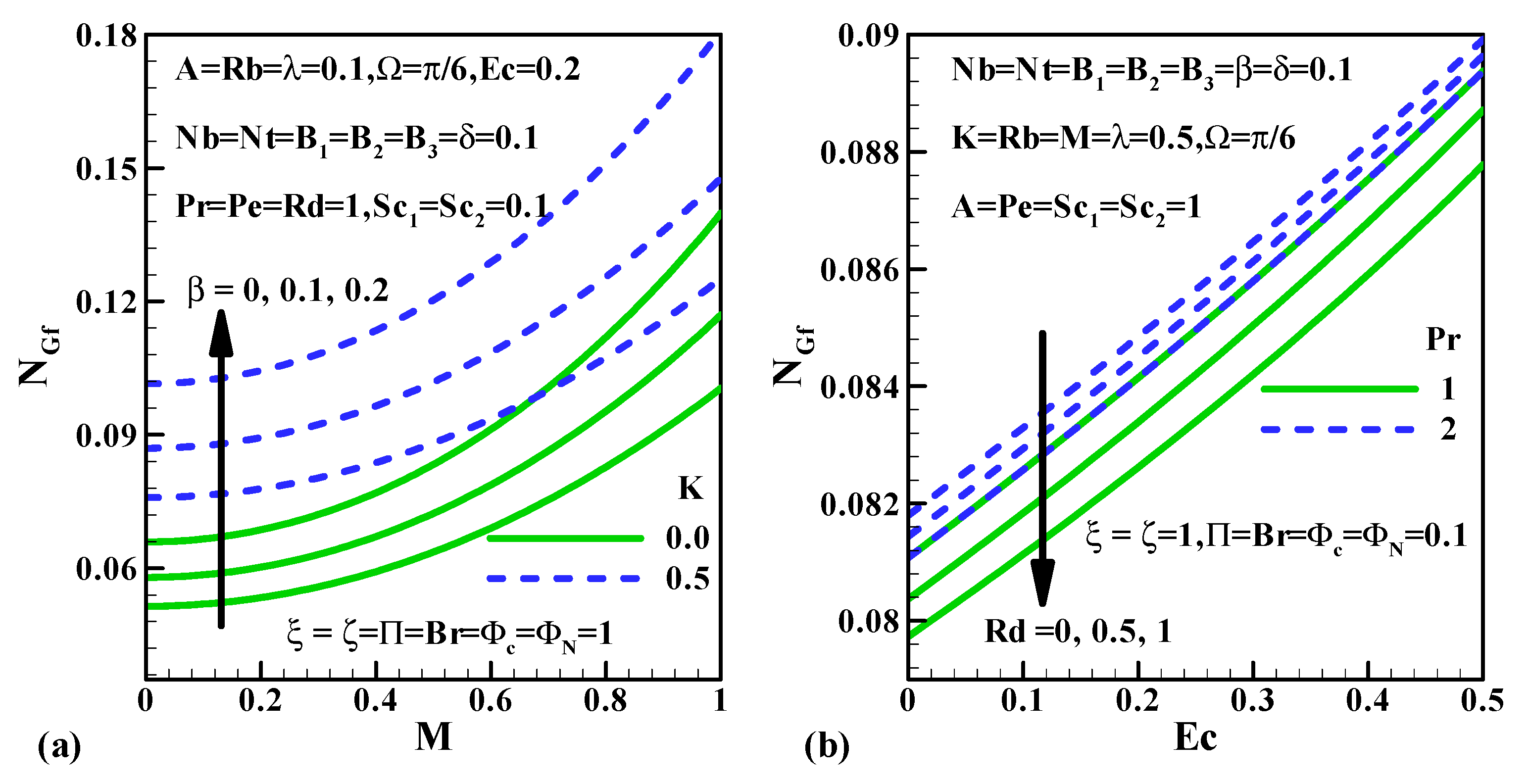

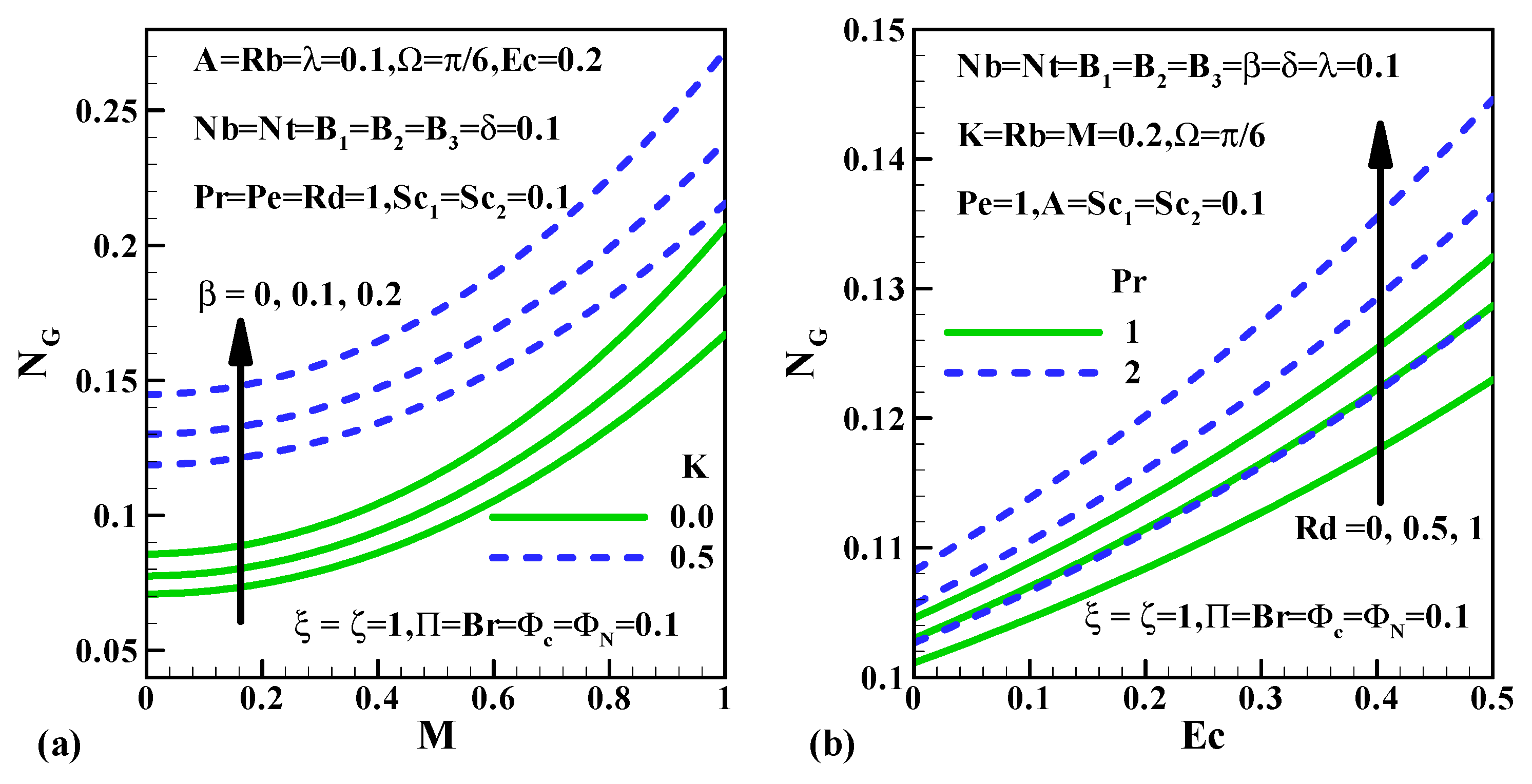

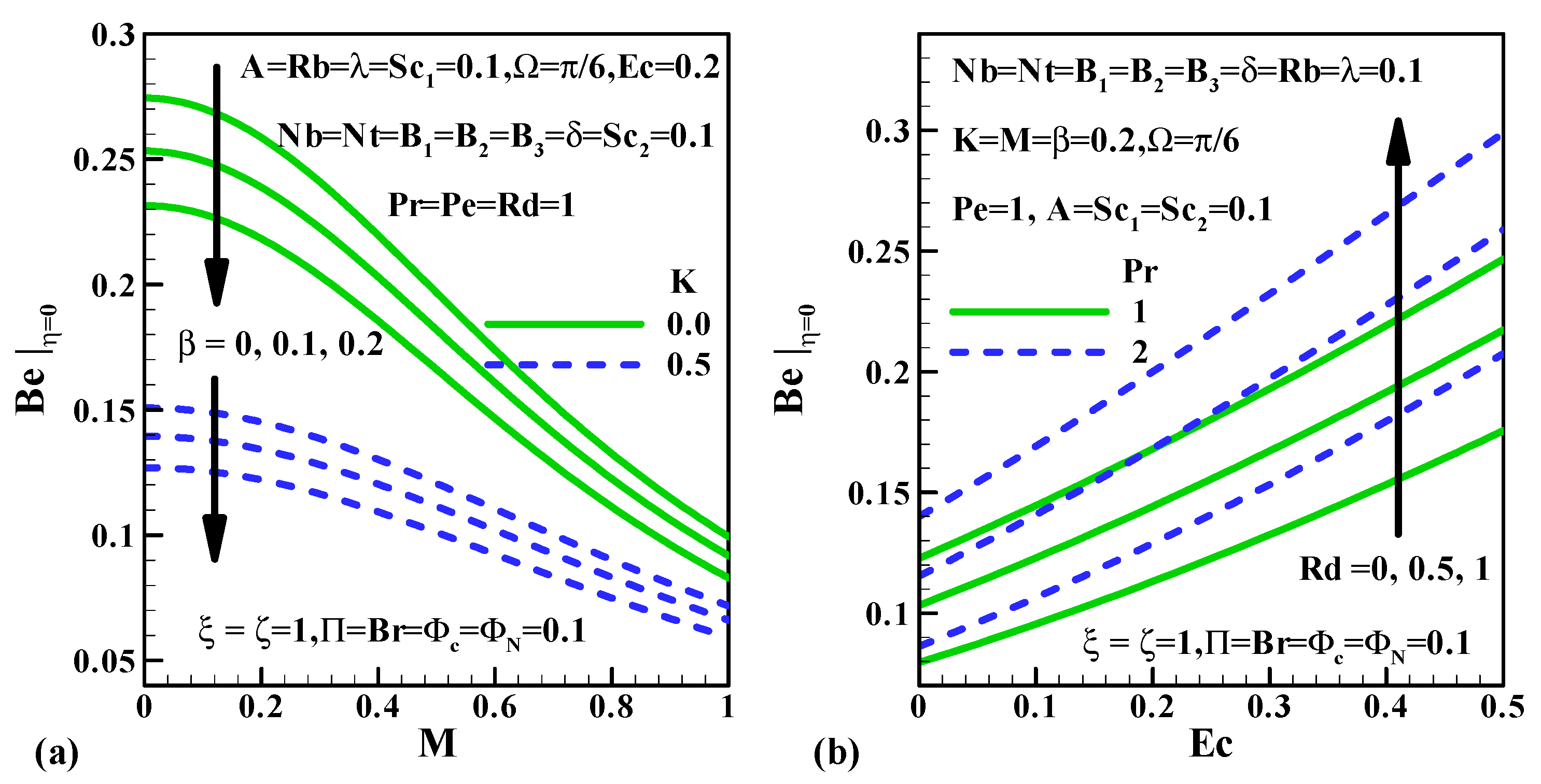

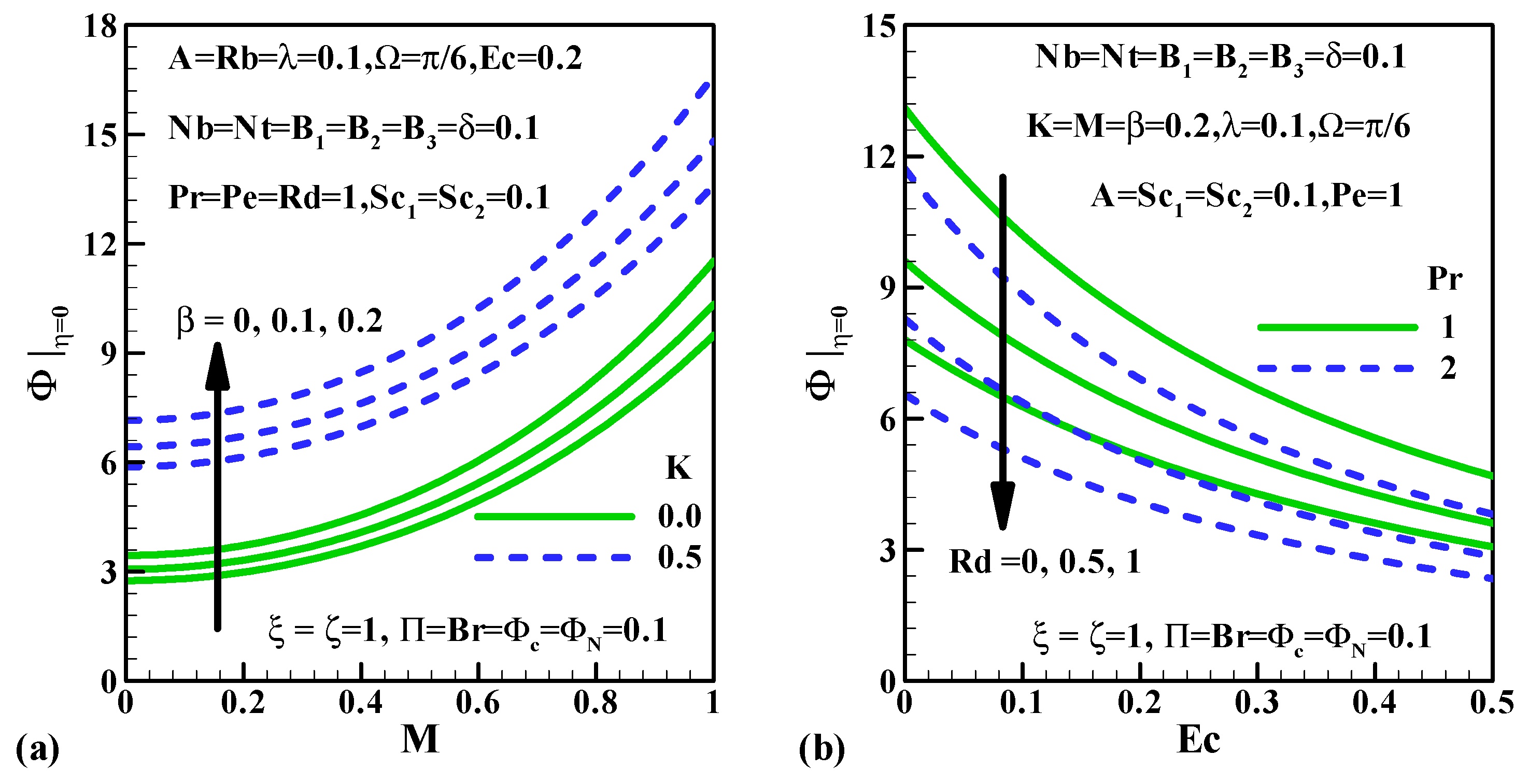

5.6. Entropy Generation, Bejan Number and Irreversibility Ratio

6. Conclusions

- ➢

- The escalation in values of declines the velocity gradient and improves the thermal and concentration gradients.

- ➢

- The inclination in radiation parameter improves the thermal gradient.

- ➢

- The rise in values of the Schmidt number declines the mass transfer characteristics but the converse trend is depicted for the boost up values of .

- ➢

- The escalating values of decline the thermal gradient.

- ➢

- The rise in values of and declines the microorganism density characteristics.

- ➢

- The inclination in and escalates the entropy generation rate.

- ➢

- The upsurge in declines the Bejan number and the irreversibility ratio but the converse trend is depicted in both the profiles for inclined values of .

- ➢

- The upsurge in declines the rate of heat transfer but the converse trend is depicted for inclined values of .

- ➢

- The escalation in increases the mass transfer rate but the converse trend is depicted for inclined values of .

- ➢

- The inclination in and improves the rate of a microorganism’s transfer.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| velocity components | average volume of a microorganisms | ||

| directions | chemotaxis constant | ||

| magnetic field strength | Fluid particle density | ||

| Sherwood number | Prandtl number | ||

| positive constant | Microorganisms density | ||

| concentration | local modified Grashof number | ||

| temperature of the fluid | surface concentration of microorganisms | ||

| fluid viscosity | Brownian diffusion coefficient | ||

| ambient nanoparticle concentration of microorganisms | motile microorganisms transfer coefficient | ||

| electrical conductivity | thermophoretic diffusion coefficient | ||

| acceleration due to gravity | diffusivity of microorganisms | ||

| coefficient of volumetric expansion | maximum speed of swimming cell | ||

| rate of chemical reaction | permeability of the porous medium | ||

| Porosity parameter | convective fluid temperature | ||

| ambient temperature | Brownian motion parameter | ||

| convective liquid concentration | ambient nanoparticle concentration | ||

| concentration density of microorganisms | bioconvection Rayleigh number | ||

| ratio of concentration to thermal buoyancy forces | thermal conductivity | ||

| magnetic field | convective heat transfer coefficient | ||

| convective mass transfer coefficient | skin friction | ||

| Rosseland mean spectral absorption coefficient | Stefan–Boltzmann radiation | ||

| Williamson parameter | magnetic field parameter | ||

| chemical reaction parameter | Schmidt number | ||

| mixed convection parameter | Eckert number | ||

| radiation parameter | Gas constant | ||

| thermophoresis parameter | local Grashof number | ||

| Biot number due to heat transfer | Biot number due to mass transfer | ||

| Biot number due to microorganism’s transfer | Schmidt number | ||

| bioconvection Schmidt number | nanoparticle Sherwood number | ||

| characteristic of entropy generation rate | dimensionless temperature difference | ||

| concentration difference | microorganism’s concentration difference | ||

| diffusive constant parameter via nanoparticles concentration | diffusive constant parameter via gyrotactic microorganism’s concentration | ||

| Brinkman number | Reynolds number | ||

| bioconvection Peclet number | Nusselt number |

References

- Eid, M.R.; Al-Hossainy, A.F. Synthesis, DFT calculations, and heat transfer performance large-surface TiO2: Ethylene glycol nanofluid and coolant applications. Eur. Phys. J. Plus 2020, 135, 596. [Google Scholar] [CrossRef]

- Eid, M.R. Thermal Characteristics of 3D Nanofluid Flow over a Convectively Heated Riga Surface in a Darcy–Forchheimer Porous Material with Linear Thermal Radiation: An Optimal Analysis. Arab. J. Sci. Eng. 2020, 45, 9803–9814. [Google Scholar] [CrossRef]

- Alaidrous, A.A.; Eid, M.R. 3-D electromagnetic radiative non-Newtonian nanofluid flow with Joule heating and higher-order reactions in porous materials. Sci. Rep. 2020, 10, 1–19. [Google Scholar] [CrossRef]

- Eid, M.R.; Al-Hossainy, A.F. Combined experimental thin film, DFT-TDDFT computational study, flow and heat transfer in [PG-MoS2/ZrO2]C hybrid nanofluid. Waves Random Complex Media 2021, 1–26. [Google Scholar] [CrossRef]

- Al-Hossainy, A.F.; Eid, M.R. Combined experimental thin films, TDDFT-DFT theoretical method, and spin effect on [PEG-H2O/ZrO2+MgO]h hybrid nanofluid flow with higher chemical rate. Surf. Interfaces 2021, 23, 100971. [Google Scholar] [CrossRef]

- Prasannakumara, B.C.; Gireesha, B.J.; Gorla, R.S.R.; Krishnamurthy, M.R. Effects of Chemical Reaction and Nonlinear Thermal Radiation on Williamson Nanofluid Slip Flow over a Stretching Sheet Embedded in a Porous Medium. J. Aerosp. Eng. 2016, 29, 04016019. [Google Scholar] [CrossRef]

- Mabood, F.; Ibrahim, S.M.; Lorenzini, G.; Lorenzini, E. Radiation effects on Williamson nanofluid flow over a heated surface with magnetohydrodynamics. Int. J. Heat Technol. 2017, 35, 196–204. [Google Scholar] [CrossRef]

- Rasool, G.; Zhang, T.; Chamkha, A.J.; Shafiq, A.; Tlili, I.; Shahzadi, G. Entropy Generation and Consequences of Binary Chemical Reaction on MHD Darcy–Forchheimer Williamson Nanofluid Flow over Non-Linearly Stretching Surface. Entropy 2019, 22, 18. [Google Scholar] [CrossRef]

- Haq, F.; Kadry, S.; Chu, Y.-M.; Khan, M. Modeling and theoretical analysis of gyrotactic microorganisms in radiated nanomaterial Williamson fluid with activation energy. J. Mater. Res. Technol. 2020, 9, 10468–10477. [Google Scholar] [CrossRef]

- Bejan, A. A Study of Entropy Generation in Fundamental Convective Heat Transfer. J. Heat Transf. 1979, 101, 718–725. [Google Scholar] [CrossRef]

- Yusuf, T.A.; Adesanya, S.O.; Gbadeyan, J.A. Entropy generation in MHD Williamson nanofluid over a convectively heated stretching plate with chemical reaction. Heat Transf. 2020, 49, 1982–1999. [Google Scholar] [CrossRef]

- Azam, M.; Mabood, F.; Xu, T.; Waly, M.; Tlili, I. Entropy optimized radiative heat transportation in axisymmetric flow of Williamson nanofluid with activation energy. Results Phys. 2020, 19, 103576. [Google Scholar] [CrossRef]

- Bhatti, M.M.; Riaz, A.; Zhang, L.; Sait, S.M.; Ellahi, R. Biologically inspired thermal transport on the rheology of Williamson hydromagnetic nanofluid flow with convection: An entropy analysis. J. Therm. Anal. Calorim. 2020, 1–16. [Google Scholar] [CrossRef]

- Waqas, S.H.; Khan, S.U.; Imran, M.; Bhatti, M.M. Thermally developed Falkner–Skan bioconvection flow of a magnetized nanofluid in the presence of a motile gyrotactic microorganism: Buongiorno’s nanofluid model. Phys. Scr. 2019, 94, 115304. [Google Scholar] [CrossRef]

- Khan, S.U.; Shehzad, S.A.; Ali, N. Bioconvection flow of magnetized Williamson nanoliquid with motile organisms and variable thermal conductivity. Appl. Nanosci. 2020, 10, 3325–3336. [Google Scholar] [CrossRef]

- Hayat, T.; Bashir, Z.; Qayyum, S.; Alsaedi, A. Nonlinear radiative flow of nanofluid in presence of gyrotactic microorganisms and magnetohydrodynamic. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 3039–3055. [Google Scholar] [CrossRef]

- Jayadevamurthy, P.G.R.; Rangaswamy, N.K.; Prasannakumara, B.C.; Nisar, K.S. Emphasis on unsteady dynamics of bioconvective hybrid nanofluid flow over an upward–downward moving rotating disk. Numer. Methods Partial. Differ. Eq. 2020. [Google Scholar] [CrossRef]

- Hosseinzadeh, K.; Gholinia, M.; Jafari, B.; Ghanbarpour, A.; Olfian, H.; Ganji, D.D. Nonlinear thermal radiation and chemical reaction effects on Maxwell fluid flow with convectively heated plate in a porous medium. Heat Transf. Asian Res. 2019, 48, 744–759. [Google Scholar] [CrossRef]

- Dogonchi, A.S.; Waqas, M.; Seyyedi, S.M.; Hashemi-Tilehnoee, M.; Ganji, D.D. Numerical simulation for thermal radiation and porous medium characteristics in flow of CuO-H2O nanofluid. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 249. [Google Scholar] [CrossRef]

- Yusuf, T.; Mabood, F.; Khan, W.; Gbadeyan, J. Irreversibility analysis of Cu-TiO2-H2O hybrid-nanofluid impinging on a 3-D stretching sheet in a porous medium with nonlinear radiation: Darcy-Forchhiemer’s model. Alex. Eng. J. 2020, 59, 5247–5261. [Google Scholar] [CrossRef]

- Shehzad, S.; Reddy, M.G.; Vijayakumari, P.; Tlili, I. Behavior of ferromagnetic Fe2SO4 and titanium alloy Ti6Al4v nanoparticles in micropolar fluid flow. Int. Commun. Heat Mass Transf. 2020, 117, 104769. [Google Scholar] [CrossRef]

- Khan, M.I.; Alzahrani, F.; Hobiny, A.; Ali, Z. Estimation of entropy generation in Carreau-Yasuda fluid flow using chemical reaction with activation energy. J. Mater. Res. Technol. 2020, 9, 9951–9964. [Google Scholar] [CrossRef]

- Khan, M.I.; Alsaedi, A.; Hayat, T. Entropy generation optimization in flow of non-Newtonian nanomaterial with binary chemical reaction and Arrhenius activation energy. Phys. A Stat. Mech. Its Appl. 2020, 538, 122806. [Google Scholar] [CrossRef]

- Khan, M.I.; Khan, S.A.; Hayat, T.; Qayyum, S.; Alsaedi, A. Entropy generation analysis in MHD flow of viscous fluid by a curved stretching surface with cubic autocatalysis chemical reaction. Eur. Phys. J. Plus 2020, 135, 249. [Google Scholar] [CrossRef]

- Alsaadi, F.E.; Hayat, T.; Khan, S.A.; Alsaadi, F.E.; Khan, M.I. Investigation of physical aspects of cubic autocatalytic chemically reactive flow of second grade nanomaterial with entropy optimization. Comput. Methods Programs Biomed. 2020, 183, 105061. [Google Scholar] [CrossRef] [PubMed]

- Kotresh, M.J.; Ramesh, G.K.; Shashikala, V.K.R.; Prasannakumara, B.C. Assessment of Arrhenius activation energy in stretched flow of nanofluid over a rotating disc. Heat Transf. 2020. [Google Scholar] [CrossRef]

- Nadeem, S.; Hussain, S.T.; Lee, C. Flow of a Williamson fluid over a stretching sheet. Braz. J. Chem. Eng. 2013, 30, 619–625. [Google Scholar] [CrossRef]

- Mabood, F.; Das, K. Melting heat transfer on hydromagnetic flow of a nanofluid over a stretching sheet with radiation and second-order slip. Eur. Phys. J. Plus 2016, 131, 1–12. [Google Scholar] [CrossRef]

| 0 | 1 | 5 | 10 | 50 | 100 | 500 | |

|---|---|---|---|---|---|---|---|

| Mabood & Das [28] | 1.000008 | −1.4142135 | −2.4494897 | −3.3166247 | −7.1414284 | −10.049875 | −22.383029 |

| Present results | 1.00000 | −1.4142136 | −2.4494897 | −3.3166247 | −7.1414284 | −10.049876 | −22.383029 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yusuf, T.A.; Mabood, F.; Prasannakumara, B.C.; Sarris, I.E. Magneto-Bioconvection Flow of Williamson Nanofluid over an Inclined Plate with Gyrotactic Microorganisms and Entropy Generation. Fluids 2021, 6, 109. https://doi.org/10.3390/fluids6030109

Yusuf TA, Mabood F, Prasannakumara BC, Sarris IE. Magneto-Bioconvection Flow of Williamson Nanofluid over an Inclined Plate with Gyrotactic Microorganisms and Entropy Generation. Fluids. 2021; 6(3):109. https://doi.org/10.3390/fluids6030109

Chicago/Turabian StyleYusuf, Tunde A., Fazle Mabood, B. C. Prasannakumara, and Ioannis E. Sarris. 2021. "Magneto-Bioconvection Flow of Williamson Nanofluid over an Inclined Plate with Gyrotactic Microorganisms and Entropy Generation" Fluids 6, no. 3: 109. https://doi.org/10.3390/fluids6030109

APA StyleYusuf, T. A., Mabood, F., Prasannakumara, B. C., & Sarris, I. E. (2021). Magneto-Bioconvection Flow of Williamson Nanofluid over an Inclined Plate with Gyrotactic Microorganisms and Entropy Generation. Fluids, 6(3), 109. https://doi.org/10.3390/fluids6030109