3.1. Mechanical and Dynamic Results

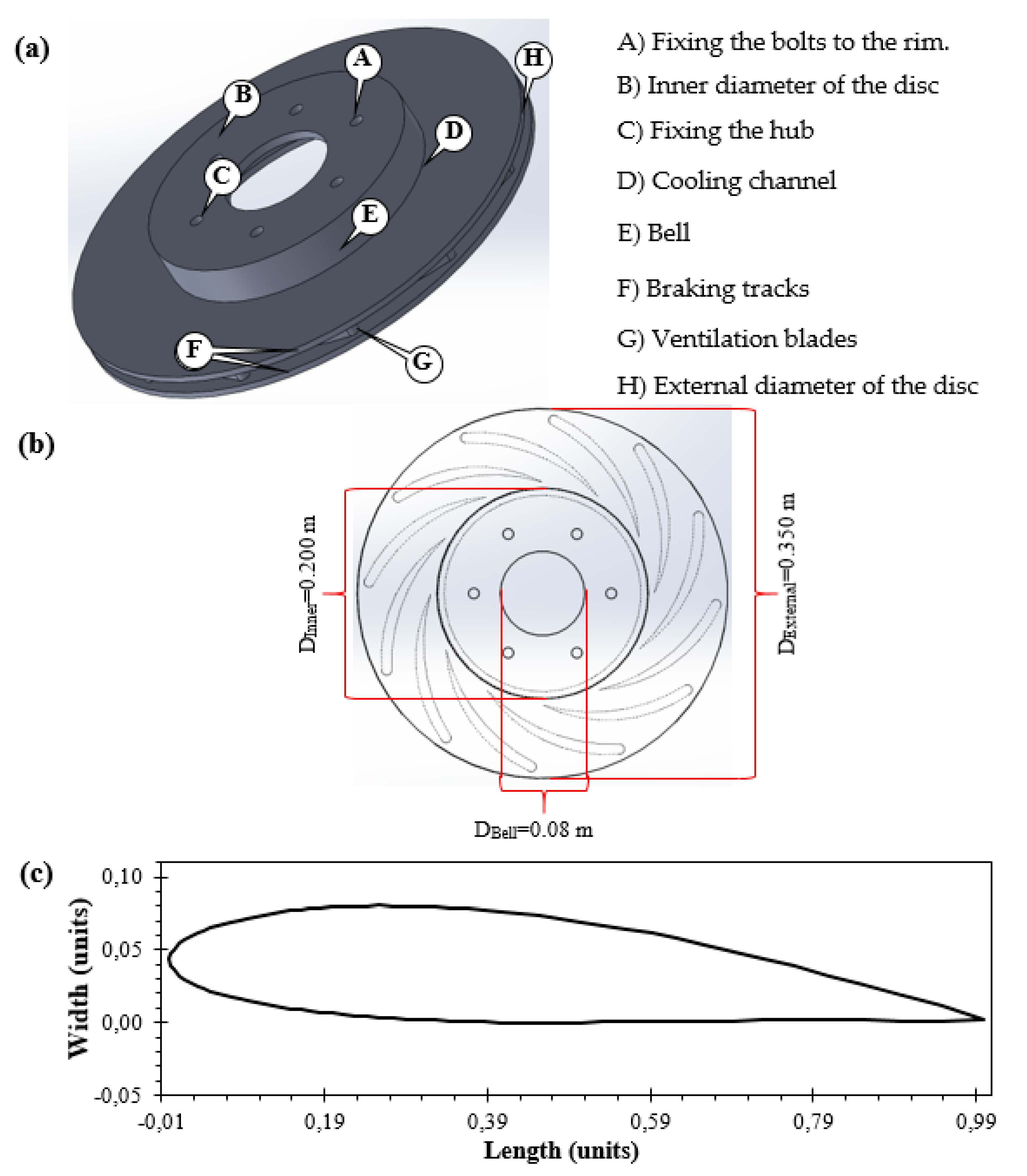

Table 6 presents the most relevant parameters and dimensions of the disc brake analyzed, such as rolling coefficient, rolling resistance, maximum braking deceleration, braking force, pedal force, peripheral disc speed, the contact area between the pad and disc, and braking performance. Notice that the deceleration is constant for the disc analyzed concerning the speed for each angle of descent (θ, theta). It was observed that the vehicle braking deceleration as to the angle of descent increases, the decelerations increase because the gravitational resistance increases, considering that, in this particular case, it is also a propelling force. It is important to mention that the results of the Equations presented in

Table 6 were used to develop 2D maps, considering Equations (13), (17), and (18) under different braking operating conditions.

Currently, in many cases, the driver could not exert enough force to stop the vehicle at the ideal distance; therefore, the force is multiplied using levers or hydraulic circuits, thus obtaining a greater friction force. During real braking conditions, the maximum braking force on all four wheels of the vehicle is difficult to achieve simultaneously due to the weight distribution on the vehicle (passengers, road incline, undulations) being variable. This action determines its limit of adhesion, which varies dynamically during the braking process. The weight distribution on the wheels is too variable, and the operating conditions change every fraction of a second.

Notice that maximum deceleration (a

Max) for a vehicle inclination angle of θ = 0 is equal to 8.3385, where, compared with the calculating in Equation (12), there is a difference of 0.981 when it is determined that the deceleration fulfills each condition of descent during the sliding. The value of a

Max is exceeded when the angle reaches a value of the inclination angle of θ = 10, considering that it is the negative variation in the speed; that is, the physical magnitude that expresses the passage of a moving body from one speed to another with lower speed, always following the same path. These results are similar to those reported by [

38]. However, it is possible to determine the adhesion coefficient (μ) mathematically for a dry road with an average speed of 100 km/h at 27 °C, where for a new tire under dry and wet conditions, the μ value will be 0.80. On the other hand, it was observed that the braking force of a braking system for a vehicle that circulates on a dry concrete or asphalt surface, at different masses, and with a rolling resistance coefficient of 0.015.

The braking efficiency is the magnitude of the braking system performance, where the vehicle must stop at a required time and distance, according to the operating conditions and the force applied on the brake pedal; in this way, the effectiveness of the braking system is considered to reach 100% when the measured deceleration is equal to the acceleration due to gravity. From

Figure 2, it was observed that when the inclination angle and speed difference increased, the braking system required more energy power to be dissipated (red areas), with values around 930,003.35 to 510,794.44 W. On the other hand, lesser H values were found for speed difference values of 5 m/s for all ranges of inclination angles with values around 102,085.31 to 185,866.71 W product, with less energy to dissipate according to the speed that the vehicle had (green areas). Notice that a light increase is evidenced when the inclination degree is more than 10, with severe power dissipating energy at a high sliding speed of the vehicle as a product of the kinetic energy.

As is observed in

Figure 3, considering the calculations developed using Equation (17), the braking time increased with speed and decreased with the angle of descent, with present values around 0.65 to 1.73 s. However, high values were found at high speed and high inclination angle with values around 4.72 to 8.67 s. This behavior is due to more inclination angle; the vehicle needs more energy to dissipate the energy that generates during movement. Therefore, for this calculation, the reaction time of the driver t

RC is not considered, which is the time that arises from when there is an unforeseen circumstance until the driver acts on the brake pedal; the value varies between 0.5 and 2.0 s. In addition, the reaction time of the t

RS system is not considered, which is the time that elapses from when the brake pedal is actuated until the required force is achieved; this is an approximate value of 3 s. On the other hand, the aerodynamic actions are not considered since the aerodynamic resistance affects the vehicle from more than 90–100 km/h.

The braking distance is an important parameter to design brake discs due to the safety and performance during the braking process. This dynamic parameter is the time that the driver delays when performing this process (this assumption was not considered in the calculation). The drivers should always maintain a safe distance between the front vehicle, considering that it may generate severe braking. To calculate this dynamic parameter is important to consider the speed during the vehicle motion, which depends on many parameters such as vehicle mass, road condition, tires quality, disc brake type, pad type, and others. According to [

38], the phase of effective braking occurs during the phase of settled braking without wheels locked, resulting in high deceleration values at the constant braking phase and the end, where at the same time, this variable increases with the initial sliding speed of the vehicle. However, the results from the mathematical calculations in this study indicated that inclination angle exhibits deceleration values from 7.358 to 10.712 for 0 and 20 theta (θ) degrees, respectively, which is influenced mainly by the braking force and vehicle mass. These results are similar to those reported by [

9,

39].

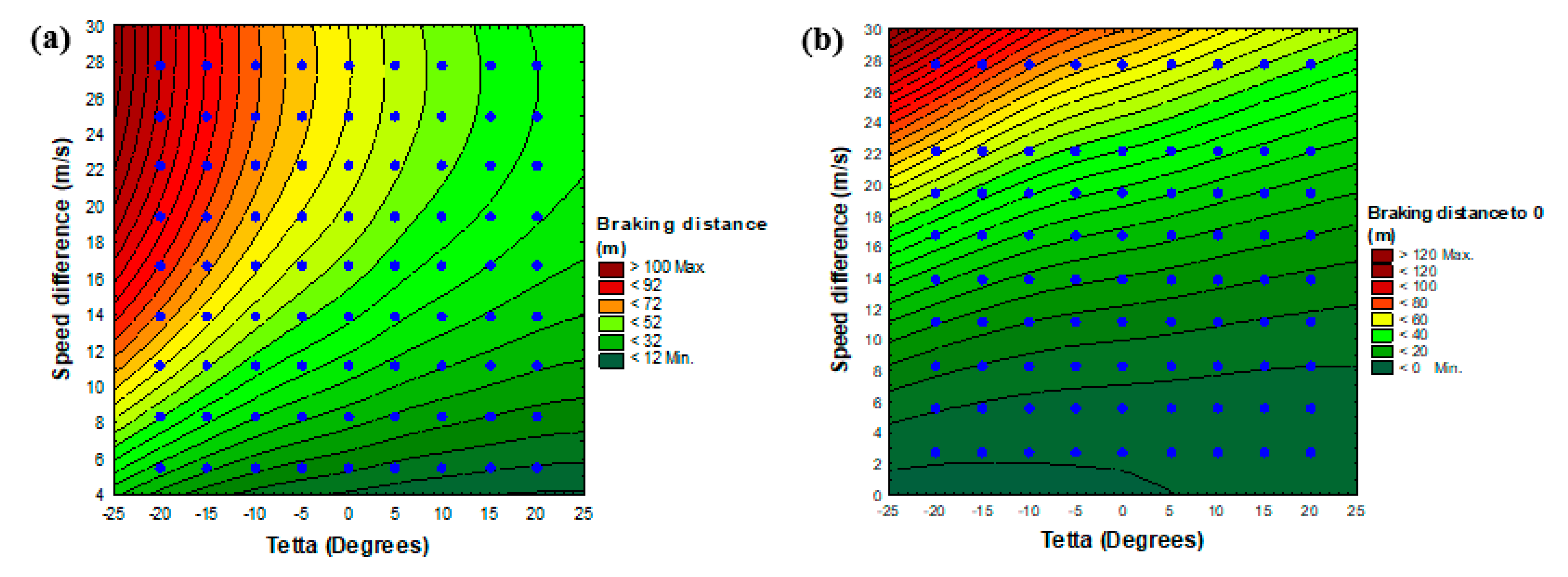

The braking distance was calculated, as is shown in

Figure 4 using Equation (18).

Figure 4a shows a high pronunciation value of braking distance when the inclination angle increases in a negative way (0 to −20) influenced by the increase in the speed difference of more than 10 m/s that change with positive values of inclination angle, thus obtaining a total braking distance of around 63.85 to 114.96 m (red areas) and 40.15 to 22.60 m (green areas).

Figure 4b shows the behavior of the braking distance to decelerate the vehicle until cero. Notice that the braking distance behavior is less than a gradual with speed difference, where a maximum braking distance reach values of around 44.20 to 114.96 m (red areas), which appears from a speed difference of more than 22 m/s for the inclination angles in a negative way (0 to −20), for the remaining 2D map green areas dominate with values around 0.45 to 31.70 m. Moreover, from

Figure 4b, blue mathematical points calculated are not presented for 25 m/s because of the assumptions shown in

Table 2 for the operating conditions of the disc brake.

The braking progression is a mechanical process where the physical and kinetic energy act considering the mass and speed with the vehicle moves. When braking in a progressive way, the energy turns into heat and disappears by the braking action. In the opposite case, when severely braking, the energy is absorbed by the vehicle and the occupants; thus, the bodily injury gravity increase by the speed when the braking.

3.2. Thermal Results

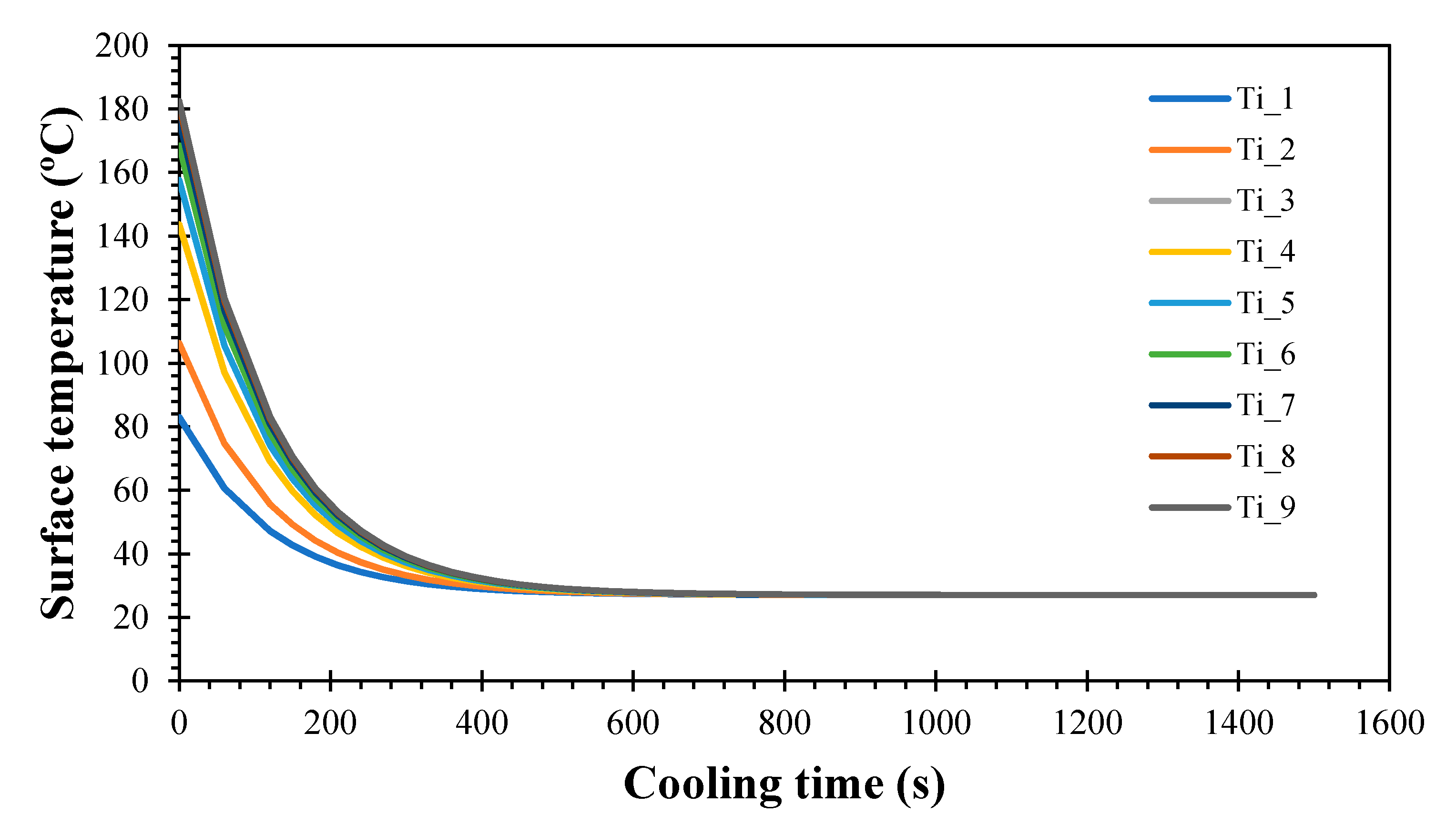

Table 7 summarized the main thermal variables calculated in terms of energy for the disc brake with N-38 type ventilation blades, obtaining values similar to those reported by [

40,

41]. By considering Equation (15), it was possible to obtain the instantaneous temperature on the surface of the disc brake; thus, Equation (16) was used to obtain the cooling time considering Newton’s law under natural convection (that is, the air in the environment must have a speed equal to zero [

1,

15,

42]) under intervals of 100 s. Notice that natural convection during cooling is the addition of the convection in the bell and the periphery of the disc brake, considering the assumptions previously mentioned for the mathematical calculations. It is important to mention that the dissipation heat is influenced by the geometry and material of the disc brake (a big disc brake provides quick heat dissipation and performance of the braking process). Different operating conditions (mass, speed, and roadway conditions) of the vehicle affect the braking system’s performance, and thus energy and temperature values of the disc brake [

34]. Notice that the instantaneous temperature increases (182.48 °C) according to the speed difference increase due to the braking system’s need to dissipate kinetic energy in heat (tribological behavior). This behavior causes an increase in the temperature in contrast when the deceleration is minor (82.94 °C) relative to the speed difference.

The disc brake reaches an ambient temperature of 27 °C in around 10 min (800 s) after being subjected to the different temperatures on the surface of the braking track during the friction process between the disc and the pad (See

Figure 5). In most cases, the heat dissipation is more pronounced according to the surface temperature; thus, the sliding speed provides a significant influence on the disc brake temperature on the surface by tribological contact. When the temperature differential increases, the surface temperature also increases. Therefore, the final shock generated on the disc’s surface is greater, so performance is compromised during the braking process due to abrupt temperature changes when disc brake cooling is carried out in less than 800 s. According to [

19], the temperature on the disc increase conforms to an increase in the vehicle’s sliding motion.

The speed of the vehicle influences the kinetic energy that is generated during the movement. It does not affect it linearly but increases its value exponentially. This means that a vehicle of the same weight but twice the speed of another vehicle does not require double braking force to stop the vehicle, but rather it requires four times more force. Therefore, the stopping distance will be longer, as long as the vehicle rides on a flat road [

43,

44]. On the other hand, the material of the brake pad influences the thermodynamic properties of the disc brake and thus causes an increase in temperature. However, the disc brake material, geometry, and the configuration of the blades are relevant factors in the heat dissipation to the environment; they affect the useful life of the brake pads components of the braking system [

30].