3.1. Modeling of the Continous Phase

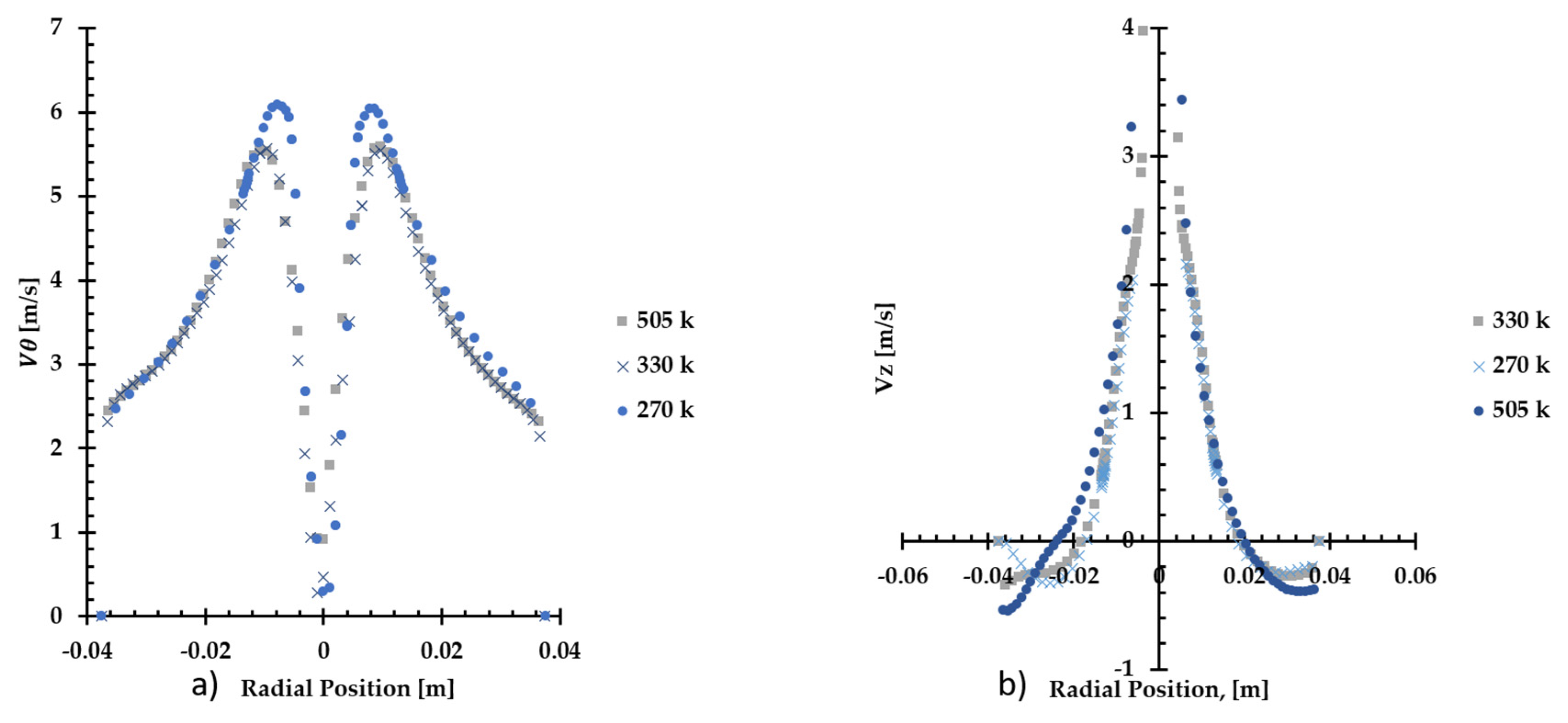

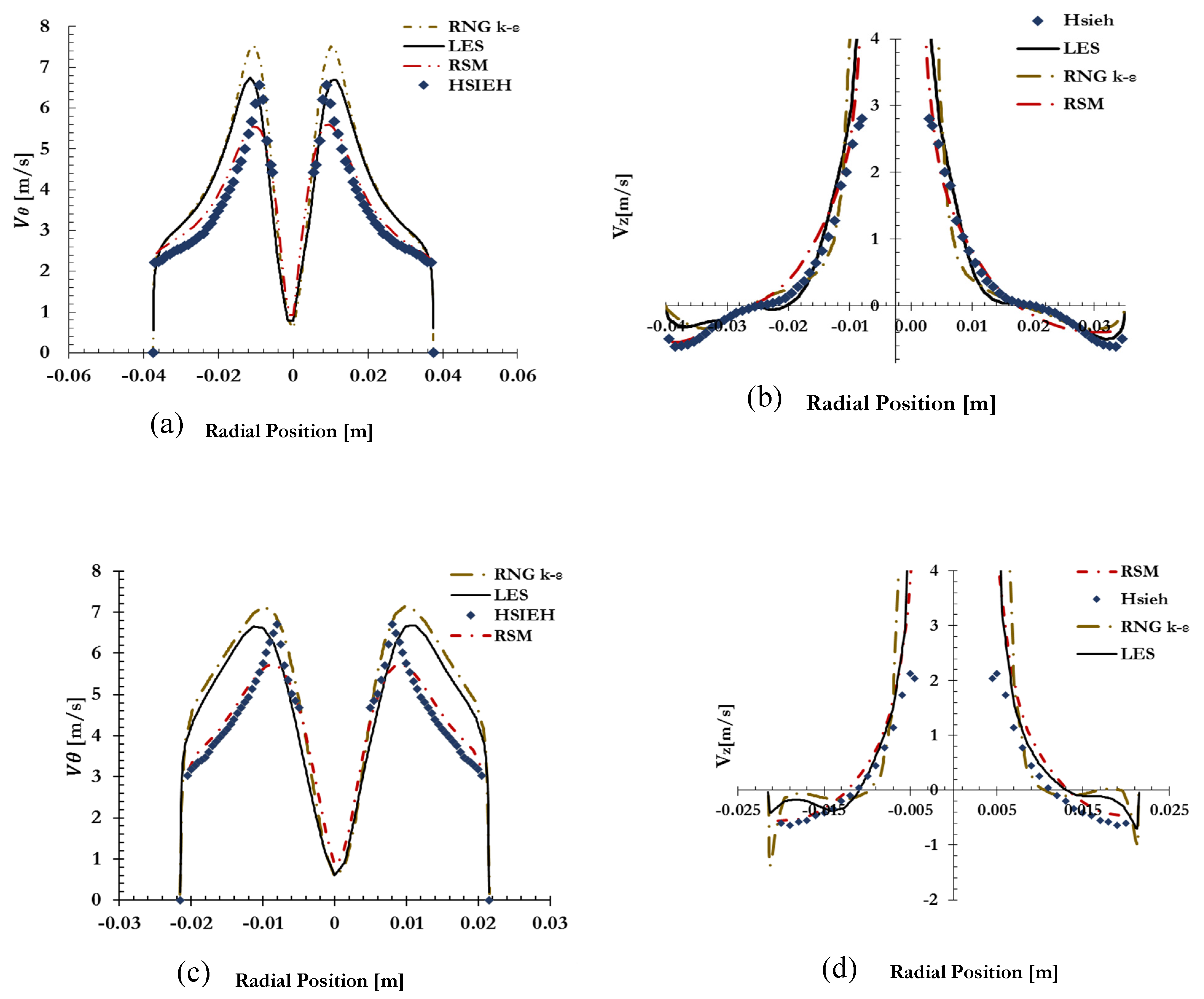

In order to assess the performance of the computational model developed in this study, the experimental data published by Hsieh was used to validate the results. There are two different axial positions at which experimental data is available, 60 mm and 120 mm from the top of the cylinder of the hydrocyclone. The tangential and axial velocity profiles are analyzed at both locations.

Figure 5a,c show the tangential velocity profiles at the 60 mm and 120 mm locations, respectively. While all models accurately predict the tangential velocity profile in the central forced vortex, both RNG k-

ε and LES have difficulties in the free vortex region closer to the walls where the velocity is overestimated by these models. At both locations, the LES model is better at predicting the peak velocity, although its radial position is slightly offset. RSM underpredicts the peak velocity, while RNG k-

ε overpredicts it at both locations.

The axial velocity profiles, shown in

Figure 5b,d, show relatively good agreement between all models and the experimental data, although both RNG k

-ε and LES present some disagreement in the free vortex region closer to the wall.

The RSM model is part of the RANS family of turbulence models. In such models, the turbulent viscosity tends to diffuse the most pronounced velocity peaks, which might help explain the observed results. Although the RNG k-ε model was not expected to predict flow characteristics so accurately, this model combined with the higher than normal swirl factor constant () yields good results.

LES accurately predicts values of the tangential velocity (within 2.86% compared to Hsieh) in the forced vortex region, including the peak velocity. Nevertheless, it was observed that LES overestimates the values of tangential velocity in the free vortex region closer to the wall. As for the axial velocity profiles, LES also has some problems closer to the wall. These results suggest that a finer mesh might be required in order to accurately capture the flow hydrodynamics near the wall when using a fixed Smagorinsky constant model.

Nevertheless, the mesh used in this work is finer than that used in previous works [

3,

6], where better results were obtained for the velocity profile at the free vortex region. A possible explanation is that for values of y

+ ranging from 40 to 100 (as in previous works), the inertial sublayer is well described by the logarithmic law of the wall [

14], as usually used in Ansys Fluent for this range of values of y

+. The y

+ value of 20 falls into the buffer layer, for which such law of the wall might not be adequate. A finer grid might have been needed to improve the model.

On the other hand, it is worth pointing out that studies such as Rudolf [

22] are consistent with the results of this work in which LES overestimates the velocity in the free vortex region. This indicates that trying to describe the hydrodynamics behavior of hydrocyclones using the LES model is not recommended unless using a finer mesh, which is expensive in terms of computational cost.

The pressure contours predicted by the different models are shown in

Figure 6.

Table 4 presents the net pressure drop calculated for each model, showing differences of 2.3%, 16.0%, and 1.9%, respectively, for RNG k-

ε, RMS, and LES. By comparing with results from [

4], it can be seen that high values of pressure drop are correlated with the gradient of the tangential velocity in the radial direction. This relation can be explained by the pressure gradients equalizing the centrifugal forces in the flow. The higher the pressure gradients, the higher the velocity gradient.

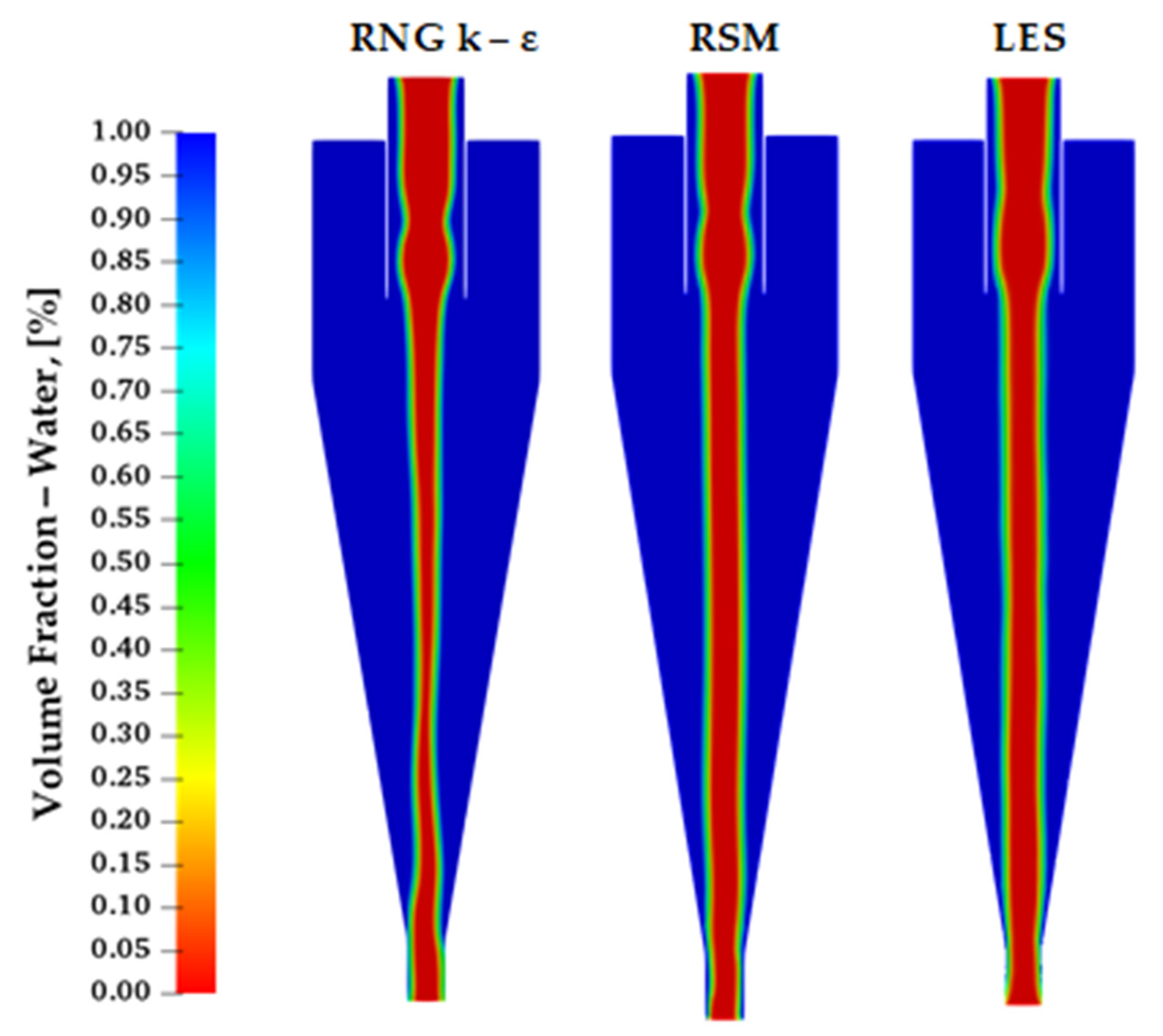

Air core diameter and the water split ratio are the last two factors to be validated for each turbulence model.

Figure 7 shows that the three models can predict the formation of the air core. The RNG k-

ε turbulence model accurately predicts this phenomenon, although no study mentions it previously.

Table 4 quantitatively summarizes these results. The air core diameter is better predicted by RSM and LES, while the water split ratio is better predicted by RSM. For the purpose of iteratively improving the design of the hydrocyclones, it was found that RSM is the best model, as it accurately predicts the main variables, while maintaining a relatively low computational cost. Therefore, this model will be implemented for particle tracking and the exploration of new geometric hydrocyclone designs.

Table 4 summarizes the results of the validation of turbulence models for the continuous phase.

3.2. Modeling of a Discrete Phase

The discrete phase validation was executed in a steady state from the Ansys© Fluent

® post-processor. One-way coupling with Lagrangian particle tracking was implemented given the low concentration of particles (4.88 wt%).

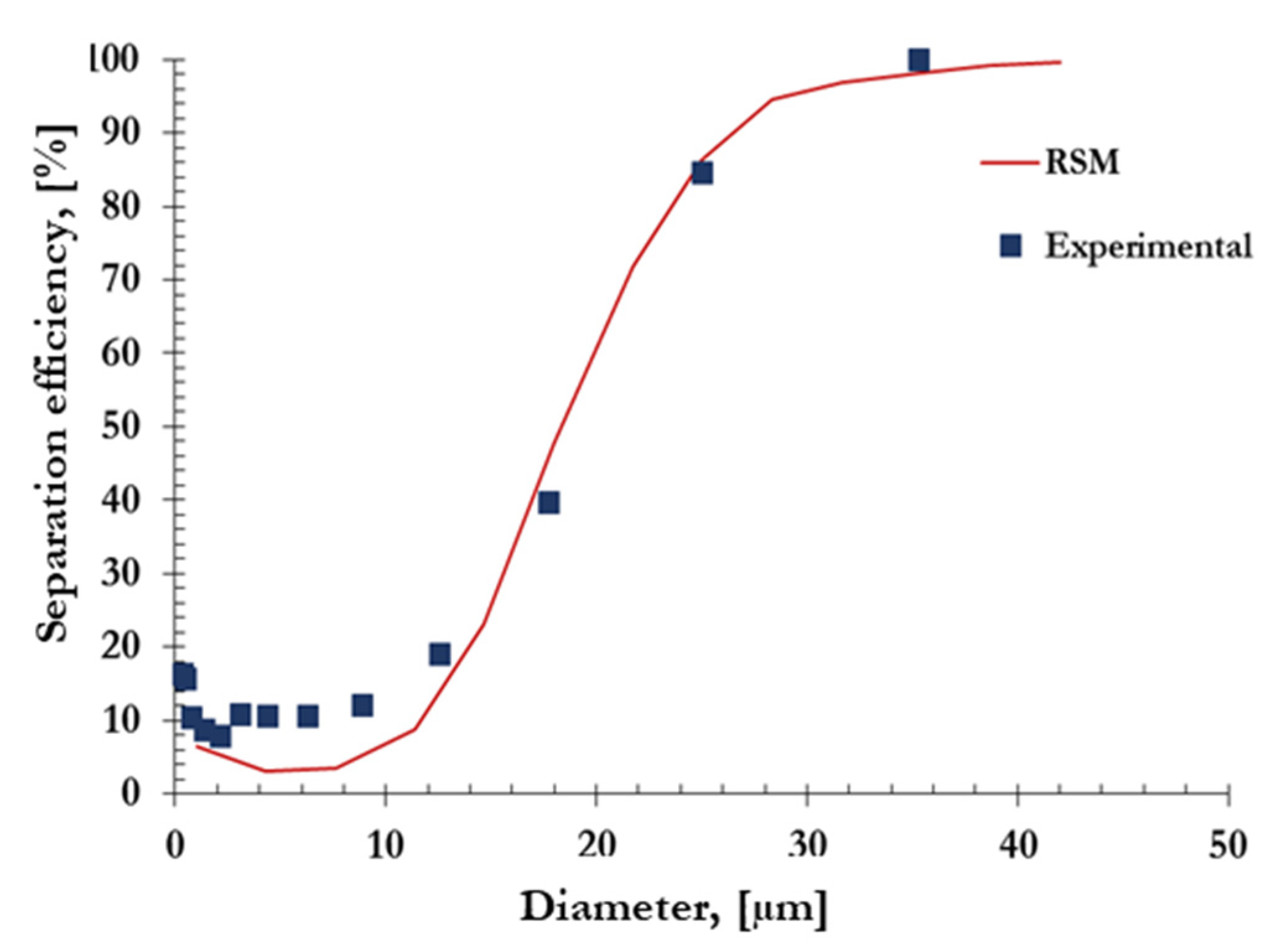

Figure 8 shows the comparison of experimental results with respect to the simulated CFD analysis.

The “Fish Hook” effect is evident in the portion of the curve from 1 to 5 µm. The used turbulence model tries to capture this phenomenon but fails to estimate the probability of separation in that region. However, the parameters obtained—namely, the sharpness of separation and cut diameter (d50)—are experimentally consistent with the CFD simulation, and they have an accuracy of 4% and 7%, respectively. The previous results confirm that the one-way model, with steady tracking, is suitable for predicting the efficiency curve.

In summary, the computational model offers reliable results enabling the understanding of flow characteristics, which are not easily identified in experimental procedures. In terms of cost, this model converges with a few iterations, so it is possible to test more than one geometrical configuration to meet the needs and performance required for industrial applications.