4.1. Baseline Simulations

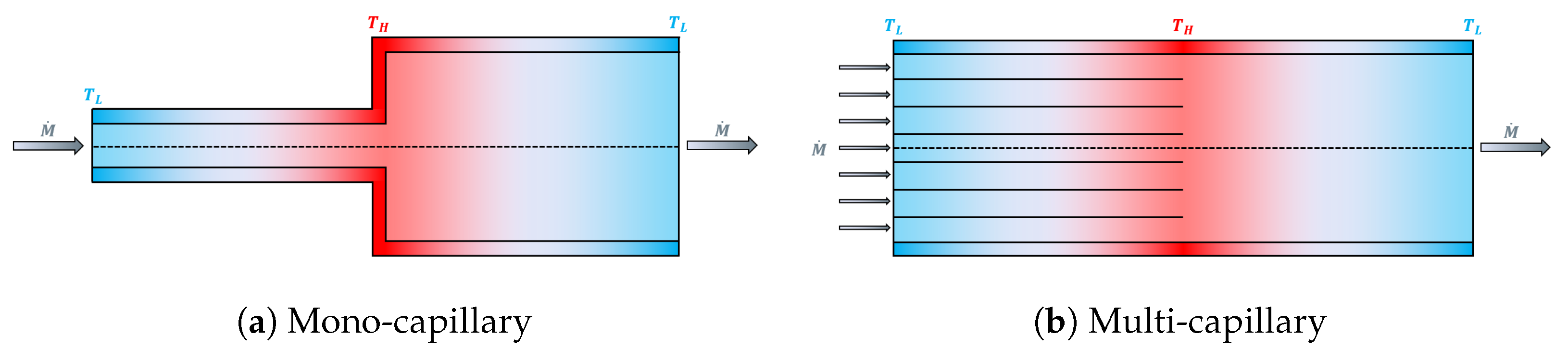

Table 5 presents the results of the baseline simulations performed for a multi-capillary Knudsen compressor with a rectangular cross section and a circular cross section.

These results help conclude that the heat pump coupled with a Knudsen compressor, with the currently chosen baseline parameters, cannot produce desirable results given their very small orders of magnitude, which consequently yields a poor performance.

To conclude this section, it is worth clarifying the lower

of the circular cross-section geometry, compared with the rectangular cross-section geometry, which is observed in the results. To begin with, let us recall that the mass flow rate is given by Equation (

4), where

L denotes the Knudsen compressor length,

A gives the capillary cross-section area,

is the characteristic dimension in the capillary section,

is the pressure at the left extremity of the Knudsen compressor,

gives the temperature at the left extremity of the Knudsen compressor,

m is the molecular mass of water vapor, and

G corresponds to the reduced flow rate. Thus, for fixed

L,

,

,

m, and

G, we have

. For the rectangular geometry,

, whereas for the circular geometry,

; here,

is the characteristic dimension (height for the rectangular geometry, radius for the circular geometry) and

represents the width of the rectangular geometry. Because

(the connector section is much wider than the capillary section), for

,

, and consequently,

,

, and thus, it follows that

. Given that the mass flow rate is directly proportional to

, the circular geometry exhibits a much smaller COP as a consequence of the lower

.

4.2. Parametric Studies

Figure 12 presents the results of the parametric study performed for

for 0 m

m, that is, the characteristic dimension of the capillary section.

Figure 12 evidences an increase in

and

at a micro-scale level, where

becomes sufficiently small and thermal transpiration effects are predominant, thus positively influencing the flow. For the rectangular and circular geometries, both

and

reach their peak values at

m and

m, respectively. This is followed by a significant decrease in

and

, where the Poiseuille contribution overcomes the thermal transpiration contribution, subsequently leading to negative values of

and

(the latter not being shown in the graph due to the logarithmic scale of the y-axis), indicating reversed flow directions uncharacteristic of heat pump systems. Thus, the range of

values that leads to these reversed flow conditions should be avoided.

In contrast,

remains constant and equal to

for both cases throughout the variation of

, as

does not influence enthalpy values within the KHP system. Based on these results, values of

m (rectangular) and

m (circular) were selected for the enhanced simulations, corresponding to the optimal

values within the studied range. These values fall into the typical micro-scale dimensions where the KC should operate, as indicated in previous studies [

21,

22].

Figure 13 provides the graphical results developed during the parametric study of the characteristic dimension to width ratio

for a range of

.

While variations in do not influence , decreasing results in an increase in both and . This increase in is attributed to the expansion of the rectangular cross-section area, primarily driven by an increase in the compressor width b. As , b, and consequently and , tends towards infinity. As in the previous parametric study with , remains constant at , as does not affect the enthalpy values in the KHP system. To comply with performance and geometric feasibility, a value of was selected for the enhanced efficiency simulations, as it provides near-optimal results without requiring unrealistically large values for the compressor width b.

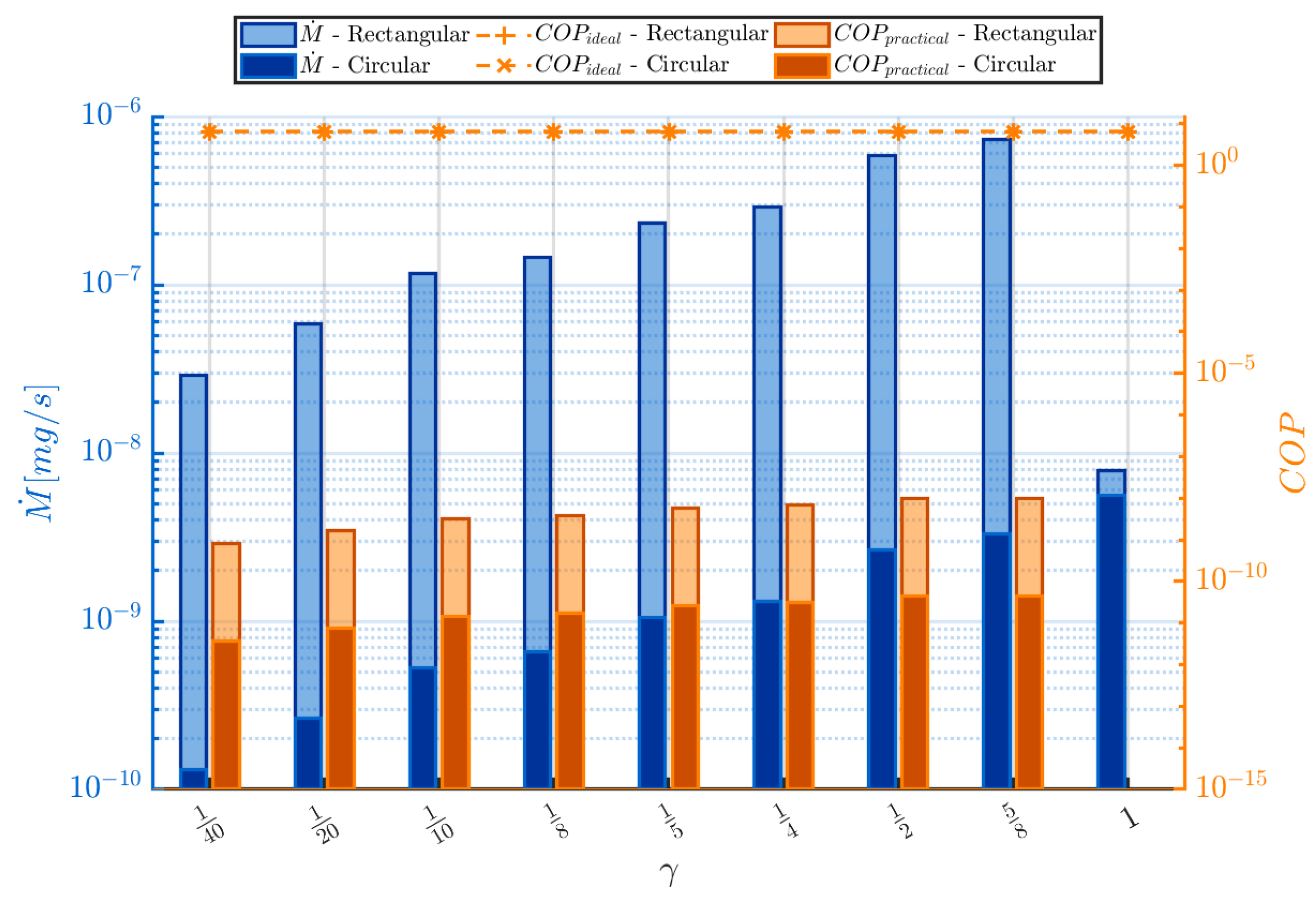

Figure 14 indicates the evolution of the results with capillary section fraction

.

The data depicted in

Figure 14 shows that

is generally sensitive to variations in

across both geometric configurations, especially at

. At this value,

decreases significantly in the rectangular geometry and increases in the circular geometry. Notably,

is also not affected by variations of

. Furthermore, the

collapses at

, where the geometry is fully capillary. An optimal value of

has been selected for the enhanced efficiency simulations in both geometric cases, which corresponds to the

value that returns the highest

.

Figure 15 presents the graphical results of the parametric study carried out for the number of capillaries

.

An increase in the number of capillaries positively influences and in both geometric configurations, leading to their asymptotic increase. As expected, remains unaffected, holding constant at , indicating that it does not depend on . Based on these findings, has been selected for the enhanced efficiency simulations in both configurations, as further increase in this parameter yields negligible improvement of the KHP performance and would only increase the size and complexity of the Knudsen compressor.

Figure 16 outlines the results for the number of stages

parametric study.

For both geometries, a notable decrease in the mass flow rate

, and consequently

, is observed with the increase in the number of stages

, due to its inverse dependence on the total length of the Knudsen compressor

L, which increases with the increase in

(refer to Equation (

4)).

A similar trend is observed for both and , where a continuous decrease is observed with the increase in . Each additional stage increases the number of capillary sections requiring heat input and promotes conductive and radiative heat losses, thereby raising , , and . Since is not affected, this imbalance leads to a reduction in both performance parameters.

Notably, as reported by Kugimoto et al. [

19], the efficiency of a multi-stage Knudsen compressor scales inversely with the number of stages, such that the efficiency of an

-stage compressor is approximately

of the efficiency of a single-stage unit. This theoretical prediction is qualitatively supported by the trend observed in the simulation results presented in

Figure 16, where

drops as

increases, confirming the inverse efficiency relationship and reinforcing the impracticality of using a high number of stages from a performance standpoint.

For this study, shall remain equal to 1 for the enhanced efficiency simulations in both geometric configurations.

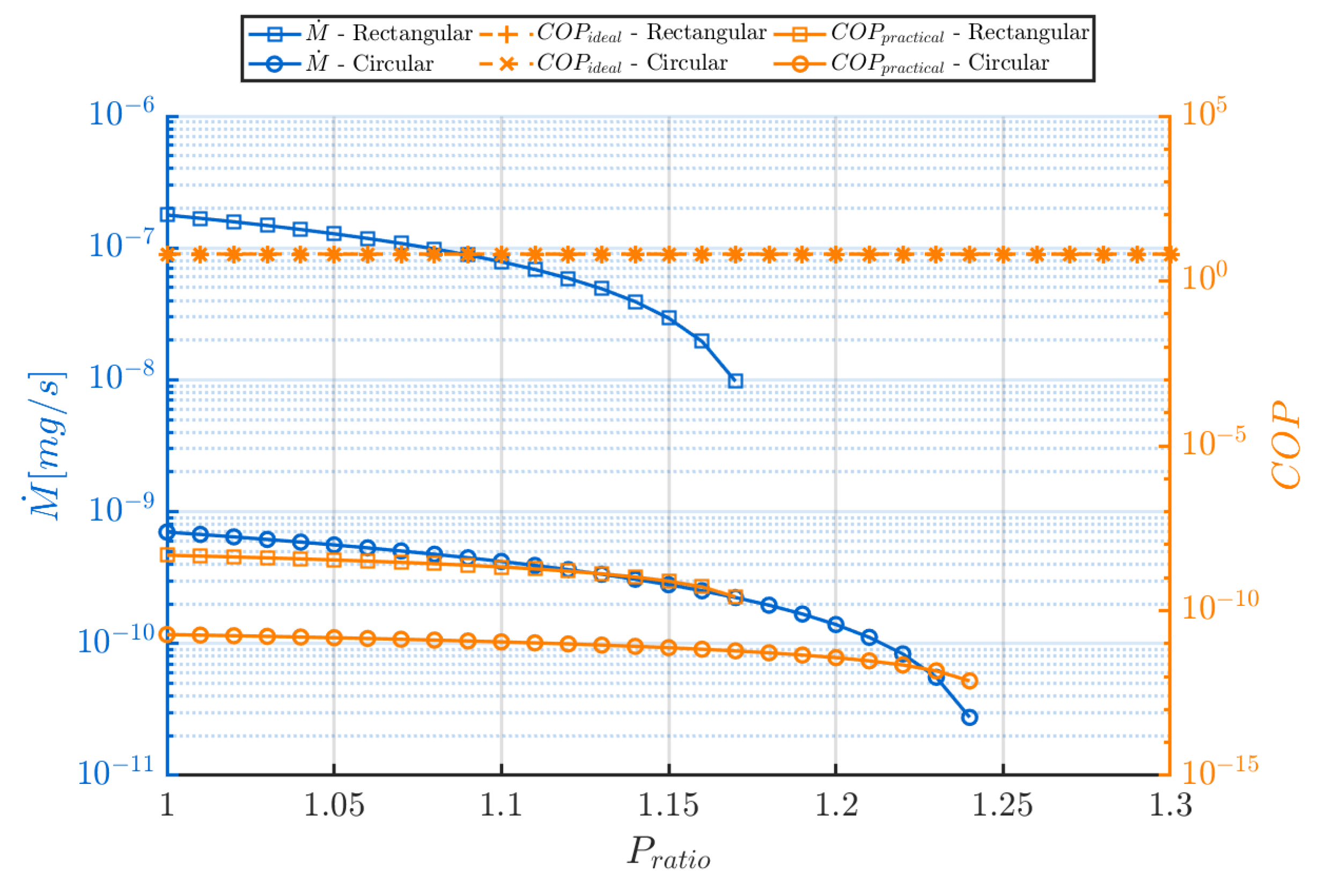

Figure 17 illustrates the results of the parametric study executed for the pressure ratio

.

The graphical results show that increasing the pressure ratio negatively impacts both and . This trend is expected, as a pressure gradient within the Knudsen compressor enhances the Poiseuille flow contribution, which opposes the thermal transpiration-driven flow, thus shifting the net gas flow through the Knudsen heat pump system. For the rectangular and circular configurations, respectively, when and , the flow direction reverses, causing and to become negative (although this is not visually evident in the plots due to the logarithmic y-axis scales).

In theory, optimal performance would be achieved when approaches unity, minimizing adverse Poiseuille flow, allowing thermal transpiration to dominate and for to reach its most enhanced value. Unlike conventional heat pump systems, the KHP does not require an externally imposed pressure differential for operation, and a pressure gradient will be generated internally via thermal transpiration. Therefore, a value of , as initially chosen, shall remain for the enhanced efficiency simulations in order to maintain performance while satisfying practical constraints.

Figure 18 illustrates the results for the temperature ratio

parametric study.

The results indicate that the mass flow rate increases continuously with due to enhanced thermal transpiration effects induced by the growing temperature gradient across the system. For the rectangular and circular configurations, respectively, reaches a peak at and , before declining at further values of . This decline in beyond the optimal point is attributed to the disproportionate growth of , , and , which overcome the increase in .

In the case of , a steady decrease is observed with increasing , as the rise in outweighs the gains in . Therefore, the optimal performance is achieved for the rectangular and circular configurations, respectively, at and , which are selected for the enhanced efficiency simulations.

4.3. Heated Surface Coating

One of the main factors limiting the performance of the KHP refers to the thermal losses, which directly affect its efficiency. The material choice for the Knudsen compressor is therefore a critical design parameter, as it must address both conductive and radiative heat losses. In a study by Kugimoto et al. [

19], a glass fiber membrane was employed as the material for the Knudsen compressor. While glass fiber exhibits relatively low thermal conductivity, its emissivity is extremely high, practically assumed to be

, meaning that radiative losses become predominant, thus significantly diminishing the KHP performance.

The present work considers the application of a low-emissivity flaky aluminum powder coating or silver nanoparticle coating on the heated wall of the Knudsen compressor, which can reduce surface emissivity to values of around 0.25 [

38] and 0.015 [

39], respectively, in order to overcome this limitation. By combining such a coating in the glass fiber surface, it is possible to suppress significant radiative losses.

Table 6 presents the impact of surface coating on

and

.

The application of silver coating results in a dramatic reduction in radiative heat losses, with dropping 98.5% in both geometries when compared with the uncoated case. Aluminum, though less effective than silver, still provides a substantial 75% reduction.

In the rectangular cross section, silver coating improves by 33.16%, while aluminum achieves a 23.40% improvement. For the circular geometry, performance gains are more modest due to inherently lower baseline COP values; nonetheless, silver still provides a 33.12% improvement compared with 2.26% for aluminum. These results confirm that minimizing surface emissivity via coating is an effective strategy for reducing radiative heat loss and enhancing overall system efficiency, particularly in rectangular geometries.

For the enhanced simulations, a surface coating using silver nanoparticles () is selected, as it yields superior performance compared with the aluminum coating in terms of reduced radiative heat losses and improved overall system efficiency. It should be noted that economic and coating stability considerations are beyond the scope of this work and, thus, were not used as decisive factors for the choice of material. The material is selected solely in order to increase . While the total area to be coated in the KC is small (so material usage is minimal), deposition/processing can dominate cost. If investment if limited, aluminum (Al) provides a lower-cost alternative compared with silver with only a small increase in emissivity. Regarding stability, the layer is assumed to be protected against factors like dewetting that diminish the stability, using a thin Ti/Cr adhesion layer beneath it, therefore preserving its low emissivity. A detailed techno-economic analysis and an assessment of long-term coating stability shall be the subject of a future work.

4.4. Enhanced Setup

The following operating parameters are selected, as the optimal choices, from the preceding studies for the rectangular cross-section geometry: m; ; ; ; ; , ; and, for the circular cross-section geometry: m; ; ; ; , .

Table 7 presents the results obtained by using these parameters and the corresponding percentage comparison with the baseline simulations (

Table 5).

A comparison with the baseline simulations clearly highlights significant performance gains in the Knudsen heat pump resulting from the new implemented parameters, with the rectangular cross-section geometry influencing the most substantial improvements in the system.

For the rectangular cross section, nearly all performance metrics show marked enhancement. , and as a consequence , and all increase by more than 100%. Additionally, radiative heat loss () is reduced by 98.80%, promoted by the application of silver nanoparticle surface coatings in the Knudsen compressor. Both and improve considerably, with the latter increasing from to 6.006. Conductive heat transfer () is shown to increase by 27.09%, which comes from the cross-section area increase and —mainly influenced by the increase in and . Although an unfavorable outcome, this does not hinder the system’s efficiency, as evidenced by the substantial gain in , indicating an overall improvement in energy conversion performance.

The circular geometry also benefits from the applied enhancements, though the magnitude of improvement is comparatively lower. Increases of over 100% are observed in , , and , while radiative losses decrease by 99.14%, also due to surface coating using silver nanoparticles. Notably, the rises from 6.514 to 8.920—a 39.96% increase that even surpasses the 13.72% improvement observed for the rectangular configuration. However, remains significantly lower than that of the rectangular case.

These results suggest that the rectangular geometry is more responsive to the applied enhancements. This is largely attributed to the modification of the parameter, which strongly influences mass flow rate and, consequently, . Since is unique to the rectangular configuration, its optimization led to substantial performance gains not observed in the circular configuration. Therefore, the rectangular Knudsen compressor demonstrates more advantageous characteristics for KHP applications.