The Study and Determination of Rational Hydraulic Parameters of a Prototype Multi-Gear Pump

Abstract

1. Introduction

- (1)

- The presence of unbalanced radial forces arising from the pressure difference between the inlet and outlet ports. The action of radial forces leads to increased friction and wear of the gears and the inner surface of the pump housing; increased load on the bearings; and it may lead to bending of the drive gear shaft.

- (2)

- Uneven fluid delivery and high acoustic noise levels due to pressure fluctuations in the pump cavities caused by constantly changing volumes in the pump discharge cavity as a result of the teeth alternately engaging and disengaging.

- (3)

- Increased clearances during operation, causing increased leakage and, consequently, a decrease in volumetric efficiency. Fluid leaks in a gear pump are caused by overflow from the discharge chamber to the suction chamber through three main channels: through the radial clearance between the cylindrical surfaces of the gears and the bores in the housing; through the meshing zone due to tooth contact errors; and through the clearance between the end surfaces of the gears and the sealing parts.

2. Materials and Methods

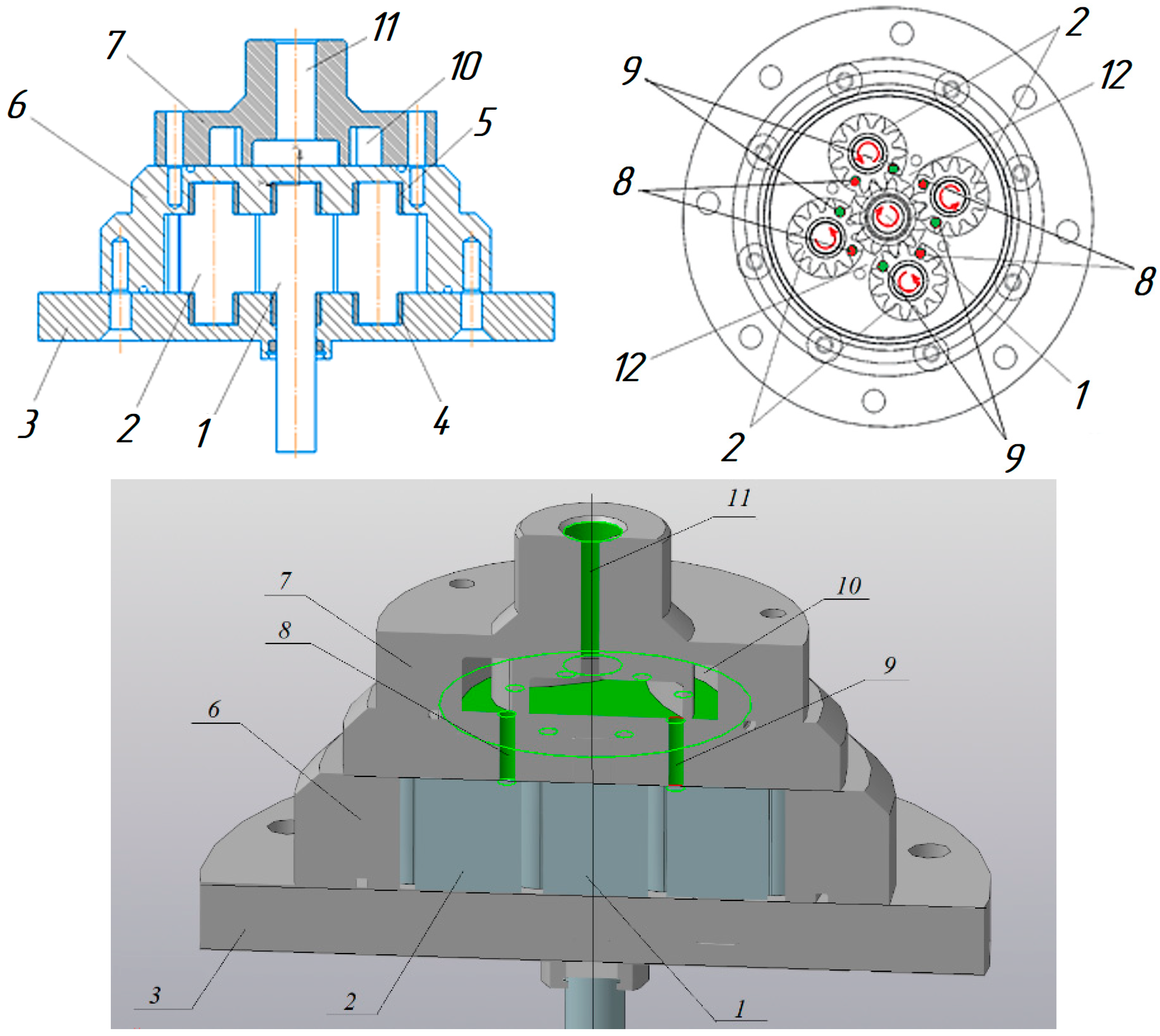

2.1. The Object of This Research

- -

- Working volume V = 81 cm3;

- -

- Diameter of the pitch circle of the gear d = 55 mm;

- -

- Diameter of one suction hole dsuc = 18 mm;

- -

- Discharge hole diameter dd = 25 mm;

- -

- Overall dimensions of the pump assembly: height H = 258 mm;

- -

- Diameter of front cover D = 330 mm.

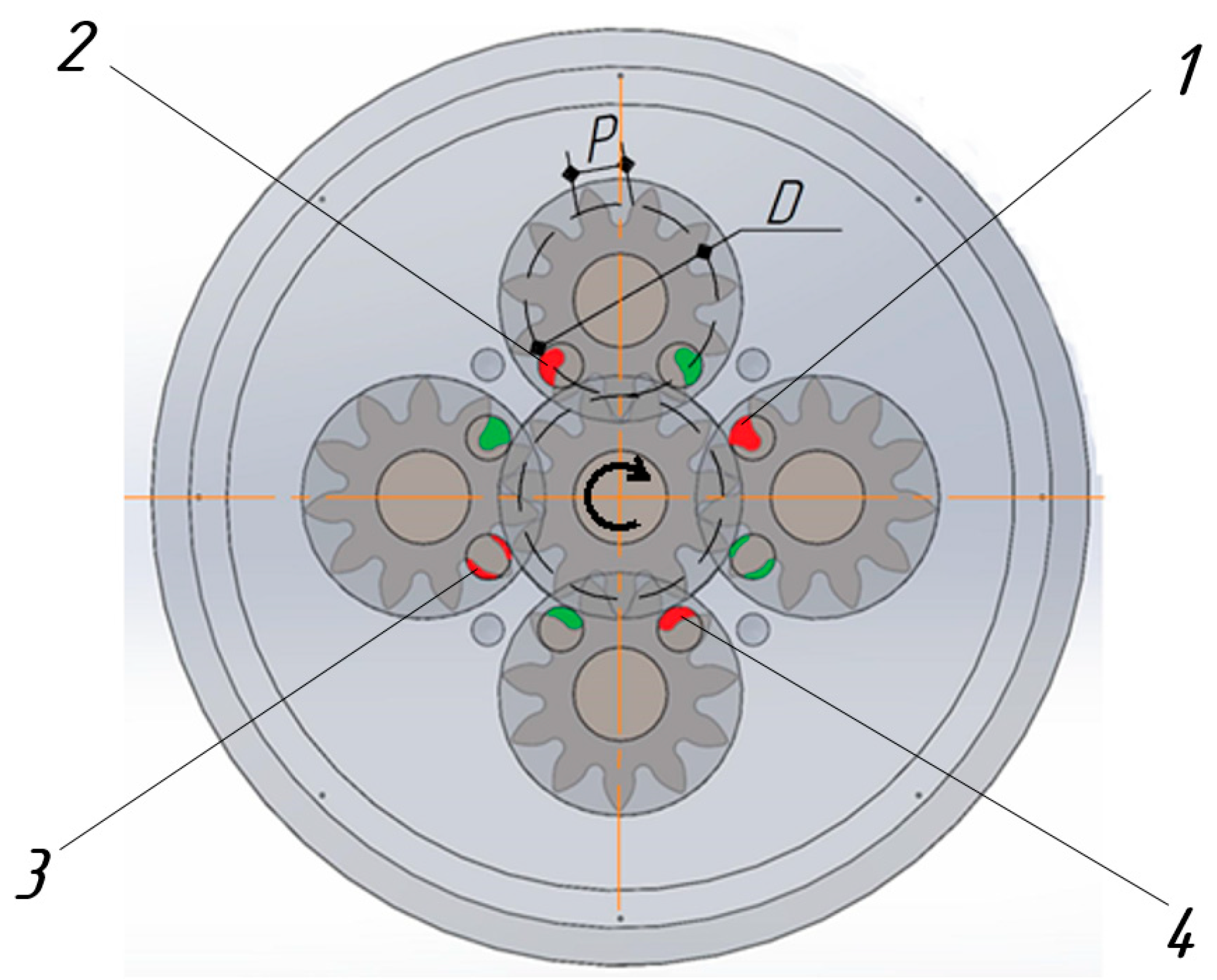

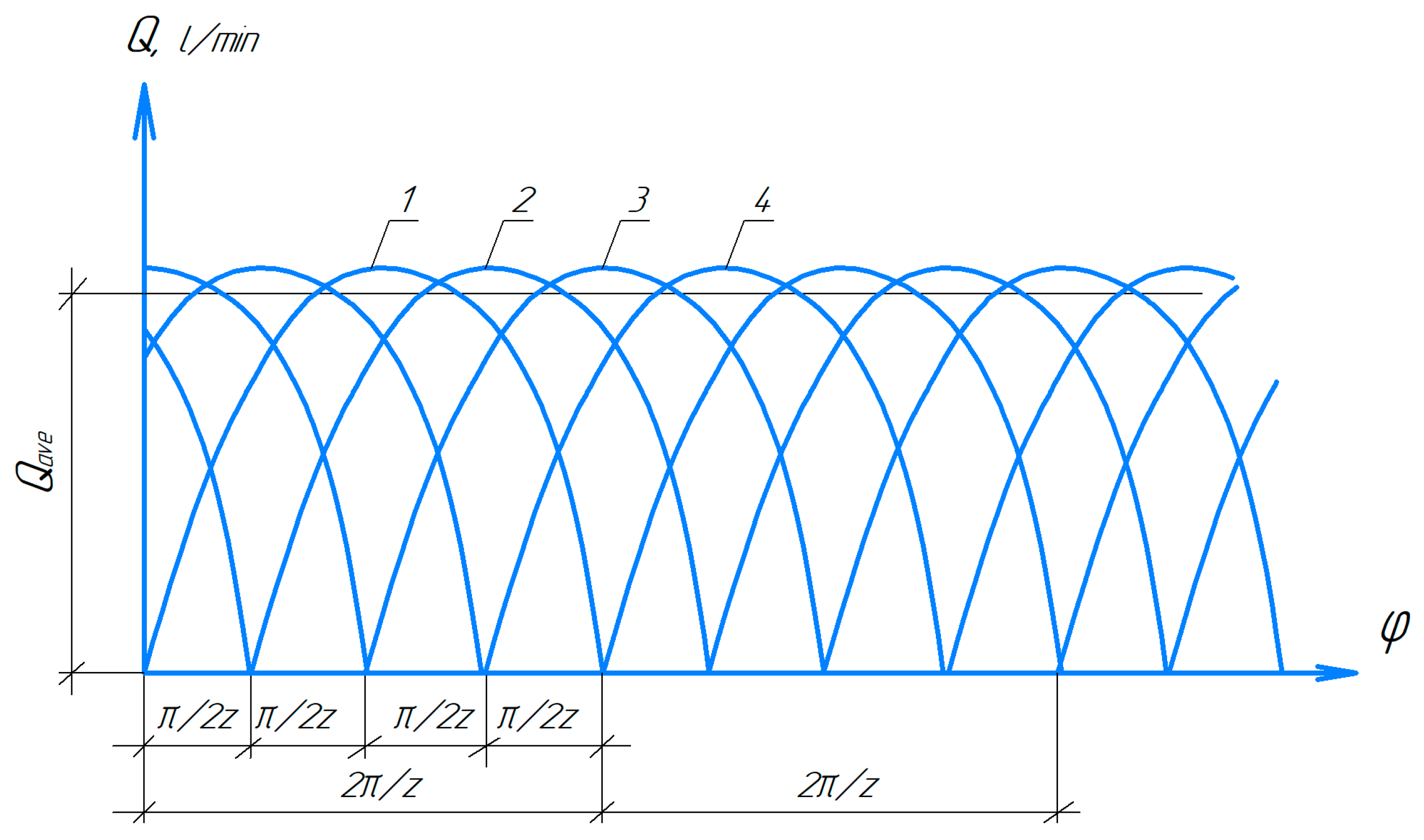

2.2. The Operation Principle of the Multi-Gear Pump

- -

- Pitch diameter of gears: d = m·z, where m is the tooth module, mm; z is the number of teeth;

- -

- Circumference length along the pitch diameter: L = π·d;

- -

- Gear pitch P = π·m, which corresponds to a gear rotation angle of (2·180o)/z.

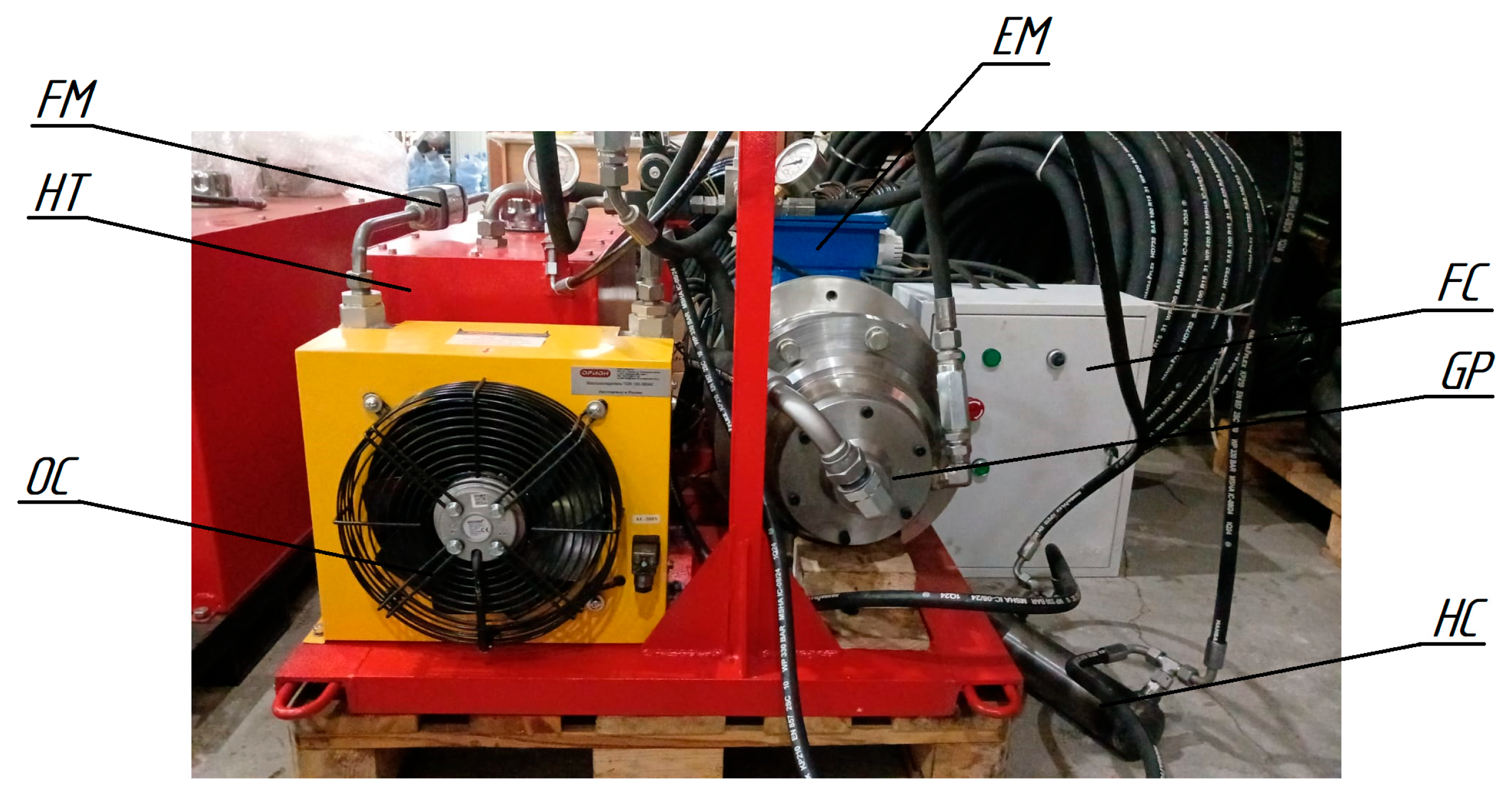

2.3. Test Stand

2.4. Tested Characteristics and Test Procedure

- (1)

- Using the screw of safety valve 7 and pressure gauge 5, the pressure in the hydraulic system was adjusted to the values of 5; 10; 15; 20; and 26 MPa. When adjusting, hydraulic valve 8 must be switched to the working position (position a or b).

- (2)

- With the pressure set in the system during the tests, using the frequency converter, the rotation frequency of the drive shaft of the electric motor was regulated to the values of 1450; 1200; 900; 600; and 300 rpm.

- (3)

- Measurements of pump flow without load and with load were taken with the help of a flow meter.

- (4)

- Measurements of the pump noise level were taken with a noise meter.

- (5)

- The temperature of the working fluid was monitored with a thermometer.

3. Results and Discussion

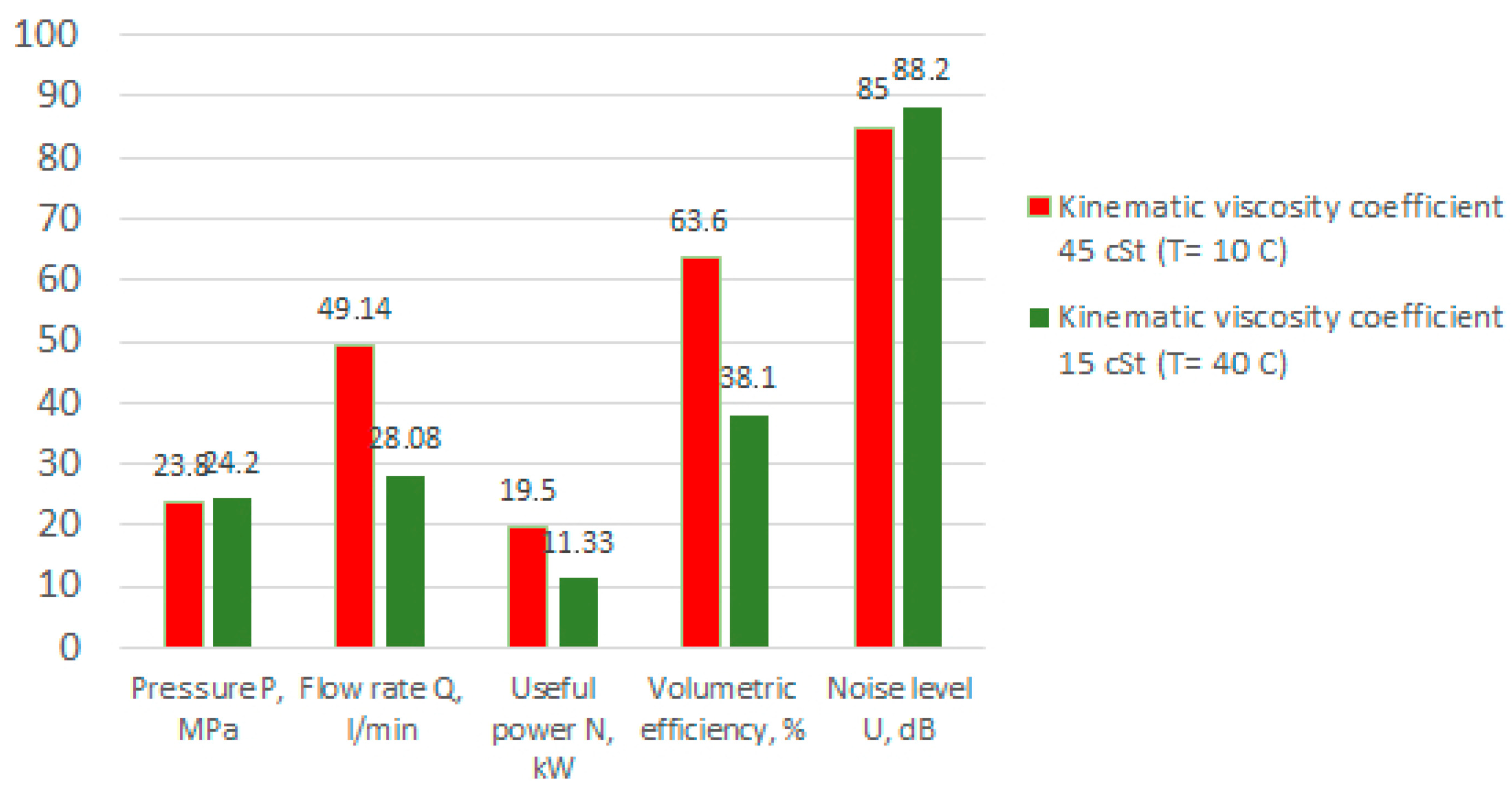

3.1. Determining Speed at Kinematic Viscosity

3.2. Determination of Working Fluid Pressure at Rotational Speed

- -

- Flow meter—2%;

- -

- Manometer—1.5%;

- -

- Noise meter—2%.

- -

- Use the prototype for further studies of dynamic and energy characteristics;

- -

- Adjust the design documentation based on the test results;

- -

- Use the prototype pump and test results to improve the design;

- -

- Carry out work to improve the technological effectiveness of the pump’s structural elements, and improve the pump’s sealing system;

- -

- Improve the design of the multi-gear pump housing and its gears in order to minimize clearances through manufacturing technology.

- (1)

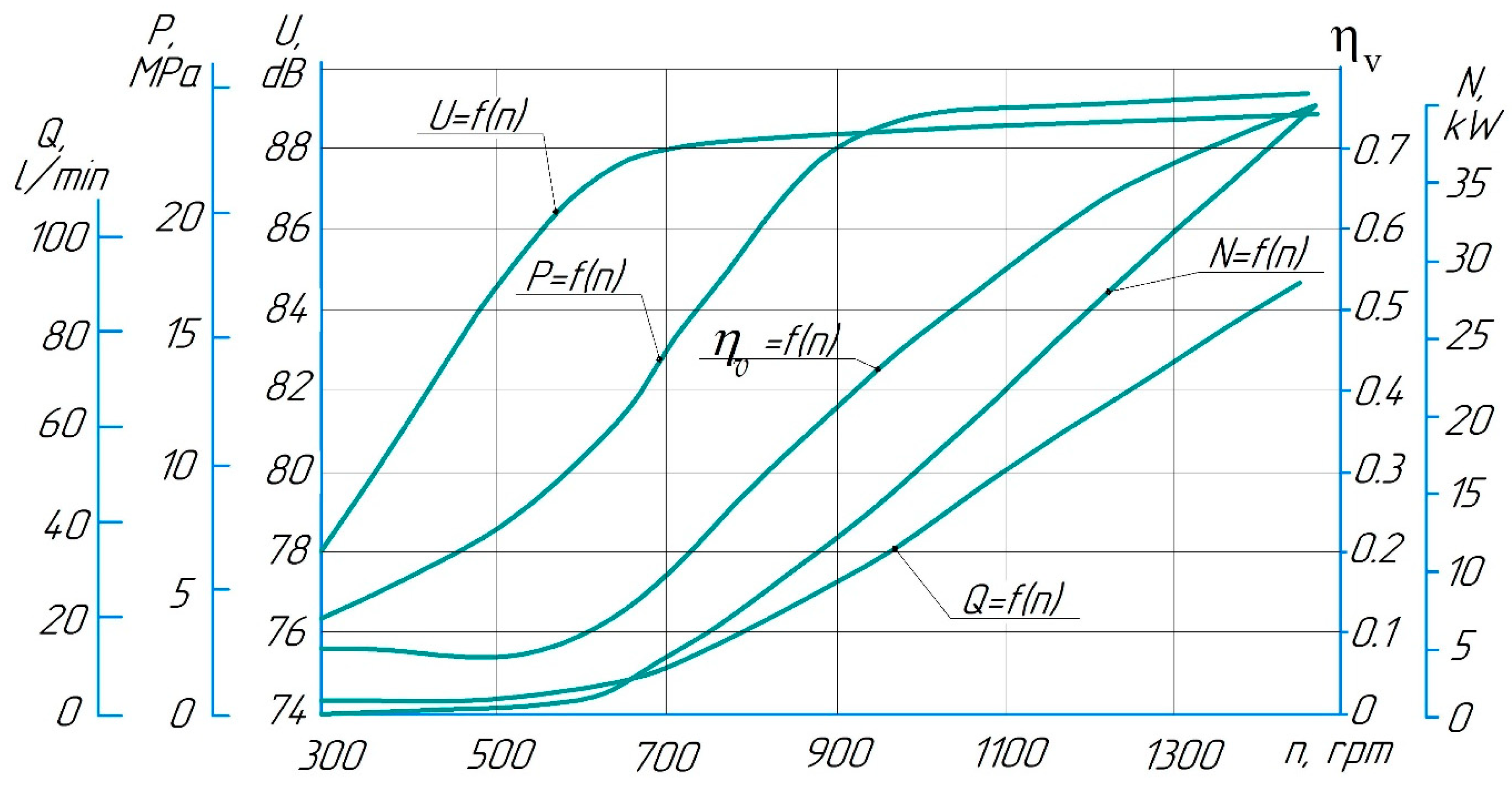

- It was found that the most efficient operation of the pump is achieved in the range of drive shaft speeds from 900 to 1450 rpm. In this range, the volumetric efficiency demonstrates rather high values varying from 0.7 to 0.88 when working with VMGZ hydraulic oil with a kinematic viscosity of 45 cSt.

- (2)

- Reducing the speed below 900 rpm leads to a significant increase in internal leakage and a drop in volumetric efficiency to 0.3 at 300 rpm, as well as a decrease in the developing pressure to 9 MPa at a valve setting pressure of 26 MPa.

- (3)

- When the kinematic viscosity decreases from 45 cSt to 15 cSt (due to heating up to 40 °C), there is an overall reduction in capacity and power of about 15–20%, while the noise level increases slightly by 2 dB.

- (4)

- There is a linear dependence of the increase in useful power with increasing system pressure, reaching 19.5 kW at 900 rpm and 31.15 kW at 1200 rpm at a maximum pressure of 26 MPa.

- (5)

- Maximum noise levels recorded in the range of 88.5–88.9 dB at pressures of 15–20 MPa at 900 and 1200 rpm.

- (6)

- The expected increase in operating fluid leakage with increasing pressure was also observed, amounting to 4 L/min at 1450 rpm and 26 MPa pressure.

- (7)

- The optimal characteristics for this multi-gear pump design are operating pressure—5–25 MPa; rotation speed—900–1450 rpm.

4. Conclusions

- -

- Adjusting the design documentation based on the test results;

- -

- Improving the manufacturability of pump components and the pump sealing system;

- -

- Optimizing the design of the housing and bottom cover of the multi-gear pump;

- -

- Lightening the design of the multi-stage pump;

- -

- Determining the most effective application of the pump in technological machines and equipment, taking into account factors such as power, expected operating and maintenance conditions, performance level, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zeleny, Z.; Vodicka, V.; Novotny, V.; Mascuch, J. Gear pump for low power output ORC—an efficiency analysis. Energy Procedia 2017, 129, 1002–1009. [Google Scholar] [CrossRef]

- Kravchenko, I.N.; Velichko, S.A.; Martynov, A.V.; Barmina, O.V.; Apatenko, A.S.; Sevryugina, N.S. Evaluation of the Operational Reliability of Gear Hydraulic Pumps Repaired Using the Electric Spark Processing Method. J. Mach. Manuf. Reliab. 2023, 52, 220–226. [Google Scholar] [CrossRef]

- Lakshmanana, K.; Tessicini, F.; Gil, A.J.; Auricchio, F. A fault prognosis strategy for an external gear pump using Machine Learning algorithms and synthetic data generation methods. Appl. Math. Model. 2023, 123, 348–372. [Google Scholar] [CrossRef]

- Rituraj, R.; Vacca, A. Investigation of flow through curved constrictions for leakage flow modeling in hydraulic gear pumps. Mech. Syst. Signal Process. 2021, 153, 107503. [Google Scholar] [CrossRef]

- Choudhuri, K.; Biswas, N.; Mandal, S.K.; Mitra, C.; Biswas, S. A numerical study of an external gear pump operating under different conditions. Mater. Today Proc. 2022; in press. [Google Scholar] [CrossRef]

- Frosina, E.; Senatore, A.; Rigosi, M. Study of a High-Pressure External Gear Pump with a Computational Fluid Dynamic Modeling Approach. Energies 2017, 10, 1113. [Google Scholar] [CrossRef]

- Ghionea, I.G.; Ghionea, A.L.; Ćuković, S.; Pleşa, M.I. Analysis on the measurement results of the precision grades and their influence on the performance of the hydraulic pumps with spur gears. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 682, p. 012005. [Google Scholar] [CrossRef]

- Zhao, X.; Vacca, A. Theoretical Investigation into the Ripple Source of External Gear Pumps. Energies 2019, 12, 535. [Google Scholar] [CrossRef]

- Li, G.; Zhang, L.; Han, W. Profile design and displacement analysis of the low pulsating gear pump. Adv. Mech. Eng. 2018, 10, 168781401876700. [Google Scholar] [CrossRef]

- Fiebig, W. Influence of the Inter Teeth s on the Noise Generation in External Gear Pumps. Arch. Acoust. 2015, 39, 261–266. [Google Scholar] [CrossRef]

- Bakman, I.; Gevorkov, L.; Vodovozov, V. Optimization of method of adjustment of productivity of multi-pump system containing directly connected motors. In Proceedings of the Engineering Electric Power Quality and Supply Reliability Conference (PQ), Rakvere, Estonia, 11–13 June 2014. [Google Scholar] [CrossRef]

- Schänzle, C.; Störmer, N.; Pelz, P.F. Modeling the efficiency of external gear pumps based on similarity considerations. In Proceedings of the 2018 Bath/ASME Symposium on Fluid Power and Motion Control FPMC, Bath, UK, 12–14 September 2018. [Google Scholar] [CrossRef]

- Zhao, X.; Vacca, A. Formulation and optimization of involute spur gear in external gear pump. Mech. Mach. Theory 2017, 117, 114–132. [Google Scholar] [CrossRef]

- Opperwall, T.; Vacca, A. Combined FEM/BEM model and experimental investigation into the effects of fluid-borne noise sources on the air-borne noise generated by hydraulic pumps and motors. Proc. Inst. Mech. Eng. Part C 2014, 228, 457–471. [Google Scholar] [CrossRef]

- Xu, B.; Liu, Q.; Zhu, Z.; Gao, Y.; Li, C.; Zhang, Y. Influence of the Rotation Speed on the Internal Flow Characteristics of an Aircraft Fuel Gear Pump. Processes 2024, 12, 576. [Google Scholar] [CrossRef]

- Antoniak, P.; Stryczek, J. Visualization study of the flow processes and phenomena in the external gear pump. Arch. Civ. Mech. Eng. 2018, 18, 1103–1115. [Google Scholar] [CrossRef]

- Corvaglia, A.; Rundo, M.; Bonati, S.; Rigosi, M. Simulation and Experimental Activity for the Evaluation of the Filling Capability in External Gear Pumps. Fluids 2023, 8, 251. [Google Scholar] [CrossRef]

- Ferrari, C.; Morselli, S.; Miccoli, G.; Hamiche, K. Integrated CFD-FEM approach for external gear pump vibroacoustic field. Front. Mech. Eng. 2024, 10, 1298260. [Google Scholar] [CrossRef]

- Egbe, E.A.P. Design Analysis and Testing of a Gear Pump. Res. Inventy. Int. J. Eng. Sci. 2013, 3, 1–7. [Google Scholar]

- Yanikoren, M. Experimental investigation of the performance and energy consumption efficiency of elliptical gear hydraulic pump and evaluation by Taguchi method. Eng. Sci. Technol. Int. J. 2025, 62, 101941. [Google Scholar] [CrossRef]

- Dalmis, S.; Eruslu, O.; Bahtiyar, M. Experimental Test of Hydraulic External Gear Pumps. In Proceedings of the International Scientific Conference, Gabrovo, Bulgaria, 17–18 November 2017; pp. 422–427. [Google Scholar]

- Zhan, P.; Yan, Q.; Jiang, Z.; Yang, R.; Wei, L. Study on Mechanism and Suppression Method of Flow-Induced Noise in High-Speed Gear Pump. Arch. Acoust. 2024, 49, 49–60. [Google Scholar] [CrossRef]

- Metalsi, T.F.; Bourdim, A. Study of feasibility of plastic gear to reduce noise in a gear pump. Adv. Prod. Eng. Manag. 2012, 7, 143–149. [Google Scholar] [CrossRef]

- Kaczmarczyk, T.Z. Experimental research of a pumping engine in a micro-ORC system with a lowboiling medium. Arch. Thermodyn. 2024, 45, 125–140. [Google Scholar] [CrossRef]

- Kaczmarczyk, T.; Ihnatowicz, E.; Żywica, G.; Kaniecki, M. Experimental study of the prototype of a Roto-Jetpump for the domestic ORC power plant. Arch. Thermodyn. 2019, 40, 83–108. [Google Scholar] [CrossRef]

- Awais, M.; Ashraf, M.; Zaidi, Z. Investigating the Characteristics of a Gear Pump. Int. J. Med. Res. Health Sci. 2025, 14, 1–8. [Google Scholar]

- Zhang, X.H.; Liu, P.Y.; Wei, W.J.; Li, H.T.; Tian, G.P. Chapter: Design and simulation analysis of a new type of multi-gear pump. In Civil, Architecture and Environmental Engineering; CRC Press: London, UK, 2017. [Google Scholar] [CrossRef]

- Guerra, D.; Polastri, M.; Battarra, M.; Suman, A.; Mucchi, E.; Pinelli, M. Design Multistage External Gear Pumps for Dry Sump Systems: Methodology and Application. Math. Probl. Eng. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Zharkevich, O.; Nikonova, T.; Gierz, Ł.; Reshetnikova, O.; Berg, A.; Warguła, Ł.; Berg, A.; Wieczorek, B.; Łykowski, W.; Nurzhanova, O. Improving the Design of a Multi-Gear Pump Switchgear Using CFD Analysis. Appl. Sci. 2024, 14, 5394. [Google Scholar] [CrossRef]

- Zharkevich, O.; Reshetnikova, O.; Nikonova, T.; Berg, A.; Berg, A.; Zhunuspekov, D.; Nurzhanova, O. CFD-FEM Analysis for Functionality Prediction of Multi-Gear Pumps. Designs 2024, 8, 115. [Google Scholar] [CrossRef]

- Zharkevich, O.; Nikonova, T.; Gierz, Ł.; Berg, A.; Berg, A.; Zhunuspekov, D.; Warguła, Ł.; Łykowski, W.; Fryczyński, K. Parametric Optimization of a New Gear Pump Casing Based on Weight Using a Finite Element Method. Appl. Sci. 2023, 13, 12154. [Google Scholar] [CrossRef]

- Radzevich, S. Dudley’s Handbook of Practical Gear Design and Manufacture; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Oxfordshire, UK, 2016. [Google Scholar]

- Yakubova, M.Z.; Serikov, T.G.; Mekhtiev, A.D.; Yurchenko, A.; Alkina, A.D.; Neshina, Y.G. Development and imitating modeling in the developed network consisting of several knots removed among themselves on NetCracker 4.1. In Proceedings of the 2016 Dynamics of Systems, Mechanisms and Machines (Dynamics), Omsk, Russia, 15–17 November 2016; p. 7819108. [Google Scholar] [CrossRef]

| Component | Model | Range of Parameters | Accuracy | Manufacturer |

|---|---|---|---|---|

| Pressure sensor | HKPTA600MK | Measuring range: 0–600 bar | ±0.5% | HANSA-FLEX |

| Flow meter | HK602S015 | Measuring range: 5–125 L/min Pmax: 350 bar | ±2% | HANSA-FLEX |

| Manometer | GMM63-400 | Measuring range: 0–400 bar | ±1.6% | HANSA-FLEX |

| Frequency converter | ATV310 | Three phase Rated mains voltage: 380–460 V −15–10% Drive output frequency: 0.5–400 Hz | ±0.3% | Schneider electric, Rueil, France |

| Thermometer | - | Measuring range: −20 °C–+120 °C | ±1.5% | UNI-T, Dongguan, China |

| Hydraulic cylinder | custom design | Piston diameter: 60 mm Rod diameter 30: mm Stroke: 200 mm | - | HANSA-FLEX Hydraulic Almaty |

| Multi-gear hydraulic pump | custom design | V = 80.1 cm3 | - | Abylkas Saginov technical university, Karaganda, Kazakhstan |

| Electric motor | AИP 225 M4 | P = 55 kW n = 1450 rpm | - | Practic, London, UK |

| Check valve | HKV15010008 | Pmax: 350 bar Qmax: 160 L/min | - | HANSA-FLEX |

| Three-way ball valve | 3BKR13LK | Pmax: 350 bar | - | HANSA-FLEX |

| Solenoid valve | HKDHE0714X00DC | Model 4/3 Operating pressure: 300 bar Qmax = 120 L/min | - | ATOS, Bezon, France |

| Manual valve | HKBM40ZA1 | Model 4/3 Operating pressure: 300 bar Qmax = 120 L/min | - | HANSA-FLEX |

| Oil cooler | TOR100-380AC-Y | Qmax: 130 L/min Pmax: 20 bar Rated power: 60 W | - | Orion, Seoul, Republic of Korea |

| Receiving filter | FISGEMP0095M901/2 | Pmax: 12 bar Filtration fineness: 90 µm | - | HANSA-FLEX |

| Return flow filter | FIRL048P10NVG1/2 | Pmax: 8 bar Filtration fineness: 10 µm | - | HANSA-FLEX |

| Safety relief valve | HKV01230008 | Pressure adjustment range = 80–300 bar Qmax = 125 L/min | - | HANSA-FLEX |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zharkevich, O.; Berg, A.; Reshetnikova, O.; Berg, A.; Nurzhanova, O.; Altynbayev, A.; Zhunuspekov, D.; Stukach, O. The Study and Determination of Rational Hydraulic Parameters of a Prototype Multi-Gear Pump. Fluids 2025, 10, 211. https://doi.org/10.3390/fluids10080211

Zharkevich O, Berg A, Reshetnikova O, Berg A, Nurzhanova O, Altynbayev A, Zhunuspekov D, Stukach O. The Study and Determination of Rational Hydraulic Parameters of a Prototype Multi-Gear Pump. Fluids. 2025; 10(8):211. https://doi.org/10.3390/fluids10080211

Chicago/Turabian StyleZharkevich, Olga, Alexandra Berg, Olga Reshetnikova, Andrey Berg, Oxana Nurzhanova, Asset Altynbayev, Darkhan Zhunuspekov, and Oleg Stukach. 2025. "The Study and Determination of Rational Hydraulic Parameters of a Prototype Multi-Gear Pump" Fluids 10, no. 8: 211. https://doi.org/10.3390/fluids10080211

APA StyleZharkevich, O., Berg, A., Reshetnikova, O., Berg, A., Nurzhanova, O., Altynbayev, A., Zhunuspekov, D., & Stukach, O. (2025). The Study and Determination of Rational Hydraulic Parameters of a Prototype Multi-Gear Pump. Fluids, 10(8), 211. https://doi.org/10.3390/fluids10080211