Abstract

In the field of mechanical motion, friction loss and material wear are common problems. As one of the essential components for enhancing the lubricating performance of gel-like lubricants, nano-additives leverage their unique physical and chemical properties to form an efficient protective film on friction surfaces. This effectively reduces friction resistance and inhibits wear progression, thereby playing a significant role in promoting energy conservation, emissions reduction, and the implementation of green development principles. This study first introduces the physical and chemical preparation processes of gel-like lubricant nanoadditives. It then classifies them (mainly based on metal bases, metal oxides, nanocarbon materials, and other nanoadditives). Then, the performance of gel-like lubricant nano-additives is evaluated (mainly in terms of anti-wear, friction reduction, oxidation resistance, and load carrying capacity), and the surface analysis technology used is described. Finally, we summarize the application scenarios of gel-like lubricant nano-additives, identify the challenges faced, and discuss future prospects. This study provides new insights and directions for the design and synthesis of novel gel-like lubricants with significant lubricating and anti-wear properties in the future.

1. Introduction

With the continuous increase in energy demand, energy scarcity has gradually become a bottleneck restricting development [1]. Energy loss is undoubtedly a significant negative factor affecting the smooth and efficient operation of society in such a large environment. Friction consumption accounts for about one-fifth of the world’s energy consumption. One third of all energy used in transportation is used to overcome friction [2]. Reducing energy loss becomes an urgent issue [3]. In automotive engines, 40% of the total energy is wasted due to mechanical losses, with the piston-cylinder system accounting for 50% of the friction losses and the piston rings accounting for another 70–80% of the friction losses in this system. Inadequate lubrication can trigger component wear, seizing and even catastrophic failure. Much of the energy in mechanical losses is frictional losses, including direct friction between components. Additional wear and tear due to inadequate lubrication, friction of sealing devices, etc. [4]. Friction loss will not only reduce the efficiency of machinery, but also lead to heat and wear of components, shortening the service life of machinery. Thus, in the course of mechanical design and operation, usually take various measures to reduce friction loss [5]. Adding gel-like lubricant to friction points is one of the key ways to reduce friction [6]. In the process of mechanical equipment operation, the lubrication system plays a very important role. Once lubrication is inadequate, it can lead to a number of serious problems [7]. The primary function of lubrication is to form a film of oil on the surface of parts, reducing direct contact between parts and thereby lowering their coefficient of friction [8]. When the lubrication is not sufficient, this oil film can not completely and effectively cover the surface of the parts, and dry friction or boundary friction will occur between the parts [9]. This high-intensity friction will rapidly accelerate part surface wear [10]. With the increasing wear and tear, the microstructure of the part surface is gradually destroyed, and the originally smooth surface becomes rough and uneven [11]. Therefore, it can be said that good lubrication to enhance the energy utilization efficiency of machinery, to alleviate the problem of energy loss in the context of energy scarcity, has an irreplaceable role, 34.4% of machine failures originated from insufficient lubrication, 19.6% from improper lubrication. In other words, About 54% of machine failures are due to lubrication problems.

Grease is a complex mixture composed of base oil, thickener, and additives [12], with varying proportions of each component: Base oil accounts for 80–95% and is the primary component of grease. It is made from petroleum, synthetic hydrocarbons, or vegetable oils, and its properties directly influence the grease’s service life and lubricating performance. Greases can be classified into mineral oil-based, synthetic oil-based, and vegetable oil-based greases. Among these, mineral oil-based greases are the most commonly used due to their high availability, low cost, and good compatibility with additives, while synthetic oil-based greases offer superior performance in terms of oxidation stability and other properties [13]; Thickeners account for 2–15% and serve to increase viscosity, form a three-dimensional framework to adsorb and fix the base oil, and maintain grease stability. They are divided into metal soap-based (including single soap-based and composite soap-based, such as composite lithium-based) and non-metal soap-based (inorganic and organic categories) [14]; Additives account for 0–10% of the formulation, though their small proportion is critical for tribological performance. These include rust inhibitors, antioxidants, etc., which improve performance and extend service life. Among them, anti-wear additives reduce surface compression and lower friction wear.

Traditional grease generally refers to grease prepared using classic formulas and processes, with metal soap thickeners and mineral base oils as the main components. It has a long history of application and mature technology, and is the most common type of grease in the industrial field.

Gel-like grease are another important category of lubricants, characterized by the use of non-soap-based thickening agent systems. These thickening agents primarily include gels and polymers, such as organically modified clays, polyureas, polytetrafluoroethylene (PTFE), silica, and specific high-molecular-weight polymers. These thickeners bind the base oil by forming three-dimensional network structures (such as clay platelet stacking, polymer chain entanglement, or physical/chemical cross-linking), imparting unique gel-like rheological properties to the grease. Unlike soap-based greases, gel-based greases typically exhibit higher thermal stability, better water resistance, or compatibility with specific base oils/additives, making them suitable for high-temperature, vacuum, or specific chemical environments.

Although traditional additives are widely used in the lubrication field, there is still a big difference between their performance and that of nano grease additives. As shown in Table 1. The addition of nano grease additives provides new ideas for the development of traditional additives.

Table 1.

Comparison of traditional and nano additives in gel-like lubricants.

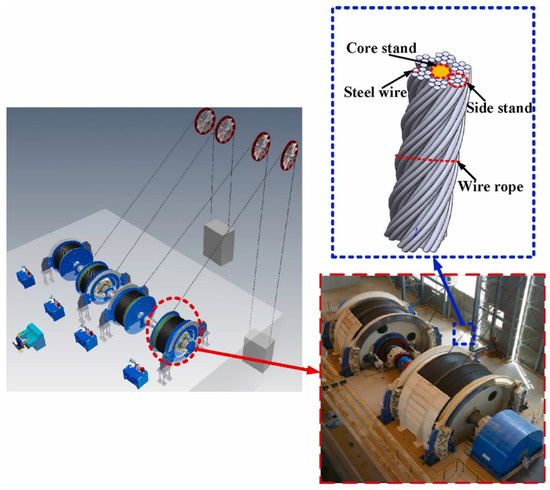

Gel-like lubricants have found widespread application in the field of mechanical lubrication due to their unique properties [16]. From rolling bearings to sliding bearings, from gears to pivots, from couplings to rails, and from pin bushings to sliding contacts, gel-like lubricants are the lubricant of choice for many mechanical equipment components. Advantages include good sealing performance to prevent leakage, as well as corrosion resistance and virtually no maintenance [17]. In the global economy, lubricating grease plays a pivotal role. It is indispensable in ensuring the normal operation of various mechanical equipment, lowering friction and wear during operation, and extending the service life of mechanical equipment [18]. Gel-like lubricants offer better sealing and leak-proof properties than lubricating oils. With the continuous development and progress of modern industry, the demand for lubricants will continue to grow [19]. Since nanomaterials typically exhibit excellent tribological properties, their use in gel-like lubricants to enhance anti-wear and friction-reducing performance has become a research hotspot in the field of lubrication [20].

The remainder of this paper is organized as follows. Section 2 focuses on the preparation process of nano-additives in gel-like lubricants, providing a comprehensive analysis of the two core technologies: physical preparation methods and chemical synthesis methods; Section 3 systematically classifies nano-additives in gel-like lubricants based on their functional characteristics and mechanisms of action; Section 4 delves into the lubrication and anti-wear performance of nano-additives in gel-like lubricants, while summarizing and categorizing the surface analysis techniques employed in performance studies; Section 5 examines the application scenarios of nano-additives in gel-like lubricants from industrial and mechanical perspectives, highlighting their technological innovation advantages through comparisons with traditional lubricants; Section 6 summarizes the research findings, draws conclusions, and, based on the current state of research, outlines future research trends in areas such as performance optimization and application expansion, providing direction for the future development of nano-additives in gel-like lubricants.

2. Preparation of Nano-Additives in Gel-like Lubricants

The preparation methods for nano-additives in gel-like lubricants primarily include physical methods (such as ball milling, ultrasonic processing, etc.) and chemical synthesis methods (such as sol-gel, hydrothermal synthesis, chemical reduction, etc.). Different preparation methods have their own advantages and disadvantages in terms of cost, process complexity, yield, and material performance, and should be selected based on actual application requirements.

2.1. Physical Preparation

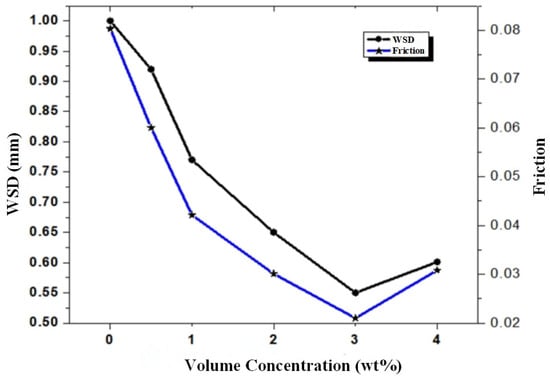

Kamel et al. [21] prepared graphene nanosheets (GNS) by modified Hummer method and investigated the effect of different concentrations (0.5–4 wt%) of GNS on the tribological properties of calcium-based gel-like lubricant. The results showed that the addition of GNS significantly enhanced the wear-reducing and anti-wear properties of the grease, with a 61% reduction in the coefficient of friction and a 45% reduction in the wear scar diameter (WSD). This suggests that GNS, as a grease additive, can significantly improve the tribological properties and has an important potential for application in the field of efficient lubricating materials. Zhou et al. [22] used orthogonal experimental method to prepare calcium fluoride from phosphogypsum and successfully prepared high quality calcium fluoride nanoparticles from calcined phosphogypsum in aqueous solution by direct precipitation method, and it was found that the average particle size of calcium fluoride was around 70 nm. Liu et al. [23] prepared stable graphene water dispersions (polyethylenimine-reduced graphene oxide nanosheets) by improving the Hummer method and water bath method. In steel ball plate friction tests, the water-based lubricant containing 0.05 wt% PEI-RGO demonstrated excellent performance: compared to pure water, the friction coefficient was reduced by 54.6%, and the wear rate was reduced by 45.0%. This superior performance is attributed to the unique protective film formation and repair mechanism of PEI-RGO nanosheets. During friction, PEI-RGO nanosheets fill micro-defects on the worn surface through physical adsorption (the amino groups of PEI can form hydrogen bonds or electrostatic interactions with the metal surface) or chemical bonding, forming a continuous protective film that directly reduces the metal contact area and effectively lowers the friction coefficient. Additionally, the amount of iron oxide on the wear surface was significantly reduced, as the PEI-RGO in the protective film blocks water and oxygen from contacting the metal, inhibiting the formation of iron oxide. The presence of PEI-RGO on the worn surface was detected in experiments, directly proving that the nanomaterials deposit during friction and participate in membrane formation. This indicates that PEI-RGO nanosheets, as water-based lubricant additives, not only significantly reduce friction and wear but also possess excellent surface protection functions. Their unique protective membrane mechanism makes them of significant practical value in environmentally friendly, high-efficiency lubrication systems.

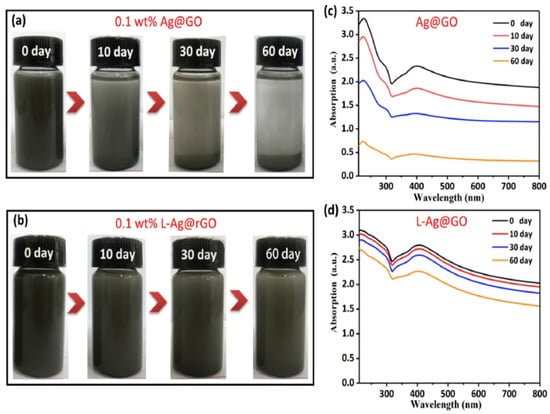

Wang et al. [24] used ultrasonic dispersion technology to prepare a lubricant containing gel-like boron nitride (BN) nanoparticles. The study found that BN nanoparticles can form a lubricating film on the friction surface, providing protective effects; simultaneously, their layered structure facilitates sliding at the friction interface. The synergistic effect of the lubricating film and layered structure significantly reduces the friction coefficient, enhancing the anti-friction performance of the grease. This indicates that BN nanoparticles, as grease additives, effectively reduce friction through the synergistic mechanism of lubricating film protection and layered structure sliding, providing a new direction for the development of high-performance lubricating materials. Wang et al. [25] prepared silver/graphene nanocomposites by one-step laser irradiation, which effectively avoided material aggregation and had good dispersion stability. The results showed that the friction coefficient of the composites with the addition of 0.1 wt% was reduced by 40%, and the wear point diameter was reduced by 36% (Figure 1 below).

Figure 1.

(a,b) Optical microscope images of pure PL after adding 0.1 wt% Ag@GO and 0.1 wt% L-Ag@rGO at different times. (c,d) UV-visible absorption spectra of additives in base oil after different settling times. (Reprinted with permission from Reference [25]. Copyright 2020 Elsevier).

Jin [26] used co-precipitation, nucleation/crystallization isolation, urea hydrothermal method and regulated the crystallization time to prepare different Layered Double Hydroxides (LDHs). The results showed that the antioxidant capacity of LDHs prepared by urea hydrothermal method was poor. The antioxidant properties of LDHs prepared by the co-precipitation method were gradually weakened with the extension of the crystallization time. The antioxidant properties of LDHs prepared by nucleation/crystallization isolation method showed an increasing trend after crystallization. Lei [27] prepared zinc oxide (ZnO) particles with different morphologies by hydrothermal synthesis and added them to lithium-based, lithium complex and polyurea greases. The experiments showed that ZnO particles significantly enhanced the load-bearing capacity of lithium grease and reduced the coefficient of friction by 32.7% compared with the base grease. ZnO particles as grease additives can effectively enhance the load-bearing performance of the grease and significantly reduce the friction, and they have a great potential to optimize the comprehensive performance of the grease.

Physical preparation methods demonstrate significant process advantages when applied to the production of gel-like lubricant nano-additives. Their operational procedures are straightforward and easy to understand, with low requirements for production equipment, and the process is intuitive and controllable, facilitating large-scale mass production. Certain processes, such as ball milling, are particularly suitable for industrialization due to their low equipment investment and operating costs. However, this method still faces technical challenges in practical applications. Due to the lack of precise control mechanisms, it is difficult to finely regulate the size and morphology of nanomaterials, resulting in a wide particle size distribution range and affecting the uniformity of material properties. Additionally, the preparation process may introduce impurities or structural defects, reducing material purity and performance; nanoparticle agglomeration is highly likely during dispersion, resulting in insufficient dispersion and stability in lubricant systems. To address these issues, the industry often combines nano-additives with gel carriers to improve dispersion performance, enhance stability, and optimize their effectiveness in lubricants.

2.2. Chemical Synthesis

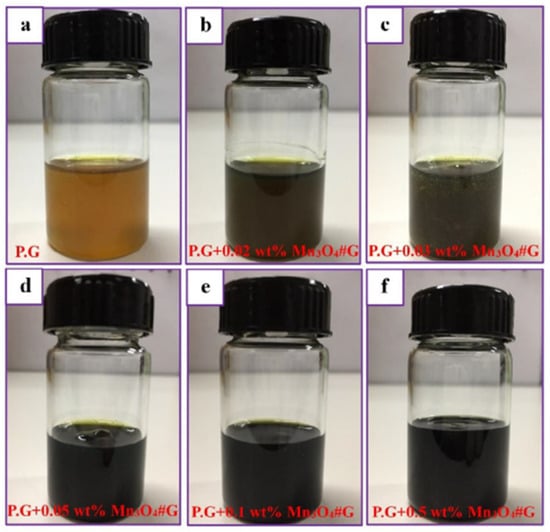

Compared with the physical preparation method chemical synthesis is highly accurate and the size, morphology and composition of the nanomaterials can be regulated by precisely controlling the reaction conditions (e.g., temperature, pressure, concentration, etc.). Excellent material properties enable the synthesis of nanomaterials with high purity, homogeneous structure and specific functionality for a wide range of applications [28]. In the chemical preparation process, in situ gelation technology has attracted much attention, whereby gels are formed directly in the chemical reaction system, allowing nanoparticles to be uniformly embedded in the gel network. Wang et al. [29] synthesized uniformly sized nickel nanoparticles using a direct reduction method. After mechanical stirring, they were added to a lithium-based gel-like lubricant. The results showed that when the mass fraction of nickel nanoparticles was 0.2%, the anti-wear and friction-reducing performance of the grease was significantly improved. Jin et al. [30] investigated nanocomposite additives to improve the lubricating properties of grease and synthesized Mn3O4/graphene nanocomposites as lubricant additives by hydrothermal method. As shown in Figure 2.

Figure 2.

Photographs of lubricating grease samples with different Mn3O4#G additive contents: (a) Base lubricating grease (P.G); (b) P.G + 0.02 wt% Mn3O4#G; (c) P.G + 0.03 wt% Mn3O4#G; (d) P.G + 0.05 wt% Mn3O4#G; (e) P.G + 0.1 wt% Mn3O4#G; (f) P.G + 0.5 wt% Mn3O4#G [30].

Li et al. [31] synthesized a novel thiophosphate, 3-(O,O-dodecylphenol dithiophosphate)-2-methylpropanoic acid (NDMA), and added it as an extreme pressure and anti-wear additive to lithium composite gel-like lubricant. The results showed that NDMA had better shear stability, reduced friction, anti-wear properties, and load-bearing capacity than zinc dialkyldithiophosphate (ZDDP). Wu et al. [32] investigated the tribological properties of chemical composites and physical mixtures of ZnO and SiO2 nanoparticles as additives in gel-like lubricants. They selected harder SiO2 nanoparticles and softer ZnO nanoparticles, synthesized hard-shell soft-core composite nanoparticles (ZnO@SiO2) via chemical vapor deposition, and used them for the first time as lubricant additives. The results showed that the composite ZnO@SiO2 nanoparticles exhibited better dispersion and tribological properties than the physically mixed nanoparticles (ZnO/SiO2). Yang et al. [33] synthesized titanium dioxide-silica composite nanoparticles (TiO2@SiO2) by chemical deposition method and doped them into polytetrafluoroethylene (PTFE) grease as additives. The results showed that TiO2@SiO2 significantly enhanced the friction reduction characteristics and insulating properties of PTFE grease through the surface coating and synergistic effects, demonstrating the potential application value in the field of multifunctional lubricating materials such as high insulating working conditions. Wang et al. [34] prepared calcium fluoride (CaF2) nanocrystals with an average particle size of 60 nm using a precipitation method. After friction testing, a composite boundary film composed of CaF2, CaO, iron oxide, and organic compounds formed on the friction surface, with a thickness of approximately 12 nm. This effectively reduced friction and wear, providing new design ideas for the development of high-performance nano-additives in gel-like lubricants. Nassef et al. [35] used reduced graphene oxide (rGO) and zinc oxide (ZnO) nanoadditives to modify palm oil grease. ZnO forms a protective zinc compound layer on the metal surface through chemical reactions, achieving boundary lubrication; rGO reduces friction through a unique physical lubrication mechanism, specifically manifested as layer slip effects and surface coverage effects. The two-dimensional layers of rGO form a slip layer between friction surfaces, akin to “molecular-scale sliding plates”, effectively reducing shear resistance. Simultaneously, rGO adsorbs onto the metal surface, forming a physical barrier layer that reduces direct wear through a nano-repair mechanism. Experimental results show that after adding ZnO and rGO, the load-carrying capacity of palm oil grease increases by 30% and 60%, respectively, while the friction coefficient decreases by 60%. This indicates that ZnO and rGO, as nano-additives, significantly enhance the performance of palm oil grease, with rGO exhibiting a more pronounced synergistic effect. Their distinct mechanisms of action complement each other, collectively improving the overall performance of the grease.

Wu et al. [36] synthesized four types of modified carbon quantum dots (CQDs) with different alkyl chain lengths using a hydrothermal method and combined them with lithium-based gel-like lubricants. The study found that the alkyl chain length affects the interfacial adsorption of CQDs and the formation of lubricating films, thereby regulating tribological properties. Longer alkyl chains may enhance interfacial stability and anti-friction effects.

In summary, in the field of preparing gel-like lubricating materials and their composite systems, physical and chemical preparation methods exhibit significant technical differences, as shown in Table 2. Physical preparation techniques, such as mechanical stirring and ultrasonic dispersion, are characterized by their simple operating procedures and low process implementation thresholds, enabling efficient mixing and molding of nanoparticles with gel matrices, and are particularly suitable for large-scale industrial production scenarios. Chemical preparation methods, including sol-gel and emulsion polymerization, can precisely shape the microstructure of gel-like lubricants and the size and morphology of nano-additives through molecular-level precise control. In actual production practice, the preparation of gel-like lubricants requires a comprehensive balance of key factors such as economic cost, production efficiency, and environmental friendliness. For physical preparation methods, advanced techniques such as microfluidic technology and dynamic shear dispersion can be introduced to effectively improve the dispersion precision of nano-additives in the gel matrix. The development of chemical preparation methods should focus on green improvements, such as adopting water-based reaction systems and recyclable catalysts, to reduce production costs and environmental impact. By promoting the deep integration of physical and chemical preparation technologies and continuous process innovation, it is possible to tailor optimal preparation schemes based on different application requirements, thereby maximizing the performance potential of nano-additives in gel-like lubricants.

Table 2.

Differences between physical and chemical methods for preparing nano-additives in gel-like lubricants.

3. Classification of Nano-Additives in Gel-like Lubricants

3.1. Metal-Based Nano-Additives

The origin of metal-based nano-additives can be traced back to the early development of nanotechnology [44]. The concept of nanotechnology was first introduced by scientist Taniguchi in 1974 to describe fine machining [45]. However, research on nanoparticles can be traced back much earlier to the 19th century. In 1857, Michael Faraday successfully prepared gold nanosols, one of the first metallic nanoparticles [46]. With the advancement of science and technology, methods such as glow discharge and gas-phase evaporation were developed to prepare a wide range of ultrafine particles of metals and oxides [47]. Until the late 1980s and early 1990s, nanotechnology developed rapidly with the invention of microscopic characterization and manipulation techniques such as scanning tunneling microscopy (STM) and atomic force microscopy (AFM), which allowed us to study the properties and applications of nanoparticles in greater depth and promoted the development and application of metal-based nanoadditives [48]. Metal-based nanoadditives mainly include monolithic or alloy materials such as copper (Cu) nanoparticles, silver (Ag) nanoparticles, nickel (Ni) nanoparticles, and aluminum (Al) nanoparticles [49]. The core advantage of such additives lies in their self-healing functionality, primarily through a nano-repair mechanism. During friction, active substances (wear particles, additive reaction products) or the material itself are “crushed” or “welded” onto the worn surface (especially at defects such as micro-cracks and micro-pits) under the high temperature and pressure of friction contact, filling the damaged areas to restore surface smoothness and form a protective film [50], thereby preventing crack propagation and reducing wear rates. Furthermore, mixing metal-based nanoadditives with base oils can significantly improve the performance of gel-like lubricants [51]. For example, chromate nanoparticles can form passivation films on metal surfaces and inhibit corrosion, and zinc oxide nanoparticles can absorb ultraviolet light and retard polymer aging [52].

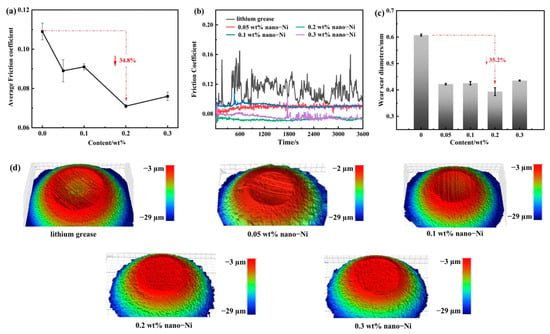

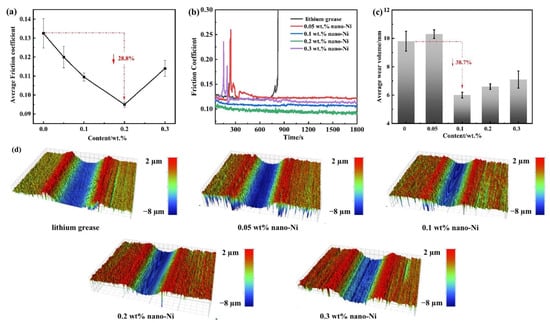

Wang et al. [29] significantly enhanced the tribological properties of lithium grease by adding 0.2 wt% nickel nanoparticles. The friction reduction and antiwear properties were enhanced by 28.8–34.8% and 35.2–38.7% for point-to-point contact (Figure 3) and point-to-plane contact (Figure 4), respectively. It is shown that nickel nanoparticles are effective additives to improve the performance of lithium grease for complex working conditions and provide a new strategy for the development of high-load, low-wear lubricant materials.

Figure 3.

Tribological properties of lithium-based grease and nickel composite materials under point contact mode:(a) Average COF; (b) COF curves; (c) Average WSD; (d) WLI morphologies of wear scar [29].

Figure 4.

Performance study of lithium-based grease-nickel mixture system in point contact friction: (a) Average COF; (b) COF curves; (c) Average WSD; (d) WLI morphologies of wear scar [29].

Zhu et al. [53] found that the prepared copper additives can improve the tribological properties and electrical conductivity of lithium-based gel-like lubricants because they can adhere to and deposit on the steel surface that has been subjected to friction, forming a boundary lubrication film composed of cupric oxide, copper oxide, iron oxide, etc. The lubrication film formed can protect the metal from damage. Bai et al. [54] added liquid metal gallium-based liquid metal (GBLM) as an additive to lithium-based gel-like lubricant. Research shows that pure GBLM has poor anti-wear performance under low loads and inadequate lubrication performance under high loads. However, when combined with lithium-based grease, its extreme pressure lubrication capability is significantly enhanced, while its anti-wear performance under low loads remains unaffected. When the mass ratio of GBLM to lithium-based grease is 1:1, the welding load exceeds 10 kN to reach the limit value, indicating that the composite of GBLM and lithium-based grease can enhance extreme pressure performance, maintain low-load anti-wear capability, and exhibit synergistic lubrication potential under extreme high-load conditions. Tarmizi et al. [55] investigated the effect of micro-cobalt and nano-cobalt ferrite (CoFe2O4) on the viscous behavior of magnetorheological grease. The results show that microcobalt gives the largest reduction in grease viscosity (43.2% reduction), which is superior to nano-CoFe2O4 (26%), as shown in Figure 5. micrometer-sized particles perform better in terms of viscosity reduction. This suggests that microcobalt has more potential to modulate the rheological properties of magnetorheological materials (e.g., viscosity reduction, flow enhancement). This section focuses on the application of various metal-based nano-additives in gel-like lubricants. Nano-nickel significantly enhances the anti-friction and wear-resistant properties of lithium-based grease (improvement of 28.8–38.7%), making it suitable for complex operating conditions; copper additives improve the tribological properties and conductivity of lithium-based grease by forming a boundary lubrication film; when combined with lithium-based grease, liquid metal GBLM significantly enhances extreme pressure lubrication capability (welding load exceeding 10 kN) while maintaining low-load wear resistance; Micro-cobalt outperforms nano-cobalt ferrite in regulating the viscosity (reduction rate of 43.2%) and flowability of magnetorheological lubricating grease. Through these studies, it can be concluded that different material additives optimize lubricating grease performance through mechanisms such as film protection, synergistic lubrication, or rheological regulation, providing diverse strategies for the development of high-performance lubricating materials under high-load and extreme operating conditions. The unique three-dimensional network structure of hydrogels and organic gels can serve as a dispersion carrier and performance regulation platform for nano-metal particles. The polymer network of the gel restricts the Brownian motion of nanoparticles through physical confinement, effectively inhibiting particle agglomeration and maintaining their nanoscale dispersion state. Additionally, the gel’s swelling properties confer dynamic response capabilities to the lubrication system: under friction heat or pressure, the gel absorbs the surrounding medium (such as water or organic solvents) and swells, prompting the encapsulated nano-metal particles to migrate toward the friction interface, thereby achieving targeted release of the additives. The composite of the gel and nano-metal particles produces a synergistic effect: the gel’s viscoelastic properties cushion the impact on the friction pair, while the nano-particles enhance the load-bearing capacity of the lubricating film. Together, they improve the overall performance of the lubricating material.

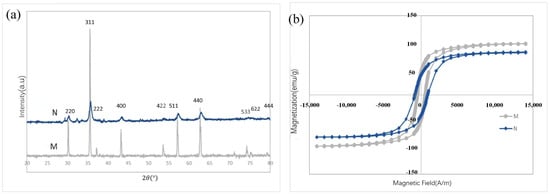

Figure 5.

(a) XRD diffraction patterns of nano-sized (N) and micron-sized (M) cobalt ferrite, confirming the formation of their crystal structures; (b) Magnetic hysteresis loops of the synthesized CoFe2O4 particles that show the magnetization of M is higher as compared to N. (M: CoFe2O4 particles; N: CoFe2O4 nanoparticles) [55].

3.2. Metal Oxide Nanoadditives

The origin of metal oxide nano-additives is closely related to the development of nanotechnology [56]. The concept of nanotechnology was first introduced by Richard Feynman in 1959, and with the advancement of science and technology, especially the invention of the microscope, scientists are able to observe and manipulate materials on the nanoscale. Typical materials include titanium dioxide nanoparticles, silicon dioxide nanoparticles, zinc oxide nanoparticles, and alumina nanoparticles, which are characterized by high chemical stability, oxide surface inertness, and resistance to high-temperature oxidation [57]. With high load-bearing capacity, hard oxides (e.g., Al2O3) disperse the contact stresses through the “micro-support effect” to enhance the extreme pressure performance [58]. He et al. [59] used nano-Al2O3, nano-ZnO, and composite nano-particles of the two as additives in gel-like lubricants. They found that when the Al2O3 content in the additives was 0.4 wt% and the ZnO content was 0.6 wt%, the composite nano-particle-based gel-like lubricant had the lowest average COF and wear scar diameter, which were approximately 160% and 28% lower than those of the base lubricant, respectively. Wu et al. [60] prepared three base lubricants—composite gel lithium-based (LCG), polyurea (PG), and composite calcium sulfonate (CSCG)—as well as corresponding lubricants containing 1% mass fraction copper oxide (CuO) nanoparticles (six types in total). The results showed that the polyurea lubricant (PG) containing CuO exhibited the best tribological performance, with significantly reduced friction coefficients and wear scar diameters, and a smoother and finer wear surface. The performance improvement was attributed to the synergistic lubrication mechanism between the layered thickener structure of the polyurea lubricant and the CuO nanoparticles. He et al. [61] found that adding 0.6 wt% of nano-cerium oxide (CeO2) significantly improved the friction reduction (friction coefficient reduced by 28%) and anti-wear (wear scar diameter reduced by 13%) properties of lithium-based gel-like lubricants. At 50 °C, the friction coefficient and wear width of the lubricant reached their lowest values, indicating that the performance was optimal at this temperature. Wu et al. [62] used zinc oxide-silicon dioxide core-shell composite nanoparticles (ZnO/SiO2) as additives in gel-like lubricants and found that under light loads, the coefficient of friction decreased by 18% and the diameter of the wear scar decreased by 22%. Under heavy loads, the anti-friction and wear-resistant effects were even better, with the coefficient of friction decreasing by 15% and the diameter of the wear scar decreasing by 28%. The synergistic interaction between ZnO and SiO2 in the core-shell structure enhances the stability and load-bearing capacity of the interface lubrication film, indicating that these composite particles significantly improve grease performance under different load conditions. Du et al. [63] found that composite nanoparticles containing grease exhibited a low coefficient of friction and excellent anti-wear properties. When the ratio of TiO2 to CeO2 was 6:4, the samples showed the best tribological properties, with a 30.5% reduction in the coefficient of friction and a 29.2% reduction in the diameter of the wear point compared to the base grease. In addition, the roughness of the wear point surface and the maximum depth of the wear marks were significantly reduced. Sooraj Singh Rawat et al. [64] showed the greatest reduction in mean wear volume (MWV) (~36% and ~56%) by adding CuO and ZnO nano-additives at 0.2% w/w, respectively, in paraffin grease. The energy consumption was reduced by ~31% and 28% by dispersing ZnO and CuO nano-additives in paraffin grease at the same concentration, as shown in Figure 6.

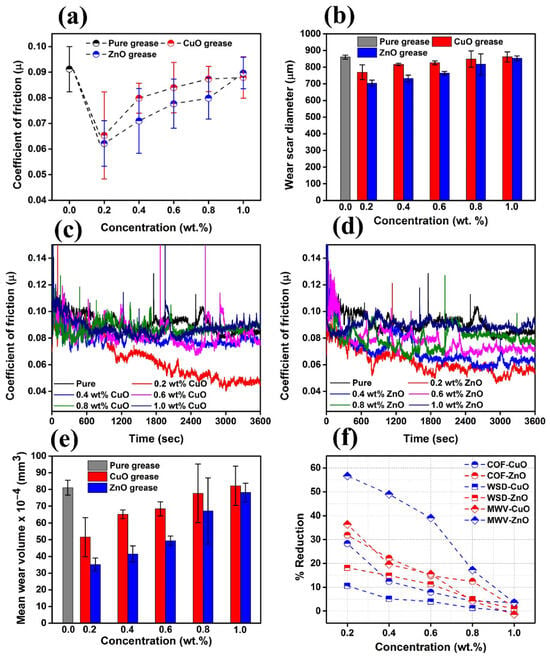

Figure 6.

(a) Effect of different concentrations of ZnO and CuO nanoparticles on the average coefficient of friction (COF). (b) Influence of changes in ZnO and CuO nanoparticle concentrations on the wear scar diameter (WSD). (c) Time-dependent characteristics of the coefficient of friction with varying concentrations of CuO nanoparticles. (d) Time-dependent characteristics of the coefficient of friction with varying concentrations of ZnO nanoparticles. (e) Effect of varying concentrations of ZnO and CuO nanoparticles on the average wear volume (MWV). (f) Percentage reduction in COF, WSD, and MWV caused by ZnO and CuO nanoparticles [64].

Qiang et al. [65] studied the performance of nanorods-Al2O3 as a grease additive and found that it can significantly improve lubrication performance. When the addition amount is 0.3 wt%, the average friction coefficient and scratch diameter of the grease are the lowest, the worn steel surface is smooth with no obvious defects, and there is a correlation between the tribological and rheological properties of lithium grease. Additionally, the composite of nano-metal oxides (such as Al2O3, TiO2) with gel materials is an important direction in the field of lubrication. Among these, nano-Al2O3, due to its high hardness, chemical stability, and good dispersibility, can fill micro-pits on friction surfaces and enhance the load-bearing capacity of the lubricating film. Titanium dioxide (TiO2) exhibits outstanding performance during friction processes due to its unique photocatalytic and self-healing properties. The mechanisms of its photocatalytic and self-healing effects are as follows: Under friction heat or light exposure, TiO2 may promote the decomposition of surface oxides through photocatalytic effects or undergo chemical reactions with metal surfaces to form low-shear-strength titanium compounds, such as titanates formed by TiO2 and metals. These compounds fill surface defects and form a lubricating film. The protective film has low shear strength, enabling interlayer slippage during friction to reduce friction resistance while preventing wear caused by abrasion from hard particles. Additionally, the introduction of smart gel materials (such as thermosensitive, pressure-sensitive, or pH-responsive polymer gels) provides new avenues for precise regulation of nanoadditives, potentially further optimizing the performance of TiO2 and other nanoadditives in lubrication applications. This section systematically explores the application mechanisms and performance optimization pathways of metal oxide nanoadditives in gel-like lubricants. The results indicate that different types of additives, through diverse mechanisms such as interfacial film formation, synergistic lubrication, and functional response, provide a systematic solution for the development of high-performance lubricants under extreme operating conditions. The introduction of smart gel materials (such as thermosensitive, pressure-sensitive, or pH-responsive polymer gels) has provided new avenues for precise control of nano-additives. As carriers, smart gels can dynamically regulate the release and distribution of nano-oxides through physical or chemical response mechanisms in response to changes in environmental temperature or pressure. The “smart carrier-nano-additive” synergistic system not only achieves dynamic optimization of lubrication performance but also endows lubrication materials with self-regulatory capabilities, providing innovative strategies for friction control under extreme conditions (such as high temperatures, heavy loads, and complex environments).

3.3. Carbon Nanomaterial Additives

The origin of additives for carbon nanomaterials can be traced back to the late 1980s and early 1990s, and has evolved with the discovery of carbon nanomaterials and further research [66]. Buckminsterfullerene C60 was first reported in 1985 by Kroto et al. [67]. Fullerene is a spherical molecule composed of 60 carbon atoms through 12 five-membered and 20 six-membered rings, and is considered to represent a zero-dimensional nanocarbon material due to its unique structure and properties [68]. Carbon nanotubes were discovered in 1991 by scientist Iijima [69]. Carbon nanotubes are circular tubular structures formed by hybridization of carbon atoms in SP2 and SP3, which have excellent electrical conductivity and structural buildability [70]. The discovery of carbon nanotubes has further promoted the study of carbon nanomaterials. In 2004, AndreGeim and KonstantinNovoselov succeeded in isolating a single layer of graphene from graphite [71]. Graphene is a two-dimensional material composed of a single layer of carbon atoms with extremely high electrical and thermal conductivity and mechanical strength [72]. Its unique advantage lies in the laminar lubrication mechanism, where graphene and C60 reduce the coefficient of friction by interlayer slip [73]. With the continuous progress of the preparation technology of nanocarbon materials and the in-depth study of their properties, the application fields of nanocarbon material additives are gradually expanding [74]. Nanocarbon materials such as nanodiamond and graphene are used to prepare high-performance grease additives [75]. Rukhov et al. [76] investigated the performance impact of graphite nanoplatelets (GNP) as an additive in gel-like lubricants. As the GNP concentration increased from 0 to 150 ppm, the residual water content of the lubricant rose from 0.6 wt% to 2.3 wt%, while penetration decreased from 44 mm to 31 mm (increased consistency). At a GNP concentration of 150 ppm, the wear spot size was smallest (0.215 mm), and the anti-wear performance was optimal. A balance must be struck between optimizing performance and controlling moisture content when determining the application concentration of GNP. Kamel et al. [21] found that graphene nanosheets (GNS) significantly improve the performance of calcium-based gel-like lubricants when used as additives: friction was reduced by 61%, the wear scar diameter (WSD) was reduced by 45%, and the anti-wear performance was significantly enhanced; at the addition of 3 wt% of GNS, the extreme pressure performance (EP) was enhanced by 60%, showing excellent high load stability. This indicates that GNS can significantly improve the comprehensive performance of the grease, especially in the friction reduction, anti-wear and extreme pressure, as shown in Figure 7.

Figure 7.

Functional relationship between graphene concentration gradient and friction coefficient. (Reprinted with permission from Reference [21]. Copyright 2016 Engineering & Technology).

Kumar et al. [77] investigated the effect of different particle sizes of graphite nano-additives on tribological properties and showed that all sizes were advantageous for all selected properties and the larger the particle size, the lower the performance improvement. Kamel et al. [78] found that adding multi-walled carbon nanotubes (MWCNT) and aluminum oxide (Al2O3) at a ratio of 4 wt% to a lithium-calcium-based gel-like lubricant significantly optimizes its performance. At this point, the grease exhibits the lowest wear scar diameter (WSD) and friction coefficient, with optimal anti-wear and friction-reducing properties. Additionally, the weld point increases by 26%, the drop point by 32%, and the thermal conductivity by 75%, demonstrating excellent extreme pressure performance, high-temperature stability, and thermal conductivity, as shown in Figure 8.

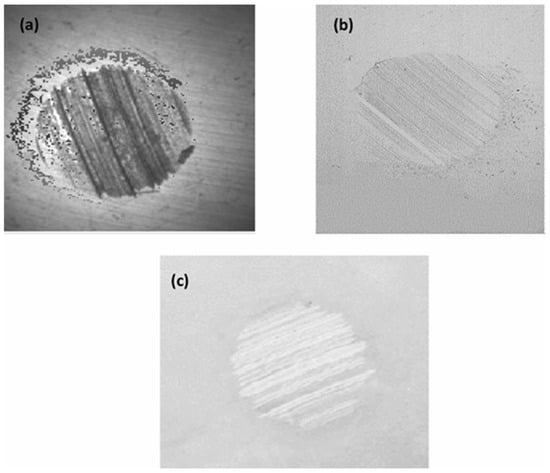

Figure 8.

(a) Basic lithium-based composite grease (LCG). (b) LCG/MWCNTs containing 4 wt% multi-walled carbon nanotubes. (c) LCG/Al2O3 containing 4 wt% aluminum oxide [78].

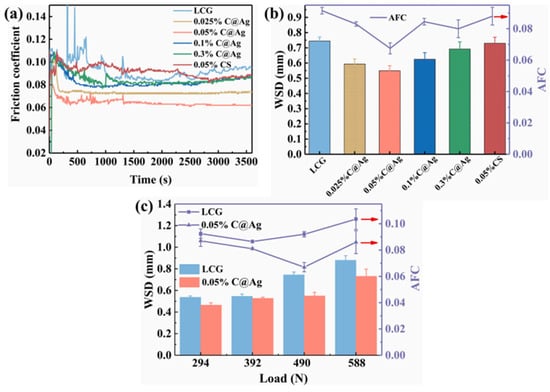

Goti et al. [79] utilized innovative nano-additives such as graphene to improve the performance of conventional lubricants and showed that the right amount of graphene reduces friction and wear because graphene enhances the resistance of the lubrication film to wear. However, excessive amounts are harmful and interfere with lubrication. Ren et al. [80] found that C@Ag core-shell materials, when used as gel-like lubricant additives, can reduce the average friction coefficient of grease by 27.17% and decrease the diameter of wear spots by 26.12%. The mechanism behind this enhanced performance lies in the hard carbon core (C) providing support and wear resistance, while the soft silver shell (Ag) performs lubrication and self-repair functions. The two work synergistically to achieve rolling, filling of wear pits, and surface self-repair effects, significantly enhancing the lubricant’s overall performance, as shown in Figure 9.

Figure 9.

Friction coefficients (a) and corresponding AFC and WSD results (b,c) for various grease samples. (Reprinted with permission from Reference [80]. Copyright 2024 Elsevier).

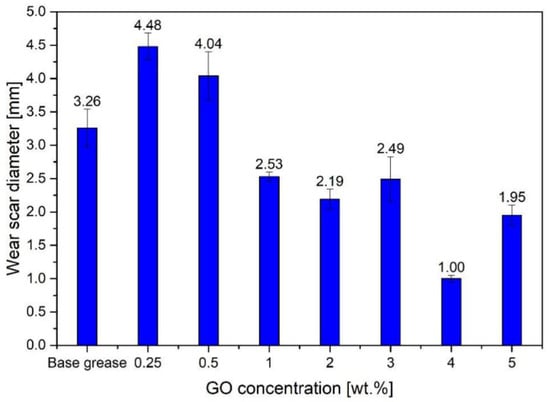

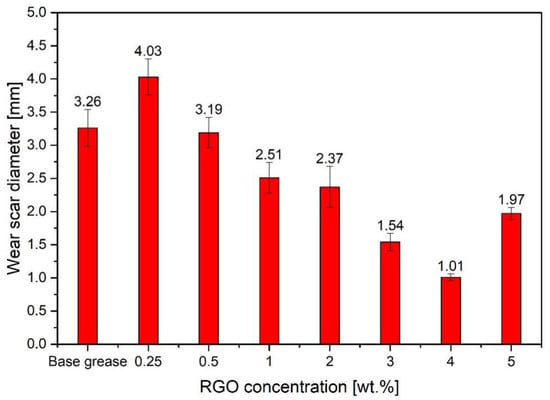

Li et al. [81] studied the tribological properties of gel-like lithium-based grease with a small amount of graphene (FLG) added. The results showed that when the mass fraction of few-layer graphene (FLG) was 0.1%, the reduction rate of the coefficient of friction was the highest, and the wear scar diameter (WSD) was the smallest. Wang et al. [82] used AI-assisted design to develop chemically functionalized graphene (FGR) and functionalized carbon nanotubes (FCNT) as grease additives. When the FGR content was 0.14 wt% and the FCNT content was 0.16 wt%, the friction-reducing performance of the grease improved by 25.66%, and the anti-wear performance improved by 29.34%. The performance optimization stems from the synergistic lubricating effect of FGR and FCNT. This study utilized AI to optimize the functionalization process, achieving efficient lubrication at extremely low addition levels while maintaining cost-effectiveness. Djas et al. [83] used flake graphene (graphene oxide GO and reduced graphene oxide RGO) as grease additives and found that it exhibited excellent antiwear properties at a concentration of 4 wt%. Compared with the base lubricant, the wear scar diameter (WSD) was reduced by nearly 70%, which significantly reduces wear and improves lubricant durability, as shown in Figure 10 and Figure 11. Graphene exhibits an extremely strong anti-wear effect at high concentrations, and it is suitable for high load and high wear conditions.

Figure 10.

The Impact of GO Additive Content on the Tribological Properties of Lubricants [83].

Figure 11.

The Impact of RGO Additive Content on the Tribological Properties of Lubricants [83].

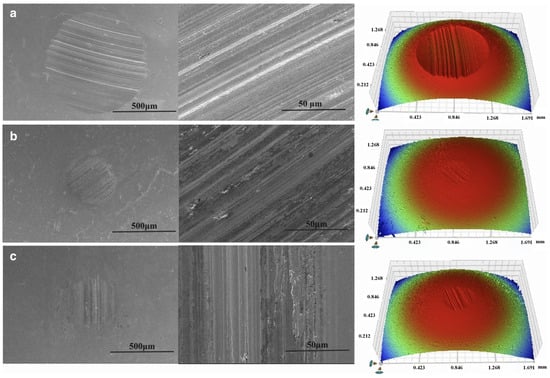

Sun et al. [84] studied the effect of graphene and graphite composite additives on the micro-motor tribological behavior of steel wires in grease. The results show that the addition of multilayer graphene or micron-sized graphite can significantly improve the anti-wear ability of the grease, and the composite additive makes the micro-cutting phenomenon on the wear surface significantly reduced, effectively inhibiting the material surface damage. The synergistic effect of graphene and graphite optimizes the tribological performance of the grease, which is especially suitable for precision or high wear scenarios such as steel wire microfriction. From the perspective of manufacturing industry, nanocarbon material additives can significantly improve the performance of materials, in metal processing, it can improve the strength and toughness of the metal, so that the metal products produced are more durable, which is conducive to improving product quality, and then improve production efficiency and reduce production costs. In chemical production, it helps to optimize the reaction process, enhance the activity of the catalyst, making chemical production more efficient and environmentally friendly. Not only that, nanocarbon additives in the biological field also has important applications. Xie et al. [85] used multilayer graphene additives to enhance the lubricity of bio-lubricants. The results indicated that the addition of multilayer graphene can improve the load-carrying capacity and high-temperature lubricity of natural wax. This section focuses on the application of nanocarbon material additives in gel-like lubricants, finding that carbon-based materials such as graphite nanoplatelets, graphene, and carbon nanotubes, as well as aluminum oxide, can significantly enhance the lubricant’s anti-friction, wear resistance, extreme pressure, and high-temperature stability through mechanisms such as film formation, filling, and synergistic lubrication. Additive concentration and particle size have a significant impact on performance. AI-assisted design and composite additives (such as graphene and graphite) can optimize lubrication performance, providing direction for the development of high-performance lubrication materials.

In summary, the addition of carbon nanomaterials can significantly enhance the load-bearing and anti-wear capabilities of lubricating grease, driving the development of gel-based lubricating grease technology. However, their large specific surface area and high surface energy make them prone to agglomeration, leading to uneven dispersion in lubricating grease. In the future, nanocarbon materials will develop in the direction of green and low-cost applications. Systems formed by the composite of carbon-based nanomaterials (such as carbon nanotubes and graphene) with polymer gel matrices hold great potential in the field of tribology. The unique viscoelastic properties of this composite gel system allow carbon-based nanomaterials to distribute uniformly across the contact interface during friction, enabling adaptive deformation to reconstruct the surface. Under shear stress, nanocarbon materials align in an oriented manner, while the reversible deformation of the gel phase provides movement space, enabling them to fill microscopic defects in the friction pair, reduce surface roughness, and lower the friction coefficient. Additionally, the high mechanical strength and low shear resistance of carbon-based nanomaterials, combined with the viscoelastic properties of the gel phase, form an efficient energy dissipation system, offering new insights for the development of high-performance gel-like lubricants.

3.4. Other Nano Additives

Other types of nano-additives are used in a variety of applications and can be applied to industrial fields, plastic modification and so on. Nucleus-shell structured additives are a novel class of materials that achieve functional synergy through a hierarchical “core-shell” design. Their unique structural advantages confer irreplaceable application value across multiple industrial and research fields. The core primarily provides foundational properties such as mechanical support, catalytic activity, and magnetic response. The shell, on the other hand, primarily regulates these functions by imparting additional properties such as dispersibility, compatibility, and responsiveness through surface modification and interface modification techniques. Interface synergy is achieved through chemical bonding or gradient transition layers between the core and shell, which suppress phase separation and enable complementary performance. Wang et al. [86] used vacuum impregnation to adsorb ionic liquids (ILs) onto PTFE@dendritic silica (DFNS) core-shell particles, successfully preparing soft/hard/liquid three-phase composite particles (PTFE@DFNS@ILs). Adding these particles to epoxy resin coatings significantly improved the coatings’ hardness, modulus, and anti-friction wear resistance. The superior performance stems from the synergistic effects of PTFE’s lubrication, DFNS’s rolling wear resistance, and ILs’ promotion of transfer film formation. This work provides a new method for introducing liquid lubricants into micro/nano composite particles, demonstrating the immense potential of solid-liquid-core-shell structures in the field of lubrication. Liu et al. [87] developed a multi-layered core-shell structured nanocomposite C@SiO2@C using polymethyl methacrylate (PMMA) and ethyl cellulose as carbon sources to replace traditional sulfur/phosphorus-containing friction modifiers with stronger corrosive properties. When 4.0 wt% of this additive was added to PAO10 base oil, the friction coefficient and wear volume were significantly reduced by 45.8% and 75.6%, respectively. Its excellent lubricating performance is attributed to a triple-action mechanism: the high load-bearing capacity of spherical particles disperses contact stress, the carbon components released upon particle fracture form a physical isolation deposit film at the friction interface, and the friction-induced chemical reactions at the interface generate a protective friction chemical film. This dual synergistic mechanism of physical barrier and chemical film formation makes C@SiO2@C nanocomposites a promising candidate additive for industrial applications, combining low corrosion and high-efficiency lubrication performance. Haque et al. [88] employed a simple hot water treatment process (75 °C constant temperature for 24 h) to directly grow three-dimensional leaf-like CuO nanostructures on the surface of copper powder, successfully preparing a binder-free core-shell type CuO/Cu electrode. The microstructure, elemental composition, crystal structure, and high specific surface area characteristics of the electrode were confirmed through multi-dimensional characterization methods. Electrochemical testing showed that in Na2SO4 electrolyte, the electrode exhibited a specific capacitance of approximately 220 F/g at a scan rate of 5 mV/s, although the capacitance retention rate was approximately 38% after 1500 cycles. The research results indicate that this CuO/Cu core-shell material prepared via hot water treatment technology demonstrates excellent application potential as a pseudocapacitive supercapacitor electrode, and its simple synthesis process provides new insights for innovations in energy storage technology. Incorporating nano additives into plastics, such as nano calcium carbonate and nano montmorillonite, can improve the mechanical properties of plastics, increase the strength, hardness, toughness, etc., and also enhance the heat resistance, water resistance, and barrier properties of plastics [89]. Surface-grafted nanoparticles refer to a class of composite materials in which functional molecular chains (such as polymers, organic small molecules, biomolecules, etc.) are introduced onto the surface of nanoparticles via chemical or physical methods. The primary targets for grafting are active sites on the surface of nanoparticles (such as SiO2, TiO2, Fe3O4, graphene, etc.), such as hydroxyl groups and unsaturated bonds, which form covalent bonds or physical adsorption with functional molecules. Grafting can improve the dispersion of nanoparticles in solvents/matrices, enhance interface compatibility with polymer matrices, and confer specific functionalities (such as magnetic properties, catalytic activity, and bio-targeting). Haque et al. [90] proposed a two-step modification process (methacrylic acid graft polymerization + in situ introduction of zinc oxide nanoparticles), successfully preparing ZnO NPs-modified polyamide composite reverse osmosis membranes (ZnO NPs-PMAA-g-PA (TFC)). Characterization results indicated that ZnO nanoparticles were stably anchored on the membrane surface. The modified membrane material exhibits significantly enhanced hydrophilicity (water contact angle reduced to ~50°), along with excellent desalination performance: total salt rejection rate of 97%, with 99% retention of divalent ions and 98% retention of monovalent ions, and potential resistance to Escherichia coli contamination. This modification method, by synergistically enhancing the membrane material’s hydrophilicity, selective permeability, and resistance to biological contamination, provides an effective solution for optimizing the performance of reverse osmosis membranes used in seawater desalination. Lin et al. [91] revealed the critical importance of maintaining the highly dispersed state of nanoparticles (NPs) throughout the entire process of preparing polymer-grafted nanoparticle (PGNP) gas separation membranes. Studies have shown that even if the initial NPs exhibit good dispersion, surface functionalization treatment can still cause NP agglomeration (equivalent to an increase in core particle size), leading to a significant decline in the permeability performance of the final PGNP membrane. By introducing a protective layer before functionalization to inhibit NP agglomeration and then implementing grafting modification, PGNP membrane materials with significantly improved permeability performance were successfully prepared. The core mechanism lies in the fact that, under the same grafting parameters, nanoscale-dispersed NPs exhibit superior membrane separation performance compared to agglomerated NPs. This result highlights that strictly controlling the dispersion state of particles throughout the preparation process is a core technical element for optimizing the separation performance of PGNP membranes. Nayak et al. [92] used GISAXS and XRR characterization techniques to discover that polyethylene glycol (PEG)-grafted silver nanoparticles (AgNPs), gold nanoparticles (AuNPs), and their mixed systems can self-assemble at the gas-liquid interface to form environmentally stable hexagonal ordered thin film structures. Among these, nanoparticles grafted with short-chain PEG exhibit a dense, ordered arrangement, while those with long-chain PEG form a low-density quasi-bilayer structure. Due to their higher grafting density, AuNPs exhibit significantly superior ordered arrangement at the interface compared to AgNPs. In the binary mixed system, AuNPs dominate the gas-liquid interface, while AgNPs embedded in the system cause lattice parameter expansion, but no formation of a binary superlattice structure was observed. This study provides an important theoretical foundation for understanding the interface assembly mechanism of PEG-grafted nanoparticles and optimizing the preparation of ordered films.

In the field of biomedicine, gel-like lubricants have emerged as highly promising multifunctional biological carriers due to their unique rheological properties and biocompatibility. Their continuous-phase network structure enables the formation of stable composite systems with nanomaterials, thereby enhancing the dispersion and stability of nanocarriers within biological systems. Common drug carriers such as nanoliposomes and nanopolymers, though possessing good biocompatibility and modifiability, tend to aggregate or undergo rapid metabolism in vivo, affecting drug efficacy. However, dispersing them in gel-like lubricants can utilize the gel’s three-dimensional network to physically confine nanoparticles, slowing degradation rates and enhancing drug controlled-release performance [93]. Cheng et al. [94] addressed the challenge of tissue adhesion commonly encountered during Achilles tendon repair by developing an injectable lubricating hydrogel (ILH) with motion responsiveness and anti-adhesion properties. In vitro cell experiments and coagulation tests demonstrated that ILH exhibits excellent cell compatibility and blood compatibility. In functional validation, it significantly prevents tendon adhesion and promotes tendon healing, providing an innovative material solution for addressing adhesion issues in Achilles tendon repair.

The swelling properties of the gel enable it to achieve controlled release of the nanomedicine carrier in response to changes in the local microenvironment (such as pH, temperature, and enzyme concentration), thereby further enhancing the efficiency and precision of drug targeted delivery. This gel-nanomaterial composite system not only reduces the toxic side effects of drugs on normal tissues but also provides innovative solutions for biomedical applications such as cancer treatment and tissue repair [95]. In the field of environmental protection can be carried out in the treatment of wastewater, nano titanium dioxide, nano activated carbon, etc. has a large specific surface area and adsorption properties, can be used in wastewater treatment, can adsorb and degrade heavy metal ions, organic matter and other pollutants in the water, to achieve the purpose of purifying the water quality [96]. Wang et al. [34] found that CaF2 nanocrystals as grease additives have excellent antiwear, friction reduction and extreme pressure properties. The additive amount was not linearly positively correlated with the grease performance, and an optimal additive ratio existed. CaF2 nanocrystals can significantly improve the comprehensive tribological properties of grease, but the additive amount needs to be optimized to achieve the best effect. Senyk et al. [97] found that additives with smaller particle sizes, a larger proportion of the nanoparticle fraction, and a more developed porous structure were more effective by investigating the effects of nano-hexagonal boron nitride and micrometer particles on the structure, thermal and mechanical stability of lithium-calcium based greases. Wang et al. [98] studied polyurea grease containing molybdenum dialkyl dithiophosphate (MoDDP) and potassium borate (PB) additives. The results showed that MoDDP, as a polar additive, significantly enhanced the colloidal stability of the grease, increased its apparent viscosity, and improved its structural strength; however, PB had a minimal effect on the colloidal structure and structural strength of the grease. This indicates that different additives have notable discrepancies in their modulatory effects on grease performance. Shu et al. [99] compared the performance of polypropylene (PP) thickened grease and lithium complex (Li-composite) grease to test the effect of pure grease and the addition of 2 wt% ZDDP and/or MoDTC. It was found that in polypropylene greases, the combination of ZDDP and MoDTC showed optimal performance with the lowest coefficient of friction and longer service life, and demonstrated broad applicability independent of sliding speed, contact pressure, temperature or type of sliding. Polypropylene-based greases offer a better overall performance than lithium complex greases with the same additive formulation. The synergistic action of the polypropylene thickener and the ZDDP+MoDTC additive package significantly improves the friction reduction and durability of the grease for a wide range of operating conditions. Kumar et al. [100] investigated the performance characteristics of lithium grease containing PTFE particles as additives, lithium based synthetic grease with polyalphaolefin as base stock and different sizes of PTFE particles (4 wt%), 50 nm, 6 µm, 9 µm and 12 µm and shape as functional additives. The results show that the smaller the size, the better the overall performance. Zhong et al. [101] used a variety of analytical methods to explore the effect of temperature on the characteristics of baijiu. The results showed that temperature can significantly alter the content of volatile components, ethanol-water structure, intermolecular forces, and viscosity of baijiu, thereby affecting its mouthfeel and flavor perception. The study further clarified that baijiu exhibits optimal mouthfeel and flavor experience at 25 °C, providing a scientific basis for selecting the optimal drinking temperature for baijiu.

Yan et al. [102] investigated the effect of calcium borate as an additive on the tribological properties of gel-based lithium-based grease and polyurea-based grease. The results showed that calcium borate forms a boundary lubrication layer with the soap fibers in the grease, significantly optimizing the tribological properties. SEM analysis revealed that the soap fibers in polyurea-based grease were more dispersed, smaller, and shorter, while those in lithium-based grease had a more compact structure. The polyurea-based grease exhibited superior anti-wear and friction-reducing properties due to its more dispersed soap fiber structure and higher oxide content. Nano-additives, with their unique physicochemical properties, have demonstrated outstanding performance and broad application potential across various fields such as electronics, catalysis, and biomedicine. The viscoelasticity of the gel synergizes with the high strength and high modulus characteristics of nano-additives, enabling the composite grease to maintain excellent lubrication performance under extreme conditions such as heavy loads and high temperatures. In summary, the composite of nano-additives and gel-based grease not only optimizes and upgrades the original performance of grease but also provides innovative solutions for high-end equipment lubrication, demonstrating broad application prospects. This section systematically explores the applications and innovations of nano-additives in the fields of biomedicine, environmental protection, and lubricant materials. In the field of biomedicine, the gel swelling properties of nano-additives enable nano-drug carriers to achieve microenvironment-responsive release, thereby enhancing the precision of targeted therapy; In environmental protection, nanomaterials with high adsorption capacity effectively treat pollutants in wastewater. In lubrication materials, additives such as CaF2 and hexagonal boron nitride enhance the anti-wear and friction-reducing properties of lubricants through optimized ratios, particle sizes, and synergistic interactions with the matrix. New systems based on polypropylene demonstrate superior adaptability to various operating conditions, providing critical support for technological breakthroughs across multiple fields. Table 3 summarizes the different types of additives and their application areas.

Table 3.

Nano-additives classification.

4. Performance Analysis and Evaluation of Nano Additives in Gel-like Lubricants

4.1. Anti-Wear

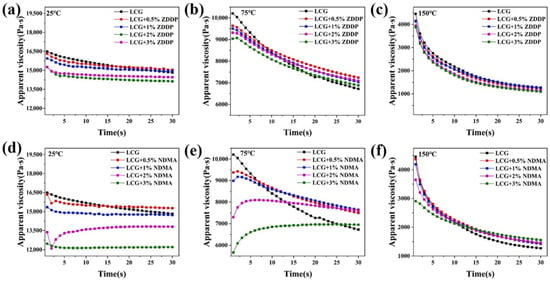

Wear refers to the surface of the object in relative motion, due to mechanical, chemical and other factors that lead to the gradual loss of material or surface properties of the phenomenon of change, will cause harm to equipment, production, safety and other aspects. Mechanical equipment can reduce accuracy, such as machine tools and instrumentation can lead to increased fit clearance, decreased motion accuracy, increased energy consumption, increased surface roughness of parts, and increased frictional resistance [106]. In the mechanical transmission process, in order to overcome the increased friction, the equipment needs to consume more energy to maintain operation, resulting in lower energy utilization and increased energy consumption [107]. Excessive wear and tear on critical components may lead to sudden equipment failure downtime [108]. It can produce very serious hazards in the production process, affecting the efficiency in industrial production, leading to a decline in equipment performance, unstable operation, and the need for frequent downtime for maintenance and replacement of parts [109]. Wear and tear not only affects the accuracy of the equipment itself, but also directly affects the quality of the product and cause serious safety accidents [110]. Gel-like lubricant nano-additives play a crucial role in preventing wear and tear [111]. Extreme pressure antiwear additives are mainly suitable for extreme working conditions such as high loads and high temperatures, where the contact pressure on the surfaces of mechanical parts is extremely high, and the oil film formed by ordinary grease is extremely easy to be destroyed [112]. Extreme pressure antiwear additives will play a key role at this point, and they mainly contain active elements such as sulfur, phosphorus, and chlorine [113]. When the contact pressure on the component surfaces reaches a certain level, these additives will react chemically with the metal surfaces to generate a chemically reactive film with low shear strength, which effectively separates the metal surfaces and prevents them from coming into direct contact with each other under high loads, thus greatly reducing the coefficient of friction and minimizing wear [114]. Li et al. [31] applied the novel thiophosphate 3-(O,O-dinonylphenol dithiophosphate)-2-methylpropionic acid (NDMA) as an extreme pressure (EP) and antiwear additive in lithium complex grease. It was found that NDMA significantly enhanced the oil film stability and improved the oil separation performance of the grease under high pressure and high temperature conditions. Compared with conventional ZDDP additives, NDMA exhibits superior shear resistance, better friction reduction, stronger wear resistance and higher load carrying capacity, as shown in Figure 12.

Figure 12.

Apparent viscosity curves of LCG containing ZDDP (a–c) and LCG containing NDMA (d–f) at 25 °C, 75 °C, and 150 °C [31].

Shen et al. [115] conducted a systematic evaluation of the tribological performance of lithium-based grease (LG) under the influence of three single additives (potassium borate PB, zinc dialkyldithiophosphate ZDDP, molybdenum dialkyldithiophosphate MoDDP) and two composite additives. Among these, MoDDP undergoes thermal decomposition during friction, releasing S and Mo elements that react with the metal surface to form nanoscale MoS2 layers. The interlayer van der Waals forces of these layers are weak, facilitating slip, while also filling surface grooves to form a “repair-type” lubricating film. Meanwhile, PB hydrolyzes or oxidizes to form borate/oxides, forming a hard and dense protective layer on the metal surface. This layer complements the soft MoS2 layer, creating a synergistic effect that enhances the film’s load-bearing capacity while reducing surface defects through “repair,” thereby lowering wear. The results indicate that the PB+MoDDP composite additive exhibits the best overall performance, significantly improving friction-reducing performance, enhancing wear resistance, and enhancing extreme pressure (EP) performance. Due to the formation of a boundary protective film primarily composed of oxides and MoS2 during friction, this film has low shear strength and high load-bearing capacity, thereby improving the friction-reducing and wear-resistant performance of the grease. Oily additive molecules generally have a long chain structure with a polar group at one end and a non-polar hydrocarbon-based chain at the other end [116]. Polar groups have a strong affinity for metal surfaces and can be tightly adsorbed on metal surfaces to form a molecular film with a directional arrangement [117]. This film has good flexibility and lubricity, which can effectively reduce the friction between metal surfaces even under low load and low speed working conditions. Due to its intermolecular forces, it can form a more stable lubrication layer on the surface of the parts, which has the effect of reducing friction and wear [118].

Hou et al. [119] studied the preparation of potassium borate/graphene (PB/GN) nanocomposite grease additives suitable for marine diesel engines. The study was carried out by pin-on-disc friction tester at various loads and temperatures, and the friction surface was comprehensively analyzed by scanning electron microscope and energy spectrometer. The results showed that the tribological properties of the base oil were enhanced due to the synergistic effect of PB and GN.

Anti-wear polymer additives are composed of high-molecular-weight polymers and exist in a dispersed state in gel-like lubricating grease. When mechanical parts move relative to each other, these polymer molecules form a physically adsorbed film on the metal surface, filling in microscopic irregularities on the surface and making it smoother. In addition, during friction, polymer molecules undergo deformation and orientation, further enhancing the anti-wear performance of the film. At the same time, it can also work synergistically with other additives to improve the overall anti-wear effect of the gel-like lubricant. Zhao et al. [120] found that molybdenum dialkyl dithiocarbamate (MoDTC) exhibits excellent anti-friction and anti-wear properties when used as an additive in aluminum-based gel-type lubricating grease, and exhibits significant synergistic effects with ZDDP. During friction, the two form a composite boundary lubrication film rich in phosphates/pyrophosphates and MoS2, with the P element promoting the conversion of MoDTC to MoS2, thereby enhancing lubrication performance. This composite film has low shear strength and high wear resistance, with synergistic effects superior to those of a single additive. The shape of nanoparticles can effectively enhance tribological performance, reducing friction and wear. Kamel et al. [121] prepared a calcium-based gel-like lubricant using graphene nanosheets (GNs) and TiO2 as additives. The study found that GNs and TiO2 exhibit synergistic effects in the lubricant, with friction-reducing and wear-resistant properties improved by 46.7% and 43.9%, respectively. Xia et al. [122] investigated the performance of MoS2/AlOOH nanocomposites as lubrication additives. The results showed that MoS2 was assembled in situ on the surface of AlOOH, which significantly improved the dispersion and optimized the lubrication performance. At the optimal addition concentration of 0.5 wt%, the average coefficient of friction was reduced by 50.47%, the diameter of abrasion marks was reduced by 42.34%, and the amount of wear was drastically reduced by 86.57% compared with that of the base oil. The lubrication mechanism lies in the formation of highly dispersive lubricant film by the nanocomposite structure during the friction process, which reduces friction and wear.

Research indicates that the molecular structure design of additives, the synergistic effects of multi-component systems, and the interfacial film-forming mechanisms are central to optimizing the performance of lubricating greases, providing a critical technological pathway for the development of high-performance lubricating materials under extreme operating conditions.

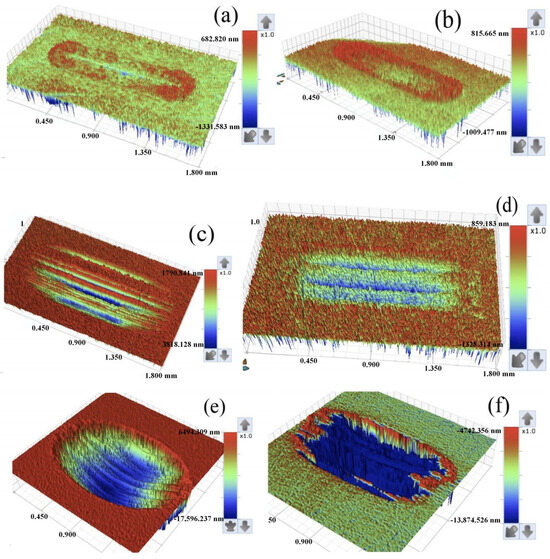

Nano-additives enhance the anti-wear performance of gel-like lubricants through multi-scale synergistic effects. At the microscopic level, hard nano-particles form a supportive structure, while layered nano-materials create a transfer film, reducing surface contact and shear stress. The three-dimensional network of the gel matrix provides a stable dispersion environment for the nano-particles, and its viscoelastic properties aid in transporting the particles to the friction interface. During friction, nanoparticles repair surface damage, and some active materials undergo friction chemical reactions with metal to form protective lubricating films. This multi-mechanism synergy enhances the grease’s extreme pressure performance and durability. The dispersion state, particle size, and surface chemical properties of nanoparticles are key factors determining anti-wear performance, providing guidance for optimizing grease formulations.

Table 4 summarizes the reduction in friction coefficients under the influence of different types of nano-additives when complying with ISO standards.

Table 4.

Friction coefficient of nano-additives based on ISO standards.

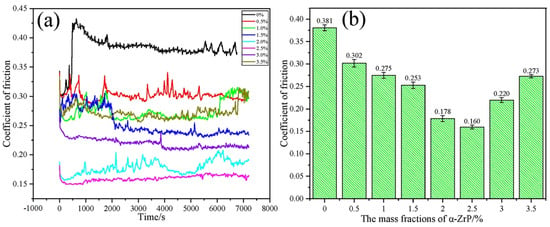

4.2. Friction Reduction

Gel-like lubricant nano-additives have unique advantages in reducing friction. They significantly improve grease performance through multiple mechanisms, reducing friction loss between mechanical components [128]. The microscopic filling and smoothing effects of nanoparticles can fill microscopic defects [129]. The surfaces of mechanical components are not completely smooth at the microscopic level, with numerous tiny bumps, depressions and scratches [130]. The nanoparticles in gel-like lubricant nanoadditives are extremely small, typically ranging from a few nanometers to several hundred nanometers, and can easily fill these microscopic defects [131]. Silica nanoparticles can be embedded in tiny grooves on metal surfaces, flattening an otherwise rough surface on a microscopic scale [132]. This microscopic flattening reduces the direct contact area and mutual occlusion between the surfaces when the parts are moving relative to each other, thus reducing the frictional resistance [133].