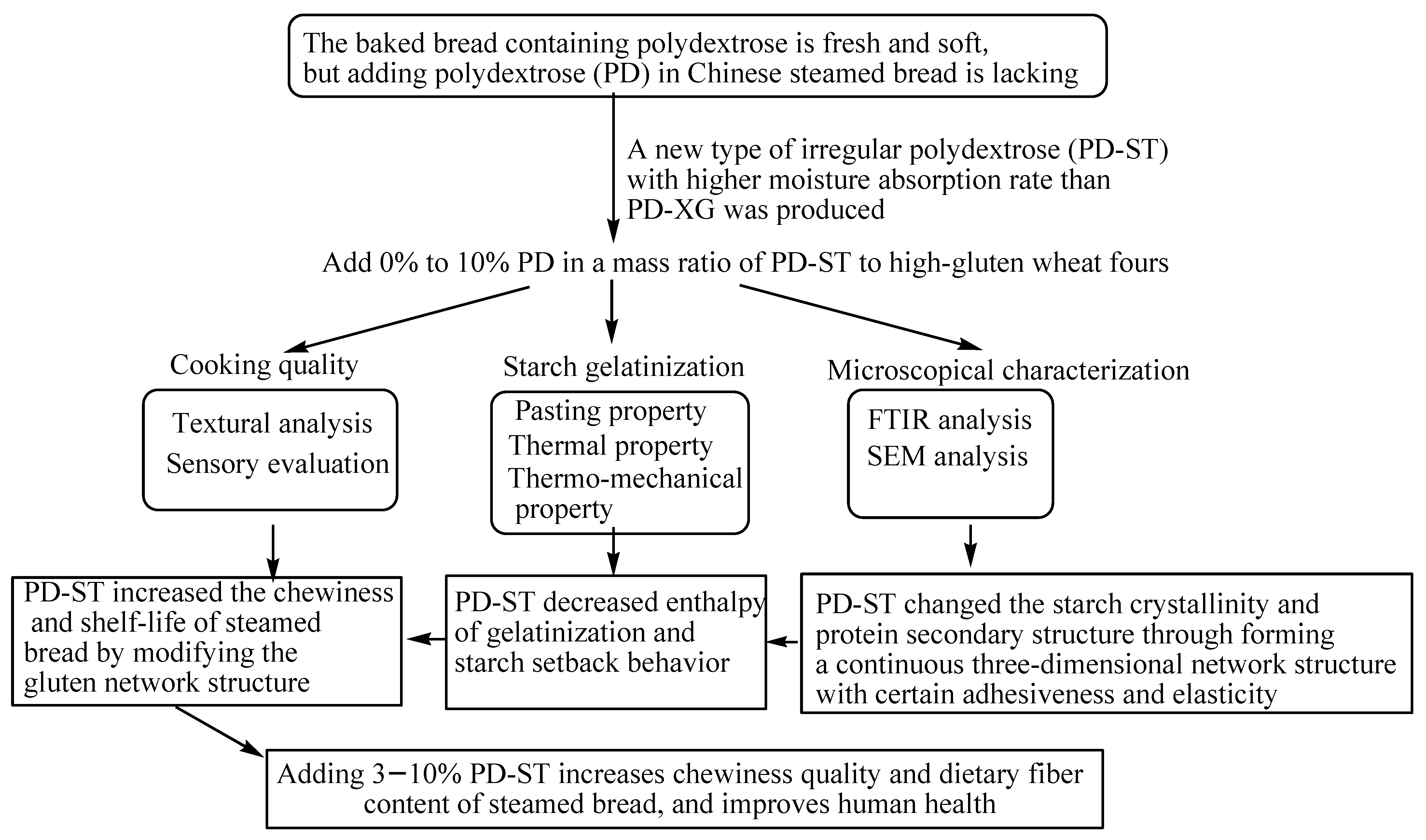

Polydextrose Addition Improves the Chewiness and Extended Shelf-Life of Chinese Steamed Bread Through the Formation of a Sticky, Elastic Network Structure

Abstract

1. Introduction

2. Results and Discussion

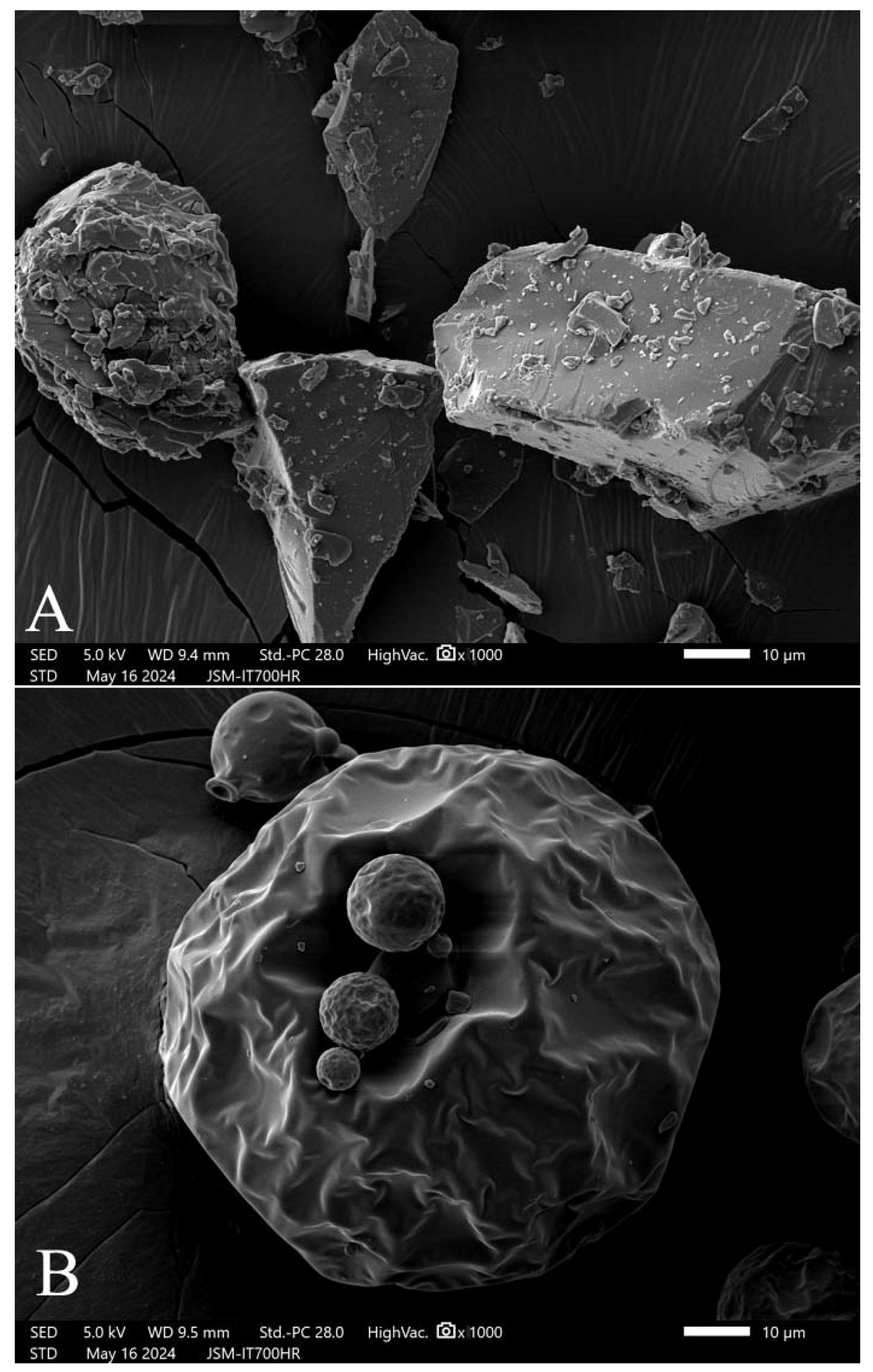

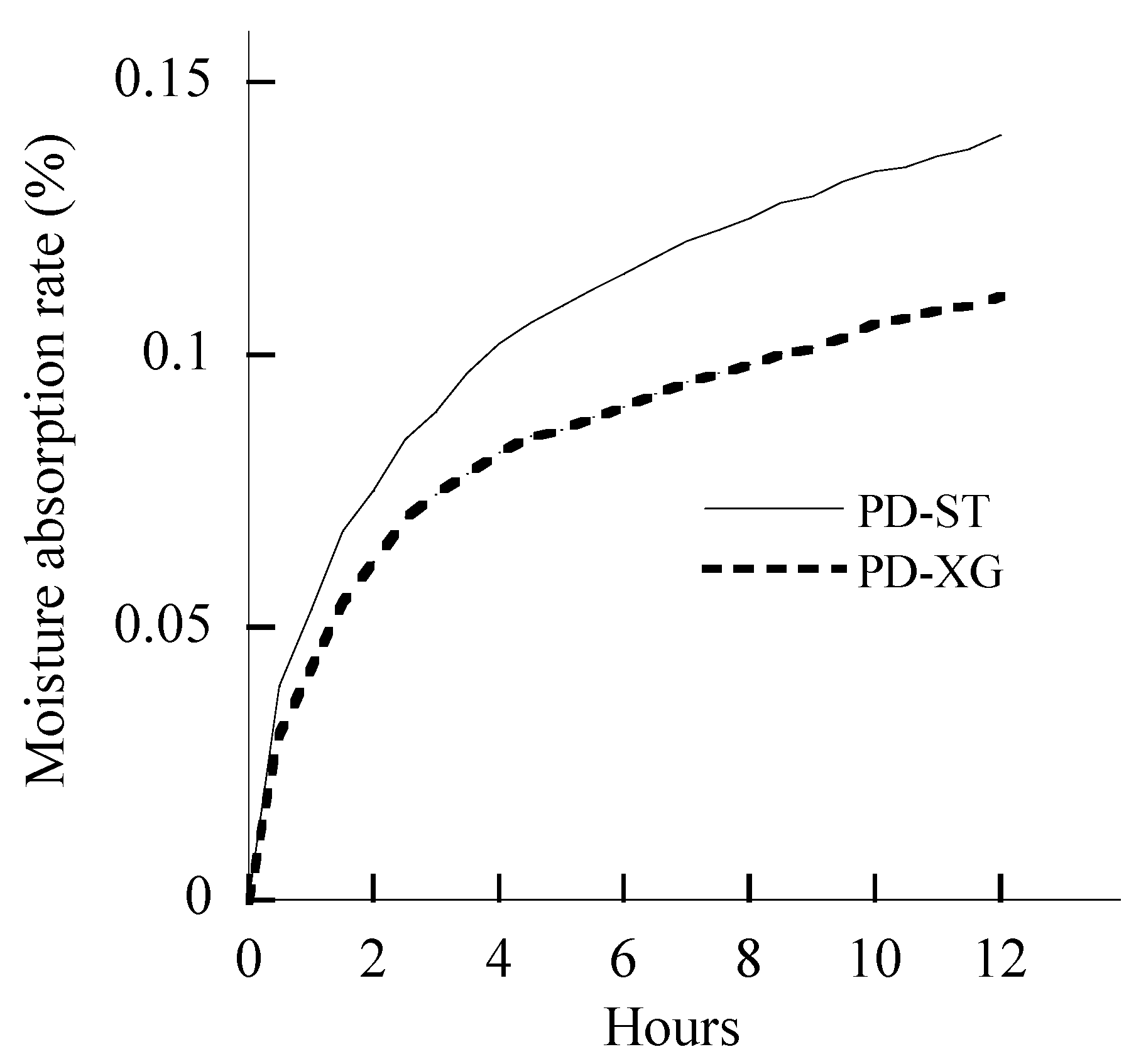

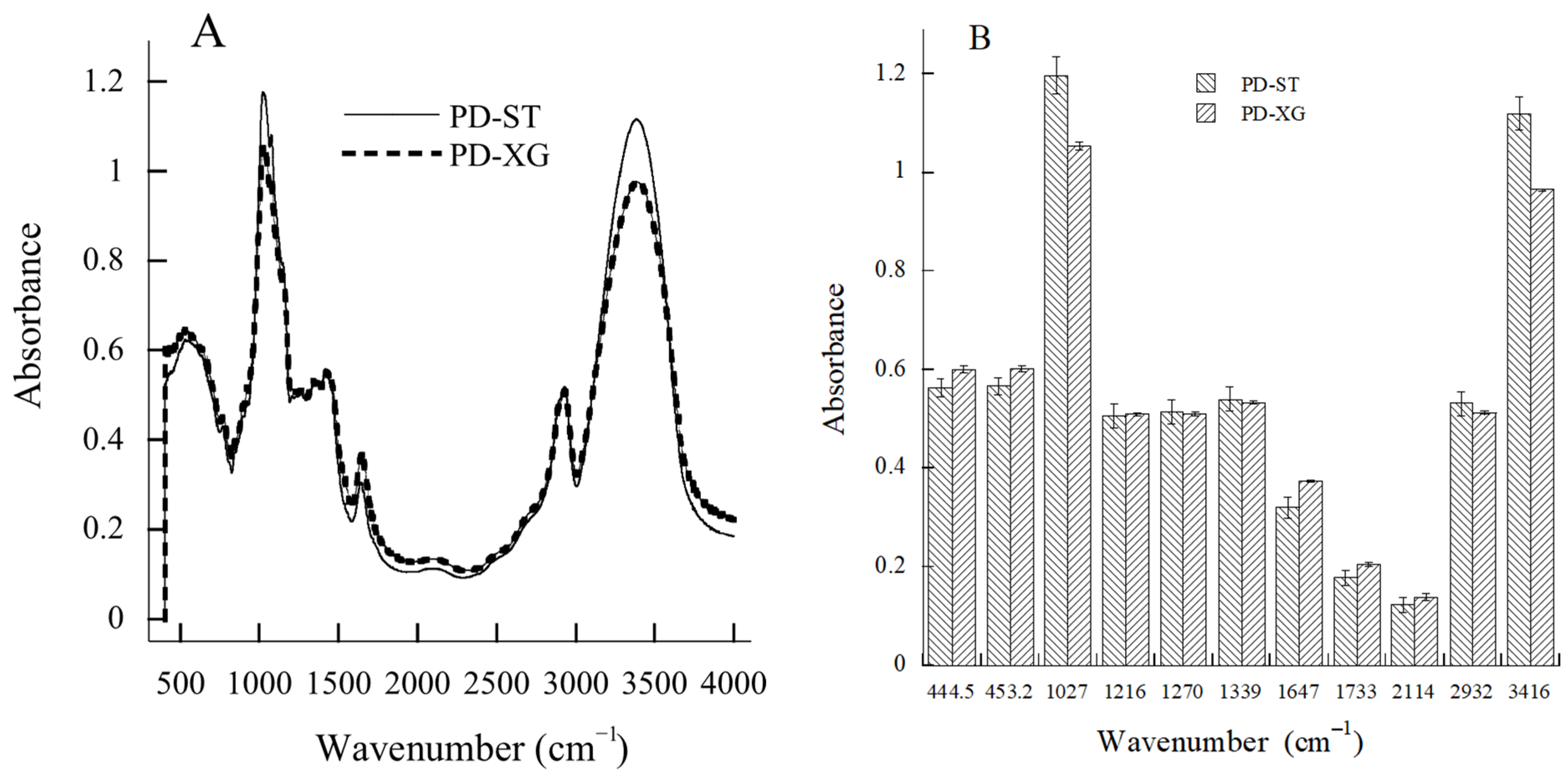

2.1. Comparison of New Polydextrose and Conventional Polydextrose

2.2. Effect of Added Polydextrose on the Texture Profile and Appearance of Steamed Bread

2.3. Effect of Added Polydextrose on the Sensory Attributes of Steamed Bread

2.4. Effect of Added Polydextrose on the Pasting and Thermal Parameters of Wheat Flours

2.5. Effect of Added Polydextrose on the Thermo-Mechanical Property of Wheat Dough Without Yeast Powder

2.6. Effect of Added Polydextrose on Starch Crystallinity and Protein Conformation

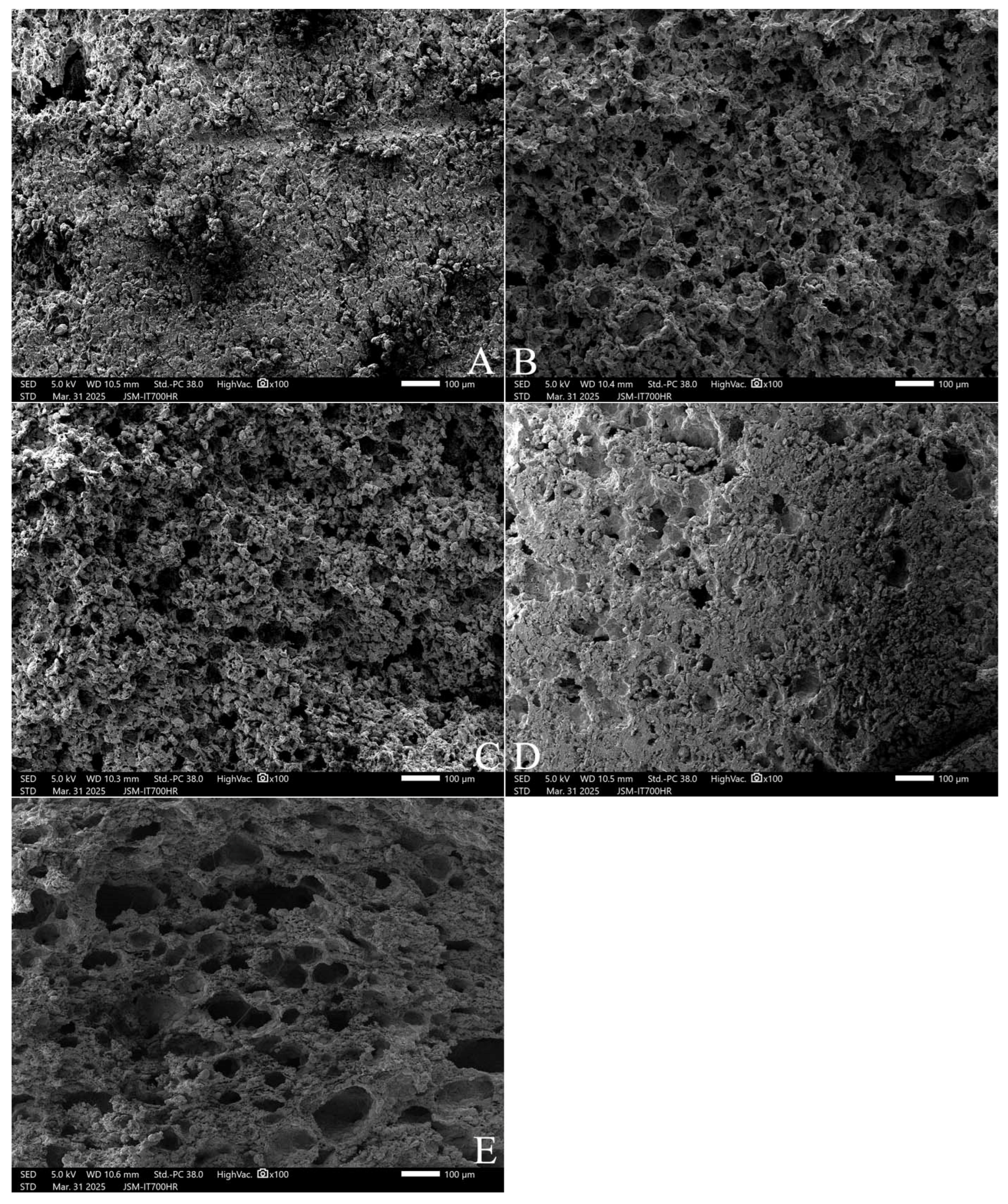

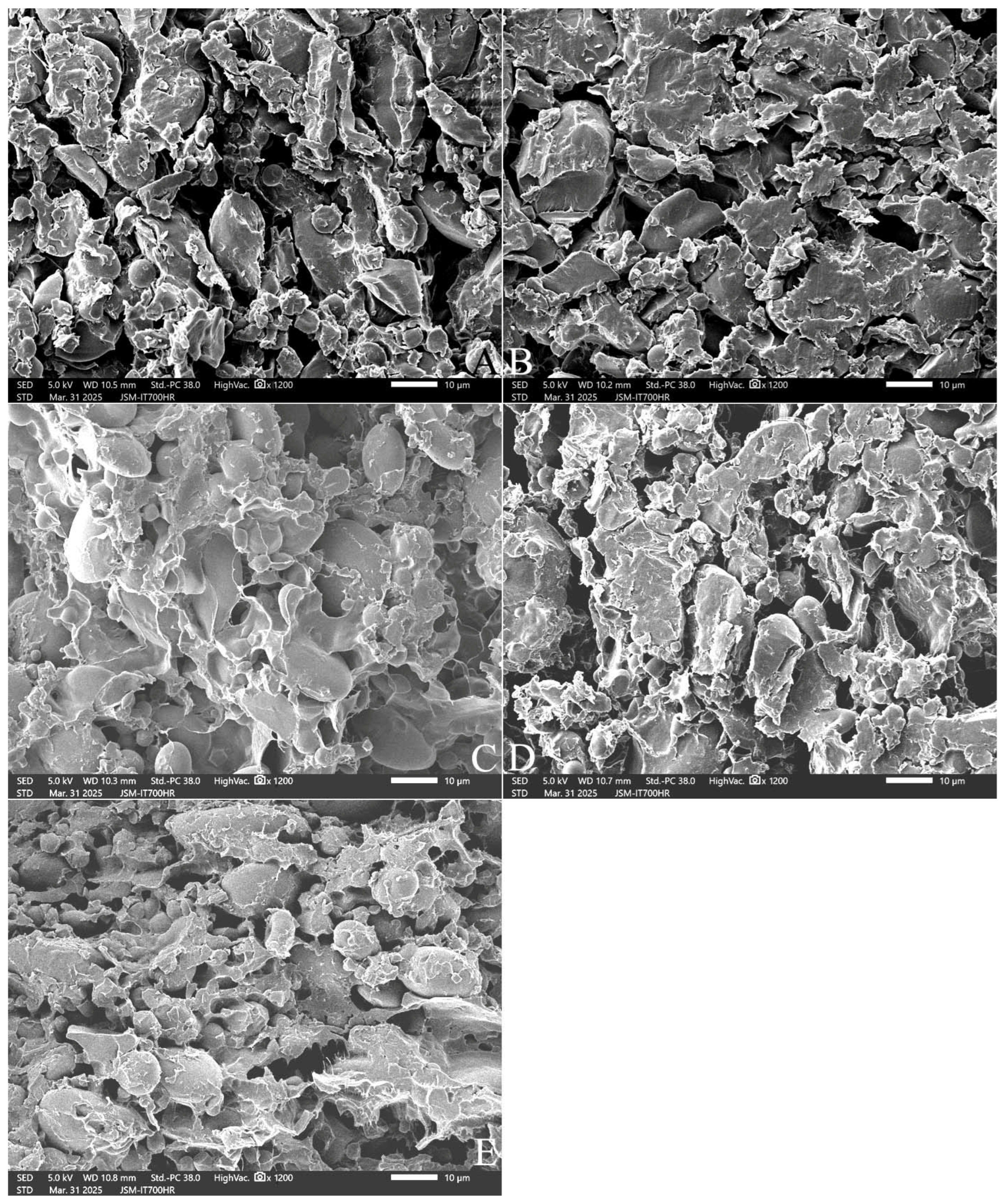

2.7. Effect of Added Polydextrose on the Microstructure of Unfermented Dough

3. Conclusions

4. Materials and Methods

4.1. Samples

4.2. The Moisture Absorption Rate of Polydextrose

4.3. Textural Profile of Wheat Steamed Bread

4.4. Specific Volume and Color of Steamed Bread

4.5. Pasting Characteristics

4.6. Thermal Properties

4.7. Thermo-Mechanical Characteristics

4.8. Fourier Transform Infrared Spectroscopy (FTIR)

4.9. Sensory Attributes of Wheat Steamed Bread

4.10. Scanning Electron Microscopy (SEM)

4.11. Data Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The Society of Chinese Nutrition. Dietary Nutrient Reference Intakes for Chinese Residents, 2013rd ed.; Science Press: Beijing, China, 2014; p. 464. [Google Scholar]

- Jiang, W.; Zhang, L.C.; Li, W.H.; Chang, C.; Ji, Y.; Li, Y.H. The trend of changes in the level of health literacy for the prevention and treatment of chronic diseases among Chinese residents from 2012 to 2017 and its influencing factors: Age-period-cohort analysis. China Public Health 2021, 37, 915–920. [Google Scholar]

- Saeedi, P.; Petersohn, I.; Salpea, P.; Malanda, B.; Karuranga, S.; Unwin, N.; Colagiuris, S.; Guariguata, L.; Motala, A.A.; Ogurtsova, K.; et al. Global and regional diabetes prevalence estimates for 2019 and projections for 2030 and 2045: Results from the International Diabetes Federation Diabetes Atlas, 9th edition. Diabetes Res. Clin. Pract. 2019, 157, 107843. [Google Scholar] [CrossRef] [PubMed]

- Interpretation of Healthy China Action-Implementation Plan of diabetes Prevention and Control Action (2024–2030). China Rural Health 2024, 16, 9.

- Huang, F.F.; Wang, H.J.; Zhang, B.; Wang, Z.H. Update of the China dietary guideline index: CDGI-2022. Acta Nutr. Sin. 2024, 46, 313–319. [Google Scholar] [CrossRef]

- Ansari, F.; Pimentel, T.C.; Pourjafar, H.; Ibrahim, S.A.; Jafari, S.M. The influence of prebiotics on wheat flour, dough, and bread properties; Resistant starch, polydextrose, and inulin. Foods 2022, 11, 3366. [Google Scholar] [CrossRef]

- Canale, M.; Sanfilippo, R.; Strano, M.C.; Bavaro, A.R.; Amenta, M.; Bizzini, M.; Allegra, M.; Blangiforti, S.; Spina, A. Technological properties of inulin-enriched doughs and breads, Influence on short-term storage and glycemic Response. Foods 2024, 13, 2711. [Google Scholar] [CrossRef]

- Topping, D. Cereal complex carbohydrates and their contribution to human health. J. Cereal Sci. 2007, 46, 220–229. [Google Scholar] [CrossRef]

- Yang, Y.Y.; Ma, S.; Wang, X.X.; Zheng, X.L. Modification and application of dietary fiber in foods. J. Chem. 2017, 2017, 9340427. [Google Scholar] [CrossRef]

- Jing, Y.; Wang, W.X.; Yang, L.Z.; Liu, Y.Q.; Shi, M.M. Effect of resistant starch and polydextrose on the quality of steamed bread. Sci. Technol. Food Ind. 2020, 41, 76–81. [Google Scholar] [CrossRef]

- Liu, T.; Duan, H.; Mao, X.; Yu, X. Influence of flaxseed flour as a partial replacement for wheat flour on the characteristics of Chinese steamed bread. RSC Adv. 2020, 10, 28114–28120. [Google Scholar] [CrossRef]

- Kim, J.E.; Baik, B.K.; Park, C.S.; Son, J.H.; Choi, C.H.; Mo, Y.; Park, T.I.; Kang, C.S.; Cho, S.W. Relationship between physicochemical characteristics of Korean wheat flour and quality attributes of steamed bread. J. Integr. Agric. 2019, 18, 2652–2663. [Google Scholar] [CrossRef]

- Dong, X.; Hu, X.; Sun, L.; Zhang, H.; Wu, L.; Wang, B. Volatile compounds of wheat flour and steamed bread as affected by wheat storage time. SM Anal. Bioanal. Tech. 2018, 3, 1–7. [Google Scholar] [CrossRef]

- Staub, H.W.; Mardones, B.; Shah, N. Modern dietary fiber product development and nutrient bioavailability. In Dietary Fiber; Birch, G.G., Parker, K.J., Eds.; Applied Science Publishers: New York, NY, USA, 1983; pp. 37–100. [Google Scholar]

- Kilibwa, M. Polydextrose As a Fat Absorption Inhibitor in Fried Foods. U.S. Patent No. 6,001,399, 14 December 1999. [Google Scholar]

- Guan, Q.Q.; Shao, X.B.; Yang, T.T.; Dou, G.M.; Xu, T.C.; Gan, Z.B. A study on the preparation process of polydextrose. Agric. Technol. 2018, 38, 247–248. [Google Scholar]

- Lauridsen, K. Use of Polydextrose in Edible Products, Edible Products Containing Polydextrose and Processes for Including Polydextrose in Edible Products. U.S. 2004/0213882A1, 28 October 2004. [Google Scholar]

- Schirmer, M.; Jekle, M.; Arendt, E.; Becker, T. Physicochemical interactions of polydextrose for sucrose replacement in pound cake. Food Res. Int. 2012, 48, 291–298. [Google Scholar] [CrossRef]

- Guanyan Research Report. The Forecast of the Market Competition Pattern and Development Trend of China Polyglucose Industry on the Analysis Report of 2021 Year. 2021. Available online: https://market.chinabaogao.com/shipin/101455602R021.html (accessed on 14 October 2021).

- Zhong, J.; Luo, B.Y.; Xiang, M.J.; Liu, H.W.; Zhai, Z.K.; Wang, T.S.; Craig, S.A. Studies on the effects of polydextrose intake on physiologyic functions in Chinese people. Am. J. Clin. Nutr. 2000, 72, 1503–1509. [Google Scholar]

- do Carmo, M.M.R.; Walker, J.C.L.; Novello, D.; Caselato, V.M.; Sgarbient, V.C.; Ouwehand, A.C.; Andreollo, N.A.; Hiane, P.A.; dos Santos, E.F. Polydextrose: Physiological function and effects on health. Nutrients 2016, 8, 553. [Google Scholar] [CrossRef]

- Li, Q.E.; Schmidt, S.J. Use of ramping and equilibrium water-vapor sorption methods to determine the critical relative humidity at which the glassy to rubbery transition occurs in polydextrose. J. Food Sci. 2011, 76, E149–E157. [Google Scholar] [CrossRef]

- Xie, X.H.; Hao, M.Y.; Fan, Y.C.; Zhang, B.; Wang, N.; Guo, F.J. Effect of polydextrose on hydration and structure of gluten during frozen storage. Food Ferment. Ind. 2020, 46, 78–83. [Google Scholar] [CrossRef]

- Guimarães, D.J.S.; Zambelli, R.A.; Afonso, M.R.A.; Pontes, D.F. Cryoprotective potential of vegetable powders and polydextrose in frozen bread doughs. Int. J. Refrig. 2025, 172, 108–119. [Google Scholar] [CrossRef]

- Li, J.T.; Wang, M. Effect of composite powder of chickpea and pea on dough characteristics and the quality of steamed bread. Food Res. Dev. 2020, 41, 68–72. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, T.T.; Su, C.H.; Li, Q.; Yu, X.Z. Fortification of Chinese steamed bread with flaxseed flour and evaluation of its physicochemical and sensory properties. Food Chem. X 2022, 13, 100267. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Wang, M.Y.; Song, H.D.; Cao, Z.Y.; Jie, Y.; Li, X.J.; Ning, G.Q. A study on the mechanism of polydextrose moisture absorption analyzed by Hailwood-Horrobin equilibrium moisture model. Sci. Technol. Cereals Oils Foods 2024, 32, 140–147. [Google Scholar] [CrossRef]

- GB1986.385-2025; National Food Safety Standard, Food Additive—Polydextrose. China National Standard: Beijing, China, 2025.

- Rosenthal, A.J. Application of aged egg in enabling increased substitution of sucrose by Litesse (Polydextrose) in high-ratio cakes. J. Sci. Food Agric. 1995, 68, 127–131. [Google Scholar] [CrossRef]

- Jiang, Y. Preliminary evaluation of the application function of polydextrose in bread making. Tianjin Sci. Technol. 2009, 3, 72–73. [Google Scholar] [CrossRef]

- Ficco, D.B.M.; Canale, M.; Giannone, V.; Strano, M.C.; Allegra, M.; Zingale, S.; Spina, A. Durum wheat bread with a potentially high health value through the addition of durum wheat thin bran or barley flour. Plants 2023, 12, 397. [Google Scholar] [CrossRef]

- He, Y.; Guo, J.; Ren, G.; Cui, G.; Han, S.; Liu, J. Effects of konjac glucomannan on the water distribution of frozen dough and corresponding steamed bread quality. Food Chem. 2020, 330, 127243. [Google Scholar] [CrossRef]

- Brasil, J.A.; Silveira, K.C.D.; Salgado, S.M.; Livera, A.V.S.; Faro, Z.P.D.; Guerra, N.B. Effect of the addition of inulin on the nutritional, physical and sensory parameters of bread. Braz. J. Pharm. Sci. 2011, 47, 185–191. [Google Scholar] [CrossRef]

- Wang, M.Y.; Liu, C.; Luo, X.H.; Wu, J.Z.; Li, X.J. Effect of polydextrose on the cooking and gelatinization properties and microstructure of Chinese early indica rice. Gels 2025, 11, 171. [Google Scholar] [CrossRef]

- Pateras, I.M.C.; Howells, K.F.; Rosenthal, A.J. Hot-stage microscopy of cake batter bubbles during simulated baking: Sucrose replacement by polydextrose. J. Food Sci. 1994, 59, 168–170. [Google Scholar] [CrossRef]

- Hicsasmaz, Z.; Yazgan, Y.; Bozoglu, F.; Katnas, Z. Effect of polydextrose-substitution on the cell structure of the high-ratio cake system. Lebensm. Wiss. Technol. 2003, 36, 441–450. [Google Scholar] [CrossRef]

- Kocer, D.; Hicsasmaz, Z.; Bayindirli, A.; Katnas, S. Bubble and pore formation of the high-ratio cake formulation with polydextrose as a sugar- and fat-replacer. J. Food Eng. 2007, 78, 953–964. [Google Scholar] [CrossRef]

- Ding, C.H.; Su, Y.X.; Jiang, Y.M.; Yong, J.Z. Differences in texture, nutritional value and microstructure of steamed buns with different amounts of gelatin. Mod. Food Sci. Technol. 2024, 40, 274–282. [Google Scholar] [CrossRef]

- Seabourn, B.W.; Chung, O.K.; Seib, P.A.; Mathewson, P.R. Determination of secondary structural changes in gluten proteins during mixing using Fourier transform horizontal attenuated total reflectance spectroscopy. J. Agric. Food Chem. 2008, 56, 4236–4243. [Google Scholar] [CrossRef] [PubMed]

- GB/T 35991–2018; Inspection of Grain and Oils—Quality Evaluation of Wheat Steamed Bread. China National Standard: Beijing, China, 2018.

- GB/T 21118–2007; Chinese Steamed Bread Made of Wheat Flour. China National Standard: Beijing, China, 2007.

- GB/T 24852–2010; Determination of Pasting Properties of Rice–Rapid Visco Analyzer Method. China National Standard: Beijing, China, 2010.

- Ha, M.; Jeong, H.Y.; Lim, S.T.; Chung, H.J. The cooking method features controlling eating quality of cooked rice: An explanation from the view of starch structure in leachate and morphological characteristics. Food Res. Int. 2022, 162, 111980. [Google Scholar] [CrossRef] [PubMed]

- Hang, Y.Y.; Zhang, T.T.; Qi, D.; Hu, Y.Q. Effects and mechanism of polydextrose on the freezing-thawing stability of tilapia surimi. China Food Addit. 2024, 10, 131–138. [Google Scholar] [CrossRef]

- SPSS Inc. SPSS for Windows, Release 17.0.1; SPSS Inc.: Chicago, IL, USA, 2006.

| PD-ST Addition (%) | Hardness (g) | Adhesive Force (g) | Adhesiveness (0.1 mJ) | Resilience (0.1) | Cohesiveness (0.1) | Springiness (mm) | Gumminess (g) | Chewiness (mJ) |

|---|---|---|---|---|---|---|---|---|

| 0 | 1171 ± 78 d | 3.05 ± 0.07 a | 0. 2 ± 0.0 b | 4.13 ± 0.25 ab | 7.80 ± 0.17 ab | 10.84 ± 0.11 a | 829 ± 35 c | 87.7 ± 3.1 c |

| 3 | 1067 ± 58 d | 1.20 ± 1.13 b | 0. 2 ± 0.1 b | 4.63 ± 0.42 a | 8.03 ± 0.15 a | 10.89 ± 0.25 a | 872 ± 60 b | 93.2 ± 7.7 bc |

| 5 | 1394 ± 71 a | 4.17 ± 3.18 ab | 3.9 ± 0.3 a | 3.97 ± 0.25 ab | 7.77 ± 0.21 ab | 10.90 ± 0.09 a | 1081 ± 86 a | 115.7 ± 10.1 a |

| 7 | 1237 ± 84 b | 1.00 ± 0.44 b | 3.9 ± 0.2 a | 3.97 ± 0.15 b | 7.63 ± 0.06 b | 10.78 ± 0.14 a | 948 ± 59 b | 100.3 ± 7.5 b |

| 10 | 1244 ± 54 c | 1.07 ± 0.15 b | 4.7 ± 0.7 a | 4.01 ± 0.21 b | 7.61 ± 0.21 b | 10.79 ± 0.11 a | 1101 ± 64 a | 117.8 ± 9.0 a |

| PD-ST Addition (%) | Volume (cm3) | Mass (g) | Specific Volume (cm3/g) |

|---|---|---|---|

| 0 | 190.1 ± 0.9 b | 95.0 ± 0.5 c | 2.00 ± 0.01 a |

| 3 | 192.1 ± 1.2 ab | 99.8 ± 0.9 b | 1.92 ± 0.02 b |

| 5 | 192.5 ± 2.5 ab | 100.0 ± 1.3 b | 1.92 ± 0.03 b |

| 7 | 194.4 ± 2.1 a | 102.5 ± 0.7 a | 1.89 ± 0.02 b |

| 10 | 195.5 ± 0.6 a | 103.4 ± 0.5 a | 1.89 ± 0.01 b |

| PD-ST (%) | L | −a | b | ΔE |

|---|---|---|---|---|

| 0 | 77.39 ± 0.54 b | 1.707 ± 0.029 a | 12.89 ± 0.25 b | 21.03 ± 0.66 c |

| 3 | 78.40 ± 0.39 b | 1.642 ± 0.023 b | 13.32 ± 0.17 a | 22.34 ± 0.39 b |

| 5 | 80.44 ± 0.51 a | 1.502 ± 0.046 c | 13.44 ± 0.28 a | 24.35 ± 0.51 a |

| 7 | 80.15 ± 0.31 a | 1.697 ± 0.023 a | 13.51 ± 0.12 a | 24.09 ± 0.30 a |

| 10 | 80.33 ± 0.12 a | 1.721 ± 0.011 a | 13.55 ± 0.11 a | 24.39 ± 0.28 a |

| PD-ST (%) | Specific Volume | Width/Height Ratio | Elasticity | Surface Color | Surface Structure |

| 0 | 8.00 ± 0.00 a | 4.00 ± 0.00 a | 7.00 ± 0.58 a | 7.00 ± 0.58 a | 7.40 ± 0.73 a |

| 3 | 7.00 ± 0.00 b | 3.00 ± 0.00 b | 7.60 ± 0.45 a | 6.80 ± 0.68 a | 7.80 ± 0.37 a |

| 5 | 7.00 ± 0.00 b | 3.00 ± 0.00 b | 7.20 ± 1.06 a | 6.80 ± 0.37 a | 8.40 ± 0.45 a |

| 7 | 6.50 ± 0.00 c | 3.00 ± 0.00 b | 7.40 ± 0.45 a | 6.80 ± 0.89 a | 7.60 ± 0.93 a |

| 10 | 6.50 ± 0.00 c | 3.00 ± 0.00 b | 6.80 ± 0.37 a | 7.40 ± 0.73 a | 7.40 ± 0.73 a |

| PD-ST (%) | Internal Structure | Toughness | Adhesiveness | Taste | Total Score |

| 0 | 15.40 ± 0.45 b | 7.40 ± 0.93 a | 7.60 ± 0.93 a | 4.60 ± 0.45 a | 68.40 ± 2.05 a |

| 3 | 16.20 ± 0.37 ab | 6.80 ± 0.68 a | 7.80 ± 0.68 a | 4.60 ± 0.45 a | 67.60 ± 2.21 a |

| 5 | 16.20 ± 1.57 ab | 7.40 ± 0.45 a | 7.60 ± 0.45 a | 5.00 ± 0.00 a | 68.60 ± 1.59 a |

| 7 | 16.40 ± 1.48 ab | 7.00 ± 0.82 a | 8.20 ± 0.37 a | 4.80 ± 0.37 a | 67.70 ± 2.61 a |

| 10 | 17.20 ± 1.21 a | 7.60 ± 0.93 a | 8.40 ± 0.73 a | 4.80 ± 0.37 a | 69.10 ± 1.69 a |

| PD-ST (%) | Peak Viscosity (cp) | Trough Viscosity (cp) | Breakdown Viscosity (cp) | Final Viscosity (cp) | Setback Viscosity (cp) | Peak Time (min) | Pasting Temp. (°C) |

|---|---|---|---|---|---|---|---|

| 0 | 2061 ± 15 a | 1228 ± 7 a | 833 ± 18 a | 2522 ± 8 a | 1293 ± 14 a | 6.11 ± 0.03 a | 69.33 ± 0.08 d |

| 3 | 1854 ± 8 b | 1125 ± 15 b | 729 ± 10 b | 2322 ± 10 b | 1197 ± 23 b | 6.09 ± 0.08 ab | 69.83 ± 0.51 cd |

| 5 | 1806 ± 6 c | 1095 ± 13 c | 711 ± 19 b | 2285 ± 3 c | 1190 ± 13 b | 6.09 ± 0.03 a | 70.13 ± 0.03 c |

| 7 | 1634 ± 17 d | 1000 ± 28 d | 634 ± 18 c | 2096 ± 6 d | 1096 ± 31 c | 6.04 ± 0.10 ab | 87.42 ± 0.43 b |

| 10 | 1481 ± 13 e | 913 ± 16 e | 569 ± 4 d | 1943 ± 10 e | 1030 ± 9 d | 6.00 ± 0.01 b | 87.95 ± 0.09 a |

| PD-ST (%) | ΔH (J/g) | Tp (°C) | To (°C) | Tc (°C) | Peak Width (°C) | Peak Height (0.01 mW/mg) |

|---|---|---|---|---|---|---|

| 0 | 5.57 ± 0.25 a | 63.27 ± 0.15 d | 57.47 ± 0.06 c | 70.00 ± 0.40 bc | 5.90 ± 0.10 a | 11.77 ± 0.80 ab |

| 3 | 5.37 ± 0.02 a | 63.60 ± 0.17 c | 57.70 ± 0.20 bc | 70.00 ± 0.20 c | 5.80 ± 0.10 ab | 11.77 ± 0.30 a |

| 5 | 5.10 ± 0.11 b | 63.97 ± 0.25 bc | 57.93 ± 0.15 b | 70.30 ± 0.26 bc | 5.80 ± 0.01 ab | 11.36 ± 0.18 a |

| 7 | 4.88 ± 0.11 bc | 64.67 ± 0.68 ab | 58.73 ± 0.21 a | 71.00 ± 0.66 ab | 5.87 ± 0.15 ab | 10.68 ± 0.34 b |

| 10 | 4.81 ± 0.11 c | 64.57 ± 0.15 a | 58.77 ± 0.06 a | 70.67 ± 0.06 a | 5.73 ± 0.06 b | 10.84 ± 0.30 b |

| PD-ST (%) | ΔH (J/g) | Tp (°C) | To (°C) | Tc (°C) | Peak Width (°C) | Peak Height (0.01 mW/mg) | Aging (%) |

|---|---|---|---|---|---|---|---|

| 0 | 1.43 ± 0.19 a | 53.80 ± 0.85 ab | 46.57 ± 0.21 c | 62.53 ± 0.21 b | 8.80 ± 0.53 a | 2.30 ± 0.28 a | 25.72 ± 4.35 a |

| 3 | 1.05 ± 0.13 b | 53.20 ± 3.40 ab | 48.20 ± 0.01 b | 62.47 ± 0.25 bc | 8.50 ± 0.20 a | 1.87 ± 0.12 b | 19.58 ± 2.51 ab |

| 5 | 0.82 ± 0.09 b | 52.60 ± 0.61 b | 49.30 ± 0.10 a | 63.73 ± 0.25 a | 7.80 ± 0.26 b | 1.59 ± 0.14 c | 16.19 ± 2.15 b |

| 7 | 0.82 ± 0.01 c | 53.83 ± 0.71 ab | 48.27 ± 0.80 ab | 61.97 ± 0.25 c | 7.90 ± 0.36 b | 1.54 ± 0.06 c | 16.80 ± 0.40 b |

| 10 | 0.77 ± 0.04 c | 54.50 ± 0.01 a | 49.23 ± 0.98 a | 62.03 ± 0.25 c | 7.60 ± 0.46 b | 1.52 ± 0.08 c | 16.11 ± 1.10 b |

| PD-ST (%) | DDT (min) | DST (min) | C1–Cs (0.1 Nm) | C3 (Nm) | C3/C4 |

| 0 | 3.55 ± 0.36 e | 4.83 ± 0.42 d | 2.28 ± 0.17 a | 1.57 ± 0.02 a | 1.149 ± 0.011 ab |

| 3 | 4.55 ± 0.17 d | 7.03 ± 0.32 c | 0.74 ± 0.09 b | 1.55 ± 0.02 a | 1.151 ± 0.014 ab |

| 5 | 5.32 ± 0.34 c | 8.30 ± 0.10 a | 0.27 ± 0.07 c | 1.46 ± 0.01 b | 1.126 ± 0.006 c |

| 7 | 6.91 ± 1.05 b | 7.27 ± 0.78 b | 0.05 ± 0.04 d | 1.46 ± 0.01 b | 1.126 ± 0.014 bc |

| 10 | 8.59 ± 0.06 a | 5.25 ± 0.07 d | 0.08 ± 0.02 d | 1.32 ± 0.01 c | 1.159 ± 0.009 a |

| PD-ST (%) | C3–C4 (0.1 Nm) | C5–C4 (0.1 Nm) | α (−0.01 Nm) | β (0.01 Nm) | γ (−0.01 Nm) |

| 0 | 2.05 ± 0.12 a | 6.74 ± 0.10 a | 4.93 ± 0.31 c | 46.73 ± 1.15 b | 2.80 ± 1.91 a |

| 3 | 2.03 ± 0.16 ab | 7.05 ± 0.43 a | 4.73 ± 0.81 bc | 45.27 ± 1.80 b | 3.07 ± 1.15 a |

| 5 | 1.63 ± 0.08 d | 6.23 ± 0.15 b | 5.47 ± 0.81 bc | 45.93 ± 4.69 abc | 2.33 ± 1.67 a |

| 7 | 1.62 ± 0.16 cd | 6.04 ± 0.13 b | 6.00 ± 0.72 ab | 50.47 ± 0.61 a | 14.87 ± 1.96 a |

| 10 | 1.81 ± 0.08 bc | 5.11 ± 0.08 c | 6.50 ± 0.14 a | 41.70 ± 0.99 c | 3.10 ± 0.14 a |

| PD-ST (%) | R1022/995 | R1047/1022 | R1068/1022 | |

| 0 | 1.0419 ± 0.0006 b | 0.9147 ± 0.0022 d | 0.7492 ± 0.0038 e | |

| 3 | 1.0334 ± 0.0004 c | 0.9259 ± 0.0019 a | 0.7840 ± 0.0049 a | |

| 5 | 1.0333 ± 0.0015 c | 0.9227 ± 0.0007 b | 0.7742 ± 0.0023 b | |

| 7 | 1.0426 ± 0.0004 b | 0.9185 ± 0.0009 c | 0.7628 ± 0.0012 d | |

| 10 | 1.0486 ± 0.0017 a | 0.9189 ± 0.0002 c | 0.7688 ± 0.0001 c | |

| PD-ST (%) | β-sheet (%) | Random coil (%) | α-helix (%) | β-turn (%) |

| 0 | 48.928 ± 0.102 d | 17.291 ± 0.043 a | 17.281 ± 0.025 a | 16.499 ± 0.035 a |

| 3 | 50.244 ± 0.258 b | 16.928 ± 0.073 d | 16.807 ± 0.088 c | 16.022 ± 0.096 c |

| 5 | 49.507 ± 0.146 c | 17.141 ± 0.041 c | 17.073 ± 0.061 b | 16.278 ± 0.045 b |

| 7 | 49.361 ± 0.065 c | 17.202 ± 0.014 b | 17.145 ± 0.031 b | 16.292 ± 0.021 b |

| 10 | 50.184 ± 0.037 a | 16.992 ± 0.015 d | 16.826 ± 0.007 c | 15.998 ± 0.020 c |

| PD-ST (%) | R1022/995 | R1047/1022 | R1068/1022 | |

| 0 | 1.0249 ± 0.0005 a | 0.9402 ± 0.0037 c | 0.8316 ± 0.0083 c | |

| 3 | 1.0183 ± 0.0010 bc | 0.9473 ± 0.0018 b | 0.8554 ± 0.0017 b | |

| 5 | 1.0175 ± 0.0008 c | 0.9501 ± 0.0034 b | 0.8644 ± 0.0076 b | |

| 7 | 1.0201 ± 0.0010 b | 0.9351 ± 0.0024 c | 0.8306 ± 0.0011 c | |

| 10 | 1.0162 ± 0.0016 c | 0.9565 ± 0.0021 a | 0.8784 ± 0.0045 a | |

| PD-ST (%) | β-sheet (%) | Random coil (%) | α-helix (%) | β-turn (%) |

| 0 | 52.587 ± 0.348 bc | 16.345 ± 0.081 b | 15.853 ± 0.126 b | 15.214 ± 0.142 bc |

| 3 | 52.933 ± 0.235 b | 16.283 ± 0.081 b | 15.605 ± 0.134 bc | 15.178 ± 0.123 c |

| 5 | 52.456 ± 0.146 c | 16.267 ± 0.026 b | 15.886 ± 0.179 b | 15.391 ± 0.072 b |

| 7 | 52.669 ± 0.106 bc | 16.467 ± 0.014 a | 16.169 ± 0.057 a | 15.694 ± 0.035 a |

| 10 | 53.599 ± 0.202 a | 16.074 ± 0.064 c | 15.489 ± 0.060 c | 14.837 ± 0.079 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Dai, B.; Luo, X.; Song, H.; Li, X. Polydextrose Addition Improves the Chewiness and Extended Shelf-Life of Chinese Steamed Bread Through the Formation of a Sticky, Elastic Network Structure. Gels 2025, 11, 545. https://doi.org/10.3390/gels11070545

Liu C, Dai B, Luo X, Song H, Li X. Polydextrose Addition Improves the Chewiness and Extended Shelf-Life of Chinese Steamed Bread Through the Formation of a Sticky, Elastic Network Structure. Gels. 2025; 11(7):545. https://doi.org/10.3390/gels11070545

Chicago/Turabian StyleLiu, Chang, Bing Dai, Xiaohong Luo, Hongdong Song, and Xingjun Li. 2025. "Polydextrose Addition Improves the Chewiness and Extended Shelf-Life of Chinese Steamed Bread Through the Formation of a Sticky, Elastic Network Structure" Gels 11, no. 7: 545. https://doi.org/10.3390/gels11070545

APA StyleLiu, C., Dai, B., Luo, X., Song, H., & Li, X. (2025). Polydextrose Addition Improves the Chewiness and Extended Shelf-Life of Chinese Steamed Bread Through the Formation of a Sticky, Elastic Network Structure. Gels, 11(7), 545. https://doi.org/10.3390/gels11070545