Pulsed Light: Challenges of a Non-Thermal Sanitation Technology in the Winemaking Industry

Abstract

1. Introduction

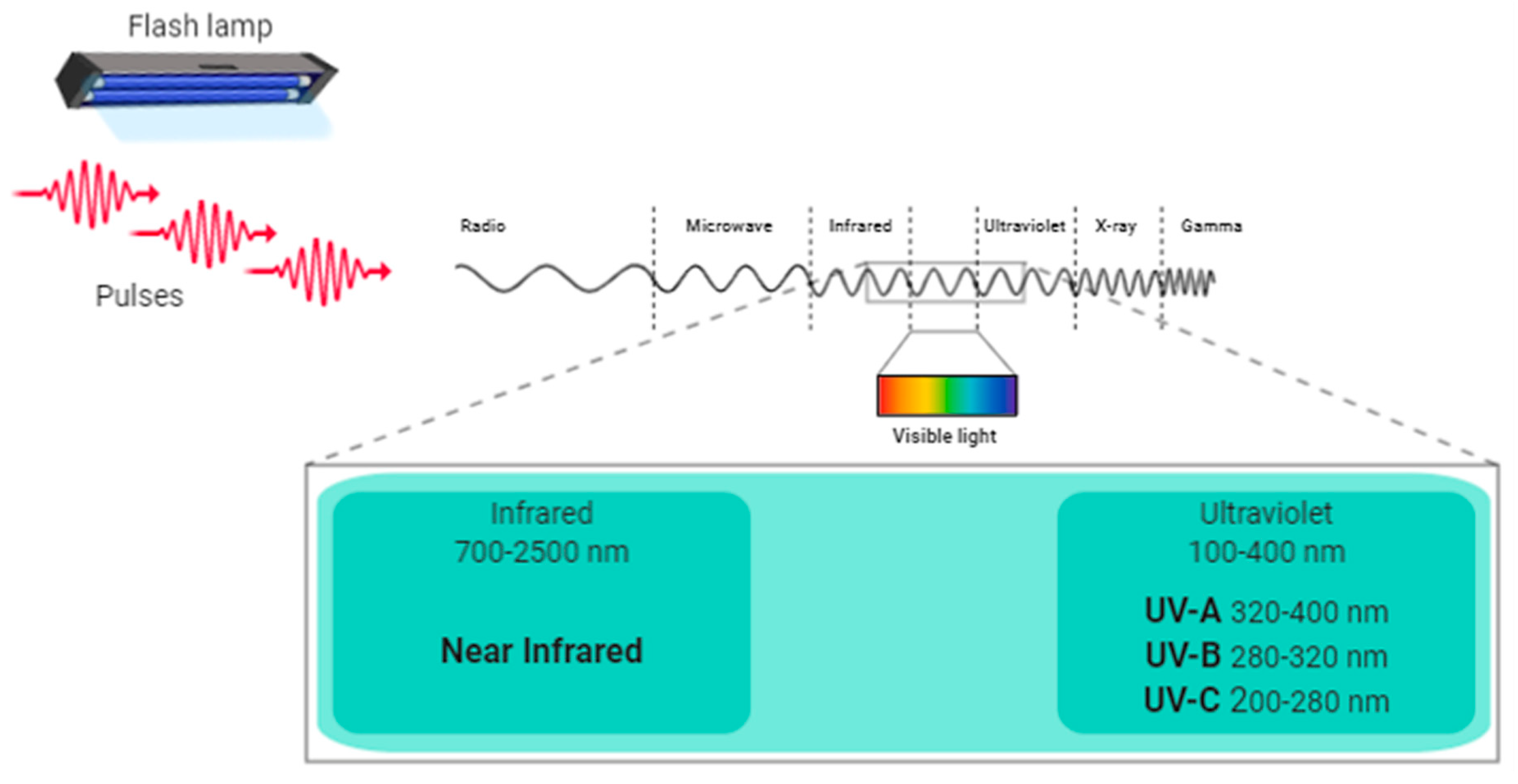

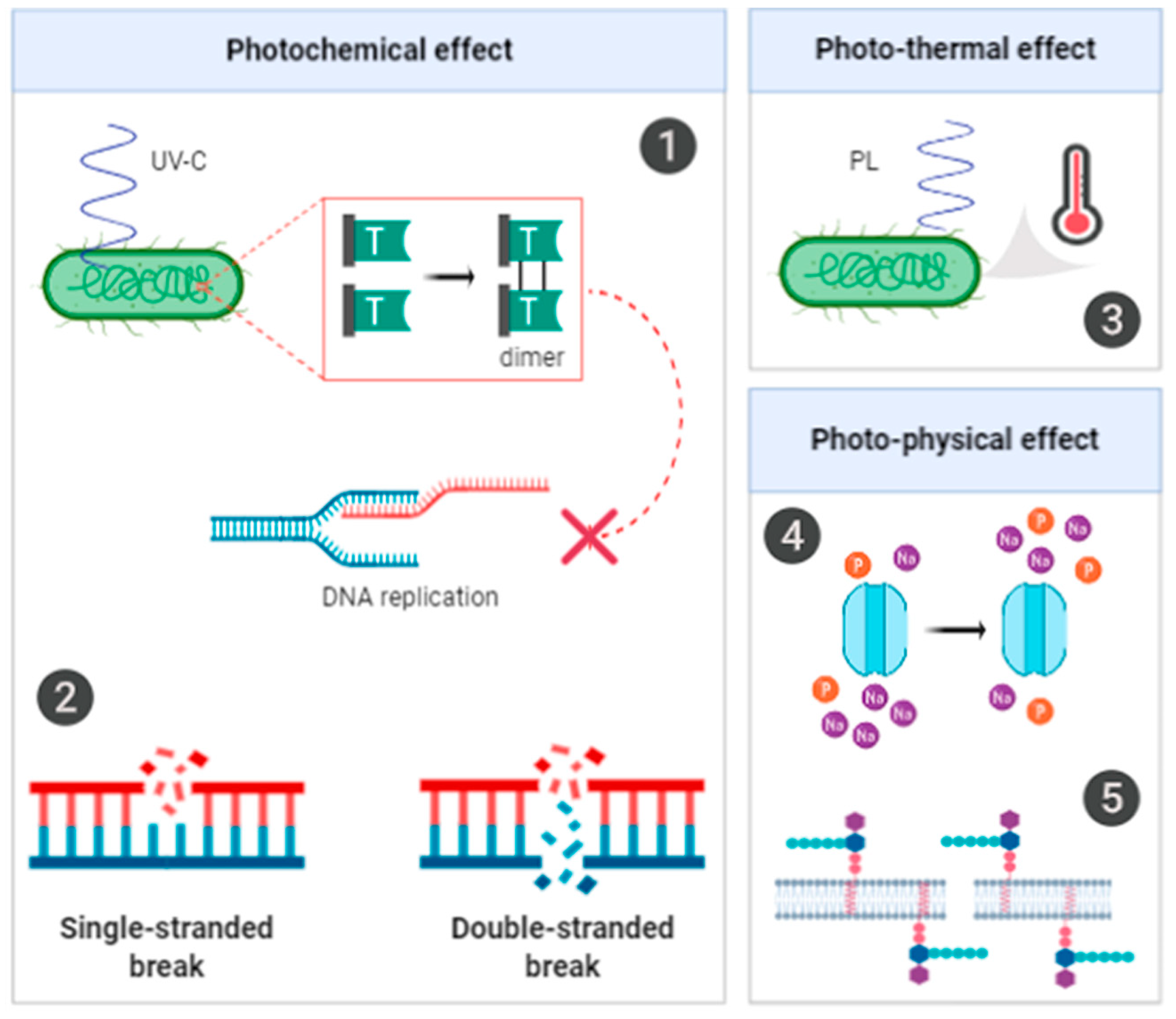

2. Pulsed Light Treatment Mechanism

3. Food Spoilage Microorganisms and Pathogens Elimination

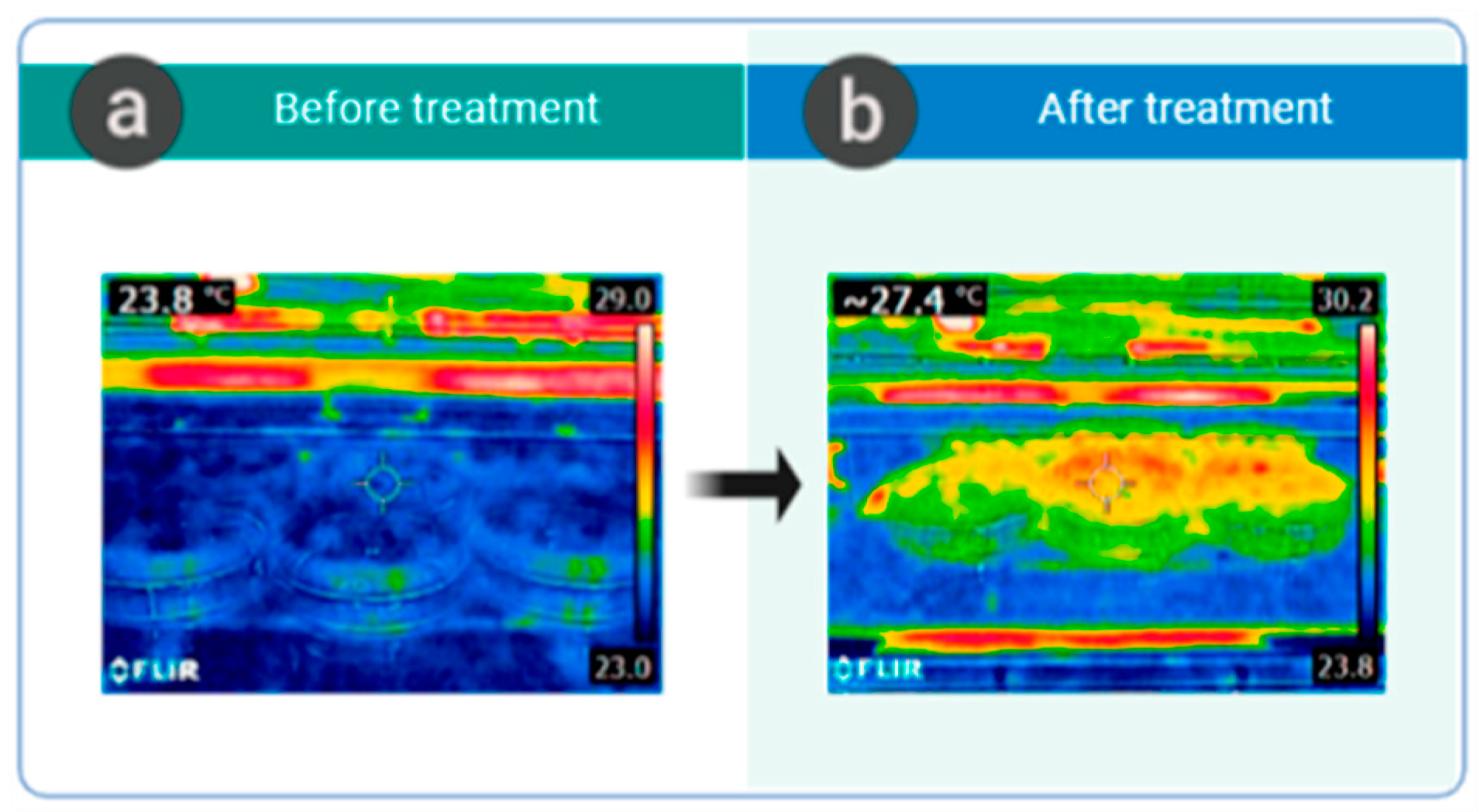

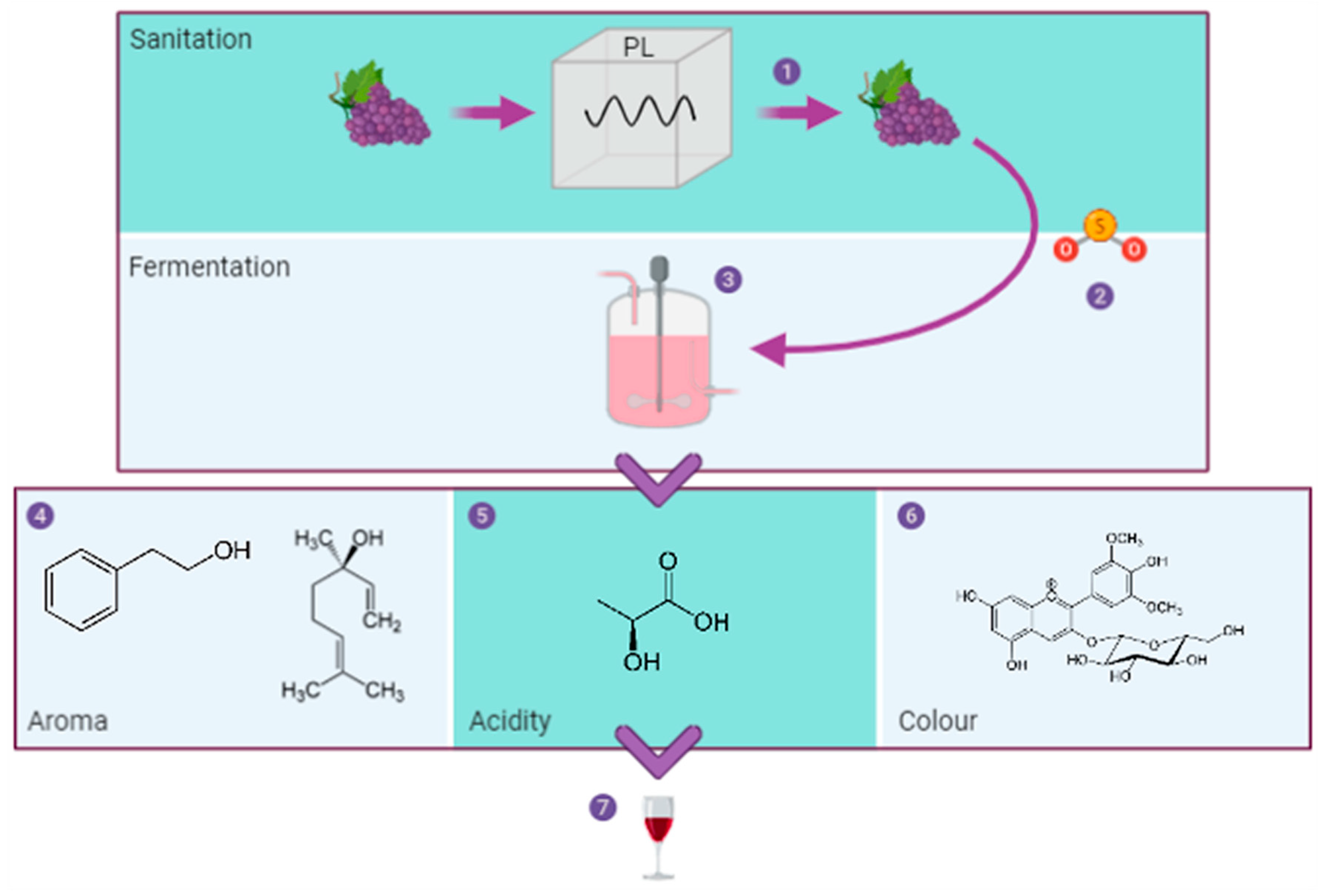

4. Use of Pulsed Light for Grape Sanitation

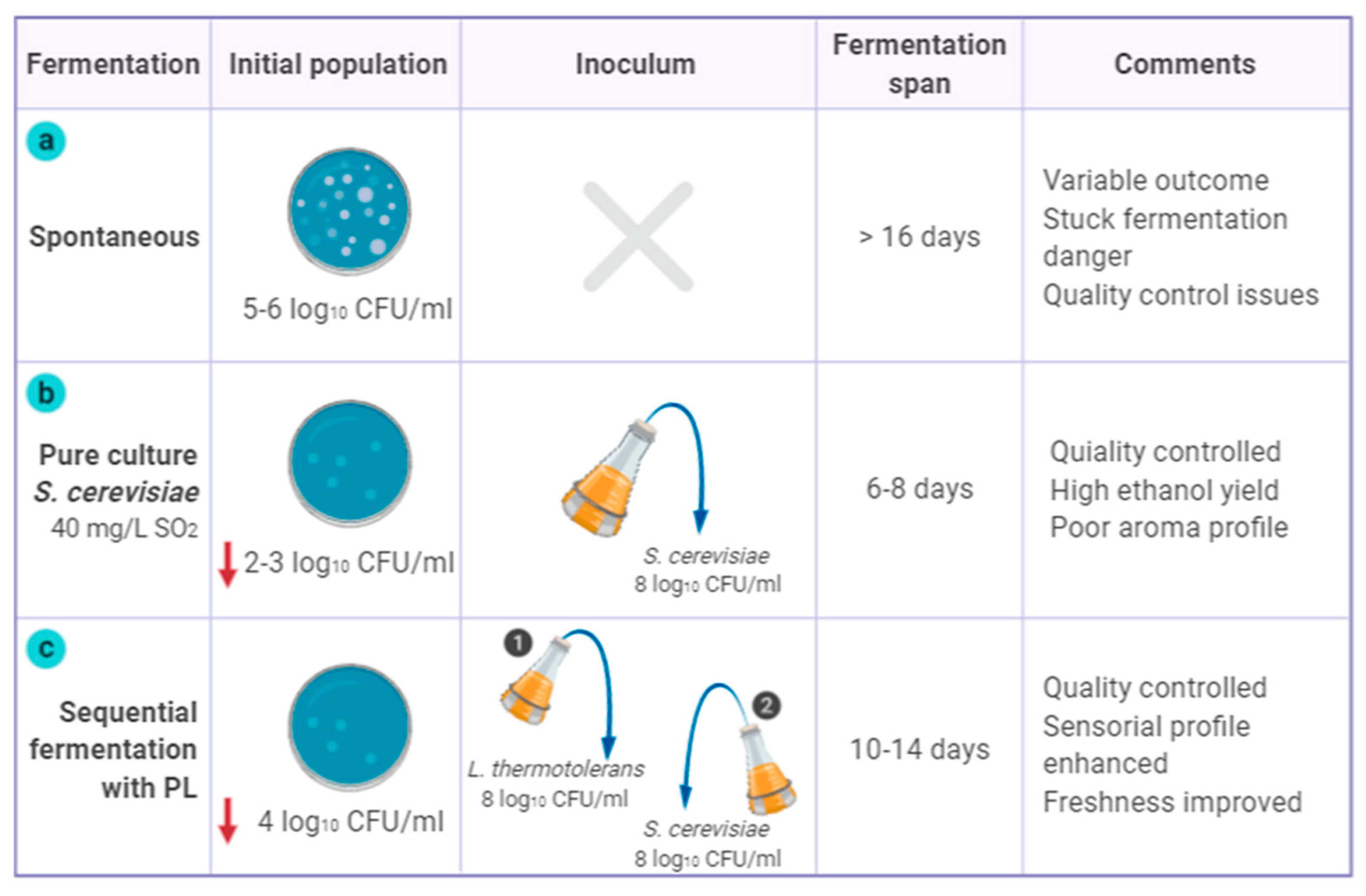

5. Influence of Pulsed Light on the Implantation of Non-Saccharomyces Yeasts in Musts

6. Repercussion of Pulsed Light in the Wine Freshness

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Barbosa-Canovas, G.V.; Schaffner, D.W.; Pierson, M.D.; Zhang, Q.H. Pulsed Light Technology. J. Food Sci. 2000, 65, 82–85. [Google Scholar] [CrossRef]

- Johan, L.; Nilsson, A.; Gb, S.; Lefort, L.; Fr, L.; Hugh, J.; Price, V.; Gb, C. Pulsed light sources. U.S. Patent US6917631B2, 12 July 2005. [Google Scholar]

- Unni, L.E.; Chauhan, O.P. Use of Pulsed Light in Food Processing. In Non-Thermal Processing of Foods; Chauhan, O.P., Ed.; CRC Press: Boca Raton, FL, USA, 2019; pp. 173–188. [Google Scholar]

- Kirkpatrick, A.R. Method involving pulsed light processing of semiconductor devices. U.S. Patent US4151008, 24 April 1979. [Google Scholar]

- Ryu, J.; Kim, H.S.; Hahn, H.T. Reactive sintering of copper nanoparticles using intense pulsed light for printed electronics. J. Electron. Mater. 2011, 40, 42–50. [Google Scholar] [CrossRef]

- Babilas, P.; Schreml, S.; Szeimies, R.M.; Landthaler, M. Intense pulsed light (IPL): A review. Lasers Surg. Med. 2010, 42, 93–104. [Google Scholar] [CrossRef] [PubMed]

- Negishi, K.; Tezuka, Y.; Kushikata, N.; Wakamatsu, S. Photorejuvenation for Asian skin by intense pulsed light. Dermatol. Surg. 2001, 27, 627–632. [Google Scholar] [PubMed]

- Goldberg, D.J. New collagen formation after dermal remodeling with an intense pulsed light source. J. Cutan. Laser Ther. 2000, 2, 59–61. [Google Scholar] [CrossRef] [PubMed]

- Schroeter, C.A.; Below, S.H.-V.; Neumann, H.A.M. Effective treatment of rosacea using intense pulsed light systems. Dermatol. Surg. 2005, 31, 1285–1289. [Google Scholar] [CrossRef]

- Angermeier, M.C. Treatment of facial vascular lesions with intense pulsed light. J. Cosmet. Laser Ther. 1999, 1, 95–100. [Google Scholar] [CrossRef]

- Hernández-Pérez, E.; Colombo-Charrier, E.; Valencia-Ibiett, E. Intense pulsed light in the treatment of striae distensae. Dermatol. Surg. 2002, 28, 1124–1130. [Google Scholar]

- Gold, M.H.; Bell, M.W.; Foster, T.D.; Street, S. Long-term epilation using the EpiLight broad band, intense pulsed light Hair Removal System. Dermatol. Surg. 1997, 23, 909–913. [Google Scholar] [CrossRef]

- Pollock, A.M.; Singh, A.P.; Ramaswamy, H.S.; Ngadi, M.; Singh, P. Pulsed light destruction kinetics of L. monocytogenes. LWT-Food Sci. Technol. 2017, 84, 114–121. [Google Scholar] [CrossRef]

- MacGregor, S.J.; Rowan, N.J.; McIlvaney, L.; Anderson, J.G.; Fouracre, R.A.; Farish, O. Light inactivation of food-related pathogenic bacteria using a pulsed power source. Lett. Appl. Microbiol. 1998, 27, 67–70. [Google Scholar] [CrossRef] [PubMed]

- Rowan, N.J.; MacGregor, S.J.; Anderson, J.G.; Fouracre, R.A.; McIlvaney, L.; Farish, O. Pulsed-Light Inactivation of Food-Related Microorganisms. Appl. Environ. Microbiol. 1999, 65, 1312–1315. [Google Scholar] [CrossRef] [PubMed]

- Elmnasser, N.; Guillou, S.; Leroi, F.; Orange, N.; Bakhrouf, A.; Federighi, M. Pulsed-light system as a novel food decontamination technology: A review. Can. J. Microbiol. 2007, 53, 813–821. [Google Scholar] [CrossRef]

- Brown, A.C. Understanding Food-Principles and Preparation, 3rd ed.; Thomson Wadsworth: Belmont, CA, USA, 2008; ISBN 9780495107453. [Google Scholar]

- Song, K.; Taghipour, F.; Mohseni, M. Microorganisms inactivation by wavelength combinations of ultraviolet light-emitting diodes (UV-LEDs). Sci. Total Environ. 2019, 665, 1103–1110. [Google Scholar] [CrossRef] [PubMed]

- Gómez-López, V.M.; Ragaert, P.; Debevere, J.; Devlieghere, F. Pulsed light for food decontamination: A review. Trends Food Sci. Technol. 2007, 18, 464–473. [Google Scholar] [CrossRef]

- Wiktor, A.; Mandal, R.; Singh, A.; Singh, A.P. Pulsed Light treatment below a Critical Fluence. Foods 2019, 8, 1–13. [Google Scholar]

- Martín-belloso, O.; Soliva-fortuny, R.; Elez-Martínez, P.; Marsellés-Fontanet, R.; Vega-mercado, H. Non-thermal Processing Technologies. In Food Safety Management; Motarjemi, Y., Lelieveld, H., Eds.; Academic Press Inc.: London, UK, 2014; pp. 443–465. ISBN 9780123815040. [Google Scholar]

- Rowan, N.J. Pulsed light as an emerging technology to cause disruption for food and adjacent industries–Quo vadis? Trends Food Sci. Technol. 2019, 88, 316–332. [Google Scholar] [CrossRef]

- Wekhof, A. Disinfection with flash lamps. PDA J. Pharm. Sci. Technol. 2000, 54, 264–276. [Google Scholar]

- Kumar, P.; Han, J.H. Packaging materials for non-thermal processing of food and beverages. In Emerging Food Packaging Technologies; Yan, K., Lee, D.S., Eds.; Woodhead Publishing: Oxford, UK, 2012; pp. 323–334. [Google Scholar]

- Morris, C.; Brody, A.L.; Wicker, L. Non-Thermal Food Processing/Preservation Technologies: A Review with Packaging Implications. Packag. Tech. Sci. 2007, 20, 275–286. [Google Scholar] [CrossRef]

- Agüero, M.V.; Jagus, R.J.; Martín-Belloso, O.; Soliva-Fortuny, R. Surface decontamination of spinach by intense pulsed light treatments: Impact on quality attributes. Postharvest Biol. Technol. 2016, 121, 118–125. [Google Scholar] [CrossRef]

- Llano, K.R.A.; Marsellés-Fontanet, A.R.; Martín-Belloso, O.; Soliva-Fortuny, R. Impact of pulsed light treatments on antioxidant characteristics and quality attributes of fresh-cut apples. Innov. Food Sci. Emerg. Technol. 2016, 33, 206–215. [Google Scholar] [CrossRef]

- Valdivia-Nájar, C.G.; Martín-Belloso, O.; Giner-Seguí, J.; Soliva-Fortuny, R. Modeling the Inactivation of Listeria innocua and Escherichia coli in Fresh-Cut Tomato Treated with Pulsed Light. Food Bioprocess. Technol. 2017, 10, 266–274. [Google Scholar] [CrossRef]

- Leng, J.; Mukhopadhyay, S.; Sokorai, K.; Ukuku, D.O.; Fan, X.; Olanya, M.; Juneja, V. Inactivation of Salmonella in cherry tomato stem scars and quality preservation by pulsed light treatment and antimicrobial wash. Food Control. 2020, 110, 107005. [Google Scholar] [CrossRef]

- Ignat, A.; Manzocco, L.; Maifreni, M.; Bartolomeoli, I.; Nicoli, M.C. Surface decontamination of fresh-cut apple by pulsed light: Effects on structure, colour and sensory properties. Postharvest Biol. Technol. 2014, 91, 122–127. [Google Scholar] [CrossRef]

- Tao, T.; Ding, C.; Han, N.; Cui, Y.; Liu, X.; Zhang, C. Evaluation of pulsed light for inactivation of foodborne pathogens on fresh-cut lettuce: Effects on quality attributes during storage. Food Packag. Shelf Life 2019, 21, 100358. [Google Scholar] [CrossRef]

- Keklik, N.M.; Demirci, A.; Puri, V.M. Decontamination of unpackaged and vacuum-packaged boneless chicken breast with pulsed ultraviolet light. Poult. Sci. 2010, 89, 570–581. [Google Scholar] [CrossRef]

- Xu, W.; Wu, C. The impact of pulsed light on decontamination, quality, and bacterial attachment of fresh raspberries. Food Microbiol. 2016, 57, 135–143. [Google Scholar] [CrossRef]

- Aguiló-Aguayo, I.; Charles, F.; Renard, C.M.G.C.; Page, D.; Carlin, F. Pulsed light effects on surface decontamination, physical qualities and nutritional composition of tomato fruit. Postharvest Biol. Technol. 2013, 86, 29–36. [Google Scholar] [CrossRef]

- Aguiló-Aguayo, I.; Oms-Oliu, G.; Martín-Belloso, O.; Soliva-Fortuny, R. Impact of pulsed light treatments on quality characteristics and oxidative stability of fresh-cut avocado. LWT-Food Sci. Technol. 2014, 59, 320–326. [Google Scholar] [CrossRef]

- Valdivia-Nájar, C.G.; Martín-Belloso, O.; Soliva-Fortuny, R. Impact of pulsed light treatments and storage time on the texture quality of fresh-cut tomatoes. Innov. Food Sci. Emerg. Technol. 2018, 45, 29–35. [Google Scholar] [CrossRef]

- Taştan, Ö.; Pataro, G.; Donsì, F.; Ferrari, G.; Baysal, T. Decontamination of fresh-cut cucumber slices by a combination of a modified chitosan coating containing carvacrol nanoemulsions and pulsed light. Int. J. Food Microbiol. 2017, 260, 75–80. [Google Scholar] [CrossRef] [PubMed]

- Ramos-Villarroel, A.Y.; Martín-Belloso, O.; Soliva-Fortuny, R. Combined effects of malic acid dip and pulsed light treatments on the inactivation of Listeria innocua and Escherichia coli on fresh-cut produce. Food Control. 2015, 52, 112–118. [Google Scholar] [CrossRef]

- Huang, Y.; Ye, M.; Cao, X.; Chen, H. Pulsed light inactivation of murine norovirus, Tulane virus, Escherichia coli O157:H7 and Salmonella in suspension and on berry surfaces. Food Microbiol. 2017, 61, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Huang, R.; Chen, H. Evaluation of pulsed light treatments on inactivation of Salmonella on blueberries and its impact on shelf-life and quality attributes. Int. J. Food Microbiol. 2017, 260, 17–26. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Chen, H.; Wu, C. Salmonella and Escherichia coli O157:H7 inactivation, color, and bioactive compounds enhancement on raspberries during frozen storage after decontamination using new formula sanitizer washing or pulsed light. J. Food Prot. 2016, 79, 1107–1114. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Chen, H.; Huang, Y.; Wu, C. Decontamination of Escherichia coli O157: H7 on green onions using pulsed light (PL) and PL-surfactant-sanitizer combinations. Int. J. Food Microbiol. 2013, 166, 102–108. [Google Scholar] [CrossRef]

- Fernández, M.; Hospital, X.F.; Cabellos, C.; Hierro, E. Effect of pulsed light treatment on Listeria inactivation, sensory quality and oxidation in two varieties of Spanish dry-cured ham. Food Chem. 2020, 316, 126294. [Google Scholar] [CrossRef]

- Koch, F.; Wiacek, C.; Braun, P.G. Pulsed light treatment for the reduction of Salmonella Typhimurium and Yersinia enterocolitica on pork skin and pork loin. Int. J. Food Microbiol. 2019, 292, 64–71. [Google Scholar] [CrossRef]

- Vaclavik, V.A.; Christian, E.W. Essentials of Food Science, 4th ed.; Heldman, D.R., Ed.; Springer: New York, NY, USA, 2008; Volume 45, ISBN 9781461491378. [Google Scholar]

- Marriott, N.G.; Gravani, R.B. Principles of Food Sanitation, 5th ed.; Springer: New York, NY, USA, 2006; ISBN 9780387250250. [Google Scholar]

- Mahendran, R.; Ramanan, K.R.; Barba, F.J.; Lorenzo, J.M.; López-Fernández, O.; Munekata, P.E.S.; Roohinejad, S.; Sant’Ana, A.S.; Tiwari, B.K. Recent advances in the application of pulsed light processing for improving food safety and increasing shelf life. Trends Food Sci. Technol. 2019, 88, 67–79. [Google Scholar] [CrossRef]

- Oms-Oliu, G.; Martín-Belloso, O.; Soliva-Fortuny, R. Pulsed light treatments for food preservation. A review. Food Bioprocess. Technol. 2010, 3, 13–23. [Google Scholar] [CrossRef]

- Guerrero-Beltrán, J.Á.; Welti-Chanes, J.; Barbosa-Cánovas, G.V. Ultraviolet-C light processing of grape, cranberry and grapefruit juices to inactivate Saccharomyces cerevisiae. J. Food Process. Eng. 2009, 32, 916–932. [Google Scholar] [CrossRef]

- Valero, A.; Begum, M.; Leong, S.L.; Hocking, A.D.; Ramos, A.J.; Sanchis, V.; Marín, S. Effect of germicidal UVC light on fungi isolated from grapes and raisins. Lett. Appl. Microbiol. 2007, 45, 238–243. [Google Scholar] [CrossRef] [PubMed]

- Pala, Ç.U.; Toklucu, A.K. Effects of UV-C Light Processing on Some Quality Characteristics of Grape Juices. Food Bioprocess. Technol. 2013, 6, 719–725. [Google Scholar] [CrossRef]

- Escott, C.; Vaquero, C.; del Fresno, J.M.; Bañuelos, M.A.; Loira, I.; Han, S.; Bi, Y.; Morata, A.; Suárez-Lepe, J.A. Pulsed light effect in red grape quality and fermentation. Food Bioprocess. Technol. 2017, 10, 1540–1547. [Google Scholar] [CrossRef]

- Marquenie, D.; Michiels, C.W.; Van Impe, J.F.; Schrevens, E.; Nicolaï, B.N. Pulsed white light in combination with UV-C and heat to reduce storage rot of strawberry. Postharvest Biol. Technol. 2003, 28, 455–461. [Google Scholar] [CrossRef]

- Fava, J.; Hodara, K.; Nieto, A.; Guerrero, S.; Alzamora, S.M.; Castro, M.A. Structure (micro, ultra, nano), color and mechanical properties of Vitis labrusca L. (grape berry) fruits treated by hydrogen peroxide, UV-C irradiation and ultrasound. Food Res. Int. 2011, 44, 2938–2948. [Google Scholar] [CrossRef]

- Morata, A.; Loira, I.; Vejarano, R.; González, C.; Callejo, M.J.; Suárez-Lepe, J.A. Emerging preservation technologies in grapes for winemaking. Trends Food Sci. Technol. 2017, 67, 36–43. [Google Scholar] [CrossRef]

- Morata, A.; Loira, I.; Guamis, B.; Raso, J.; del Fresno, J.M.; Escott, C.; Bañuelos, M.A.; Álvarez, I.; Tesfaye, W.; González, C.; et al. Emerging technologies to increase extraction, control microorganisms, and reduce SO2. In Winemaking-Stabilization, Aging Chemistry and Biochemistry; Cosme, F., Ed.; IntechOpen: London, UK, 2020; pp. 1–20. [Google Scholar]

- Canonico, L.; Comitini, F.; Oro, L.; Ciani, M. Sequential Fermentation with Selected Immobilized Non-Saccharomyces Yeast for Reduction of Ethanol Content in Wine. Front. Microbiol. 2016, 7, 278–289. [Google Scholar] [CrossRef]

- Contreras, A.; Hidalgo, C.; Schmidt, S.; Henschke, P.A.; Curtin, C.; Varela, C. The application of non-Saccharomyces yeast in fermentations with limited aeration as a strategy for the production of wine with reduced alcohol content. Int. J. Food Microbiol. 2015, 205, 7–15. [Google Scholar] [CrossRef]

- Loira, I.; Morata, A.; González, C.; Suárez-Lepe, J.A. Selection of Glycolytically Inefficient Yeasts for Reducing the Alcohol Content of Wines from Hot Regions. Food Bioprocess. Technol. 2012, 5, 2787–2796. [Google Scholar] [CrossRef]

- Bisson, L.F.; Joseph, C.M.L.; Domizio, P. Yeasts. In Biology of Microorganisms on Grapes, in Must and in Wine; König, H., Unden, G., Fröhlich, J., Eds.; Springer International Publishing AG: Cham, Switzerland, 2017; pp. 65–102. ISBN 9783319600208. [Google Scholar]

- Rêgo, E.S.B.; Rosa, C.A.; Freire, A.L.; Machado, A.M.d.R.; Gomes, F.d.C.O.; Costa, A.S.P.d.; Mendonça, M.d.C.; Hernández-Macedo, M.L.; Padilha, F.F. Cashew wine and volatile compounds produced during fermentation by non-Saccharomyces and Saccharomyces yeast. LWT 2020, 126, 109291. [Google Scholar] [CrossRef]

- Del Fresno, J.M.; Morata, A.; Loira, I.; Bañuelos, M.A.; Escott, C.; Benito, S.; Chamorro, C.G.; Suárez-Lepe, J.A. Use of non-Saccharomyces in single-culture, mixed and sequential fermentation to improve red wine quality. Eur. Food Res. Technol. 2017, 243, 2175–2185. [Google Scholar] [CrossRef]

- Liu, P.T.; Lu, L.; Duan, C.Q.; Yan, G.L. The contribution of indigenous non-Saccharomyces wine yeast to improved aromatic quality of Cabernet Sauvignon wines by spontaneous fermentation. LWT-Food Sci. Technol. 2016, 71, 356–363. [Google Scholar] [CrossRef]

- Morata, A.; Escott, C.; Loira, I.; del Fresno, J.M.; González, C.; Suárez-Lepe, J.A. Influence of Saccharomyces and non-Saccharomyces Yeasts in the Formation of Pyranoanthocyanins and Polymeric Pigments during Red Wine Making. Molecules 2019, 24, 4490. [Google Scholar] [CrossRef] [PubMed]

- Suárez-Lepe, J.A.; Morata, A. New trends in yeast selection for winemaking. Trends Food Sci. Technol. 2012, 23, 39–50. [Google Scholar] [CrossRef]

- Pateraki, C.; Paramithiotis, S.; Doulgeraki, A.I.; Kallithraka, S.; Kotseridis, Y.; Drosinos, E.H. Effect of sulfur dioxide addition in wild yeast population dynamics and polyphenolic composition during spontaneous red wine fermentation from Vitis vinifera cultivar Agiorgitiko. Eur. Food Res. Technol. 2014, 239, 1067–1075. [Google Scholar] [CrossRef]

- Martins, V.; Lopez, R.; Garcia, A.; Teixeira, A.; Gerós, H. Vineyard calcium sprays shift the volatile profile of young red wine produced by induced and spontaneous fermentation. Food Res. Int. 2020, 131, 108983. [Google Scholar] [CrossRef] [PubMed]

- Morata, A.; Escott, C.; Bañuelos, M.A.; Loira, I.; Del Fresno, J.M.; González, C.; Suárez-lepe, J.A. Contribution of non-Saccharomyces yeasts to wine freshness. A review. Biomolecules 2020, 10, 34. [Google Scholar] [CrossRef]

- Delsart, C.; Grimi, N.; Boussetta, N.; Sertier, C.M.; Ghidossi, R.; Peuchot, M.M.; Vorobiev, E. Comparison of the effect of pulsed electric field or high voltage electrical discharge for the control of sweet white must fermentation process with the conventional addition of sulfur dioxide. Food Res. Int. 2015, 77, 718–724. [Google Scholar] [CrossRef]

- Mozell, M.R.; Thachn, L. The impact of climate change on the global wine industry: Challenges & solutions. Wine Econ. Policy 2014, 3, 81–89. [Google Scholar]

- Keller, M. Managing grapevines to optimise fruit development in a challenging environment: A climate change primer for viticulturists. Aust. J. Grape Wine Res. 2010, 16, 56–69. [Google Scholar] [CrossRef]

- Portu, J.; López, R.; Baroja, E.; Santamaría, P.; Garde-Cerdán, T. Improvement of grape and wine phenolic content by foliar application to grape-vine of three different elicitors: Methyl jasmonate, chitosan, and yeast extract. Food Chem. 2016, 201, 213–221. [Google Scholar] [CrossRef] [PubMed]

- Pataro, G.; Sinik, M.; Capitoli, M.M.; Donsì, G.; Ferrari, G. The influence of post-harvest UV-C and pulsed light treatments on quality and antioxidant properties of tomato fruits during storage. Innov. Food Sci. Emerg. Technol. 2015, 30, 103–111. [Google Scholar] [CrossRef]

- Zhang, B.-Q.; Shen, J.-Y.; Duan, C.-Q.; Yan, G.-L. Use of indigenous Hanseniaspora vineae and Metschnikowia pulcherrima co-fermentation with Saccharomyces cerevisiae to improve the aroma diversity of Vidal Blanc icewine. Front. Microbiol. 2018, 9, 2303. [Google Scholar] [CrossRef]

- Martin, V.; Giorello, F.; Fariña, L.; Minteguiaga, M.; Salzman, V.; Boido, E.; Aguilar, P.S.; Gaggero, C.; Dellacassa, E.; Mas, A.; et al. De novo synthesis of benzenoid compounds by the yeast Hanseniaspora vineae increases the flavor diversity of wines. J. Agric. Food Chem. 2016, 64, 4574–4583. [Google Scholar] [CrossRef] [PubMed]

- Giorello, F.; Valera, M.J.; Martin, V.; Parada, A.; Salzman, V.; Camesasca, L.; Fariña, L.; Boido, E.; Medina, K.; Dellacassa, E.; et al. Genomic and transcriptomic basis of Hanseniaspora vineae’s impact on flavor diversity and wine quality. Appl. Environ. Microbiol. 2019, 85, 1–43. [Google Scholar]

- Senses-Ergul, S.; Ágoston, R.; Belák, Á.; Deák, T. Characterization of some yeasts isolated from foods by traditional and molecular tests. Int. J. Food Microbiol. 2006, 108, 120–124. [Google Scholar] [CrossRef] [PubMed]

- Morata, A.; Loira, I.; Tesfaye, W.; Bañuelos, M.; González, C.; Lepe, J.S. Lachancea thermotolerans applications in wine technology. Fermentation 2018, 4, 53. [Google Scholar] [CrossRef]

- Lucio, O.; Pardo, I.; Heras, J.M.; Krieger-Weber, S.; Ferrer, S. Use of starter cultures of Lactobacillus to induce malolactic fermentation in wine. Aust. J. Grape Wine Res. 2017, 23, 15–21. [Google Scholar] [CrossRef]

- Krieger-Weber, S.; Heras, J.M.; Suarez, C. Lactobacillus plantarum, a New Biological Tool to Control Malolactic Fermentation: A Review and an Outlook. Beverages 2020, 6, 23. [Google Scholar] [CrossRef]

- Morata, A.; Bañuelos, M.A.; López, C.; Song, C.; Vejarano, R.; Loira, I.; Palomero, F.; Lepe, J.A.S. Use of fumaric acid to control pH and inhibit malolactic fermentation in wines. Food Addit. Contam.-Part A Chem. Anal. Control. Expo. Risk Assess. 2020, 37, 228–238. [Google Scholar] [CrossRef] [PubMed]

- Morata, A.; Bañuelos, M.A.; Vaquero, C.; Loira, I.; Cuerda, R.; Palomero, F.; González, C.; Suárez-Lepe, J.A.; Wang, J.; Han, S.; et al. Lachancea thermotolerans as a tool to improve pH in red wines from warm regions. Eur. Food Res. Technol. 2019, 245, 885–894. [Google Scholar] [CrossRef]

- Escott, C.; Morata, A.; Loira, I.; Tesfaye, W.; Suarez-Lepe, J.A. Characterization of polymeric pigments and pyranoanthocyanins formed in microfermentations of non-Saccharomyces yeasts. J. Appl. Microbiol. 2016, 121, 1346–1356. [Google Scholar] [CrossRef] [PubMed]

- Escott, C.; Del Fresno, J.M.; Loira, I.; Morata, A.; Tesfaye, W.; González, C.; Suárez-Lepe, J.A. Formation of polymeric pigments in red wines through sequential fermentation of flavanol-enriched musts with non-Saccharomyces yeasts. Food Chem. 2018, 239, 975–983. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, J.; de Freitas, V.; Mateus, N. Polymeric Pigments in Red Wines. In Red Wine Technology; Morata, A., Ed.; Academic Press: London, UK, 2019; pp. 207–218. ISBN 9780128144008. [Google Scholar]

| Food Product | Microorganism | Processing Conditions | Reduction (log10 CFU/mL) | Reference |

|---|---|---|---|---|

| Raspberry | Escherichia coli O157:H7 Salmonella Total viable count Yeast and moulds | Total fluence (J/cm2): 28.2 Peak power (J/cm2/pulse): 1.27 Exposure time (s): 30 Distance from the lamp (cm): 13 | 3.9 4.5 1.5 1.6 | [33] |

| Tomato fruit | Microflora in skin and peduncle Saccharomyces cerevisiae | Total fluence (J/cm2): 4 (microflora) and 2.2 (Cerevisiae) Pulse width (µs): 250 Discharge voltage (V): 2500 | 1 2.3 | [34] |

| Avocado | Aerobic mesophilic microorganisms | Total fluence (J/cm2): 14 Peak power (J/cm2/pulse): 0.4 Pulse width (µs): 300 Distance from the lamp (cm): 5 | 1.2 | [35] |

| Fresh-cut tomatoes | Psychrophilic bacteria Moulds and yeasts | Total fluence (J/cm2): 4, 6 and 8 Peak power (J/cm2/pulse): 0.4 Pulse width (µs): 300 Stored for 20 days at 4 °C | Up to 1.8 Up to 0.5 | [36] |

| Fresh-cut tomato | Listeria innocua Escherichia coli | Total fluence (J/cm2): 4, 6 and 8 Peak power (J/cm2/pulse): 0.4 Pulse width (µs): 300 Distance above and below from the lamp (cm): 8.5 Stored for 20 days at 4 °C | 0.9 1.4 | [28] |

| Spinach leaves | Listeria innocua Escherichia coli | Total fluence (J/cm2): 0.8 Peak power (J/cm2/pulse): 0.4 Pulse width (µs): 300 Distance from the lamp (cm): 8.5 | 1.85 1.72 | [26] |

| Mesophilic aerobic bacteria Psychrotrophic bacteria Coliforms Listeria ssp Yeast and moulds | Total fluence (J/cm2): 4 Pulse width (µs): 300 Distance from the lamp (cm): 8.5 | 0.5–2.2 | ||

| Fresh-cut apple slices | Mesophilic and psychrophilic aerobic bacteria Moulds and yeasts | Total fluence (J/cm2): 16 Peak power (J/cm2/pulse): 0.4 Pulse width (µs): 300 Distance above and below from the lamp (cm): 8.5 | 1.55 2.3 | [27] |

| Fresh-cut apple slices | Total viable counts Lactobacillus brevis Listeria monocytogenes | Number of pulses: 9 Peak power (J/cm2/pulse): 1.75 Pulse width (µs): 500 Distance from the lamp (cm): 1 | 1.0 3.0 2.7 | [30] |

| Cherry tomato | Salmonella enterica | Total fluence (J/cm2): 31.5 Peak power (J/cm2/pulse): 0.35 Pulse width (µs): 500 Exposure time (s): 30 Distance from the lamp (cm): 14 | 2.3 | [29] |

| Fresh-cut cucumber slices | Escherichia coli ATCC 26 | Total fluence (J/cm2): 12 Peak power (J/cm2/pulse): 0.43 Pulse width (µs): 360 Exposure time (s): 12.4 Distance from the lamp (cm): 10.8 | 2.8 | [37] |

| Fresh-cut avocado, watermelon and mushrooms | Escherichia coli Listeria innocua | Total fluence (J/cm2): 12 Peak power (J/cm2/pulse): 0.4 Pulse width (µs): 300 Distance from the lamp (cm): 8.5 | 2.58, 2.88 and 2.97 2.25, 2.17 and 3.62 | [38] |

| Strawberries (S) and blueberries (B) | Murine norovirus (MNV-1) Escherichia coli Salmonella | Total fluence (J/cm2): 22.5 Exposure time (s): 24 Number of pulses: 16 Distance from the lamp (cm): 16 | S: 0.9 B: 3.8 S: 1.9 B: 5.7 S: 2.1 B: 4.2 | [39] |

| Blueberries | Salmonella | Total fluence (J/cm2): 6 Peak power (J/cm2/pulse): 0.066 Pulse width (µs): 360 Exposure time (s): 30 | 0.9 spot inoculation 0.6 dip inoculation | [40] |

| Fresh-cut lettuce | Salmonella enteritidis Escherichia coli Staphylococcus aureus Listeria monocytogenes | Total fluence (J/cm2): 16.8 Peak power (J/cm2/pulse): 0.33 Pulse width (µs): 300 Exposure time (s): 25 Distance from the lamp (cm): 9 | 5.40 5.08 6.56 4.00 | [31] |

| Total bacteria count Yeast and moulds | Total fluence (J/cm2): 4–16.8 Peak power (J/cm2/pulse): 0.33 Pulse width (µµs): 300 Exposure time (s): 6–25 Distance from the lamp (cm): 9 | 2.73 1.14 | ||

| Raspberries | Salmonella Newport Escherichia coli | Total fluence (J/cm2): 14.3 Peak power (J/cm2/pulse): 1.27 Exposure time (s): 15 | 3.4 3.3 | [41] |

| Green onion | Escherichia coli | Total fluence (J/cm2): 5 Peak power (J/cm2/pulse): 1.27 Exposure time (s): 5 | Spot inoculation: stems 4.8 and leaves 4.1 Dip inoculation: stems 0.2 and leaves 0.6 | [42] |

| Food Product | Microorganism | Treatment | Reduction (log10 CFU/mL) | Reference |

|---|---|---|---|---|

| Serrano ham slices Iberian ham slices | Listeria innocua | Total fluence (J/cm2): 0, 2.1, 4.2 and 8.4 Peak power (J/cm2/pulse): 0.3 Stored for 4 days at 20 °C | 1 2 | [43] |

| Pork loin | Salmonella typhimurium Yersinia enterocolitica | Total fluence (J/cm2): 0.52–19.11 Peak power (J/cm2/pulse): 1.27 Pulse width (µs): 300 Exposure time (s): 1–30 Distance from the lamp (cm): 8.3–13.4 | 0.4–1.71 0.39–1.69 | [44] |

| Pork skin | Total fluence (J/cm2): 19.11 Peak power (J/cm2/pulse): 1.27 Pulse width (µs): 300 Exposure time (s): 30 Distance from the lamp (cm): 8.3 | 2.97 4.19 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santamera, A.; Escott, C.; Loira, I.; del Fresno, J.M.; González, C.; Morata, A. Pulsed Light: Challenges of a Non-Thermal Sanitation Technology in the Winemaking Industry. Beverages 2020, 6, 45. https://doi.org/10.3390/beverages6030045

Santamera A, Escott C, Loira I, del Fresno JM, González C, Morata A. Pulsed Light: Challenges of a Non-Thermal Sanitation Technology in the Winemaking Industry. Beverages. 2020; 6(3):45. https://doi.org/10.3390/beverages6030045

Chicago/Turabian StyleSantamera, Aitana, Carlos Escott, Iris Loira, Juan Manuel del Fresno, Carmen González, and Antonio Morata. 2020. "Pulsed Light: Challenges of a Non-Thermal Sanitation Technology in the Winemaking Industry" Beverages 6, no. 3: 45. https://doi.org/10.3390/beverages6030045

APA StyleSantamera, A., Escott, C., Loira, I., del Fresno, J. M., González, C., & Morata, A. (2020). Pulsed Light: Challenges of a Non-Thermal Sanitation Technology in the Winemaking Industry. Beverages, 6(3), 45. https://doi.org/10.3390/beverages6030045