Thermal and Non-Thermal Physical Methods for Improving Polyphenol Extraction in Red Winemaking

Abstract

1. Introduction

2. Thermal Technologies for Improving Polyphenol Extraction

2.1. Thermovinification, MPC, and KZHE

2.1.1. Description of the Techniques

2.1.2. Equipment

2.1.3. Impact of the Treatment in the Composition of Wine

2.2. Flash Release

2.2.1. Description of the Technique

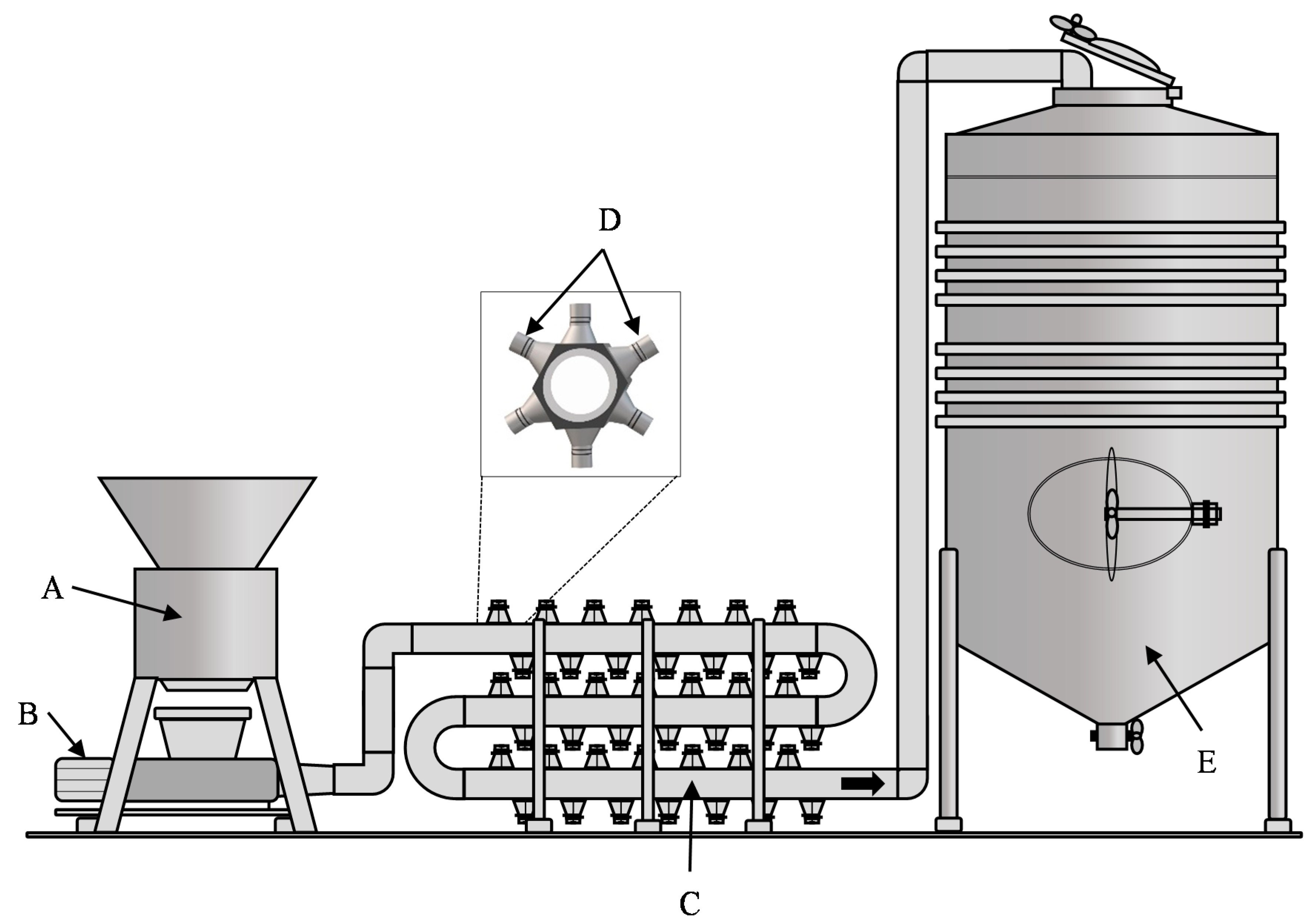

2.2.2. Equipment

2.2.3. Impact of the Treatment in the Composition of Wine

3. Non-Thermal Techniques for Improving Polyphenol Extraction

3.1. Pulsed Electric Fields (PEF)

3.1.1. Description of the Technique

3.1.2. Equipment

3.1.3. Impact of the Treatment in the Composition of Wine

3.2. Ultrasound

3.2.1. Description of the Technique

3.2.2. Equipment

3.2.3. Impact of the Treatment in the Composition of Wine

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Genc, M.; Genc, S.; Goksungur, Y. Exergy analysis of wine production: Red wine production process as a case study. Appl. Therm. Eng. 2017, 117, 511–521. [Google Scholar] [CrossRef]

- Arnold, R.A.; Noble, A.C. Bitterness and Astringency of Grape Seed Phenolics in a Model Wine Solution. Am. J. Enol. Vitic. 1978, 29, 150–152. [Google Scholar]

- Perez-Vizcaino, F.; Fraga, C.G. Research trends in flavonoids and health. Arch. Biochem. Biophys. 2018, 646, 107–112. [Google Scholar] [CrossRef] [PubMed]

- Boulton, R.; Singleton, V.L.; Bisson, L.F.; Kunkee, R.E. Principles and Practices of Winemaking; Springer Science & Business Media: Berlin, Germany, 2013; ISBN 978-1-4757-6255-6. [Google Scholar]

- Zanoni, B.; Siliani, S.; Canuti, V.; Rosi, I.; Bertuccioli, M. A kinetic study on extraction and transformation phenomena of phenolic compounds during red wine fermentation. Int. J. Food Sci. Technol. 2010, 45, 2080–2088. [Google Scholar] [CrossRef]

- Cerpa-Calderón, F.K.; Kennedy, J.A. Berry Integrity and Extraction of Skin and Seed Proanthocyanidins during Red Wine Fermentation. J. Agric. Food Chem. 2008, 56, 9006–9014. [Google Scholar] [CrossRef]

- Hernández-Jiménez, A.; Kennedy, J.A.; Bautista-Ortín, A.B.; Gómez-Plaza, E. Effect of Ethanol on Grape Seed Proanthocyanidin Extraction. Am. J. Enol. Vitic. 2012, 63, 57–61. [Google Scholar] [CrossRef]

- Setford, P.C.; Jeffery, D.W.; Grbin, P.R.; Muhlack, R.A. Factors affecting extraction and evolution of phenolic compounds during red wine maceration and the role of process modelling. Trends Food Sci. Technol. 2017, 69, 106–117. [Google Scholar] [CrossRef]

- Marais, J. Effect of Different Wine-Making Techniques on the Composition and Quality of Pinotage Wine. II. Juice/Skin Mixing Practices. S. Afr. J. Enol. Vitic. 2003, 24. [Google Scholar] [CrossRef][Green Version]

- Togores, J.H. Tratado de Enología; Mundi-Prensa: Madrid, España, 2011; ISBN 978-84-8476-531-8. [Google Scholar]

- Lowe, E.J.; Oey, A.; Turner, T.M. Gasquet Thermovinification System Perspective after Two Years’ Operation. Am. J. Enol. Vitic. 1976, 27, 130–133. [Google Scholar]

- Pezzi, F.; Caprara, C.; Friso, D.; Ranieri, B. Technical and economic evaluation of maceration of red grapes for production everyday wine. J. Agric. Eng. 2013, 323–326. [Google Scholar] [CrossRef][Green Version]

- Morel-Salmi, C.; Souquet, J.-M.; Bes, M.; Cheynier, V. Effect of Flash Release Treatment on Phenolic Extraction and Wine Composition. J. Agric. Food Chem. 2006, 54, 4270–4276. [Google Scholar] [CrossRef] [PubMed]

- Atanacković, M.; Petrović, A.; Jović, S.; Bukarica, L.G.-; Bursać, M.; Cvejić, J. Influence of winemaking techniques on the resveratrol content, total phenolic content and antioxidant potential of red wines. Food Chem. 2012, 131, 513–518. [Google Scholar] [CrossRef]

- Fischer, U.; Strasser, M.; Gutzler, K. Impact of fermentation technology on the phenolic and volatile composition of German red wines. Int. J. Food Sci. Technol. 2000, 35, 81–94. [Google Scholar] [CrossRef]

- Delsart, C.; Ghidossi, R.; Poupot, C.; Cholet, C.; Grimi, N.; Vorobiev, E.; Milisic, V.; Peuchot, M.M. Enhanced Extraction of Phenolic Compounds from Merlot Grapes by Pulsed Electric Field Treatment. Am. J. Enol. Vitic. 2012, 63, 205–211. [Google Scholar] [CrossRef]

- El Darra, N.; Grimi, N.; Maroun, R.G.; Louka, N.; Vorobiev, E. Pulsed electric field, ultrasound, and thermal pretreatments for better phenolic extraction during red fermentation. Eur. Food Res. Technol. 2013, 236, 47–56. [Google Scholar] [CrossRef]

- López, N.; Puértolas, E.; Condón, S.; Álvarez, I.; Raso, J. Application of pulsed electric fields for improving the maceration process during vinification of red wine: Influence of grape variety. Eur. Food Res. Technol. 2008, 227, 1099. [Google Scholar] [CrossRef]

- Leong, S.Y.; Burritt, D.J.; Oey, I. Evaluation of the anthocyanin release and health-promoting properties of Pinot Noir grape juices after pulsed electric fields. Food Chem. 2016, 196, 833–841. [Google Scholar] [CrossRef] [PubMed]

- Rankine, B.C. Heat extraction of color from red grapes of increasing importance. Wines Vines 1973, 54, 33–36. [Google Scholar]

- Girard, B.; Yuksel, D.; Cliff, M.A.; Delaquis, P.; Reynolds, A.G. Vinification effects on the sensory, colour and GC profiles of Pinot noir wines from British Columbia. Food Res. Int. 2001, 34, 483–499. [Google Scholar] [CrossRef]

- Ribéreau-Gayon, P.; Dubourdieu, D.; Donèche, B.; Lonvaud, A. Handbook of Enology, Volume 1: The Microbiology of Wine and Vinifications; John Wiley & Sons: Hoboken, NJ, USA, 2006; ISBN 978-0-470-01035-8. [Google Scholar]

- Nordestgaard, S. Fermentation: Pre-fermentation heating of red grapes: A useful tool to manage compressed vintages? Aust. N. Z. Grapegrow. Winemak. 2017, 637, 54–61. [Google Scholar]

- Auw, J.M.; Blanco, V.; O’Keefe, S.F.; Sims, C.A. Effect of Processing on the Phenolics and Color of Cabernet Sauvignon, Chambourcin, and Noble Wines and Juices. Am. J. Enol. Vitic. 1996, 47, 279–286. [Google Scholar]

- de Andrade Neves, N.; de Araújo Pantoja, L.; dos Santos, A.S. Thermovinification of grapes from the Cabernet Sauvignon and Pinot Noir varieties using immobilized yeasts. Eur. Food Res. Technol. 2014, 238, 79–84. [Google Scholar] [CrossRef]

- Martinière, P.; Ribéreau-Gayon, J. Modification of the fermentation process by previous heating of the grapes. Comptes Rendus Hebd. Seances Acad. Sci. Ser. D Sci. Nat. 1969, 269, 925–928. [Google Scholar]

- Geffroy, O.; Lopez, R.; Feilhes, C.; Violleau, F.; Kleiber, D.; Favarel, J.-L.; Ferreira, V. Modulating analytical characteristics of thermovinified Carignan musts and the volatile composition of the resulting wines through the heating temperature. Food Chem. 2018, 257, 7–14. [Google Scholar] [CrossRef] [PubMed]

- Niculaua, M.; Tudose-Sandu-Ville, S.; Cotea, V.V.; Luchian, C.E.; Tudose-Sandu-Ville, O.-F. Phenolic Compounds Content in Merlot Wines Obtained through Different Thermomaceration Techniques. Not. Bot. Horti Agrobot. Cluj-Napoca 2017, 45, 548–552. [Google Scholar] [CrossRef][Green Version]

- Piccardo, D.; González-Neves, G. Extracción de polifenoles y composición de vinos tintos Tannat elaborados por técnicas de maceración prefermentativa. Agrociencia Urug. 2013, 17, 36–44. [Google Scholar]

- Gao, L.; Girard, B.; Mazza, G.; Reynolds, A.G. Changes in Anthocyanins and Color Characteristics of Pinot Noir Wines during Different Vinification Processes. J. Agric. Food Chem. 1997, 45, 2003–2008. [Google Scholar] [CrossRef]

- Geffroy, O.; Lopez, R.; Serrano, E.; Dufourcq, T.; Gracia-Moreno, E.; Cacho, J.; Ferreira, V. Changes in analytical and volatile compositions of red wines induced by pre-fermentation heat treatment of grapes. Food Chem. 2015, 187, 243–253. [Google Scholar] [CrossRef]

- Girard, B.; Kopp, T.G.; Reynolds, A.G.; Cliff, M. Influence of Vinification Treatments on Aroma Constituents and Sensory Descriptors of Pinot noir Wines. Am. J. Enol. Vitic. 1997, 48, 198. [Google Scholar]

- De Boubée, D.R.; Cumsille, A.M.; Pons, M.; Dubourdieu, D. Location of 2-Methoxy-3-isobutylpyrazine in Cabernet Sauvignon Grape Bunches and Its Extractability during Vinification. Am. J. Enol. Vitic. 2002, 53, 1–5. [Google Scholar]

- Markakis, P. Chapter 6-Stability of Anthocyanins in Foods. In Anthocyanins as Food Colors; Markakis, P., Ed.; Academic Press: Cambridge, MA, USA, 1982; pp. 163–180. ISBN 978-0-12-472550-8. [Google Scholar] [CrossRef]

- Kelebek, H.; Canbas, A.; Selli, S.; Saucier, C.; Jourdes, M.; Glories, Y. Influence of different maceration times on the anthocyanin composition of wines made from Vitis vinifera L. cvs. Boğazkere and Öküzgözü. J. Food Eng. 2006, 77, 1012–1017. [Google Scholar] [CrossRef]

- Morata, A.; Gómez-Cordovés, M.C.; Suberviola, J.; Bartolomé, B.; Colomo, B.; Suárez, J.A. Adsorption of Anthocyanins by Yeast Cell Walls during the Fermentation of Red Wines. J. Agric. Food Chem. 2003, 51, 4084–4088. [Google Scholar] [CrossRef] [PubMed]

- Ageron, D.; Escudier, J.L.; Abbal, P.; Moutounet, M. Prétraitement des raisins par flash détente sous vide poussé. Rev. Fr. Oenologie 1995, 35, 50–53. [Google Scholar]

- Doco, T.; Williams, P.; Cheynier, V. Effect of Flash Release and Pectinolytic Enzyme Treatments on Wine Polysaccharide Composition. J. Agric. Food Chem. 2007, 55, 6643–6649. [Google Scholar] [CrossRef] [PubMed]

- Baggio, P. Flash Extraction–What Can It Do for You? Web page. Available online: https://www.dtpacific.com/dev/wp-content/uploads/2017/03/Art-ASVO-Flash-Bio-Thermo-Extraction-What-can-it-do-for-you.pdf (accessed on 1 April 2018).

- Vernhet, A.; Bes, M.; Bouissou, D.; Carrillo, S.; Brillouet, J.-M. Characterization of suspended solids in thermo-treated red musts. J. Int. Sci. Vigne Vin 2016, 50, 9. [Google Scholar] [CrossRef]

- Escudier, J.L.; Bes, M.; Morel-Salmi, C.; Micolajczak, M.; Sanson, A. Vinification en rouge: Macérations post-fermentaires, macérations carboniques, flash-détente sous vide. Rev. Fr. OEnol. 2006, 216, 11–19. [Google Scholar]

- Kotséridis, Y.; Escudier, J.L.; Moutounet, M. Flash détente et qualité des vins. Progr. Agric. Vitic. 2002, 20, 438–442. [Google Scholar]

- Razungles, A. Extraction technologies and wine quality. In Managing Wine Quality; Elsevier: Amsterdam, The Netherlands, 2010; pp. 589–630. ISBN 978-1-84569-798-3. [Google Scholar] [CrossRef]

- Besnard, É.; Laffargue, F.; Relhié, F.; Fro, H.; Alibert, V. Influence de l’itinéraire de vinification après Flash-détente dans l’élaboration d’une nouvelle gamme de vins du Lot. Web page. Available online: http://www.vignevin-occitanie.com/wp-content/uploads/2018/08/flash-detente-lot-malbec.pdf (accessed on 1 April 2019).

- Toepfl, S.; Mathys, A.; Heinz, V.; Knorr, D. Review: Potential of High Hydrostatic Pressure and Pulsed Electric Fields for Energy Efficient and Environmentally Friendly Food Processing. Food Rev. Int. 2006, 22, 405–423. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Meullemiestre, A.; Turk, M.; Perino, S.; Fabiano-Tixier, A.-S.; Abert-Vian, M. Review of Green Food Processing techniques. Preservation, transformation, and extraction. Innov. Food Sci. Emerg. Technol. 2017, 41, 357–377. [Google Scholar] [CrossRef]

- Tsong, T.Y. Electroporation of Cell Membranes. In Electroporation and Electrofusion in Cell Biology; Neumann, E., Sowers, A.E., Jordan, C.A., Eds.; Springer: Boston, MA, USA, 1989; pp. 149–163. ISBN 978-1-4899-2528-2. [Google Scholar] [CrossRef]

- Weaver, J.C.; Chizmadzhev, Y.A. Theory of electroporation: A review. Bioelectrochem. Bioenerg. 1996, 41, 135–160. [Google Scholar] [CrossRef]

- Toepfl, S. Pulsed electric field food processing –industrial equipment design and commercial applications. Stewart Postharvest Rev. 2012, 8, 1–7. [Google Scholar] [CrossRef]

- Puértolas, E.; Luengo, E.; Álvarez, I.; Raso, J. Improving Mass Transfer to Soften Tissues by Pulsed Electric Fields: Fundamentals and Applications. Annu. Rev. Food Sci. Technol. 2012, 3, 263–282. [Google Scholar] [CrossRef] [PubMed]

- Luengo, E.; Franco, E.; Ballesteros, F.; Álvarez, I.; Raso, J. Winery Trial on Application of Pulsed Electric Fields for Improving Vinification of Garnacha Grapes. Food Bioprocess Technol. 2014, 7, 1457–1464. [Google Scholar] [CrossRef]

- Toepfl, S. Pulsed Electric Field food treatment-scale up from lab to industrial scale. Procedia Food Sci. 2011, 1, 776–779. [Google Scholar] [CrossRef]

- Puértolas, E.; López, N.; Condón, S.; Álvarez, I.; Raso, J. Potential applications of PEF to improve red wine quality. Trends Food Sci. Technol. 2010, 21, 247–255. [Google Scholar] [CrossRef]

- Cholet, C.; Delsart, C.; Petrel, M.; Gontier, E.; Grimi, N.; L’Hyvernay, A.; Ghidossi, R.; Vorobiev, E.; Mietton-Peuchot, M.; Gény, L. Structural and Biochemical Changes Induced by Pulsed Electric Field Treatments on Cabernet Sauvignon Grape Berry Skins: Impact on Cell Wall Total Tannins and Polysaccharides. J. Agric. Food Chem. 2014, 62, 2925–2934. [Google Scholar] [CrossRef]

- Saldaña, G.; Cebrián, G.; Abenoza, M.; Sánchez-Gimeno, C.; Álvarez, I.; Raso, J. Assessing the efficacy of PEF treatments for improving polyphenol extraction during red wine vinifications. Innov. Food Sci. Emerg. Technol. 2017, 39, 179–187. [Google Scholar] [CrossRef]

- Ricci, A.; Parpinello, G.P.; Versari, A. Recent Advances and Applications of Pulsed Electric Fields (PEF) to Improve Polyphenol Extraction and Color Release during Red Winemaking. Beverages 2018, 4, 18. [Google Scholar] [CrossRef]

- Puértolas, E.; Hernández-Orte, P.; Saldaña, G.; Álvarez, I.; Raso, J. Improvement of winemaking process using pulsed electric fields at pilot-plant scale. Evolution of chromatic parameters and phenolic content of Cabernet Sauvignon red wines. Food Res. Int. 2010, 43, 761–766. [Google Scholar] [CrossRef]

- Puértolas, E.; Saldaña, G.; Condón, S.; Álvarez, I.; Raso, J. Evolution of polyphenolic compounds in red wine from Cabernet Sauvignon grapes processed by pulsed electric fields during aging in bottle. Food Chem. 2010, 119, 1063–1070. [Google Scholar] [CrossRef]

- López-Alfaro, I.; González-Arenzana, L.; López, N.; Santamaría, P.; López, R.; Garde-Cerdán, T. Pulsed electric field treatment enhanced stilbene content in Graciano, Tempranillo and Grenache grape varieties. Food Chem. 2013, 141, 3759–3765. [Google Scholar] [CrossRef]

- Garde-Cerdán, T.; González-Arenzana, L.; López, N.; López, R.; Santamaría, P.; López-Alfaro, I. Effect of different pulsed electric field treatments on the volatile composition of Graciano, Tempranillo and Grenache grape varieties. Innov. Food Sci. Emerg. Technol. 2013, 20, 91–99. [Google Scholar] [CrossRef]

- Cravotto, G.; Cintas, P. Power ultrasound in organic synthesis: Moving cavitational chemistry from academia to innovative and large-scale applications. Chem. Soc. Rev. 2006, 35, 180–196. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.-G.; Meullemiestre, A.; Fabiano-Tixier, A.-S.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef]

- González-Centeno, M.R.; Knoerzer, K.; Sabarez, H.; Simal, S.; Rosselló, C.; Femenia, A. Effect of acoustic frequency and power density on the aqueous ultrasonic-assisted extraction of grape pomace (Vitis vinifera L.)—A response surface approach. Ultrason. Sonochem. 2014, 21, 2176–2184. [Google Scholar] [CrossRef]

- Celotti, E.; Ferraretto, P. Studies for the ultrasound application in winemaking for a low impact enology. In Proceedings of the 39th World Congress of Vine and Wine, Bento Gonçalves, Brazil, 23–28 October 2016; p. 132. [Google Scholar]

- Zhang, Q.-A.; Shen, Y.; Fan, X.-H.; García Martín, J.F. Preliminary study of the effect of ultrasound on physicochemical properties of red wine. CyTA-J. Food 2016, 14, 55–64. [Google Scholar] [CrossRef]

- Bautista-Ortín, A.B.; Jiménez-Martínez, M.D.; Jurado, R.; Iniesta, J.A.; Terrades, S.; Andrés, A.; Gómez-Plaza, E. Application of high-power ultrasounds during red wine vinification. Int. J. Food Sci. Technol. 2017, 52, 1314–1323. [Google Scholar] [CrossRef]

- Del Fresno, J.M.; Morata, A.; Escott, C.; Loira, I.; Cuerda, R.; Suárez-Lepe, J. Sonication of Yeast Biomasses to Improve the Ageing on Lees Technique in Red Wines. Molecules 2019, 24, 635. [Google Scholar] [CrossRef]

- Singleton, V.L.; Draper, D.E. Ultrasonic Treatment with Gas Purging as a Quick Aging Treatment for Wine. Am. J. Enol. Vitic. 1963, 14, 23–35. [Google Scholar]

| Technology | Treatment | Variety | Total Polyphenolic Content | Colour Intensity | Total Anthocyanin Content | Ref. |

|---|---|---|---|---|---|---|

| Thermovinification | 82 °C 1 h | Merlot | 36% | N/A | 26% | [28] |

| Flow rate: 500 kg/h | ||||||

| Maceration time: 5 days | ||||||

| Flash-release | 95 °C for 6 min Strong vacuum (>100 mbar) | Carignan | 11% | 30% | 30% | [13] |

| Flow rate: N/A | ||||||

| Maceration time: 5 days | ||||||

| PEF | 5 kV/cm, 150 µs (50 pulses 3 µs, 3.67 kJ/kg) | Cabernet Sauvignon | 23% | 38% | 34% | [57] |

| Flow rate: 118 kg/h | ||||||

| Maceration time: 4 days | ||||||

| Ultrasound | 2500 W; 28 kHz; 8 W/cm2 | Monastrell | 32% | 31% | 13% | [66] |

| Flow rate: 400 kg/h | ||||||

| Maceration time: 4 days |

| Technology | Advantage | Disadvantages | Ref. |

|---|---|---|---|

| Thermovinification | Possibility of obtaining red wines without maceration For obtaining table wines. Permits to inactive enzymes and microorganisms Approved by OIV | Poor color stability Possible degradation of anthocyanins Loss of varietal aromatic compounds Wines not usually used for aging Addition of starter cultures for initiating fermentation required High energetic requirement. Supplies of methane or diesel oil required | [12,25,27,28,29] |

| Flash-release | Mainly for obtaining table wines. Permits to inactive enzymes and microorganisms Obtaining of more complex sensory characteristics Approved by OIV | Possible degradation of anthocyanins Wines not usually used for aging Addition of starter cultures for initiating fermentation required High energetic requirement. Supplies of methane or diesel oil required Renovations are required in the winery for installation (Large facilities: >100 m2) | [13,39,44] |

| PEF | Demonstrated the ability of aging of the wines in oak barrels Easy implementation in the winery (small facilities:<10 m2) Possibility of renting the PEF unit Possibility of conducting fermentations with wild yeast Possibility of using for other applications in winery (microbial inactivation or accelerating aging on the lees) Low energy requirements | Maceration of few days is required for obtaining red wines Approval for the OIV in process. No enzymatic inactivation. | [16,51,53,58] |

| Ultrasound | Easy implementation in the winery (small facilities:<10 m2) Possibility of renting the ultrasound unit Possibility of conducting fermentations with wild yeast Possibility of using for other applications in winery (accelerating aging on the lees) Low energy requirements | Maceration of few days is required for obtaining red wines Approval for the OIV in process. No enzymatic inactivation. | [66,67,68] |

| Technology | Specific Energy Delivered to the Grape (kJ/kg) | Additional Specific Energy * (kJ/kg) | Total Specific Energy (kJ/kg) | kWh/tn | €/tn a |

|---|---|---|---|---|---|

| Thermovinification | 161.92 | 40.68 | 202.6 | 56.28 | 7.32 |

| Flash-release | 251.88 | 45.86 | 297.7 | 82.70 | 10.75 |

| PEF | 6.70 | - | 6.70 | 1.86 | 0.24 |

| Ultrasound | 21.60 | - | 21.60 | 6.0 | 0.78 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maza, M.; Álvarez, I.; Raso, J. Thermal and Non-Thermal Physical Methods for Improving Polyphenol Extraction in Red Winemaking. Beverages 2019, 5, 47. https://doi.org/10.3390/beverages5030047

Maza M, Álvarez I, Raso J. Thermal and Non-Thermal Physical Methods for Improving Polyphenol Extraction in Red Winemaking. Beverages. 2019; 5(3):47. https://doi.org/10.3390/beverages5030047

Chicago/Turabian StyleMaza, Marcos, Ignacio Álvarez, and Javier Raso. 2019. "Thermal and Non-Thermal Physical Methods for Improving Polyphenol Extraction in Red Winemaking" Beverages 5, no. 3: 47. https://doi.org/10.3390/beverages5030047

APA StyleMaza, M., Álvarez, I., & Raso, J. (2019). Thermal and Non-Thermal Physical Methods for Improving Polyphenol Extraction in Red Winemaking. Beverages, 5(3), 47. https://doi.org/10.3390/beverages5030047