1. Introduction

The traditional method of production of sparkling wines requires that still wines (referred to as base wines) are produced and stabilized before being bottled in presence of sugar and yeast (tirage solution) to induce a second alcoholic fermentation that leads to the carbonation of the product. After a generally long period of ageing, yeast lees are removed from the wine by a process named disgorging, and bottles are topped up with a solution, named dosage, that generally contains sugar, wine, and sulphur dioxide [

1].

Consumers of sparkling wines generally relate the quality of the wine with the appearance of the foam produced in the glass upon pouring. Of particular relevance is the volume of the foam produced (foam height), the persistence of the foam after pouring and the formation of a persistent collar of small bubbles in the glass [

2,

3,

4,

5]. Among sparkling wines produced with different methods, the bottle-fermented ones are those generally considered as having foam of higher quality [

6], a fact attributable to the release of foam active compounds as a result of the yeast autolysis during bottle ageing [

1,

3,

5,

7].

An important aspect of sparkling wine production relates to the problem of “gushing” during disgorging, an occurrence resulting in an uncontrolled foaming of the wine once it is opened, with consequent loss of product and economical damage [

1]. Gushing during disgorging, a major issue during sparkling wine production, can be due to several factors, including: the presence of tannins from red varieties, the shaking of the bottles, the disgorging operation conducted at ambient temperature and/or exposure to UV light, the presence of cork dust, an incomplete riddling of yeast lees, the presence of heat-unstable proteins, and an incomplete tartaric stabilization of the base wines [

1,

8,

9]. Base wines can be stabilized by different methods, including; the classic cold stabilization to favour tartrate crystals precipitation prior to bottling, ion exchange treatments, electrodialysis, and addition of substances that inhibits potassium hydrogen tartrate crystals from forming, such as metatartaric acid, mannoproteins, and carboxymethyl cellulose (CMC) [

10,

11].

CMC is a soluble polysaccharide made of polymers of β-

d-glucose units on which the primary or secondary alcohol groups are esterified by sodium acetate groups (−CH

2−COONa) [

12]. Since 2008 CMC can be added to white wines at rates up to 100 mg/L to prevent the formation of tartrate crystals [

13], a quantity that is considered sufficient for the stabilization of base wines for sparkling wine production [

14]. Grape and yeast polysaccharides have been repeatedly reported to be able to influence foamability and foam stability of wines [

1,

5,

7], while no information is available on the possible effects of the addition of an exogenous polysaccharide as CMC. CMC is commonly added to base wines before tirage to stabilize them against tartrate precipitation. However, several manufacturers of oenological products are currently marketing CMC as an additive to be used either at tirage or within the dosage solution used to top up bottle-fermented sparkling wines after disgorging. While there has been some attention on assessing the cold stabilization efficacy of such a practice on different wines [

1,

10,

12,

15,

16], there are no published data on the possible effects of CMC added at the dosage stage on the composition and foaming properties of sparkling wines. Anecdotally, given that this is a practice increasingly adopted by sparkling wine producers to mitigate against tartaric acid crystals formation, it is important to gather information on the impact that this practice has on key quality attributes of these wines. Therefore, in this work the effect of adding increasing concentrations of CMC on the composition and foamability attributes of a bottle-fermented sparkling wine was assessed.

2. Materials and Methods

2.1. Analytical Methods

The base wine was tested for protein stability using the heat test [

17], and for cold stability using the three day cold stability test (absence of crystals after incubation at 4 °C for 72 h) [

16]. Alcohol, pH, titratable acidity, free and total SO

2, and volatile acidity analyses were performed by the commercial services of Campden BRI (Nutfield, UK) using a Foss WineScanTM FT 120, as described by the manufacturer (Foss, Hillerød, Denmark). Glucose and fructose content resulting from the hydrolysis of the sucrose added at dosage was measured by high-performance liquid chromatography (HPLC) according to Moro et al. [

18]. The concentrations of malic acid was determined by HPLC as described previously [

19]. Bottle pressure was measured using a Lipagal™ crown cap aphrometer with a Bourdon™ pressure gauge, type 316SS (Cormontreuil, France), and data were expressed at 20 °C using the Agabaliantz tables as previously reported [

20].

2.2. Experimental Wine Samples

A commercially-prepared bottle-fermented English sparkling wine produced by Plumpton Estate Winery (Plumpton, East Sussex, UK) from a 50:50 blend of cold and protein stable Seyval-Chardonnay base wine was used. After tirage, bottles were stored horizontally at 12–14 °C for 30 months of lees ageing before being riddled over 10 days using a Gyropallette (OENO Concept™, Epernay Cedex, France). The plug of lees was removed by placing the bottles upside down in a rotary neck freezer (ChampagelTM, Epernay Cedex, France) set at −27 ± 1 °C for 10 min. Once the lees portion had frozen, the bottle necks were washed and transferred to the disgorging area where the crown cap and lees were removed using a sterile semi-automatic disgorging and dosage unit (TDD machines: DDV EcoTM, Epernay Cedex, France) and then immediately hermetically sealed using a pneumatic crown capping machine (Vigo Ltd., Dunkeswell, Honiton, Devon, UK). A dosage stock solution was prepared mixing 51 g of granulated cane sugar (Tate and Lyle™, London, UK) with 100 mL of previously-disgorged wine. A commercial cellulose gum solution (CMC) liquid product (Celstab by Laffort™, Bordeaux, France) made of a highly-purified vegetal-origin cellulose polymer, with a low degree of polymerization and viscosity, was used. Disgorged bottles were opened and added with 14.7 mL of the dosage stock solution to reach a final concentration of 10 g/L of sucrose. Afterwards, increasing volumes (from 0 to 1 mL/L) of the commercial CMC stock solution (100 g/L) were added to the wines to obtain five different CMC addition rates (0, 25, 50, 75, 100 mg/L). Subsequently bottles were topped up with disgorged wine to a final volume of 750 mL. Bottles were then crown capped, vigorously shaken, and stored at 12 °C for six weeks before analysis. For each treatment six replicates were prepared: three reserved for free pour foam analysis and three for modified mosalux and chemical analysis.

2.3. Foam Analysis

Foamability of wines was analysed using two methods: a free pour method and a modified version of the mosalux technique as previously described [

19].

2.4. Viscosity Measurement

Viscosity was determined by using a Brookfield DV-II + viscometer with LV5 spindle (Grant™, Cambridge, UK) as previously described [

19].

2.5. Statistical Analysis

Statistical analysis was performed using GraphPad Prism (version 7.01 for Windows, GraphPad Software, La Jolla, CA, USA), with statistical significance determined using an alpha value of 0.05. One-way Analyses of Variance (ANOVA) followed by post-hoc Tukey test were performed on each basic wine parameter separately, with CMC addition as the main factor. One-way and Repeated Measures (RM) ANOVA with post-hoc Tukey tests were performed on both modified mosalux and free pour data. Foam height and collar width kinetics were measured by two-way RM ANOVA.

3. Results and Discussion

CMC is commonly used by makers of bottle-fermented sparkling wines to prevent tartrates formation in the bottles that could lead to gushing [

1]. Despite CMC utilization increasing, no data on its possible effect on the foam attributes of the resulting sparkling wines is available. In this study, a protein and cold stable bottle fermented sparkling wine commercially prepared was riddled, disgorged and finished with a standard addition at dosage stage of 10 g/L of sucrose (Brut style) and four increasing rates of CMC (25, 50, 75 and 100 mg/L of final concentration).

Analysis on the composition and key characteristics of the five different wines produced revealed that CMC additions had a very limited impact on the key compositional characteristics of the wines (

Table 1). Some very small, but statistically significant, changes from the control (CMC0) were found for parameters as alcohol (CMC100), glucose + fructose (CMC25), total SO

2 (CMC50 and CMC100), titratable acidity (CMC50 and CMC75), and viscosity (all samples containing CMC). Most likely the source of these variations is attributable to a small variability in the preparation of the wines. The significant increase in total SO

2 is attributable to the introduction of small amounts of this compound (up to 3 mg/L for CMC100) as, according to the information provided by the manufacturer, it is present in the liquid CMC stock solution at a concentration of 3 g/L. Nevertheless, all of the variations from the control sample (CMC0) are very small, and despite some being statistically significant, can safely be considered as unimportant from a winemaking perspective. The only exception to this statement is viscosity, and this will be discussed separately later.

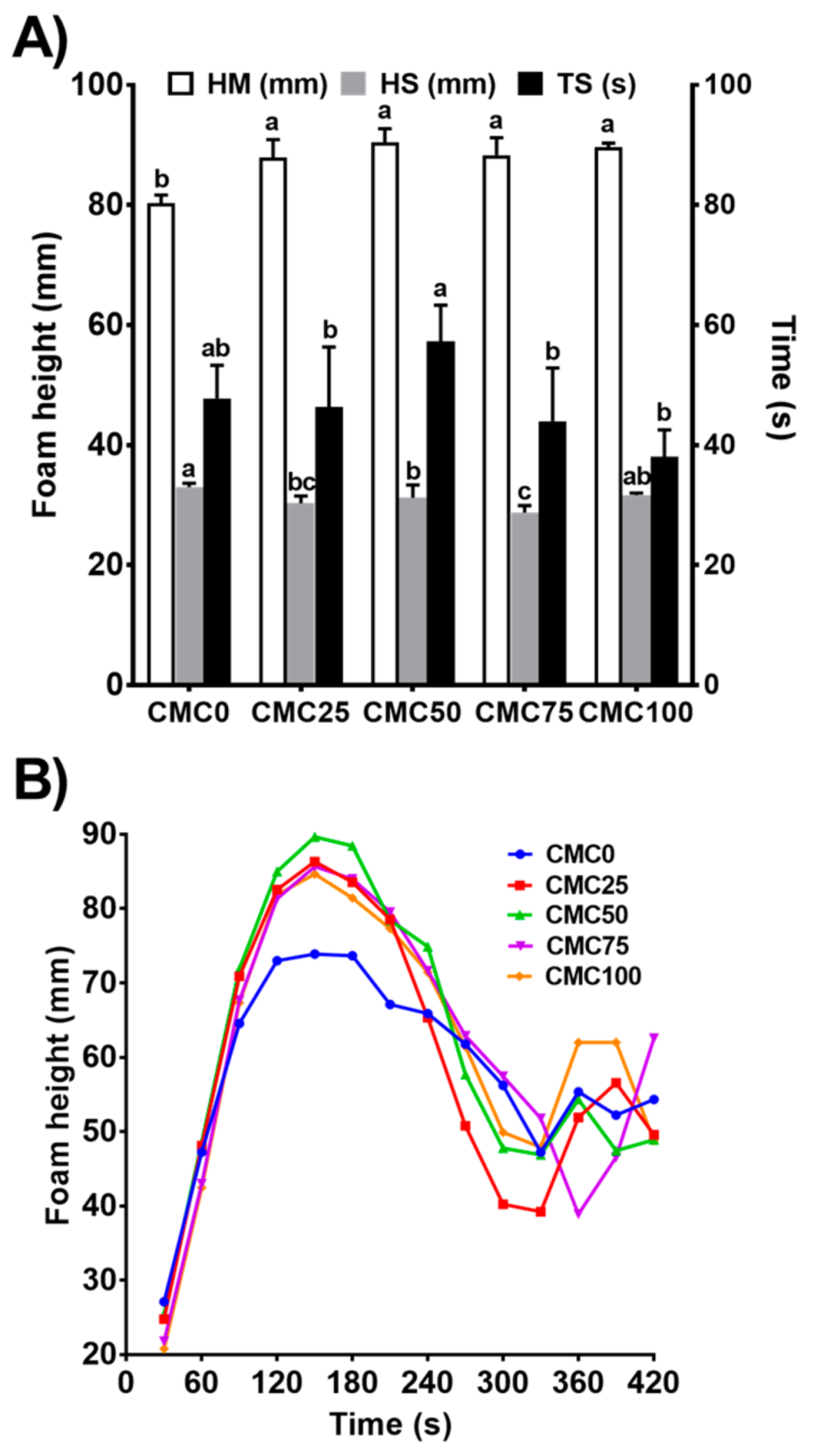

The study of the effects of increasing additions of CMC on the most relevant foam attributes was at first conducted using degassed wines with a modified version of the mosalux method (

Figure 1).

Figure 1A shows that CMC significantly impacted the maximum foam height (HM, white bars) (F

(4, 40) = 29.5,

p < 0.0001, one-way ANOVA), although this increase in HM was not dose-related, as no significant differences were observed between the increasing doses of CMC used. This indicates that small amounts of CMC are able to modify the wine matrix and, consequently, the wine’s ability to produce higher foam, but increasing levels of CMC do not result in a further increase in HM, at least up to the rates tested. The effect of CMC on the stability of foam (HS, grey bars) was also found to be statistically significant (F

(4, 40) = 13.95,

p < 0.0001, one-way ANOVA). The control wine (CMC0) showed the highest stability of foam, while intermediate additions of CMC (25 to 75 mg/L) all resulted in a small decrease in HS, while for the higher rate used HS was not different form the control. Despite having statistical significance, these differences are very small and therefore the impact of CMC addition on HS does not seem to be very important. Additionally, CMC significantly affected the stability of foam (TS, black bars) (F

(4, 40) = 8.309,

p < 0.0001, one-way ANOVA), with a time for foam disappearance (TS) that increased up to 50 mg/L of CMC addition, before decreasing at higher rates. Despite this trend, none of the wines with CMC added had a TS that differed significantly from the control (CMC0), suggesting that CMC has little effect on this parameter too.

To gain further information on the behaviour of the foam over time, the modified mosalux method was used to monitor the foam height (HM) kinetics of wines prepared with different CMC rates over 7 min (

Figure 1B). Results showed that the rate of CMC used had a significant effect on HM over time (F

(52, 416) = 1.829,

p = 0.0007, two-way RM ANOVA), meaning that the speed at which foam changed was dependent on the concentration of CMC added. The only significant differences between the control (CMC0) and the four CMC treatments was detected after 120 s, which was also the point at which the maximum height was reached. Overall, data of

Figure 1B suggest that any addition of CMC at dosage resulted in a slightly faster increase in the speed of foam to reach the HM, in a significantly higher HM achieved after 120 s, and in a sharper decrease in foam when compared to the control. These data are consistent with those of

Figure 1A in which any sample added with CMC produced higher foam than the control, but did not show great differences in terms of foam stability and time for foam disappearance.

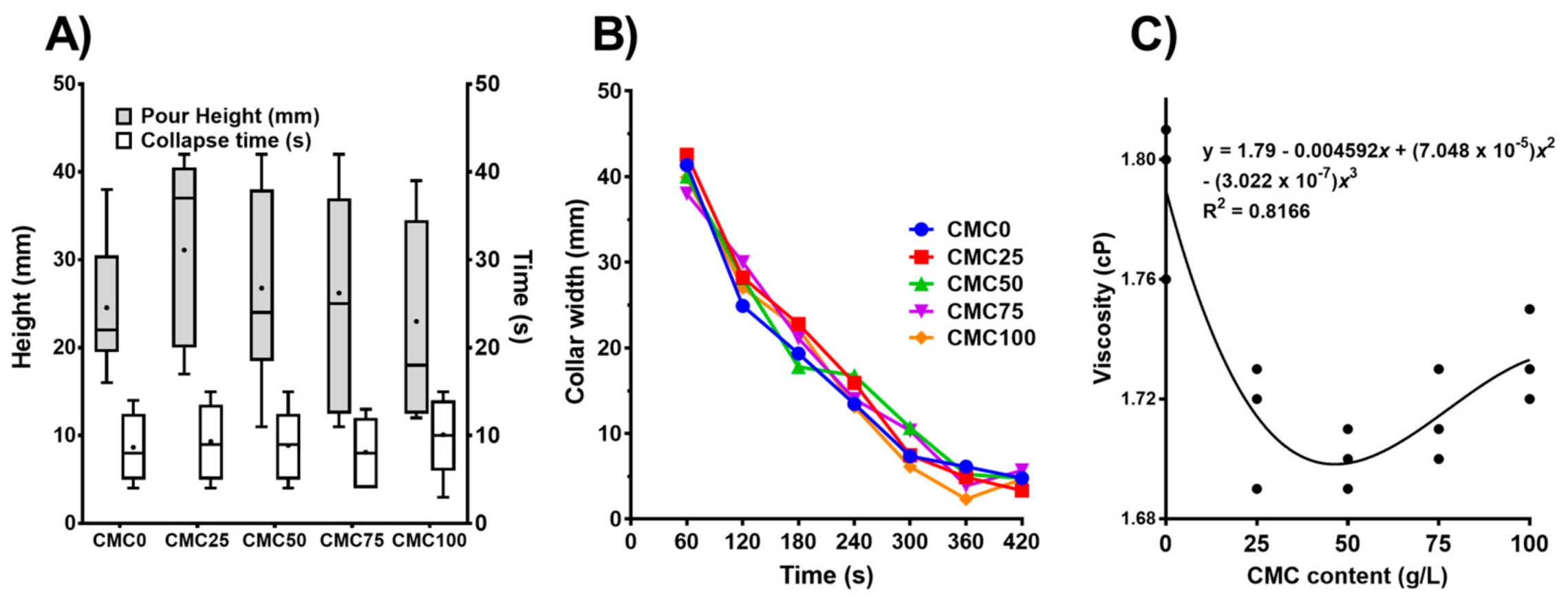

Foam height and time for foam disappearance after pouring were measured using the free pour method (

Figure 2) as it better represents the real serving conditions of a sparkling wine than the modified mosalux version and, therefore, was considered more suited to provide indications on the effect of CMC on the foam attributes [

2,

5,

19]. In order to compare the foaming properties of wine in real serving conditions it is crucial that the CO

2 content of a wine and its resulting pressure are similar to avoid differences in foamability driven by differences in wine pressure. The average pressure of the bottles prepared for this experiment was not statistically different and ranged between 3.36 and 4.44 atm (

Table 1). This means that the foamability data discussed below are comparable between CMC additions as bottle pressure would not interfere. Despite some trends mimicking the behaviour observed in

Figure 1A, data on

Figure 2A show that pour height (F

(4, 40) = 0.7328,

p = 0.5750, one-way ANOVA) and collapse time (F

(4, 40) = 0.3093,

p = 0.8701, One way ANOVA) did not differ significantly among CMC treatments. Differences in findings among the two methods are attributable to their different principles, as artificially sparging a degassed wine with a constant flow of CO

2 yields different foaming results than observing the foam originating only from the CO

2 present in a bottle, discrepancies already highlighted by others [

2,

5,

19].

Data on the collar formed by bubbles upon pouring (

Figure 2B), an important quality parameter for bottle-fermented sparkling wines [

21], indicate that CMC addition did not affect the width of the collar over time (F

(24, 70) = 1.298,

p = 0.1990, Two-way RM ANOVA).

A somewhat surprising finding is that the addition of a slightly viscous compound as CMC, regardless of the concentration used, decreased the viscosity relative to the control treatment (F

(4, 10) = 11.18,

p < 0.001,

Table 1).

Figure 2C shows that the relationship between viscosity and CMC concentration is best described by a third-order polynomial (cubic) curve indicating that small amounts of CMC resulted in a significant reduction of wine viscosity, and only at increasing rates of additions the viscosity level started to increase. However, at the maximum rate used (100 mg/L), the viscosity was still lower than the sample with no CMC added, and seemed to start becoming asymptotic. It can be hypothesized that in reacting with some wine components, CMC solubility would be modified, thus decreasing the overall viscosity of the wine. The obvious candidate for this occurrence would be the ethanol.

4. Conclusions

Investigation on one bottle-fermented English sparkling wine clearly showed that CMC additions at rates within the legal limit of 100 mg/L did not cause major changes in wine parameters, with the exception of wine viscosity (

Table 1). The key foam attributes relating to sparkling wine quality were measured with two approaches. When looking at foamability data it can be seen that samples with a lower viscosity resulted in a significantly higher foam produced (+9.4 to 12.6%) by the modified mosalux method (

Figure 1A), while no noticeable differences were visible with the free pour method (

Figure 2A), a system that is to be considered more representative of real wine serving conditions [

2,

19]. Other important parameters as foam stability (measured by modified mosalux) and collar width (measured by free pour method) were also broadly unaffected by the CMC. This confirms the overall impression that CMC addition at dosage stage does not result in major modification of the foamability of the wine used, especially when analysed in real serving conditions. This also suggests that CMC can be used at varying levels without negative effects on wine composition and foamability, an information that will be welcomed by sparkling winemakers as they will benefit from using CMC at dosage to prevent gushing issue, a potentially costly fault.

Given that adding the dosage solution is the final opportunity that sparkling winemakers have to modify their wines, more research is needed to shed light on the possible impacts that this operation has on wine quality attributes, with a few studies starting to investigate this aspect more systematically [

19,

22]. To the best of our knowledge, this is the first study on the effect of CMC on wine foam attributes. However, considering that data presented here were obtained on one sparkling wine only, it will be important to conduct further investigation considering different CMC treatments. This may include analysing the wines over a longer period of time, studying different wine styles from different countries to further validate the major findings of this study, as well as conducting analysis on wine tartrate stability after CMC addition at dosage. Additionally, of interest is the measurement of the actual CMC contents in the wines before and after addition to allow for the comparison between additions made with different commercial CMC products.