Antioxidant Capacity of Tempura Deep-Fried Products Prepared Using Barley, Buckwheat, and Job’s Tears Flours

Abstract

1. Introduction

2. Materials and Methods

2.1. Ingredients

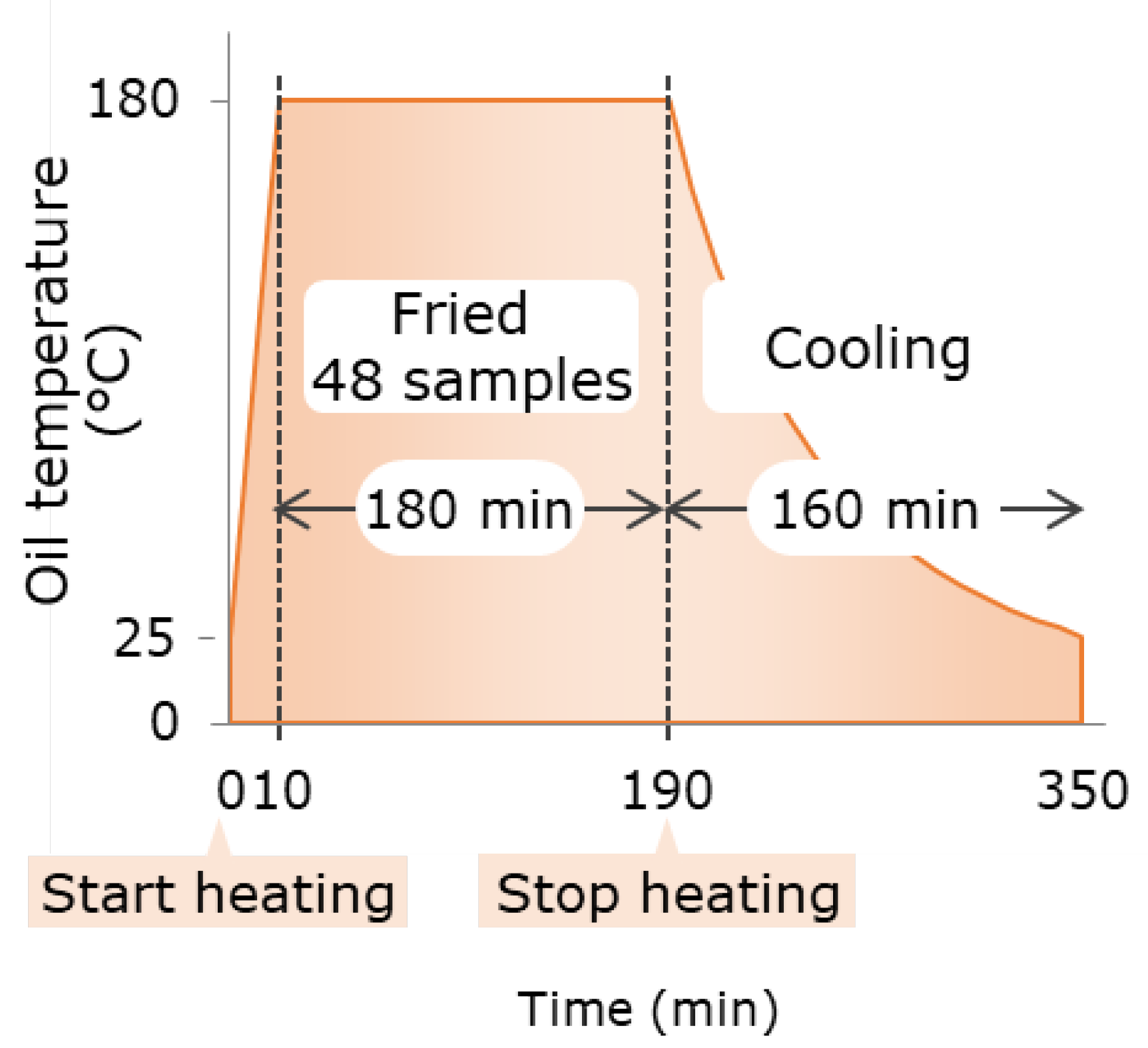

2.2. Preparation of Tempura Samples

2.3. Preparation of Oil after Frying Samples

2.4. Chemiluminescence Method

2.5. Analysis of Oil Oxidation

2.6. Polyphenol Contents

2.7. Statistical Analysis

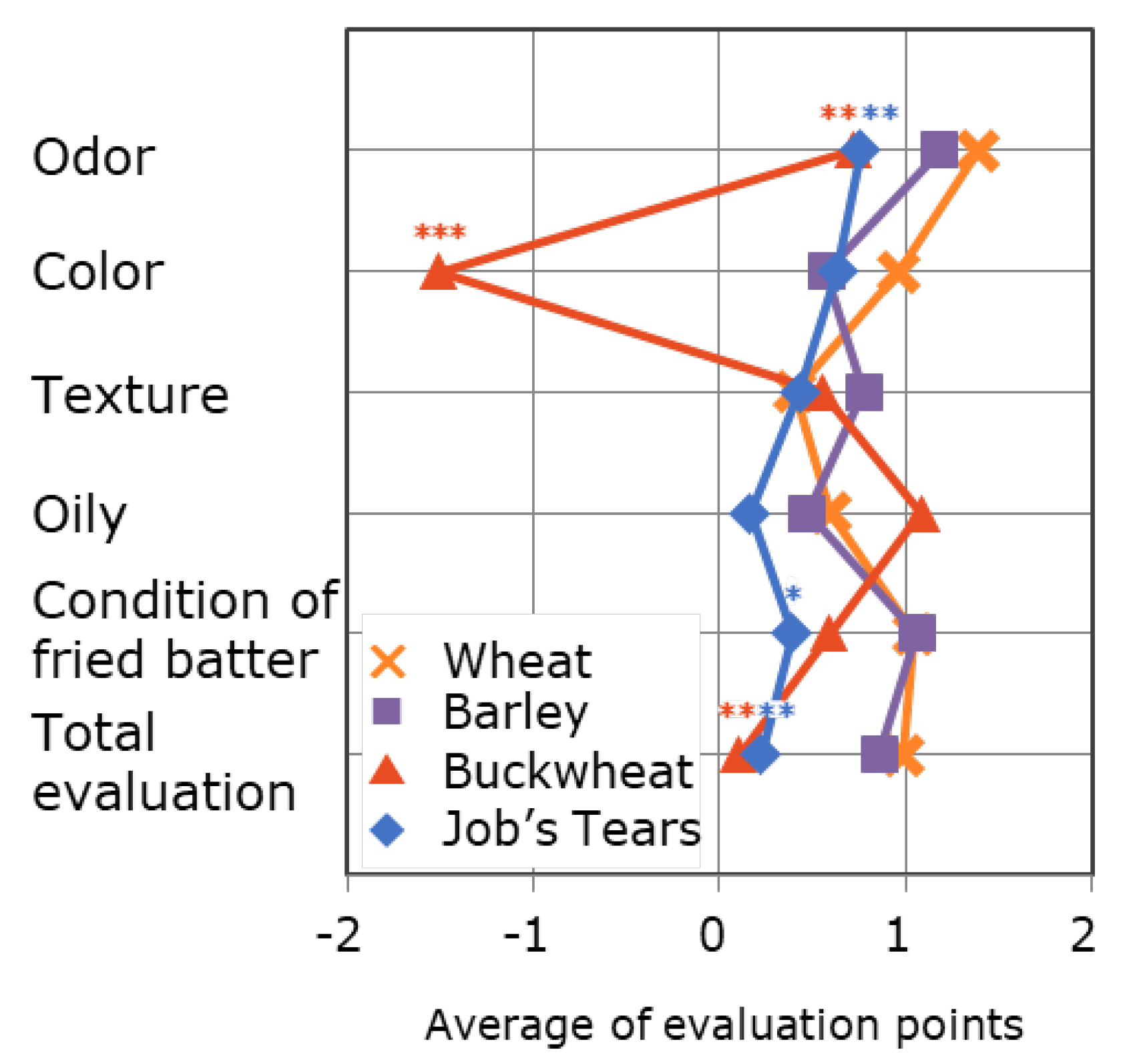

3. Results

3.1. Antioxidant Capacity of Barley, Buckwheat, and Job’s Tears Flours and Their Tempura

3.2. Oxidation of the Oil Used in Frying

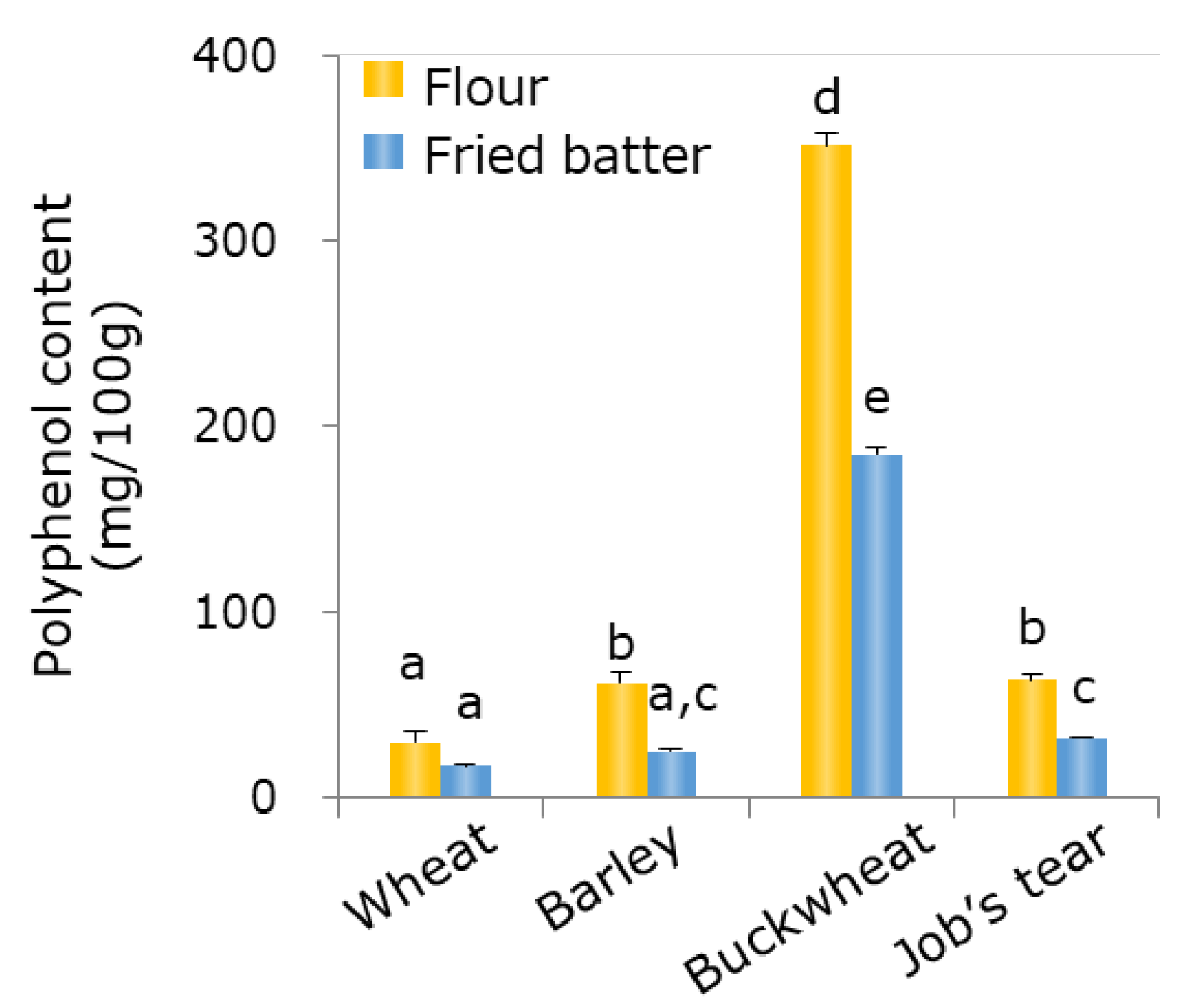

3.3. Polyphenol Content

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Matsunaga, K.; Kawasaki, S.; Takeda, Y. Influence of physicochemical properties of starch on crispness of Tempura fried batter. Cereal Chem. 2003, 80, 339–345. [Google Scholar] [CrossRef]

- Nakamura, S.; Ohtsubo, K. Influence of physicochemical properties of rice flour on oil uptake of tempura frying batter. Biosci. Biotechnol. Biochem. 2010, 74, 2484–2489. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, M.J.; Ruiz-Carrascal, J. Improving crunchiness and crispness of fried squid rings through innovative tempura coatings: Addition of alcohol and CO2 incubation. J. Food Sci. Technol. 2018, 55, 2068–2078. [Google Scholar] [CrossRef]

- Martínez-Pineda, M.; Yagüe-Ruiz, C.; Vercet, A. How batter formulation can modify fried tempura-battered zucchini chemical and sensory characteristics? Foods 2020, 9, 626. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, C.; Kihara, M.; Aoe, S.; Araki, S.; Ito, K.; Hayashi, K.; Watari, J.; Sakata, Y.; Ikegami, S. Effect of high β–glucan barley on serum cholesterol concentrations and visceral fat area in Japanese men—A randomized, double–blinded, placebo–controlled trial. Plant Foods Hum. Nutr. 2008, 63, 21–25. [Google Scholar] [CrossRef]

- Giménez–Bastida, A.; Zieliński, H. Buckwheat as a functional food and its effects on health. J. Agric. Food Chem. 2015, 63, 7896–7913. [Google Scholar] [CrossRef]

- Ukita, T.; Tanimura, A. Studies on the anti–tumor component in the seeds of Coix Lachryma–Jobi L. VAR. Ma–yuen (ROMAN.) STAPF. I.: Isolation and anti–tumor activity of coixenolide. Chem. Pharm. Bull. 1961, 9, 43–46. [Google Scholar] [CrossRef]

- Morishita, T.; Yamaguchi, H.; Degi, K. The contribution of polyphenols to antioxidative activity in common buckwheat and tartary buckwheat grain. Plant Prod. Sci. 2007, 10, 99–104. [Google Scholar] [CrossRef]

- Adom, K.K.; Liu, R.H. Antioxidant activity of grains. J. Agric. Food Chem. 2002, 50, 6182–6187. [Google Scholar] [CrossRef]

- Taniguchi, A.; Maruyama, R.; Kyogoku, N.; Nagao, K.; Kobayashi, R. Evaluation of suitability of millet flour in tempura batter based on quality and palatability. J. Cook. Sci. Jpn. 2019, 52, 376–385. (In Japanese) [Google Scholar]

- Yoshikawa, T.; Naito, Y. What is oxidative stress? Jpn. Med. Assoc. J. 2002, 45, 271–276. [Google Scholar]

- Kalyanaraman, B. Teaching the basics of redox biology to medical and graduate students: Oxidants, antioxidants and disease mechanisms. Redox Biol. 2013, 1, 244–257. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Health and Welfare Notification. Specifications and Standards for Food, Food Additives, etc. 1959; No. 370. Available online: https://www.mhlw.go.jp/english/topics/foodsafety/positivelist060228/dl/r01_a.pdf (accessed on 4 September 2020).

- Taniguchi, A.; Maruyama, R.; Kyogoku, N.; Kimura-Watanabe, H.; Nagao, K.; Kobayashi, R. Preparing method of Tempura batter using millet flour based on basic grain properties. J. Home Econ. Jpn. 2018, 69, 217–224. (In Japanese) [Google Scholar]

- Awatsuhara, R.; Harada, K.; Maeda, T.; Nomura, T.; Nagao, K. Antioxidative activity of the buckwheat polyphenol rutin in combination with ovalbumin. Mol. Med. Rep. 2010, 3, 121–125. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Japan Oil Chemists’ Society. The JOCS Standard Methods for the Analysis of Fats, Oils and Related Materials. AV; 2.3.1-2013, AnV; 2.5.3-2013, PC; 2.5.5-2013; Japan Oil Chemists’ Society: Tokyo, Japan, 2013. [Google Scholar]

- Folin, O.; Denis, W. A colorimetic method for the determination of phenols (and phenol derivatives) in urine. J. Biol. Chem. 1912, 12, 239–243. [Google Scholar]

- Hwang, H.S.; Winkler-Moser, J.K.; Bakota, E.L.; Berhow, M.A.; Liu, S.X. Antioxidant activity of sesamol in soybean oil under frying conditions. J. Am. Oil Chem. Soc. 2013, 90, 659–666. [Google Scholar] [CrossRef]

- Ravi Kiran, C.; Sasidharan, I.; Soban Kumar, D.R.; Sundaresan, A. Influence of natural and synthetic antioxidants on the degradation of Soybean oil at frying temperature. J. Food Sci. Technol. 2015, 52, 5370–5375. [Google Scholar] [CrossRef]

- Srivastava, Y.; Semwal, A.D. A study on monitoring of frying performance and oxidative stability of virgin coconut oil (VCO) during continuous/prolonged deep fat frying process using chemical and FTIR spectroscopy. J. Food Sci. Technol. 2015, 52, 984–991. [Google Scholar] [CrossRef]

- Khatun, M.; Eguchi, S.; Yamaguchi, T.; Takamura, H.; Matoba, T. Effect of thermal treatment on radical-scavenging activity of some spices. Food Sci. Technol. Res. 2006, 12, 178–185. [Google Scholar] [CrossRef]

- Nile, S.H.; Park, S.W. Chromatographic analysis, antioxidant, anti-inflammatory, and xanthine oxidase inhibitory activities of ginger extracts and its reference compounds. Ind. Crop Prod. 2015, 70, 238–244. [Google Scholar] [CrossRef]

- Do, T.T.; Muhlhausler, B.; Box, A.; Able, A.J. Enrichment of antioxidant capacity and vitamin E in pita made from barley. J. Food Sci. 2016, 81, H777–H785. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Jan, U.; Gani, A.; Ahmad, M.; Shah, U.; Baba, W.N.; Massogi, F.A.; Gani, A.; Wani, I.A.; Wani, S.M. Characterization of cookies made from wheat flour blended with buckwheat flour and effect on antioxidant properties. J. Food Sci. Technol. 2015, 52, 6334–6344. [Google Scholar] [CrossRef] [PubMed]

- Firestone, D. Worldwide Regulation of Frying Fats and Oils. INFORMS 1993, 4, 1366–1371. [Google Scholar]

- Kaunitz, H.; Slanetz, C.A.; Johnson, R.E. Antagonism of fresh fat to the toxicity of heated and aerated cottonseed oil. J. Nutr. 1955, 55, 577–587. [Google Scholar] [CrossRef]

- Idehen, E.; Tang, Y.; Sang, S. Bioactive phytochemicals in barley. J. Food Drug Anal. 2017, 25, 148–161. [Google Scholar] [CrossRef]

- Zhang, G.; Xu, Z.; Gao, Y.; Huang, X.; Zou, Y.; Yang, T. Effects of germination on the nutritional properties, phenolic profiles, and antioxidant activities of buckwheat. J. Food Sci. 2015, 80, H1111–H1119. [Google Scholar] [CrossRef]

- Wang, L.; Chen, J.; Xie, H.; Ju, X.; Liu, R.H. Phytochemical profiles and antioxidant activity of adlay varieties. J. Agric. Food Chem. 2013, 61, 5103–5113. [Google Scholar] [CrossRef]

| PV | AnV | |

|---|---|---|

| Wheat | 4.82 ± 1.66 a | 39.3 ± 1.98 a |

| Barley | 2.61 ± 1.22 b | 53.2 ± 6.58 b |

| Buckwheat | 3.02 ± 1.26 b | 43.8 ± 1.30 a,b |

| Job’s Tears | 3.15 ± 1.71 b | 45.6 ± 3.00 a,b |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taniguchi, A.; Kyogoku, N.; Kimura, H.; Kondo, T.; Nagao, K.; Kobayashi, R. Antioxidant Capacity of Tempura Deep-Fried Products Prepared Using Barley, Buckwheat, and Job’s Tears Flours. Foods 2020, 9, 1246. https://doi.org/10.3390/foods9091246

Taniguchi A, Kyogoku N, Kimura H, Kondo T, Nagao K, Kobayashi R. Antioxidant Capacity of Tempura Deep-Fried Products Prepared Using Barley, Buckwheat, and Job’s Tears Flours. Foods. 2020; 9(9):1246. https://doi.org/10.3390/foods9091246

Chicago/Turabian StyleTaniguchi, Asuka, Nami Kyogoku, Hiroko Kimura, Tsubasa Kondo, Keiko Nagao, and Rie Kobayashi. 2020. "Antioxidant Capacity of Tempura Deep-Fried Products Prepared Using Barley, Buckwheat, and Job’s Tears Flours" Foods 9, no. 9: 1246. https://doi.org/10.3390/foods9091246

APA StyleTaniguchi, A., Kyogoku, N., Kimura, H., Kondo, T., Nagao, K., & Kobayashi, R. (2020). Antioxidant Capacity of Tempura Deep-Fried Products Prepared Using Barley, Buckwheat, and Job’s Tears Flours. Foods, 9(9), 1246. https://doi.org/10.3390/foods9091246