Amino Acid Composition of Novel Plant Drinks from Oat, Lentil and Pea

Abstract

1. Introduction

2. Materials and Methods

2.1. Ingredients and Chemicals

2.2. Production of PBD Samples

2.3. Amino Acid Composition

2.4. Other Analyses

3. Results

3.1. The Amino Acids

3.2. Mass Balance and pH

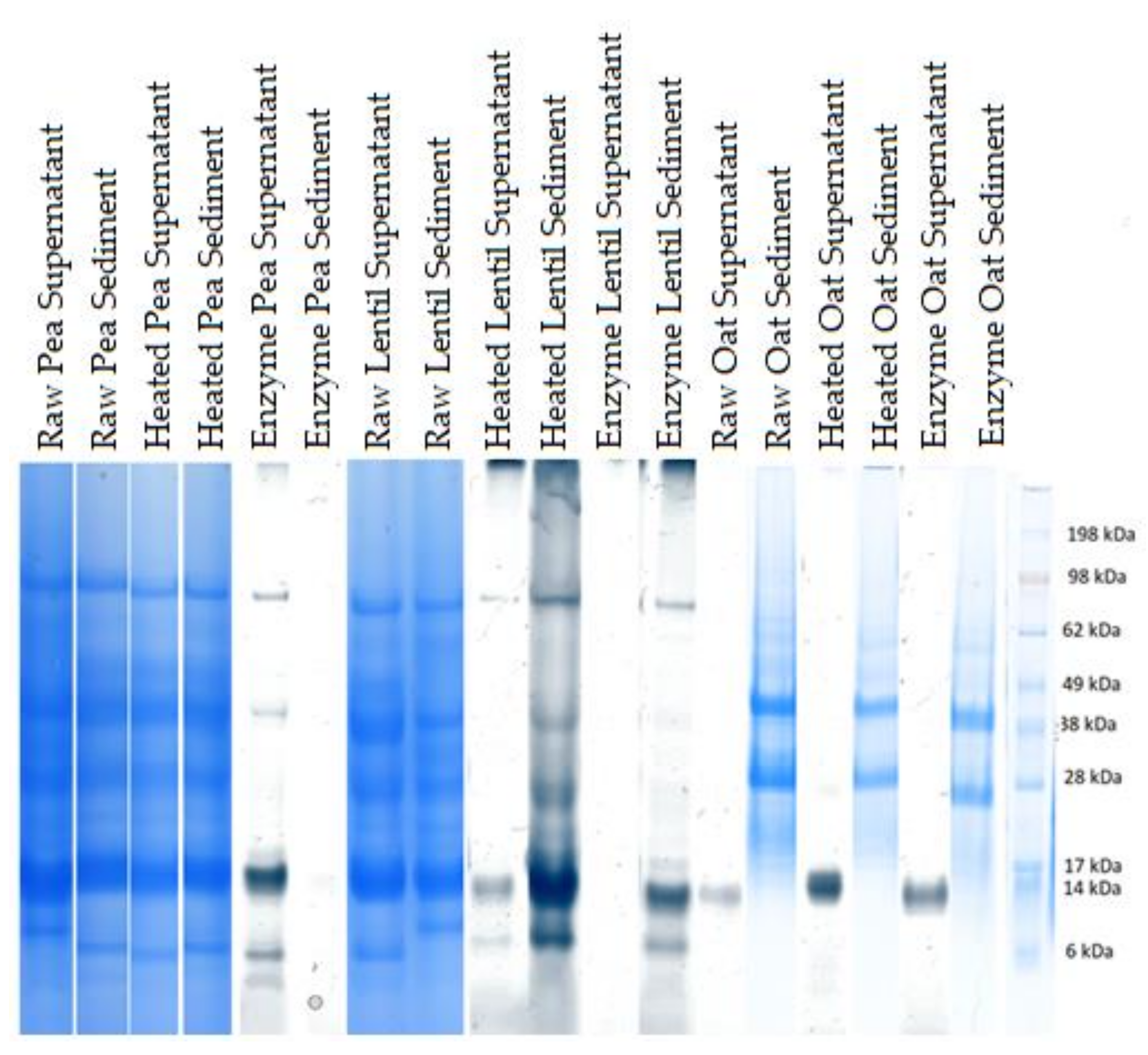

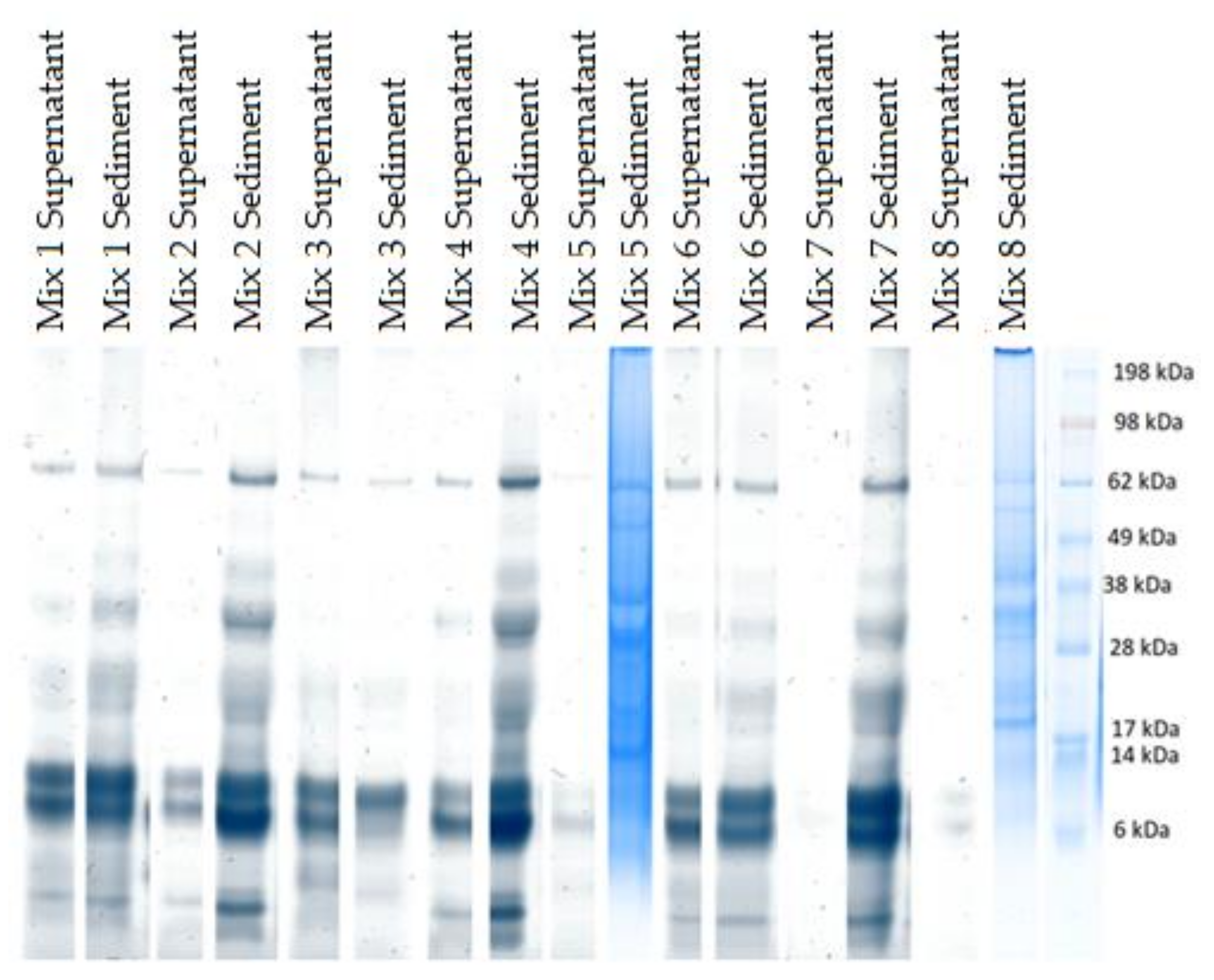

3.3. SDS-PAGE

3.4. Stability Assessment

3.5. Sensory Assessment

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Grand View Research. Dairy Alternatives Market Size, Share & Trends Analysis Report By Product (Soy Milk, Almond Milk, Rice Milk), by Formulation (Plain, Flavored), by Application (Food, Beverages), and Segment Forecasts, 2019–2025; Grand View Research: Maharashtra, India, 2019. [Google Scholar]

- Nisgaard, A. Soya-, Ris- Og Havredrik: Traditionel Komælk Får Nu Kamp Til Stregen; DR Viden: Copenhagen, Denmark, 2018; Available online: https://www.dr.dk/nyheder/viden/soya-ris-og-havredrik-traditionel-komaelk-faar-nu-kamp-til-stregen (accessed on 3 December 2018).

- Sethi, S.; Tyagi, S.K.; Anurag, R.K. Plant-based milk alternatives an emerging segment of functional beverages: A review. J. Food Sci. Technol. 2016, 53, 3408–3423. [Google Scholar] [CrossRef] [PubMed]

- Reipurth, M.; Hørby, L.; Gregersen, C.G.; Bonke, A.; Perez-Cueto, F.J.A. Barriers and facilitators towards adopting a more plant-based diet in a sample of Danish consumers. Food Qual. Prefer. 2019, 73, 288–292. [Google Scholar] [CrossRef]

- DVF. Statistik Om Danmark—Hvor Mange Lever Vegetarisk Eller Vegansk? Dansk Vegetarisk Forening: København, Denmark, 2018; Available online: https://vegetarisk.dk/statistik-om-danmark/ (accessed on 17 November 2018).

- Wang, J.; Raghavan, V. How well do plant based alternatives fare nutritionally compared to cow’s milk? J. Food Sci. Technol. 2017, 55, 10–20. [Google Scholar]

- Muehlhoff, E.; Bennet, A.; McMahon, D. Milk and Dairy Products in Human Nutrition; FAO: Rome, Italy, 2013. [Google Scholar]

- Jeske, S.; Zannini, E.; Arendt, E. Evaluation of Physicochemical and Glycaemic Properties of Commercial Plant-Based Milk Substitutes. Plant Foods Hum. Nutr. 2017, 72, 26–33. [Google Scholar] [CrossRef]

- WHO. Protein and Amino Acid Requirements in Human Nutrition; Technical Report TRS 931; WHO: Geneva, Switzerland, 2007. [Google Scholar]

- Fødevareinstituttet. Fødevaredata; Danmarks Tekniske Universitet: Lyngby, Denmark, 2018. [Google Scholar]

- Khan, M.A.; Jacobsen, I.; Eggum, B.O. Nutritive value of some improved varieties of legumes. J. Sci. Food Agric. 1979, 30, 395–400. [Google Scholar] [CrossRef] [PubMed]

- Pomeranz, Y.; Robbins, G.S.; Briggle, L.W. Amino acid composition of oat groats. J. Agric. Food Chem. 1971, 19, 536–539. [Google Scholar] [CrossRef]

- Wuttisela, K.; Shobsngob, S.; Triampo, W. Amylose/Amylopectin Simple Determination in Acid Hydrolyzed Tapioca Starch. J. Chil. Chem. Soc. 2008, 53. [Google Scholar] [CrossRef][Green Version]

- FAO. Fao Food and Nutrition Paper 77: Food Energy—Methods of Analysis and Conversion Factors; FAO: Rome, Italy, 2003. [Google Scholar]

- Tester, R.F.; Karkalas, J. Swelling and gelatinization of oat starches. Cereal Chem. 1996, 73, 271–277. [Google Scholar]

- Sun, X.D.; Arntfield, S.D. Gelation properties of salt-extracted pea protein isolate induced by heat treatment: Effect of heating and cooling rate. Food Chem. 2011, 124, 1011–1016. [Google Scholar] [CrossRef]

- SternEnzym. Production of Functional Non-Alcoholic Drinks Based on Cereals; SternEnzym: Ahrensburg, Germany, 2019; Available online: https://sternenzym.de/downloads/cereal-drinks-flyer-e.pdf (accessed on 1 January 2019).

- Sorensen, H.; Sørensen, S.; Bjergegaard, C.; Michaelsen, S. Chromatography and Capillary Electrophoresis in Food Analysis; Royal Society of Chemistry (RSC): London, UK, 1999. [Google Scholar]

- Tsochatzis, E.; Papageorgiou, M.; Kalogiannis, S. Validation of a HILIC UHPLC-MS/MS Method for Amino Acid Profiling in Triticum Species Wheat Flours. Foods 2019, 8, 514. [Google Scholar] [CrossRef]

- Kang, J.-W.; Yang, Y.-T.; You, J.-M.; Ou, Q.-Y. Fast chiral separation of amino acid derivatives and acidic drugs by co-electroosmotic flow capillary electrophoresis with vancomycin as chiral selector. J. Chromatogr. A 1998, 825, 81–87. [Google Scholar] [CrossRef]

- Thorsén, G.; Bergquist, J. Chiral separation of amino acids in biological fluids by micellarelectrokinetic chromatography with laser-induced fluorescencedetection. J. Chromatogr. B 2000, 745, 389–397. [Google Scholar] [CrossRef]

- Yu, H.; Xu, L.; You, T. Indirect electrochemiluminescence detection of lysine and histidine separated by capillary electrophoresis based on charge displacement. Luminscence 2012, 28, 217–221. [Google Scholar] [CrossRef] [PubMed]

- Louis, S.; Delobel, B.; Gressent, F.; Rahioui, I.; Quilien, L.; Vallier, A.; Rahbé, Y. Molecular and biological screening for insect-toxic seed albumins from four legume species. J. Plant Sci. 2004, 167, 705–714. [Google Scholar] [CrossRef]

- Higgins, T.; Beach, L.R.; Spencer, D.; Chandler, P.M.; Randall, P.J.; Blagrove, R.J.; Kortt, A.A.; Guthrie, R.E. cDNA and protein sequence of a major pea seed albumin (PA 2 : Mr?26 000). Plant Mol. Biol. 1987, 8, 37–45. [Google Scholar] [CrossRef] [PubMed]

- Kimura, A.; Fukuda, T.; Zhang, M.; Motoyama, S.; Maruyama, N.; Utsumi, S. Comparison of Physicochemical Properties of 7S and 11S Globulins from Pea, Fava Bean, Cowpea, and French Bean with Those of Soybean French Bean 7S Globulin Exhibits Excellent Properties. J. Agric. Food Chem. 2008, 56, 10273–10279. [Google Scholar] [CrossRef]

- Rerie, W.G.; Whitecross, M.; Higgins, T. Nucleotide sequence of an A-type legumin gene from pea. Nucleic Acids Res. 1990, 18, 655. [Google Scholar] [CrossRef]

- Ryan, A.J.; Royal, C.L.; Hutchinson, J.; Shaw, C.D. Genomic sequence of a 12S seed storage protein from oilseed rape (Brassica napus c.v.jet neuf). Nucleic Acids Res. 1989, 17, 3584. [Google Scholar] [CrossRef][Green Version]

- Kaminski, P.A.; Buffard, D.; Strosberg, A.D. The pea lectin gene family contains only one functional gene. Plant Mol. Biol. 1987, 9, 497–507. [Google Scholar] [CrossRef]

- Real, A.; Comino, I.; De Lorenzo, L.; Merchán, F.; Gil-Humanes, J.; Giménez, M.J.; López, M.I.T.; Cebolla, A.; Sousa, C.; Barro, F.; et al. Molecular and Immunological Characterization of Gluten Proteins Isolated from Oat Cultivars That Differ in Toxicity for Celiac Disease. PLoS ONE 2012, 7, e48365. [Google Scholar] [CrossRef]

- Tanchak, M.A.; Giband, M.; Potier, B.; Schernthaner, J.P.; Dukiandjiev, S.; Altosaar, I. Genomic clones encoding 11S globulins in oats (Avena sativa L.). Genome 1995, 38, 627–634. [Google Scholar] [CrossRef] [PubMed]

- Adebiyi, A.P.; Aluko, R.E. Functional properties of protein fractions obtained from commercial yellow field pea (Pisum sativum L.) seed protein isolate. Food Chem. 2011, 128, 902–908. [Google Scholar] [CrossRef]

- Ratnayake, W.; Hoover, R.; Warkentin, T. Pea Starch: Composition, Structure and Properties—A Review. Starch-Stärke 2002, 54, 217–234. [Google Scholar] [CrossRef]

| Percent Added | Mix | Mix | Mix | Mix | Mix | Mix | Mix | Mix |

|---|---|---|---|---|---|---|---|---|

| Ingredient w/w | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Lentil concentrate (51%) | 2.9 | 5.7 | 0.0 | 6.3 | 0.0 | 3.1 | 4.2 | 2.2 |

| Pea isolate (80%) | 1.8 | 0.0 | 3.7 | 0.0 | 4.0 | 2.0 | 1.3 | 2.6 |

| Whole grain oat flour | 8.0 | 8.0 | 8.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 |

| Total content of ingredients | 12.7 | 13.7 | 11.7 | 12.3 | 10.0 | 11.1 | 11.5 | 10.8 |

| Protein contribution from the ingredients (% w/w) | ||||||||

| Lentil concentrate (51%) | 1.5 | 2.9 | 0.0 | 3.2 | 0.0 | 1.6 | 2.1 | 1.1 |

| Pea isolate (80%) | 1.5 | 0.0 | 2.9 | 0.0 | 3.2 | 1.6 | 1.1 | 2.1 |

| Whole grain oat flour | 1.1 | 1.1 | 1.1 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Total protein concentration | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Percent Added | Oat | Lentil | Pea | Oat | Lentil | Pea | Oat | Lentil | Pea |

|---|---|---|---|---|---|---|---|---|---|

| Ingredient w/w | Raw | Raw | Raw | Heated | Heated | Heated | Enzyme | Enzyme | Enzyme |

| Lentil concentrate (51%) | 0.0 | 7.8 | 0.0 | 0.0 | 7.8 | 0.0 | 0.0 | 7.8 | 0.0 |

| Pea isolate (80%) | 0.0 | 0.0 | 5.0 | 0.0 | 0.0 | 5.0 | 0.0 | 0.0 | 5.0 |

| Whole grain oat flour | 10.0 | 0.0 | 0.0 | 10.0 | 0.0 | 0.0 | 10.0 | 0.0 | 0.0 |

| Total content of ingredients | 10.0 | 7.8 | 5.0 | 10.0 | 7.8 | 5.0 | 10.0 | 7.8 | 5.0 |

| Protein contribution from the ingredients (% w/w in the PBD formulation) | |||||||||

| Lentil concentrate (51%) | 0.0 | 4.0 | 0.0 | 0.0 | 4.0 | 0.0 | 0.0 | 4.0 | 0.0 |

| Pea isolate (80%) | 0.0 | 0.0 | 4.0 | 0.0 | 0.0 | 4.0 | 0.0 | 0.0 | 4.0 |

| Whole Grain Oat Flour | 1.3 | 0.0 | 0.0 | 1.3 | 0.0 | 0.0 | 1.3 | 0.0 | 0.0 |

| Total protein content | 1.3 | 4.0 | 4.0 | 1.3 | 4.0 | 4.0 | 1.3 | 4.0 | 4.0 |

| Raw Oat | Raw Lentil | Raw Pea | ||||

|---|---|---|---|---|---|---|

| 0.6% protein | 1.6% protein | 2.23% protein | ||||

| mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | |

| Isoleucine | 0 | 0 | 46 | 16 | 87 | 31 |

| Leucine | 0 | 0 | 91 | 17 | 152 | 28 |

| Lysine | 0 | 0 | 34 | 8 | 51 | 12 |

| Valine/Methionine | 35 | 6 | 67 | 12 | 116 | 20 |

| Phenylalanine | 0 | 0 | 214 | 77 | 308 | 118 |

| Tyrosine | 0 | 55 | 104 | |||

| Threonine | 0 | 0 | 93 | 44 | 86 | 41 |

| Histidine | 0 | 0 | 333 | 24 | 14 | 10 |

| Heated Oat | Heated Lentil | Heated Pea | ||||

| 0.5% protein | 3.7% protein | 0.96% protein | ||||

| mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | mg/100mL | % of RDI in 500 mL | |

| Isoleucine | 17 | 6 | 0 | 0 | 49 | 18 |

| Leucine | 39 | 7 | 124 | 23 | 86 | 16 |

| Lysine | 63 | 15 | 130 | 31 | 29 | 7 |

| Valine/Methionine | 17 | 3 | 151 | 26 | 66 | 11 |

| Phenylalanine | 63 | 21 | 576 | 185 | 175 | 66 |

| Tyrosine | 12 | 70 | 57 | |||

| Threonine | 33 | 16 | 1073 | 511 | 48 | 23 |

| Histidine | 12 | 9 | 0 | 0 | 8 | 6 |

| Enzyme Oat | Enzyme Lentil | Enzyme Pea | ||||

| 0.5% protein | 3.6% protein | 2.64% protein | ||||

| mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | |

| Isoleucine | 4 | 2 | 122 | 44 | 92 | 33 |

| Leucine | 23 | 4 | 257 | 47 | 160 | 29 |

| Lysine | 0 | 0 | 137 | 33 | 53 | 13 |

| Valine/Methionine | 23 | 4 | 171 | 30 | 122 | 21 |

| Phenylalanine | 101 | 30 | 385 | 161 | 323 | 123 |

| Tyrosine | 4 | 178 | 106 | |||

| Threonine | 113 | 54 | 146 | 70 | 89 | 42 |

| Histidine | 0 | 0 | 92 | 66 | 15 | 11 |

| Mix 1 3.7% Protein | Mix 2 3.4% Protein | Mix 3 4.1% Protein | Mix 4 3.1% Protein | |||||

|---|---|---|---|---|---|---|---|---|

| mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | |

| Isoleucine | 109 | 39 | 115 | 41 | 142 | 51 | 70 | 25 |

| Leucine | 253 | 46 | 267 | 49 | 380 | 70 | 175 | 32 |

| Lysine | 82 | 20 | 75 | 18 | 135 | 32 | 80 | 19 |

| Valine/Methionine | 217 | 38 | 146 | 25 | 290 | 51 | 42 | 7 |

| Phenylalanine | 194 | 75 | 84 | 25 | 120 | 45 | 92 | 63 |

| Tyrosine | 67 | 4 | 38 | 130 | ||||

| Threonine | 140 | 67 | 86 | 41 | 95 | 45 | 161 | 77 |

| Histidine | 17 | 12 | 78 | 56 | 14 | 10 | 39 | 28 |

| Mix 5 3.8% protein | Mix 6 3.8% protein | Mix 7 4.3% protein | Mix 8 3.9% protein | |||||

| mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | mg/100 mL | % of RDI in 500 mL | |

| Isoleucine | 118 | 42 | 93 | 33 | 104 | 37 | 105 | 37 |

| Leucine | 223 | 41 | 259 | 47 | 284 | 52 | 265 | 48 |

| Lysine | 88 | 21 | 41 | 10 | 92 | 22 | 88 | 21 |

| Valine/Methionine | 171 | 30 | 406 | 71 | 211 | 37 | 191 | 33 |

| Phenylalanine | 71 | 49 | 585 | 167 | 549 | 157 | 76 | 42 |

| Tyrosine | 101 | 0 | 0 | 72 | ||||

| Threonine | 178 | 85 | 280 | 133 | 305 | 145 | 169 | 80 |

| Histidine | 32 | 23 | 0 | 0 | 0 | 0 | 0 | 0 |

| - | Raw Pea | Raw Lentil | Raw Oat | Heated Pea | Heated Lentil | Heated Oat | Enzyme Pea | Enzyme Lentil | Enzyme Oat | Mix 1 | Mix 2 | Mix 3 | Mix 4 | Mix 5 | Mix 6 | Mix 7 | Mix 8 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fraction of total content that is kept in suspension in the supernatant | |||||||||||||||||

| Mass | 65% | 85% | 65% | 52% | 64% | 45% | 63% | 67% | 59% | 59% | 62% | 60% | 61% | 56% | 61% | 58% | 66% |

| DM | 27% | 24% | 19% | 18% | 26% | 19% | 28% | 26% | 22% | 28% | 25% | 28% | 25% | 27% | 27% | 30% | 28% |

| Protein | 95% | 0% | 46% | 8% | 93% | 38% | 98% | 90% | 38% | 93% | 85% | 100% | 78% | 95% | 95% | 100% | 98% |

| Moisture | 58% | 91% | 81% | 52% | 67% | 56% | 55% | 71% | 71% | 78% | 92% | 73% | 82% | 63% | 74% | 69% | 77% |

| pH | 6.49 | 7.66 | 6.32 | 6.47 | 7.55 | 6.30 | 6.20 | 7.34 | 6.24 | 6.47 | 6.28 | 6.98 | 6.21 | 7.01 | 6.53 | 6.42 | 6.66 |

| - | Pea and Lentil Proteins | Oat Proteins | ||||||

|---|---|---|---|---|---|---|---|---|

| - | Albumin 11 | Albumin 22 | Globulin3 | Legumin4 | Vicilin5 | Lectin6 | Avenin7 | Globulin8 |

| Num. of amino acids | 130 | 231 | 488 | 520 | 459 | 275 | 281 | 551 |

| Molecular weight | 14 kDa | 25 kDa | 53 kDa | 59 kDa | 52 kDa | 30 kDa | 33 kDa | 62 kDa |

| Theoretical pI | 6.68 | 5.16 | 6.84 | 6.21 | 5.39 | 4.90 | 6.69 | 9.20 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonke, A.; Sieuwerts, S.; Petersen, I.L. Amino Acid Composition of Novel Plant Drinks from Oat, Lentil and Pea. Foods 2020, 9, 429. https://doi.org/10.3390/foods9040429

Bonke A, Sieuwerts S, Petersen IL. Amino Acid Composition of Novel Plant Drinks from Oat, Lentil and Pea. Foods. 2020; 9(4):429. https://doi.org/10.3390/foods9040429

Chicago/Turabian StyleBonke, Astrid, Sander Sieuwerts, and Iben Lykke Petersen. 2020. "Amino Acid Composition of Novel Plant Drinks from Oat, Lentil and Pea" Foods 9, no. 4: 429. https://doi.org/10.3390/foods9040429

APA StyleBonke, A., Sieuwerts, S., & Petersen, I. L. (2020). Amino Acid Composition of Novel Plant Drinks from Oat, Lentil and Pea. Foods, 9(4), 429. https://doi.org/10.3390/foods9040429