Development and Consumer Perception of a Snack Machine Producing Customized Spoonable and Drinkable Products Enriched in Dietary Fiber and Protein

Abstract

1. Introduction

2. Materials and Methods

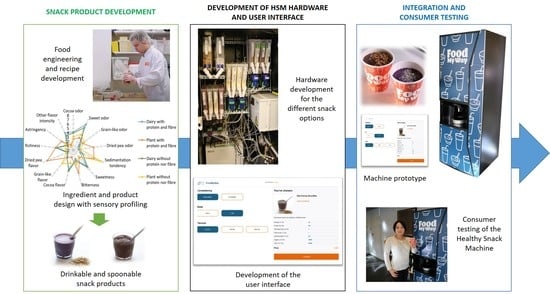

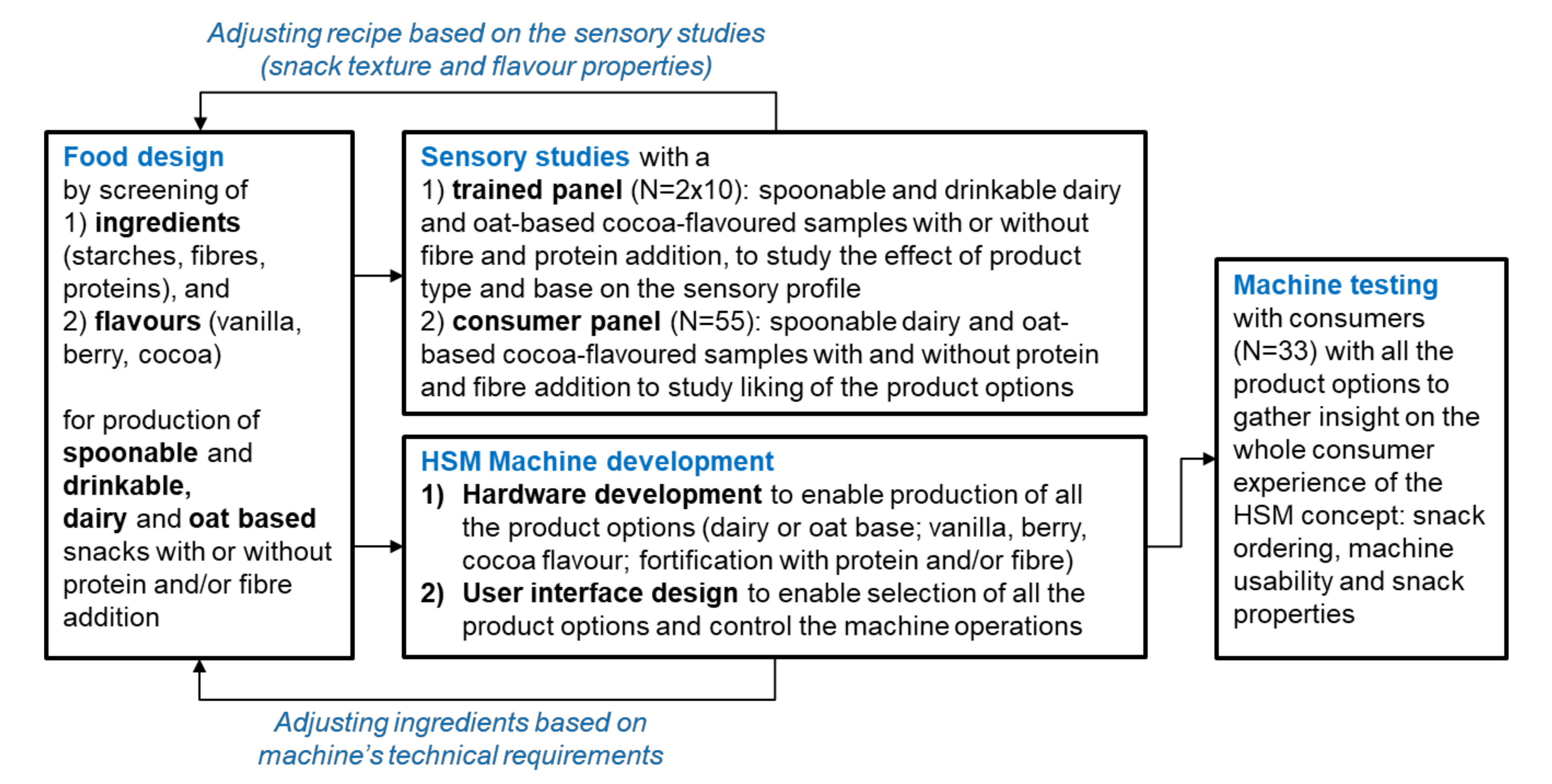

2.1. Snack Product and Machine Prototype Development

2.1.1. Snack Product Development and Characterization

2.1.2. Descriptive Sensory Profiling of the Snack Products

2.1.3. Development of HSM Hardware and User Interface

2.2. Evaluation of Snacks and HSM by Consumer Tests

2.2.1. Consumer Liking of the Snack Products by Qualitative Testing

2.2.2. Consumer Experience of HSM by Qualitative Testing

3. Results and Discussion

3.1. Snack and HSM Development

3.2. Sensory Profiling and Consumer Liking of Snacks

3.3. Consumer Perceptions on HSM via Qualitative Real-Life Experimenting

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Popkin, B.M.; Duffey, K.J. Does hunger and satiety drive eating anymore? Increasing eating occasions and decreasing time between eating occasions in the United States. Am. J. Clin. Nutr. 2010, 91, 1342–1347. [Google Scholar] [CrossRef] [PubMed]

- Kocken, P.L.; Eeuwijk, J.; Van Kesteren, N.M.C.; Dusseldorp, E.; Buijs, G.; Bassa-Dafesh, Z.; Snel, J. Promoting the purchase of low-calorie foods from school vending machines: A cluster-randomized controlled study. J. Sch. Health 2012, 82, 115–122. [Google Scholar] [CrossRef] [PubMed]

- Hess, J.M.; Jonnalagadda, S.S.; Slavin, J.L. What is a snack, why do we snack, and how can we choose better snacks? A review of the definitions of snacking, motivations to snack, contributions to dietary intake, and recommendations for improvement. Adv. Nutr. Int. Rev. J. 2016, 7, 466–475. [Google Scholar] [CrossRef]

- Carrad, A.M.; Louie, J.C.Y.; Milosavljevic, M.; Kelly, B.; Flood, V.M. Consumer support for healthy food and drink vending machines in public places. Aust. N. Z. J. Public Health 2015, 39, 355–357. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Papadaki, A. Nutritional value of foods sold in vending machines in a UK University: Formative, cross-sectional research to inform an environmental intervention. Appetite 2016, 96, 517–525. [Google Scholar] [CrossRef]

- Grech, A.; Allman-Farinelli, M. A systematic literature review of nutrition interventions in vending machines that encourage consumers to make healthier choices. Obes. Rev. 2015, 16, 1030–1041. [Google Scholar] [CrossRef]

- Vehmas, K.; Lavrusheva, O.; Seisto, A.; Poutanen, K.; Nordlund, E. Consumer insight on a snack machine producing healthy and customized foods at point of consumption. Br. Food J. 2019. [Google Scholar] [CrossRef]

- Chawla, R.; Patil, G.R. Soluble Dietary Fiber. Compr. Rev. Food Sci. Food Saf. 2010, 9, 178–196. [Google Scholar] [CrossRef]

- Morell, P.; Fiszman, S. Revisiting the role of protein-induced satiation and satiety. Food Hydrocoll. 2017, 68, 199–210. [Google Scholar] [CrossRef]

- Paddon-Jones, D.; Westman, E.; Mattes, R.D.; Wolfe, R.R.; Astrup, A.; Westerterp-Plantenga, M. Protein, weight management, and satiety. Am. J. Clin. Nutr. 2008, 87, 1558S–1561S. [Google Scholar] [CrossRef]

- Ye, Z.; Arumugam, V.; Haugabrooks, E.; Williamson, P.; Hendrich, S. Soluble dietary fiber (Fibersol-2) decreased hunger and increased satiety hormones in humans when ingested with a meal. Nutr. Res. 2015, 35, 393–400. [Google Scholar] [CrossRef]

- Calton, A.; Ma, H.; Nordlund, E.; Poutanen, K.; Sozer, N. Instant properties of ingredients used for point of consumption production of high-moisture food structures selectively fortified with protein and dietary fibre. J. Food Eng. 2019, 263, 204–212. [Google Scholar] [CrossRef]

- Kim, C.; Lee, C.; Lehto, M.R.; Yun, M.H. Evaluation of customer impressions using virtual prototypes in the internet environment. Int. J. Ind. Ergon. 2011, 41, 118–127. [Google Scholar] [CrossRef]

- European Commission Regulation (Ec) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, 49, 9–25.

- Lad, M.D.; Samanci, S.; Mitchell, J.R.; Foster, T.J. Viscosity development during competitive hydration of starch and hydrocolloids. In Proceedings of the Gums and Stabilisers for the Food Industry 15; Williams, P.A., Phillips, G.O., Eds.; Royal Society of Chemistry: London, UK, 2010; pp. 126–136. [Google Scholar]

- Moschakis, T.; Lazaridou, A.; Biliaderis, C.G. A micro- and macro-scale approach to probe the dynamics of sol–gel transition in cereal β-glucan solutions varying in molecular characteristics. Food Hydrocoll. 2014, 42, 81–91. [Google Scholar] [CrossRef]

- Chakraborty, P.; Witt, T.; Harris, D.; Ashton, J.; Stokes, J.R.; Smyth, H.E. Texture and mouthfeel perceptions of a model beverage system containing soluble and insoluble oat bran fibres. Food Res. Int. 2019, 120, 62–72. [Google Scholar] [CrossRef]

- Temelli, F.; Bansema, C.; Stobbe, K. Development of an orange-flavored barley β-glucan beverage with added whey protein isolate. J. Food Sci. 2006, 69, 237–242. [Google Scholar] [CrossRef]

- Trikusuma, M.; Paravisini, L.; Peterson, D.G. Identification of aroma compounds in pea protein UHT beverages. Food Chem. 2020, 312, 126082. [Google Scholar] [CrossRef]

- Mäkinen, O.E.; Uniacke-Lowe, T.; O’Mahony, J.A.; Arendt, E.K. Physicochemical and acid gelation properties of commercial UHT-treated plant-based milk substitutes and lactose free bovine milk. Food Chem. 2015, 168, 630–638. [Google Scholar] [CrossRef]

- Palacios, O.M.; Badran, J.; Drake, M.A.; Reisner, M.; Moskowitz, H.R. Consumer acceptance of cow’s milk versus soy beverages: Impact of ethnicity, lactose tolerance and sensory preference segmentation. J. Sens. Stud. 2009, 24, 731–748. [Google Scholar] [CrossRef]

- Önning, G.; Åkesson, B.; Öste, R.; Lundquist, I. Effects of consumption of oat milk, soya milk, or cow’s milk on plasma lipids and antioxidative capacity in healthy subjects. Ann. Nutr. Metab. 1998, 42, 211–220. [Google Scholar] [CrossRef] [PubMed]

- Sethi, S.; Tyagi, S.K.; Anurag, R.K. Plant-based milk alternatives an emerging segment of functional beverages: A review. J. Food Sci. Technol. 2016, 53, 3408–3423. [Google Scholar] [CrossRef] [PubMed]

- Zellner, D.A.; Strickhouser, D.; Tornow, C.E. Disconfirmed hedonic expectations produce perceptual contrast, not assimilation. Am. J. Psychol. 2004, 117, 363. [Google Scholar] [CrossRef] [PubMed]

- Wansink, B.; Sonka, S.; Goldsmith, P.; Chiriboga, J.; Eren, N. Increasing the acceptance of soy-based foods. J. Int. Food Agribus. Mark. 2005, 17, 35–55. [Google Scholar] [CrossRef]

- Sowers, M.F.; Colby, S.; Kavanagh, K.; Zhou, W. Testing product, pricing, and promotional strategies for vending machine interventions with a college population. J. Foodserv. Bus. Res. 2019, 22, 303–325. [Google Scholar] [CrossRef]

- Wie, S.; Giebler, K. College students’ perceptions and behaviors toward calorie counts on menu. J. Foodserv. Bus. Res. 2014, 17, 56–65. [Google Scholar] [CrossRef]

- van Buul, V.J.; Bolman, C.A.W.; Brouns, F.J.P.H.; Lechner, L. Back-of-pack information in substitutive food choices: A process-tracking study in participants intending to eat healthy. Appetite 2017, 116, 173–183. [Google Scholar] [CrossRef]

- Caruso, M.L.; Klein, E.G.; Kaye, G. Campus-based snack food vending consumption. J. Nutr. Educ. Behav. 2014, 46, 401–405. [Google Scholar] [CrossRef]

- Hua, S.V.; Ickovics, J.R. Vending Machines: A narrative review of factors influencing items purchased. J. Acad. Nutr. Diet. 2016, 116, 1578–1588. [Google Scholar] [CrossRef]

- Bos, C.; van der Lans, I.A.; van Kleef, E.; van Trijp, H.C.M. Promoting healthy choices from vending machines: Effectiveness and consumer evaluations of four types of interventions. Food Policy 2018, 79, 247–255. [Google Scholar] [CrossRef]

- Pharis, M.L.; Colby, L.; Wagner, A.; Mallya, G. Sales of healthy snacks and beverages following the implementation of healthy vending standards in City of Philadelphia vending machines. Public Health Nutr. 2018, 21, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Pechey, R.; Jenkins, H.; Cartwright, E.; Marteau, T.M. Altering the availability of healthier vs. less healthy items in UK hospital vending machines: A multiple treatment reversal design. Int. J. Behav. Nutr. Phys. Act. 2019, 16, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Story, M.; Kaphingst, K.M.; Robinson-O’Brien, R.; Glanz, K. Creating healthy food and eating environments: policy and environmental approaches. Annu. Rev. Public Health 2008, 29, 253–272. [Google Scholar] [CrossRef] [PubMed]

- Larson, N.; Story, M. Are “competitive foods” sold at school making our children fat? Health Aff. 2010, 29, 430–435. [Google Scholar] [CrossRef] [PubMed]

- Callaghan, C.; Mandich, G.; Unit, M.H. Healthier snacks in school vending machines: A pilot project in four Ontario high schools. Can. J. Diet. Pract. Res. 2010, 71, 186. [Google Scholar] [CrossRef] [PubMed]

- Klapheke, A.M. A Comparison of Demographics and Purchasing Behaviors of Snack Vending Consumers at Different Locations in a Large University. 2012. Available online: https://etd.ohiolink.edu/!etd.send_file?accession=osu1337906704&disposition=inline (accessed on 13 October 2020).

- Glanz, K.; Bader, M.D.M.; Iyer, S. Retail grocery store marketing strategies and obesity: An integrative review. Am. J. Prev. Med. 2012, 42, 503–512. [Google Scholar] [CrossRef]

| Product | Specifications | Base (g) | Added Protein (g), 2 | Added DF (g), 3 | Added Thickener (g), 4 | E from Protein (%) | DF (g/100g) | kcal/100g | Apparent Viscosity (Pa s) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 30 min | 60 min | |||||||||

| Spoonable | Dairy | 18.6 | 11.1 | 31.1 | 2.5 | 77.1 | 3.6 ± 0.2 a | 3.6 ± 0.2 a | ||

| Dairy, protein, DF | 18.6 | 6.8 | 4.2 | 11.1 | 38.5 | 4.9 | 95.0 | 0.6 ± 0.2 b | 0.7 ± 0.2 b | |

| Oat | 15.4 | 9.2 | 12.4 | 2.0 | 65.0 | 1.9 ± 0.2 c | 2.3 ± 0.2 c | |||

| Oat, protein, DF | 15.4 | 2.2 | 4.2 | 6.6 | 18.1 | 4.7 | 74.6 | 0.4 ± 0.2 d | 0.5 ± 0.2 d | |

| Drinkable | Dairy | 18.6 | 40.3 | 0.5 | 51.6 | na | na | |||

| Dairy, protein, DF | 18.6 | 6.8 | 4.2 | 47.5 | 3.2 | 73.2 | na | na | ||

| Oat | 15.4 | 10.7 | 0.7 | 48.8 | na | na | ||||

| Oat, protein, DF | 15.4 | 4.3 | 4.2 | 18.6 | 3.6 | 59.7 | na | na | ||

| Oat (A) | Vanilla | OF (55.0%) | DME (44.0%) | Vanilla aroma (1.0%) | ||

| Cocoa | OF (47.4%) | DME (44.0%) | Cocoa (8.0%) | Salt (0.6%) | ||

| Dairy (A) | Vanilla | SMP (70.0%) | DME (29.0%) | Vanilla aroma (1.0%) | ||

| Cocoa | SMP (61.4%) | DME (30.0%) | Cocoa (8.0%) | Salt (0.6%) | ||

| Oat (B) | Vanilla rev. | OF (55.0%) | DME (40.0%) | Vanilla sugar (5.0%) | ||

| Cocoa rev. | OF (42.0%) | DME (35.4%) | Cocoa (20.0%) | Vanilla sugar (2.0%) | Salt (0.6%) | |

| Dairy (B) | Vanilla rev. | SMP (71.0%) | DME (24.0%) | Vanilla sugar (5.0%) | ||

| Cocoa rev. | SMP (60.0%) | DME (17.4%) | Cocoa (20.0%) | Vanilla sugar (2.0%) | Salt (0.6%) |

| Sample | ANOVA p | Partial η2 | Dairy with Protein and Fiber | Oat with Protein and Fiber | Dairy without Protein nor Fiber | Oat without Protein nor Fiber | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Drinkable samples | ||||||||||||||

| Cocoa odor | <0.001 | 0.53 | 4.2 | (1.4) | a | 2.6 | (1.3) | c | 3.9 | (1.3) | ab | 3.1 | (1.3) | bc |

| Sweet odor | <0.001 | 0.64 | 6.7 | (1.4) | a | 3.2 | (1.8) | b | 5.8 | (1.6) | a | 4.0 | (1.8) | b |

| Grain-like odor | 0.003 | 0.40 | 1.5 | (1.5) | c | 2.7 | (1.7) | ab | 2.0 | (1.5) | bc | 3.3 | (1.5) | a |

| Dried pea odor | <0.001 | 0.67 | 1.3 | (1.6) | b | 5.1 | (2.1) | a | 1.5 | (1.4) | b | 1.8 | (1.7) | b |

| Sedimentation tendency | <0.001 | 0.83 | 1.9 | (1.4) | c | 5.5 | (1.8) | b | 2.5 | (1.7) | c | 7.4 | (1.4) | a |

| Sweetness | <0.001 | 0.88 | 5.0 | (1.4) | a | 2.3 | (1.2) | b | 5.3 | (1.6) | a | 2.0 | (1.3) | b |

| Bitterness | <0.001 | 0.55 | 2.1 | (1.8) | c | 5.5 | (2.0) | a | 2.6 | (1.7) | bc | 3.4 | (1.6) | b |

| Cocoa flavor | <0.001 | 0.76 | 4.8 | (1.0) | a | 1.7 | (0.9) | c | 5.0 | (1.0) | a | 3.1 | (1.6) | b |

| Grain-like flavor | 0.003 | 0.40 | 2.3 | (1.8) | b | 2.3 | (1.8) | b | 2.3 | (1.8) | b | 4.1 | (1.9) | a |

| Dried pea flavor | <0.001 | 0.87 | 1.7 | (1.6) | b | 6.9 | (1.7) | a | 1.4 | (1.5) | b | 1.9 | (1.9) | b |

| Richness | <0.001 | 0.51 | 4.3 | (2.2) | a | 4.4 | (2.0) | a | 4.3 | (2.1) | a | 1.8 | (1.6) | b |

| Astringency | 0.007 | 0.36 | 2.0 | (1.0) | b | 3.6 | (1.9) | a | 1.8 | (1.5) | b | 2.4 | (1.4) | b |

| Other flavor intensity | <0.001 | 0.63 | 4.5 | (2.4) | a | 1.3 | (2.7) | b | 3.8 | (2.5) | a | 0.9 | (1.6) | b |

| Spoonable samples | ||||||||||||||

| Cocoa odor | <0.001 | 0.66 | 4.0 | (1.4) | a | 2.3 | (1.4) | c | 4.1 | (1.0) | a | 3.1 | (1.2) | b |

| Grain-like odor | 0.08 | 0.22 | 2.5 | (1.7) | 2.7 | (1.8) | 2.6 | (1.7) | 3.6 | (1.5) | ||||

| Dried pea odor | <0.001 | 0.62 | 1.2 | (1.4) | b | 4.3 | (2.3) | a | 1.3 | (1.5) | b | 1.6 | (1.8) | b |

| Stretchability | 0.008 | 0.35 | 3.7 | (1.8) | b | 5.3 | (0.9) | a | 4.0 | (1.5) | b | 3.5 | (1.8) | b |

| Consistency | <0.001 | 0.75 | 1.8 | (0.9) | c | 3.1 | (0.7) | b | 4.4 | (1.1) | a | 4.7 | (1.5) | a |

| Graininess | 0.025 | 0.29 | 5.2 | (1.8) | a | 3.8 | (1.3) | b | 4.2 | (1.4) | b | 4.1 | (1.3) | b |

| Sliminess | <0.001 | 0.68 | 2.8 | (2.5) | b | 5.5 | (2.1) | a | 5.7 | (2.1) | a | 6.0 | (2.0) | a |

| Sweetness | <0.001 | 0.65 | 5.1 | (1.3) | a | 2.5 | (1.4) | b | 4.5 | (1.3) | a | 2.5 | (1.9) | b |

| Bitterness | <0.001 | 0.54 | 2.1 | (1.4) | bc | 4.4 | (2.0) | a | 1.9 | (1.5) | c | 2.6 | (1.9) | b |

| Cocoa flavor | <0.001 | 0.73 | 4.9 | (1.1) | a | 2.0 | (1.2) | c | 4.6 | (0.9) | a | 3.1 | (1.4) | b |

| Grain-like flavor | 0.027 | 0.28 | 3.5 | (1.7) | bc | 3.0 | (1.7) | c | 4.1 | (1.8) | ab | 4.7 | (1.6) | a |

| Dried pea flavor | <0.001 | 0.69 | 1.3 | (1.7) | b | 5.5 | (2.1) | a | 1.6 | (1.8) | b | 1.4 | (1.3) | b |

| Richness | 0.020 | 0.30 | 4.7 | (2.2) | b | 5.0 | (1.6) | b | 6.7 | (0.8) | a | 5.2 | (2.1) | b |

| Choice Category in the Machine Operating Principle (Figure 3) | Operation Presented to Consumer | Number of Consumers Choosing the Option |

|---|---|---|

| Viscosity | Drinkable | 17 |

| Spoonable | 15 | |

| Base | Oat | 16 |

| Dairy | 16 | |

| Flavour | Cocoa | 7 |

| Vanilla | 2 | |

| Berries | 23 | |

| Extra protein | Yes | 11 |

| No | 16 | |

| No info | 5 | |

| Extra fibre | Yes | 12 |

| No | 15 | |

| No info | 5 | |

| Garnish | Coconut & chia | 6 |

| Granola | 11 | |

| None | 10 | |

| No info | 5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vehmas, K.; Calton, A.; Grenman, K.; Aisala, H.; Sozer, N.; Nordlund, E. Development and Consumer Perception of a Snack Machine Producing Customized Spoonable and Drinkable Products Enriched in Dietary Fiber and Protein. Foods 2020, 9, 1454. https://doi.org/10.3390/foods9101454

Vehmas K, Calton A, Grenman K, Aisala H, Sozer N, Nordlund E. Development and Consumer Perception of a Snack Machine Producing Customized Spoonable and Drinkable Products Enriched in Dietary Fiber and Protein. Foods. 2020; 9(10):1454. https://doi.org/10.3390/foods9101454

Chicago/Turabian StyleVehmas, Kaisa, Alex Calton, Katri Grenman, Heikki Aisala, Nesli Sozer, and Emilia Nordlund. 2020. "Development and Consumer Perception of a Snack Machine Producing Customized Spoonable and Drinkable Products Enriched in Dietary Fiber and Protein" Foods 9, no. 10: 1454. https://doi.org/10.3390/foods9101454

APA StyleVehmas, K., Calton, A., Grenman, K., Aisala, H., Sozer, N., & Nordlund, E. (2020). Development and Consumer Perception of a Snack Machine Producing Customized Spoonable and Drinkable Products Enriched in Dietary Fiber and Protein. Foods, 9(10), 1454. https://doi.org/10.3390/foods9101454