Influence of Flour Particle Size Distribution on the Quality of Maize Gluten-Free Cookies

Abstract

1. Introduction

2. Materials and Methods

2.1. Cookie Ingredients

2.2. Flour Characterisation

2.3. Cookie Formulation

2.4. Dough Rheology

2.5. Cookie Characteristics

2.6. Statistical Analysis

3. Results

3.1. Particle Size and Hydration Properties

3.2. Dough Rheology Properties

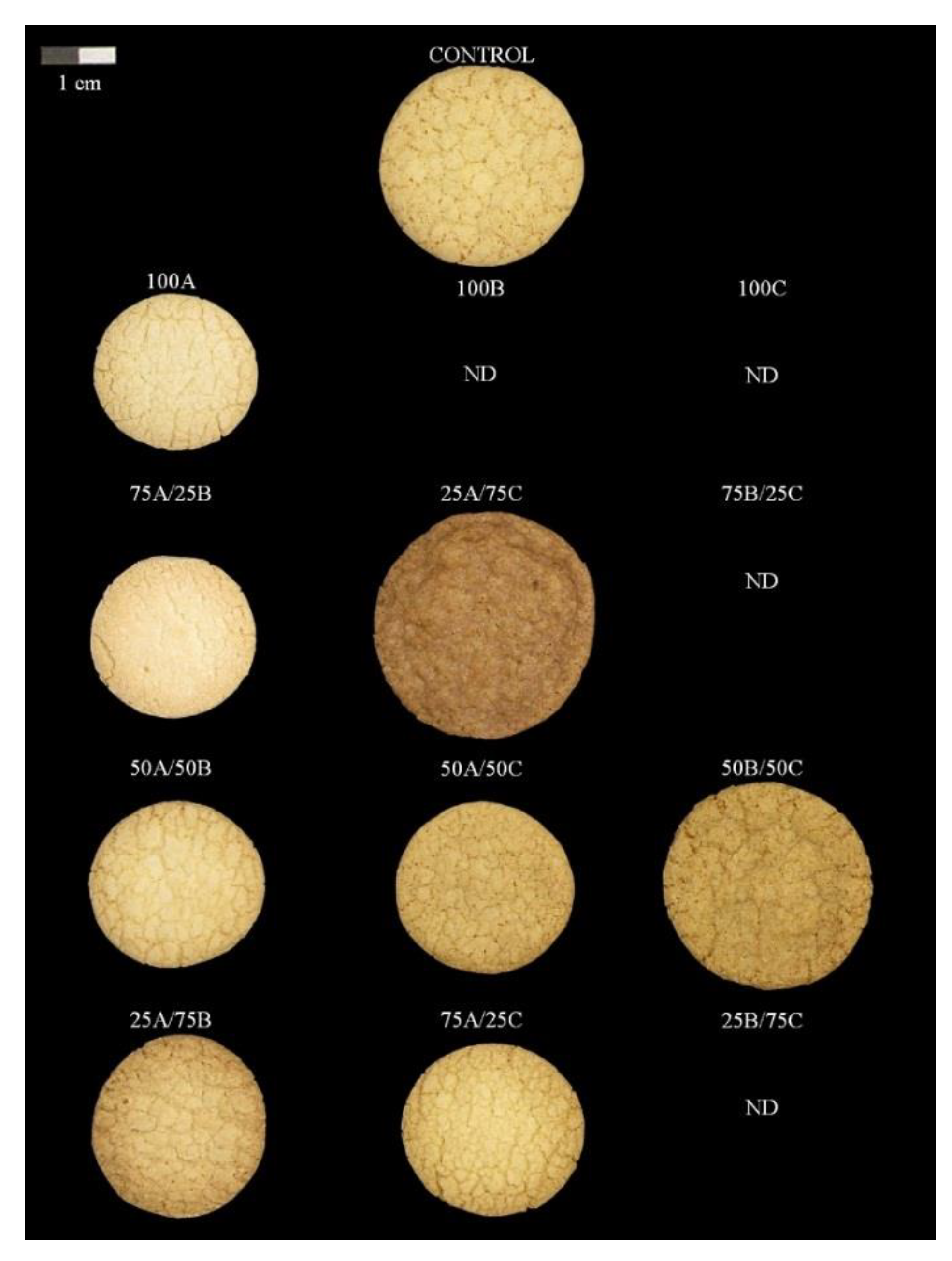

3.3. Cookie Characteristics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Crowe, S.E. Celiac disease. In Nutritional and Gastrointestinal Disease; Human Press Inc.: Totowa, NJ, USA, 2008; pp. 123–147. [Google Scholar]

- Pareyt, B.; Delcour, J.A. The role of wheat flour constituents, sugar, and fat in low moisture cereal-based products: A review on sugar-snap cookies. Crit. Rev. Food Sci. Nutr. 2008, 48, 824–839. [Google Scholar] [CrossRef] [PubMed]

- Mancebo, C.M.; Picon, J.; Gómez, M. Effect of flour properties on the quality characteristics of gluten free sugar-snap cookies. LWT 2015, 64, 264–269. [Google Scholar] [CrossRef]

- Torbica, A.; Hadnadev, M.; Hadnadev, T.D. Rice and buckwheat flour characterization and its relation to cookie quality. Food Res. Int. 2012, 48, 277–283. [Google Scholar] [CrossRef]

- Rai, S.; Kaur, A.; Singh, B. Quality characteristics of gluten free cookies prepared from different flour combinations. J. Food Sci. Technol. 2014, 51, 785–789. [Google Scholar] [CrossRef] [PubMed]

- Barak, S.; Mudgil, D.; Khatkar, B.S. Effect of flour particle size and damaged starch on the quality of cookies. J. Food Sci. Technol. 2014, 5, 1342–1348. [Google Scholar] [CrossRef] [PubMed]

- Rao, B.D.; Anis, M.; Kalpana, K.; Sunooj, K.V.; Patil, J.V.; Ganesh, T. Influence of milling methods and particle size on hydration properties of sorghum flour and quality of sorghum biscuits. LWT 2016, 67, 8–13. [Google Scholar]

- Mancebo, C.M.; Rodriguez, P.; Gómez, M. Assessing rice flour-starch-protein mixtures to produce gluten free sugar-snap cookies. LWT 2016, 67, 127–132. [Google Scholar] [CrossRef]

- Ai, Y.F.; Jin, Y.N.; Kelly, J.D.; Ng, P.K.W. Composition, functional properties, starch digestibility, and cookie-baking performance of dry bean powders from 25 Michigan-grown varieties. Cereal Chem. 2017, 94, 400–408. [Google Scholar] [CrossRef]

- Protonotariou, S.; Batzaki, C.; Yanniotis, S.; Mandala, I. Effect of jet milled whole wheat flour in biscuits properties. LWT 2016, 74, 106–113. [Google Scholar] [CrossRef]

- Barrera, G.N.; Pérez, G.T.; Ribotta, P.D.; León, A.E. Influence of damaged starch on cookie and bread-making quality. Eur. Food Res. Technol. 2007, 225, 1–7. [Google Scholar] [CrossRef]

- AACC International. AACC International Approved Methods, AACCI Method 56-30.01, Water Hydration Capacity of Protein Materials; AACC International: St. Paul, MN, USA, 1999. [Google Scholar]

- AACC International. AACC International Approved Methods, AACCI Method 44-15.02, Moisture—Air-Oven Methods; AACC International: St. Paul, MN, USA, 1999. [Google Scholar]

- Ahmed, J.; Al-Attar, H.; Arfat, Y.A. Effect of particle size on compositional, functional, pasting and rheological properties of commercial water chestnut flour. Food Hydrocoll. 2016, 52, 888–895. [Google Scholar] [CrossRef]

- De la Hera, E.; Talegón, M.; Caballero, P.; Gómez, M. Influence of maize flour particle size on gluten-free breadmaking. J. Sci. Food Agric. 2013, 93, 924–932. [Google Scholar] [CrossRef] [PubMed]

- Gujral, H.S.; Mehta, S.; Samra, I.S.; Goyal, P. Effect of wheat bran, coarse wheat flour and rice flour on the instrumental texture of cookies. Int. J. Food Prop. 2003, 6, 329–340. [Google Scholar] [CrossRef]

- Lee, S.; Inglett, G.E. Rheological and physical evaluation of jet-cooked oat bran in low calorie cookies. Int. J. Food Sci. Technol. 2006, 41, 553–559. [Google Scholar] [CrossRef]

- Mancebo, C.M.; Rodriguez, P.; Martínez, M.M.; Gómez, M. Effect of the addition of soluble (nutriose, inulin and polydextrose) and insoluble (bamboo, potato and pea) fibres on the quality of sugar-snap cookies. Int. J. Food Sci. Technol. 2018, 53, 129–136. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, Y.; Zhang, Y.; He, Z.H.; Peña, R.J. Effects of solvent retention capacities, pentosan content, and dough rheological properties on sugar snap cookie quality in Chinese soft wheat genotypes. Crop. Sci. 2007, 47, 656–664. [Google Scholar] [CrossRef]

- Inglett, G.E.; Chen, D.; Liu, S.X. Physical properties of gluten-free sugar cookies made from amaranth-oat composites. LWT 2015, 63, 214–220. [Google Scholar] [CrossRef]

- Yamazaki, W.T. The concentration of a factor in soft wheat flours affecting cookie quality. Cereal Chem. 1955, 32, 26–37. [Google Scholar]

- Hoseney, R.C.; Rogers, D.E. Mechanism of sugar functionality in cookies. In The Science of Cookie and Cracker Production; Faridi, H., Ed.; Avi: New York, NY, USA, 1994; pp. 203–226. [Google Scholar]

- Chevallier, S.; Colonna, P.A.; Della Valle, G.; Lourdin, D. Contribution of major ingredients during baking of biscuit dough systems. J. Cereal Sci. 2000, 3, 241–252. [Google Scholar] [CrossRef]

| Ingredients | CF | 100A | 100B | 100C | 50A/50B | 50A/50C | 50B/50C | 25A/75B | 75A/25B | 25A/75C | 75A/25C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| White maize flour | 173.2 | - | - | - | - | - | - | - | - | - | - |

| A (<80 μm) | - | 173.2 | - | 86.6 | 86.6 | - | 43.3 | 129.9 | 43.3 | 129.9 | |

| B (80–180 μm) | - | 173.2 | - | 86.6 | - | 86.6 | 129.9 | 43.3 | - | - | |

| C (>180 μm) | - | - | 173.2 | - | 86.6 | 86.6 | - | - | 129.9 | 43.3 | |

| White sugar | 124.8 | 124.8 | 124.8 | 124.8 | 124.8 | 124.8 | 124.8 | 124.8 | 124.8 | 124.8 | 124.8 |

| Margarine | 77.6 | 77.6 | 77.6 | 77.6 | 77.6 | 77.6 | 77.6 | 77.6 | 77.6 | 77.6 | 77.6 |

| Sodium bicarbonate | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 |

| Tap water | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 |

| D[4,3] | D(10) | D(50) | D(90) | |

|---|---|---|---|---|

| Control flour | 199.9 ± 6.4 g | 26.5 ± 1.4 c | 178.8 ± 6.5 e | 401.4 ± 8.8 e |

| 100A (<80 μm) | 61.6 ± 3.9 a | 14.6 ± 0.4 a | 49.4 ± 4.7 a | 128.3 ± 7.2 a |

| 100B (80–180 μm) | 186.3 ± 9.2 f | 88.3 ± 9.6 d | 177.0 ± 8.5 e | 304.7 ± 9.7 d |

| 100C (>180 μm) | 354.2 ± 5.4 i | 211.2 ± 1.4 f | 337.4 ± 4.5 g | 533.6 ± 12.2 h |

| 50A/50B | 124.1 ± 1.3 c | 19.1 ± 0.4 ab | 105.0 ± 0.6 c | 263.2 ± 4.2 c |

| 50A/50C | 172.2 ± 4.8 e | 18.9 ± 0.3 ab | 105.6 ± 4.5 c | 415.9 ± 8.6 e |

| 50B/50C | 261.1 ± 3.8 h | 113.1 ± 3.0 e | 242.4 ± 3.7 f | 444.7 ± 4.9 f |

| 25A/75B | 151.9 ± 3.8 d | 27.7 ± 1.3 bc | 144.0 ± 5.4 d | 287.3 ± 2.7 cd |

| 75A/25B | 101.1 ± 10.0 b | 16.9 ± 0.4 a | 74.2 ± 8.2 b | 230.7 ± 23.3 b |

| 25A/75C | 252.8 ± 3.8 h | 27.7 ± 0.1 c | 250.8 ± 3.4 f | 489.8 ± 9.0 g |

| 75A/25C | 113.1±4.4 bc | 16.5 ± 0.2 a | 66.5 ± 1.6 b | 299.5 ± 15.4 d |

| Hydration Properties | Dough Rheology | |||||

|---|---|---|---|---|---|---|

| WHC | Swelling | WBC | G’ (×106) | G” (×106) | Tan Delta | |

| Control flour | 1.57 ± 0.04 bcd | 2.09 ± 0.16 abc | 1.28 ± 0.04 de | 0.42 ± 0.02 a | 0.25 ± 0.27 a | 0.59 ± 0.54 b |

| 100A (<80 μm) | 1.85 ± 0.07 fg | 2.29 ± 0.16 d | 1.30 ± 0.01 ef | 1.36 ± 0.27 c | 0.26 ± 0.18 a | 0.15 ± 0.04 ab |

| 100B (80–180 μm) | 1.87 ± 0.13 g | 2.19 ± 0.01 bcd | 1.47 ± 0.01 g | ND | ND | ND |

| 100C (>180 μm) | 1.48 ± 0.03 bc | 2.20 ± 0.00 cd | 1.30 ± 0.01 ef | ND | ND | ND |

| 50A/50B | 1.64 ± 0.10 cde | 2.09 ± 0.14 abc | 1.27 ± 0.04 de | 0.72 ± 0.02 ab | 0.12 ± 0.17 a | 0.24 ± 0.35 ab |

| 50A/50C | 1.43 ± 0.09 ab | 1.99 ± 0.01 a | 1.19 ± 0.01 bc | 1.20 ± 0.22 c | 0.10 ± 0.13 a | 0.10 ± 0.14 ab |

| 50B/50C | 1.83 ± 0.05 fg | 2.27 ± 0.11 cd | 1.33 ± 0.01 f | ND | ND | ND |

| 25A/75B | 1.74 ± 0.11 efg | 2.18 ± 0.01 abcd | 1.15 ± 0.02 b | 0.27 ± 0.23 a | 0.05 ± 0.30 a | 0.25 ± 0.11 ab |

| 75A/25B | 1.69 ± 0.04 def | 2.19 ± 0.02 bcd | 1.05 ± 0.01 a | 1.25 ±0.18 c | 0.06 ± 0.88 a | 0.05 ± 0.08 ab |

| 25A/75C | 1.41 ± 0.02 a | 2.00 ± 0.01 ab | 1.20 ± 0.01 c | 1.49 ± 0.17 c | 0.08 ± 0.11 a | 0.01 ± 0.00 a |

| 75A/25C | 1.56 ± 0.04 abcd | 2.20 ± 0.01 cd | 1.24 ± 0.04 cd | 1.05 ± 0.15 bc | 0.06 ± 0.90 a | 0.14 ± 0.01 ab |

| Dimensions | Texture | Colour | |||||

|---|---|---|---|---|---|---|---|

| Diameter (mm) | Spread Factor | Hardness (N) | Cookie Elastic Modulus (N/mm²) | L* | a* | b* | |

| Control flour | 56.4 ± 0.40 c | 7.48 ± 0.31 de | 34.10 ± 1.22 cd | 26.90 ± 1.52 ab | 55.33 ± 1.97 c | 5.59 ± 2.79 abc | 18.33 ± 0.92 b |

| 100A (<80 μm) | 43.1 ± 1.22 a | 4.05 ± 0.24 a | 50.84 ± 1.97 f | 54.48 ± 2.73 d | 78.45 ± 0.95 f | 3.70 ± 1.40 a | 21.41 ± 1.02 bcd |

| 100B (80–180 μm) | ND | ND | ND | ND | ND | ND | ND |

| 100C (>180 μm) | ND | ND | ND | ND | ND | ND | ND |

| 50A/50B | 48.4 ± 0.22 bc | 5.54 ± 0.34 bc | 34.43 ± 1.94 cd | 33.41 ± 3.13 bc | 69.44 ± 1.27 e | 5.47 ± 1.12 abc | 21.37 ± 0.40 bcd |

| 50A/50C | 55.1 ± 0.20 d | 8.47 ± 0.20 ef | 24.25 ± 0.37 b | 27.15 ± 3.97 ab | 61.20 ± 0.11 d | 7.19 ± 0.76 bcd | 19.14 ± 1.04 b |

| 50B/50C | 54.9 ± 2.53 d | 9.47 ± 1.02 f | 25.98 ± 0.30 b | 19.83 ± 0.45 a | 51.11 ± 1.23 b | 7.85 ± 1.40 cd | 13.37 ± 1.04 a |

| 25A/75B | 50.7 ± 0.07 c | 6.31 ± 0.13 cd | 36.24 ± 0.05 d | 38.54 ± 1.38 c | 69.84 ± 1.89 e | 5.98 ± 0.55 abc | 25.23 ± 1.12 d |

| 75A/25B | 43.9 ± 1.22 a | 4.53 ± 0.19 ab | 42.82 ± 1.98 e | 38.71 ± 10.61 c | 75.66 ± 1.80 f | 4.68 ± 0.60 ab | 24.42 ± 1.32 cd |

| 25A/75C | 63.0 ± 0.71 e | 14.01 ± 1.31 g | 17.93 ± 0.8 a | 29.70 ± 5.37 abc | 46.52 ± 3.10 a | 9.71 ± 1.00 d | 12.93 ± 2.13 a |

| 75A/25C | 47.14 ± 0.79 b | 5.10 ± 0.01 abc | 33.24 ± 0.80 c | 34.81 ± 1.74 bc | 74.34 ± 2.63 f | 5.19 ± 0.08 abc | 21.06 ± 4.24 bc |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belorio, M.; Sahagún, M.; Gómez, M. Influence of Flour Particle Size Distribution on the Quality of Maize Gluten-Free Cookies. Foods 2019, 8, 83. https://doi.org/10.3390/foods8020083

Belorio M, Sahagún M, Gómez M. Influence of Flour Particle Size Distribution on the Quality of Maize Gluten-Free Cookies. Foods. 2019; 8(2):83. https://doi.org/10.3390/foods8020083

Chicago/Turabian StyleBelorio, Mayara, Marta Sahagún, and Manuel Gómez. 2019. "Influence of Flour Particle Size Distribution on the Quality of Maize Gluten-Free Cookies" Foods 8, no. 2: 83. https://doi.org/10.3390/foods8020083

APA StyleBelorio, M., Sahagún, M., & Gómez, M. (2019). Influence of Flour Particle Size Distribution on the Quality of Maize Gluten-Free Cookies. Foods, 8(2), 83. https://doi.org/10.3390/foods8020083