Effect of Microwave Drying on the Drying Characteristics, Color, Microstructure, and Thermal Properties of Trabzon Persimmon

Abstract

1. Introduction

2. Material and Methods

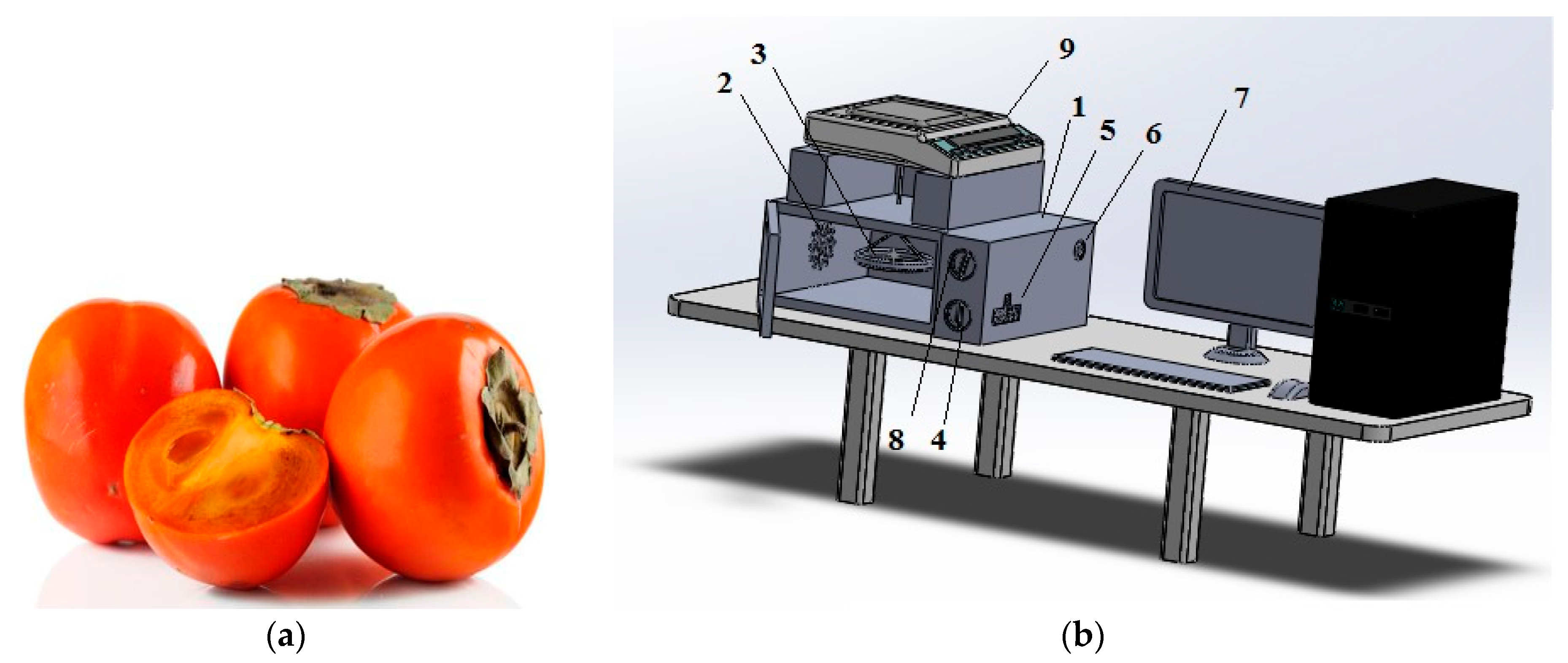

2.1. Preparation of the Persimmons

2.2. Drying Procedure

2.3. Data Analysis

2.3.1. Moisture Content and Moisture Rate

2.3.2. Drying Rate

2.3.3. Shrinkage Test

2.3.4. Moisture Diffusivity and Activation Energy

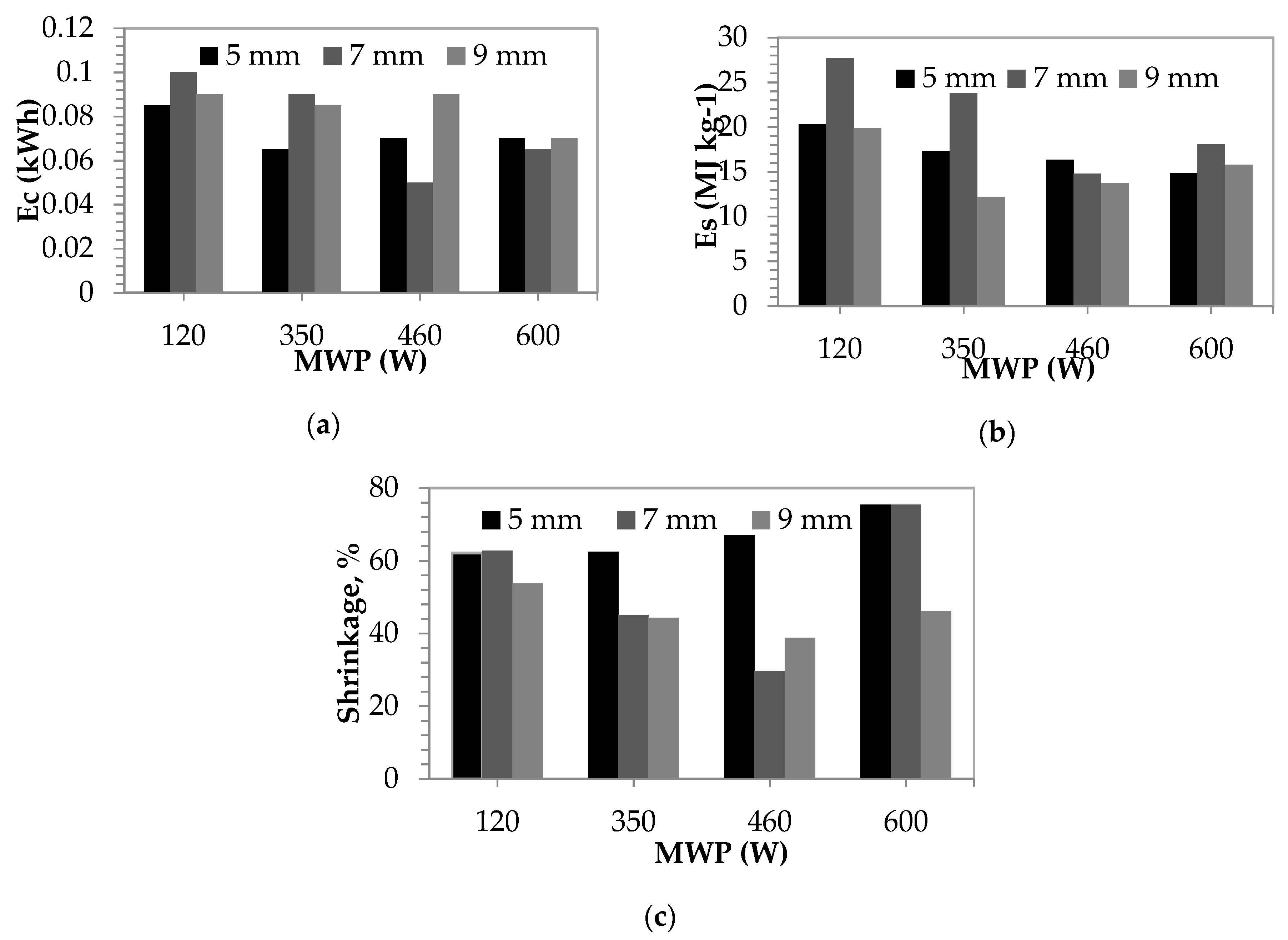

2.3.5. Specific Energy Consumption and Drying Energy Performance

2.3.6. Color Change in the Product, Scanning Electron Microscopy (SEM) and Product Temperature Measurements

2.3.7. Statistical Analyses

3. Results and Discussions

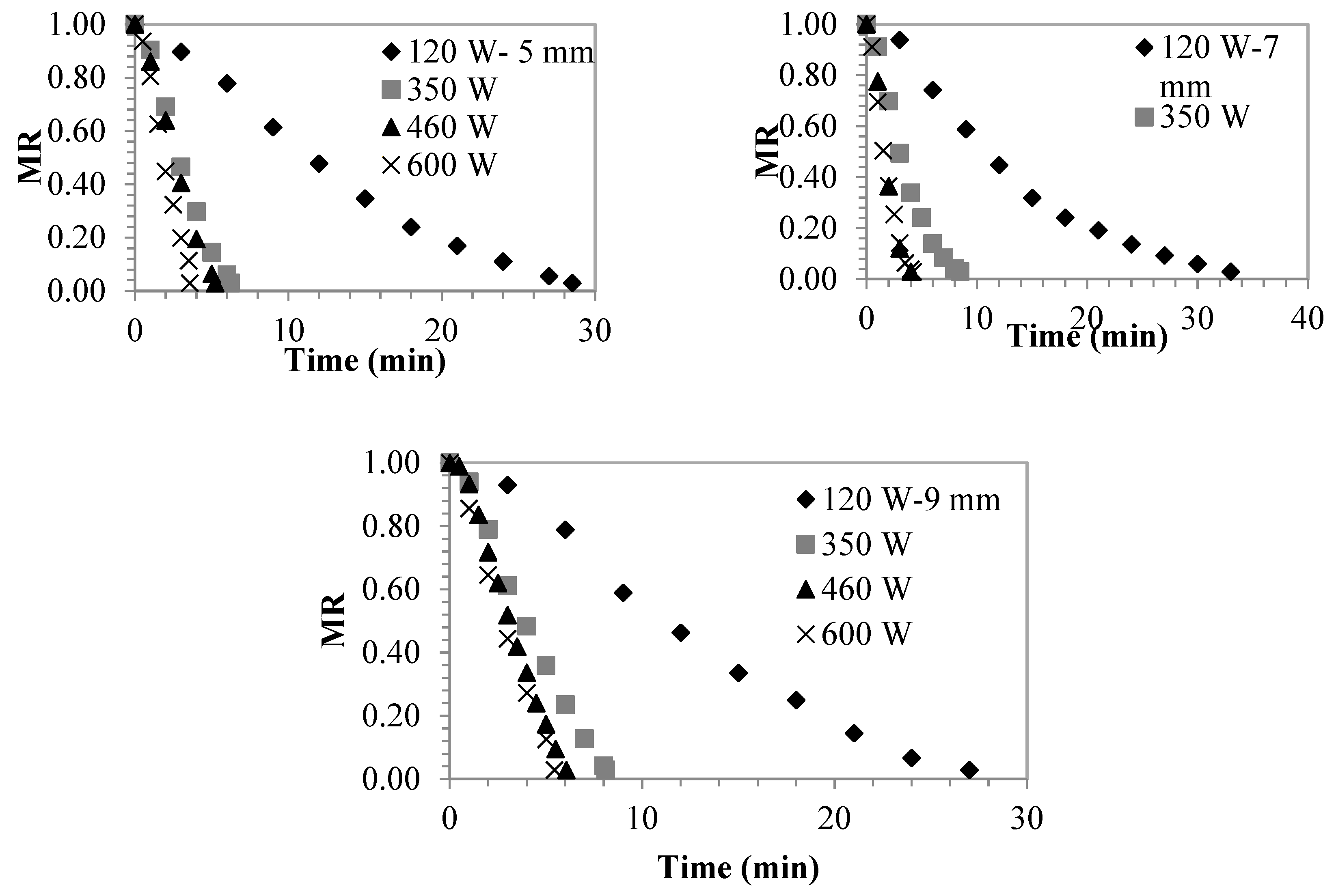

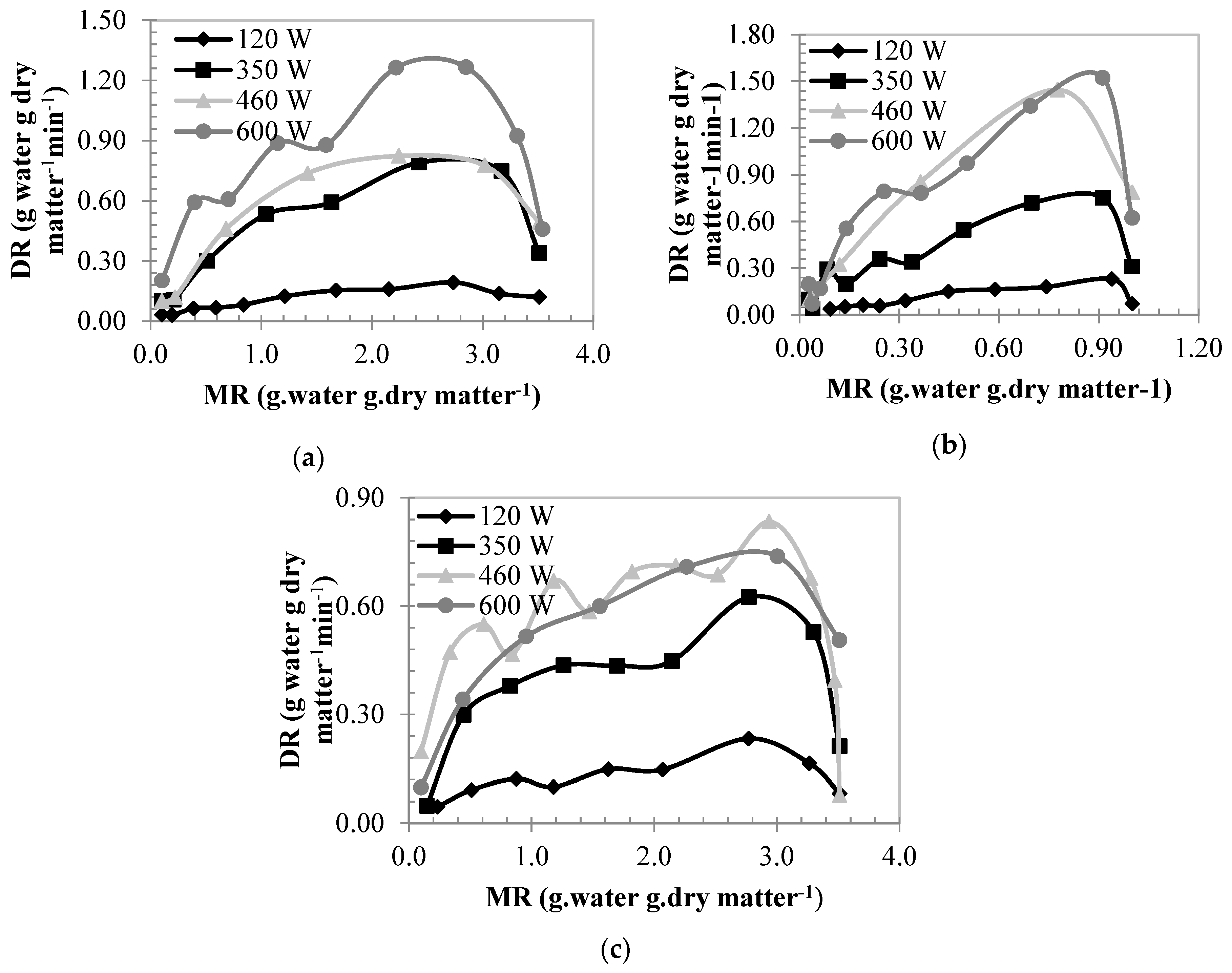

3.1. Drying Characteristics

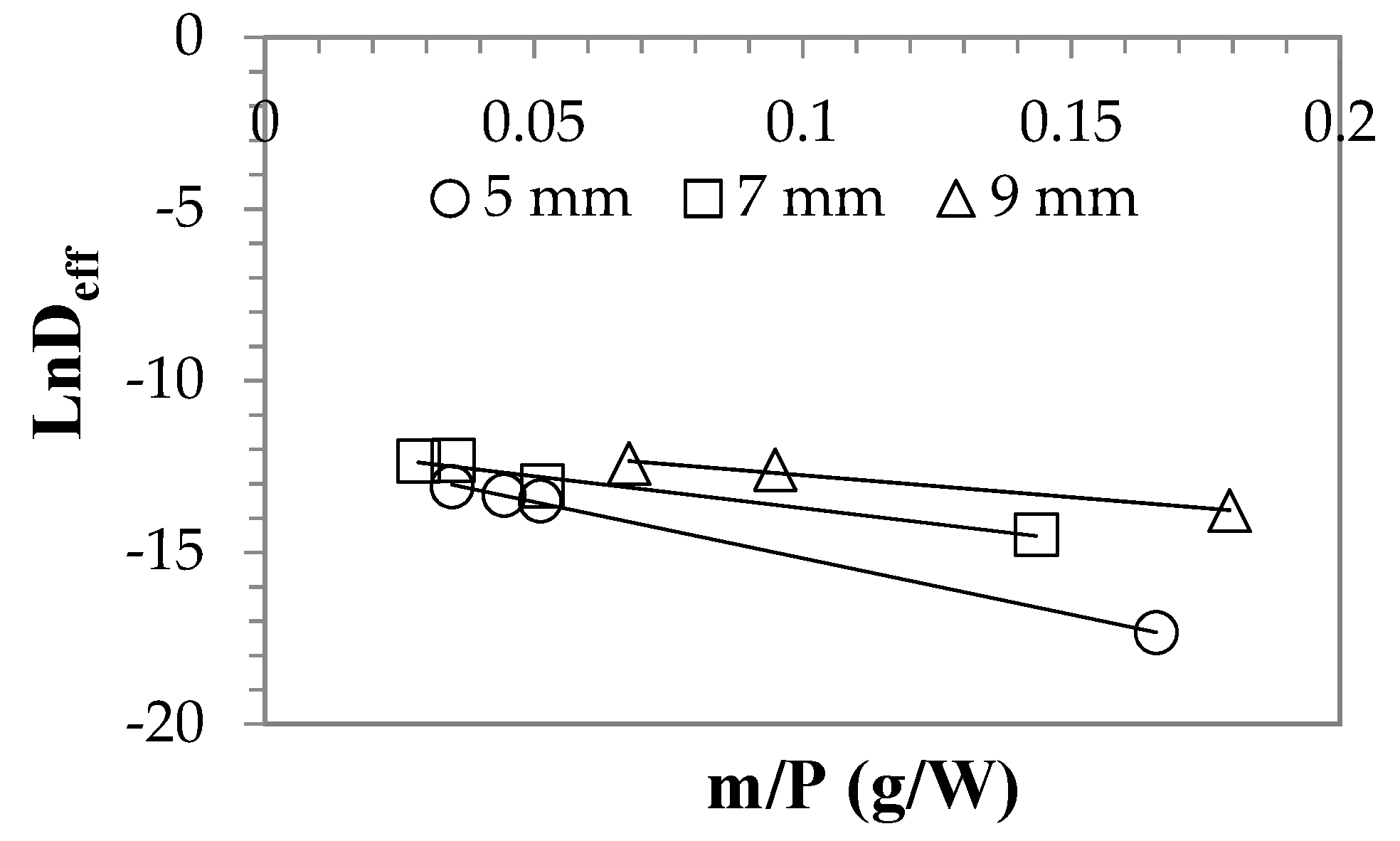

3.2. Determination of Effective Diffusivity and Activation Energy

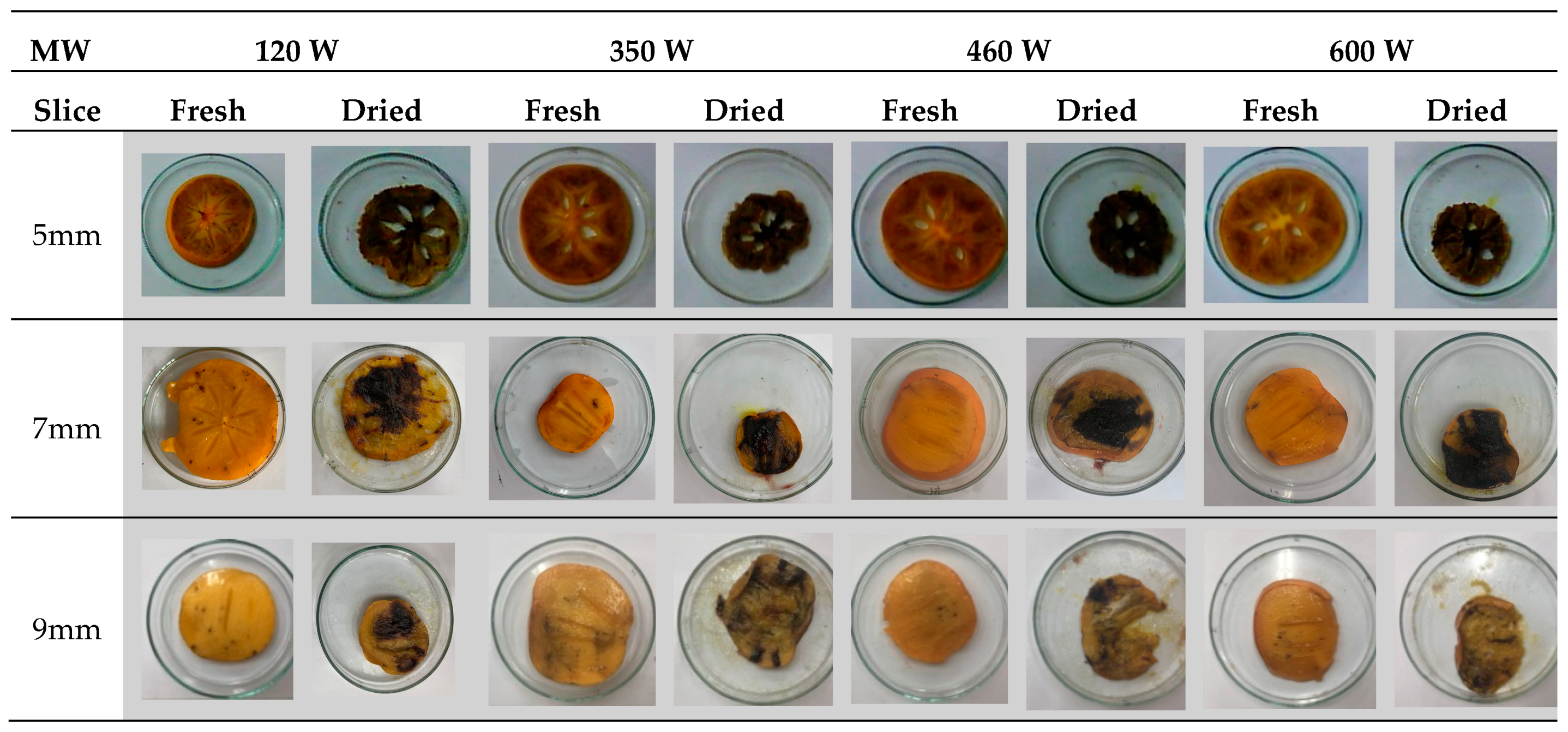

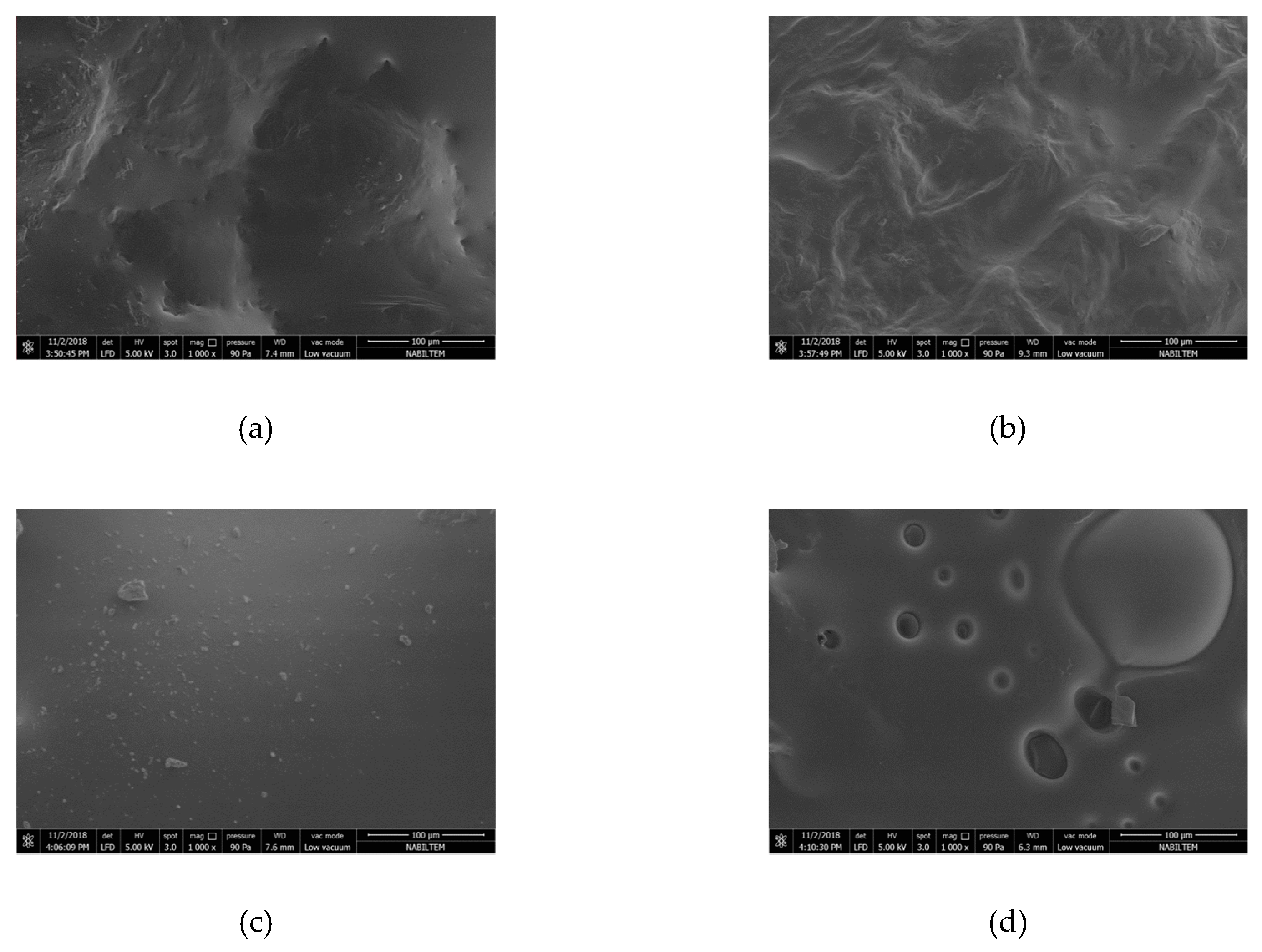

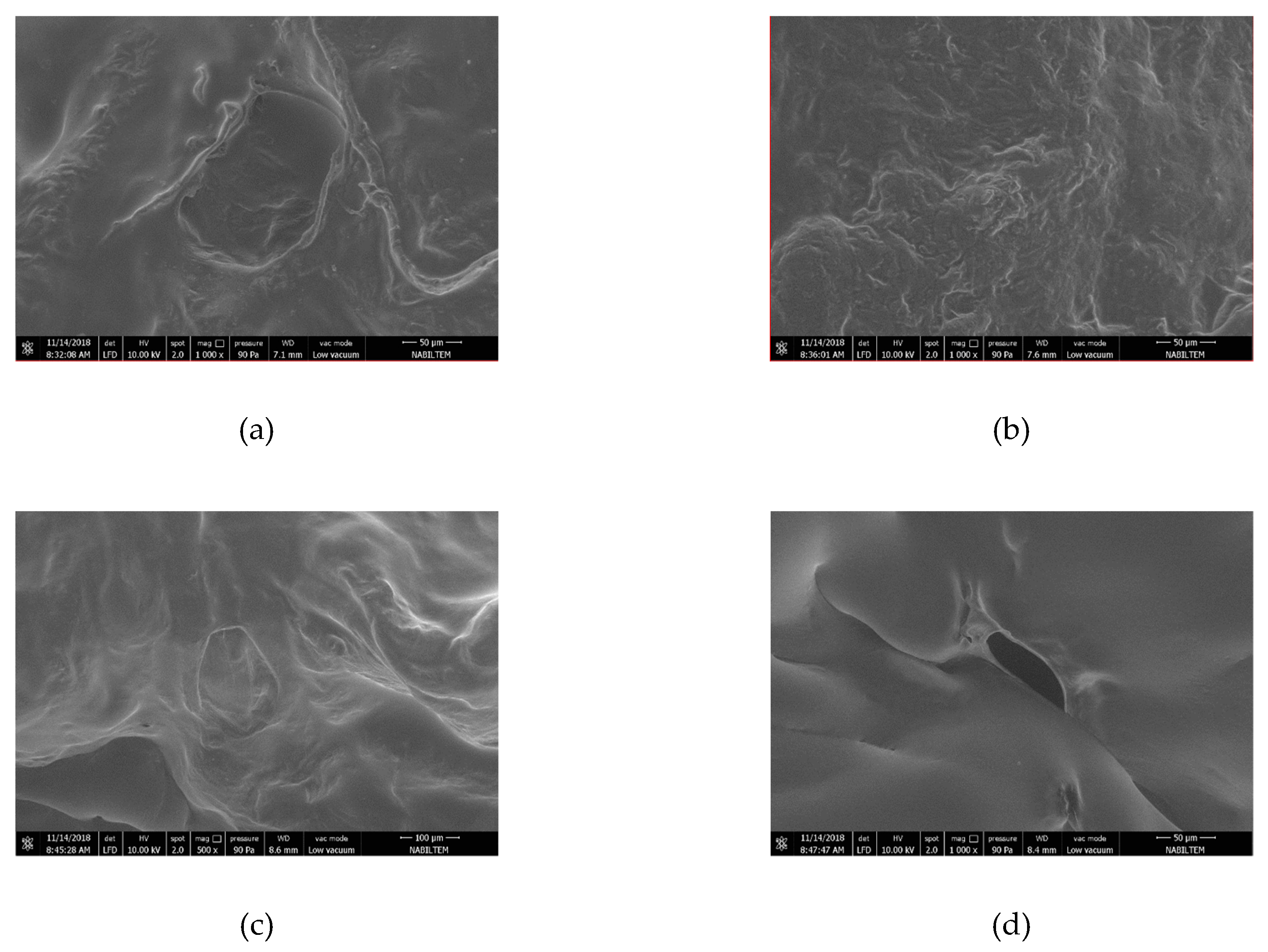

3.3. Color and SEM Analysis

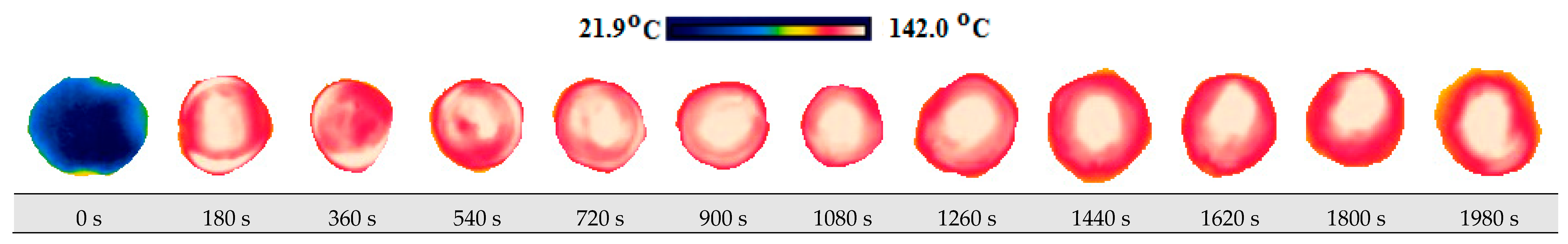

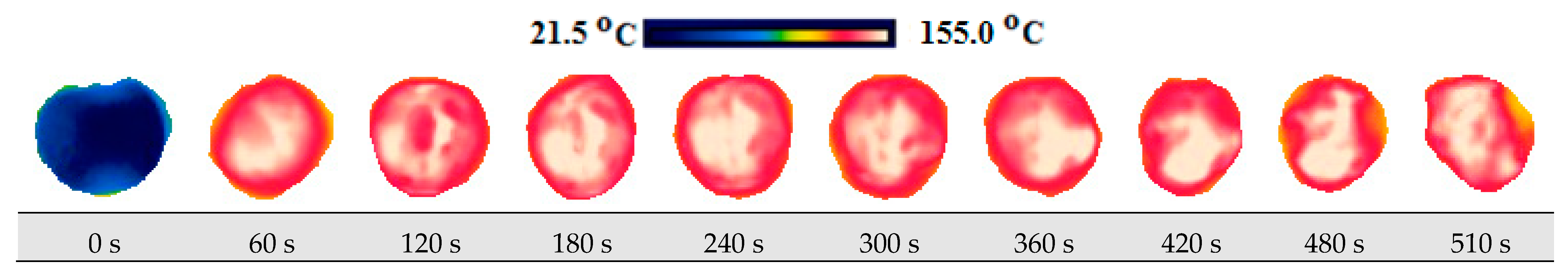

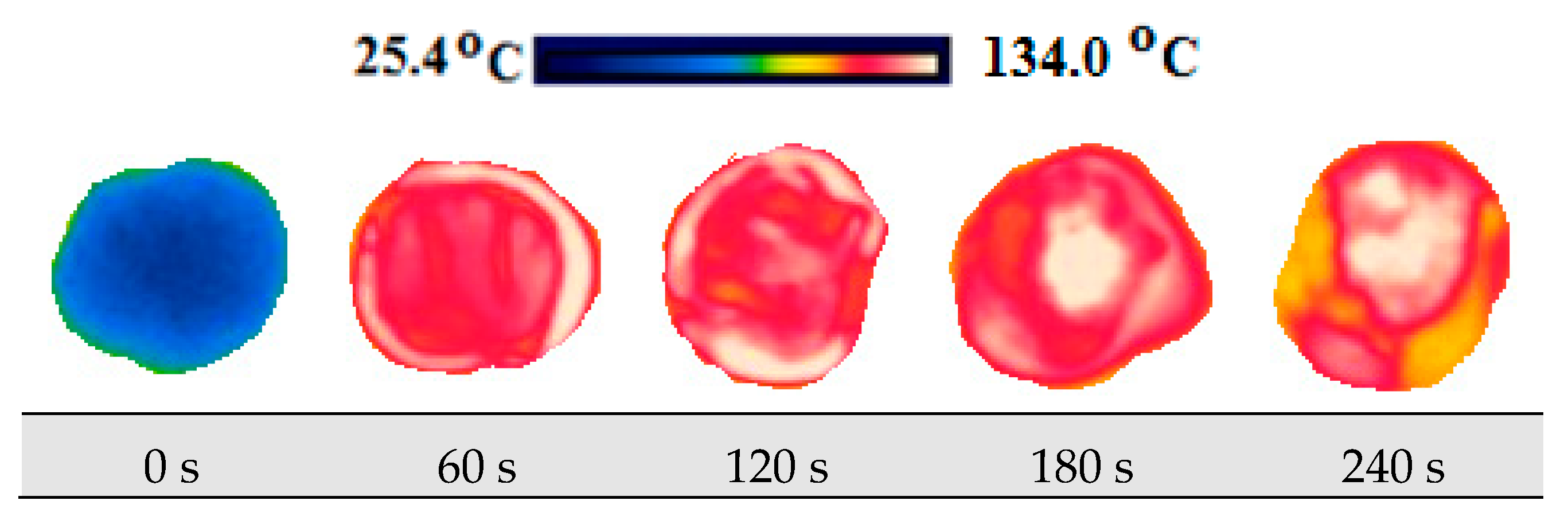

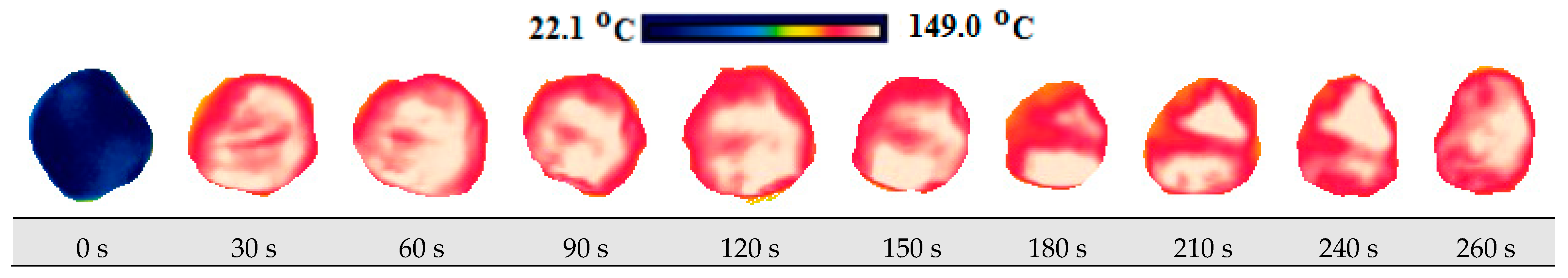

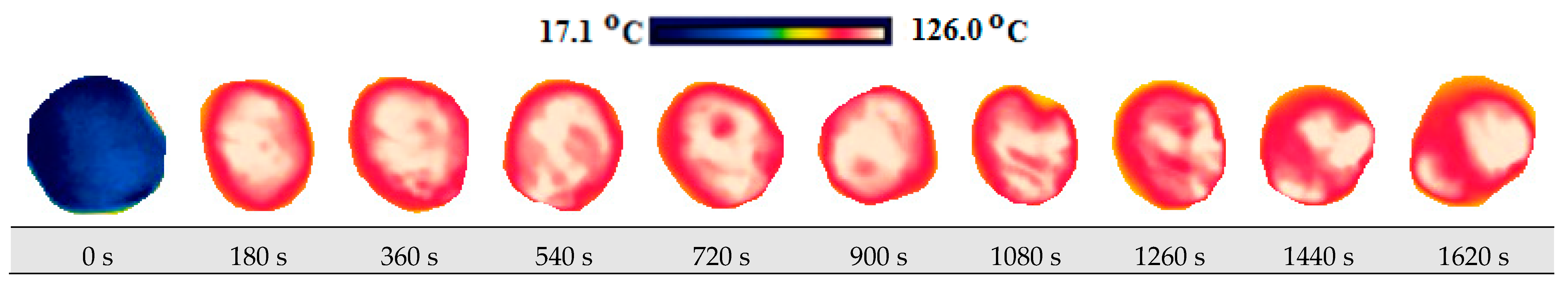

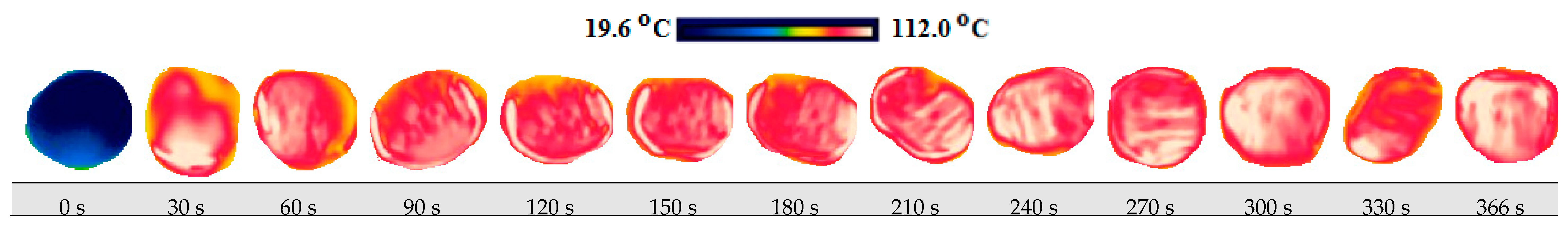

3.4. Thermal Images and Temperature Measurements

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Karakasova, L.; Babanovska-Milenkovska, F.; Lazov, M.; Karakasova, B.; Stojanova, M. Quality proparties of solar dried persimmon (Diospyros kaki). J. Hyg. Eng. Des. 2013, 4, 54–59. [Google Scholar]

- Tülek, Y.; Demiray, E. Effect of hot air drying and different pretreatments on color and drying characteristics of persimmons. J. Agric. Sci. 2014, 20, 27–37. [Google Scholar]

- Bölek, S.; Obuz, E. Quality characteristics of Trabzon persimmon dried at several temperatures and pretreated by different methods. Turk. J. Agric. For. 2014, 38, 242–249. [Google Scholar] [CrossRef]

- Kaya, A.; Kamer, M.S.; Şahin, H.E. Experimental investigation of drying kinetics of Trabzon persimmon (Diospyros kaki L.). J. Food. 2015, 40, 15–21. [Google Scholar]

- Doymaz, İ. Evaluation of some thin-layer drying models of persimmon slices (Diospyros kaki L.). Energy Convers. Manag. 2012, 56, 199–205. [Google Scholar] [CrossRef]

- Hanif, M.; Khattak, M.K.; Rehman, M.U.; Ramzan, M.; Amin, M.; Aamir, M.; Sheikh, S.; Hafizullah, S.; Khan, A.; Saeed, A.; et al. Effect of drying temperature and natural preservatives on reducing aflatoxins in solar dried persimmon (Diospyros kaki L.). Proc. Pak. Acad. Sci. 2015, 52, 361–365. [Google Scholar]

- Darıcı, S.; Şen, S. Kivi meyvesinin kurutulmasında kurutma havası hızının kurumaya etkisinin incelenmesi. Tesisat Mühendisliği 2012, 130, 51–58. (In Turkish) [Google Scholar]

- Adiletta, G.; Russo, P.; Proietti, N.; Capitani, D.; Mannina, L.; Crescitelli, A.; Di Matteo, M. Characterization of pears during drying by conventional technique and portable non invasive NMR. Chem. Eng. Trans. 2015, 44, 151–156. [Google Scholar]

- Alibas, I.; Köksal, N. Convective, vacuum and microwave drying kinetics of mallow leaves and comparison of color and ascorbic acid values of three drying methods. Food Sci. Technol. 2014, 34, 358–364. [Google Scholar] [CrossRef]

- Zorlugenç, F.K.; Fenercioğlu, H. The effect of osmo-convective dehydration on color characteristics of persimmon fruits. Çukurova Univ. Inst. Nat. Appl. Sci. 2012, 28, 149–159. [Google Scholar]

- Sorour, H.; El-Mesery, H. Effect of microwave and infrared radiation on drying of onion slices. Int. J. Appl. Res. 2014, 2, 119–130. [Google Scholar]

- Parlak, N. Investigation of drying kinetics of ginger in a fluidized bed dryer. J. Fac. Eng. Archit. Gazi Univ. 2014, 29, 261–269. [Google Scholar]

- Kutlu, N.; İşçi, A. Effect of different drying methods on drying characteristics of eggplant slices and mathematical modeling of drying processes. Acad. Food J. 2016, 14, 21–27. [Google Scholar]

- Yan, W.-Q.; Zhang, M.; Huang, L.-L.; Tang, J.; Mujumdar, A.S.; Sun, J.-C. Studies on different combined microwave drying of carrot pieces. Int. J. Food Sci. Technol. 2010, 45, 2141–2148. [Google Scholar] [CrossRef]

- Bettega, R.; Rosa, J.G.; Correa, R.G.; Freire, T. Comparison of carrot (Daucus Carota) drying in microwave and in vacuum microwave. Braz. J. Chem. Eng. 2014, 31, 403–412. [Google Scholar] [CrossRef]

- Karaaslan, S.; Tunçer, İ.K. Kırmızı biberin fan destekli mikrodalga ile kurutulmasında kuruma karakteristiklerinin incelenmesi ve uygun kuruma modelinin belirlenmesi. J. Agric. Nat. 2009, 12, 9–16. (In Turkish) [Google Scholar]

- Eren, Ö.; Soysal, Y.; Öztekin, S.; Doğantan, Z.S. Mikrodalga sistemi ile donatılmış bir bantlı kurutucuda maydanoz kurutulması, III. In Proceedings of the Tarımsal Ürünleri Kurutma Tekniği Çalıştayı, Antalya, Türkiye, 2–4 May 2005. (In Turkish). [Google Scholar]

- Maskan, M. Microwave/air and microwave finish drying of banana. J. Food Eng. 2000, 44, 71–78. [Google Scholar] [CrossRef]

- Roberts, J.S.; Kidd, D.R.; Padilla-Zakour, O. Drying kinetics of grape seeds. J. Food Eng. 2008, 89, 460–465. [Google Scholar] [CrossRef]

- Göztok, S.P.; İçier, F. Investigation of drying of apple slices in carbon fiber assisted cabin dryer at different temperatures: Drying Characteristics and Performance Evaluation. Acad. Food J. 2017, 15, 355–367. [Google Scholar]

- Yağcıoğlu, A.; Demir, V.; Günhan, T. Drying of apple slices (var, Golab) and effect on moisture diffusivity and activation energy. Tarım Makinaları Bilimi Dergisi 2007, 3, 249–256. [Google Scholar]

- Meisami-asl, E.; Rafiee, S.; Keyhani, A.; Tabatabaeefar, A. Drying of apple slices (var, Golab) and effect on moisture diffusivity and activation energy. Plant Omics 2010, 3, 97–102. [Google Scholar]

- Darvishi, H. Mathematical modeling, moisture diffusion and energy consumption in thin layer drying of Alfalfa. Middle-East J. Sci. 2012, 12, 511–516. [Google Scholar]

- Abolhasani, M.; Ansarifar, M. Study of drying characteristics and energy efficiency on white mulberry under microwave oven. JLS 2015, 5, 1515–1521. [Google Scholar]

- Aghbashlo, M.; Kianmehr, M.H.; Arabhosseini, A.; Nazghelichi, T. Modelling the carrot thin-layer drying in a semi-industrial continuous band dryer. Czech J. Food Sci. 2011, 29, 528–538. [Google Scholar] [CrossRef]

- Arslan, D.; Özcan, M.M. Study the effect of sun, oven and microwave drying on quality of onion slices. LWT-Food Sci. Technol. 2010, 43, 1121–1127. [Google Scholar] [CrossRef]

- Çelen, S.; Haksever, A.; Moralar, A. Investigation of drying kinetics of zucchini using microwave energy. Çukurova Univ. Inst. Nat. Appl. Sci. 2017, 32, 107–120. [Google Scholar]

- Yoğurtçu, H. Yanıt yüzey metodu kullanarak mikrodalga ile elma kurutmanın optimizasyonu. J. Fac. Eng. Archit. Gazi Univ. 2018. [Google Scholar] [CrossRef]

- Özbek, B.; Dadali, G. Thin-layer drying characteristics and modelling of mint leaves undergoing microwave treatment. J. Food Process. 2007, 83, 541–549. [Google Scholar] [CrossRef]

- Sobral, P.J.A.; Telis, V.R.N.; Habitante, A.M.Q.B.; Sereno, A. Phase diagram for freeze-dried persimmon. Thermochim. Acta 2001, 376, 83–89. [Google Scholar] [CrossRef]

- Yuenyongputtakal, W.; Wuttijumnong, P.; Niranjan, K. Combined osmotic and microwave-vacuum dehydration of persimmon (Diospyros kaki). Kasetsart J. Nat. Sci. 2006, 40, 680–687. [Google Scholar]

- Perez-Burillo, S.; Oliveras, M.J.; Quesada, J.; Rufian-Henares, J.A.; Pastoriza, S. Relationship between composition and bioactivity of persimmon and kiwifruit. Food Res. Int. 2018, 105, 461–472. [Google Scholar] [CrossRef] [PubMed]

- Qi, T.; Liu, X.; Zhang, Q.; Wu, H.; Yan, D.; Liu, Y.; Zhu, X.; Ren, X.; Yang, Y. Carotenoid accumulation and gene expression in fruit skins of three differently colored persimmon cultivars during fruit growth and ripening. Sci. Hortic. 2019, 248, 282–290. [Google Scholar] [CrossRef]

- Martinez-Las Heras, A.; Heredia, A.; Castello, M.L.; Andres, A. Moisture sorption isotherms and isosteric heat of sorption of dry persimmon leaves. Food Biosci. 2014, 7, 88–94. [Google Scholar] [CrossRef]

- Hongti, W.; Peng, L.; Kangquan, G. Mathematical modeling of microwave drying of crashed cotton stalks for man-made composite material. Int. J. Agric. Biol. Eng. 2016, 9, 171–178. [Google Scholar]

- Su, Y.; Zhang, M.; Adhikari, B.; Mujumdar, A.S.; Zhang, W. Improving the energy efficiency and the quality of fried products using a novel vacuum frying assisted by combined ultrasound and microwave technology. Innov. Food Sci. Emerg. Technol. 2018, 50, 148–159. [Google Scholar] [CrossRef]

- Mengeş, H.O.; Ertekin, C. Investigation of drying characteristics fort thin layer drying of carrot. J. Agric. Sci. 2006, 2, 353–362. [Google Scholar]

- Zarein, M.; Samadi, S.H.; Ghobadian, B. Investigation of microwave dryer effect on energy efficiency during drying of apple slices. J. Saudi Soc. Agric. Sci. 2015, 14, 41–47. [Google Scholar] [CrossRef]

- Darvishi, H.; Khoshyaghaza, M.H.; Najafi, G.; Nargesi, F. Mathematical modeling of green pepper drying in microwave-convective dryer. J. Agric. Sci. Technol. 2013, 15, 457–465. [Google Scholar]

- Workneh, T.S.; Raghavan, V.; Gariepy, Y. Microwave assisted hot air ventilation drying of tomato slices. In Proceedings of the International Conference on Food Engineering and Biotechnology, Singapoore, 27–30 September 2011. [Google Scholar]

- Chahbani, A.; Fakhfakh, N.; Balti, M.A.; Mabrouk, M.; El-Hatmi, H.; Zouari, N.; Kechaou, N. Microwave drying effects on drying kinetics, bioactive compounds and antioxidant activity of green peas (Pisum sativum L.). Food Biosci. 2018, 25, 32–38. [Google Scholar] [CrossRef]

- Demirel, F.M.; Ismail, O. Investigation of the effect of a hybrid drying method on the color quality of nectarine. Studia Universitatis Babes-Bolyai Chemia 2017, 62, 237–248. [Google Scholar] [CrossRef]

- Dong, W.; Cheng, K.; Hu, R.; Chu, Z.; Zhao, J.; Long, Y. Effect of microwave vacuum drying on the drying characteristics, color, microstructure, and antioxidant activity of green coffee beans. Molecules 2018, 23, 1146. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Zhang, M.; Adhikari, B.; Yang, Z. Effect of microwave air spouted drying arranged in two and three-stages on the drying uniformity and quality of dehydrated carrot cubes. J. Food Process. Eng. 2016, 177, 80–89. [Google Scholar] [CrossRef]

| Drying Type | Drying Time | References |

|---|---|---|

| microwave drying | 3.57–28.5 min | this study |

| solar drying | 16–22 h | [6] |

| convective drying | 15–40 h | [4] |

| MWP (W) | Deff (m2 s−1) | ||

|---|---|---|---|

| 5 mm | 7 mm | 9 mm | |

| 120 | 2.97 × 10−8 | 5.15 × 10−7 | 1.03 × 10−6 |

| 350 | 1.37 × 10−6 | 2.12 × 10−6 | 3.39 × 10−6 |

| 460 | 1.63 × 10−6 | 4.36 × 10−6 | 4.10 × 10−6 |

| 600 | 2.07 × 10−6 | 4.47 × 10−6 | 4.63 × 10−6 |

| Ea (W g−1) | 32.82 | 18.64 | 12.80 |

| Slice | Parameters | 120 W | 350 W | 460 W | 600 W |

|---|---|---|---|---|---|

| 5 mm | ΔL | 33.53 | 23.83 | 14.91 | 16.72 |

| ΔE | 46.09 | 34.19 | 20.28 | 29.64 | |

| 7 mm | ΔL | 28.49 | 22.19 | 28.30 | 16.36 |

| ΔE | 47.63 | 29.91 | 49.26 | 25.14 | |

| 9 mm | ΔL | 17.25 | 21.56 | 21.33 | 13.25 |

| ΔE | 17.53 | 28.84 | 29.34 | 24.32 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Çelen, S. Effect of Microwave Drying on the Drying Characteristics, Color, Microstructure, and Thermal Properties of Trabzon Persimmon. Foods 2019, 8, 84. https://doi.org/10.3390/foods8020084

Çelen S. Effect of Microwave Drying on the Drying Characteristics, Color, Microstructure, and Thermal Properties of Trabzon Persimmon. Foods. 2019; 8(2):84. https://doi.org/10.3390/foods8020084

Chicago/Turabian StyleÇelen, Soner. 2019. "Effect of Microwave Drying on the Drying Characteristics, Color, Microstructure, and Thermal Properties of Trabzon Persimmon" Foods 8, no. 2: 84. https://doi.org/10.3390/foods8020084

APA StyleÇelen, S. (2019). Effect of Microwave Drying on the Drying Characteristics, Color, Microstructure, and Thermal Properties of Trabzon Persimmon. Foods, 8(2), 84. https://doi.org/10.3390/foods8020084