Effect of Drying Methods on Aroma Profiling of Large-Leaf Green Tea (Camellia sinensis var. Assamica) Determined by HS-SPME-GC-MS

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experiment Methods

2.2.1. Sensory Evaluation and Quantitative Descriptive Analysis (QDA)

2.2.2. Determination of Volatile Components Content by HS-SPME-GC-MS

2.2.3. Quantification of Volatile Components and Odor Activity Values (OAVs)

2.2.4. Data Analysis

3. Results and Discussion

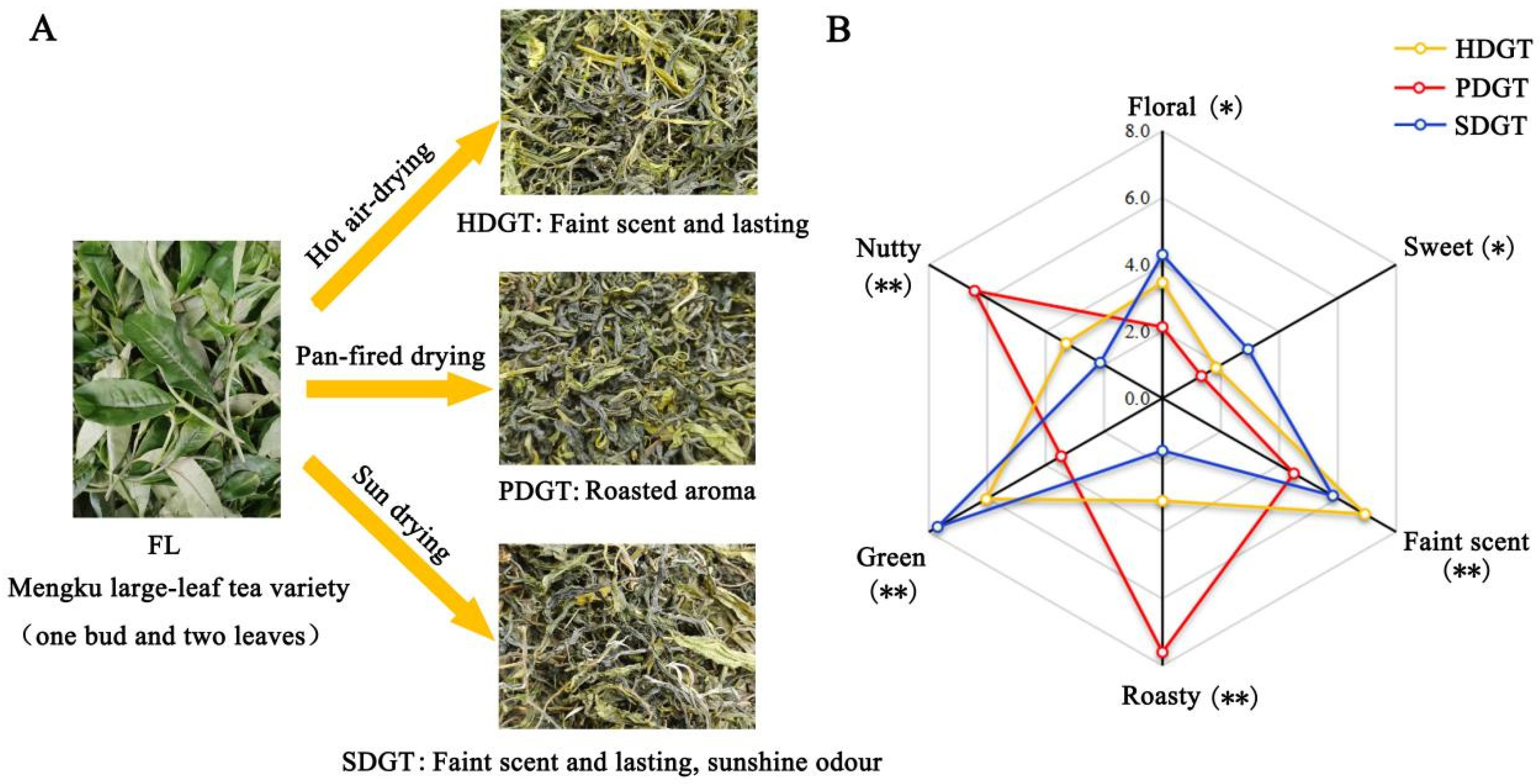

3.1. Sensory Evaluation of Aroma in Large-Leaf Green Tea Under Different Drying Methods

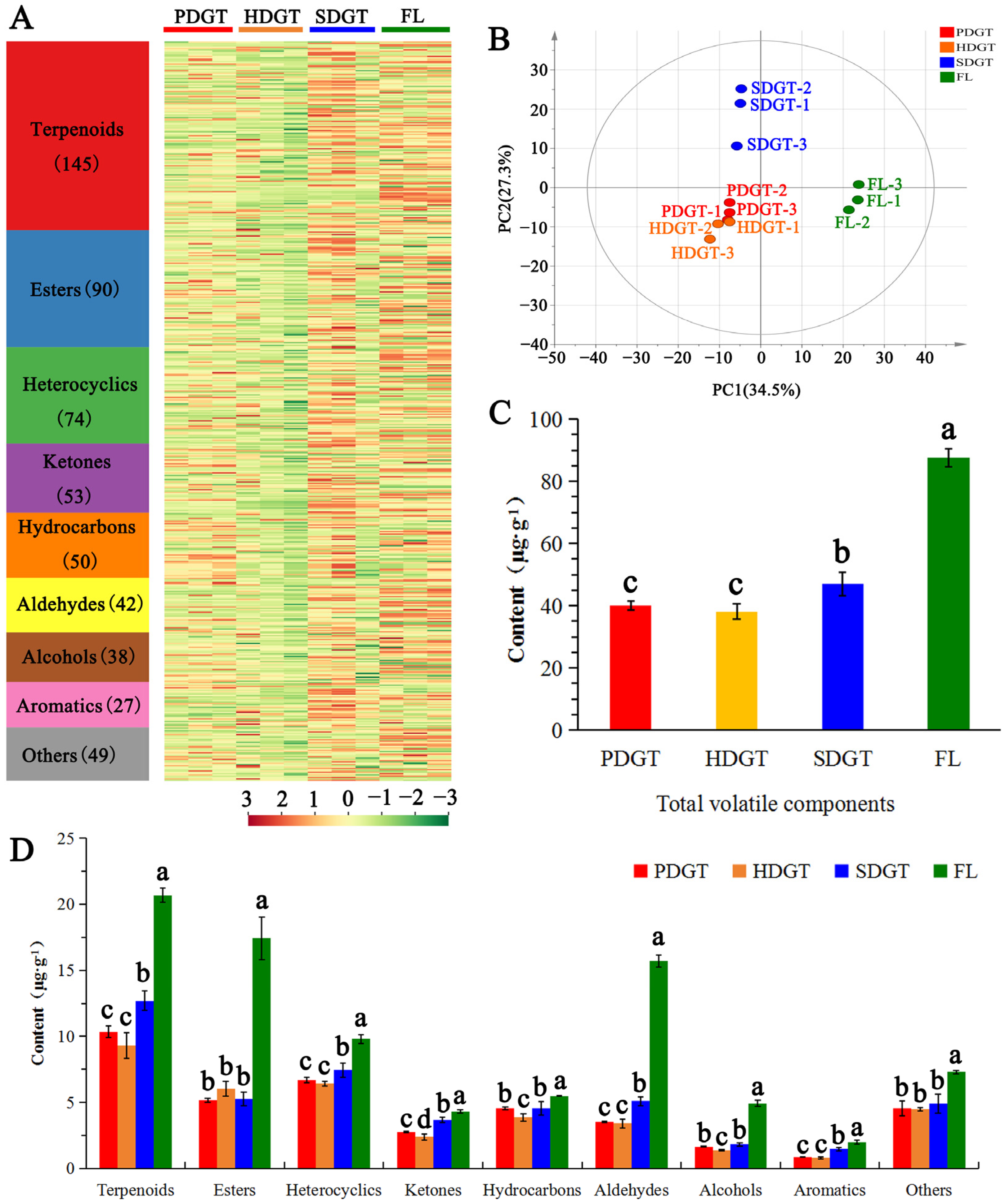

3.2. Analysis of Volatile Components Profile in Large-Leaf Green Tea Under Different Drying Methods

3.3. Analysis of Differential Volatile Components in Large-Leaf Green Tea Under Different Drying Methods

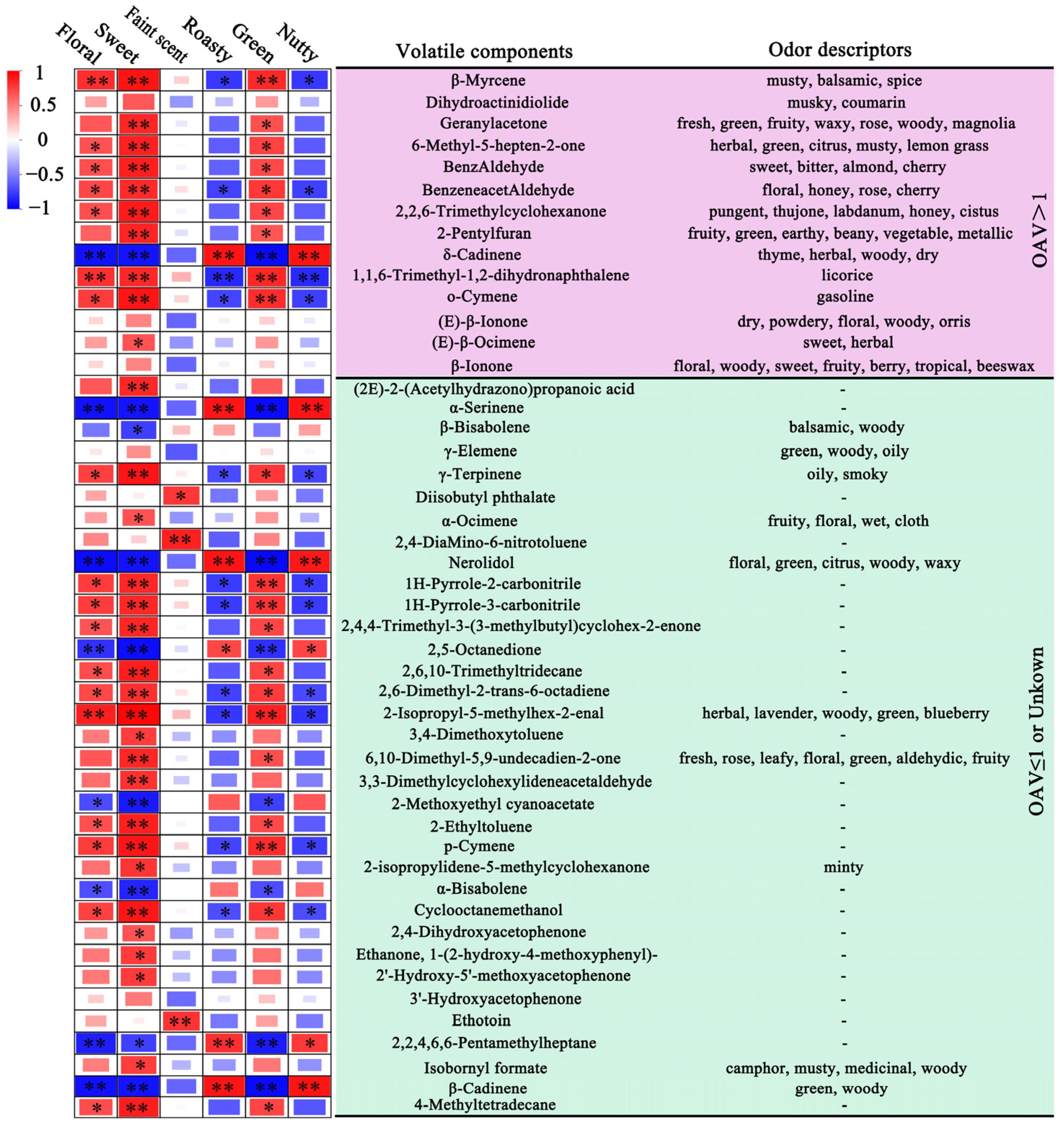

3.4. Analysis of OAVs of Differential Volatile Components in Large-Leaf Green Tea Under Different Drying Methods

3.5. Correlation Analysis of Differential Volatile Components and Main Aroma Types

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.; Chen, Q.; Zhang, C.; Ni, L. Comparative study of the anti-obesity and gut microbiota modulation effects of green tea phenolics and their oxidation products in high-fat-induced obese mice. Food Chem. 2021, 367, 130735. [Google Scholar] [PubMed]

- Liu, N.; Shen, S.; Huang, L.; Deng, G.; Wei, Y.; Ning, J.; Wang, Y. Revelation of volatile contributions in green teas with different aroma types by GC–MS and GC–IMS. Food Res. Int. 2023, 169, 112845. [Google Scholar]

- Yang, Z.; Baldermann, S.; Watanabe, N. Recent studies of the volatile compounds in tea. Food Res. Int. 2013, 53, 585–599. [Google Scholar]

- Wan, X. Tea Biochemistry, 3rd ed.; China Agriculture Press: Beijing, China, 2003. (In Chinese) [Google Scholar]

- Kumar, K.R.; Dashora, K.; Kumar, S.; Dharmaraja, S.; Sanyal, S.; Aditya, K.; Kumar, R. A review of drying technology in tea sector of industrial, non-conventional and renewable energy based drying systems. Appl. Therm. Eng. 2023, 224, 120118. [Google Scholar]

- Teshome, K.; Debela, A.; Garedew, W. Effect of drying temperature and duration on biochemical composition and quality of black tea (Camellia sinensis L.) O. Kuntze at Wush Wush, South Western Ethiopia. Asian J. Plant Sci. 2014, 12, 235–240. [Google Scholar]

- Wang, B.; Qu, F.; Wang, P.; Zhao, L.; Wang, Z.; Han, Y.; Zhang, X. Characterization analysis of flavor compounds in green teas at different drying temperature. LWT 2022, 161, 113394. [Google Scholar]

- Chen, Z.; Li, Z.; Zhao, Y.; Zhu, M.; Li, J.; Wang, K. A meta-analysis of dynamic changes of key aroma compounds during black tea processing. Food Biosci. 2024, 58, 103784. [Google Scholar]

- Han, Z.; Rana, M.; Liu, G.; Gao, M.; Li, D.; Wu, F.; Li, X.; Wan, X.; Wei, S. Green tea flavour determinants and their changes over manufacturing processes. Food Chem. 2016, 212, 739–748. [Google Scholar]

- Yang, R.; Ye, C.; Xu, J.; Jiang, Y. Simultaneous analysis of purine alkaloids and catechins in Camellia sinensis, Camellia ptilophylla and Camellia assamica var. kucha by HPLC. Food Chem. 2007, 100, 1132–1136. [Google Scholar]

- Liu, B.; Wang, L.; Zhou, J.; Tang, Y.; Cheng, H.; Wang, P.; Jiang, Y. Fingerprinting construction and genetic diversity analysis of Yunnan Dayezhong tea germplasm resources by ISSR markers. J. Plant Genet. Res. 2008, 9, 458–464. [Google Scholar]

- Liu, F.; Wang, Y.; Li, C.; Wang, X.; Tang, X.; Li, T. Research status and prospect of tea drying technology. Chin. Agric. Sci. Bull. 2015, 31, 210–215. [Google Scholar]

- Lv, H.; Zhang, Y.; Lin, Z.; Liang, Y. Processing and chemical constituents of Pu-erh tea: A review. Food Res. Int. 2013, 53, 608–618. [Google Scholar] [CrossRef]

- Lu, M.; Jiang, Y.; Zhao, W.; Zhang, J.; Chen, Z.; Ning, J. Effects of different drying methods on color difference, taste and chemical components of Yunnan Congou black tea. LWT 2025, 223, 117696. [Google Scholar] [CrossRef]

- Liu, B.; Chen, X.; Wu, X.; Zhang, W.; Wang, Z. Study of Pu’er raw materials grade classification by PCA and PLS-DA. J. Tea Sci. 2015, 35, 179–184. [Google Scholar]

- Tu, Z.; Liu, Y.; Lin, J.; Lv, H.; Zhou, W.; Zhou, X.; Qian, Y.; Zeng, X.; He, W.; Ye, Y. Comparison of volatile and nonvolatile metabolites in green tea under hot-air drying and four heat-conduction drying patterns using widely targeted metabolomics. Food Chem. X 2023, 19, 100767. [Google Scholar] [CrossRef]

- Yang, Y.; Kun, J.; Dai, H.; Tong, H. Changes in aroma compounds and selected precursors of sun-dried green tea during processing. Food Sci. 2024, 45, 133–142. [Google Scholar]

- Li, N.; Yao, Z.; Ning, J.; Sun, L.; Lin, Q.; Zhu, X.; Li, C.; Zheng, X.; Jin, J. Comparison of different drying technologies for green tea: Changes in color, non-volatile and volatile compounds. Food Chem. X 2024, 24, 101935. [Google Scholar] [CrossRef]

- GB/T 23776-2018; Methodology for Sensory Evaluation of Tea. Chinese National Standard: Beijing, China, 2018.

- Yue, C.; Cao, H.; Zhang, S.; Hao, Z.; Wu, Z.; Luo, L.; Zeng, L. Aroma characteristics of Wuyi rock tea prepared from 16 different tea plant varieties. Food Chem. X 2023, 17, 100586. [Google Scholar]

- You, Q.; Shi, Y.; Zhu, Y.; Yang, G.; Yan, H.; Lin, Z.; Lv, H. Effect of different processing technologies on the key aroma-active compounds of green tea. Food Sci. 2023, 44, 194–200. [Google Scholar]

- Lu, M.; Sheng, C.; Ke, H.; Li, T.; Liu, Q.; Zhang, J.; Li, L.; Wang, Y.; Ning, J. Revealing the differences in aroma of black tea under different drying methods based on GC–MS, GC-O. Food Chem. X 2024, 24, 101782. [Google Scholar] [CrossRef]

- Zhang, L.; Cao, S.; Ren, G.; Duan, X. The volatile compounds changes of Malus asiatica nakai under different drying methods. J. Future Foods 2025, 5, 276–282. [Google Scholar] [CrossRef]

- Liu, M.; Hu, L.; Deng, N.; Cai, Y.; Li, H.; Zhang, B.; Wang, J. Effects of different hot-air drying methods on the dynamic changes in color, nutrient and aroma quality of three chili pepper (Capsicum annuum L.) varieties. Food Chem. X 2024, 22, 101262. [Google Scholar]

- Zhu, J.; Niu, Y.; Xiao, Z. Characterization of the key aroma compounds in Laoshan green teas by application of odour activity value (OAV), gas chromatography-mass spectrometry-olfactometry (GC-MS-O) and comprehensive two-dimensional gas chromatography mass spectrometry (GC×GC-qMS). Food Chem. 2021, 339, 128136. [Google Scholar]

- Yang, Y.; Ai, L.; Mu, Z.; Liu, H.; Yan, X.; Ni, L.; Zhang, H.; Xia, Y. Flavor compounds with high odor activity values (OAV>1) dominate the aroma of aged Chinese rice wine (Huangjiu) by molecular association. Food Chem. 2022, 383, 132370. [Google Scholar] [CrossRef] [PubMed]

- Gemert, L. Odour Thresholds: Compilations of Odour Threshold Values in Air, Water and Other Media; Oliemans Punter & Partners BV: Zeist, The Netherlands, 2011. [Google Scholar]

- Cui, J.; Zhai, X.; Guo, D.; Du, W.; Gao, T.; Zhou, J.; Schwab, W.; Song, C. Characterization of key odorants in Xinyang Maojian green tea and their changes during the manufacturing process. J. Agric. Food Chem. 2022, 70, 279–288. [Google Scholar]

- Gan, S.; Chen, Y.; Zhao, L.; Zhao, X.; Qisu, T.; Zhai, X.; Dai, Q. Characterization of the aroma-active compounds in Xiaokeng green tea by three pretreatment methods combined with gas chromatography-olfactometry (GC-O). Food Res. Int. 2024, 187, 114359. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Ouyang, W.; Yu, Y.; Wang, J.; Yuan, H.; Hua, J.; Jiang, Y. Analysis of non-volatile and volatile metabolites reveals the influence of second-drying heat transfer methods on green tea quality. Food Chem. X 2022, 14, 100354. [Google Scholar] [PubMed]

- Yang, Y.; Xie, J.; Wang, Q.; Deng, Y.; Zhu, L.; Zhu, J.; Yuan, H.; Jiang, Y. Understanding the dynamic changes of volatile and non-volatile metabolites in black tea during processing by integrated volatolomics and UHPLC-HRMS analysis. Food Chem. 2024, 432, 137124. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, F.; Wang, L.; Niu, Y.; Xiao, Z. Evaluation of the synergism among volatile compounds in oolong tea infusion by odour threshold with sensory analysis and E-nose. Food Chem. 2017, 221, 1484–1490. [Google Scholar]

- Hattori, S.; Akagaki, H.; Ujimori, T. Identification of volatile compounds which enhance odor notes in Japanese green tea using the OASIS (original aroma simultaneously input to the sniffing port) method. Food Sci. Technol. Res. 2005, 11, 171–174. [Google Scholar]

- Zhu, Y.; Lv, H.; Shao, C.; Kang, S.; Zhang, Y.; Guo, L.; Dai, W.; Tan, J.; Peng, Q.; Lin, Z. Identification of key odorants responsible for chestnut-like aroma quality of green teas. Food Res. Int. 2018, 108, 74–82. [Google Scholar] [CrossRef] [PubMed]

- Yin, P.; Xiao, Z.; Yu, F.; Guo, G. Research progress of chestnut-like aroma quality of green tea. Food Res. Dev. 2020, 3, 219–224. [Google Scholar]

| No. | Compounds | Threshold (ug·g−1) [21,22,23] | PDGT | HDGT | SDGT | Mean |

|---|---|---|---|---|---|---|

| 1 | β-Ionone | 0.000007 | 133,873.74 | 77,360.89 | 162,112.84 | 124,449.16 |

| 2 | (E)-β-Ionone | 0.0002 | 4685.58 | 2707.63 | 5673.95 | 4355.72 |

| 3 | 2,2,6-Trimethylcyclohexanone | 0.0001 | 745.71 | 454.17 | 3270.06 | 1489.98 |

| 4 | Dihydroactinidiolide | 0.0021 | 54.75 | 23.70 | 88.61 | 55.69 |

| 5 | BenzeneacetAldehyde | 0.0063 | 27.23 | 38.26 | 93.28 | 52.93 |

| 6 | 2-Pentylfuran | 0.006 | 15.10 | 10.30 | 38.19 | 21.20 |

| 7 | 1,1,6-Trimethyl-1,2-dihydronaphthalene | 0.0025 | 11.07 | 17.78 | 29.55 | 19.47 |

| 8 | δ-Cadinene | 0.0015 | 16.08 | 10.90 | 6.76 | 11.25 |

| 9 | β-Myrcene | 0.015 | 5.76 | 7.31 | 14.82 | 9.30 |

| 10 | Geranylacetone | 0.01 | 4.39 | 3.34 | 12.98 | 6.90 |

| 11 | o-Cymene | 0.01144 | 3.74 | 4.20 | 8.58 | 5.51 |

| 12 | 6-Methyl-5-hepten-2-one | 0.05 | 1.11 | 0.89 | 3.60 | 1.87 |

| 13 | (E)-β-Ocimene | 0.034 | 1.20 | 0.21 | 2.30 | 1.24 |

| 14 | BenzAldehyde | 0.35 | 0.42 | 0.36 | 1.01 | 0.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Z.; Ma, L.; Zhang, Y.; Liu, Y.; Yang, R.; Dai, X.; Wang, T.; Lv, C.; Zuo, L.; Liu, Y.; et al. Effect of Drying Methods on Aroma Profiling of Large-Leaf Green Tea (Camellia sinensis var. Assamica) Determined by HS-SPME-GC-MS. Foods 2025, 14, 1275. https://doi.org/10.3390/foods14071275

Luo Z, Ma L, Zhang Y, Liu Y, Yang R, Dai X, Wang T, Lv C, Zuo L, Liu Y, et al. Effect of Drying Methods on Aroma Profiling of Large-Leaf Green Tea (Camellia sinensis var. Assamica) Determined by HS-SPME-GC-MS. Foods. 2025; 14(7):1275. https://doi.org/10.3390/foods14071275

Chicago/Turabian StyleLuo, Zhengfei, Linlong Ma, Yangtao Zhang, Yanhong Liu, Rui Yang, Xuean Dai, Tiantian Wang, Changmi Lv, Lifeng Zuo, Yanli Liu, and et al. 2025. "Effect of Drying Methods on Aroma Profiling of Large-Leaf Green Tea (Camellia sinensis var. Assamica) Determined by HS-SPME-GC-MS" Foods 14, no. 7: 1275. https://doi.org/10.3390/foods14071275

APA StyleLuo, Z., Ma, L., Zhang, Y., Liu, Y., Yang, R., Dai, X., Wang, T., Lv, C., Zuo, L., Liu, Y., Cao, D., Yuan, H., Yu, L., & Jin, X. (2025). Effect of Drying Methods on Aroma Profiling of Large-Leaf Green Tea (Camellia sinensis var. Assamica) Determined by HS-SPME-GC-MS. Foods, 14(7), 1275. https://doi.org/10.3390/foods14071275