Sterilized Processed Cheese: Principles, Technological Aspects, and Properties: A Review

Abstract

1. Introduction

2. Sterilized Processed Cheese

2.1. Usage of Sterilized Processed Cheese

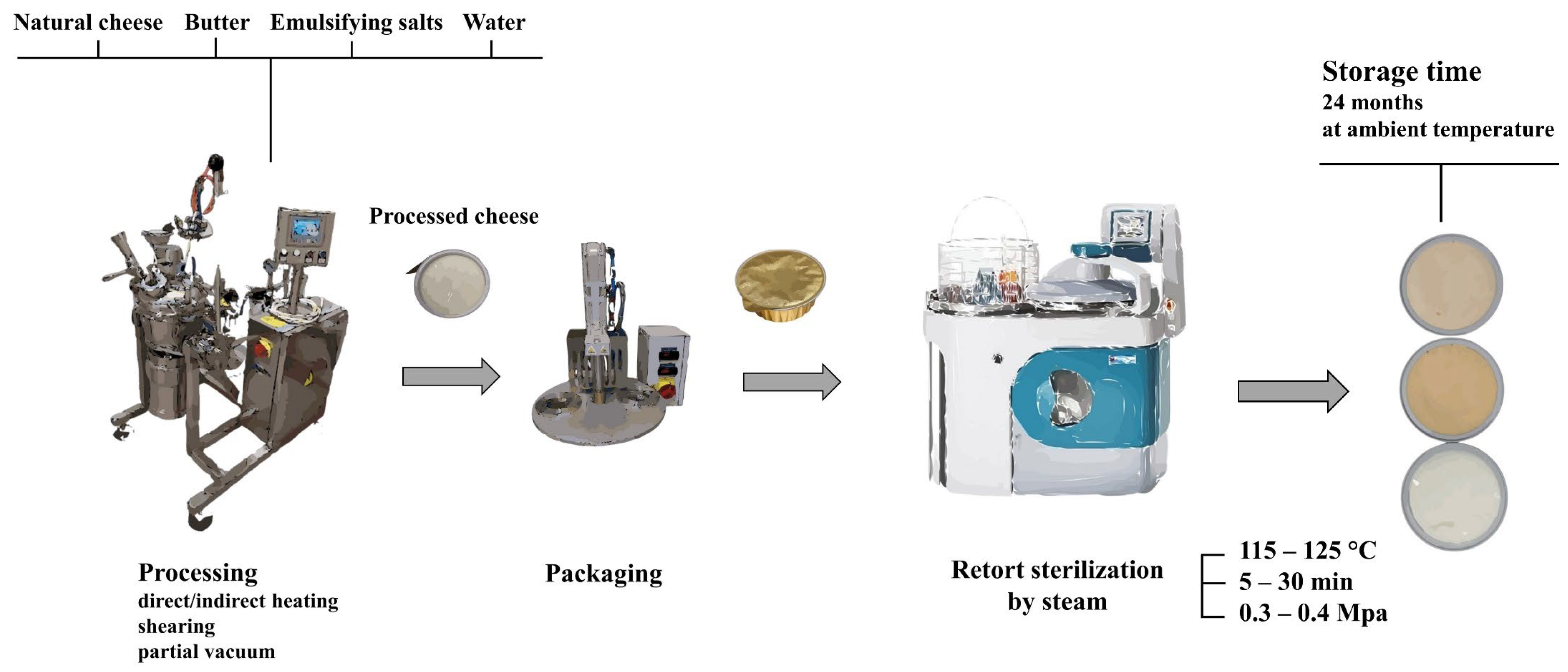

2.2. Production of Sterilized Processed Cheese

3. Principles of Sterilization

3.1. Types of Sterilization

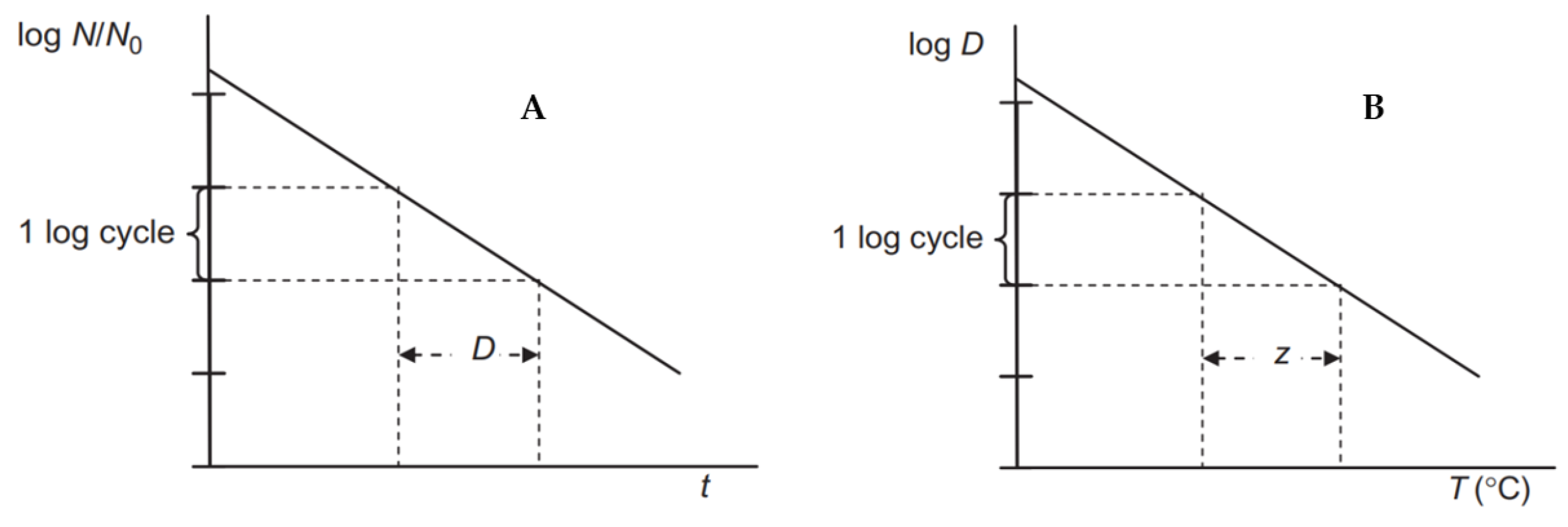

3.2. Microorganism Inactivation Kinetics

3.3. Setting Sterilization Limits

3.4. Setting Sterilization Parameters to Maximize Product Quality

4. The Effect of Sterilization and Long-Term Storage on the Quality of Sterilized Processed Cheese

4.1. Protein Changes

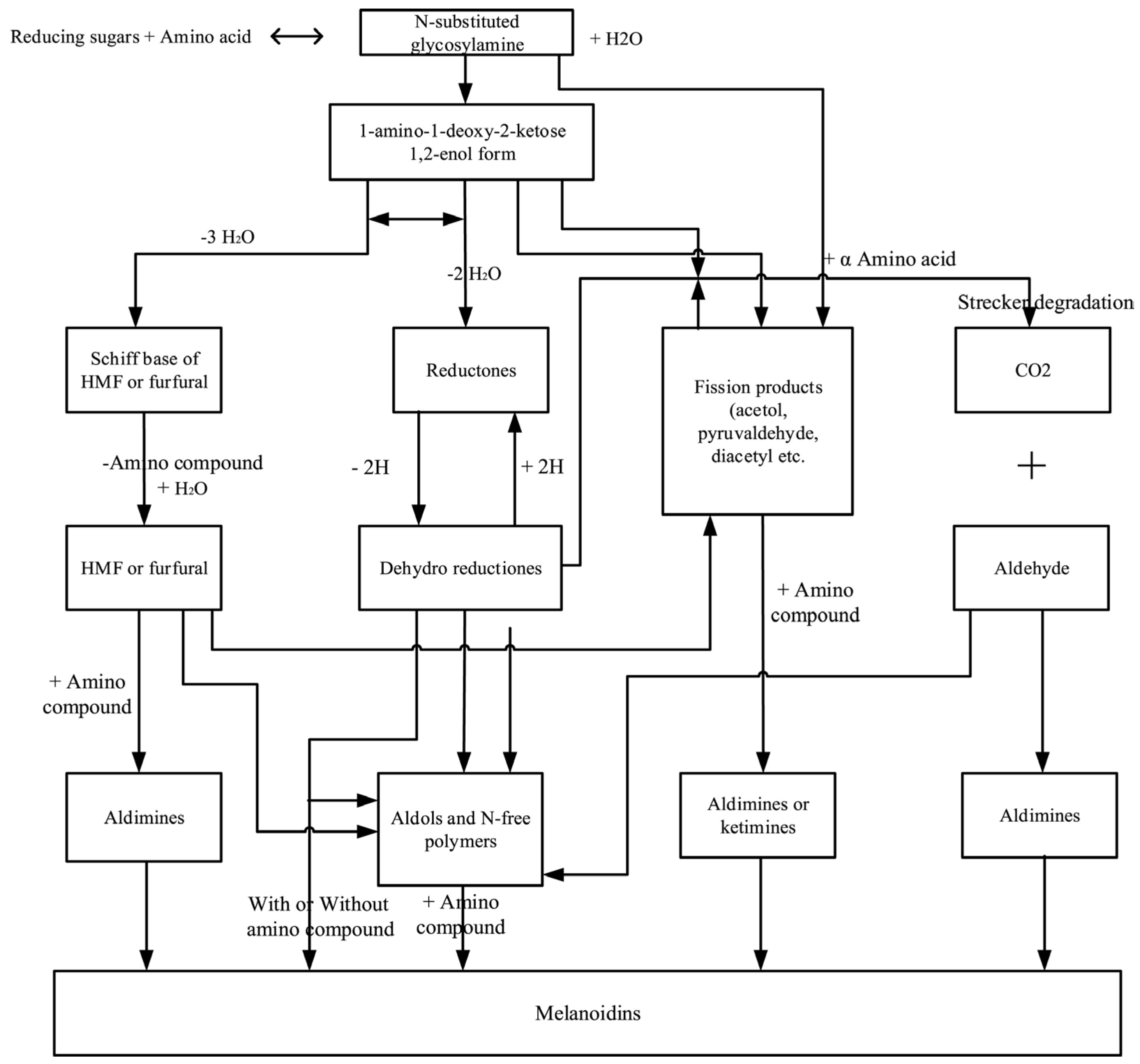

- -

- the initial phase represents the formation of glycosylamine followed by the Amadori shift (in the case of an aldose reaction) or the Heyns shift (in the case of a ketose reaction);

- -

- the intermediate phase involves dehydration and fragmentation of carbohydrates and Strecker degradation of amino acids;

- -

4.2. Lipid Changes

4.3. Saccharide Changes

4.4. Vitamin and Mineral Changes

5. Final Consideration and Recommendations

- -

- It has been verified that a lower sterilization temperature applied for an adequately longer period of time causes more significant changes in quality and can lead, in extreme cases, to unacceptable products. For the production of sterilized processed cheese, the highest sterilization temperature for the shortest possible time is recommended.

- -

- The high lactose content (mainly due to the inclusion of whey powder or milk powder in the raw material composition of processed cheeses to reduce production costs) leads to a more intense Maillard reaction complex. This results in more pronounced color changes (darkening) and the development of foreign tastes and odors. A limiting value for the lactose content to obtain acceptable products, 1% w/w, can be suggested.

- -

- Higher storage temperature and longer storage time lead to more significant changes in the quality of sterilized processed cheese, mainly due to more intense Maillard reaction complex and lipid oxidation reactions, which is reflected in a deterioration of both nutritional and sensory quality. Therefore, in order to maintain the highest possible quality, appropriate storage conditions (especially refrigerator temperatures or as shortest time at elevated temperatures as possible) should be considered.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AA | Amino acid |

| FA | Fatty acid |

| LOR | Lipid oxidation reaction |

| MO | Microorganism |

| MRC | Maillard reaction complex |

| PC | Processed cheese |

| SDS-PAGE | Sodium dodecyl sulfate polyacrylamide gel electrophoresis |

| SPC | Sterilized processed cheese |

| TBARS | Thiobarbituric acid reactive substances |

| UHT | Ultra-high temperature |

References

- Tamime, A.Y. Processed cheese and analogues: An overview. In Processed Cheese and Analogues; Tamime, A.Y., Ed.; Blackwell Publishing: Oxford, UK, 2011; pp. 1–24. [Google Scholar]

- Guinee, T.P. Pasteurized processed and imitation cheese products. In Cheese—Chemistry, Physics and Microbiology, 4th ed.; Mc. Sweeney, P.L.H., Fox, P.F., Cotter, P.D., Everett, D.W., Eds.; Academic Press: London, UK, 2017; pp. 1133–1184. [Google Scholar]

- Kapoor, R.; Metzger, L.E. Processed cheese: Scientific and technological aspects—A review. Compr. Rev. Food Sci. Food Saf. 2008, 7, 194–214. [Google Scholar] [CrossRef]

- Buňka, F.; Salek, R.N.; Kůrová, V.; Buňková, L.; Lorencová, E. The impact of phosphate- and citrate-based emulsifying salts on processed cheese techno-functional properties: A review. Int. Dairy J. 2024, 158, 106031. [Google Scholar] [CrossRef]

- Deshwal, G.K.; Gomez-Mascaraque, L.G.; Fenelon, M.; Huppertz, T. A review on the effect of calcium sequestering salts on casein micelles: From model milk protein systems to processed cheese. Molecules 2023, 28, 2085. [Google Scholar] [CrossRef]

- Regulation (EC) No 1333/2008 of the European Parliament and of the Council of 16 December 2008 on Food Additives. Available online: https://eur-lex.europa.eu/legal-content/CS/TXT/?uri=celex%3A32008R1333 (accessed on 3 February 2025).

- Schär, W.; Bosset, J.O. Chemical and physico-chemical changes in processed cheese and ready-made fondue during storage—A review. LWT 2002, 35, 15–20. [Google Scholar] [CrossRef]

- Buňka, F.; Sedlačík, M.; Foltin, P.; Lazárková, Z.; Pětová, M.; Buňková, L.; Purevdorj, K.; Talár, J.; Kůrová, V.; Novotný, M.; et al. Evaluation of processed cheese viscoelastic properties during sterilization observed in situ. J. Dairy Sci. 2023, 106, 5298–5308. [Google Scholar] [CrossRef]

- Jedounková, A.; Lazárková, Z.; Hampelová, L.; Kůrová, V.; Pospiech, M.; Buňková, L.; Foltin, P.; Salek, R.N.; Malíšek, J.; Michálek, J.; et al. Critical view on sterilisation effect on processed cheese properties designed for feeding support in crisis and emergency situations. LWT 2022, 171, 114135. [Google Scholar] [CrossRef]

- Yang, T.C.S. Thermal Processing of Rations. In Military Food Engineering and Ration Technology; Barret, A.H., Cardello, A.V., Eds.; DEStech Publications: Lancaster, PA, USA, 2012; pp. 41–67. [Google Scholar]

- Wang, W.Z.; Chen, H.M.; Ke, D.M.; Chen, W.X.; Zhong, Q.P.; Chen, W.J.; Yun, A.Y.H. Effect of sterilization and storage on volatile compounds, sensory properties and physicochemical properties of coconut milk. Microchem. J. 2020, 153, 104532. [Google Scholar] [CrossRef]

- Bubelová, Z.; Tremlová, B.; Buňková, L.; Pospiech, M.; Vítová, E.; Buňka, F. The effect of long-term storage on the quality of sterilized processed cheese. J. Food Sci. Technol. 2015, 52, 4985–4993. [Google Scholar] [CrossRef]

- Gliguem, H.; Birlouez-Aragon, I. Effects of sterilization, packaging, and storage on vitamin C degradation, protein denaturation, and glycation in fortified milks. J. Dairy Sci. 2005, 88, 891–899. [Google Scholar] [CrossRef]

- Tulach, P.; Foltin, P. Research methods in humanitarian logistics—Current approaches and future trends. In Proceedings of the 19th International Scientific Conference Business Logistics in Modern Management, Osijek, Croatia, 10–11 October 2019; Dujak, D., Ed.; Josip Juraj Strossmayer University of Osijek, Faculty of Economics: Osijek, Croatia, 2019; pp. 459–474. [Google Scholar]

- Pavlík, V.; Šafka, V. Nové balené potravinové dávky v Armádě České republiky. Mil. Med. Sci. Lett. 2022, 91, 79–80. [Google Scholar]

- STANAG 2937; Requirements of Individual Operational Rations for Military Use Version 5. NATO: Brussels, Belgium, 2019.

- AMedP-1.11; Requirements of Individual Operational Rations for Military Use; Edition B, Version 1; NATO: Brussels, Belgium, 2019.

- Foltin, P.; Brunclík, M.; Ondryhal, V.; Vogal, L. Usability of performance indicators of logistics infrastructure availability in supply chain designing. Bus. Log. Modern Manag. 2018, 18, 157–170. [Google Scholar]

- Lazárková, Z.; Buňka, F.; Buňková, L.; Valášek, P.; Kráčmar, S.; Hrabě, J. Application of different sterilising modes and the effect on processed cheese quality. Czech J. Food Sci. 2010, 28, 168–176. [Google Scholar] [CrossRef]

- Lazárková, Z.; Buňka, F.; Buňková, L.; Holáň, F.; Kráčmar, S.; Hrabě, J. The effect of different heat sterilization regimes on the quality of canned processed cheese. J. Food Process Eng. 2011, 34, 1860–1878. [Google Scholar] [CrossRef]

- Mulsow, B.B.; Jaros, D.; Rohm, H. Processed cheese and cheese analogues. In Structure of Dairy Products; Tamime, A.Y., Ed.; Blackwell Publishing: Oxford, UK, 2007; pp. 210–233. [Google Scholar]

- de Oliveira, M.N.; Ustunol, Z.; Tamime, A.Y. Manufacturing practices of processed cheese. In Processed Cheese and Analogues; Tamime, A.Y., Ed.; Blackwell Publishing: Oxford, UK, 2011; pp. 148–178. [Google Scholar]

- Černíková, M.; Buňka, F.; Salek, R.N. Technological aspects of processed cheese: Properties and structure. In Processed Cheese Science and Technology; El-Bakry, M., Mehta, B.M., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 211–247. [Google Scholar]

- Ozturk, M.; Kilic-Akyilmaz, M. Manufacture of processed cheese: Equipments used. In Processed Cheese Science And Technology; El-Bakry, M., Mehta, B.M., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 197–209. [Google Scholar]

- Buňková, L.; Buňka, F. Microflora of processed cheese and the factors affecting it. Crit. Rev. Food Sci. Nutr. 2017, 57, 2392–2403. [Google Scholar] [CrossRef]

- Onyeaka, H.N.; Nwabor, O.F. Food Preservation and Safety of Natural Products; Academic Press: London, UK, 2022. [Google Scholar]

- Shaker, A.S.; Ali, M.A.; Fathy, H.M.; Marrez, D.A. Food preservation: Comprehensive overview of techniques, applications and hazards. Egypt. J. Chem. 2022, 65, 345–353. [Google Scholar]

- Erkmen, O.; Bozoglu, T.F. Food Microbiology: Principles into Practice; John Wiley & Sons: Chichester, UK, 2016. [Google Scholar]

- Stopforth, J.D. Preservation methods for meat and poultry. In Microbial Control and Food Preservation—Theory and Practise; Juneja, V.K., Dwivedi, H.P., Sofos, J.N., Eds.; Springer: New York, NY, USA, 2017; pp. 17–40. [Google Scholar]

- Lücke, F.-K. The control of pH. In Food Preservation Techniques; Zeuthen, P., Bøgh-Sørensen, L., Eds.; Woodhead Publishing: Cambridge, UK, 2003; pp. 109–125. [Google Scholar]

- Holdsworth, S.D. Optimising the safety and quality of thermally processed packaged foods. In Improving the Thermal Processing of Foods; Richardson, P., Ed.; Woodhead Publishing: Cambridge, UK, 2004; pp. 3–31. [Google Scholar]

- Bown, G. Modelling and optimising retort temperature control. In Improving the Thermal Processing of Foods; Richardson, P., Ed.; Woodhead Publishing: Cambridge, UK, 2004; pp. 105–123. [Google Scholar]

- Mukhopadhayay, S.; Ukuku, D.O.; Juneja, V.K.; Nayak, B.; Olanya, M. Principles of food preservation. In Microbial Control and Food Preservation—Theory and Practise; Juneja, V.K., Dwivedi, H.P., Sofos, J.N., Eds.; Springer: New York, NY, USA, 2017; pp. 17–40. [Google Scholar]

- Bown, G. Developments in conventional heat treatment. In Food Preservation Techniques; Zeuthen, P., Bøgh-Sørensen, L., Eds.; Woodhead Publishing: Cambridge, UK, 2003; pp. 154–178. [Google Scholar]

- Oliveira, J.C. Optimising the efficiency and productivity of thermal processing. In Improving the Thermal Processing of Foods; Richardson, P., Ed.; Woodhead Publishing: Cambridge, UK, 2004; pp. 32–49. [Google Scholar]

- Singh, R.P.; Heldman, D.R. Introduction to Food Engineering, 5th ed.; Academic Press: London, UK, 2014. [Google Scholar]

- Fellows, P.J. Food Processing Technology: Principles and Practice, 5th ed.; Woodhead Publishing: Cambridge, UK, 2022; pp. 357–387. [Google Scholar]

- Ramesh, M.N. Canning and sterilization of foods. In Handbook of Food Preservation, 2nd ed.; Rahman, M.S., Ed.; CRC Press: Boca Raton, FL, USA, 2007; pp. 585–624. [Google Scholar]

- Deak, T.; Farkas, J. Microbiology of Thermally Preserved Foods—Canning and Novel Physical Methods; DESTech Publications: Lancaster, UK, 2013; pp. 161–178. [Google Scholar]

- Stojanović, B.; Janković, S.; Đorđević, V.; Marjanović, S.; Vasilev, D.; Stojanović, Z.; Balaban, M.; Antić, V. Determination of toxic elements in meat products from Serbia packaged in tinplate cans. Environ. Sci. Pollut. Res. 2021, 28, 48330–48342. [Google Scholar] [CrossRef]

- Stojanović, B.; Vasilev, D.; Stojanović, Z.; Parunović, N.; Janković, S.; Stanojević, S.; Balaban, M.; Antić, V. Determination of sensory properties and levels of trace elements during storage of canned meat products. J. Food Process. Preserv. 2021, 45, e152278. [Google Scholar] [CrossRef]

- Jimenez, P.S.; Bangar, S.P.; Suffern, M.; Whiteside, W.S. Understanding retort processing: A review. Food Sci. Nutr. 2024, 12, 1545–1563. [Google Scholar] [CrossRef]

- Simpson, R. Optimising the efficiency of batch processing with retort systems in thermal processing. In Improving the Thermal Processing of Foods; Richardson, P., Ed.; Woodhead Publishing: Cambridge, UK, 2004; pp. 50–81. [Google Scholar]

- den Besten, H.M.W.; Wells-Bennik, M.H.J.; Zwietering, M.H. Natural diversity in heat resistance of bacteria and bacterial spores: Impact on food safety and quality. Annu. Rev. Food Sci. Technol. 2018, 9, 383–410. [Google Scholar] [CrossRef]

- Berk, Z. Food Process Engineering and Technology, 3rd ed.; Academic Press: London, UK, 2018. [Google Scholar]

- Peleg, M. Modelling applied to process: The case of thermal preservation. In Food Preservation Techniques; Zeuthen, P., Bøgh-Sørensen, L., Eds.; Woodhead Publishing: Cambridge, UK, 2003; pp. 507–523. [Google Scholar]

- Heldman, D.R. Food Preservation Process Design; Academic Press: Burlington, MA, USA, 2011. [Google Scholar]

- Sarker, D.K. Packaging Technology and Engineering: Pharmaceutical, Medical and Food Applications; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Deák, T. Food Technologies: Sterilization. In Encyclopedia of Food Safety; Motarjemi, Y., Moy, G., Todd, E., Eds.; Elsevier: San Diego, CA, USA, 2014. [Google Scholar]

- Tucker, G.S. Validation of heat process: An overview. In Improving the Thermal Processing of Foods; Richardson, P., Ed.; Woodhead Publishing: Cambridge, UK, 2004; pp. 334–352. [Google Scholar]

- Shaw, G.H. The use of data loggers to validate thermal processes. In Improving the Thermal Processing of Foods; Richardson, P., Ed.; Woodhead Publishing: Cambridge, UK, 2004; pp. 353–364. [Google Scholar]

- Rufe, P.D. Fundamentals of Manufacturing, 3rd ed.; Society of Manufacturing Engineers: Dearborn, MI, USA, 2013. [Google Scholar]

- Jongen, W. Fruit and Vegetable Processing—Improving Quality; Woodhead Publishing: Cambridge, UK, 2002. [Google Scholar]

- Kristensen, D.; Skibsted, L.H. Comparison of three methods based on electron spin resonance spectrometry for evaluation of oxidative stability of processed cheese. J. Agric. Food Chem. 1999, 47, 3099–3104. [Google Scholar] [CrossRef]

- Buňka, F.; Hrabě, J.; Kráčmar, S. The effect of sterilisation on amino acid contents in processed cheese. Int. Dairy J. 2004, 14, 829–831. [Google Scholar]

- Murata, M. Browning and pigmentation in food through the Maillard reaction. Glycoconj. J. 2021, 38, 283–292. [Google Scholar] [PubMed]

- Xiang, J.; Liu, F.; Wang, B.; Chen, L.; Liu, W.; Tan, S. A literature review on maillard reaction based on milk proteins and carbohydrates in food and pharmaceutical products: Advantages, disadvantages, and avoidance strategies. Foods 2021, 10, 1998. [Google Scholar] [CrossRef] [PubMed]

- Lund, M.N.; Ray, C.A. Control of Maillard reactions in foods: Strategies and chemical mechanisms. J. Agric. Food Chem. 2017, 65, 4537–4552. [Google Scholar]

- Poojary, M.; Lund, N. Chemical stability of proteins in foods: Oxidation and the Maillard reaction. Annu. Rev. Food Sci. Technol. 2022, 13, 35–58. [Google Scholar] [CrossRef]

- Aalaei, K.; Rayner, M.; Sjöholm, I. Chemical methods and techniques to monitor early Maillard reaction in milk products: A review. Crit. Rev. Food Sci. Nutr. 2018, 59, 1829–1839. [Google Scholar] [CrossRef]

- Thorpe, S.R.; Baynes, J.W. Maillard reaction products in tissue proteins: New products and new perspectives. Amino Acids 2003, 25, 275–281. [Google Scholar]

- Zhou, Z.; Langrish, T. A review of Maillard reactions in spray dryers. J. Food Eng. 2021, 305, 110615. [Google Scholar]

- Pizzoferrato, L.; Manzi, P.; Vivanti, V.; Nicoletti, I.; Corradini, C.; Cogliandro, E. Maillard reaction in milk-based foods: Nutritional consequences. J. Food Prot. 1998, 61, 235–239. [Google Scholar] [CrossRef]

- Starowicz, M.; Zieliński, H. How Maillard reaction influences sensorial properties (color, flavor and texture) of food products? Food Rev. Int. 2019, 35, 707–725. [Google Scholar]

- Iriondo-DeHond, A.; Elizondo, A.S.; Iriondo-DeHond, M.; Ríos, M.B.; Mufari, R.; Mendiola, J.A.; Ibanez, E.; Del Castillo, M.D. Assessment of healthy and harmful Maillard reaction products in a novel coffee cascara beverage: Melanoidins and acrylamide. Foods 2020, 9, 620. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wu, Y.R.; Quan, W.; Jia, X.D.; He, Z.Y.; Wang, Z.J.; Adhikari, B.; Chen, J.; Zeng, M.M. Quantitation of furosine, furfurals, and advanced glycation end products in milk treated with pasteurization and sterilization methods applicable in China. Food Res. Int. 2021, 140, 110088. [Google Scholar] [CrossRef] [PubMed]

- Ferrer, E.; Alegría, A.; Farré, R.; Abellán, P.; Romero, F. Effects of thermal processing and storage on available lysine and furfural compounds contents of infant formulas. J. Agric. Food Chem. 2000, 48, 1817–1882. [Google Scholar] [CrossRef] [PubMed]

- Torbatinejad, N.M.; Rutherfurd, S.M.; Moughan, P.J. Total and reactive lysine contents in selected cereal-based food products. J. Agric. Food Chem. 2005, 53, 4454–4458. [Google Scholar] [CrossRef]

- Gaucheron, F.; Mollé, D.; Briard, V.; Léonil, J. Identification of low molar mass petides, released during sterilisation of milk. Int. Dairy J. 1999, 9, 515–521. [Google Scholar] [CrossRef]

- Daly, D.F.M.; McSweeney, P.L.H.; Sheehan, J.J. Pink discolouration defect in commercial cheese: A review. Dairy Sci. Technol. 2012, 92, 439–453. [Google Scholar] [CrossRef]

- Buňka, F.; Štětina, J.; Hrabě, J. The effect of storage temperature and time on the consistency and colour of sterilized processed cheese. Eur. Food Res. Technol. 2008, 228, 223–229. [Google Scholar] [CrossRef]

- Fann, J.; Zhang, J.; Li, H.; Jiang, S.; Gao, Y.; Zhang, L. Study of methods of inhibiting browning of stored sterilized processed cheese. J. Chin. Ins. Food Sci. Technol. 2014, 14, 204–212. [Google Scholar]

- Song, B.; Zhu, P.; Zhang, Y.; Ju, N.; Si, X.; Pang, X.; Lv, J.; Zhang, S. Preparation and quality assessment of processed cream cheese by high hydrostatic pressure combined thermal processing and spore-induced germination. J. Food Eng. 2023, 341, 111319. [Google Scholar] [CrossRef]

- Ranvir, S.; Sharma, R.; Gandhi, K.; Nikam, P.; Mann, B. Physico-chemical changes during processing and storage of UHT milk. Indian J. Dairy Sci. 2021, 74, 39–47. [Google Scholar] [CrossRef]

- Balde, A.; Aider, M. Impact of sterilization and storage on the properties of concentrated skim milk by cryoconcentration in comparison with vacuum evaporation and reverse osmosis concentration. J. Food Process Eng. 2019, 42, e13130. [Google Scholar] [CrossRef]

- Friedman, M. Food browning and its prevention: An overview. J. Agric. Food Chem. 1996, 44, 632–653. [Google Scholar] [CrossRef]

- Li, H.; Wu, Y.; Hou, D.; Zhao, S.; Li, D.; Wang, X.; Li, H.; Yu, J. Effects of pre-emulsification with whey protein and high temperature sterilisation on texture, functional characteristics and Maillard reaction products of room temperature stored processed cheese. Int. Dairy J. 2023, 140, 105610. [Google Scholar] [CrossRef]

- Long, Z.; Zhao, M.; Sun-Waterhouse, D.; Lin, Q.; Zhao, Q. Effects of sterilization conditions and milk protein composition on the rheological and whipping properties of whipping cream. Food Hydrocoll. 2016, 52, 11–18. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.; Yan, G.; Yuan, D.; Ji, B.; Zhou, F.; Li, Y.; Zhang, L. Thickening mechanism of recombined dairy cream stored at 4 °C: Changes in the composition and structure of milk protein under different sterilization intensities. Int. J. Biol. Macromol. 2023, 227, 903–914. [Google Scholar] [CrossRef]

- Dhungana, P.; Truong, T.; Bansal, N.; Bhandari, B. Apparent thermal and UHT stability of native, homogenized and recombined creams with different average fat globule sizes. Food Res. Int. 2019, 123, 153–1652. [Google Scholar] [CrossRef]

- McSweeney, S.L.; Mulvihill, D.M.; O’Callaghan, D.M. The influence of pH on the heat-induced aggregation of model milk protein ingredient systems and model infant formula emulsions stabilized by milk protein ingredients. Food Hydrocoll. 2004, 18, 109–125. [Google Scholar] [CrossRef]

- Dumpler, J.; Huppertz, T.; Kulozik, U. Invited review: Heat stability of milk and concentrated milk: Past, present, and future research objectives. J. Dairy Sci. 2020, 103, 10986–11007. [Google Scholar] [CrossRef]

- Valero, E.; Villamiel, M.; Miralles, B.; Sanz, J.; Martínez-Castro, I. Changes in flavour and volatile components during storage of whole and skimmed UHT milk. Food Chem. 2001, 72, 51–58. [Google Scholar] [CrossRef]

- Bertrand, E.; Machado-Maturana, E.; Chevarin, C.; Portanguen, S.; Mercier, F.; Tournayre, P.; Abouelkaram, S.; Guillard, A.-S.; Kondojoyan, A.; Berdafué, J.-L. Heat-induced volatiles and odour-active compounds in a model cheese. Int. Dairy J. 2011, 21, 506–8014. [Google Scholar] [CrossRef]

- Rannou, C.; Laroque, D.; Renault, E.; Prost, C.; Sérot, T. Mitigation strategies of acrylamide, furans, heterocyclicamines and browning during the Maillard reactions in foods. Food Res. Int. 2016, 90, 154–176. [Google Scholar]

- Adamiec, J.; Cejepk, K.; Rössner, J.; Velíšek, J. Novel Strecker degradation products of tyrosine and dihydroxyphenylalanine. Czech J. Food Sci. 2001, 19, 13–18. [Google Scholar]

- Kristensen, D.; Hansen, E.; Arndal, A.; Trinderup, R.A.; Skibsted, L.H. Influence of light and temperature on the colour and oxidative stability of processed cheese. Int. Dairy J. 2001, 11, 837–843. [Google Scholar]

- Popov-Raljić, J.V.; Lakić, N.S.; Laličić-Petronijević, J.G.; Barać, M.B.; Sikimić, V.M. Color Changes of UHT Milk During Storage. Sensors 2008, 8, 5961–5974. [Google Scholar] [CrossRef] [PubMed]

- Zeren, R.B.; Buzrul, S.; Bilge, G. Monitoring the changes in UHT whole milk during storage under dynamic and constant temperature profiles. J. Food Sci. Technol. 2024, early access. [Google Scholar]

- Karlsson, M.A.; Langton, M.; Innings, F.; Malmgren, B.; Höjer, A.; Wikström, M.; Lundh, Å. Changes in stability and shelf-life of ultrahigh temperature treated milk during long term storage at different temperatures. Heliyon 2019, 5, e02431. [Google Scholar]

- Malmgren, B.; Ardö, Y.; Langton, M.; Altskär, A.; Bremer, M.G.E.G.; Dejmek, P.; Paulsson, M. Changes in proteins, physical stability and structure in directly heated UHT milk during storage at different temperatures. Int. Dairy J. 2017, 71, 60–75. [Google Scholar]

- Al-Saadi, J.M.S.; Deeth, H.C. Cross-linking of proteins and other changes in UHT milk during storage at different temperatures. Austral. J. Dairy Technol. 2008, 63, 93–99. [Google Scholar]

- Turner, N.A.; Vulfson, E.N. At what temperature can enzymes maintain their catalytic activity? Enzyme Microb. Technol. 2000, 27, 108–113. [Google Scholar]

- Haki, G.D.; Rakshit, S.K. Developments in industrially important thermostable enzymes: A review. Biores. Technol. 2003, 89, 17–34. [Google Scholar]

- Synowiecki, J.; Grzybowska, B.; Zdziebło, A. Sources, properties and suitability of new thermostable enzymes in food processing. Crit. Rev. Food Sci. Nutr. 2006, 46, 197–205. [Google Scholar] [PubMed]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A comprehensive review on lipid oxidation in meat and meat products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [PubMed]

- Geng, L.; Liu, K.; Zhang, H. Lipid oxidation in foods and its implications on proteins. Front. Nutr. 2023, 10, 1192199. [Google Scholar]

- Zeng, J.; Song, Y.; Fan, X.; Luo, J.; Song, J.; Xu, J.; Xue, C. Effect of lipid oxidation on quality attributes and control technologies in dried aquatic animal products: A critical review. Crit. Rev. Food Sci. Nutr. 2023, 64, 10397–10418. [Google Scholar]

- Wagner, K.-H.; Auer, E.; Elmadfa, I. Content of trans fatty acids in margarines, plant oils, fried products and chocolate spreads in Austria. Eur. Food Res. Technol. 2000, 210, 237–241. [Google Scholar]

- Ajmal, M.; Nadeem, M.; Imran, M.; Junaid, M. Lipid compositional changes and oxidation status of ultra-high temperature treated milk. Lipids Health Dis. 2018, 17, 227. [Google Scholar]

- Li, Y.H.; Wang, W.J.; Zhang, F.; Shao, Z.P.; Guo, L. Formation of the oxidized flavor compounds at different heat treatment and changes in the oxidation stability of milk. Food Sci. Nutr. 2019, 7, 238–246. [Google Scholar]

- Luna, P.; Angel De La Fuente, M.A.; Juárez, M. Conjugated linoleic acid in processed cheeses during the manufacturing stages. J. Agric. Food Chem. 2005, 53, 2690–2695. [Google Scholar]

- Tremlová, B.; Štarha, P.; Buňka, F.; Gistingrová, Z.; Hrabě, J. The effect of sterilization on size and shape of fat globules in model processed cheese samples. Acta Vet. Brno 2006, 75, 419–425. [Google Scholar]

- Dias, F.F.G.; Augusto-Obara, T.R.; Hennebelle, M.; Chantieng, S.; Ozturk, G.; Taha, A.Y.; Ferreira de Souza Vieira, T.M.; Nobrega de Moura Bell, J.M.L. Effects of industrial heat treatments on bovine milk oxylipins and conventional markers of lipid oxidation. Prostaglandins Leukot. Essent. Fat. Acids 2020, 152, 102040. [Google Scholar]

- Ajandouz, E.H.; Tchiapke, L.S.; Dalle Ore, F.; Benajiba, A.; Puigserver, A. Effects of pH on caramelization and Maillard reaction kinetics in fructose-lysine model systems. J. Food Sci. 2001, 66, 926–931. [Google Scholar]

- de Oliveira Neves, L.N.; De Oliveira, M.A.L. Determination of lactose and lactulose isomers in UHT milk by CZE-UV. LWT 2020, 118, 108876. [Google Scholar]

- Ryley, J.; Kajda, P. Vitamins in thermal processing. Food Chem. 1994, 49, 119–129. [Google Scholar]

- Pingali, A.V.; Trumbo, P.R. Effect of sterilization of milk on vitamin B-6 composition and bioavailability. J. Agric. Food Chem. 1992, 40, 1860–1863. [Google Scholar]

- Sharma, R.; Lal, D. Influence of various heat processing treatments on some B-vitamins in buffalo and cow’s milks. J. Food Sci. Technol. 1998, 35, 524–526. [Google Scholar]

- Sachdeva, B.; Kaushik, R.; Arora, S.; Khan, A. Effect of processing conditions on the stability of native vitamin A and fortified retinol acetate in milk. Int. J. Vitam. Nutr. Res. 2021, 91, 133–142. [Google Scholar]

- Kaushik, R.; Sachdeva, B.; Arora, S. Vitamin D2 stability in milk during processing, packaging and storage. LWT 2014, 56, 421–426. [Google Scholar]

- Seiquer, I.; Delgado-Andrade, C.; Haro, A.; Navarro, M.P. Assessing the effects of severe heat treatment of milk on calcium bioavailability: In vitro and in vivo studies. J. Dairy Sci. 2010, 93, 5635–5643. [Google Scholar]

| Consequence of Sterilization and/or Storage | Type of Sterilized Food Product | References |

|---|---|---|

| Amino acid losses | Processed cheese | [12,20,55] |

| Available lysine decrease | Processed cheese | [19] |

| Ammonia increase | Processed cheese | [8,9,12,19] |

| Protein profile changes | Processed cheese | [12,20] |

| UHT milk | [69] | |

| Lipid oxidation reactions | Processed cheese | [8,9] |

| UHT milk | [100] | |

| UHT milk | [101] | |

| Fat globules changes | Processed cheese | [12,77,103] |

| Cream | [78,79] | |

| Cream cheese | [73] | |

| UHT milk | [101] | |

| Antioxidant capacity reduction | UHT milk | [104] |

| Isomerization of lactose to lactulose | UHT milk | [74,83,106] |

| Vitamin losses | UHT milk | [13,108,109,110] |

| Calcium solubility/absorption reduction | UHT milk | [112] |

| Color changes (darkening) | Processed cheese | [8,9,12,19,20,70,71,72] |

| UHT milk | [74,88,89,90] | |

| Cream cheese | [73] | |

| Concentrated milk | [75] | |

| Consistency changes (hardening, thickening) | Processed cheese | [8,9,71,77] |

| Cream | [78,79] | |

| UHT milk | [74,89] | |

| Concentrated milk | [75] | |

| Stability impairment | Cream | [80] |

| Infant formula emulsion | [81] | |

| UHT milk | [74,90,91] | |

| Concentrated milk | [82] | |

| Sensory quality deterioration | Processed cheese | [8,9,19,20,84] |

| UHT milk | [83,90] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazárková, Z.; Lorencová, E.; Pětová, M.; Novotný, M.; Salek, R.N. Sterilized Processed Cheese: Principles, Technological Aspects, and Properties: A Review. Foods 2025, 14, 1072. https://doi.org/10.3390/foods14061072

Lazárková Z, Lorencová E, Pětová M, Novotný M, Salek RN. Sterilized Processed Cheese: Principles, Technological Aspects, and Properties: A Review. Foods. 2025; 14(6):1072. https://doi.org/10.3390/foods14061072

Chicago/Turabian StyleLazárková, Zuzana, Eva Lorencová, Markéta Pětová, Martin Novotný, and Richardos Nikolaos Salek. 2025. "Sterilized Processed Cheese: Principles, Technological Aspects, and Properties: A Review" Foods 14, no. 6: 1072. https://doi.org/10.3390/foods14061072

APA StyleLazárková, Z., Lorencová, E., Pětová, M., Novotný, M., & Salek, R. N. (2025). Sterilized Processed Cheese: Principles, Technological Aspects, and Properties: A Review. Foods, 14(6), 1072. https://doi.org/10.3390/foods14061072