Exploring the Influence of Pottery Jar Formula Variables on Flavor Substances Through Feature Ranking and Machine Learning: Case Study of Maotai-Flavored Baijiu

Abstract

1. Introduction

2. Materials and Methods

2.1. Pottery Jar Samples

2.2. Baijiu Samples

2.3. Quantification of Flavor Compounds by GC-MS

2.4. Quantification of Metals by ICP-MS

2.5. Statistical Analysis and Model Construction

2.5.1. Establishment of Feature Subsets

2.5.2. RF

2.5.3. XGBoost

2.5.4. Adaboost

2.5.5. Feature Evaluation

3. Results and Discussions

3.1. Influence of Pottery Jar on Metals in Baijiu

3.2. The Influence of Metal Ions on Flavor Substances in Baijiu

3.2.1. Cluster Analysis (CA)

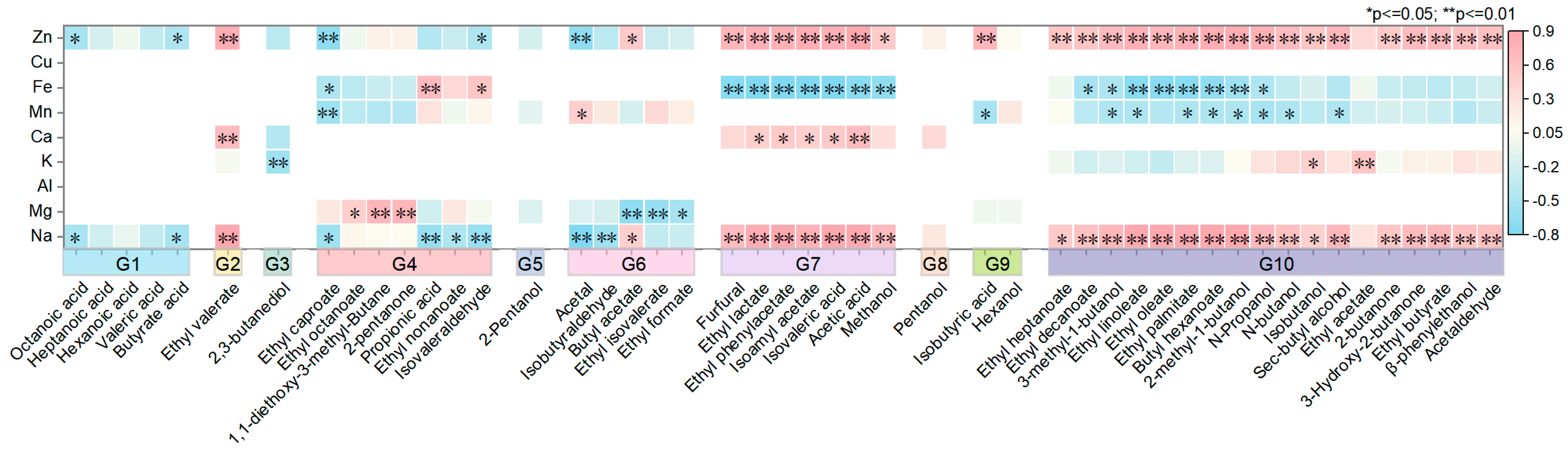

3.2.2. Correlation Analysis Based on Key Feature Selection

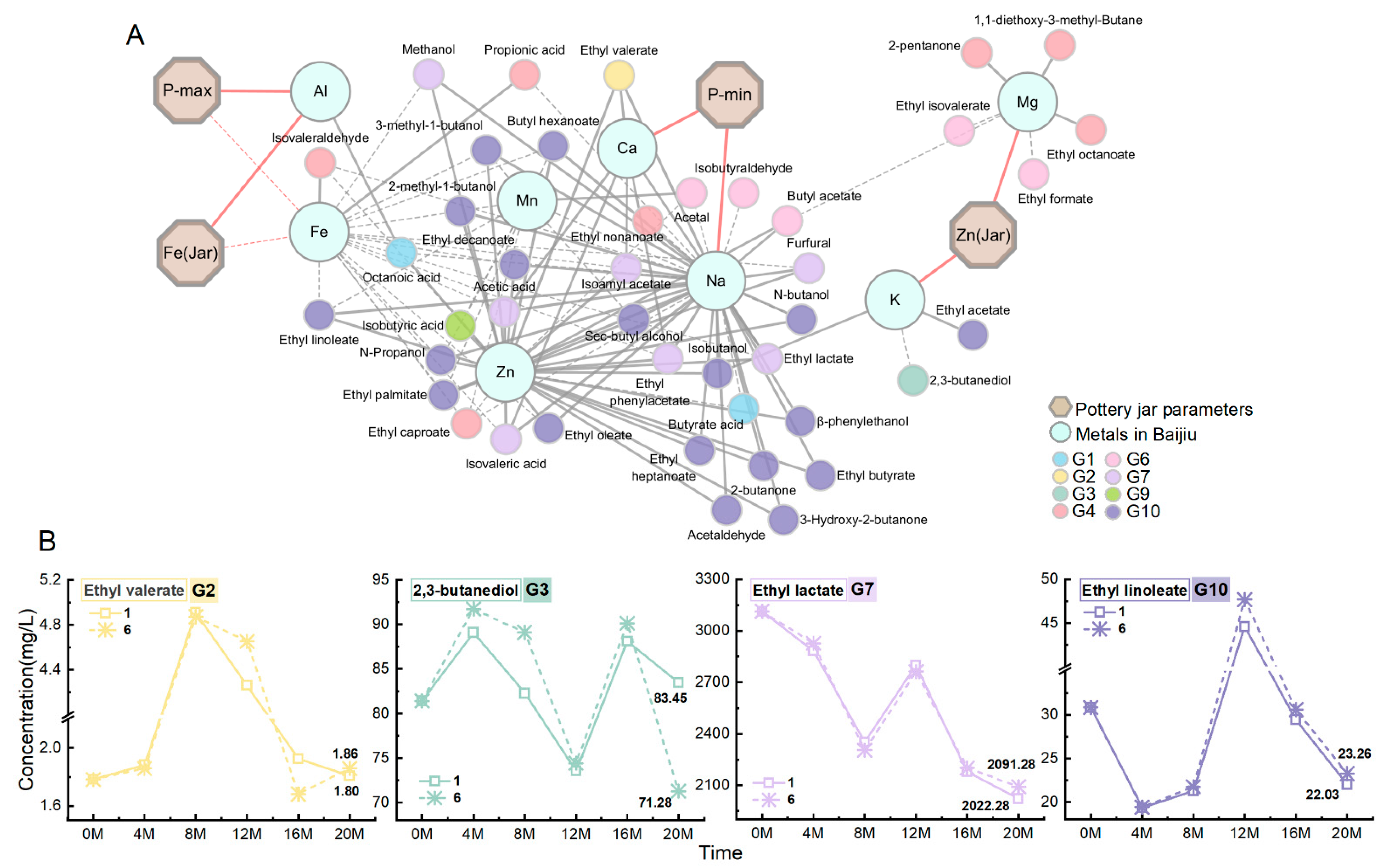

3.3. The Influence of Pottery Jar on Flavor Substances in Baijiu

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, J.P.; Xie, Z.M.; An, M.Z.; Luo, Y.; Wang, X.Q.; Zhang, Q.; Huang, J. Changes of metal elements and sensory quality of baijiu during storage in pottery jars. Liquor-Mak. Sci. Technol. 2022, 1, 47–51. [Google Scholar] [CrossRef]

- Song, X.B.; Hou, M.; Li, Z.; Zhu, L.; Zheng, F.P.; Huang, M.Q.; Sun, X.T.; Li, H.H.; Chen, F.; Sun, B.B. Multi-element analysis of baijiu (Chinese liquors) by ICP-MS and their classification according to geographical origin. Food Qual. Saf. 2018, 2, 43–49. [Google Scholar] [CrossRef]

- Bi, Y.L.; Zhong, H.; Huang, L.H.; Xie, D.; Fan, L.; Zhao, Y.; Xi, D.Z.; Qian, C.Q.; Hu, J.F. Research progress in baijiu storage technology. Liquor-Mak. Sci. Technol. 2022, 12, 80–84. [Google Scholar] [CrossRef]

- Jin, W.X.; Ma, X.P.; Wang, L.; Han, J.S.; Du, X.W. Changes of metal elements contents during different storage periods in Fen Liquor. Food Ferment. Ind. 2013, 39, 33–38. [Google Scholar] [CrossRef]

- Zhu, C.; Jiang, Y.M.; Guan, Y.; Yi, X.; Zuo, K.C.; Wan, Z.; Ke, F.; Zhan, S.; Sun, T.T.; Shi, P.; et al. Changes of different flavor types of baijiu during aging process in pottery jars. Liquor-Mak. Sci. Technol. 2023, 11, 70–76. [Google Scholar] [CrossRef]

- Fan, T.; Xie, Z.M.; Wei, J.P.; Zheng, J.; Huang, J.; Zhang, Q. Health risk exposure assessment of eight heavy metals in world distilled spirits. China Brew. 2023, 42, 228–233. [Google Scholar] [CrossRef]

- Liu, H.; Wu, R.; Guo, Q.; Hua, Z.; Wu, Y. Electronic Nose Based on Temperature Modulation of MOS Sensors for Recognition of Excessive Methanol in Liquors. ACS Omega 2021, 6, 30598–30606. [Google Scholar] [CrossRef]

- Liu, L.L.; Yang, H.; Jing, X.; Xu, C.; Zhang, Y.F.; Yan, Z.K.; Qi, Y.H. Influence of different storage containers on the aroma composition of Fengxiang type baijiu analyzed by gas chromatography-ion mobility spectroscopy and electronic nose. Food Sci. 2022, 43, 257–263. [Google Scholar] [CrossRef]

- Jiang, M.L.; Hu, X.J.; Lei, Y.; Huang, Z.X.; Chen, M.J.; Ma, X.Y.; Tian, J.P.; Huang, D. Research progress on bajiu aging. China Brew. 2022, 41, 13–17. [Google Scholar] [CrossRef]

- Huang, Z.J.; Zeng, Y.H.; Liu, W.H.; Wang, S.T.; Shen, C.H.; Shi, B. Effects of metals released in strong-flavor Baijiu on the evolution of aroma compounds during storage. Food Sci. Nutr. 2020, 8, 1904–1913. [Google Scholar] [CrossRef]

- Xiong, X.M.; Xiang, J.; Zhao, Y. Effects of metal ions on the quality of Baiyunbian raw liquor. Liquor Mak. 2013, 3, 30–32. [Google Scholar] [CrossRef]

- Li, M.; Fan, W.L.; Xu, Y. Volatile compounds sorption during the aging of Chinese liquor (baijiu) using pottery powder. Food Chem. 2021, 345, 128705. [Google Scholar] [CrossRef]

- Greener, J.G.; Kandathil, M.S.; Moffat, L.; Jones, D.T. A guide to machine learning for biologists. Nat. Rev. Mol. Cell Biol. 2022, 23, 40–55. [Google Scholar] [CrossRef]

- Zhang, X.J.; Meng, L.J.; Lu, Z.M.; Chai, L.J.; Wang, S.T.; Shi, J.S.; Shen, C.H.; Xu, Z.H. Identification of age-markers based on profiling of Baijiu volatiles over a two-year maturation period: Case study of Lu-flavor baijiu. LWT-Food Sci. Technol. 2021, 141, 110913. [Google Scholar] [CrossRef]

- Liu, Q.R.; Zhang, X.J.; Zheng, L.; Meng, L.J.; Liu, G.Q.; Yang, T.; Lu, Z.M.; Chai, L.J.; Wang, S.T.; Shi, J.S.; et al. Machine learning based age-authentication assisted by chemo-kinetics: Case study of strong-flavor Chinese baijiu. Food Res. Int. 2023, 167, 112594. [Google Scholar] [CrossRef]

- Wei, X.L.; Jiang, L.; Shi, Q.L.; Mo, Z.H. Machine-learning-assisted SERS nanosensor platform toward chemical fingerprinting of baijiu flavors. Microchim. Acta 2023, 190, 207. [Google Scholar] [CrossRef]

- Miao, Z.J.; Bai, Y.; Wang, X.L.; Han, C.; Wang, B.W.; Li, Z.X.; Sun, J.Y.; Zheng, F.P.; Zhang, Y.H.; Sun, B.G. Unravelling metabolic heterogeneity of Chinese baijiu fermentation in age-gradient vessels. Foods 2023, 12, 3425. [Google Scholar] [CrossRef]

- Wei, L.L.; Hu, J.F.; Pan, C.K.; Cheng, P.Y.; Zhang, J.; Xi, D.Z.; Chen, M.X.; Lu, L.W.; Hu, L.; Hu, F. Effects of different storage containers the flavor characteristics of Jiangxiangxing baijiu. Food Res. Int. 2023, 172, 113196. [Google Scholar] [CrossRef]

- Xiang, S.Y.; Xu, Z.H.; Zhang, Y.W.; Zhang, Q.; Zhou, X.; Yu, H.; Li, B.; Li, Y.F. Construction and application of ReliefF-RFE feature selection algorithm for hyperspectral image classification. Spectrosc. Spectr. Anal. 2022, 42, 3283–3290. [Google Scholar] [CrossRef]

- Zhuang, H.; Liu, X.L.; Wang, H.; Qin, C.L.; Li, Y.X.; Li, W.S.; Shi, Y.H. Diagnosis of early stage parkinson’s disease on quantitative susceptibility mapping using complex network with one-way anova f-test feature selection. J. Mech. Med. Biol. 2021, 21, 2140026. [Google Scholar] [CrossRef]

- Zhou, H.F.; Xin, Y.B.; Li, S.L. A diabetes prediction model based on boruta feature selection and ensemble learning. BMC Bioinform. 2023, 24, 224. [Google Scholar] [CrossRef]

- Liang, M.H.; Tao, J.C.; Ma, N.; Kuang, Y.; Zhang, Y.Y.; Wu, S.; Jiang, X.J.; He, Y.; Chen, C.R.; Yang, W.D. Prediction of CCN spectra parameters in the North China plain using a random forest model. Atmos. Environ. 2022, 289, 119323. [Google Scholar] [CrossRef]

- Wu, Q.S.; Xu, L.J.; Zou, Z.Y.; Wang, J.; Zeng, Q.F.; Wang, Q.L.; Zhen, J.B.; Wang, Y.C.; Zhao, Y.P.; Zhou, M. Rapid nondestructive detection of peanut varieties and peanut mildew based on hyperspectral imaging and stacked machine learning models. Front. Plant Sci. 2022, 11, 1047479. [Google Scholar] [CrossRef]

- Xiao, F.Y.; Wang, Y.; He, L.G.; Wang, H.; Li, W.H.; Liu, Z.S. Motion estimation from surface electromyogram using adaboost regression and average feature values. IEEE Access 2019, 7, 13121–13134. [Google Scholar] [CrossRef]

- Wang, C.X.; Wang, S.L.; He, X.G.; Wu, L.G.; Li, Y.L.; Guo, J.H. Combination of spectra and texture data of hyperspectral imaging for prediction and visualization of palmitic acid and oleic acid contents in lamb meat. Meat Sci. 2020, 169, 108194. [Google Scholar] [CrossRef]

- Hang, Y.X.; Tian, J.P.; Yang, H.L.; Hu, X.J.; Han, L.P.; Fei, X.; He, K.L.; Liang, Y.; Xie, L.L.; Huang, D. Detection of wheat saccharification power and protein content using stacked models integrated with hyperspectral imaging. J. Sci. Food Agric. 2024, 104, 4145–4156. [Google Scholar] [CrossRef]

- Xie, Z.J.; Tang, Y.M.; Huang, X.Y.; Yang, J. Determination and PCA of metallic elementsin nongxiang baijiu (liquor) produced in different placesin sichuan. Liquor-Mak. Sci. Technol. 2014, 245, 87–89,93. [Google Scholar] [CrossRef]

- Guo, Y.Z.; Zhang, H.M.; Wang, Y. Functions of trace metal elements in baijiu. Liquor-Mak. Sci. Technol. 2017, 12, 45–49. [Google Scholar] [CrossRef]

- Yang, Z.; Lei, W.T.; Yao, Y.; Chen, H.; Yu, H.Y.; Feng, Z.Q.; Huang, M.S.; Jang, Z.Y.; Wang, L.; Peng, B.; et al. Optimization and application of storage process of baijiu in pottery jars. Liquor-Mak. Sci. Technol. 2024, 355, 112–114,139. [Google Scholar] [CrossRef]

- Chen, Z.Q. Investigation on liquor storage mechanism (stored by pottery jar under high-temperature). Liquor-Mak. Sci. Technol. 2006, 145, 69–70. [Google Scholar] [CrossRef]

| Number | Cu (mg/L) a | Fe (mg/L) a | Zn (mg/L) a | P-Max (μm) a | P-Min (μm) a |

|---|---|---|---|---|---|

| 1 | 0 | 5.12 | 0.0077 | 76.78 | 5.86 |

| 2 | 0.024 | 5.28 | 0.06 | 84.83 | 6.42 |

| 3 | 0.088 | 5.29 | 0.06 | 105.16 | 2.27 |

| 4 | 0.18 | 5.32 | 0.15 | 89.29 | 2.33 |

| 5 | 0.22 | 5.19 | 0.35 | 74.93 | 2.42 |

| 6 | 0.11 | 6.01 | 0.23 | 150.48 | 5.88 |

| Flavor Substance | Initial a | 12 Months a | 16 Months a | 20 Months a | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| N1 | N3 | N6 | N1 | N3 | N6 | N1 | N3 | N6 | ||

| Acetaldehyde | 354.39 | 770.22 | 740.07 | 751.41 | 499.76 | 469.83 | 473.64 | 609.08 | 571.53 | 593.79 |

| Ethyl formate | 26.21 | 70.78 | 69.4 | 69.82 | 58.28 | 55.21 | 57.02 | 99.36 | 97.12 | 98.44 |

| Isobutyraldehyde | 0 | 0.04 | 0.02 | 0.03 | 0.04 | 0.02 | 0.03 | 3.63 | 3.27 | 3.54 |

| Ethyl acetate | 2668.95 | 3319.56 | 3284.1 | 3302.1 | 2773.44 | 2712.24 | 2740.59 | 3243.26 | 3229.35 | 3270.77 |

| Acetal | 188.56 | 198.51 | 190.77 | 193.38 | 222.62 | 217.2 | 224.82 | 261.88 | 260.49 | 260.88 |

| 2-butanone | 5.39 | 6.7 | 6.63 | 6.59 | 6.03 | 6.04 | 6.05 | 6.11 | 6.12 | 6.25 |

| Methanol | 105.83 | 125.87 | 122.66 | 121.28 | 107.98 | 105.67 | 102.81 | 40.57 | 40.49 | 42.24 |

| Isovaleraldehyde | 42.89 | 15.78 | 16.73 | 18.39 | 21.54 | 22.51 | 24.66 | 55.92 | 55.78 | 56 |

| 2-pentanone | 2.97 | 0.02 | 0.02 | 0.03 | 0.02 | 0.02 | 0.03 | 0.02 | 0.02 | 0.03 |

| Ethyl butyrate | 14.27 | 19.48 | 19.05 | 19.35 | 16.16 | 16.05 | 15.97 | 16.73 | 16.69 | 16.84 |

| Sec-butyl alcohol | 55.89 | 64.68 | 63.9 | 64.48 | 54.87 | 54.84 | 54.79 | 58.36 | 58.36 | 58.92 |

| N-Propanol | 1052.19 | 1151.37 | 1142.55 | 1148.04 | 1015.74 | 1014.39 | 1014.12 | 1057.42 | 1054.77 | 1065.42 |

| Ethyl isovalerate | 2.75 | 6.61 | 7.17 | 6.57 | 6.82 | 6.48 | 6.46 | 8.37 | 8.11 | 8.29 |

| Butyl acetate | 1.36 | 3.89 | 4.32 | 3.97 | 2.74 | 2.31 | 2.4 | 2.96 | 3.38 | 2.79 |

| 1,1-diethoxy-3-methyl-Butane | 16.56 | 0.03 | 0.03 | 0.03 | 0.02 | 0.03 | 0.03 | 0.02 | 0.03 | 0.03 |

| Isobutanol | 118.65 | 135.57 | 134.36 | 135.07 | 117.2 | 117.14 | 117.15 | 128.79 | 128.49 | 129.61 |

| Isoamyl acetate | 6.28 | 5.49 | 5.31 | 5.59 | 3.99 | 4.07 | 4.05 | 3.88 | 4.05 | 3.9 |

| Ethyl valerate | 1.78 | 4.26 | 4.73 | 4.65 | 1.92 | 1.73 | 1.68 | 1.81 | 1.85 | 1.86 |

| 2-Pentanol | 0.47 | 0 | 0 | 0.54 | 0.43 | 0.41 | 0.45 | 0.52 | 0.47 | 0.4 |

| N-butanol | 47.43 | 54.11 | 53.51 | 54.11 | 45.98 | 45.91 | 45.9 | 49.79 | 49.72 | 50.04 |

| 2-methyl-1-butanol | 56.52 | 368.06 | 365.37 | 366.96 | 56.52 | 56.3 | 56.17 | 61.78 | 61.77 | 62.17 |

| 3-methyl-1-butanol | 190.53 | 272.18 | 270.1 | 271.57 | 194.59 | 193.96 | 193.85 | 213.86 | 213.22 | 215.23 |

| Ethyl caproate | 9.76 | 7.84 | 7.82 | 7.57 | 6.03 | 5.11 | 5.05 | 6.47 | 6.42 | 6.5 |

| Pentanol | 1.15 | 4.24 | 3.81 | 3.99 | 3.33 | 3.33 | 3.53 | 3.57 | 3.4 | 3.59 |

| Vinegar buzz | 28.85 | 40.86 | 40.25 | 40.74 | 33.61 | 33.93 | 33.67 | 35.69 | 34.89 | 34.45 |

| Ethyl heptanoate | 0.45 | 5.13 | 3.58 | 2.76 | 3.22 | 0.67 | 0 | 0.65 | 0.63 | 0.84 |

| Ethyl lactate | 3113.46 | 2798.19 | 2771.37 | 2761.83 | 2178.54 | 2237.13 | 2201.58 | 2022.28 | 2067.91 | 2091.28 |

| Hexanol | 3.61 | 5.44 | 5.24 | 5.3 | 6.11 | 5.69 | 5.55 | 3.8 | 3.82 | 4.05 |

| Butyl hexanoate | 0.87 | 2.35 | 2.4 | 2.15 | 0.91 | 0.87 | 0.9 | 0.61 | 0.6 | 0.54 |

| Ethyl octanoate | 5.58 | 1.11 | 1.61 | 2.19 | 1.78 | 1.78 | 1.76 | 1.41 | 1.44 | 1.46 |

| Acetic acid | 2375.73 | 2883.87 | 2839.95 | 2827.89 | 1994.04 | 1997.91 | 1963.98 | 1831.8 | 1878.21 | 1898.92 |

| Furfural | 246.25 | 201.48 | 199.04 | 198.57 | 159.76 | 163.2 | 160.93 | 153.34 | 157.42 | 159.22 |

| Ethyl nonanoate | 1.63 | 0.02 | 0.02 | 0.03 | 0.02 | 0.02 | 0.03 | 1.23 | 1.21 | 1.23 |

| Propionic acid | 0 | 12.24 | 11.78 | 11.36 | 16.96 | 15.96 | 15.05 | 81.03 | 84.3 | 85.45 |

| Isobutyric acid | 17.57 | 20.31 | 20.61 | 20.5 | 13.76 | 13.83 | 13.51 | 3.37 | 8.12 | 8.05 |

| 2,3-butanediol | 81.43 | 73.57 | 73.79 | 74.42 | 88.12 | 89.78 | 90.14 | 83.45 | 71.52 | 71.28 |

| Ethyl decanoate | 1.14 | 1.77 | 1.54 | 1.41 | 0.96 | 1.17 | 1.32 | 1.04 | 0.8 | 1.26 |

| Butyrate | 7.1 | 17.78 | 13.25 | 12.4 | 19.78 | 10.64 | 9.14 | 8.81 | 6.09 | 6.1 |

| Isovaleric acid | 21.63 | 27.44 | 26.85 | 26.83 | 19.77 | 19.95 | 19.84 | 14.53 | 14.84 | 15.05 |

| Valeric acid | 0.19 | 2.1 | 1.56 | 1.68 | 3.8 | 1.51 | 0.96 | 0.96 | 0.42 | 0.47 |

| Ethyl phenylacetate | 5.89 | 5.73 | 6.04 | 5.91 | 5.01 | 5.01 | 4.94 | 4.58 | 4.44 | 4.57 |

| Hexanoic acid | 7.69 | 18 | 7.55 | 4.58 | 64.64 | 14.21 | 8.03 | 6.66 | 2.92 | 3.45 |

| β-phenylethanol | 12.59 | 17.04 | 16.81 | 16.86 | 12.52 | 12.97 | 12.82 | 14.61 | 14.77 | 14.96 |

| Heptanoic acid | 0.03 | 0.03 | 0.02 | 0.02 | 1.19 | 0.15 | 0.19 | 0.03 | 0.03 | 0.02 |

| Octanoic acid | 0 | 1.17 | 0 | 0 | 2.38 | 1.68 | 1.4 | 1.32 | 0.9 | 0.91 |

| Ethyl palmitate | 43.93 | 76.07 | 76.26 | 76.11 | 40.62 | 42.91 | 41.65 | 29.55 | 30.02 | 30.54 |

| Ethyl oleate | 16.42 | 26.82 | 26.4 | 25 | 16.51 | 17.16 | 16.89 | 10.07 | 10.26 | 10.59 |

| Ethyl linoleate | 30.83 | 44.57 | 50.22 | 47.68 | 29.44 | 31.45 | 30.6 | 22.03 | 22.62 | 23.27 |

| Flavor Group | Representative Flavor Substance | Feature Number | RF | XGBoost | Adaboost | Final Key Features | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rp2 | RMSEP (mg/L) | RPD | Rp2 | RMSEP (mg/L) | RPD | Rp2 | RMSEP (mg/L) | RPD | ||||

| G1 | Octanoic acid | 2 | 0.884 | 0.326 | 2.14 | 0.927 | 0.219 | 2.66 | 0.928 | 0.181 | 2.68 | Zn Na |

| 9 | 0.953 | 0.164 | 3.3 | 0.897 | 0.159 | 2.26 | 0.901 | 0.391 | 2.31 | |||

| G2 | Ethyl valerate | 4 | 0.985 | 0.169 | 5.79 | 0.951 | 0.311 | 3.23 | 0.983 | 0.187 | 5.45 | Zn Na Ca K |

| 9 | 0.893 | 0.402 | 2.22 | 0.952 | 0.296 | 3.27 | 0.971 | 0.192 | 4.18 | |||

| G3 | 2,3-butanediol | 3 | 0.863 | 2.658 | 1.98 | 0.983 | 1.136 | 5.45 | 0.975 | 1.191 | 4.5 | Zn Ca K |

| 9 | 0.883 | 2.501 | 2.13 | 0.892 | 2.664 | 2.21 | 0.967 | 1.498 | 3.93 | |||

| G4 | Ethyl caproate | 5 | 0.909 | 0.407 | 2.4 | 0.951 | 0.254 | 3.23 | 0.881 | 0.219 | 2.11 | Zn Na Fe Mg Mn |

| 9 | 0.907 | 0.298 | 2.37 | 0.916 | 0.27 | 2.49 | 0.908 | 0.305 | 2.39 | |||

| Propionic acid | 5 | 0.874 | 0.44 | 2.06 | 0.938 | 0.304 | 2.88 | 0.992 | 0.107 | 7.92 | ||

| 9 | 0.843 | 15.19 | 1.86 | 0.97 | 6.435 | 4.11 | 0.949 | 6.409 | 3.17 | |||

| G5 | 2-Pentanol | 4 | 0.932 | 0.055 | 2.76 | Zn Mn Mg | ||||||

| 9 | 0.908 | 0.382 | 2.39 | |||||||||

| G6 | Acetal | 4 | 0.911 | 9.472 | 2.42 | 0.986 | 3.872 | 6 | 0.964 | 3.993 | 3.76 | Zn Na Mg Mn |

| 9 | 0.874 | 12.49 | 2.06 | 0.955 | 4.984 | 3.37 | 0.91 | 4.789 | 2.41 | |||

| Butyl acetate | 4 | 0.905 | 0.279 | 2.35 | 0.892 | 0.29 | 2.21 | |||||

| 9 | 0.794 | 0.455 | 1.64 | 0.93 | 0.202 | 2.72 | ||||||

| G7 | Furfural | 4 | 0.909 | 6.387 | 2.4 | 0.999 | 0.444 | 22.3 | 0.993 | 1.676 | 8.47 | Zn Na Fe Ca |

| 9 | 0.936 | 5.454 | 2.84 | 0.981 | 2.726 | 5.15 | 0.948 | 3.816 | 3.14 | |||

| Ethyl lactate | 4 | 0.999 | 0.004 | 22.3 | 0.998 | 0.029 | 15.82 | |||||

| 9 | 0.946 | 75.75 | 3.08 | 0.919 | 16.28 | 2.54 | ||||||

| G8 | Pentanol | 3 | 0.93 | 0.079 | 2.72 | Zn Na Mn | ||||||

| 9 | 0.896 | 0.035 | 2.25 | |||||||||

| G9 | Isobutyric acid | 3 | 0.967 | 1.06 | 3.93 | 0.91 | 2.081 | 2.41 | 0.996 | 0.176 | 11.19 | Zn Mn Mg |

| 9 | 0.963 | 1.08 | 3.71 | 0.892 | 0.952 | 2.21 | 0.918 | 0.32 | 2.52 | |||

| G10 | Ethyl heptanoate | 5 | 0.894 | 0.436 | 2.23 | 0.917 | 0.303 | 2.51 | 0.88 | 0.565 | 2.11 | Zn Na Fe Mn K |

| 9 | 0.977 | 0.167 | 4.69 | 0.811 | 0.506 | 1.71 | 0.891 | 0.433 | 2.2 | |||

| Ethyl acetate | 5 | 0.896 | 85.05 | 2.25 | 0.989 | 31.39 | 6.76 | |||||

| 9 | 0.887 | 91.57 | 2.17 | 0.958 | 56.24 | 3.49 | ||||||

| Acetaldehyde | 5 | 0.917 | 46.98 | 2.51 | 0.959 | 22.44 | 3.53 | 0.936 | 14.26 | 2.84 | ||

| 9 | 0.829 | 0.307 | 1.79 | 0.885 | 40.14 | 2.15 | 0.959 | 26.17 | 3.53 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Hu, X.; Tian, J.; Xie, L.; Chen, M.; Huang, D. Exploring the Influence of Pottery Jar Formula Variables on Flavor Substances Through Feature Ranking and Machine Learning: Case Study of Maotai-Flavored Baijiu. Foods 2025, 14, 1063. https://doi.org/10.3390/foods14061063

Yang H, Hu X, Tian J, Xie L, Chen M, Huang D. Exploring the Influence of Pottery Jar Formula Variables on Flavor Substances Through Feature Ranking and Machine Learning: Case Study of Maotai-Flavored Baijiu. Foods. 2025; 14(6):1063. https://doi.org/10.3390/foods14061063

Chicago/Turabian StyleYang, Haili, Xinjun Hu, Jianpin Tian, Liangliang Xie, Manjiao Chen, and Dan Huang. 2025. "Exploring the Influence of Pottery Jar Formula Variables on Flavor Substances Through Feature Ranking and Machine Learning: Case Study of Maotai-Flavored Baijiu" Foods 14, no. 6: 1063. https://doi.org/10.3390/foods14061063

APA StyleYang, H., Hu, X., Tian, J., Xie, L., Chen, M., & Huang, D. (2025). Exploring the Influence of Pottery Jar Formula Variables on Flavor Substances Through Feature Ranking and Machine Learning: Case Study of Maotai-Flavored Baijiu. Foods, 14(6), 1063. https://doi.org/10.3390/foods14061063