Impact of Formulation on the Rheological, Textural, and Sensory Properties of Pistachio Spread

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Proximate Analysis of Pistachio

2.3. Analysis of Particle Size Distribution

2.4. Instrumental Color Analysis

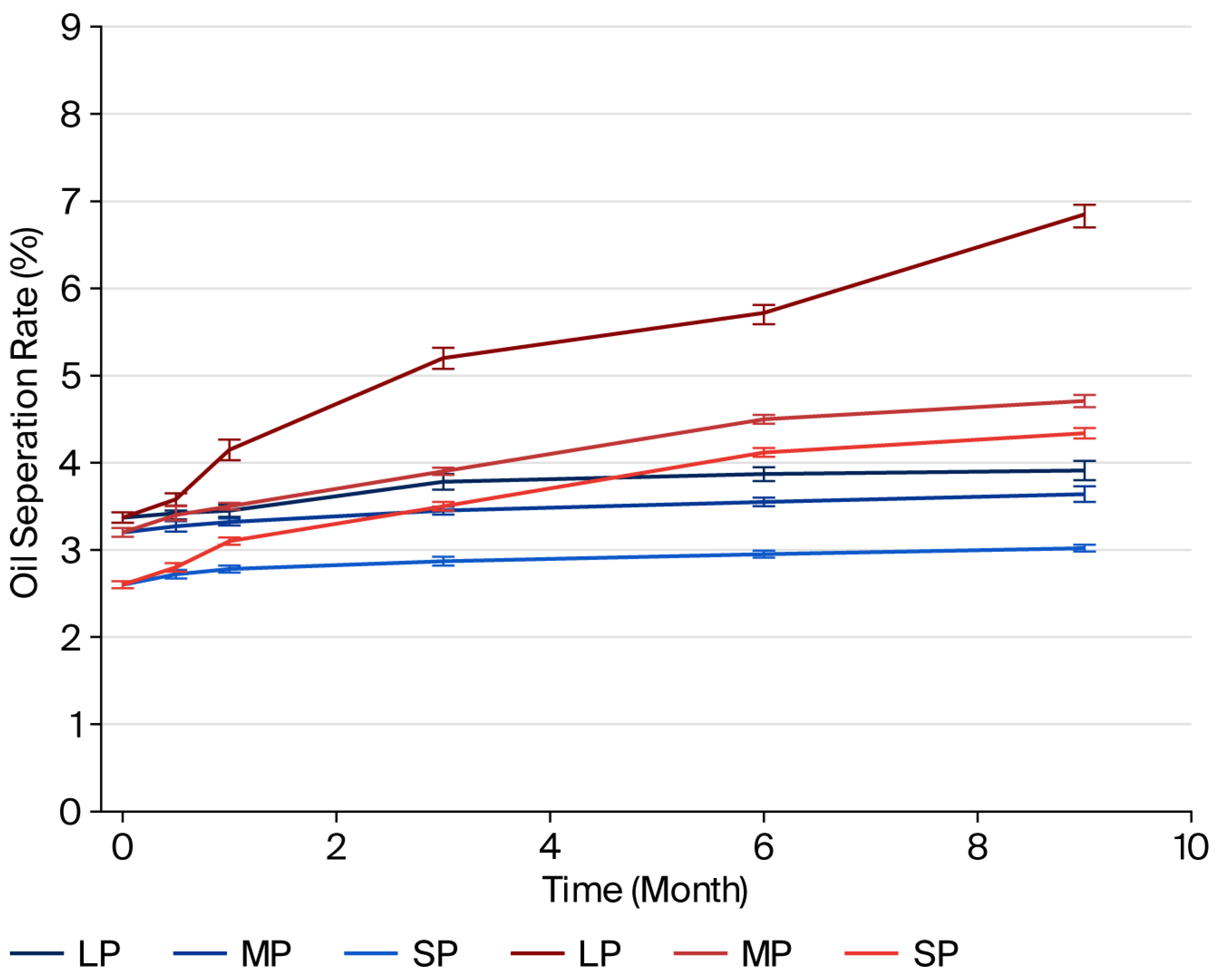

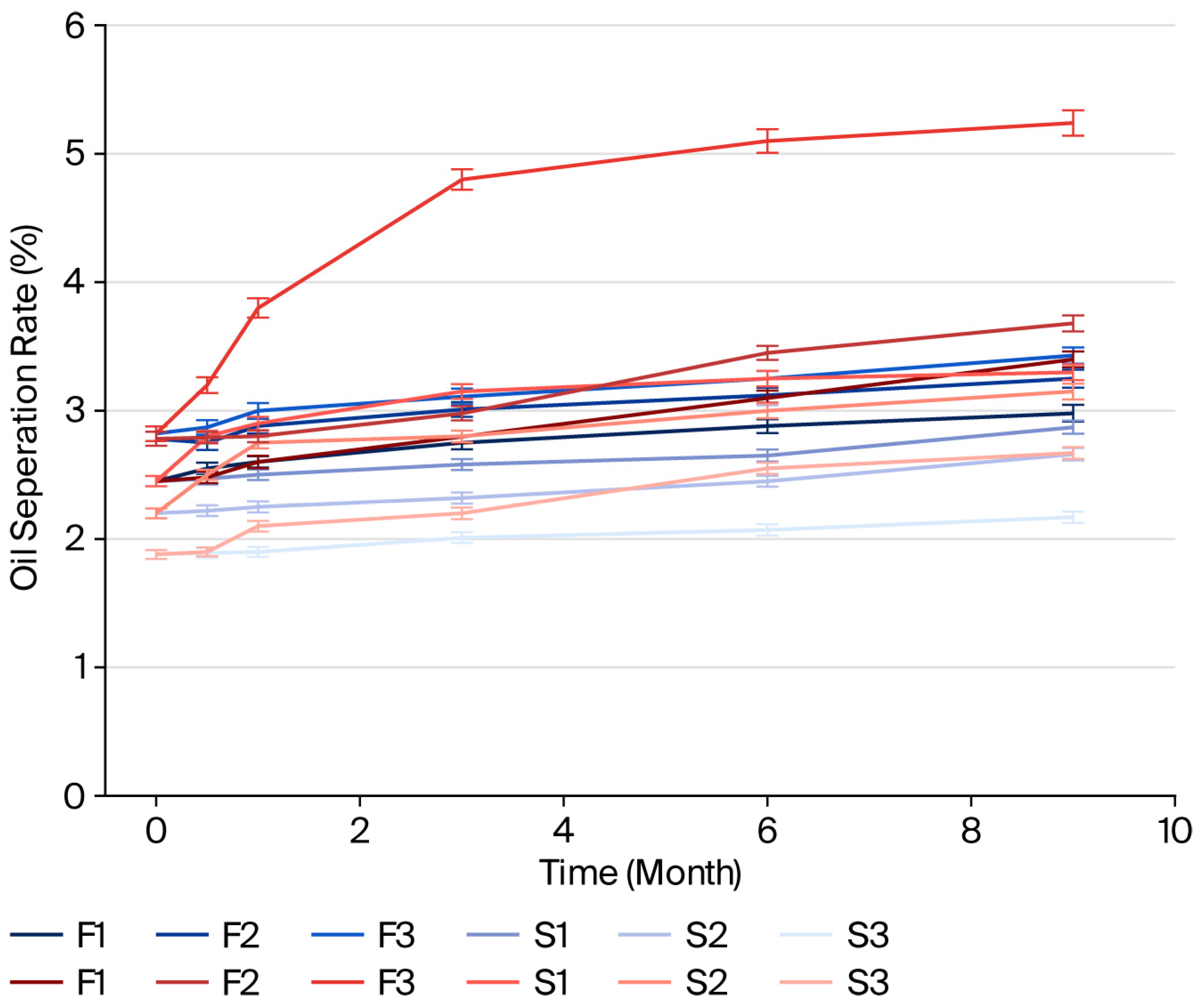

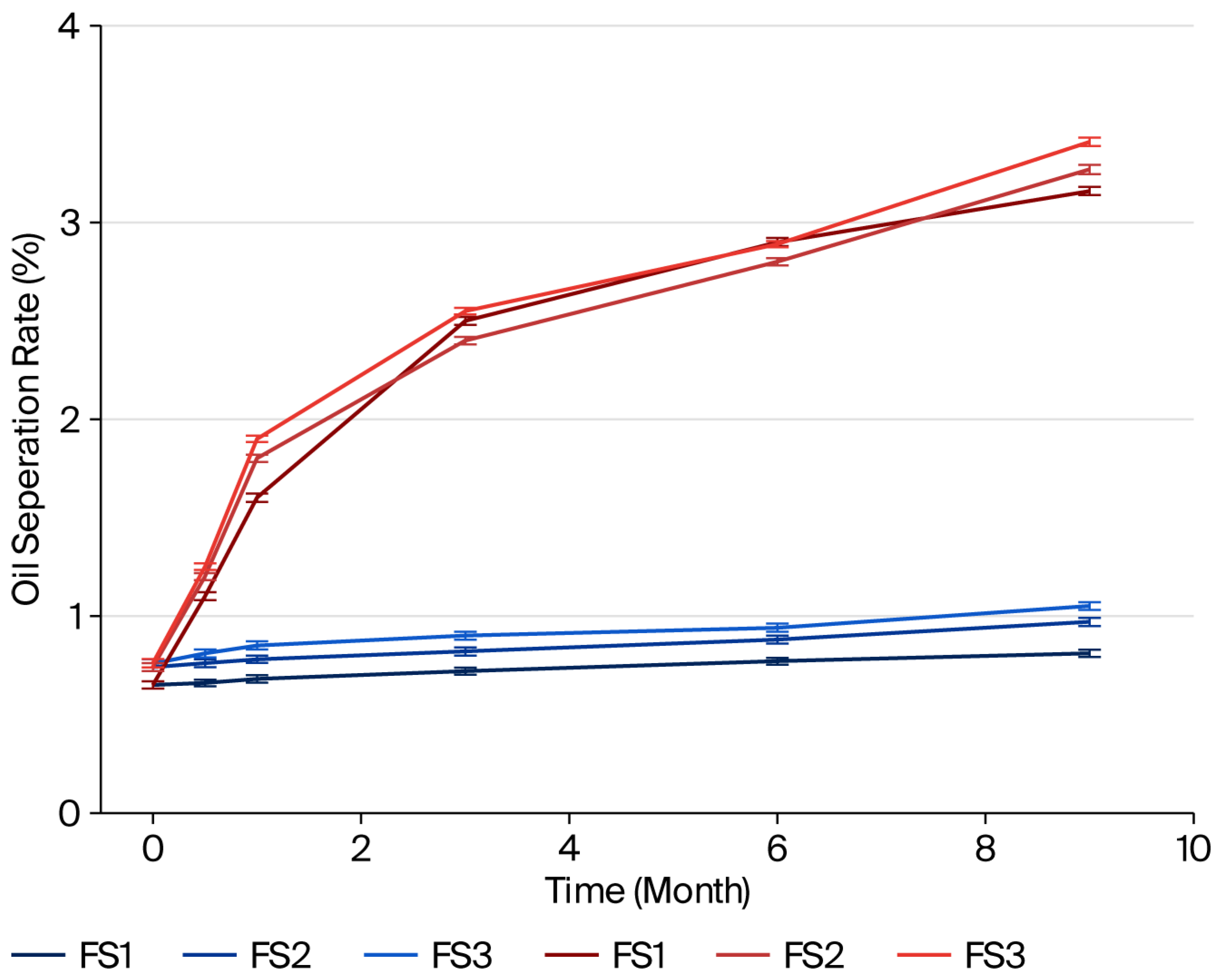

2.5. Oil Separation Rate

2.6. Rheological Analysis

- τ = shear stress (Pa);

- τ0 = yield stress (Pa), which is the stress required to initiate flow;

- K = consistency index (Pa·s), indicating the fluid’s viscosity;

- n = flow behavior index (dimensionless);

- γ = shear rate (s−1).

- K = consistency coefficient (Pa·s);

- k0 = Arrhenius constant (Pa·s);

- Ea = activation energy (J/mol), which represents the stability of the system;

- R = universal gas constant (8.314 J/mol);

- T = absolute temperature (°K).

2.7. Instrumental Textural Analysis

2.8. Sensory Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. Composition of Pistachio

3.2. Particle Size Distribution of Pistachio Pastes

3.3. Color of Pistachio Pastes and Spreads

3.4. Oil Separation Rate of Pistachio Spreads and Pastes

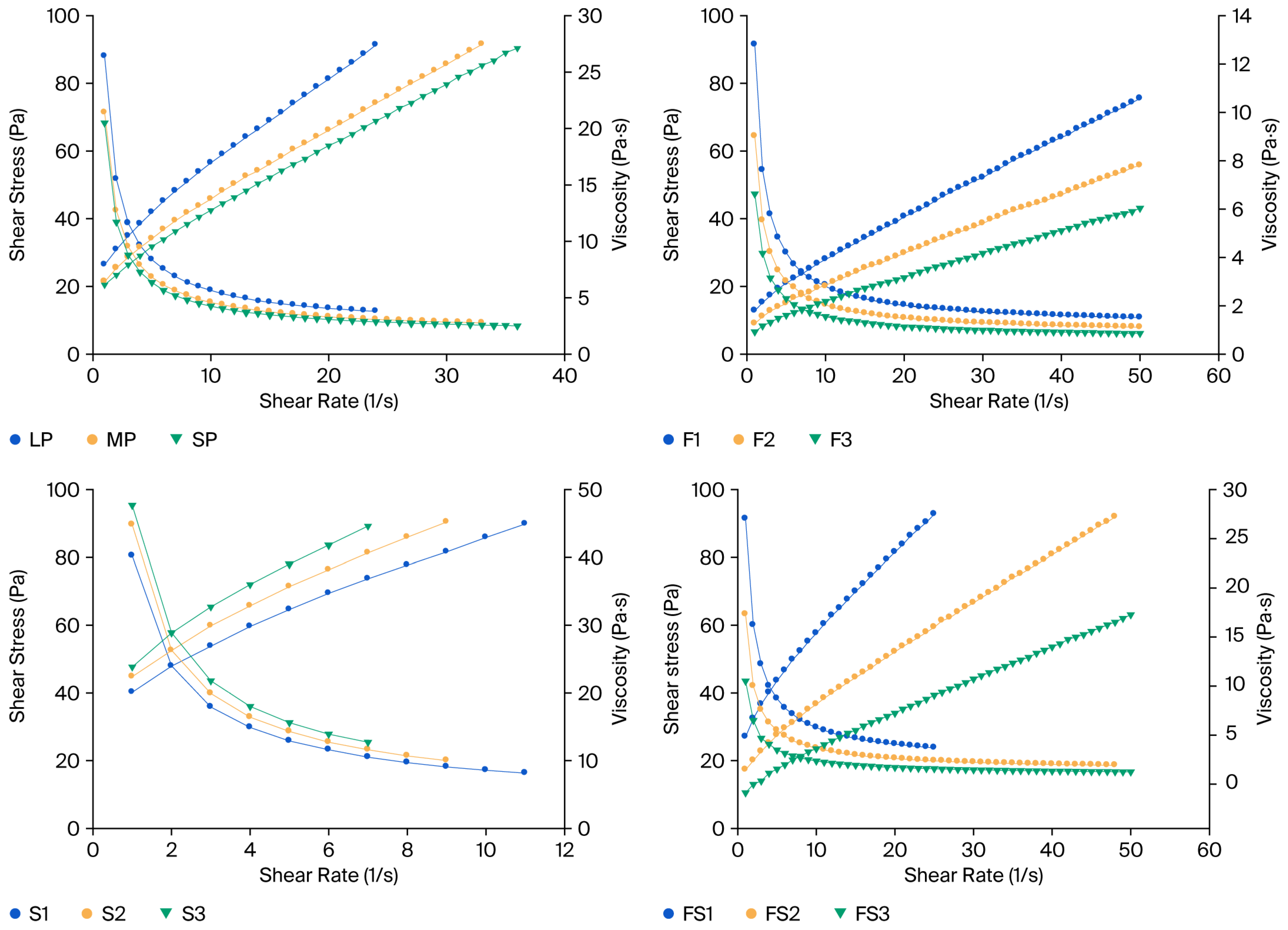

3.5. Rheological Behavior of Pistachio Paste and Spread

3.5.1. Effect of Milk Fat

3.5.2. Effect of Sugar

3.5.3. Combined Effect of Milk Fat and Sugar

3.6. Textural Properties of Pistachio Paste and Spread

3.7. Sensory Properties of Pistachio Paste and Spread

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Sample | 20 °C | 25 °C | 30 °C | 35 °C | 40 °C | 45 °C |

|---|---|---|---|---|---|---|

| LP | 15.70 ± 0.70 f | 11.28 ± 0.66 h | 9.28 ± 0.10 h | 7.42 ± 0.10 g | 6.50 ± 0.27 g | 5.38 ± 0.21 f |

| MP | 11.47 ± 0.20 e | 8.91 ± 0.29 g | 6.95 ± 0.10 g | 5.65 ± 0.10 f | 4.80 ± 0.10 f | 4.14 ± 0.15 e |

| SP | 9.76 ± 0.64 d | 7.94 ± 0.25 f | 6.18 ± 0.13 f | 5.10 ± 0.14 e | 4.20 ± 0.10 e | 3.53 ± 0.01 d |

| F1 | 6.05 ± 0.01 b | 4.46 ± 0.07 c | 3.65 ± 0.06 d | 2.98 ± 0.06 c | 2.45 ± 0.02 c | 2.22 ± 0.02 c |

| F2 | 4.76 ± 0.05 a | 3.19 ± 0.01 b | 2.46 ± 0.03 b | 2.00 ± 0.06 a | 1.86 ± 0.01 b | 1.59 ± 0.09 ab |

| F3 | 6.88 ± 0.22 c | 2.73 ± 0.11 a | 1.94 ± 0.01 a | 1.69 ± 0.02 a | 1.47 ± 0.01 a | 1.33 ± 0.02 a |

| S1 | nd | nd | 17.28 ± 0.73 j | 15.43 ± 0.04 i | 13.90 ± 0.25 i | 13.03 ± 0.27 h |

| S2 | nd | nd | 20.01 ± 0.50 k | 17.54 ± 0.21 j | 15.88 ± 0.29 j | 14.62 ± 0.52 i |

| S3 | nd | nd | nd | 25.16 ± 0.62 k | 22.58 ± 0.35 k | 19.96 ± 0.76 j |

| FS1 | 19.01 ± 0.21 g | 12.96 ± 0.20 i | 10.18 ± 0.21 i | 8.37 ± 0.17 h | 7.61 ± 0.07 h | 7.20 ± 032 g |

| FS2 | 9.12 ± 0.46 d | 7.06 ± 0.05 e | 5.06 ± 0.10 e | 4.02 ± 0.05 d | 3.39 ± 0.06 d | 3.16 ± 0.04 d |

| FS3 | 15.22 ± 0.19 f | 6.16 ± 0.05 d | 2.97 ± 0.04 c | 2.48 ± 0.02 b | 2.19 ± 0.01 c | 2.03 ± 0.04 bc |

References

- Mateos, R.; Salvador, M.D.; Fregapane, G.; Goya, L. Why Should Pistachio Be a Regular Food in Our Diet? Nutrients 2022, 14, 3207. [Google Scholar] [CrossRef]

- Kola, O.; Hayoğlu, İ.; Türkoğlu, H.; Parıldı, E.; Ak, B.E.; Akkaya, M.R. Physical and Chemical Properties of Some Pistachio Varieties (Pistacia vera L.) and Oils Grown under Irrigated and Non-Irrigated Conditions in Turkey. Qual. Assur. Saf. Crops Foods 2018, 10, 383–388. [Google Scholar] [CrossRef]

- Bulló, M.; Juanola-Falgarona, M.; Hernández-Alonso, P.; Salas-Salvadó, J. Nutrition Attributes and Health Effects of Pistachio Nuts. Br. J. Nutr. 2015, 113, S79–S93. [Google Scholar] [CrossRef]

- International Nut and Dried Fruit Council (INC). Global Statistical Yearbook 2024: World Tree Nut and Dried Fruit Production and Consumption Trends; International Nut and Dried Fruit Council: Tarragona, Spain, 2024; Available online: https://www.nutfruit.org (accessed on 25 September 2025).

- Turkish Statistical Institute (TÜİK). Plant Production Statistics 2024: Pistachio (Antep fıstığı) Production by Region; Turkish Statistical Institute: Ankara, Turkey, 2024. Available online: https://data.tuik.gov.tr (accessed on 25 September 2025).

- Mandalari, G.; Barreca, D.; Gervasi, T.; Roussell, M.A.; Klein, B.; Feeney, M.J.; Carughi, A. Pistachio Nuts (Pistacia vera L.): Production, Nutrients, Bioactives and Novel Health Effects. Plants 2022, 11, 18. [Google Scholar] [CrossRef]

- Bellomo, M.G.; Fallico, B. Anthocyanins, Chlorophylls and Xanthophylls in Pistachio Nuts (Pistacia vera) of Different Geographic Origin. J. Food Compos. Anal. 2007, 20, 352–359. [Google Scholar] [CrossRef]

- European Commission. Commission Implementing Regulation (EU) 2025/1245 of 25 June 2025 Entering “Antep Fıstığı Ezmesi” into the Register of Protected Geographical Indications (PGI). Official Journal of the European Union. 2025. Available online: https://eur-lex.europa.eu (accessed on 28 August 2025).

- Shakerardekani, A. Consumer Acceptance and Quantitative Descriptive Analysis of Pistachio Spread. J. Agric. Sci. Technol. 2017, 19, 85–95. Available online: https://jast.modares.ac.ir/article-23-1009-en.html (accessed on 25 September 2025).

- De Jonge, N.; Kaszab, T.; Badak-Kerti, K. Physical Properties of Different Nut Butters. Progress 2023, 19, 77–86. [Google Scholar] [CrossRef]

- Tsantili, E.; Takidelli, C.; Christopoulos, M.V.; Lambrinea, E.; Rouskas, D.; Roussos, P.A. Physical, Compositional and Sensory Differences in Nuts among Pistachio (Pistachia vera L.) Varieties. Sci. Hortic. 2010, 125, 562–568. [Google Scholar] [CrossRef]

- Shuai, X.; Li, Y.; Zhang, Y.; Wei, C.; Zhang, M.; Du, L. Gelation of whole macadamia butter by different oleogelators affects the physicochemical properties and applications. LWT 2024, 198, 115961. [Google Scholar] [CrossRef]

- Hitlamani, V.; Huded, P.; Kumar, G.S.; Chetana, R. Development of high-fiber and high-protein virgin coconut oil-based spread and its physico-chemical and sensory qualities. J. Food Sci. Technol. 2024, 61, 2196–2204. [Google Scholar] [CrossRef]

- Leahu, A.; Ghinea, C.; Ropciuc, S. Rheological, Textural, and Sensorial Characterization of Walnut Butter. Appl. Sci. 2022, 12, 10976. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Ditschun, T.L.; Riddell, E.; Qin, W.; Graves, K.; Jegede, O.; Sharafbafi, N.; Pendergast, T.; Chidichimo, D.; Wilson, S.F. Overview of Mouthfeel from the Perspective of Sensory Scientists in Industry. Comp. Rev. Food Sci. Food Safe 2025, 24, e70126. [Google Scholar] [CrossRef]

- Shakerardekani, A. Effect of Milling Process on Colloidal Stability, Color and Rheological Properties of Pistachio Paste. J. Nuts 2014, 5, 57–65. [Google Scholar]

- Taghizadeh, M.; Razavi, S.M.A. Modeling Time-Independent Rheological Behavior of Pistachio Butter. Int. J. Food Prop. 2009, 12, 331–340. [Google Scholar] [CrossRef]

- Shahidi-Noghabi, M.; Naji-Tabasi, S.; Sarraf, M. Effect of emulsifier on rheological, textural and microstructure properties of walnut butter. J. Food Meas. Charact. 2018, 13, 785–792. [Google Scholar] [CrossRef]

- Li, L.; Huan, Y.; Shi, C. Effect of Sorbitol on Rheological, Textural and Microstructural Characteristics of Peanut Butter. Food Sci. Technol. Res. 2014, 20, 739–747. [Google Scholar] [CrossRef]

- Wagener, E.A.; Kerr, W.L. Effects of oil content on the sensory, textural, and physical properties of pecan butter (Carya illinoinensis). J. Texture Stud. 2017, 49, 286–292. [Google Scholar] [CrossRef]

- Principato, L.; Carullo, D.; Gruppi, A.; Lambri, M.; Bassani, A.; Spigno, G. Correlation of rheology and oral tribology with sensory perception of commercial hazelnut and cocoa-based spreads. J. Texture Stud. 2024, 55, e12850. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, T.; Yang, R. Effect of Roasting and Grinding on the Processing Characteristics and Organoleptic Properties of Sesame Butter. Euro J. Lipid Sci. Technol. 2019, 121, 1800401. [Google Scholar] [CrossRef]

- Pekmez, H.; Özkanlı, O.; Şekeroğlu, G.; Kaya, A. Influence of Particle Size on the Color, Rheological, and Textural Properties of Sesame Paste. Qual. Assur. Saf. Crops Foods 2025, 17, 146–160. [Google Scholar] [CrossRef]

- Malvano, F.; Muccio, E.; Galgano, F.; Marra, F.; Albanese, D. Design of a high protein, no added sugar pistachio spread using oleogel as fat replacer. LWT 2024, 198, 115993. [Google Scholar] [CrossRef]

- Berk, B.; Cosar, S.; Mazı, B.G.; Oztop, M.H. Textural, rheological, melting properties, particle size distribution and NMR of cocoa-hazelnut spread with inulin/stevia. J. Texture Stud. 2024, 55, e12834. [Google Scholar] [CrossRef]

- Prakansamut, N.; Adulpadungsak, K.; Sonwai, S.; Aryusuk, K.; Lilitchan, S. Application of functional oil blend-based oleogels as novel structured oil alternatives in chocolate spread. LWT 2024, 203, 116322. [Google Scholar] [CrossRef]

- Tonetto, M.L.; Teixeira, G.L.; Kechinski, C.P.; Block, J.M.; Feltes, M.M.C. Turning nuts and peanuts into functional spreads with bioactive compounds as an opportunity for innovation. Discov. Food 2025, 5, 131. [Google Scholar] [CrossRef]

- da Silva, T.L.T.; Martini, S. Recent Advances in Lipid Crystallization in the Food Industry. Annu. Rev. Food Sci. Technol. 2024, 15, 355–379. [Google Scholar] [CrossRef] [PubMed]

- Shakerardekani, A.; Karim, R.; Ghazali, H.M.; Chin, N.L. Development of Pistachio (Pistacia vera L.) Spread. J. Food Sci. 2013, 78, S484–S489. [Google Scholar] [CrossRef]

- Wang, B.; Hou, L.; Yang, M.; Jin, L.; Liu, H.; Wang, X. An Evaluation of the Physicochemical Properties of Sesame Paste Produced by Ball Milling Compared against Conventional Colloid Milling. J. Oleo Sci. 2024, 73, 645–655. [Google Scholar] [CrossRef]

- Latimer, G.W. (Ed.) Official Methods of Analysis of AOAC International, 22nd ed.; Oxford University Press: New York, NY, USA, 2023; ISBN 978-0-19-761013-8. [Google Scholar]

- Commission Internationale de l’Éclairage (CIE). Colorimetry, 4th ed.; CIE Publication No. 15:2018; CIE Central Bureau: Vienna, Austria, 2018. [Google Scholar]

- Arena, E.; Campisi, S.; Fallico, B.; Maccarone, E. Distribution of Fatty Acids and Phytosterols as a Criterion to Discriminate Geographic Origin of Pistachio Seeds. Food Chem. 2007, 104, 403–408. [Google Scholar] [CrossRef]

- Martínez, M.L.; Fabani, M.P.; Baroni, M.V.; Huaman, R.N.M.; Ighani, M.; Maestri, D.M.; Wunderlin, D.; Tapia, A.; Feresin, G.E. Argentinian Pistachio Oil and Flour: A Potential Novel Approach of Pistachio Nut Utilization. J. Food Sci. Technol. 2016, 53, 2260–2269. [Google Scholar] [CrossRef]

- Shakerardekani, A.; Karim, R. Optimization of Processing Variables for Pistachio Paste Production. Pist. Health J. 2018, 1, 13–19. [Google Scholar] [CrossRef]

- Glicerina, V.; Balestra, F.; Rosa, M.D.; Bergenhstål, B.; Tornberg, E.; Romani, S. The influence of different processing stages on particle size, microstructure, and appearance of dark chocolate. J. Food Sci. 2014, 79, 1359–1365. [Google Scholar] [CrossRef]

- Shakerardekani, A.; Karim, R.; Ghazali, H.; Chin, N. Textural, Rheological and Sensory Properties and Oxidative Stability of Nut Spreads—A Review. Int. J. Mol. Sci. 2013, 14, 4223–4241. [Google Scholar] [CrossRef] [PubMed]

- Hayoglu, I.; Faruk Gamli, O. Water Sorption Isotherms of Pistachio Nut Paste. Int. J. Food Sci. Technol. 2007, 42, 224–227. [Google Scholar] [CrossRef]

- Yuzer, M.O.; Genccelep, H. Effect of Sesame Protein/PVA Nanofibers on Oil Separation and Rheological Properties in Sesame Paste. J. Food Process Eng. 2024, 47, e14534. [Google Scholar] [CrossRef]

- Huo, Y.; Hou, X.; Yu, Y.; Wen, X.; Ding, Y.; Li, Y.; Wang, Z. Improving the Thermal and Oxidative Stability of Food-Grade Phycocyanin from Arthrospira Platensis by Addition of Saccharides and Sugar Alcohols. Foods 2022, 11, 1752. [Google Scholar] [CrossRef] [PubMed]

- Cornacchia, L.; Roos, Y.H. Solid–Liquid Transitions and Stability of HPKO-in-Water Systems Emulsified by Dairy Proteins. Food Biophys. 2011, 6, 288–294. [Google Scholar] [CrossRef]

- Zhu, Q.; Pan, Y.; Jia, X.; Li, J.; Zhang, M.; Yin, L. Review on the Stability Mechanism and Application of Water-in-Oil Emulsions Encapsulating Various Additives. Comp. Rev. Food Sci. Food Safe 2019, 18, 1660–1675. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Bao, H.; Jiang, M.; Zhu, W.; Zhao, Y.; Zhang, R.; Zhu, K. Effect of Hot--air Drying on Drying Characteristics and Quality of Tiger Nut. J. Sci. Food Agric. 2025, 105, 255–265. [Google Scholar] [CrossRef]

- Walton, D.; Randall, B.; Poienou, M.; Nevenimo, T.; Moxon, J.; Wallace, H. Shelf Life of Tropical Canarium Nut Stored under Ambient Conditions. Horticulturae 2017, 3, 24. [Google Scholar] [CrossRef]

- Faruk Gamlı, Ö.; Hayoğlu, İ. The Effect of the Different Packaging Storage Conditions on the Quality of Pistachio Nut Paste. J. Food Eng. 2007, 78, 443–448. [Google Scholar] [CrossRef]

- Emadzadeh, B.; Razavi, S.M.A.; Hashemi, M.; Mahallati, M.N.; Farhoosh, R. Optimization of Fat Replacers and Sweetener Levels to Formulate Reduced-Calorie Pistachio Butter: A Response Surface Methodology. Int. J. Nuts Relat. Sci. 2011, 2, 37–54. [Google Scholar]

- Shakerardekani, A.; Karim, R.; Ghazali, H.M.; Chin, N.L. The Effect of Monoglyceride Addition on the Rheological Properties of Pistachio Spread. J. Americ Oil Chem. Soc. 2013, 90, 1517–1521. [Google Scholar] [CrossRef]

- Fidaleo, M.; Miele, N.A.; Mainardi, S.; Armini, V.; Nardi, R.; Cavella, S. Effect of Refining Degree on Particle Size, Sensory and Rheological Characteristics of Anhydrous Paste for Ice Creams Produced in Industrial Stirred Ball Mill. LWT Food Sci. Technol. 2017, 79, 242–250. [Google Scholar] [CrossRef]

- Emadzadeh, B.; Razavi, S.M.A.; Mahallati, M.N. Effects of Fat Replacers and Sweeteners on the Time-Dependent Rheological Characteristics and Emulsion Stability of Low-Calorie Pistachio Butter: A Response Surface Methodology. Food Bioprocess Technol. 2012, 5, 1581–1591. [Google Scholar] [CrossRef]

- Emadzadeh, B.; Razavi, S.M.A.; Rezvani, E.; Schleining, G. Steady Shear Rheological Behavior and Thixotropy of Low-Calorie Pistachio Butter. Int. J. Food Prop. 2015, 18, 137–148. [Google Scholar] [CrossRef]

- Rao, M.A. Rheology of Fluid, Semisolid, and Solid Foods: Principles and Applications; Food Engineering Series; Springer: Boston, MA, USA, 2014; ISBN 978-1-4614-9229-0. [Google Scholar]

- Razavi, S.M.A.; Taghizadeh, M.; Shakerardekani, A. Modeling the Time-Dependent Rheological Properties of Pistachio Butter. Int. J. Nuts Related Sci. 2010, 1, 38–45. [Google Scholar]

- Dubost, N.J.; Shewfelt, R.L.; Eitenmiller, R.R. Consumer Acceptabılıty, Sensory and Instrumental Analysıs of Peanut Soy Spreads. J. Food Qual. 2003, 26, 27–42. [Google Scholar] [CrossRef]

- Emadzadeh, B.; Razavi, S.M.A.; Schleining, G. Dynamic Rheological and Textural Characteristics of Low-Calorie Pistachio Butter. Int. J. Food Prop. 2013, 16, 512–526. [Google Scholar] [CrossRef]

- Rabadán, A.; Gallardo-Guerrero, L.; Gandul-Rojas, B.; Álvarez-Ortí, M.; Pardo, J.E. Effect of Roasting Conditions on Pigment Composition and Some Quality Parameters of Pistachio Oil. Food Chem. 2018, 264, 49–57. [Google Scholar] [CrossRef]

- Shakerardekani, A.; Karim, R.; Ghazali, H.M.; Chin, N.L. Oxidative Stability of Pistachio (Pistacia vera L.) Paste and Spreads. J. Am. Oil Chem. Soc. 2015, 92, 1015–1021. [Google Scholar] [CrossRef]

- Mousazadeh, M.; Mousavi, M.; Emam-Djomeh, Z.; Ali Ahmed, S.; Hadinezhad, M.; Hassanzadeh, H. Sensorial, Textural, and Rheological Analysis of Novel Pistachio-based Chocolate Formulations by Quantitative Descriptive Analysis. Food Sci. Nutr. 2023, 11, 7120–7129. [Google Scholar] [CrossRef] [PubMed]

- Guinard, J.-X.; Mazzucchelli, R. The Sensory Perception of Texture and Mouthfeel. Trends Food Sci. Technol. 1996, 7, 213–219. [Google Scholar] [CrossRef]

- Cruz, M.; Freitas, F.; Torres, C.A.V.; Reis, M.A.M.; Alves, V.D. Influence of Temperature on the Rheological Behavior of a New Fucose-Containing Bacterial Exopolysaccharide. Int. J. Biol. Macromol. 2011, 48, 695–699. [Google Scholar] [CrossRef]

- Małkowska, M.; Staniewski, B.; Ziajka, J. Analyses of milk fat crystallization and milk fat fractions. Int. J. Food Prop. 2021, 24, 325–336. [Google Scholar] [CrossRef]

- Woodbury, T.J.; Pitts, S.L.; Pilch, A.M.; Smith, P.; Mauer, L.J. Mechanisms of the different effects of sucrose, glucose, fructose, and a glucose–fructose mixture on wheat starch gelatinization, pasting, and retrogradation. J. Food Sci. 2022, 88, 293–314. [Google Scholar] [CrossRef]

- Rasouli Pirouzian, H.; Alakas, E.; Cayir, M.; Yakisik, E.; Toker, O.S.; Kaya, Ş.; Tanyeri, O. Buttermilk as Milk Powder and Whey Substitute in Compound Milk Chocolate: Comparative Study and Optimisation. Int. J. Dairy Technol. 2021, 74, 246–257. [Google Scholar] [CrossRef]

- Marra, F.; Lavorgna, A.; Incarnato, L.; Malvano, F.; Albanese, D. Optimization of Hazelnut Spread Based on Total or Partial Substitution of Palm Oil. Foods 2023, 12, 3122. [Google Scholar] [CrossRef]

- Manzocco, L.; Calligaris, S.; Camerin, M.; Pizzale, L.; Nicoli, M.C. Prediction of Firmness and Physical Stability of Low-Fat Chocolate Spreads. J. Food Eng. 2014, 126, 120–125. [Google Scholar] [CrossRef]

- Liu, L.; Gao, Z.; Chen, G.; Yao, J.; Zhang, X.; Qiu, X.; Liu, L. A comprehensive review: Impact of oleogel application on food texture and sensory properties. Food Sci. Nutr. 2024, 12, 3849–3862. [Google Scholar] [CrossRef] [PubMed]

| Sample | D10 (µm) | D50 (µm) | D90 (µm) |

|---|---|---|---|

| LP | 5.72 ± 0.06 c | 16.71 ± 0.12 c | 434.80 ± 9.30 c |

| MP | 2.02 ± 0.04 b | 11.89 ± 0.08 b | 395.40 ± 7.90 b |

| SP | 1.88 ± 0.03 a | 7.18 ± 0.07 a | 149.78 ± 4.60 a |

| Sample | L* | a* | b* |

|---|---|---|---|

| LP | 44.34 ± 0.02 a | −3.82 ± 0.05 a | 45.86 ± 0.05 g |

| MP | 44.41 ± 0.02 b | −3.77 ± 0.03 ab | 44.91 ± 0.06 e |

| SP | 44.42 ± 0.03 b | −3.64 ± 0.04 cde | 44.55 ± 0.05 c |

| F1 | 44.76 ± 0.02 c | −3.53 ± 0.07 f | 44.21 ± 0.06 a |

| F2 | 44.91 ± 0.04 d | −3.56 ± 0.08 ef | 44.37 ± 0.11 b |

| F3 | 45.25 ± 0.03 e | −3.72 ± 0.06 bc | 44.77 ± 0.09 d |

| S1 | 46.79 ± 0.02 f | −3.57 ± 0.03 ef | 44.19 ± 0.12 a |

| S2 | 47.23 ± 0.03 g | −3.66 ± 0.06 cd | 44.28 ± 0.09 ab |

| S3 | 47.40 ± 0.03 h | 3.42 ± 0.04 g | 44.72 ± 0.08 d |

| FS1 | 48.11 ± 0.03 j | −3.61 ± 0.02 def | 44.73 ± 0.03 d |

| FS2 | 48.28 ± 0.03 k | −3.56 ± 0.03 ef | 44.64 ± 0.05 cd |

| FS3 | 48.02 ± 0.04 i | −3.59 ± 0.02 def | 45.10 ± 0.06 f |

| Sample | Temperature (°C) | τ0 (Pa) | K | n |

|---|---|---|---|---|

| LP | 20 | 19.80 ± 0.93 a | 15.70 ± 0.70 e | 0.770 ± 0.02 a |

| 25 | 20.64 ± 0.56 a | 11.28 ± 0.66 d | 0.809 ± 0.06 a | |

| 30 | 20.28 ± 0.26 a | 9.28 ± 0.10 c | 0.803 ± 0.01 a | |

| 35 | 20.40 ± 0.11 a | 7.42 ± 0.10 b | 0.812 ± 0.01 a | |

| 40 | 20.52 ± 0.65 a | 6.50 ± 0.27 a | 0.797 ± 0.01 a | |

| 45 | 21.03 ± 0.57 a | 5.38 ± 0.21 a | 0.783 ± 0.01 a | |

| MP | 20 | 19.64 ± 0.56 c | 11.47 ± 0.20 f | 0.823 ± 0.01 ab |

| 25 | 18.07 ± 0.83 ab | 8.91 ± 0.29 e | 0.825 ± 0.01 ab | |

| 30 | 17.35 ± 0.40 a | 6.95 ± 0.10 d | 0.835 ± 0.01 b | |

| 35 | 17.26 ± 0.41 a | 5.65 ± 0.10 c | 0.835 ± 0.01 b | |

| 40 | 17.39 ± 0.10 a | 4.80 ± 0.10 b | 0.828 ± 0.01 ab | |

| 45 | 18.37 ± 0.29 b | 4.14 ± 0.15 a | 0.820 ± 0.01 a | |

| SP | 20 | 19.62 ± 0.71 b | 9.76 ± 0.64 f | 0.848 ± 0.04 a |

| 25 | 17.13 ± 0.82 a | 7.94 ± 0.25 e | 0.837 ± 0.01 a | |

| 30 | 16.56 ± 0.85 a | 6.18 ± 0.13 d | 0.847 ± 0.01 a | |

| 35 | 16.25 ± 0.68 a | 5.10 ± 0.14 c | 0.844 ± 0.01 a | |

| 40 | 16.48 ± 0.23 a | 4.20 ± 0.10 b | 0.846 ± 0.01 a | |

| 45 | 17.48 ± 0.12 a | 3.53 ± 0.01 a | 0.844 ± 0.01 a |

| Sample | Temperature (°C) | τ0 (Pa) | K | n |

|---|---|---|---|---|

| F1 | 20 | 12.71 ± 0.69 b | 6.05 ± 0.01 f | 0.868 ± 0.001 b |

| 25 | 12.57 ± 0.20 b | 4.46 ± 0.07 e | 0.884 ± 0.004 d | |

| 30 | 11.45 ± 0.26 a | 3.65 ± 0.06 d | 0.880 ± 0.004 cd | |

| 35 | 11.25 ± 0.21 a | 2.98 ± 0.06 c | 0.879 ± 0.003 c | |

| 40 | 11.47 ± 0.10 a | 2.45 ± 0.02 b | 0.878 ± 0.002 c | |

| 45 | 11.52 ± 0.20 a | 2.22 ± 0.02 a | 0.858 ± 0.001 a | |

| F2 | 20 | 9.73 ± 0.05 c | 4.76 ± 0.05 f | 0.871 ± 0.003 b |

| 25 | 9.06 ± 0.20 b | 3.19 ± 0.01 e | 0.893 ± 0.001 c | |

| 30 | 8.75 ± 0.07 b | 2.46 ± 0.03 d | 0.901 ± 0.002 d | |

| 35 | 8.92 ± 0.40 b | 2.00 ± 0.06 c | 0.900 ± 0.006 d | |

| 40 | 8.19 ± 0.03 a | 1.86 ± 0.01 b | 0.872 ± 0.001 b | |

| 45 | 8.24 ± 0.05 a | 1.59 ± 0.09 a | 0.852 ± 0.005 a | |

| F3 | 20 | 10.51 ± 0.16 d | 6.88 ± 0.22 e | 0.801 ± 0.007 a |

| 25 | 8.10 ± 0.14 c | 2.73 ± 0.11 d | 0.897 ± 0.008 e | |

| 30 | 6.41 ± 0.02 b | 1.94 ± 0.01 c | 0.896 ± 0.002 e | |

| 35 | 6.11 ± 0.07 a | 1.69 ± 0.02 b | 0.880 ± 0.002 d | |

| 40 | 6.11 ± 0.02 a | 1.47 ± 0.01 a | 0.867 ± 0.002 c | |

| 45 | 6.05 ± 0.02 a | 1.33 ± 0.02 a | 0.849 ± 0.002 b |

| Sample | Temperature (°C) | τ0 (Pa) | K | n |

|---|---|---|---|---|

| S1 | 20 | nd | nd | nd |

| 25 | nd | nd | nd | |

| 30 | 26.94 ± 0.86 bc | 17.28 ± 0.73 d | 0.710 ± 0.015 d | |

| 35 | 25.22 ± 0.05 a | 15.43 ± 0.04 c | 0.693 ± 0.001 c | |

| 40 | 26.04 ± 0.33 ab | 13.90 ± 0.25 b | 0.674 ± 0.003 b | |

| 45 | 27.46 ± 0.52 c | 13.03 ± 0.27 a | 0.642 ± 0.010 a | |

| S2 | 20 | nd | nd | nd |

| 25 | nd | nd | nd | |

| 30 | 28.48 ± 0.20 a | 20.01 ± 0.50 d | 0.689 ± 0.014 c | |

| 35 | 27.60 ± 0.39 a | 17.54 ± 0.21 c | 0.675 ± 0.010 bc | |

| 40 | 27.70 ± 0.30 a | 15.88 ± 0.29 b | 0.662 ± 0.010 ab | |

| 45 | 29.80 ± 0.84 b | 14.62 ± 0.52 a | 0.648 ± 0.011 a | |

| S3 | 20 | nd | nd | nd |

| 25 | nd | nd | nd | |

| 30 | nd | nd | nd | |

| 35 | 24.20 ± 0.33 a | 25.16 ± 0.62 c | 0.581 ± 0.010 a | |

| 40 | 24.96 ± 0.37 a | 22.58 ± 0.35 b | 0.572 ± 0.010 a | |

| 45 | 27.82 ± 0.82 b | 19.96 ± 0.76 a | 0.581 ± 0.019 a |

| Sample | Temperature (°C) | τ0 (Pa) | K | n |

|---|---|---|---|---|

| FS1 | 20 | 16.48 ± 0.03 a | 19.01 ± 0.21 f | 0.692 ± 0.004 a |

| 25 | 18.98 ± 0.02 b | 12.96 ± 0.20 e | 0.751 ± 0.005 cd | |

| 30 | 19.17 ± 0.38 bc | 10.18 ± 0.21 d | 0.759 ± 0.007 d | |

| 35 | 19.68 ± 0.16 cd | 8.37 ± 0.17 c | 0.763 ± 0.006 d | |

| 40 | 19.82 ± 0.11 d | 7.61 ± 0.07 b | 0.740 ± 0.002 c | |

| 45 | 20.47 ± 0.54 e | 7.20 ± 0.32 a | 0.715 ± 0.011 b | |

| FS2 | 20 | 14.45 ± 0.39 b | 9.12 ± 0.46 e | 0.811 ± 0.012 a |

| 25 | 14.20 ± 0.10 ab | 7.06 ± 0.05 e | 0.823 ± 0.002 a | |

| 30 | 13.91 ± 0.13 a | 5.06 ± 0.10 d | 0.838 ± 0.009 b | |

| 35 | 14.60 ± 0.26 bc | 4.02 ± 0.05 c | 0.848 ± 0.003 b | |

| 40 | 14.90 ± 0.23 cd | 3.39 ± 0.06 b | 0.845 ± 0.004 b | |

| 45 | 15.07 ± 0.20 d | 3.16 ± 0.04 a | 0.823 ± 0.003 a | |

| FS3 | 20 | 16.78 ± 0.41 b | 15.22 ± 0.19 f | 0.716 ± 0.007 a |

| 25 | 13.40 ± 0.14 b | 6.16 ± 0.05 e | 0.814 ± 0.002 b | |

| 30 | 9.52 ± 0.20 a | 2.97 ± 0.04 d | 0.879 ± 0.020 e | |

| 35 | 9.39 ± 0.02 a | 2.48 ± 0.02 c | 0.872 ± 0.002 e | |

| 40 | 9.30 ± 0.02 a | 2.19 ± 0.01 b | 0.858 ± 0.002 d | |

| 45 | 9.38 ± 0.02 a | 2.03 ± 0.04 a | 0.836 ± 0.005 c |

| Sample | Ea | k0 | r2 |

|---|---|---|---|

| LP | 32.1 | 2.8 × 10−5 | 0.9866 |

| MP | 31.8 | 2.4 × 10−5 | 0.9926 |

| SP | 31.8 | 2.1 × 10−5 | 0.9986 |

| F1 | 27.5 | 6.4 × 10−5 | 0.9860 |

| F2 | 22.2 | 3.6 × 10−4 | 0.9714 |

| F3 | 20.4 | 5.9 × 10−4 | 0.9963 |

| S1 | 15.3 | 4.0 × 10−2 | 0.9891 |

| S2 | 18.4 | 2.6 × 10−2 | 0.9916 |

| S3 | 18.9 | 1.6 × 10−2 | 0.9978 |

| FS1 | 18.2 | 7.0 × 10−3 | 0.9336 |

| FS2 | 25.4 | 2.0 × 10−4 | 0.9569 |

| FS3 | 20.3 | 9.0 × 10−4 | 0.9720 |

| Samples | Firmness (N) | Spreadability (N·s) | Adhesiveness (N·s) |

|---|---|---|---|

| LP | 2.69 ± 0.04 f | 1.589 ± 0.021 f | −0.667 ± 0.012 g |

| MP | 2.68 ± 0.04 f | 1.568 ± 0.019 f | −0.631 ± 0.011 f |

| SP | 2.36 ± 0.03 e | 1.432 ± 0.018 e | −0.538 ± 0.009 e |

| F1 | 1.79 ± 0.02 d | 1.064 ± 0.017 d | −0.401 ± 0.008 d |

| F2 | 1.35 ± 0.02 b | 0.830 ± 0.015 b | −0.296 ± 0.004 b |

| F3 | 1.02 ± 0.02 a | 0.630 ± 0.012 a | −0.224 ± 0.004 a |

| S1 | 5.05 ± 0.06 h | 2.995 ± 0.032 h | −1.272 ± 0.012 j |

| S2 | 5.10 ± 0.06 h | 3.014 ± 0.041 h | −1.212 ± 0.011 i |

| S3 | 5.33 ± 0.05 i | 3.192 ± 0.040 i | −1.300 ± 0.014 k |

| FS1 | 3.66 ± 0.04 g | 2.143 ± 0.028 g | −0.796 ± 0.010 h |

| FS2 | 2.39 ± 0.03 e | 1.426 ± 0.017 e | −0.544 ± 0.008 e |

| FS3 | 1.65 ± 0.03 c | 0.970 ± 0.016 c | −0.352 ± 0.004 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kılıç, N.F.; Şekeroğlu, G.; Kaya, A. Impact of Formulation on the Rheological, Textural, and Sensory Properties of Pistachio Spread. Foods 2025, 14, 4002. https://doi.org/10.3390/foods14234002

Kılıç NF, Şekeroğlu G, Kaya A. Impact of Formulation on the Rheological, Textural, and Sensory Properties of Pistachio Spread. Foods. 2025; 14(23):4002. https://doi.org/10.3390/foods14234002

Chicago/Turabian StyleKılıç, Nazlı Feray, Gülten Şekeroğlu, and Ahmet Kaya. 2025. "Impact of Formulation on the Rheological, Textural, and Sensory Properties of Pistachio Spread" Foods 14, no. 23: 4002. https://doi.org/10.3390/foods14234002

APA StyleKılıç, N. F., Şekeroğlu, G., & Kaya, A. (2025). Impact of Formulation on the Rheological, Textural, and Sensory Properties of Pistachio Spread. Foods, 14(23), 4002. https://doi.org/10.3390/foods14234002