Effects of Indica Black Rice, Konjac Powder and Water on the Quality Characteristics of Gluten-Free Taichung Sen 17 Rice Bread

Abstract

1. Introduction

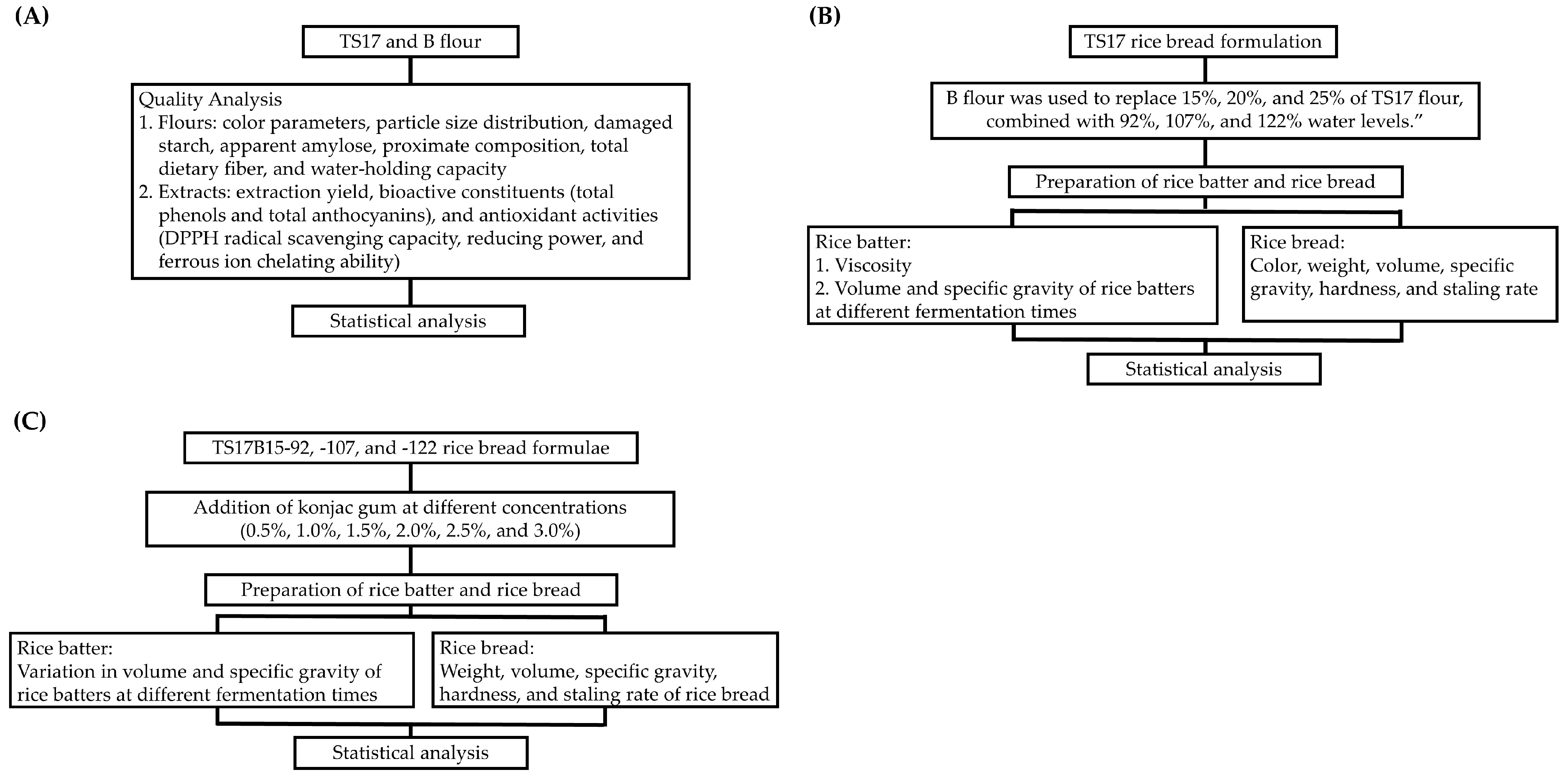

2. Materials and Methods

2.1. Materials and Reagents

2.2. Experimental Design and Rice Bread Preparation

2.3. Determination of Physicochemical Characteristics of Rice Flours, and Bioactive Components and Antioxidant Property in Their Extracts

2.4. Physicochemical Property of Rice Batter

2.5. Physical Characteristics of Rice Bread

2.6. Statistical Analysis

3. Results and Discussion

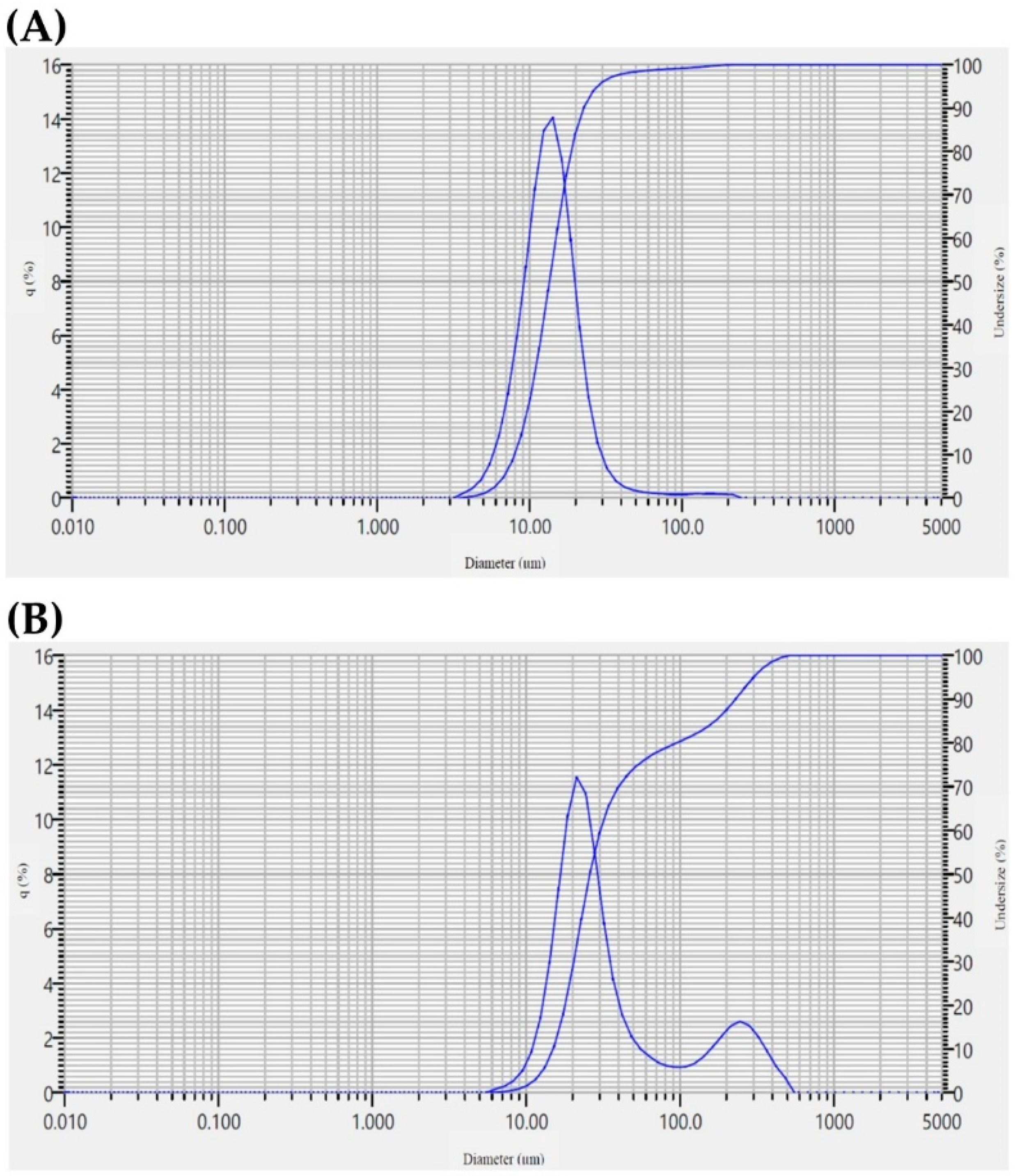

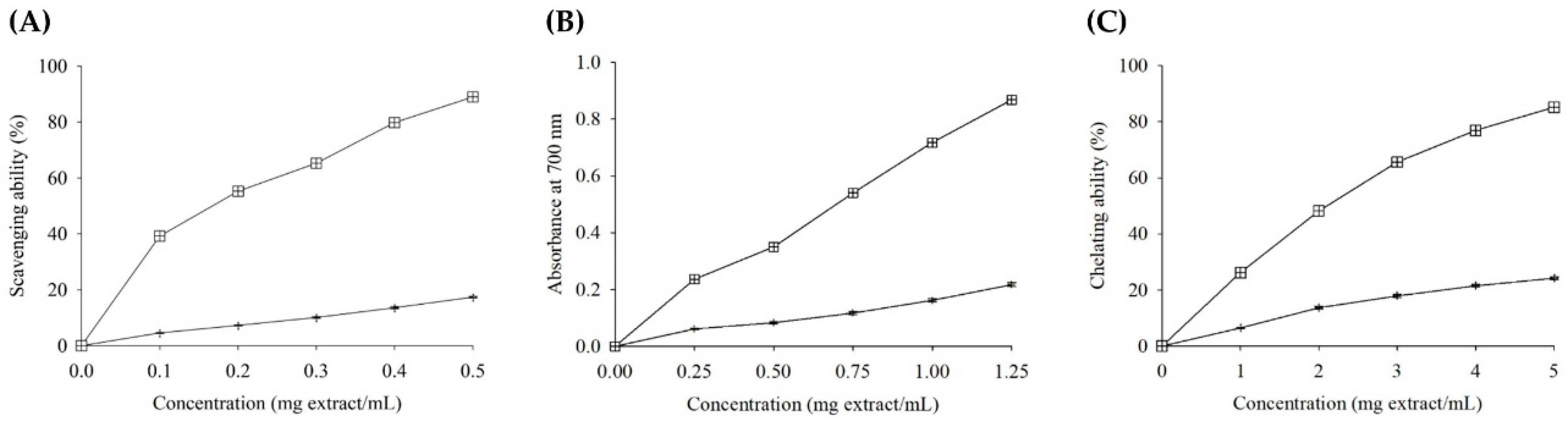

3.1. Physicochemical Characteristics of Rice Flours, and Bioactive Components and Antioxidant Property in Their Extracts

3.2. Quality Characteristics of the Rice Batter and Rice Bread Made by Replacing Part of TS17 with B

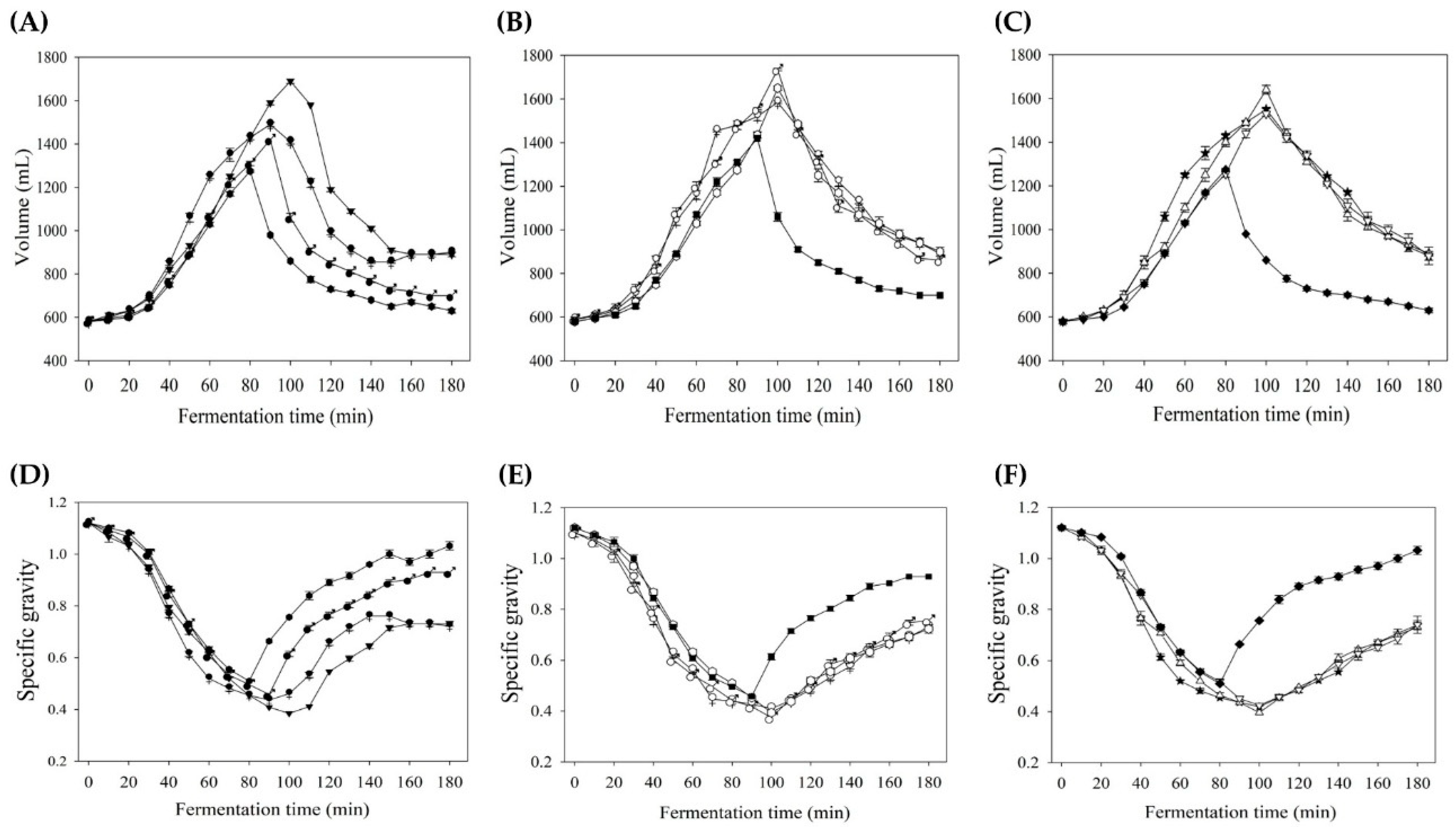

3.2.1. Quality Characteristics of the Rice Batter

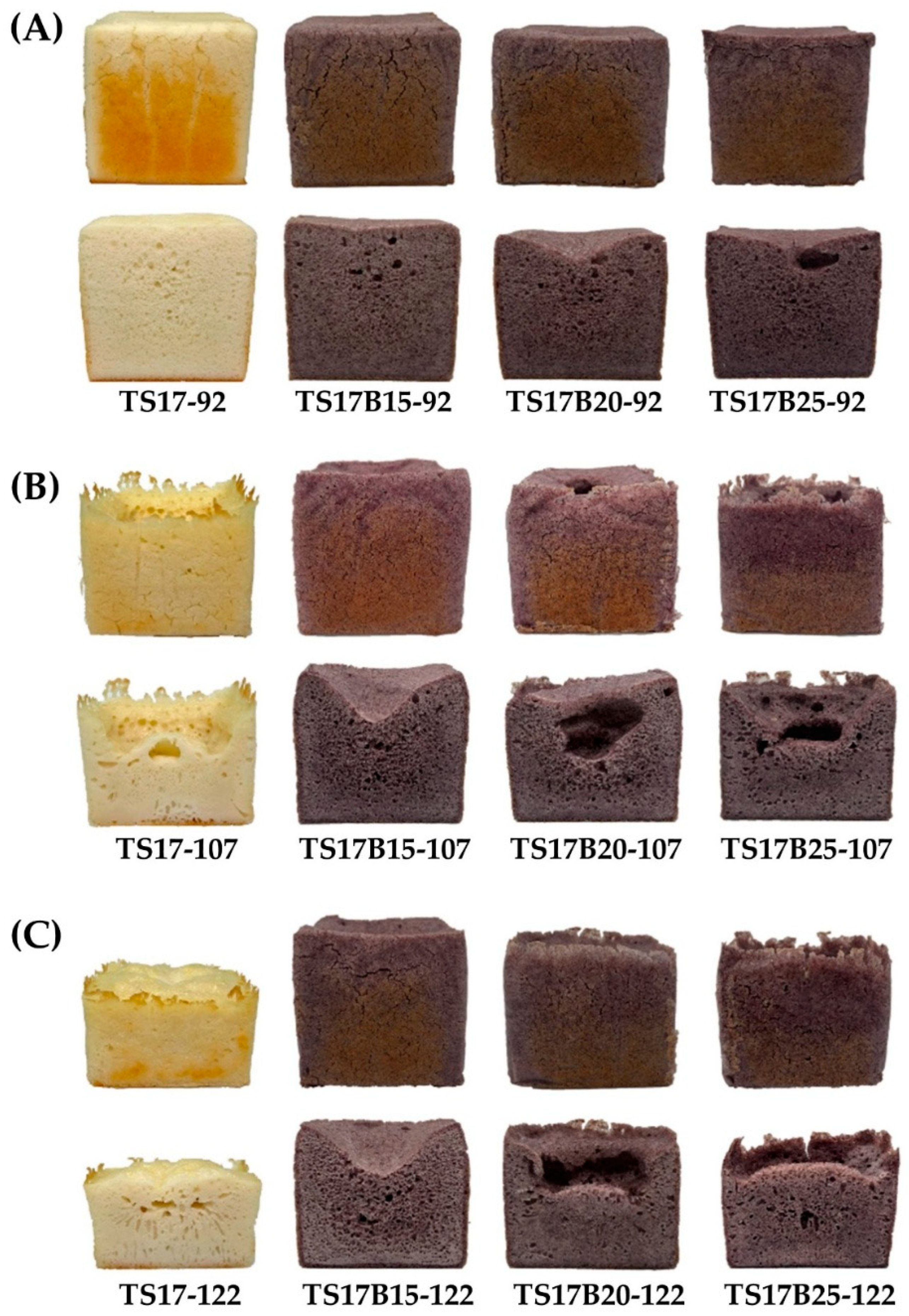

3.2.2. Quality Characteristics of the Rice Bread

3.3. Effect of Konjac Gum on the Quality of Rice Batter and Rice Bread

3.3.1. Quality Characteristics of the Rice Batter

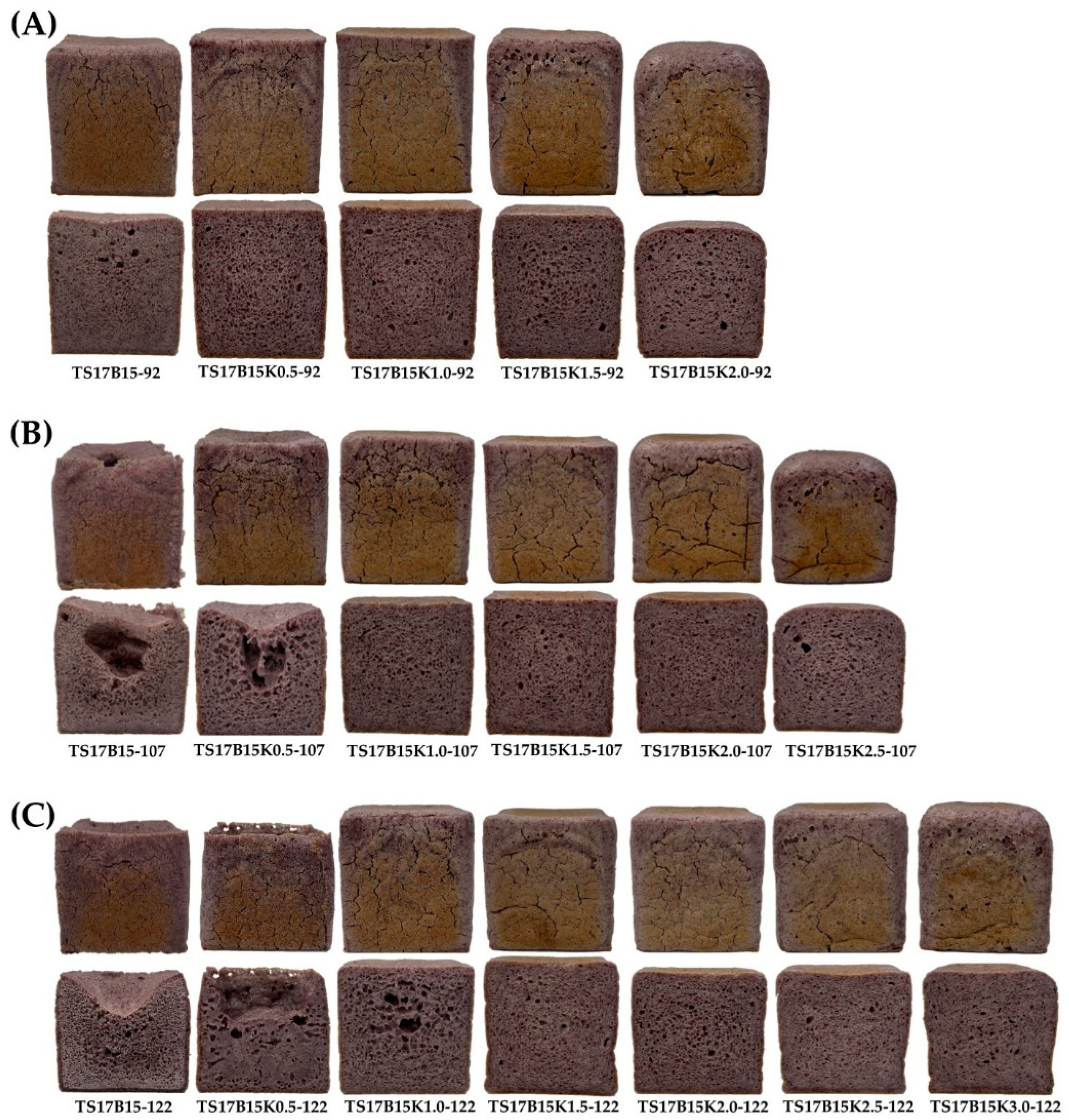

3.3.2. Quality Characteristics of Rice Bread

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| TS17 | Taichung sen 17 |

| B | Indica black rice |

| K | Konjac glucomannan |

References

- de la Hera, E.; Martinez, M.; Gómez, M. Influence of flour particle size on quality of gluten-free rice bread. LWT-Food Sci. Technol. 2013, 54, 199–206. [Google Scholar] [CrossRef]

- Skendi, A.; Mouselemidou, P.; Papageorgiou, M.; Papastergiadis, E. Effect of acorn meal-water combinations on technological properties and fine structure of gluten-free bread. Food Chem. 2018, 253, 119–126. [Google Scholar] [CrossRef]

- Pellegrini, N.; Agostoni, C. Nutritional aspects of gluten-free products. J. Sci. Food Agric. 2015, 95, 2380–2385. [Google Scholar] [CrossRef]

- Menga, V.; Amato, M.; Phillips, T.D.; Angelino, D.; Morreale, F.; Fares, C. Gluten-free pasta incorporating chia (Salvia hispanica L.) as thickening agent: An approach to naturally improve the nutritional profile and the in vitro carbohydrate digestibility. Food Chem. 2017, 221, 1954–1961. [Google Scholar] [CrossRef]

- Hassan, H.F.; Mourad, L.; Khatib, N.; Assi, R.; Akil, S.; El Khatib, S.; Hteit, R. Perceptions towards gluten free products among consumers: A narrative review. Appl. Food Res. 2024, 4, 100441. [Google Scholar] [CrossRef]

- Gorach, O.; Oksana, D.; Rezvykh, N. Innovative technology for the production of gluten-free food products of a new generation. Curr. Nutr. Food Sci. 2024, 20, 734–744. [Google Scholar] [CrossRef]

- Mattioli, N.G.; Olivera, D.F.; Salvadori, V.O.; Marra, F.; Goñi, S.M. Ohmic baking of gluten free sponge cake: Analysis of technological and quality characteristics. LWT-Food Sci. Technol. 2024, 203, 116357. [Google Scholar] [CrossRef]

- Avelar, Z.; Pereira, R.N.; Vicente, A.A.; Rodrigues, R.M. Protein quality of cereals: Technological and functional perspectives. J. Cereal Sci. 2024, 117, 103922. [Google Scholar] [CrossRef]

- Abid, J.; Ahmed, S.; Xia, T.; Wang, M. Rice as a nutritional grain: Examining its role in healthy products and disease prevention. Food Rev. Int. 2024, 40, 3055–3078. [Google Scholar] [CrossRef]

- Roman, L.; Belorio, M.; Gomez, M. Gluten-free breads: The gap between research and commercial reality. Compr. Rev. Food Sci. Food Saf. 2019, 18, 690–702. [Google Scholar] [CrossRef] [PubMed]

- Lai, H.-M. Diversified Rice Processing Technology-Research and Development of Rice Flour. Agric. Biotechnol. Ind. Q. 2014, 39, 56–62. [Google Scholar]

- Qiu, X.-Y. Effect of Indica Rice, Japonica Rice and Hydrocolloids on the Quality Characteristics of Gluten-Free Rice Breads. Master’s Thesis, Hungkuang University, Taichung, Taiwan, 2024. [Google Scholar]

- Jiang, J.-K. Effect of Taichung Sen 17, Black Indica Brown Rice, Konjac Gum and Sweetened Red Bean on the Quality Characteristics of Gluten-Free Rice Bread. Master’s Thesis, Hungkuang University, Taichung, Taiwan, 2023. [Google Scholar]

- Aoki, N.; Kataoka, T.; Nishiba, Y. Crucial role of amylose in the rising of gluten- and additive-free rice bread. J. Cereal Sci. 2020, 92, 102905. [Google Scholar] [CrossRef]

- Ari Akin, P.; Brummer, Y.; Joye, I.J.; Ergün, N.; Peyronel, F.; Ramdath, D.; Cui, S.W. The impact of different hydrocolloids on gluten-free bazlama bread quality. Food Hydrocoll. 2024, 156, 110236. [Google Scholar] [CrossRef]

- Di Renzo, T.; Trivisonno, M.C.; Nazzaro, S.; Reale, A.; Messia, M.C. Effect of different hydrocolloids on the qualitative characteristics of fermented gluten-free quinoa dough and bread. Foods 2024, 13, 1382. [Google Scholar] [CrossRef]

- González, L.C.; Álvarez Barreto, C.I.; Tolaba, M.P. Effect of different hydrocolloids on the quality and aging of gluten-free bread based on pre-hydrated rice grains. Food Biosci. 2025, 69, 106857. [Google Scholar] [CrossRef]

- Maghaydah, S.; Abdul-Hussain, S.; Ajo, R.; Tawalbeh, Y.; Alsaydali, O. Utilization of different hydrocolloid combinations in gluten-free bread making. Food Nutr. Sci. 2013, 04, 496–502. [Google Scholar] [CrossRef]

- Vidaurre-Ruiz, J.; Matheus-Diaz, S.; Salas-Valerio, F.; Barraza-Jauregui, G.; Schoenlechner, R.; Repo-Carrasco-Valencia, R. Influence of tara gum and xanthan gum on rheological and textural properties of starch-based gluten-free dough and bread. Eur. Food Res. Technol. 2019, 245, 1347–1355. [Google Scholar] [CrossRef]

- Foschia, M.; Horstmann, S.; Arendt, E.K.; Zannini, E. Nutritional therapy–Facing the gap between coeliac disease and gluten-free food. Int. J. Food Microbiol. 2016, 239, 113–124. [Google Scholar] [CrossRef]

- Chauhan, K.; Rao, A. Clean-label alternatives for food preservation: An emerging trend. Heliyon 2024, 10, e35815. [Google Scholar] [CrossRef]

- Kapoor, D.U.; Sharma, H.; Maheshwari, R.; Pareek, A.; Gaur, M.; Prajapati, B.G.; Castro, G.R.; Thanawuth, K.; Suttiruengwong, S.; Sriamornsak, P. Konjac glucomannan: A comprehensive review of its extraction, health benefits, and pharmaceutical applications. Carbohydr. Polym. 2024, 339, 122266. [Google Scholar] [CrossRef]

- Jian, X.; Jian, S.; Deng, B. Konjac glucomannan: A functional food additive for preventing metabolic syndrome. J. Funct. Foods 2024, 115, 106108. [Google Scholar] [CrossRef]

- Choi, K.H.; Kim, S.T.; Bin, B.H.; Park, P.J. Effect of konjac glucomannan (KGM) on the reconstitution of the dermal environment against UVB-induced condition. Nutrients 2020, 12, 2779. [Google Scholar] [CrossRef]

- Laignier, F.; Akutsu, R.d.C.C.d.A.; Maldonade, I.R.; Bertoldo Pacheco, M.T.; Silva, V.S.N.; Mendonça, M.A.; Zandonadi, R.P.; Raposo, A.; Botelho, R.B.A. Amorphophallus konjac: A novel alternative flour on gluten-free bread. Foods 2021, 10, 1206. [Google Scholar] [CrossRef]

- Nakamura, R.; Teshima, Y.; Miura, M.; Konishi, F. Effect of adding glucomannan on the rheological properties, sensory characteristics and staling of gluten-free rice bread. J. Jpn. Assoc. Home Econ. Educ. 2016, 67, 141–150. [Google Scholar]

- Mau, J.-L.; Lee, C.-C.; Chen, Y.-P.; Lin, S.-D. Physicochemical, antioxidant and sensory characteristics of chiffon cake prepared with black rice as replacement for wheat flour. LWT-Food Sci. Technol. 2017, 75, 434–439. [Google Scholar] [CrossRef]

- American Association of Cereal Chemists. International Approved Methods of the AACC, 10th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2000. [Google Scholar]

- Association of Official Analytical Chemists International. AOAC Official Method 985.29. Total Dietary Fiber in Foods: Enzymatic-Gravimetric Method, 17th ed.; Association of Official Analytical Chemists International: Gaithersburg, MD, USA, 2023. [Google Scholar]

- Mau, J.-L.; Lee, C.-C.; Yang, C.-W.; Chen, R.-W.; Zhang, Q.-F.; Lin, S.-D. Physicochemical, antioxidant and sensory characteristics of bread partially substituted with aerial parts of sweet potato. LWT-Food Sci. Technol. 2020, 117, 108602. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- Wang, C.-W.; Shen, H.-S.; Yang, C.-W.; Syu, P.-C.; Lin, S.-D. Physicochemical, antioxidant, starch digestibility, and sensory properties of wheat bread fortified with Taiwanese cocoa bean shells. Foods 2024, 13, 2854. [Google Scholar] [CrossRef] [PubMed]

- Lu, T.-M.; Lee, C.-C.; Mau, J.-L.; Lin, S.-D. Quality and antioxidant property of green tea sponge cake. Food Chem. 2010, 119, 1090–1095. [Google Scholar] [CrossRef]

- Sahin, A.W.; Wiertz, J.; Arendt, E.K. Evaluation of a new method to determine the water addition level in gluten-free bread systems. J. Cereal Sci. 2020, 93, 102971. [Google Scholar] [CrossRef]

- Luo, S.; Yan, X.; Fu, Y.; Pang, M.; Chen, R.; Liu, Y.; Chen, J.; Liu, C. The quality of gluten-free bread made of brown rice flour prepared by low temperature impact mill. Food Chem. 2021, 348, 129032. [Google Scholar] [CrossRef]

- Tong, L.-T.; Gao, X.; Lin, L.; Liu, Y.; Zhong, K.; Liu, L.; Zhou, X.; Wang, L.; Zhou, S. Effects of semidry flour milling on the quality attributes of rice flour and rice noodles in China. J. Cereal Sci. 2015, 62, 45–49. [Google Scholar] [CrossRef]

- Wu, T.; Wang, L.; Li, Y.; Qian, H.; Liu, L.; Tong, L.; Zhou, X.; Wang, L.; Zhou, S. Effect of milling methods on the properties of rice flour and gluten-free rice bread. LWT-Food Sci. Technol. 2019, 108, 137–144. [Google Scholar] [CrossRef]

- Ronie, M.E.; Abdul Aziz, A.H.; Mohd Noor, N.Q.I.; Yahya, F.; Mamat, H. Characterisation of Bario rice flour varieties: Nutritional compositions and physicochemical properties. Appl. Sci. 2022, 12, 9064. [Google Scholar] [CrossRef]

- Oppong, D.; Panpipat, W.; Chaijan, M. Chemical, physical, and functional properties of thai indigenous brown rice flours. PLoS ONE 2021, 16, e0255694. [Google Scholar] [CrossRef]

- Sapwarobol, S.; Saphyakhajorn, W.; Astina, J. Biological functions and activities of rice bran as a functional ingredient: A review. Nutr. Metab. Insights 2021, 14, 1–11. [Google Scholar] [CrossRef]

- Li, A.-N.; Li, S.; Zhang, Y.-J.; Xu, X.-R.; Chen, Y.-M.; Li, H.-B. Resources and biological activities of natural polyphenols. Nutrients 2014, 6, 6020–6047. [Google Scholar] [CrossRef]

- Chaiyasut, C.; Sivamaruthi, B.; Pengkumsri, N.; Keapai, W.; Kesika, P.; Saelee, M.; Tojing, P.; Sirilun, S.; Chaiyasut, K.; Peerajan, S.; et al. Germinated Thai black rice extract protects experimental diabetic rats from oxidative stress and other diabetes-related consequences. Pharmaceuticals 2016, 10, 3. [Google Scholar] [CrossRef]

- Fan, M.-J.; Wang, I.-C.; Hsiao, Y.-T.; Lin, H.-Y.; Tang, N.-Y.; Hung, T.-C.; Quan, C.; Lien, J.-C.; Chung, J.-G. Anthocyanins from black rice (Oryza sativa L.) demonstrate antimetastatic properties by reducing MMPs and NF-ΚB expressions in human oral cancer CAL 27 cells. Nutr. Cancer 2015, 67, 327–338. [Google Scholar] [CrossRef]

- Mapoung, S.; Semmarath, W.; Arjsri, P.; Thippraphan, P.; Srisawad, K.; Umsumarng, S.; Phromnoi, K.; Jamjod, S.; Prom-u-Thai, C.; Dejkriengkraikul, P. Comparative analysis of bioactive-phytochemical characteristics, antioxidants activities, and anti-inflammatory properties of selected black rice germ and bran (Oryza sativa L.) varieties. Eur. Food Res. Technol. 2023, 249, 451–464. [Google Scholar] [CrossRef]

- Yamuangmorn, S.; Prom-u-Thai, C. The potential of high-anthocyanin purple rice as a functional ingredient in human health. Antioxidants 2021, 10, 833. [Google Scholar] [CrossRef]

- Huang, Z.-C. Effect of Various Starch on the Quality of Turnip Cake. Master’s Thesis, Taipei University of Marine Technology, New Taipei, Taiwan, 2020. [Google Scholar]

- Luchese, C.L.; Sperotto, N.; Spada, J.C.; Tessaro, I.C. Effect of blueberry agro-industrial waste addition to corn starch-based films for the production of a pH-indicator film. Int. J. Biol. Macromol. 2017, 104, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, J.S.; Farage, P.; Zandonadi, R.P.; Botelho, R.B.A.; de Oliveira, L.d.L.; Raposo, A.; Shakeel, F.; Alshehri, S.; Mahdi, W.A.; Araújo, W.M.C. A systematic review on gluten-free bread formulations using specific volume as a quality. Foods 2021, 10, 614. [Google Scholar] [CrossRef]

- Hager, A.-S.; Arendt, E.K. Influence of hydroxypropylmethylcellulose (HPMC), xanthan gum and their combination on loaf specific volume, crumb hardness and crumb grain characteristics of gluten-free breads based on rice, maize, teff and buckwheat. Food Hydrocoll. 2013, 32, 195–203. [Google Scholar] [CrossRef]

- Culetu, A.; Duta, D.E.; Papageorgiou, M.; Varzakas, T. The role of hydrocolloids in gluten-free bread and pasta; rheology, characteristics, staling and glycemic index. Foods 2021, 10, 3121. [Google Scholar] [CrossRef]

- Choi, Y.; Jeong, H.-S.; Lee, J. Antioxidant activity of methanolic extracts from some grains consumed in Korea. Food Chem. 2007, 103, 130–138. [Google Scholar] [CrossRef]

- Marco, C.; Rosell, C.M. Breadmaking performance of protein enriched, gluten-free breads. Eur. Food Res. Technol. 2008, 227, 1205–1213. [Google Scholar] [CrossRef]

- Espert, M.; Borreani, J.; Hernando, I.; Quiles, A.; Salvador, A.; Sanz, T. Relationship between cellulose chemical substitution, structure and fat digestion in o/w emulsions. Food Hydrocoll. 2017, 69, 76–85. [Google Scholar] [CrossRef]

- Šmídová, Z.; Rysová, J. Gluten-free bread and bakery products technology. Foods 2022, 11, 480. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Li, Y.; Li, C.; Ban, X.; Cheng, L.; Hong, Y.; Gu, Z.; Li, Z. Co-supported hydrocolloids improve the structure and texture quality of gluten-free bread. LWT-Food Sci. Technol. 2021, 152, 112248. [Google Scholar] [CrossRef]

), TS17B20-92 (

), TS17B20-92 ( ), TS17B25-92 (⬣). TS17-107 (■), TS17B15-107 (♀), TS17B20-107 (♂), TS17B25-107 (⬡). TS17-122 (◆), TS17B15-122 (★), TS17B20-122 (△), TS17B25-122 (▽).

), TS17B25-92 (⬣). TS17-107 (■), TS17B15-107 (♀), TS17B20-107 (♂), TS17B25-107 (⬡). TS17-122 (◆), TS17B15-122 (★), TS17B20-122 (△), TS17B25-122 (▽).

), TS17B20-92 (

), TS17B20-92 ( ), TS17B25-92 (⬣). TS17-107 (■), TS17B15-107 (♀), TS17B20-107 (♂), TS17B25-107 (⬡). TS17-122 (◆), TS17B15-122 (★), TS17B20-122 (△), TS17B25-122 (▽).

), TS17B25-92 (⬣). TS17-107 (■), TS17B15-107 (♀), TS17B20-107 (♂), TS17B25-107 (⬡). TS17-122 (◆), TS17B15-122 (★), TS17B20-122 (△), TS17B25-122 (▽).

), TS17B15K0.5-92 (✩), TS17B15K1.0-92 (◩), TS17B15K1.5-92 (◑), TS17B15K2.0-92 (⊕), TS17B15-107 (♀), TS17B15K0.5-107 (♣), TS17B15K1.0-107 (♥), TS17B15K1.5-107 (◇), TS17B15K2.0-107 (❋), TS17B15K2.5-107 (❂), TS17B15-122 (★), TS17B15K0.5-122 (♠), TS17B15K1.0-122 (⌂), TS17B15K1.5-122 (✔), TS17B15K2.0-122 (✖), TS17B15K2.5-122 (✠), TS17B15K3.0-122 (✦).

), TS17B15K0.5-92 (✩), TS17B15K1.0-92 (◩), TS17B15K1.5-92 (◑), TS17B15K2.0-92 (⊕), TS17B15-107 (♀), TS17B15K0.5-107 (♣), TS17B15K1.0-107 (♥), TS17B15K1.5-107 (◇), TS17B15K2.0-107 (❋), TS17B15K2.5-107 (❂), TS17B15-122 (★), TS17B15K0.5-122 (♠), TS17B15K1.0-122 (⌂), TS17B15K1.5-122 (✔), TS17B15K2.0-122 (✖), TS17B15K2.5-122 (✠), TS17B15K3.0-122 (✦).

), TS17B15K0.5-92 (✩), TS17B15K1.0-92 (◩), TS17B15K1.5-92 (◑), TS17B15K2.0-92 (⊕), TS17B15-107 (♀), TS17B15K0.5-107 (♣), TS17B15K1.0-107 (♥), TS17B15K1.5-107 (◇), TS17B15K2.0-107 (❋), TS17B15K2.5-107 (❂), TS17B15-122 (★), TS17B15K0.5-122 (♠), TS17B15K1.0-122 (⌂), TS17B15K1.5-122 (✔), TS17B15K2.0-122 (✖), TS17B15K2.5-122 (✠), TS17B15K3.0-122 (✦).

), TS17B15K0.5-92 (✩), TS17B15K1.0-92 (◩), TS17B15K1.5-92 (◑), TS17B15K2.0-92 (⊕), TS17B15-107 (♀), TS17B15K0.5-107 (♣), TS17B15K1.0-107 (♥), TS17B15K1.5-107 (◇), TS17B15K2.0-107 (❋), TS17B15K2.5-107 (❂), TS17B15-122 (★), TS17B15K0.5-122 (♠), TS17B15K1.0-122 (⌂), TS17B15K1.5-122 (✔), TS17B15K2.0-122 (✖), TS17B15K2.5-122 (✠), TS17B15K3.0-122 (✦).

| Ingredient (%) | TS17-92 1 | TS17B15-92 2 | TS17B20-92 | TS17B25-92 |

| TS17 flour | 100 | 85 | 80 | 75 |

| B flour | - | 15 | 20 | 25 |

| Sugar | 10 | 10 | 10 | 10 |

| Sodium chloride | 1.5 | 1.5 | 1.5 | 1.5 |

| Yeast | 1.0 | 1.0 | 1.0 | 1.0 |

| Unsalted butter | 6.0 | 6.0 | 6.0 | 6.0 |

| Water | 92 | 92 | 92 | 92 |

| Total | 210.2 | 210.5 | 210.5 | 210.5 |

| Ingredient (%) | TS17-107 | TS17B15-107 | TS17B20-107 | TS17B25-107 |

| TS17 flour | 100 | 85 | 80 | 75 |

| B flour | - | 15 | 20 | 25 |

| Sugar | 10 | 10 | 10 | 10 |

| Sodium chloride | 1.5 | 1.5 | 1.5 | 1.5 |

| Yeast | 1.0 | 1.0 | 1.0 | 1.0 |

| Unsalted butter | 6.0 | 6.0 | 6.0 | 6.0 |

| Water | 107 | 107 | 107 | 107 |

| Total | 225.5 | 225.5 | 225.5 | 225.5 |

| Ingredient (%) | TS17-122 | TS17B15-122 | TS17B20-122 | TS17B25-122 |

| TS17 flour | 100 | 85 | 80 | 75 |

| B flour | - | 15 | 20 | 25 |

| Sugar | 10 | 10 | 10 | 10 |

| Sodium chloride | 1.5 | 1.5 | 1.5 | 1.5 |

| Yeast | 1.0 | 1.0 | 1.0 | 1.0 |

| Unsalted butter | 6.0 | 6.0 | 6.0 | 6.0 |

| Water | 122 | 122 | 122 | 122 |

| Total | 240.5 | 240.5 | 240.5 | 240.5 |

| Ingredient (%) | TS17B15K0.5-92 1 | TS17B15K1.0-92 | TS17B15K1.5-92 | TS17B15K2.0-92 | ||

| TS17 flour | 85 | 85 | 85 | 85 | ||

| B flour | 15 | 15 | 15 | 15 | ||

| Sugar | 10 | 10 | 10 | 10 | ||

| Sodium chloride | 1.5 | 1.5 | 1.5 | 1.5 | ||

| Yeast | 1.0 | 1.0 | 1.0 | 1.0 | ||

| Unsalted butter | 6.0 | 6.0 | 6.0 | 6.0 | ||

| Water | 92 | 92 | 92 | 92 | ||

| Konjac gum (K) | 0.5 | 1.0 | 1.5 | 2.0 | ||

| Total | 211.0 | 211.5 | 212.0 | 212.5 | ||

| Ingredient (%) | TS17B15K0.5-107 | TS17B15K1.0-107 | TS17B15K1.5-107 | TS17B15K2.0-107 | TS17B15K2.5-107 | |

| TS17 flour | 85 | 85 | 85 | 85 | 85 | |

| B flour | 15 | 15 | 15 | 15 | 15 | |

| Sugar | 10 | 10 | 10 | 10 | 10 | |

| Sodium chloride | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Yeast | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | |

| Unsalted butter | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | |

| Water | 107 | 107 | 107 | 107 | 107 | |

| Konjac gum (K) | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | |

| Total | 226.0 | 226.5 | 227.0 | 227.5 | 228.0 | |

| Ingredient (%) | TS17B15K0.5-122 | TS17B15K1.0-122 | TS17B15K1.5-122 | TS17B15K2.0-122 | TS17B15K2.5-122 | TS17B15K3.0-122 |

| TS17 flour | 85 | 85 | 85 | 85 | 85 | 85 |

| B flour | 15 | 15 | 15 | 15 | 15 | 15 |

| Sugar | 10 | 10 | 10 | 10 | 10 | 10 |

| Sodium chloride | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Yeast | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Unsalted butter | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 |

| Water | 122 | 122 | 122 | 122 | 122 | 122 |

| Konjac gum (K) | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 |

| Total | 241.0 | 241.5 | 242.0 | 242.5 | 243.0 | 243.5 |

| TS17 1 | B | |

|---|---|---|

| L* | 97.46 ± 0.15 a 3 | 76.75 ± 0.04 b |

| a* | 0.17 ± 0.01 b | 2.85 ± 0.02 a |

| b* | 2.81 ± 0.05 b | 3.93 ± 0.06 a |

| WI* | 96.21 ± 0.13 a | 76.25 ± 0.04 b |

| Median size (μm) | 13.51 ± 0.41 b | 25.93 ± 0.58 a |

| Damaged starch (%) | 5.30 ± 0.18 a | 0.19 ± 0.02 b |

| Apparent amylose (%, dry basis) | 30.47 ± 0.22 a | 9.89 ± 0.17 b |

| Water holding capacity (g H2O absorbed/g sample) | 0.96 ± 0.01 b | 1.24 ± 0.02 a |

| Moisture (g/100 g sample) | 5.06 ± 0.01 b | 8.08 ± 0.02 a |

| Crude protein (g/100 g sample) | 7.89 ± 0.03 b | 8.73 ± 0.04 a |

| Crude fat (g/100 g sample) | 0.35 ± 0.02 b | 0.71 ± 0.05 a |

| Crude ash (g/100 g sample) | 0.28 ± 0.03 b | 1.06 ± 0.05 a |

| Carbohydrate (g/100 g sample) | 86.42 ± 0.08 a | 81.42 ± 0.11 b |

| Total dietary fiber (g/100 g sample) | 1.51 ± 0.02 b | 3.36 ± 0.02 a |

| Rice flour extract | TS17 1 | B |

| Yield (g extract/100 g powder) | 0.80 ± 0.02 b | 3.71 ± 0.12 a |

| Total phenols (mg GAE 2/g lyophilized extract) | 4.30 ± 0.16 b | 42.52 ± 0.28 a |

| Total anthocyanin content (mg C3GE 2/g lyophilized extract) | nd | 1.26 ± 0.01 a |

| Viscosity (cp) | |

|---|---|

| TS17-92 | 8257 ± 166 D 1 |

| TS17B15-92 | 9207 ± 31 C |

| TS17B20-92 | 12,213 ± 122 B |

| TS17B25-92 | 16,787 ± 42 A |

| TS17-107 | 3123 ± 125 H |

| TS17B15-107 | 3393 ± 114 G |

| TS17B20-107 | 4467 ± 90 F |

| TS17B25-107 | 6113 ± 153 E |

| TS17-122 | 1417 ± 55 L |

| TS17B15-122 | 1427 ± 50 K |

| TS17B20-122 | 1953 ± 83 J |

| TS17B25-122 | 2620 ± 100 I |

| L* | a* | b* | h* (°) | c* | ΔE | |

|---|---|---|---|---|---|---|

| TS17-92 | 75.69 ± 1.33 B 1 | −1.39 ± 0.05 H | 8.49 ± 0.31 C | 8.61 ± 0.31 C | ||

| TS17B15-92 | 51.81 ± 0.82 C | 6.33 ± 0.54 A | 1.81 ± 0.33 FG | 16.18 ± 1.48 C | 6.60 ± 0.53 D | 26.01 ± 1.67 E |

| TS17B20-92 | 49.47 ± 0.85 DE | 5.69 ± 0.20 B | 1.35 ± 0.19 HI | 13.28 ± 1.54 C | 5.86 ± 0.22 E | 28.11 ± 1.85 D |

| TS17B25-92 | 47.24 ± 0.92 F | 5.27 ± 0.24 C | 1.21 ± 0.14 I | 12.95 ± 1.55 C | 5.41 ± 0.23 FG | 30.13 ± 1.52 C |

| TS17-107 | 80.55 ± 1.70 A | −0.92 ± 0.08 G | 10.91 ± 0.20 A | 10.95 ± 0.20 A | ||

| TS17B15-107 | 51.25 ± 0.93 C | 5.26 ± 0.43 C | 2.67 ± 0.12 D | 27.19 ± 2.83 A | 5.92 ± 0.35 E | 31.10 ± 1.19 BC |

| TS17B20-107 | 49.90 ± 0.40 DE | 5.14 ± 0.08 C | 2.26 ± 0.09 E | 23.74 ± 1.08 B | 5.62 ± 0.05 EF | 31.81 ± 0.68 BC |

| TS17B25-107 | 45.88 ± 1.45 G | 4.60 ± 0.26 EF | 1.81 ± 0.13 FG | 21.41 ± 3.63 B | 4.96 ± 0.28 HI | 36.30 ± 2.59 A |

| TS17-122 | 80.31 ± 1.54 A | −1.14 ± 0.11 GH | 9.39 ± 0.36 B | 9.46 ± 0.36 B | ||

| TS17B15-122 | 50.60 ± 0.54 CD | 5.01 ± 0.15 CD | 2.14 ± 0.44 EF | 23.09 ± 4.69 B | 5.48 ± 0.15 FG | 31.24 ± 1.44 BC |

| TS17B20-122 | 49.10 ± 0.26 E | 4.84 ± 0.12 DE | 1.90 ± 0.24 FG | 21.43 ± 2.70 B | 5.21 ± 0.12 GH | 32.68 ± 1.39 B |

| TS17B25-122 | 46.09 ± 0.42 FG | 4.47 ± 0.11 F | 1.65 ± 0.15 GH | 20.20 ± 1.54 B | 4.78 ± 0.15 I | 35.57 ± 1.70 A |

| Weight (g) | Volume (mL) | Specific Volume (mL/g) | Hardness (N, 2 h After Baking) | Hardness (N, 24 h After Baking) | Staling Rate | |

|---|---|---|---|---|---|---|

| TS17-92 | 600.2 ± 2.05 G 1 | 1032 ± 6 A | 1.72 ± 0.01 A | 12.79 ± 1.63 B 1 | 30.23 ± 4.31 C 1 | 1.36 ± 0.28 E |

| TS17B15-92 | 609.3 ± 0.80 C | 1042 ± 5 A | 1.71 ± 0.01 A | 8.09 ± 1.26 D | 21.06 ± 2.63 E | 1.60 ± 0.36 C |

| TS17B20-92 | 610.9 ± 0.30 B | 980 ± 4 B | 1.60 ± 0.01 B | 7.58 ± 1.21 E | 19.14 ± 2.45 F | 1.53 ± 0.34 CD |

| TS17B25-92 | 611.2 ± 0.65 A | 935 ± 5 C | 1.53 ± 0.01 C | 6.81 ± 0.67 F | 18.13 ± 1.91 F | 1.24 ± 0.34 F |

| TS17-107 | 594.4 ± 1.92 J | 872 ± 4 E | 1.47 ± 0.01 D | 13.21 ± 1.09 B | 52.31 ± 4.95 B | 2.96 ± 0.24 A |

| TS17B15-107 | 602.2 ± 1.70 F | 917 ± 3 D | 1.52 ± 0.01 C | 8.42 ± 0.83 CD | 24.24 ± 1.42 D | 1.49 ± 0.25 D |

| TS17B20-107 | 604.1 ± 1.55 E | 872 ± 2 E | 1.44 ± 0.01 E | 7.48 ± 0.22 E | 20.66 ± 1.64 E | 1.18 ± 0.16 G |

| TS17B25-107 | 607.5 ± 0.70 D | 812 ± 5 F | 1.34 ± 0.01 F | 6.88 ± 2.35 F | 18.36 ± 0.57 F | 1.04 ± 0.08 H |

| TS17-122 | 591.8 ± 1.81 L | 642 ± 3 I | 1.08 ± 0.01 I | 32.28 ± 5.10 A | 101.82 ± 12.49 A | 2.15 ± 0.31 B |

| TS17B15-122 | 593.3 ± 1.05 K | 775 ± 5 G | 1.30 ± 0.01 G | 8.83 ± 0.16 C | 23.27 ± 1.89 D | 1.64 ± 0.21 C |

| TS17B20-122 | 595.7 ± 0.50 I | 761 ± 3 G | 1.28 ± 0.01 G | 7.59 ± 0.27 E | 18.57 ± 0.95 F | 1.45 ± 0.10 D |

| TS17B25-122 | 598.3 ± 1.05 H | 732 ± 5 H | 1.22 ± 0.01 H | 6.77 ± 0.20 F | 14.86 ± 0.58 G | 1.19 ± 0.04 FG |

| Weight (g) | Moisture (%) | Volume (mL) | Hardness (N) (2 h After Baking) | Hardness (N) (24 h After Baking) | Staling Rate | |

|---|---|---|---|---|---|---|

| TS17B15-92 | 609.30 ± 0.80 E 1 | 46.62 ± 0.27 O | 1042 ± 5 CD | 8.09 ± 1.26 C | 21.06 ± 2.63 C | 1.60 ± 0.36 A |

| TS17B15K0.5-92 | 612.43 ± 0.50 D | 47.23 ± 0.17 N | 1045 ± 5 BC | 2.57 ± 0.35 H | 5.63 ± 0.33 L | 1.22 ± 0.25 EF |

| TS17B15K1.0-92 | 614.70 ± 0.36 C | 47.83 ± 0.16 M | 1062 ± 4 A | 3.16 ± 0.25 G | 6.60 ± 0.56 J | 1.10 ± 0.07 F |

| TS17B15K1.5-92 | 616.83 ± 0.40 B | 48.36 ± 0.16 L | 1030 ± 6 FG | 3.74 ± 0.19 F | 8.90 ± 0.55 G | 1.39 ± 0.17 D |

| TS17B15K2.0-92 | 618.30 ± 0.53 A | 49.08 ± 0.12 K | 1005 ± 5 I | 4.36 ± 0.33 E | 10.70 ± 0.53 F | 1.46 ± 0.22 C |

| TS17B15-107 | 602.20 ± 1.70 G | 48.54 ± 0.28 L | 917 ± 3 K | 9.72 ± 0.83 A | 24.24 ± 1.42 AB | 1.49 ± 0.25 BC |

| TS17B15K0.5-107 | 606.30 ± 0.72 F | 48.66 ± 0.12 L | 979 ± 3 J | 2.17 ± 0.17 I | 5.50 ± 0.31 L | 1.54 ± 0.13 B |

| TS17B15K1.0-107 | 608.50 ± 1.20 E | 49.11 ± 0.22 K | 1045 ± 2 BC | 2.71 ± 0.25 H | 6.61 ± 0.56 J | 1.45 ± 0.18 C |

| TS17B15K1.5-107 | 611.50 ± 1.21 D | 49.98 ± 0.15 J | 1063 ± 3 C | 3.18 ± 0.14 G | 7.27 ± 0.39 I | 1.29 ± 0.07 E |

| TS17B15K2.0-107 | 614.43 ± 0.42 C | 50.70 ± 0.25 I | 1053 ± 5 A | 3.66 ± 0.17 FG | 8.95 ± 0.29 G | 1.46 ± 0.16 C |

| TS17B15K2.5-107 | 617.33 ± 0.45 AB | 51.26 ± 0.25 H | 1005 ± 5 I | 4.50 ± 0.23 DE | 11.56 ± 0.65 E | 1.57 ± 0.19 AB |

| TS17B15-122 | 593.25 ± 1.05 K | 53.18 ± 0.13 G | 775 ± 5 M | 8.83 ± 0.16 B | 23.27 ± 1.89 B | 1.64 ± 0.21 A |

| TS17B15K0.5-122 | 595.67 ± 0.67 J | 53.87 ± 0.16 F | 788 ± 4 L | 9.91 ± 0.53 A | 25.02 ± 1.54 A | 1.53 ± 0.06 B |

| TS17B15K1.0-122 | 597.90 ± 0.46 I | 54.29 ± 0.16 E | 1028 ± 3 G | 2.54 ± 0.21 H | 6.04 ± 0.60 K | 1.38 ± 0.17 D |

| TS17B15K1.5-122 | 600.43 ± 0.93 H | 54.93 ± 0.23 D | 1035 ± 5 EF | 3.22 ± 0.21 G | 7.35 ± 0.61 I | 1.28 ± 0.13 E |

| TS17B15K2.0-122 | 603.40 ± 0.70 G | 55.33 ± 0.10 C | 1063 ± 2 A | 3.88 ± 0.14 F | 8.35 ± 0.34 H | 1.15 ± 0.07 F |

| TS17B15K2.5-122 | 606.60 ± 1.37 F | 56.04 ± 0.15 B | 1038 ± 2 DE | 4.34 ± 0.26 E | 10.34 ± 0.67 F | 1.38 ± 0.11 D |

| TS17B15K3.0-122 | 609.90 ± 0.44 E | 56.63 ± 0.14 A | 1012 ± 2 H | 4.99 ± 0.32 D | 12.39 ± 1.00 D | 1.47 ± 0.11 C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.-K.; Chen, S.-Y.; Yang, C.-W.; Shen, H.-S.; Lin, S.-D. Effects of Indica Black Rice, Konjac Powder and Water on the Quality Characteristics of Gluten-Free Taichung Sen 17 Rice Bread. Foods 2025, 14, 3831. https://doi.org/10.3390/foods14223831

Jiang J-K, Chen S-Y, Yang C-W, Shen H-S, Lin S-D. Effects of Indica Black Rice, Konjac Powder and Water on the Quality Characteristics of Gluten-Free Taichung Sen 17 Rice Bread. Foods. 2025; 14(22):3831. https://doi.org/10.3390/foods14223831

Chicago/Turabian StyleJiang, Jin-Kuan, Shin-Yu Chen, Chih-Wei Yang, Hui-Shan Shen, and Sheng-Dun Lin. 2025. "Effects of Indica Black Rice, Konjac Powder and Water on the Quality Characteristics of Gluten-Free Taichung Sen 17 Rice Bread" Foods 14, no. 22: 3831. https://doi.org/10.3390/foods14223831

APA StyleJiang, J.-K., Chen, S.-Y., Yang, C.-W., Shen, H.-S., & Lin, S.-D. (2025). Effects of Indica Black Rice, Konjac Powder and Water on the Quality Characteristics of Gluten-Free Taichung Sen 17 Rice Bread. Foods, 14(22), 3831. https://doi.org/10.3390/foods14223831