Dual-Sensor Hyperspectral Fusion for Prediction of Sorghum Tannin Content Oriented to Liquor Brewing

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials of Sorghum Grains

2.2. Hyperspectral Image Acquisition and Chemical Determination of Tannin Content

2.2.1. Hyperspectral Image Acquisition

2.2.2. Chemical Determination of Tannin Content

2.3. Data Fusion Strategy for Dual Hyperspectral Sensors

2.3.1. Data Layer Fusion

2.3.2. Feature Layer Fusion

2.3.3. Methodological Implementation of Feature Fusion Strategies

2.4. Hyperspectral Data Extraction and Dataset Partitioning

2.4.1. Spectral Data Extraction

2.4.2. Dataset Partitioning

2.5. Feature Variable Extraction

2.6. Prediction Models and Evaluation Indexes

2.6.1. Prediction Models

2.6.2. Model Development, Hyperparameter Tuning, and Overfitting Prevention

2.6.3. Evaluation Indexes

3. Results

3.1. Analysis of Chemical Measurements

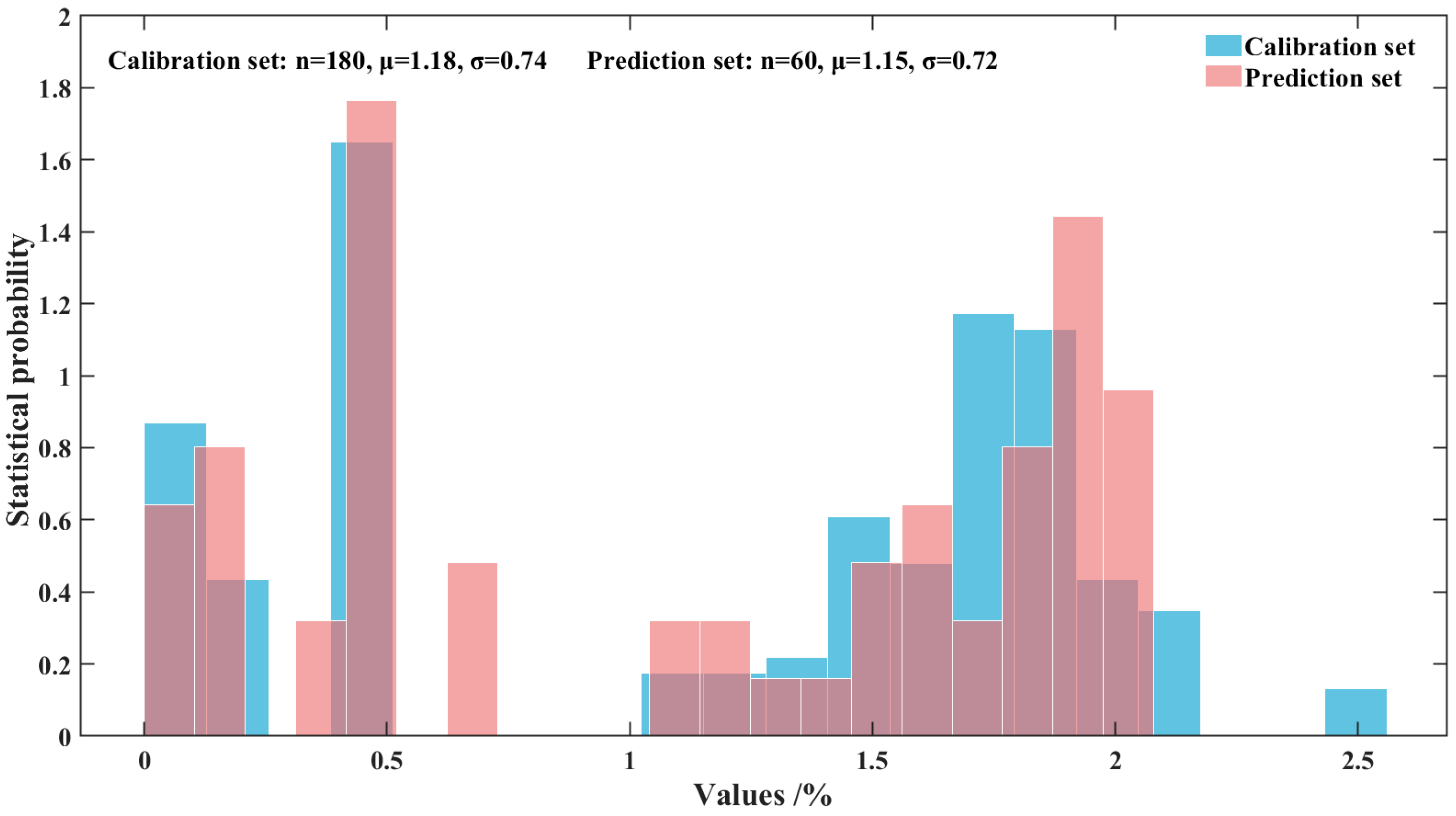

3.1.1. Analysis of Chemical Measurement Results of Tannin Content

3.1.2. Analysis of Dataset Partitioning Results

3.2. Results of Raw Spectral Data

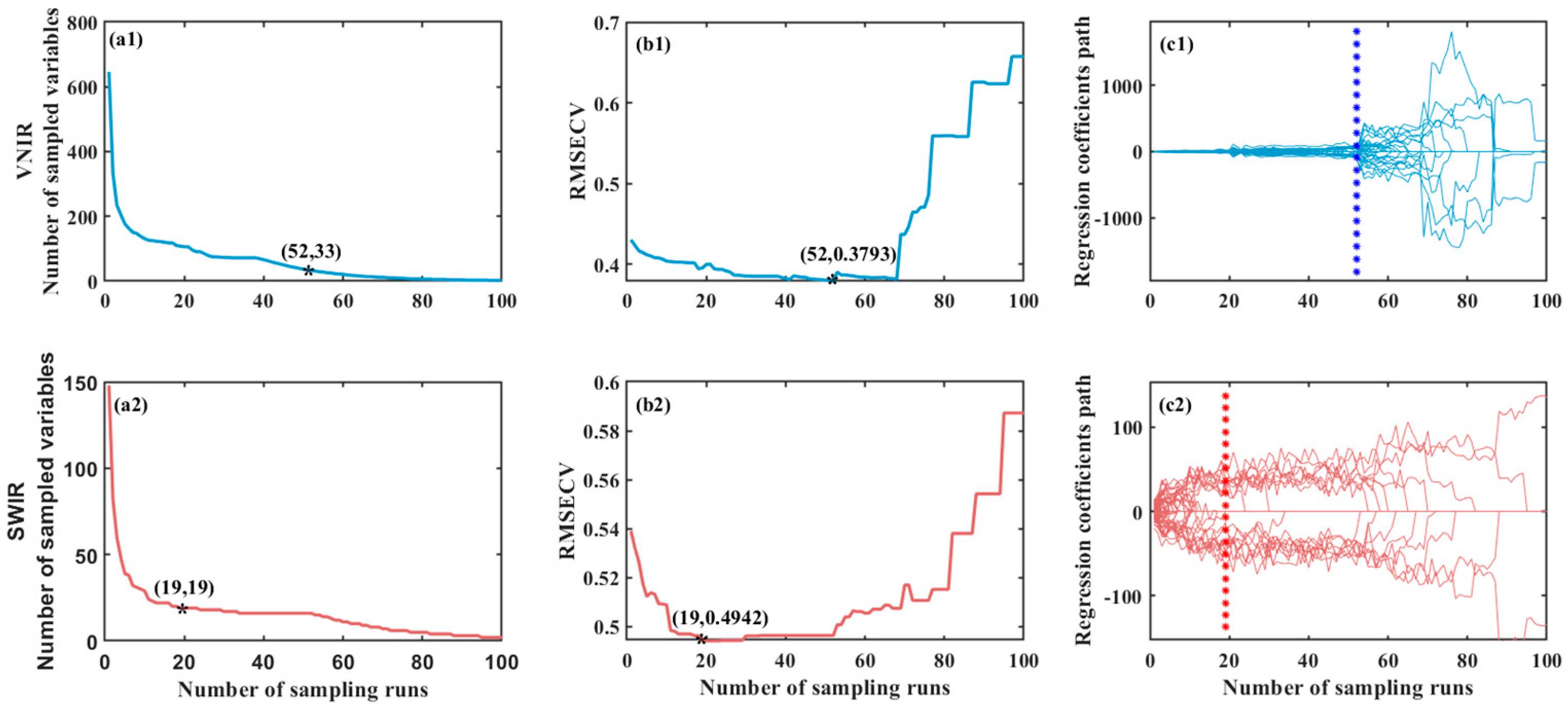

3.3. Feature Variables Analysis

3.4. Comparison of Prediction Models and Optimal Prediction Model

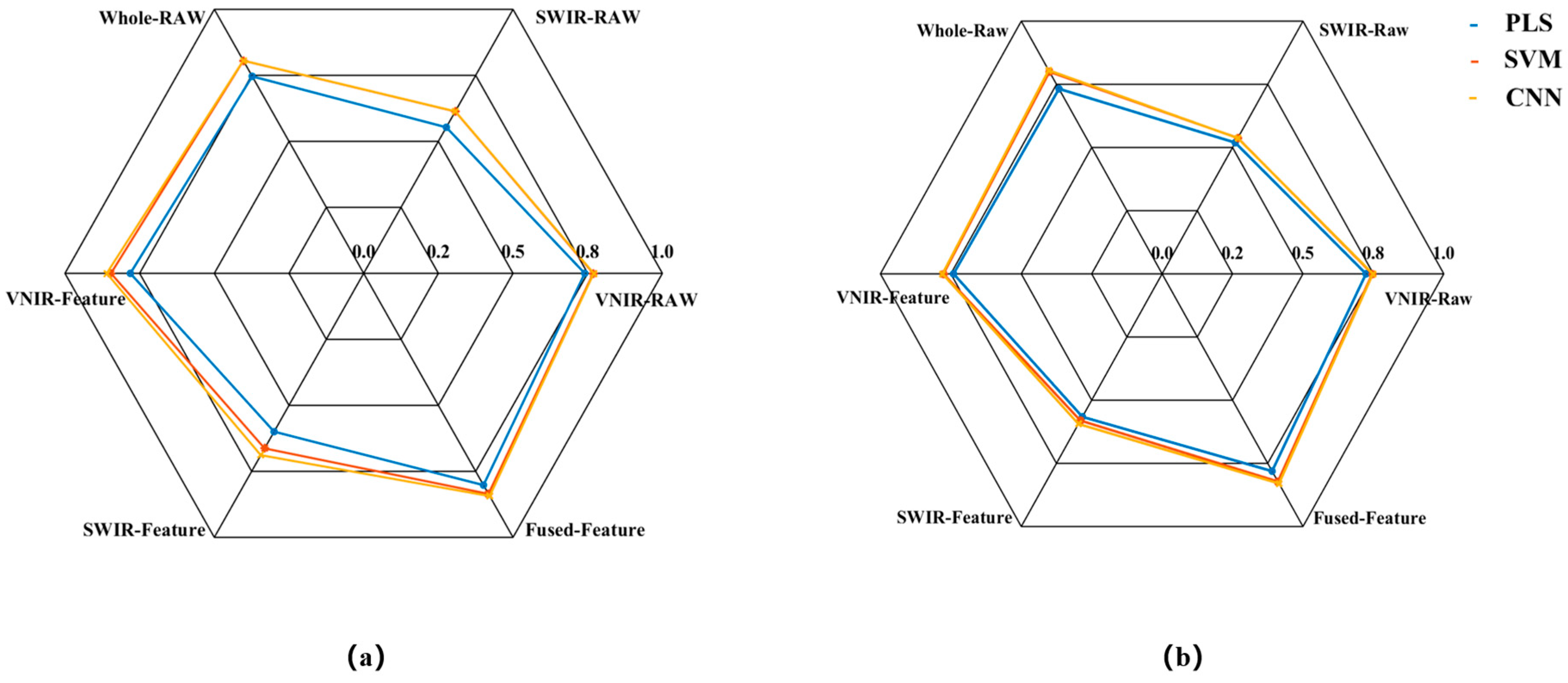

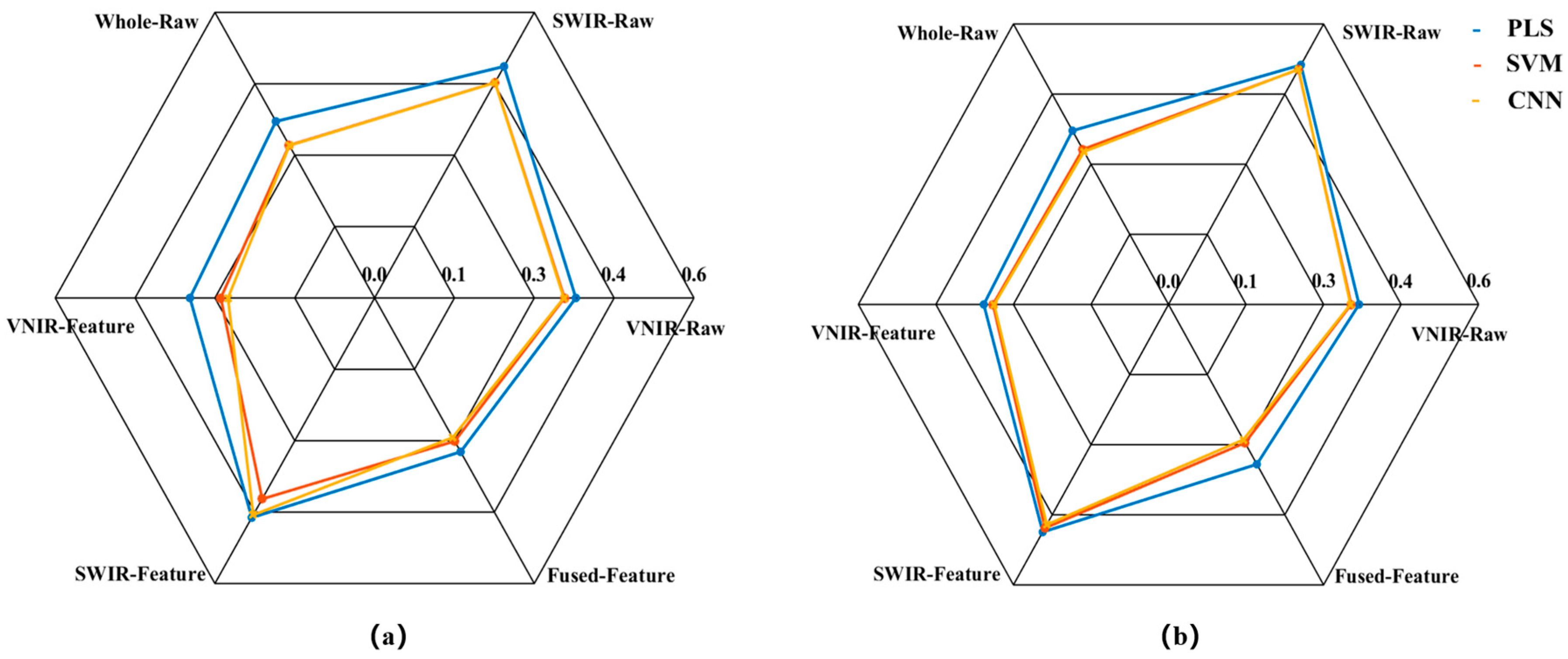

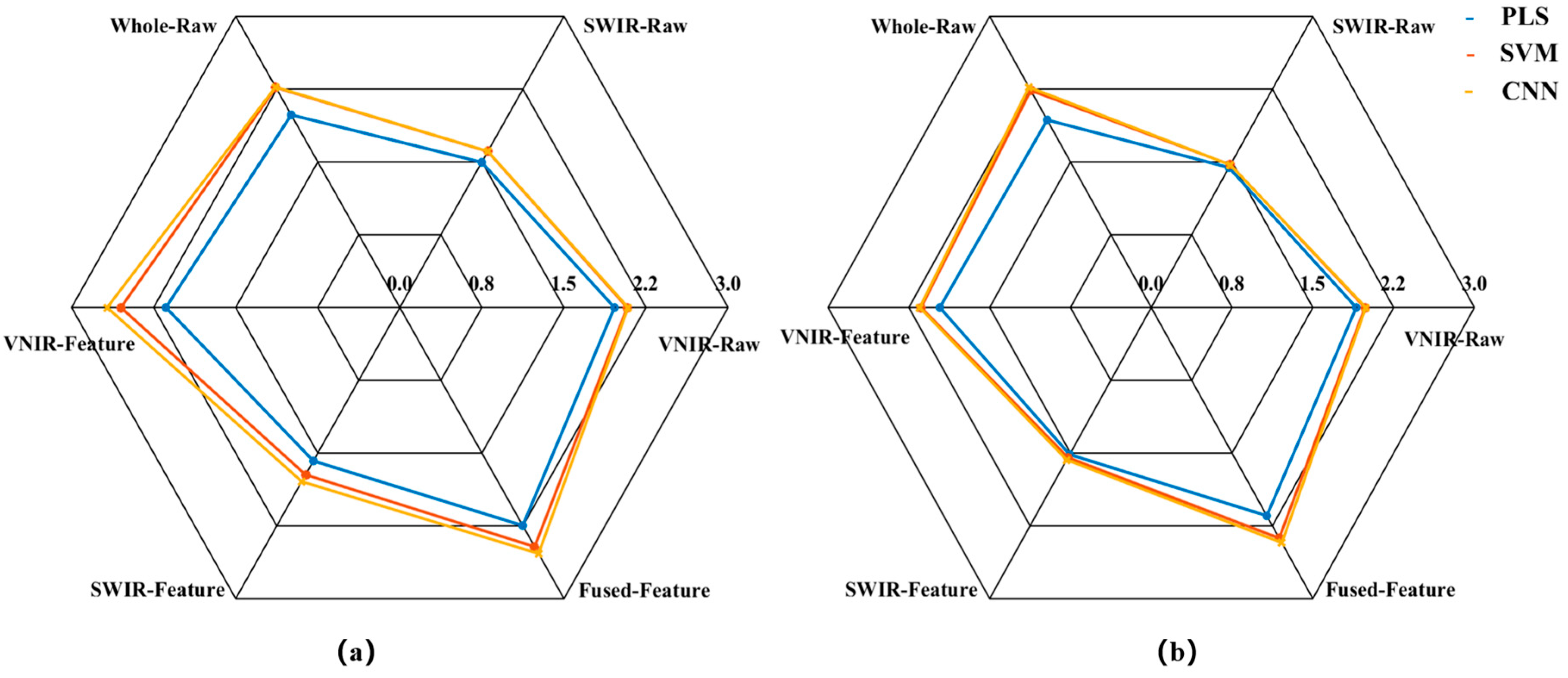

3.4.1. Comparison of Prediction Models

3.4.2. Optimal Prediction Model

4. Discussion

4.1. Discussion of Sample Representativeness and Dataset Reliability

4.2. Discussion of Dual Hyperspectral Data Sources and Feature Fusion Strategy

4.2.1. Complementarity of Dual Hyperspectral Data

4.2.2. The Impact of Feature Extraction and Fusion on Model Performance

4.3. Discussion on Predictive Model Performance

4.3.1. Comparative Analysis of Linear Versus Nonlinear Models

4.3.2. Comparative Analysis of SVM Versus CNN

4.4. Industrial Application, Techno-Economic Assessment and Operational Considerations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| VNIR | Visible and Near-Infrared |

| SWIR | Short-Wave Infrared |

| PLS | Partial Least Squares |

| SVM | Support Vector Machine |

| CNN | Convolutional Neural Network |

| CARS | Competitive Adaptive Reweighted Sampling |

References

- Fan, W.; Xu, Y. History and Technology of Chinese Liquor. In Science and Engineering of Chinese Liquor (Baijiu) Microbiology, Chemistry and Process Technology; Springer Nature: Singapore, 2023; pp. 3–41. [Google Scholar] [CrossRef]

- Tanwar, R.; Panghal, A.; Chaudhary, G.; Kumari, A.; Chhikara, N. Nutritional, phytochemical and functional potential of sorghum: A review. Food Chem. Adv. 2023, 3, 100501. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, J.; Ding, Y.; Cao, N.; Gao, X.; Feng, Z.; Li, K.; Cheng, B.; Zhou, L.; Zou, G.; et al. GWAS of grain color and tannin content in Chinese sorghum based on whole-genome sequencing. Theor. Appl. Genet. 2023, 136, 77. [Google Scholar] [CrossRef] [PubMed]

- Pérez, M.; Dominguez-López, I.; Lamuela-Raventós, R.M. The chemistry behind the folin–ciocalteu method for the estimation of (poly) phenol content in food: Total phenolic intake in a mediterranean dietary pattern. J. Agric. Food Chem. 2023, 71, 17543–17553. [Google Scholar] [CrossRef]

- Sang, M.; Liu, Q.; Li, D.; Dang, J.; Lu, C.; Liu, C.; Wu, Q. Heat stress and microbial stress induced defensive phenol accumulation in medicinal plant sparganium stoloniferum. Int. J. Mol. Sci. 2024, 25, 6379. [Google Scholar] [CrossRef]

- Doan, T.K.Q.; Chiang, K.Y. Characteristics and kinetics study of spherical cellulose nanocrystal extracted from cotton cloth waste by acid hydrolysis. Sustain. Environ. Res. 2022, 32, 26. [Google Scholar] [CrossRef]

- Oh, Y.J.; Hong, J. Application of the MTT-based colorimetric method for evaluating bacterial growth using different solvent systems. LWT 2022, 153, 112565. [Google Scholar] [CrossRef]

- Drant, T.; Garcia-Caurel, E.; Perrin, Z.; Sciamma-O’Brien, E.; Carrasco, N.; Vettier, L.; Heng, K. Optical constants of exoplanet haze analogs from 0.3 to 30 µm: Comparative sensitivity between spectrophotometry and ellipsometry. Astron. Astrophys. 2024, 682, A6. [Google Scholar] [CrossRef]

- Thilakarathna, R.C.N.; Madhusankha, G.D.M.P.; Navaratne, S.B. Potential food applications of sorghum (Sorghum bicolor) and rapid screening methods of nutritional traits by spectroscopic platforms. J. Food Sci. 2022, 87, 36–51. [Google Scholar] [CrossRef]

- Sun, D.W.; Pu, H.; Yu, J. Applications of hyperspectral imaging technology in the food industry. Nat. Rev. Electr. Eng. 2024, 1, 251–263. [Google Scholar] [CrossRef]

- Zhang, J.; Lei, Y.; He, L.; Hu, X.; Tian, J.; Chen, M.; Huang, D.; Luo, H. The rapid detection of the tannin content of grains based on hyperspectral imaging technology and chemometrics. J. Food Compos. Anal. 2023, 123, 105604. [Google Scholar] [CrossRef]

- Baek, M.W.; Choi, H.R.; Hwang, I.G.; Tilahun, S.; Jeong, C.S. Prediction of tannin content and quality parameters in astringent persimmons from visible and near-infrared spectroscopy. Front. Plant Sci. 2023, 14, 1260644. [Google Scholar] [CrossRef]

- Savitri, K.P.; Hecker, C.; van der Meer, F.D.; Sidik, R.P. VNIR-SWIR infrared (imaging) spectroscopy for geothermal exploration: Current status and future directions. Geothermics 2021, 96, 102178. [Google Scholar] [CrossRef]

- Sedghi, M.; Golian, A.; Soleimani-Roodi, P.; Ahmadi, A.; Aami-Azghadi, M. Relationship between color and tannin content in sorghum grain: Application of image analysis and artificial neural network. Braz. J. Poult. Sci. 2012, 14, 57–62. [Google Scholar] [CrossRef]

- GB/T 15686-2008; Sorghum-Determination of Tannin Content. Standards Press of China: Beijing, China, 2008.

- Kardel, M.; Taube, F.; Schulz, H.; Schuetze, W.; Gierus, M. Different approaches to evaluate tannin content and structure of selected plant extracts–review and new aspects. J. Appl. Bot. Food Qual 2013, 86, 154–166. [Google Scholar]

- Li, X.; Cai, M.; Li, M.; Wei, X.; Liu, Z.; Wang, J.; Jia, K.; Han, Y. Combining Vis-NIR and NIR hyperspectral imaging techniques with a data fusion strategy for the rapid qualitative evaluation of multiple qualities in chicken. Food Control 2023, 145, 109416. [Google Scholar] [CrossRef]

- Fan, S.; Li, C.; Huang, W.; Chen, L.P. Data fusion of two hyperspectral imaging systems with complementary spectral sensing ranges for blueberry bruising detection. Sensors 2018, 18, 4463. [Google Scholar] [CrossRef]

- Cozzolino, D.; Williams, P.J.; Hoffman, L.C. An overview of pre-processing methods available for hyperspectral imaging applications. Microchem. J. 2023, 193, 109129. [Google Scholar] [CrossRef]

- Li, Y.; Tan, X.; Zhang, W.; Jiao, Q.-B.; Xu, Y.-X.; Li, H.; Zou, Y.-B.; Yang, L.; Fang, Y.-P. Research and application of several key techniques in hyperspectral image preprocessing. Front. Plant Sci. 2021, 12, 627865. [Google Scholar] [CrossRef]

- Seraj, A.; Mohammadi-Khanaposhtani, M.; Daneshfar, R.; Naseri, M.; Esmaeili, M.; Baghban, A.; Eslamian, S. Cross-validation. In Handbook of Hydroinformatics; Elsevier: Amsterdam, The Netherlands, 2023; pp. 89–105. [Google Scholar] [CrossRef]

- Bates, S.; Hastie, T.; Tibshirani, R. Cross-validation: What does it estimate and how well does it do it? J. Am. Stat. Assoc. 2024, 119, 1434–1445. [Google Scholar] [CrossRef]

- Li, Y.; Yang, X. Quantitative analysis of near infrared spectroscopic data based on dual-band transformation and competitive adaptive reweighted sampling. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2023, 285, 121924. [Google Scholar] [CrossRef]

- Xing, C.; Yuan, J.; Shi, C.; Chen, X.; Li, S. Utilizing X-ray diffraction in conjunction with competitive adaptive reweighted sampling (CARS) and principal component analysis for the discrimination of medicinal pearl powder and nacre powder. Anal. Sci. 2024, 40, 1889–1897. [Google Scholar] [CrossRef]

- Zeng, W.; Zhang, D.; Fang, Y.; Wu, J.; Huang, J. Comparison of partial least square regression, support vector machine, and deep-learning techniques for estimating soil salinity from hyperspectral data. J. Appl. Remote Sens. 2018, 12, 022204. [Google Scholar] [CrossRef]

- Saeed, F.; Khan, M.A.; Sharif, M.; Mittal, M.; Goyal, L.M.; Roy, S. Deep neural network features fusion and selection based on PLS regression with an application for crops diseases classification. Appl. Soft Comput. 2021, 103, 107164. [Google Scholar] [CrossRef]

- Hasan, H.; Shafri, H.Z.; Habshi, M. A comparison between support vector machine (SVM) and convolutional neural network (CNN) models for hyperspectral image classification. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 357, p. 012035. [Google Scholar] [CrossRef]

- Mansuri, S.M.; Chakraborty, S.K.; Mahanti, N.K.; Pandiselvam, R. Effect of germ orientation during Vis-NIR hyperspectral imaging for the detection of fungal contamination in maize kernel using PLS-DA, ANN and 1D-CNN modelling. Food Control 2022, 139, 109077. [Google Scholar] [CrossRef]

- Nicolai, B.M.; Beullens, K.; Bobelyn, E.; Peirs, A.; Saeys, W.; Theron, K.I.; Lammertyn, J. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: A review. Postharvest Biol. Technol. 2007, 46, 99–118. [Google Scholar] [CrossRef]

- Williams, P.C.; Sobering, D.C. Comparison of commercial near infrared transmittance and reflectance instruments for analysis of whole grains and seeds. J. Near Infrared Spectrosc. 1993, 1, 25–32. [Google Scholar] [CrossRef]

- Singha, C.; Swain, K.C.; Sahoo, S.; Govind, A. Prediction of soil nutrients through PLSR and SVMR models by VIs-NIR reflectance spectroscopy. Egypt. J. Remote Sens. Space Sci. 2023, 26, 901–918. [Google Scholar] [CrossRef]

- Oliveira, A.K.D.S.; Rizzo, R.; Silva, C.A.A.C.; Ré, N.C.; Caron, M.L.; Fiorio, P.R. Prediction of Corn Leaf Nitrogen Content in a Tropical Region Using Vis-NIR-SWIR Spectroscopy. AgriEngineering 2024, 6, 4135–4153. [Google Scholar] [CrossRef]

- Conceição, R.R.P.; Queiroz, V.A.V.; Medeiros, E.P.; Araújo, J.B.; Araújo, D.D.S.; Miguel, R.D.A.; Stoianoff, M.A.R.; Simeone, M.L.F. Determination of fumonisin content in maize using near-infrared hyperspectral imaging (NIR-HSI) technology and chemometric methods. Braz. J. Biol. 2024, 84, e277974. [Google Scholar] [CrossRef]

- Lehmann, J.R.K.; Große-Stoltenberg, A.; Römer, M.; Oldeland, J. Field spectroscopy in the VNIR-SWIR region to discriminate between Mediterranean native plants and exotic-invasive shrubs based on leaf tannin content. Remote Sens. 2015, 7, 1225–1241. [Google Scholar] [CrossRef]

- Tziolas, N.; Ordoudi, S.A.; Tavlaridis, A.; Karyotis, K.; Zalidis, G.; Mourtzinos, I. Rapid assessment of anthocyanins content of onion waste through visible-near-short-wave and mid-infrared spectroscopy combined with machine learning techniques. Sustainability 2021, 13, 6588. [Google Scholar] [CrossRef]

- Liu, J.; Dong, Z.; Xia, J.; Wang, H.; Meng, T.; Zhang, R.; Xie, J. Estimation of soil organic matter content based on CARS algorithm coupled with random forest. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2021, 258, 119823. [Google Scholar] [CrossRef] [PubMed]

- Bilal, M.; Arslan, M.; Iqbal, W.; Khan, S.; Tahir, H.E.; Li, Z.; Xia, S.; Xiaobo, Z. Fusion of NIR and MIR Spectroscopy with Advanced CARS-PLS Techniques for Precise Quantification of Total Polyphenols in Peanut Seeds. Phytochem. Anal. 2025, 36, 1820–1828. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Qian, J.; Chen, J.; Ruiz-Garcia, L.; Dong, C.; Chen, Q.; Liu, Z.; Xiao, P.; Zhao, Z. Recent advances of machine learning in the geographical origin traceability of food and agro-products: A review. Compr. Rev. Food Sci. Food Saf. 2025, 24, e70082. [Google Scholar] [CrossRef]

- Zhang, K.; Zhou, R.; Adhikarla, E.; Yan, Z.; Liu, Y.; Yu, J.; Liu, Z.; Chen, X.; Davison, B.D.; Sun, L.; et al. A generalist vision–language foundation model for diverse biomedical tasks. Nat. Med. 2024, 30, 3129–3141. [Google Scholar] [CrossRef]

- Ni, Q.; Ji, J.C.; Feng, K.; Zhang, Y.; Lin, D.; Zheng, J. Data-driven bearing health management using a novel multi-scale fused feature and gated recurrent unit. Reliab. Eng. Syst. Saf. 2024, 242, 109753. [Google Scholar] [CrossRef]

- Aw, E.C.X.; Tan, G.W.H.; Chuah, S.H.W.; Ooi, K.B.; Hajli, N. Be my friend! Cultivating parasocial relationships with social media influencers: Findings from PLS-SEM and fsQCA. Inf. Technol. People 2023, 36, 66–94. [Google Scholar] [CrossRef]

- SaiTeja, C.; Seventline, J.B. A hybrid learning framework for multi-modal facial prediction and recognition using improvised non-linear SVM classifier. AIP Adv. 2023, 13, 47–53. [Google Scholar] [CrossRef]

- De Santana, F.B.; Otani, S.K.; de Souza, A.M.; Poppi, R.J. Comparison of PLS and SVM models for soil organic matter and particle size using vis-NIR spectral libraries. Geoderma Reg. 2021, 27, e00436. [Google Scholar] [CrossRef]

- Thissen, U.; Pepers, M.; Üstün, B.; Melssen, W.; Buydens, L. Comparing support vector machines to PLS for spectral regression applications. Chemom. Intell. Lab. Syst. 2004, 73, 169–179. [Google Scholar] [CrossRef]

- Ning, C.; Xie, Y.; Sun, L. LSTM, WaveNet, and 2D CNN for nonlinear time history prediction of seismic responses. Eng. Struct. 2023, 286, 116083. [Google Scholar] [CrossRef]

- Wanda, P. RunMax: Fake profile classification using novel nonlinear activation in CNN. Soc. Netw. Anal. Min. 2022, 12, 158. [Google Scholar] [CrossRef]

- GB/T 8231-2024; Sorghum. Standards Press of China: Beijing, China, 2024.

- Zhou, L.; Wang, C.; Gao, X.; Ding, Y.; Cheng, B.; Zhang, G.; Cao, N.; Xu, Y.; Shao, M.; Zhang, L. Genome-wide variations analysis of sorghum cultivar Hongyingzi for brewing Moutai liquor. Hereditas 2020, 157, 19. [Google Scholar] [CrossRef] [PubMed]

| Tannin Content | Calibration Set | Prediction Set | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Max | Min | SD | CV | Mean | Max | Min | SD | CV | |

| VINR | 1.16 | 2.56 | 0.05 | 0.74 | 0.64 | 1.21 | 2.09 | 0.05 | 0.71 | 0.58 |

| SWIR | 1.15 | 2.56 | 0.05 | 0.73 | 0.64 | 1.26 | 2.56 | 0.05 | 0.75 | 0.59 |

| VINR + SWIR | 1.18 | 2.56 | 0.05 | 0.74 | 0.63 | 1.15 | 2.07 | 0.05 | 0.72 | 0.63 |

| Sensor | Wavelength of Feature Variable/nm | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VNIR | 522.115 | 533.744 | 534.471 | 536.651 | 538.831 | 564.269 | 565.723 | 567.903 | 570.811 | 571.537 |

| 573.718 | 594.795 | 595.522 | 596.249 | 597.702 | 599.156 | 602.063 | 629.681 | 630.408 | 632.589 | |

| 633.315 | 634.769 | 648.578 | 650.032 | 652.212 | 681.284 | 703.088 | 828.824 | 843.36 | 854.989 | |

| 858.623 | 885.515 | 893.509 | ||||||||

| SWIR | 1048.94 | 1129.09 | 1133.8 | 1180.95 | 1289.39 | 1327.11 | 1350.68 | 1383.68 | 1402.54 | 1416.69 |

| 1430.83 | 1473.26 | 1482.69 | 1520.41 | 1553.41 | 1558.13 | 1572.27 | 1595.84 | 1633.56 | ||

| Sensor | Method | Number of Variables | Calibration Set | |||||

|---|---|---|---|---|---|---|---|---|

| RC2 | RMSEC | RPDC | RCV2 | RMSECV | RPDCV | |||

| VINR | whole-PLS | 646 | 0.74 | 0.38 | 1.96 | 0.68 | 0.42 | 1.77 |

| CARS-PLS | 33 | 0.78 | 0.35 | 2.14 | 0.74 | 0.38 | 1.96 | |

| SWIR | whole-PLS | 148 | 0.55 | 0.49 | 1.50 | 0.48 | 0.53 | 1.39 |

| CARS-PLS | 19 | 0.60 | 0.46 | 1.58 | 0.54 | 0.49 | 1.47 | |

| VNIR-SWIR | Whole-PLS | 794 | 0.75 | 0.37 | 1.98 | 0.69 | 0.41 | 1.81 |

| CARS-PLS | 52 | 0.79 | 0.34 | 2.18 | 0.76 | 0.36 | 2.05 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, K.; Hao, C.; Guo, W.; Li, Z.; Zheng, D. Dual-Sensor Hyperspectral Fusion for Prediction of Sorghum Tannin Content Oriented to Liquor Brewing. Foods 2025, 14, 3880. https://doi.org/10.3390/foods14223880

Wu K, Hao C, Guo W, Li Z, Zheng D. Dual-Sensor Hyperspectral Fusion for Prediction of Sorghum Tannin Content Oriented to Liquor Brewing. Foods. 2025; 14(22):3880. https://doi.org/10.3390/foods14223880

Chicago/Turabian StyleWu, Kai, Chengli Hao, Wei Guo, Zhiwei Li, and Decong Zheng. 2025. "Dual-Sensor Hyperspectral Fusion for Prediction of Sorghum Tannin Content Oriented to Liquor Brewing" Foods 14, no. 22: 3880. https://doi.org/10.3390/foods14223880

APA StyleWu, K., Hao, C., Guo, W., Li, Z., & Zheng, D. (2025). Dual-Sensor Hyperspectral Fusion for Prediction of Sorghum Tannin Content Oriented to Liquor Brewing. Foods, 14(22), 3880. https://doi.org/10.3390/foods14223880