Impact of Whole Cereal–Pulse Flours on the Functionality and Antioxidant Properties of Gluten-Free Extruded Flours

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials and Blend Formulation

2.2. Extrusion Cooking

2.3. Bulk Density

2.4. Distribution of Particle Size

2.5. Sample Preparation for Hydration Analysis

2.5.1. Water Absorption Index (WAI) and Water Solubility Index (WSI)

2.5.2. Oil Absorption Index (OAI)

2.5.3. Paste Viscosity

2.6. Bioactive Compounds

2.6.1. Total Phenolic Compounds (TPC)

2.6.2. Antioxidant Capacity (ABTS+ Radical Scavenging)

2.6.3. Antioxidant Capacity (DPPH Radical)

2.7. Emulsion Activity and Emulsion Stability Index

2.8. Instrumental Color

2.9. Statistical Analysis and Multivariate Data Analysis

3. Results and Discussion

3.1. Proximate Composition of the Raw Formulations

3.2. Specific Mechanical Energy (SME)

3.3. Bulk Density (BD)

3.4. Particle Size Distribution (PSD)

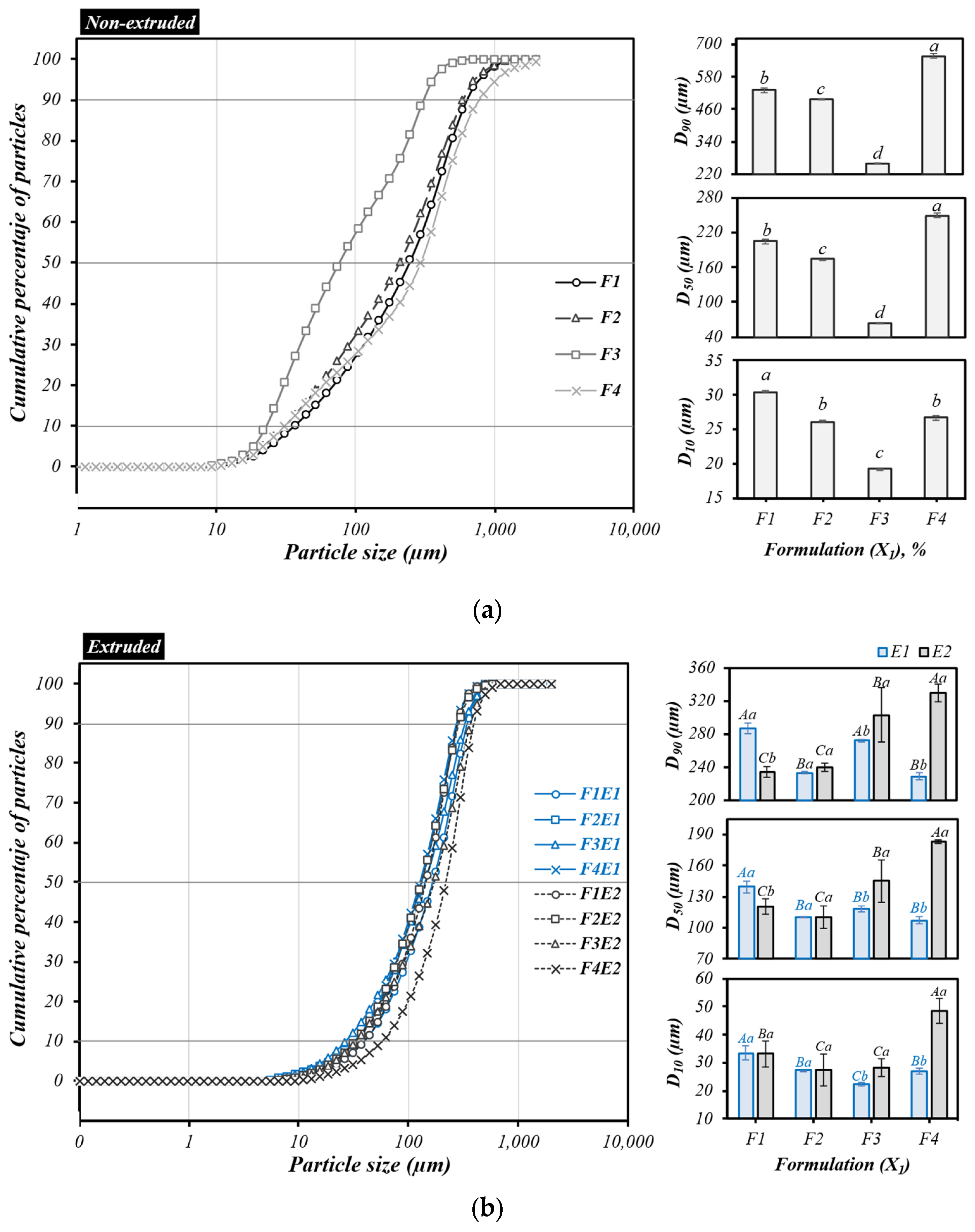

3.5. Functional Properties

3.5.1. Water Solubility and Water Absorption Indexes

3.5.2. Oil Absorption Index

3.5.3. Emulsifying Properties

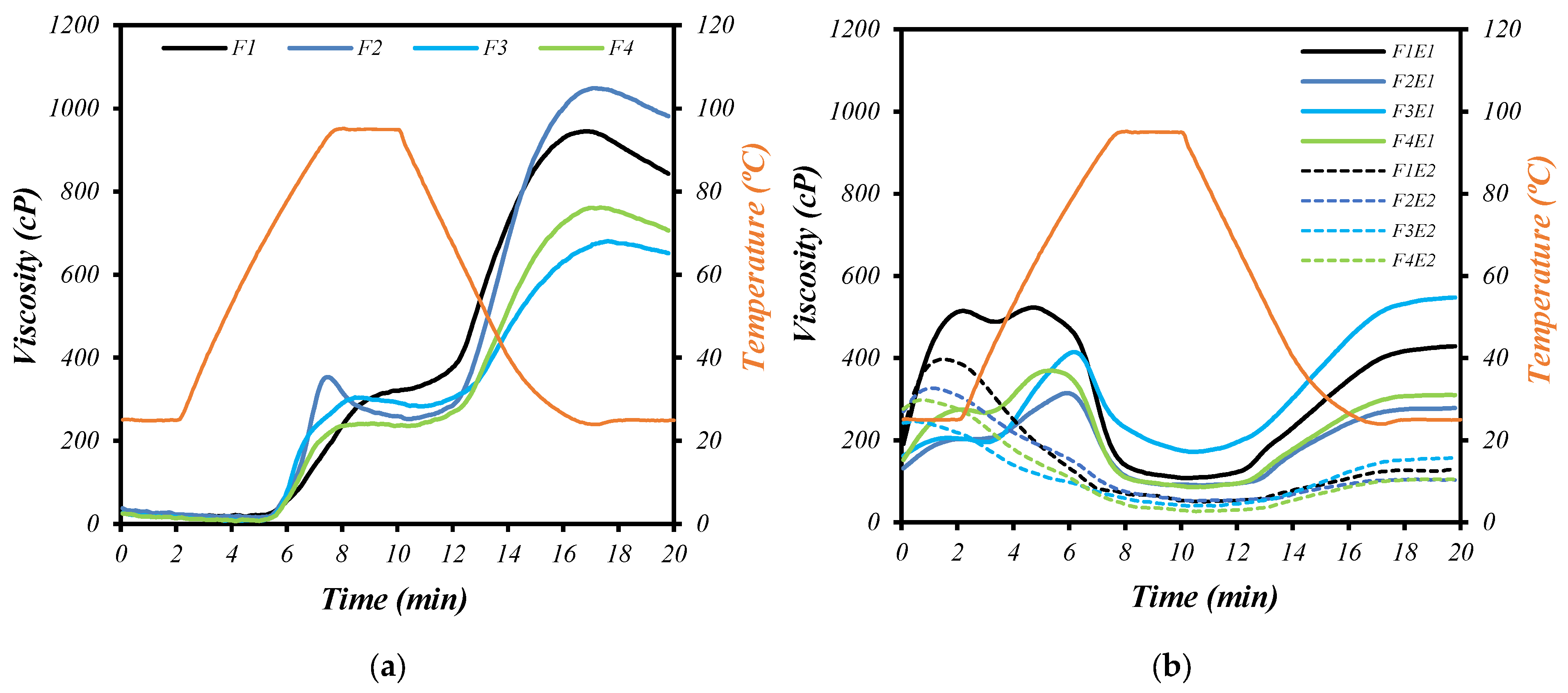

3.5.4. Paste Properties

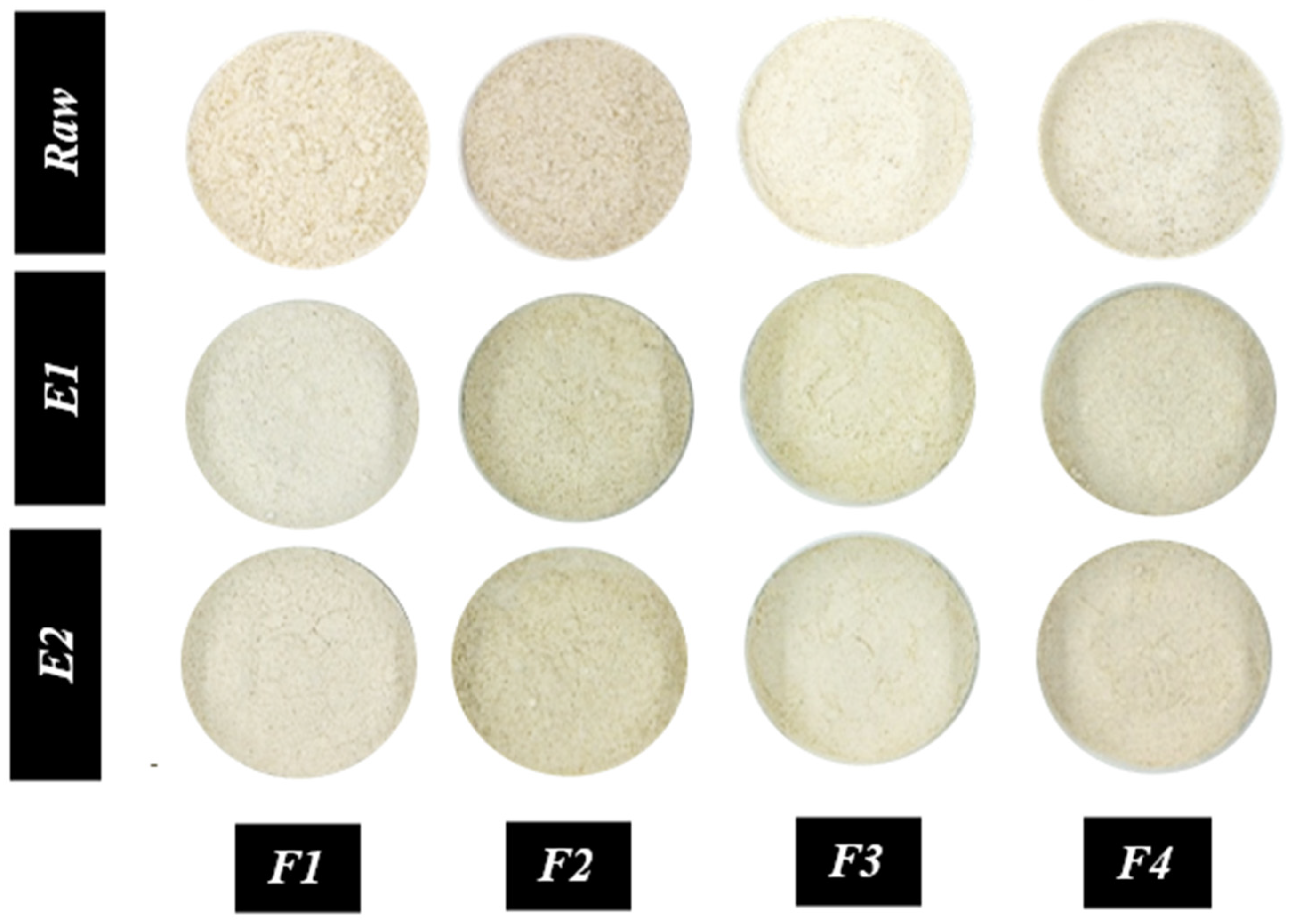

3.6. Instrumental Color Measurement

- Discussion of functional properties

- Extrusion Condition E1 (30% moisture/300 rpm)

- Extrusion Condition E2 (18% moisture/600 rpm)

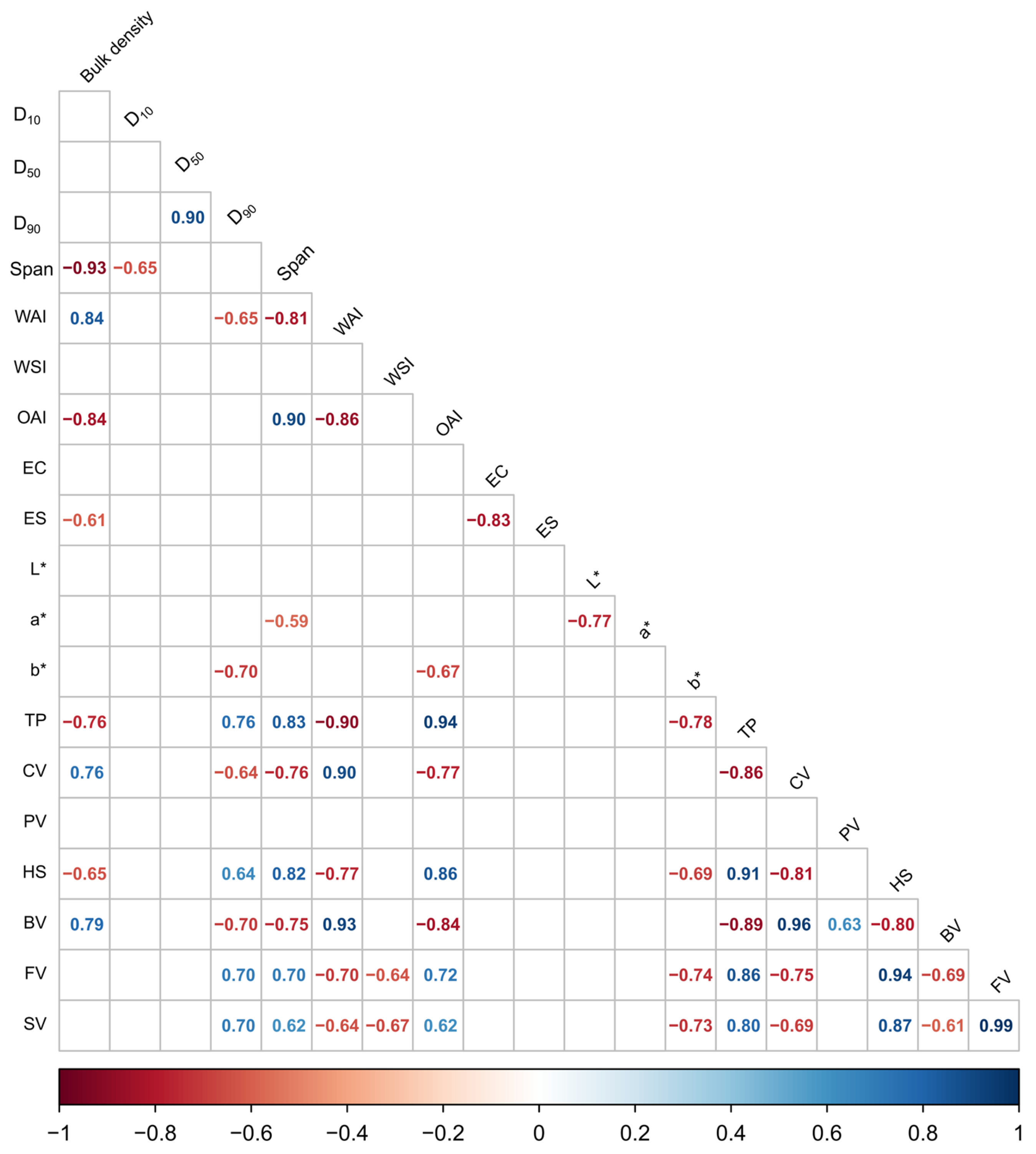

3.7. Correlation Analysis of Physical and Functional Properties

3.8. Changes in Antioxidant Properties of the Raw Materials, Blends, and Extruded Flours

3.8.1. Total Phenolic Compounds (TPC)

3.8.2. Antioxidant Capacity (ABTS+ and DPPH Radical)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PM | Pearl millet |

| PR | Parboiled brown rice |

| CP | Chickpea |

| CB | Carioca bean |

| BT | Barrel temperature |

| SS | Screw speed |

| FM | Feed moisture |

| BD | Bulk density |

| PSD | Particle-size distribution |

| WAI | Water absorption index |

| WSI | Water solubility index |

| OAI | Oil absorption index |

| RVA | Rapid Visco Analyzer |

| PT | Pasting temperature |

| CV | Cold viscosity |

| PV | Peak viscosity |

| HS | Holding strength |

| BV | Breakdown viscosity |

| FV | Final Viscosity |

| SV | Setback viscosity |

| cP | Centipoise |

| TPC | Total phenolic compounds |

| EC | Emulsifying capacity |

| ES | Emulsifying stability |

References

- Rico, D.; Cano, A.B.; Martín-Diana, A.B. Pulse-Cereal Blend Extrusion for Improving the Antioxidant Properties of a Gluten-Free Flour. Molecules 2021, 26, 5578. [Google Scholar] [CrossRef]

- Mironeasa, S.; Coţovanu, I.; Mironeasa, C.; Ungureanu-Iuga, M. A Review of the Changes Produced by Extrusion Cooking on the Bioactive Compounds from Vegetal Sources. Antioxidants 2023, 12, 1453. [Google Scholar] [CrossRef]

- Kaur, H.; Bobade, H.; Sharma, R.; Sharma, S. Influence of extruded whole wheat flour addition on quality characteristics of pasta. Int. J. Food Sci. Technol. 2023, 59, 1129–1137. [Google Scholar] [CrossRef]

- Jain, R.; Goomer, S. Understanding extrusion technology for cereal-pulse blends: A review. Cogent Food Agric. 2023, 9, 2253714. [Google Scholar] [CrossRef]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and extruded products: Changes in quality attributes as affected by extrusion process parameters: A review. Crit. Rev. Food Sci. Nutr. 2016, 56, 445–473. [Google Scholar] [CrossRef] [PubMed]

- Bunkar, D.S.; Bharti, P.; Meena, K.K.; Goyal, S.K.; Paswan, V.K. Studies on the optimization and development of functional instant kodo millet based porridge mix. Int. J. Curr. Microbiol. Appl. Sci. 2020, 9, 146–180. [Google Scholar] [CrossRef]

- Martha, G.R.-G.; Miguel, Á.S.-M.; Armando, Q.-R. The Extrusion Cooking Process for the Development of Functional Foods. In Extrusion of Metals, Polymers, and Food Products; Sayyad Zahid, Q., Ed.; IntechOpen: Rijeka, Croatia, 2017; Chapter 5. [Google Scholar]

- Patil, S.S.; Kaur, C. Current trends in extrusion: Development of functional foods and novel ingredients. Food Sci. Technol. Res. 2018, 24, 23–34. [Google Scholar] [CrossRef]

- Awol, S.J.; Kidane, S.W.; Bultosa, G. The effect of extrusion condition and blend proportion on the physicochemical and sensory attributes of teff-soybean composite flour gluten free extrudates. Meas. Food 2024, 13, 100120. [Google Scholar] [CrossRef]

- Tiwari, A.; Jha, S. Extrusion cooking technology: Principal mechanism and effect on direct expanded snacks—An overview. Int. J. Food Stud. 2017, 6. [Google Scholar] [CrossRef]

- Mariscal-Moreno, R.M.; Chuck-Hernández, C.; Figueroa-Cárdenas, J.D.; Serna-Saldivar, S.O. Physicochemical and Nutritional Evaluation of Bread Incorporated with Ayocote Bean (Phaseolus coccineus) and Black Bean (Phaseolus vulgaris). Processes 2021, 9, 1782. [Google Scholar] [CrossRef]

- Vargas-Solórzano, J.W.; Ascheri, J.L.R.; Carvalho, C.W.P.; Takeiti, C.Y.; Galdeano, M.C. Impact of the Pretreatment of Grains on the Interparticle Porosity of Feed Material and the Torque Supplied During the Extrusion of Brown Rice. Food Bioprocess Technol. 2020, 13, 88–100. [Google Scholar] [CrossRef]

- Dos Santos, T.B.; da Silva Freire Neto, R.; Collantes, N.F.; Chávez, D.W.H.; Queiroz, V.A.V.; de Carvalho, C.W.P. Exploring starches from varied sorghum genotypes compared to commercial maize starch. J. Food Process Eng. 2023, 46, e14251. [Google Scholar] [CrossRef]

- Becker, A.; Hill, S.E.; Mitchell, J.R. Milling—A Further Parameter Affecting the Rapid Visco Analyser (RVA) Profile. Cereal Chem. 2001, 78, 166–172. [Google Scholar] [CrossRef]

- Vargas-Solórzano, J.W.; Carvalho, C.W.P.; Takeiti, C.Y.; Ascheri, J.L.R.; Queiroz, V.A.V. Physicochemical properties of expanded extrudates from colored sorghum genotypes. Food Res. Int. 2014, 55, 37–44. [Google Scholar] [CrossRef]

- Ahn, H.J.; Kim, J.H.; Ng, P.K.W. Functional and Thermal Properties of Wheat, Barley, and Soy Flours and Their Blends Treated with a Microbial Transglutaminase. J. Food Sci. 2005, 70, c380–c386. [Google Scholar] [CrossRef]

- Carvalho, C.W.P.; Takeiti, C.Y.; Onwulata, C.I.; Pordesimo, L.O. Relative effect of particle size on the physical properties of corn meal extrudates: Effect of particle size on the extrusion of corn meal. J. Food Eng. 2010, 98, 103–109. [Google Scholar] [CrossRef]

- Georgé, S.; Brat, P.; Alter, P.; Amiot, M.J. Rapid Determination of Polyphenols and Vitamin C in Plant-Derived Products. J. Agric. Food Chem. 2005, 53, 1370–1373. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT—Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- de Paiva Gouvêa, L.; Caldeira, R.; de Lima Azevedo, T.; Galdeano, M.C.; Felberg, I.; Lima, J.R.; Grassi Mellinger, C. Physical and techno-functional properties of a common bean protein concentrate compared to commercial legume ingredients for the plant-based market. Food Hydrocoll. 2023, 137, 108351. [Google Scholar] [CrossRef]

- Bernardo, C.O.; Ascheri, J.L.R.; Chávez, D.W.H.; Carvalho, C.W.P. Ultrasound Assisted Extraction of Yam (Dioscorea bulbífera) Starch: Effect on Morphology and Functional Properties. Starch-Stärke 2018, 70, 1700185. [Google Scholar] [CrossRef]

- Kharat, S.; Medina-Meza, I.G.; Kowalski, R.J.; Hosamani, A.; CT, R.; Hiregoudar, S.; Ganjyal, G.M. Extrusion processing characteristics of whole grain flours of select major millets (foxtail, finger, and pearl). Food Bioprod. Process. 2019, 114, 60–71. [Google Scholar] [CrossRef]

- Singh, R.; Koksel, F. Effects of particle size distribution and processing conditions on the techno-functional properties of extruded soybean meal. LWT 2021, 152, 112321. [Google Scholar] [CrossRef]

- Ali, S.; Singh, B.; Sharma, S. Development of high-quality weaning food based on maize and chickpea by twin-screw extrusion process for low-income populations. J. Food Process Eng. 2017, 40, e12500. [Google Scholar] [CrossRef]

- Oliveira, L.C.; Barros, J.H.T.; Rosell, C.M.; Steel, C.J. Physical and thermal properties and X-ray diffraction of corn flour systems as affected by whole grain wheat flour and extrusion conditions. Starch—Stärke 2017, 69, 1600299. [Google Scholar] [CrossRef]

- Anberbir, S.M.; Satheesh, N.; Abera, A.A.; Kassa, M.G.; Tenagashaw, M.W.; Asres, D.T.; Tiruneh, A.T.; Habtu, T.A.; Sadik, J.A.; Wudineh, T.A.; et al. Evaluation of nutritional composition, functional and pasting properties of pearl millet, teff, and buckwheat grain composite flour. Appl. Food Res. 2024, 4, 100390. [Google Scholar] [CrossRef]

- Lagnika, C.; Houssou, P.A.; Dansou, V.; Hotegni, A.B.; Amoussa, A.M.O.; Kpotouhedo, F.Y.; Doko, S.A.; Lagnika, L. Physico-functional and sensory properties of flour and bread made from composite wheat-cassava. Pak. J. Nutr. 2019, 18, 538–547. [Google Scholar] [CrossRef]

- Ali, S.; Singh, B.; Sharma, S. Response surface analysis and extrusion process optimisation of maize–mungbean-based instant weaning food. Int. J. Food Sci. Technol. 2016, 51, 2301–2312. [Google Scholar] [CrossRef]

- Sharma, R.; Sharma, S.; Makroo, H.A.; Dar, B.N. Role of pulses to modulate the nutritive, bioactive and technological functionality of cereal-based extruded snacks: A review. Int. J. Food Sci. Technol. 2022, 57, 3882–3891. [Google Scholar] [CrossRef]

- Altaf, U.; Hussain, S.Z.; Qadri, T.; Iftikhar, F.; Naseer, B.; Rather, A.H. Investigation on mild extrusion cooking for development of snacks using rice and chickpea flour blends. J. Food Sci. Technol. 2021, 58, 1143–1155. [Google Scholar] [CrossRef]

- Jabeen, A.; Naik, H.R.; Jan, N.; Hussain, S.Z.; Shafi, F.; Amin, T. Numerical optimization of process parameters of water chestnut flour incorporated corn-based extrudates: Characterizing physicochemical, nutraceutical, and storage stability of the developed product. J. Food Process. Preserv. 2021, 45, e15569. [Google Scholar] [CrossRef]

- Mongi, R.; Ruhembe, C.; Urembo, K. Development and Evaluation of the Physical and Nutritional Qualities of Extruded Millet-soybean Composite Flour and the Consumer Acceptability of its Instant Porridge. J. Basic Appl. Res. Int. 2024, 22, 358–369. [Google Scholar]

- Madeira Moreira da Silva, E.; Ramirez Ascheri, J.L.; Wanderlei Piler de Carvalho, C.; Yoshie Takeiti, C.; de Berrios, J.J. Physical characteristics of extrudates from corn flour and dehulled carioca bean flour blend. LWT—Food Sci. Technol. 2014, 58, 620–626. [Google Scholar] [CrossRef]

- Azeem, M.; Mu, T.-H.; Zhang, M. Influence of particle size distribution on nutritional composition, microstructural and antioxidant properties of orange and purple-fleshed sweet potato flour. J. Food Process. Preserv. 2021, 45, e15283. [Google Scholar] [CrossRef]

- Cristiano, M.C.; Froiio, F.; Costanzo, N.; Poerio, A.; Lugli, M.; Fresta, M.; Britti, D.; Paolino, D. Effects of flour mean particle size, size distribution and water content on rheological properties of wheat flour doughs. Eur. Food Res. Technol. 2019, 245, 2053–2062. [Google Scholar] [CrossRef]

- Raza, H.; Ameer, K.; Zaaboul, F.; Sharif, H.R.; Ali, B.; Shoaib, M.; Akhtar, W.; Zhang, L. Effects of ball-milling on physicochemical, thermal and functional properties of extruded chickpea (Cicer arietinum L.) powder. CyTA—J. Food 2019, 17, 563–573. [Google Scholar] [CrossRef]

- Tas, A.A.; Shah, A.U. The replacement of cereals by legumes in extruded snack foods: Science, technology and challenges. Trends Food Sci. Technol. 2021, 116, 701–711. [Google Scholar] [CrossRef]

- Dalbhagat, C.G.; Mishra, H.N. Effects of extrusion process conditions on system parameters; physicochemical properties and cooking characteristics of extruded fortified rice kernels. J. Cereal Sci. 2019, 89, 102782. [Google Scholar] [CrossRef]

- Pismag, R.Y.; Polo, M.P.; Hoyos, J.L.; Bravo, J.E.; Roa, D.F. Effect of extrusion cooking on the chemical and nutritional properties of instant flours: A review. F1000Research 2023, 12, 1356. [Google Scholar] [CrossRef]

- Pasqualone, A.; Costantini, M.; Coldea, T.E.; Summo, C. Use of Legumes in Extrusion Cooking: A Review. Foods 2020, 9, 958. [Google Scholar] [CrossRef]

- Downs, B.; Skrzypczak, K.; Richter, J.K.; Krajka, T.; Ikuse, M.; Bernin, J.B.; Ganjyal, G.M. Influence of legume-derived proteins with varying solubility on the direct expansion of corn starch during twin-screw extrusion processing. J. Food Sci. 2023, 88, 4169–4179. [Google Scholar] [CrossRef] [PubMed]

- Shevkani, K.; Singh, N.; Chen, Y.; Kaur, A.; Yu, L. Pulse proteins: Secondary structure, functionality and applications. J. Food Sci. Technol. 2019, 56, 2787–2798. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Li, X.; Liu, X.; Li, J.; Zeng, X.-A.; Li, Y.; Yuan, Y.; Teng, Y.-X. Pulse Protein Isolates as Competitive Food Ingredients: Origin, Composition, Functionalities, and the State-of-the-Art Manufacturing. Foods 2024, 13, 6. [Google Scholar] [CrossRef] [PubMed]

- Olakanmi, S.J.; Jayas, D.S.; Paliwal, J.; Aluko, R.E. Impact of Particle Size on the Physicochemical, Functional, and In Vitro Digestibility Properties of Fava Bean Flour and Bread. Foods 2024, 13, 2862. [Google Scholar] [CrossRef]

- Lazou, A.; Krokida, M. Functional properties of corn and corn–lentil extrudates. Food Res. Int. 2010, 43, 609–616. [Google Scholar] [CrossRef]

- Sobowale, S.S.; Kewuyemi, Y.O.; Olayanju, A.T. Process optimization of extrusion variables and effects on some quality and sensory characteristics of extruded snacks from whole pearl millet-based flour. SN Appl. Sci. 2021, 3, 824. [Google Scholar] [CrossRef]

- Stone, A.K.; Nosworthy, M.G.; Chiremba, C.; House, J.D.; Nickerson, M.T. A comparative study of the functionality and protein quality of a variety of legume and cereal flours. Cereal Chem. 2019, 96, 1159–1169. [Google Scholar] [CrossRef]

- Garrido-Galand, S.; Asensio-Grau, A.; Calvo-Lerma, J.; Heredia, A.; Andrés, A. The potential of fermentation on nutritional and technological improvement of cereal and legume flours: A review. Food Res. Int. 2021, 145, 110398. [Google Scholar] [CrossRef]

- Leal Oliveira, D.P.; Soares Júnior, M.S.; Aparecida Correia Bento, J.; Guimaraes dos Santos, I.; Pinto de Castro Ferreira, T.A. Influence of extrusion conditions on the physical and nutritional properties of snacks from maize and pearl millet. J. Food Process. Preserv. 2021, 45, e15215. [Google Scholar] [CrossRef]

- Hoover, R.; Swamidas, G.; Kok, L.S.; Vasanthan, T. Composition and physicochemical properties of starch from pearl millet grains. Food Chem. 1996, 56, 355–367. [Google Scholar] [CrossRef]

- Muchlisyiyah, J.; Shamsudin, R.; Kadir Basha, R.; Shukri, R.; How, S.; Niranjan, K.; Onwude, D. Parboiled Rice Processing Method, Rice Quality, Health Benefits, Environment, and Future Perspectives: A Review. Agriculture 2023, 13, 1390. [Google Scholar] [CrossRef]

- Wani, I.A.; Singh, S.D.; Paras, S.; Gill, B.S. Physicochemical and pasting properties of unleavened wheat flat bread (Chapatti) as affected by addition of pulse flour. Cogent Food Agric. 2016, 2, 1124486. [Google Scholar] [CrossRef]

- Muñoz-Pabon, K.S.; Parra-Polanco, A.S.; Roa-Acosta, D.F.; Hoyos-Concha, J.L.; Bravo-Gomez, J.E. Physical and Paste Properties Comparison of Four Snacks Produced by High Protein Quinoa Flour Extrusion Cooking. Front. Sustain. Food Syst. 2022, 6, 852224. [Google Scholar] [CrossRef]

- Martínez, M.M.; Calviño, A.; Rosell, C.M.; Gómez, M. Effect of Different Extrusion Treatments and Particle Size Distribution on the Physicochemical Properties of Rice Flour. Food Bioprocess Technol. 2014, 7, 2657–2665. [Google Scholar] [CrossRef]

- Sandrin, R.; Caon, T.; Zibetti, A.W.; de Francisco, A. Effect of extrusion temperature and screw speed on properties of oat and rice flour extrudates. J. Sci. Food Agric. 2018, 98, 3427–3436. [Google Scholar] [CrossRef]

- Comettant-Rabanal, R.; Hidalgo Chávez, D.W.; Ascheri, J.L.R.; Elías-Peñafiel, C.; Carvalho, C.W.P. Functionality of pre-cooked whole-grain corn, rice and sorghum flours for gluten-free bread. Int. J. Food Sci. Technol. 2023, 58, 5781–5795. [Google Scholar] [CrossRef]

- Jozinović, A.; Šubarić, D.; Ačkar, Đ.; Babić, J.; Miličević, B. Influence of spelt flour addition on properties of extruded products based on corn grits. J. Food Eng. 2016, 172, 31–37. [Google Scholar] [CrossRef]

- Koukoumaki, D.I.; Giannoutsos, K.; Devanthi, P.V.P.; Karmiris, P.; Bourni, S.; Monemvasioti, A.; Psimouli, V.; Sarris, D.; Gkatzionis, K. Effect of Wheat Replacement by Pulse Flours on the Texture, Color, and Sensorial Characteristics of Crackers: Flash Profile Analysis. Int. J. Food Sci. 2022, 2022, 2354045. [Google Scholar] [CrossRef]

- Dalbhagat, C.G.; Mahato, D.K.; Mishra, H.N. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: A review. Trends Food Sci. Technol. 2019, 85, 226–240. [Google Scholar] [CrossRef]

- Allai, F.M.; Junaid, P.M.; Azad, Z.R.A.A.; Gul, K.; Dar, B.N.; Siddiqui, S.A.; Manuel Loenzo, J. Impact of moisture content on microstructural, thermal, and techno-functional characteristics of extruded whole-grain-based breakfast cereal enriched with Indian horse chestnut flour. Food Chem. X 2023, 20, 100959. [Google Scholar] [CrossRef]

- Martín-Diana, A.B.; Jiménez-Pulido, I.J.; Aguiló-Aguayo, I.; Abadías, M.; Pérez-Jiménez, J.; Rico, D. Peach Peel Extrusion for the Development of Sustainable Gluten-Free Plant-Based Flours. Molecules 2025, 30, 573. [Google Scholar] [CrossRef]

- Altan, A.; McCarthy, K.L.; Maskan, M. Effect of extrusion process on antioxidant activity, total phenolics and β-glucan content of extrudates developed from barley-fruit and vegetable by-products. Int. J. Food Sci. Technol. 2009, 44, 1263–1271. [Google Scholar] [CrossRef]

- Orozco-Angelino, X.; Espinosa-Ramírez, J.; Serna-Saldívar, S.O. Extrusion as a tool to enhance the nutritional and bioactive potential of cereal and legume by-products. Food Res. Int. 2023, 169, 112889. [Google Scholar] [CrossRef]

| Formulations (PR/PM/CP/CB) | Ash (g/100 g) | Protein (g/100 g) | Lipid (g/100 g) | Dietary Fiber (g/100 g) | Carbohydrates (g/100 g) |

|---|---|---|---|---|---|

| F1 (60/15/15/10) | 2.19 ± 0.00 c | 11.20 ± 0.16 d | 4.41 ± 0.15 b | 8.81 ± 0.16 c | 72.40 ± 0.33 a |

| F2 (15/60/15/10) | 2.38 ± 0.05 cb | 12.77 ± 0.00 c | 5.52 ± 0.19 a | 11.23 ± 0.72 b | 66.86 ± 0.30 b |

| F3 (15/15/60/10) | 3.33 ± 0.04 a | 17.35 ± 0.08 a | 6.22 ± 0.08 a | 13.60 ± 0.19 a | 58.08 ± 0.02 c |

| F4 (30/30/30/10) | 2.56 ± 0.13 b | 13.64 ± 0.16 b | 5.62 ± 0.32 a | 11.10 ± 0.43 b | 65.93 ± 0.13 b |

| Blends (PR/PM/CP/CB) | Condition | Specific Mechanical Energy (SME—W·h/kg) | Bulk Density (BD—g/cm3) | 10% Percentile D10 (µm) | 50% Percentile D50 (µm) | 90% Percentile D90 (µm) | Span (µm) |

|---|---|---|---|---|---|---|---|

| F1 (60/15/15/10) | Raw | - | a 0.53 ± 0.01 | a 30.40 ± 0.32 | b 204.70 ± 6.02 | b 530.07 ± 12.41 | c 2.44 ± 0.02 |

| F2 (15/60/15/10) | Raw | - | b 0.49 ± 0.01 | b 26.09 ± 0.35 | c 174.17 ± 0.81 | c 496.33 ± 02.90 | b 2.70 ± 0.01 |

| F3 (15/15/60/10) | Raw | - | c 0.39 ± 0.01 | c 19.22 ± 0.27 | d 64.21 ± 0.66 | d 259.00 ± 04.20 | a 3.73 ± 0.04 |

| F4 (30/30/30/10) | Raw | - | b 0.49 ± 0.01 | b 26.65 ± 0.52 | a 249.27 ± 6.41 | a 656.93 ± 14.03 | cb 2.53 ± 0.12 |

| Extruded flours | |||||||

| F1 (60/15/15/10) | E1 (30/300) | 073.37 ± 00.66 aB | 0.59 ± 0.02 aA | 33.50 ± 2.35 aA | 139.47 ± 5.76 aA | 287.03 ± 06.57 aA | 1.82 ± 0.05 bA |

| F2 (15/60/15/10) | E1 (30/300) | 058.04 ± 10.77 aB | 0.55 ± 0.02 bA | 27.22 ± 0.13 bA | 110.27 ± 0.59 bA | 233.28 ± 01.27 bA | 1.87 ± 0.01 bA |

| F3 (15/15/60/10) | E1 (30/300) | 056.81 ± 04.98 aB | 0.55 ± 0.01 bA | 22.32 ± 0.70 cB | 118.27 ± 2.83 bB | 272.13 ± 01.08 aB | 2.11 ± 0.05 aA |

| F4 (30/30/30/10) | E1 (30/300) | 066.53 ± 01.24 aB | 0.59 ± 0.00 aA | 27.04 ± 0.99 bB | 106.83 ± 3.35 bB | 229.02 ± 04.77 bB | 1.89 ± 0.02 bA |

| F1 (60/15/15/10) | E2 (18/600) | 208.60 ± 15.32 aA | 0.58 ± 0.01 aA | 33.22 ± 4.57 bA | 120.47 ± 7.09 cB | 234.10 ± 06.74 cB | 1.67 ± 0.08 bB |

| F2 (15/60/15/10) | E2 (18/600) | 185.45 ± 31.32 abA | 0.55 ± 0.01 aA | 27.47 ± 5.57 cA | 109.80 ± 11.07 cA | 240.17 ± 05.22 cA | 1.94 ± 0.17 aA |

| F3 (15/15/60/10) | E2 (18/600) | 151.64 ± 14.17 bA | 0.51 ± 0.02 bB | 28.08 ± 3.15 cA | 145.42 ± 20.53 bA | 303.18 ± 32.20 bA | 1.90 ± 0.07 aB |

| F4 (30/30/30/10) | E2 (18/600) | 171.72 ± 09.22 abA | 0.57 ± 0.02 aA | 48.63 ± 4.41 aA | 182.92 ± 1.50 aA | 329.25 ± 10.33 aA | 1.53 ± 0.08 cB |

| Blends (PR/PM/CP/CB) | Condition | WAI | WSI | OAI | EC | ES |

|---|---|---|---|---|---|---|

| F1 (60/15/15/10) | Raw | a 2.09 ± 0.19 | d 7.76 ± 0.28 | b 1.43 ± 0.12 | c 9.97 ± 2.32 | b 68.60 ± 3.50 |

| F2 (15/60/15/10) | Raw | b 1.62 ± 0.06 | c 8.37 ± 0.03 | b 1.31 ± 0.02 | c b10.50 ± 1.91 | a 81.05 ± 0.24 |

| F3 (15/15/60/10) | Raw | c 1.28 ± 0.10 | a 16.82 ± 0.23 | a 1.72 ± 0.01 | b 10.71 ± 0.53 | a 79.60 ± 2.47 |

| F4 (30/30/30/10) | Raw | b 1.79 ± 0.05 | b 10.57 ± 0.04 | ba 1.46 ± 0.02 | a 19.67 ± 2.08 | c 52.22 ± 0.96 |

| Extruded flours | ||||||

| F1 (60/15/15/10) | E1 (30/300) | 5.39 ± 0.52 aA | 09.64 ± 0.30 cbB | 0.93 ± 0.03 aB | 17.93 ± 1.17 aA | 51.11 ± 3.48 cA |

| F2 (15/60/15/10) | E1 (30/300) | 4.72 ± 0.56 bA | 06.78 ± 2.20 cB | 0.91 ± 0.02 abA | 15.36 ± 1.36 bB | 76.72 ± 2.41 aA |

| F3 (15/15/60/10) | E1 (30/300) | 3.85 ± 0.62 cA | 12.50 ± 1.67 aB | 0.89 ± 0.03 abB | 15.8 ± 2.82 bA | 56.58 ± 0.79 bB |

| F4 (30/30/30/10) | E1 (30/300) | 3.97 ± 0.13 cA | 10.19 ± 0.60 abB | 0.88 ± 0.01 bA | 17.9 ± 3.16 aA | 55.69 ± 3.36 bA |

| F1 (60/15/15/10) | E2 (18/600) | 4.26 ± 0.08 aB | 25.94 ± 0.59 aA | 1.04 ± 0.06 aA | 17.32 ± 0.09 aA | 43.15 ± 1.98 dB |

| F2 (15/60/15/10) | E2 (18/600) | 4.15 ± 0.37 aB | 17.84 ± 3.50 cA | 0.93 ± 0.03 bA | 16.23 ± 2.26 bA | 48.34 ± 1.51 cB |

| F3 (15/15/60/10) | E2 (18/600) | 2.92 ± 0.18 bB | 18.01 ± 2.06 cA | 0.93 ± 0.02 bA | 08.35 ± 4.55 dB | 87.06 ± 0.11 aA |

| F4 (30/30/30/10) | E2 (18/600) | 3.92 ± 0.12 aA | 21.92 ± 1.55 bA | 0.89 ± 0.01 bA | 13.64 ± 3.12 cB | 56.30 ± 5.65 bA |

| Blends (PR/PM/CP/CB) | Condition | L* | a* | b* |

|---|---|---|---|---|

| F1 (60/15/15/10) | Raw | b 82.20 ± 0.30 | c 0.57 ± 0.02 | b 15.32 ± 0.45 |

| F2 (15/60/15/10) | Raw | c 77.29 ± 0.48 | a 1.06 ± 0.00 | b 14.87 ± 0.88 |

| F3 (15/15/60/10) | Raw | a 86.05 ± 0.38 | d 0.05 ± 0.02 | a 17.05 ± 0.24 |

| F4 (30/30/30/10) | Raw | b 81.70 ± 0.28 | b 0.90 ± 0.03 | b 15.57 ± 0.22 |

| Extruded flours | ||||

| F1 (60/15/15/10) | E1 (30/300) | 82.70 ± 0.74 bA | 0.77 ± 0.08 bB | 16.46 ± 0.67 dB |

| F2 (15/60/15/10) | E1 (30/300) | 76.85 ± 0.42 dA | 1.19 ± 0.04 aB | 17.44 ± 0.22 cB |

| F3 (15/15/60/10) | E1 (30/300) | 83.41 ± 0.44 aA | 0.19 ± 0.05 cB | 20.09 ± 0.36 aA |

| F4 (30/30/30/10) | E1 (30/300) | 80.00 ± 0.49 cA | 0.85 ± 0.03 bB | 18.66 ± 0.21 bA |

| F1 (60/15/15/10) | E2 (18/600) | 82.01 ± 0.28 bB | 1.48 ± 0.05 bA | 17.93 ± 0.33 cA |

| F2 (15/60/15/10) | E2 (18/600) | 76.55 ± 0.44 dA | 1.80 ± 0.07 aA | 18.43 ± 0.26 bcA |

| F3 (15/15/60/10) | E2 (18/600) | 83.01 ± 0.32 aA | 0.53 ± 0.02 dA | 19.71 ± 0.41 aA |

| F4 (30/30/30/10) | E2 (18/600) | 80.44 ± 0.51 cA | 1.38 ± 0.11 cA | 18.67 ± 0.26 bA |

| Blends (PR/PM/CP/CB) | Condition | TPC | ABTS+ | DPPH |

|---|---|---|---|---|

| PR | Raw | d 19.37 ± 1.01 | d 1.86 ± 0.10 | - |

| PM | Raw | b 296.42 ± 4.64 | b 6.98 ± 0.15 | - |

| CP | Raw | c 60.25 ± 1.78 | c 3.06 ± 0.15 | - |

| CB | Raw | a 508.35 ± 7.59 | a 18.43 ± 0.14 | - |

| F1 (60/15/15/10) | Raw | 102.53 ± 1.52 c | 4.39 ± 0.39 c | - |

| F2 (15/60/15/10) | Raw | 284.91 ± 20.22 a | 13.20 ± 1.00 a | 9.94 ± 0.75 a |

| F3 (15/15/60/10) | Raw | 139.85 ± 6.59 b | 4.19 ± 0.05 c | - |

| F4 (30/30/30/10) | Raw | 134.00 ± 2.11 b | 5.51 ± 0.09 b | - |

| F2 (15/60/15/10) | E1 (30/300) | 273.00 ± 11.11 A | 11.62 ± 0.60 A | 5.76 ± 0.44 A |

| F2 (15/60/15/10) | E2 (18/600) | 238.31 ± 15.23 B | 10.92 ± 0.23 B | 5.29 ± 0.68 A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chuqui-Paulino, F.J.; Chávez, D.W.H.; Ascheri, J.L.R.; Mellinger, C.G.; Vargas-Solorzano, J.W.; Carvalho, C.W.P. Impact of Whole Cereal–Pulse Flours on the Functionality and Antioxidant Properties of Gluten-Free Extruded Flours. Foods 2025, 14, 3515. https://doi.org/10.3390/foods14203515

Chuqui-Paulino FJ, Chávez DWH, Ascheri JLR, Mellinger CG, Vargas-Solorzano JW, Carvalho CWP. Impact of Whole Cereal–Pulse Flours on the Functionality and Antioxidant Properties of Gluten-Free Extruded Flours. Foods. 2025; 14(20):3515. https://doi.org/10.3390/foods14203515

Chicago/Turabian StyleChuqui-Paulino, Franz J., Davy W. Hidalgo Chávez, José L. Ramírez Ascheri, Caroline Grassi Mellinger, Jhony W. Vargas-Solorzano, and Carlos W. Piler Carvalho. 2025. "Impact of Whole Cereal–Pulse Flours on the Functionality and Antioxidant Properties of Gluten-Free Extruded Flours" Foods 14, no. 20: 3515. https://doi.org/10.3390/foods14203515

APA StyleChuqui-Paulino, F. J., Chávez, D. W. H., Ascheri, J. L. R., Mellinger, C. G., Vargas-Solorzano, J. W., & Carvalho, C. W. P. (2025). Impact of Whole Cereal–Pulse Flours on the Functionality and Antioxidant Properties of Gluten-Free Extruded Flours. Foods, 14(20), 3515. https://doi.org/10.3390/foods14203515