1. Introduction

Mare milk has been consumed by humans in various cultures for centuries, and the popularity of this milk is still growing, especially in some parts of Europe. It is worth noting that the composition of mare milk is significantly different from that of cows and other animals [

1]. Mare milk is characterized by its protein content (from 15 to 28 g kg

−1), a large quantity of lactose (from 58 to 70 g kg

−1), and low levels of fat (from 3 to 20 g kg

−1) [

2]. Mare milk exhibits a distinct fatty acid profile, with a balanced distribution of saturated, monounsaturated, and polyunsaturated fatty acids. Therefore, it is worth emphasizing that mare milk has a higher percentage of unsaturated fatty acids (about 53% total fatty acids), which is similar to human milk (59.5%) and greater than that of cow milk (37%) [

3].

The presence of conjugated linoleic acid (CLA) in mare milk has been of particular interest due to its potential health-promoting effects. While mare milk does provide various fatty acids, the overall nutritional content and potential health benefits should be considered in the context of an individual’s dietary needs. According to [

3], mare milk, because of its structural and functional properties, can be used in human nutrition. Recent scientific findings on equine milk’s composition demonstrate its positive effects on patients with osteoporosis (by increasing calcium absorption), bronchial and lung diseases, stomach ulcers, cirrhosis, and anemia [

3].

Fortifying mare milk with omega-3 fatty acids, such as alpha-linolenic acid (ALA), can enhance its nutritional value. The development of different diseases, including Alzheimer’s disease, cardiovascular disease, and inflammation, may be affected by the proportions of omega-3 and omega-6 fats in one’s diet [

4]. For those who may have difficulty obtaining enough omega-3 fatty acids through their diets, supplementation plays a crucial role in maintaining health, and they are particularly important for older adults.

Flaxseed oil is extracted from the seeds of the flaxseed plant (

Linum usitatissimum L.), most often by cold pressing to preserve its beneficial nutritional properties. Freshly pressed flaxseed oil is characterized by a yellowish color, a mild characteristic smell, and a nutty taste, which may become bitter during storage [

5,

6,

7]. Flaxseed oil has been used for various applications since antiquity, but in the last three decades, flaxseed and its oil have been the focus of increased interest in the field of diet and disease research [

8]. This is due to the chemical composition of flaxseed and flaxseed oil, rich in biologically active ingredients. Flaxseed is a rich source of polyunsaturated fatty acids, dietary fibers, proteins, lignans, phenolic acids, flavonoids, vitamins (A, C, F, and E), and minerals (P, Mg, K, Na, Fe, Cu, Mn, and Zn) [

8,

9,

10]. The greatest pro-health advantage of flaxseed oil is the high content of omega-3 acids, particularly alpha-linoleic acid (ALA), which causes health-beneficial action in many diseases such as coronary heart disease, diabetes, and cancer [

9,

11]. In addition, the ALA content in flaxseed oil is beneficial for infant brain development, blood lipid reduction, arthritis, gastrointestinal disorders, eczemas, hypertension, and immune response disorders [

9,

11,

12,

13]. Due to these properties, the food industry uses flaxseed oil for food fortification, such as Indian yogurt [

14], powder soup [

15], ice cream [

16], bread [

17], and milk [

18].

However, the disadvantage of flaxseed oil is its high sensitivity to oxidation (particularly its ALA component) [

9,

11], which significantly hinders effective food fortification while preserving the beneficial properties over a longer shelf life. Effective solutions to this problem are various types of microencapsulation processes which enable obtaining microcapsules of flax seed oil with greatly improved oxidative stability. The microcapsules obtained in this way are ideally suited for food fortification, particularly dried food.

Microencapsulation is a technological process commonly applied in the areas of food, pharmacy, and biotechnology, protecting active substances against external factors (heat, moisture, light, and oxygen), preventing their evaporation and volatilization, allowing masking an unpleasant taste or smell, preventing interaction with other compounds, or controlling the release of the core material [

11,

19,

20]. The process consists of surrounding the active substance, usually called the core or inner phase, with a material or mixture of materials, usually called the outer phase, including the shell, carrier, matrix, encapsulating agent, or wall material [

11,

20,

21]. The encapsulated core material can be in various forms—liquid, solid, or gaseous particles—while the encapsulating agent in solid form creates a tight barrier, completely isolating the core material from the external environment [

20]. There are many methods of microencapsulation, from which three groups can be distinguished: chemical methods (e.g., interfacial polymerization), physical methods (e.g., spray drying, freeze drying, and fluid bed coating), and physicochemical methods (e.g., coacervation and ionotropic gelation) [

9]. The most commonly used methods in the production of food ingredients are spray and freeze drying, in which water solutions, emulsions, or dispersions are dehydrated. Due to their specificity, both methods allow achieving a high degree of bioactivity retention of the core material (spray drying due to its short drying time and freeze drying due to the low material temperature and lack of air during drying (sublimation under vacuum conditions)). However, as reported in the literature, freeze drying achieves higher-quality microencapsules than spray drying, both in terms of encapsulation of flaxseed oil [

11] and preservation of the bioactive and nutritional properties of milk [

22,

23,

24]. Therefore, the present study focused on microencapsulation via freeze drying.

The research results published by Cais-Sokolińska et al. [

25] unequivocally confirmed the possibility of freeze drying mare milk and then using the freeze-dried product to create good emulsions or foods with a low degree of aeration. Taking into account the above issues, the following hypothesis was formulated in this study: Microencapsulation of flaxseed oil in the mare milk matrix with the freeze-drying method contributes to improvement in the foaming, emulsifying, and health-promoting properties due to the change in the lipid profile.

In light of the above, the aim of this study is to evaluate the effectiveness and usefulness of fortification of mare milk with flaxseed oil as a result of microencapsulation through freeze drying and compare it with cow milk, a highly available milk. Both the obtained microcapsules of fortified milk and those reconstituted in an aqueous environment are evaluated. Useful and nutritional properties are analyzed in terms of obtaining milk drinks with specifically designed pro-health values.

2. Materials and Methods

2.1. Raw Milk

Mare milk was obtained from mares (Polish Coldblood) reared on an equine farm located in western Poland (Wielkopolska province). It was bulk milked from several mares milked on the same day to the amount of 10 L. The milk was collected in the fourth month of lactation, with foaling having occurred in February. By the fourth month of lactation, the milk’s chemical composition had already stabilized, and it was consistent in terms of density and acidity. The basic composition of the raw mare milk was as follows: fat content of 15.5 g/kg, total protein of 23.7 g/kg, lactose content of 63.1 g/kg. The milk was not centrifuged to change the fat content. The cow milk to the amount of 10 L was obtained from a farm from Holstein-Friesian cows, which were also from the same region of Wielkopolska. Both the mare milk and cow milk were collected during the same period (i.e., in June) at intervals of five days. A total of six milk collections were conducted during the month. The raw cow milk was centrifuged (Milky FJ 130 EPR separator, Janschitz GmbH, Althofen, Austria), and the fat content was normalized to 1.5% to reduce the content of this component, as in the mare milk. In the raw cow milk, after normalization of the fat content from 42.3 to 15.6 g/kg, the contents of the other basic components was as follows: total protein of 34.2 g/kg and a lactose content of 47.7 g/kg. Neither the mare milk nor the cow milk were homogenized; they were only cooled and kept for a maximum of 12 h after milking in separate SKM50 tanks from Plevnik (Dobrova, Slovenia). Both types of milk were pasteurized at 85 °C for 10 min in a Milky FJ 15 pasteurizer (Janschitz GmbH, Althofen, Austria). The experiment was performed 6 times (

n = 6) (i.e., the total volume of mare milk used was 6 × 10 L, and that for the cow milk was 6 × 10 L). The authors’ assumption was to refer to earlier scientific achievements in the field of foaming and other useful qualities of lyophilized mare milk published in 2023 [

25] by the same authors, and hence the raw materials and analytical methods used were the same.

2.2. Fortification of Raw Milk with Flaxseed Oil

In order to fortify the milk, 2% (v/v) flaxseed oil (Bunge, Kruszwica, Poland) was added to fresh cow or mare milk, pre-mixed, and homogenized at 15,000 rpm within 5 min using a TK-25 homogenizer (IKA Werke GmbH, Staufen, Germany). In total, 800 g of emulsions were prepared in 100 g portions. The emulsions prepared in this way were frozen immediately after homogenization of each portion.

2.3. Freeze Drying

Fresh cow and mare milk (CM and MM) and fortified cow and mare milk with flaxseed oil (CMFO and MMFO) were frozen using silicone cylindrical molds with dimensions of ϕ 25 × 10 mm to −40 °C (in an RLHE0845 freezer; Labcold Ltd., Chineham, UK) prior the freeze-drying process. Approximately 160 silicone cylindrical molds were used to freeze each milk product into discs. After being frozen for 24 h, the milk product discs were removed from the molds and arranged in a single layer on the trays of a freeze dryer. The freeze-drying procedure was performed on a semi-industrial scale using a CHWC-20A freeze dryer (Lyo-Tech Sp.z o.o., Międzyrzecz, Poland) to replicate an industrially relevant process. During the operation, the vacuum pressure was maintained consistently within the range of 60–70 Pa. The temperature of the heating plates was gradually adjusted, starting at 90 °C and decreasing to 40 °C by the end of the process. The entire freeze-drying process was completed within 16 h. Freeze-dried milk products, in the form of partially self-disintegrating fragile agglomerates of various sizes, were collected from the trays and subjected to a thorough powdering process. For this purpose, the products were crushed using an AGN grinder (Alexanderwerk AG, Remscheid, Germany) with a sieve (1.0 mm mesh size). The resulting powders were placed in sealed foil laminate pouches and kept at a temperature of 3 ± 0.5 °C for further analysis, with storage not exceeding two weeks. To ensure stability, the freeze-dried milk products were shielded from light during storage. However, measurements were conducted under brief exposure to light conditions (450 lx, f 590 cd, 120 lm) using a TES-1335 device (TES Electrical Electronic Corp., Taipei, Taiwan).

2.4. Samples for Physicochemical Testing

Four different milk product samples were subjected to physicochemical tests: cow milk (CM), mare milk (MM), cow milk fortified with flaxseed oil (CMFO), and mare milk fortified with flaxseed oil (MMFO). All milk product samples, depending on the physicochemical tests performed, were used in three different forms: raw, freeze-dried, and reconstituted freeze-dried samples. In the case of the reconstituted milk products, the freeze-dried powders were dissolved in distilled water at 18 °C in proportions to achieve the appropriate concentrations of raw milk products. Thus, 29.7, 24.2, 35.4, and 30.1 g of freeze-dried CM, MM, CMFO and MMFO, respectively, were dissolved in 250 mL of distilled water.

2.5. Moisture Content and Water Activity

The moisture contents of the freeze-dried milk products were measured with an HX204/M halogen apparatus (Mettler Toledo, Columbus, OH, USA) at 80 °C, while the determination of water activity was performed using an AquaLab Series 4TE device (Decagon Devices Inc., Pullman, WA, USA).

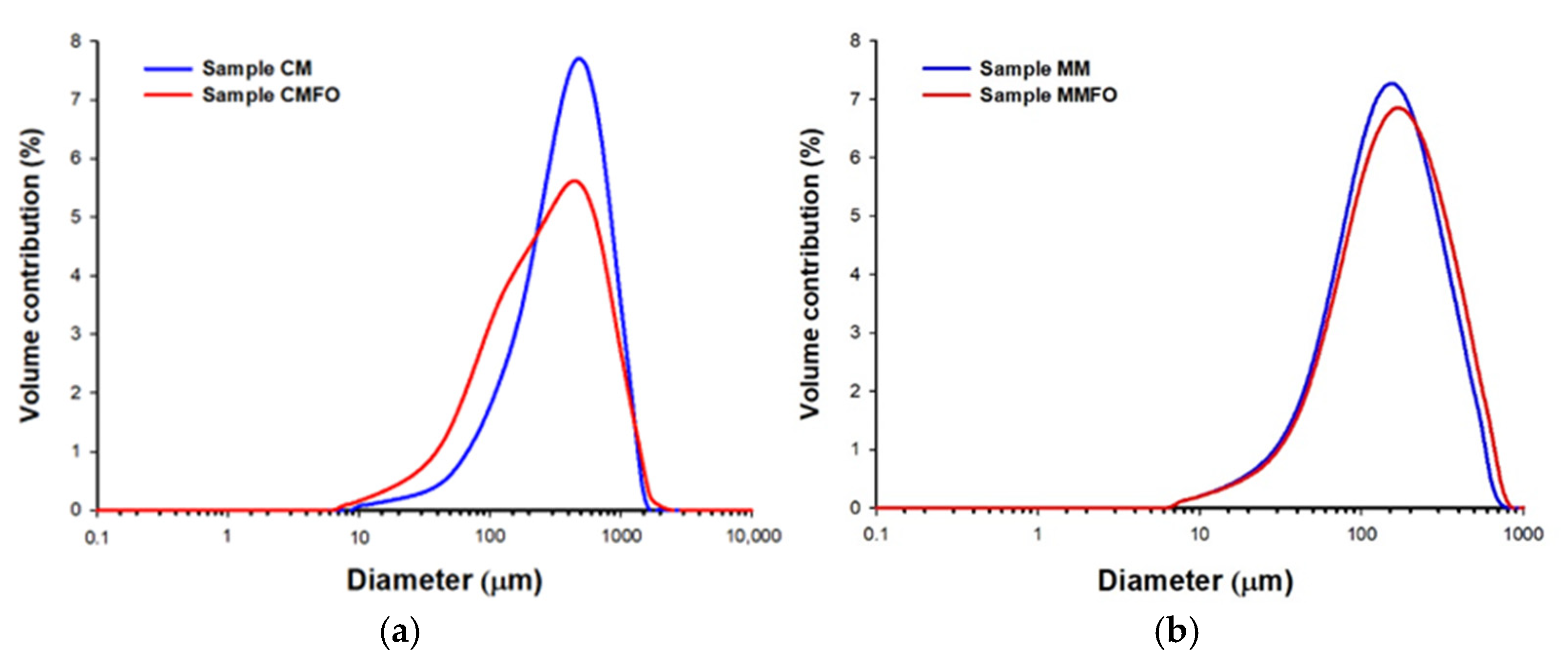

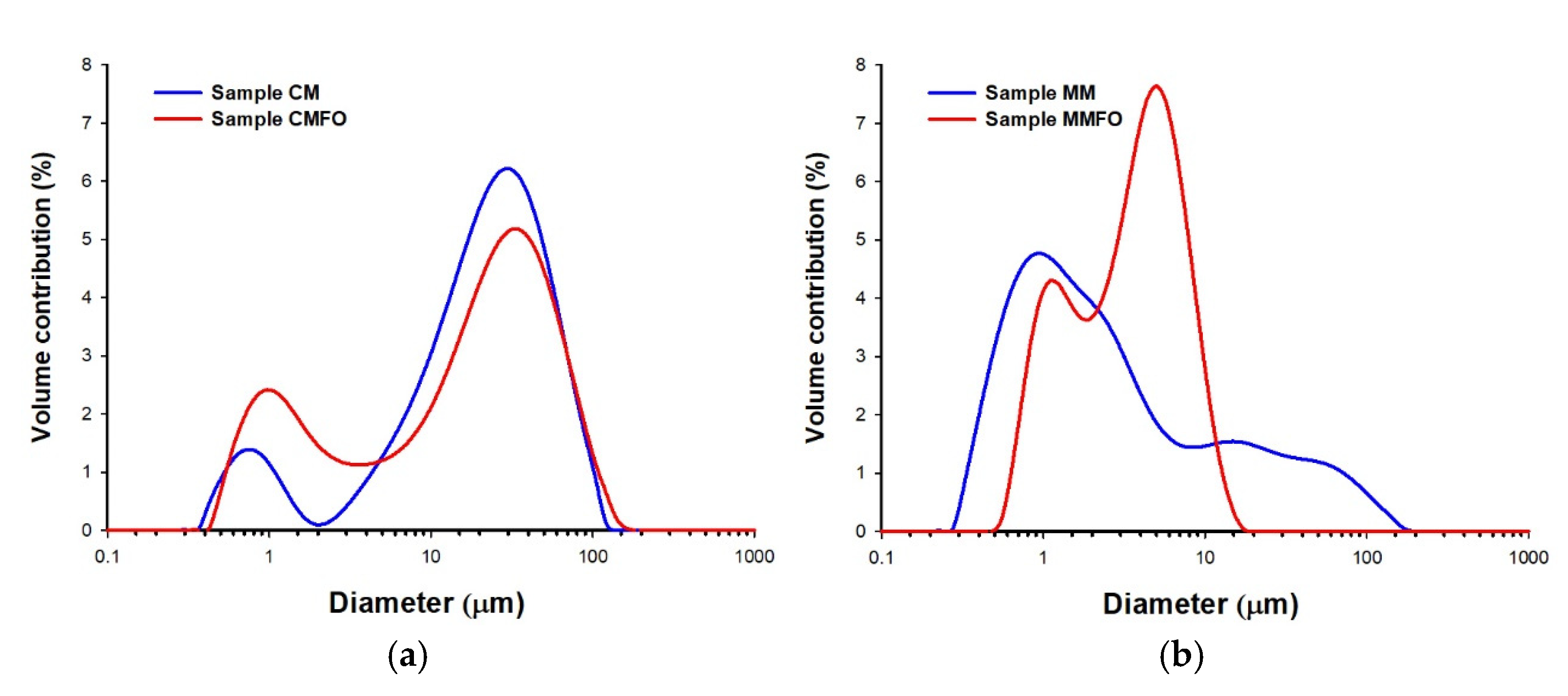

2.6. Particle Size Distribution (PSD) of Powder and Emulsion Droplets

The size distribution of the particles (PSD) was determined using a Mastersizer 2000 analyzer (Malvern Instruments Ltd., Malvern, UK), which is based on the laser diffraction method. Both measurements were carried out using the wet method with a Hydro 2000 G unit equipped with a high-speed stirrer and an ultrasonic source. In the PSD measurement of the powders, isopropanol was used as the dispersant, while the PSD measurement of the emulsion droplets was carried out in the prepared emulsion of reconstituted milk products, where water was used as the dispersant. After preparation of reconstituted freeze-dried milk product samples (methodology described in

Section 3.4), each sample was homogenized at 15,000 rpm within 5 min using a TK-25 homogenizer (IKA Werke GmbH, Staufen, Germany). Three percentiles (D

10, D

50 and D

90), the volume-weighted mean diameter D[4,3], and the span (Equation (1)) of the volume distribution were determined:

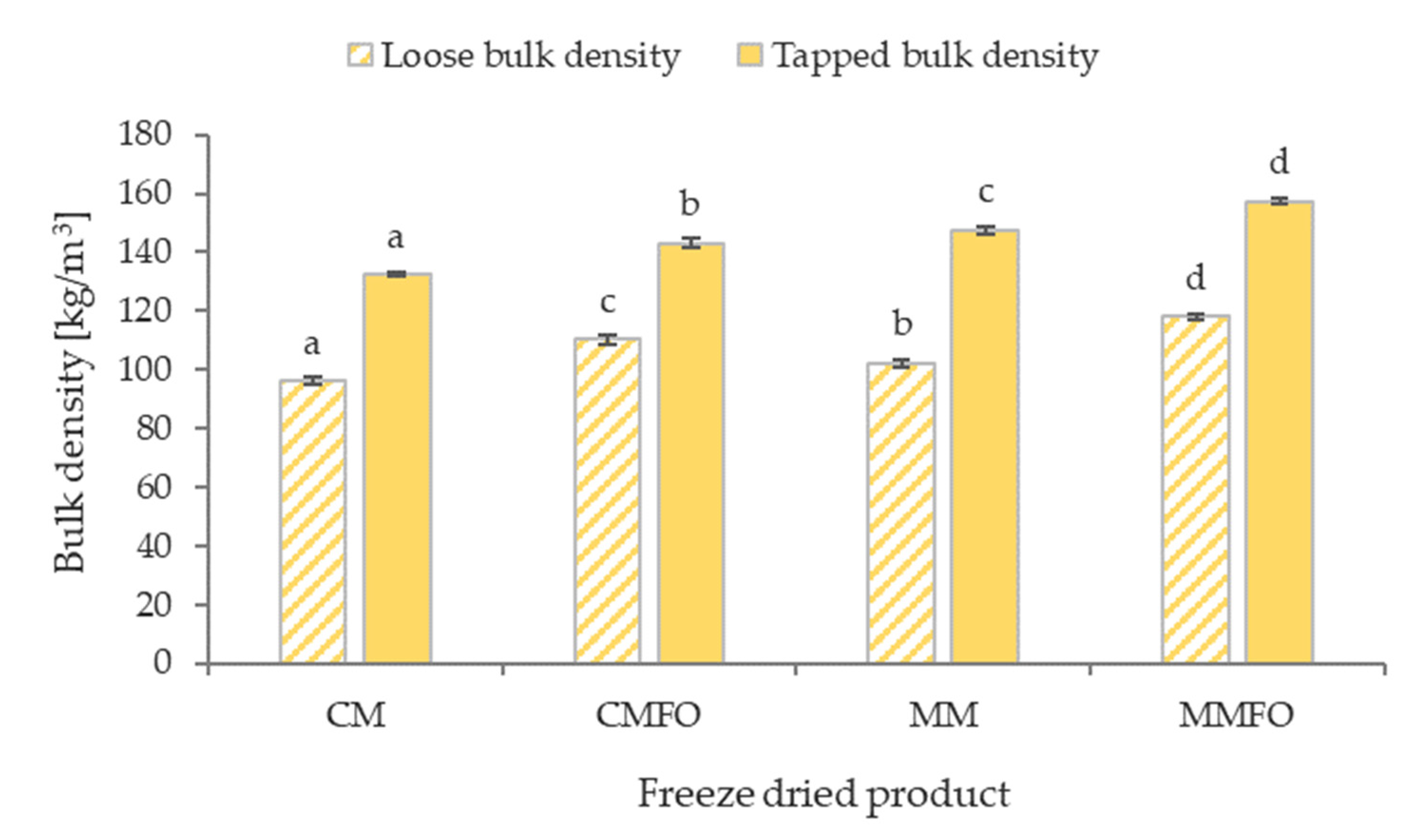

2.7. Bulk Density and Flowability

The loose bulk density (ρ

l) and tapped bulk density (ρ

t) were measured according to ASTM D6393 [

26] using a Thyr 2 vibrating laboratory apparatus (Saskia Hochvakuum und Labortechnik GmbH, Ilmenau, Germany) with appropriate adjustments. The flowability of the obtained freeze-dried powders was determined using the Hausner ratio (HR), which indicated the cohesiveness of the powders, and the Carr index (CI), which indicated the compressibility of the powders. The HR and CI were calculated according to Equations (2) and (3), respectively:

2.8. Color

The color values of the powders in the CIE L* a* b* system were measured with the reflectance method using an SP-60 spectrophotometer (X-Rite, Grandville, MI, USA) in the SPIN configuration. The L* value indicates the degree of lightness (scale: 0–100), a* indicates the red (positive values) and green (negative values) color measurements, and b* indicates the yellow (positive values) and blue (negative values) color measurements.

2.9. Fatty Acid Profile

The fatty acid profile was determined according to the methodology described by Cais-Sokolińska et al. [

25]. The atherogenic index (AI), thrombogenic index (TI), hypercholesterolemia fatty acid index (HcFA), content of fatty acids with the hypocholesterolaemia effect (DFA), and hypercholesterolemia fatty acids (OFAs) of the fat milk samples were determined in accordance with the good laboratory practices and methodologies described in other publications [

25,

27,

28].

2.10. Statistical Analysis

All determined physicochemical parameters were expressed as mean values ± standard deviation (SD) based on the measurements of 3 replicates at minimum. Statistical differences in the results for different milk products were verified by applying one-factor analysis of variance (ANOVA). Tukey’s HSD test was selected as the post hoc test, and the significance level was α = 0.05. Calculations were performed using Statistica software v. 13.1 (StatSoft Poland, Cracow, Poland).

4. Conclusions

This study showed that freeze drying allows obtaining useful pure milk powder products as well as those enriched with oil.

The freeze-dried powders made from mare milk (both raw and fortified with flaxseed oil) showed better health-promoting properties in the nutritional areas of the fatty acid profile than the cow milk products. This was evidenced by the values of several indices, including the AI, TI, HcFA, DFA, and OFA, as well as the n-3/n-6 ratio.

For both types of milk, the products fortified with flaxseed oil had a lower moisture content, higher loose and tapped bulk densities, better flowability, as well as lower particle sizes for the reconstituted emulsion droplets than their pure counterparts. Additionally, fortification with flaxseed oil enhanced the health-promoting properties in the case of the DFA and OFA parameters (for mare milk) and the n-6/n-3 ratio (for cow milk).

The tested composite product, which was flaxseed oil microencapsulated via freeze drying in a mare milk matrix, showed good physicochemical, handling, and nutritional properties, which indicates its potential for use as a valuable, health-promoting food ingredient. However, one limitation may be the low availability of mare milk as well as the need to further determine the product’s stability regarding lipid oxidation.