Microwave Drying of Tricholoma Matsutake: Dielectric Properties, Mechanism, and Process Optimization

Abstract

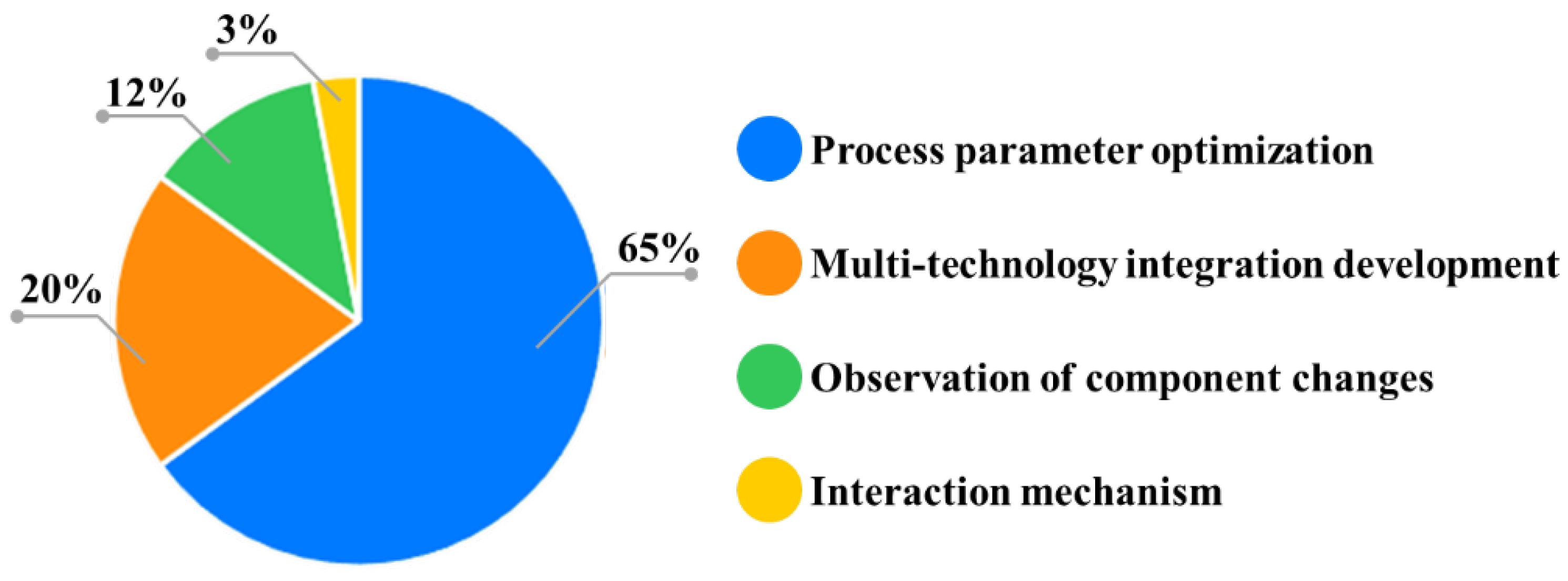

1. Introduction

2. Materials and Methods

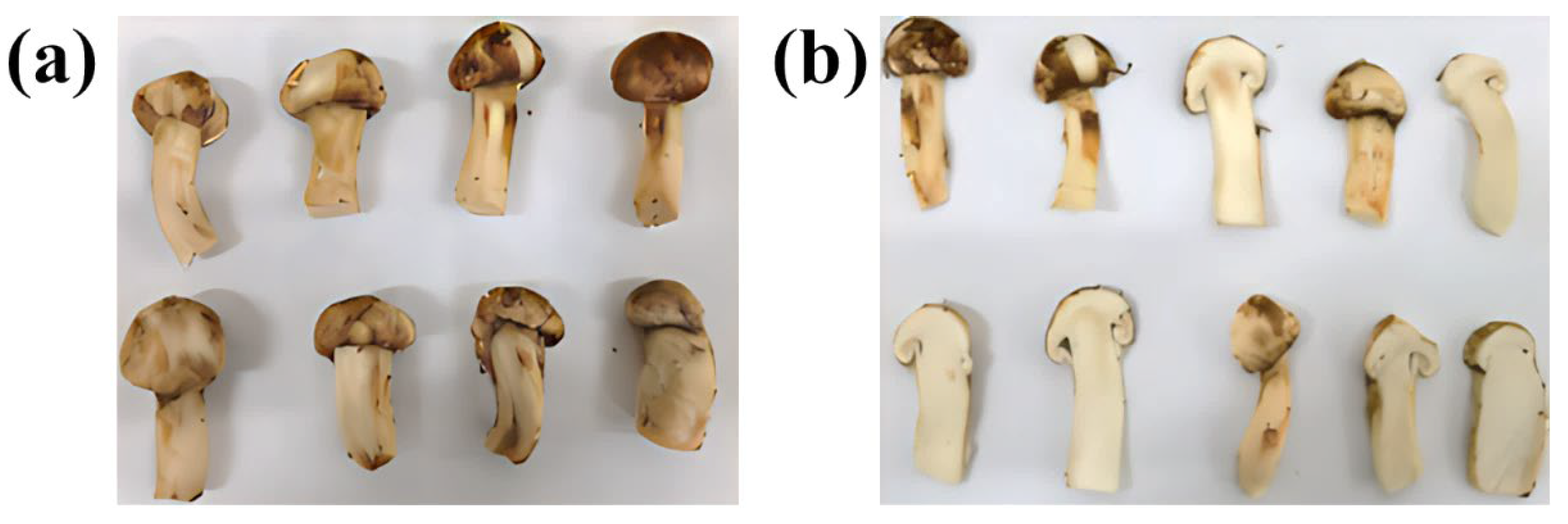

2.1. Materials

2.2. Dehydration Ratio Determination in Fresh TM

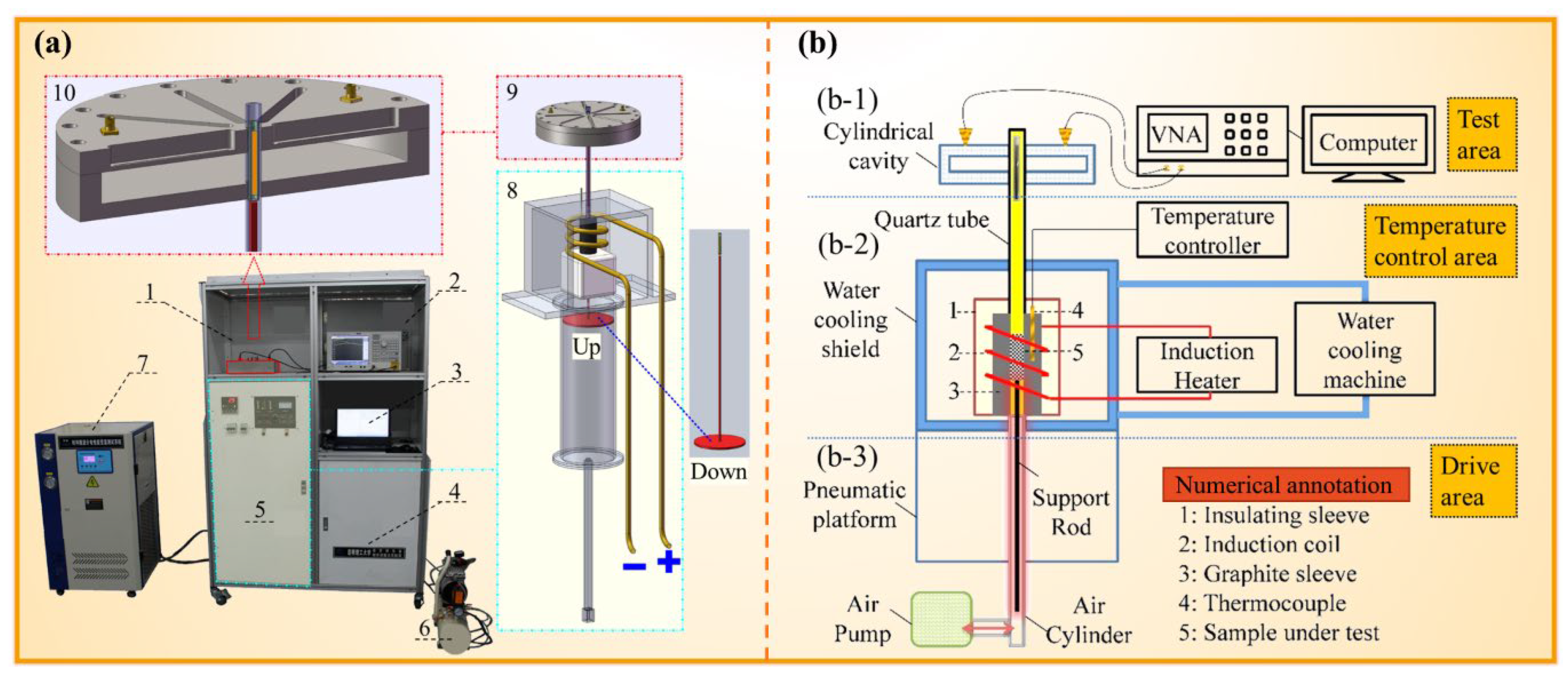

2.3. Dielectric Property Measurement of TM

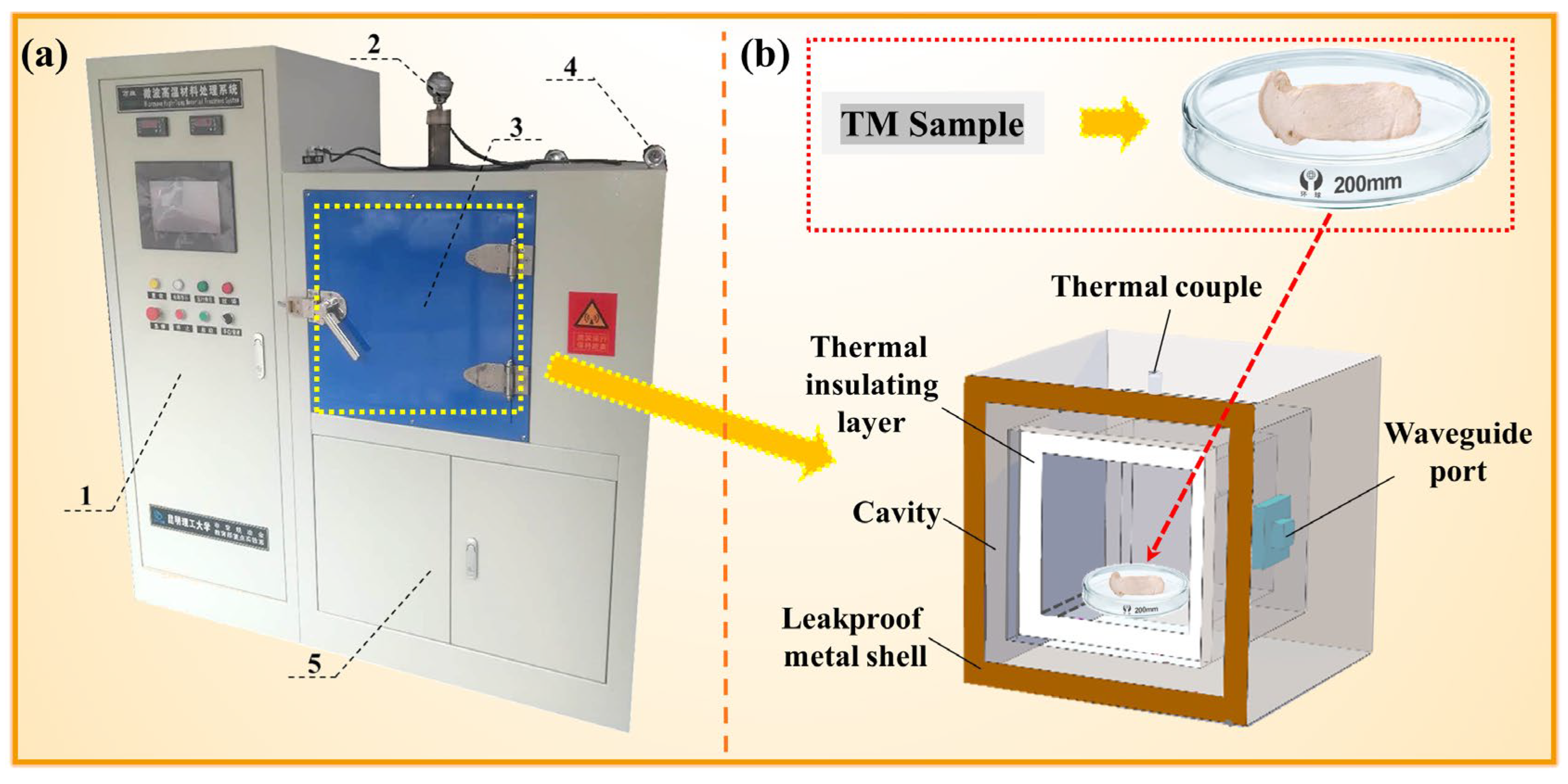

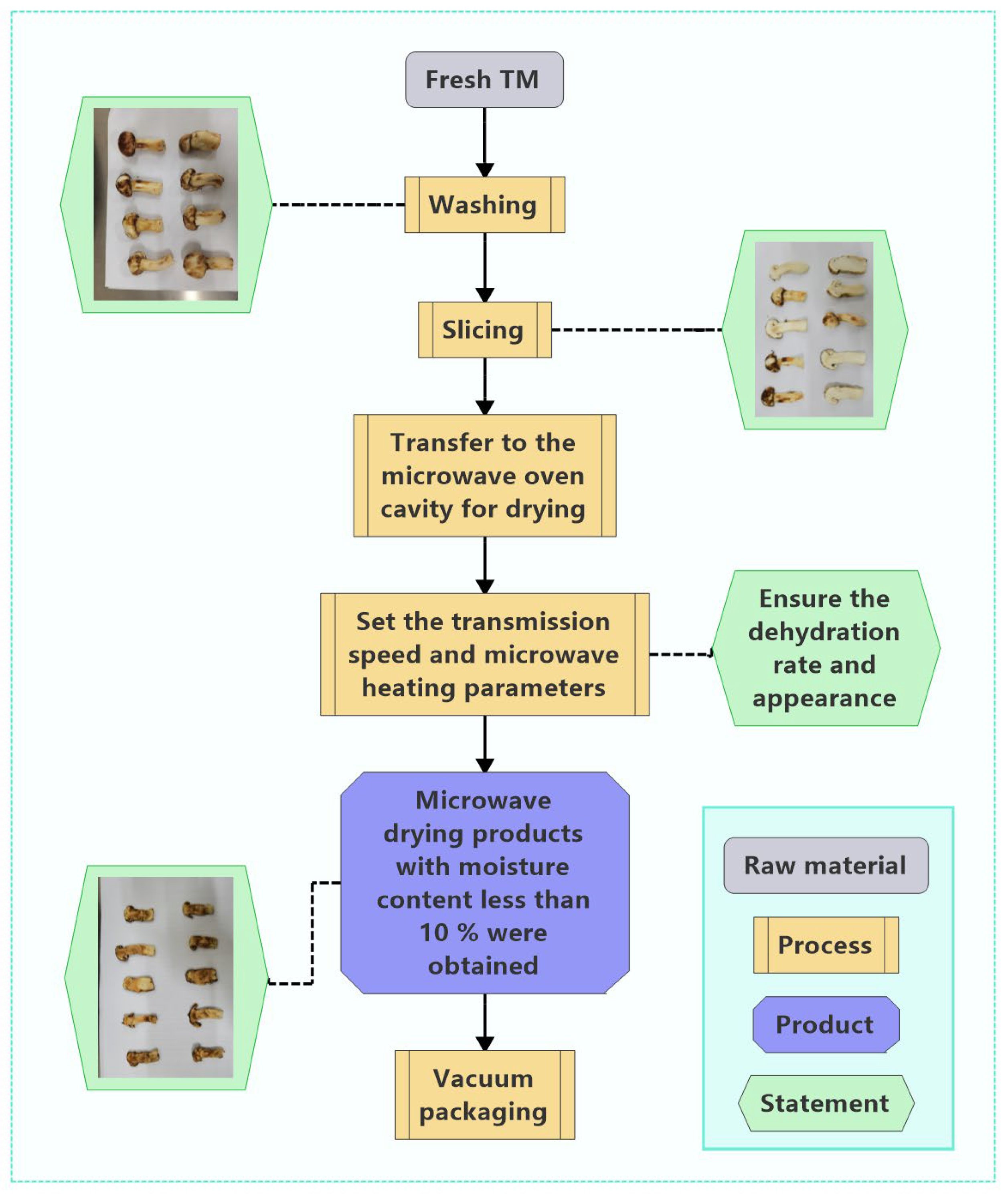

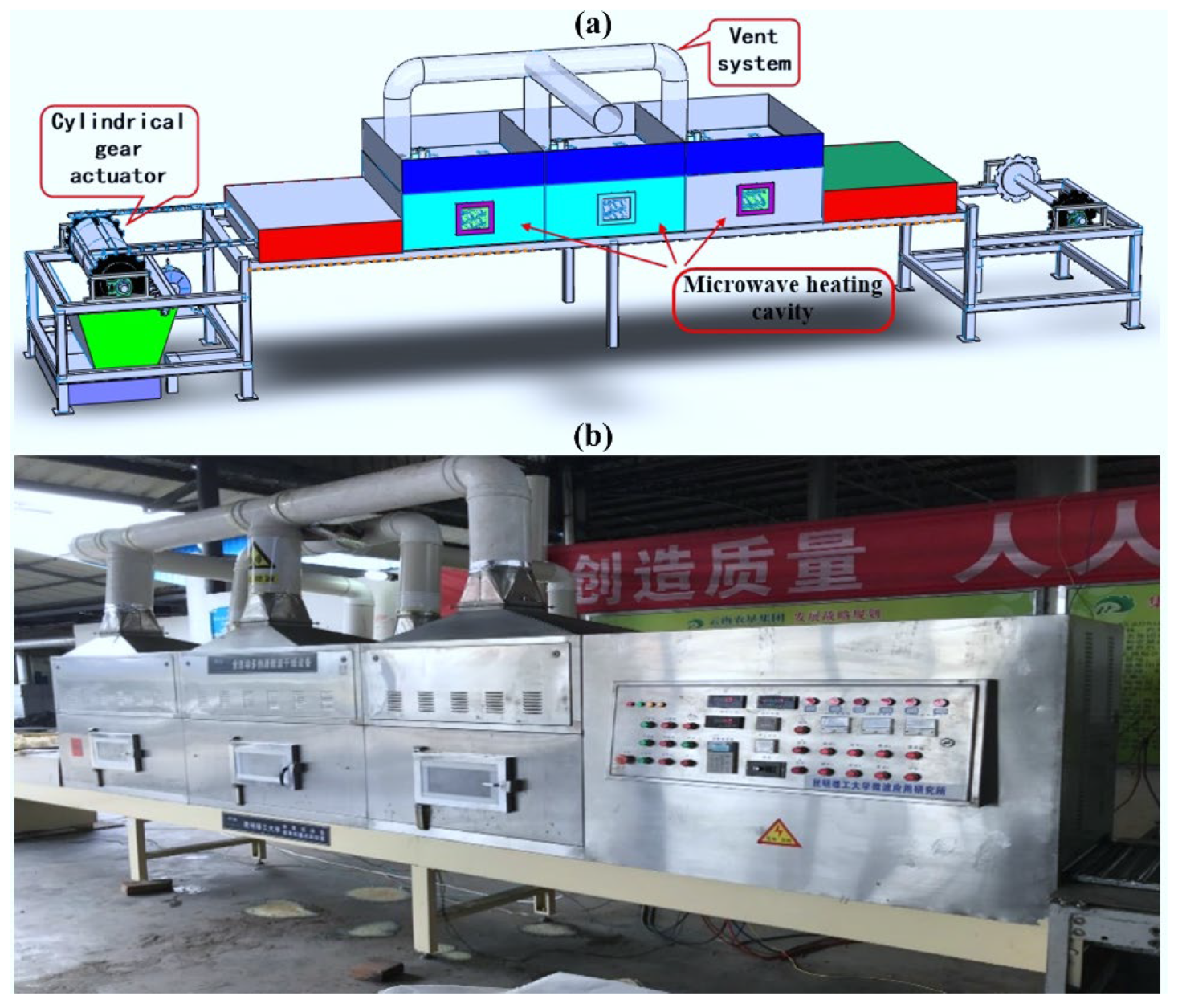

2.4. MD of TM

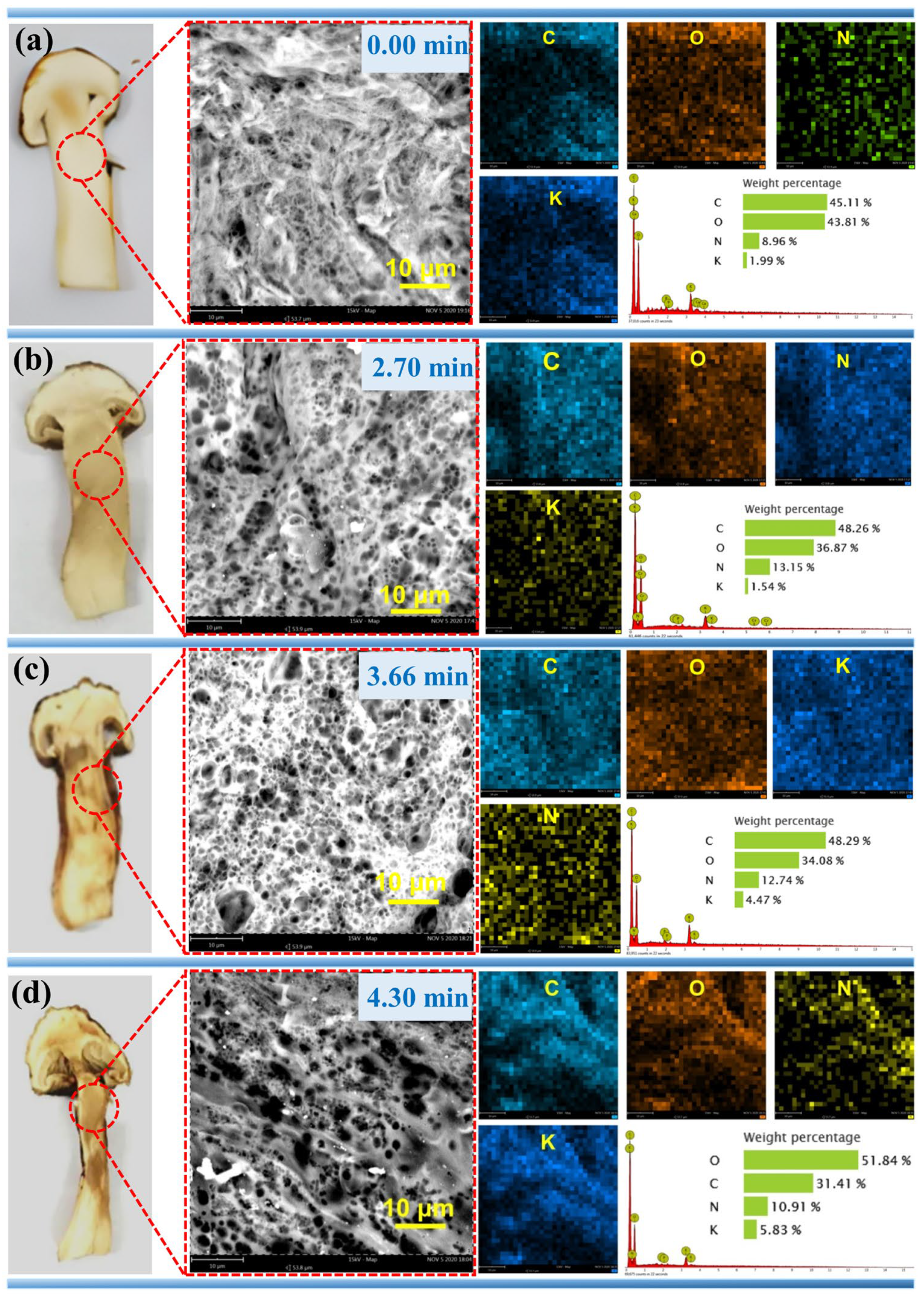

2.5. Thermogravimetric (TG) and SEM-EDS Analysis

2.6. Statistical Analysis

3. Results and Discussion

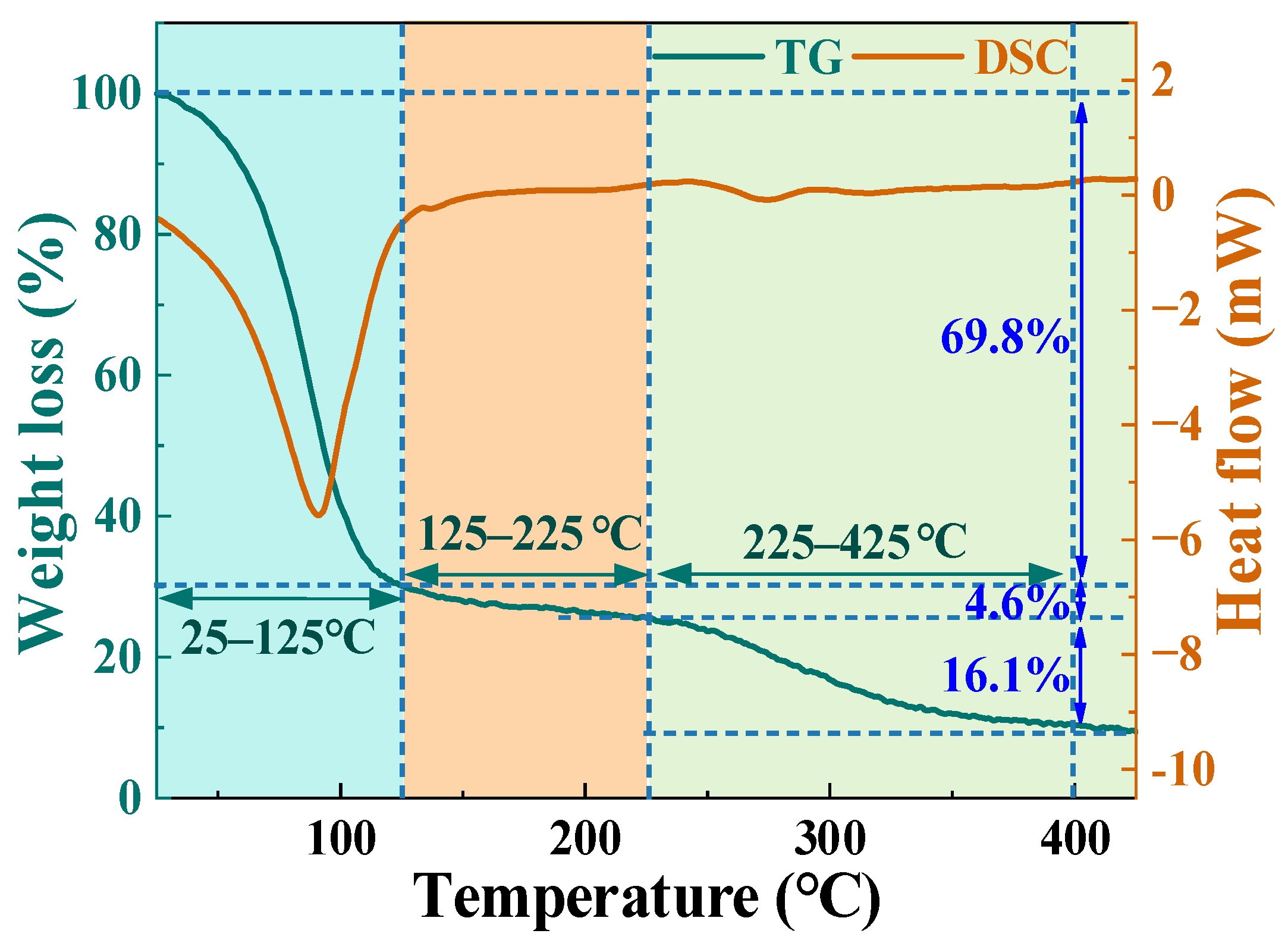

3.1. Thermogravimetric Analysis of TM

3.2. Dielectric Properties Analysis of TM

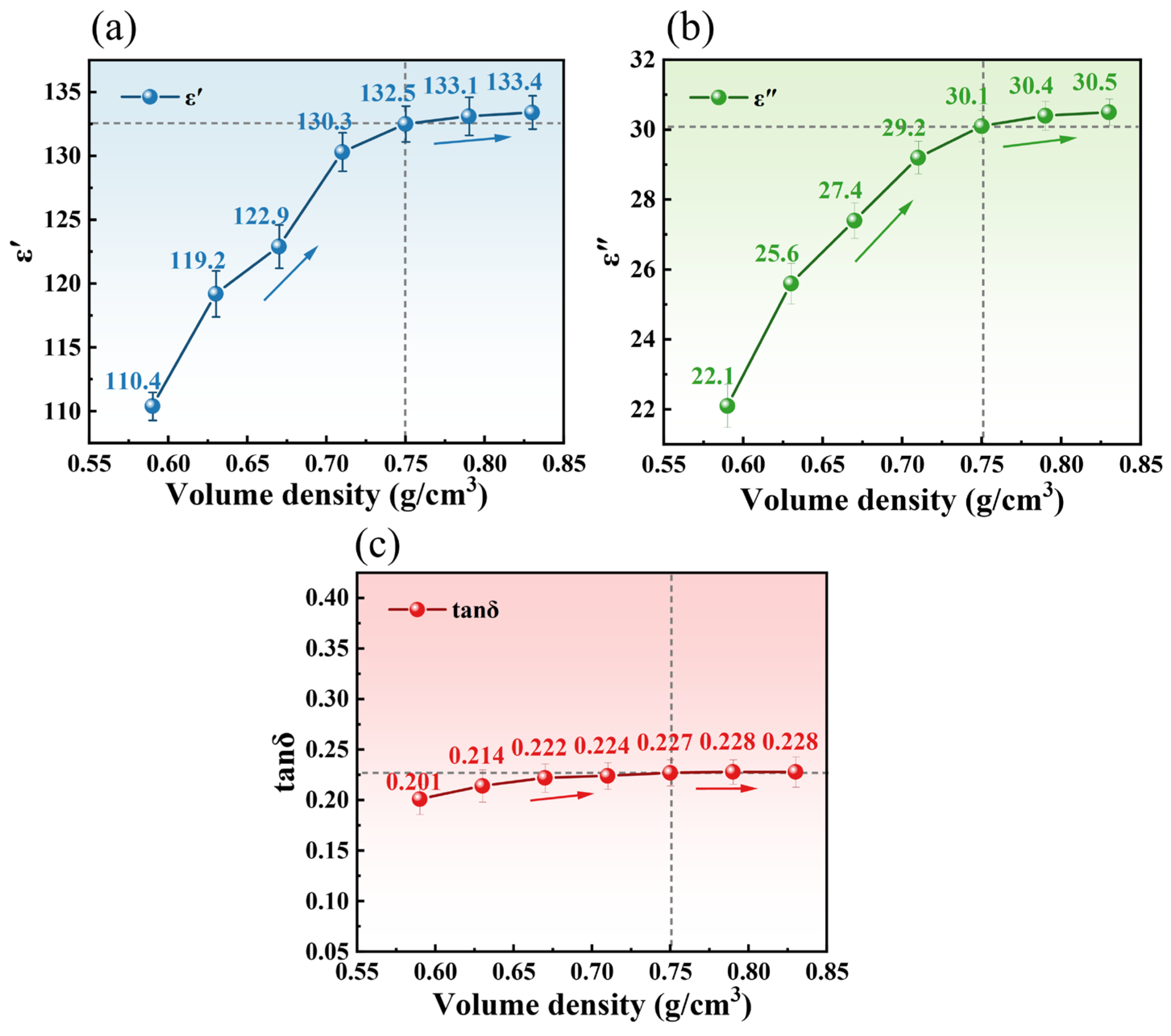

3.2.1. Effect of Apparent Density on Dielectric Properties

3.2.2. Effect of Temperature on Dielectric Properties

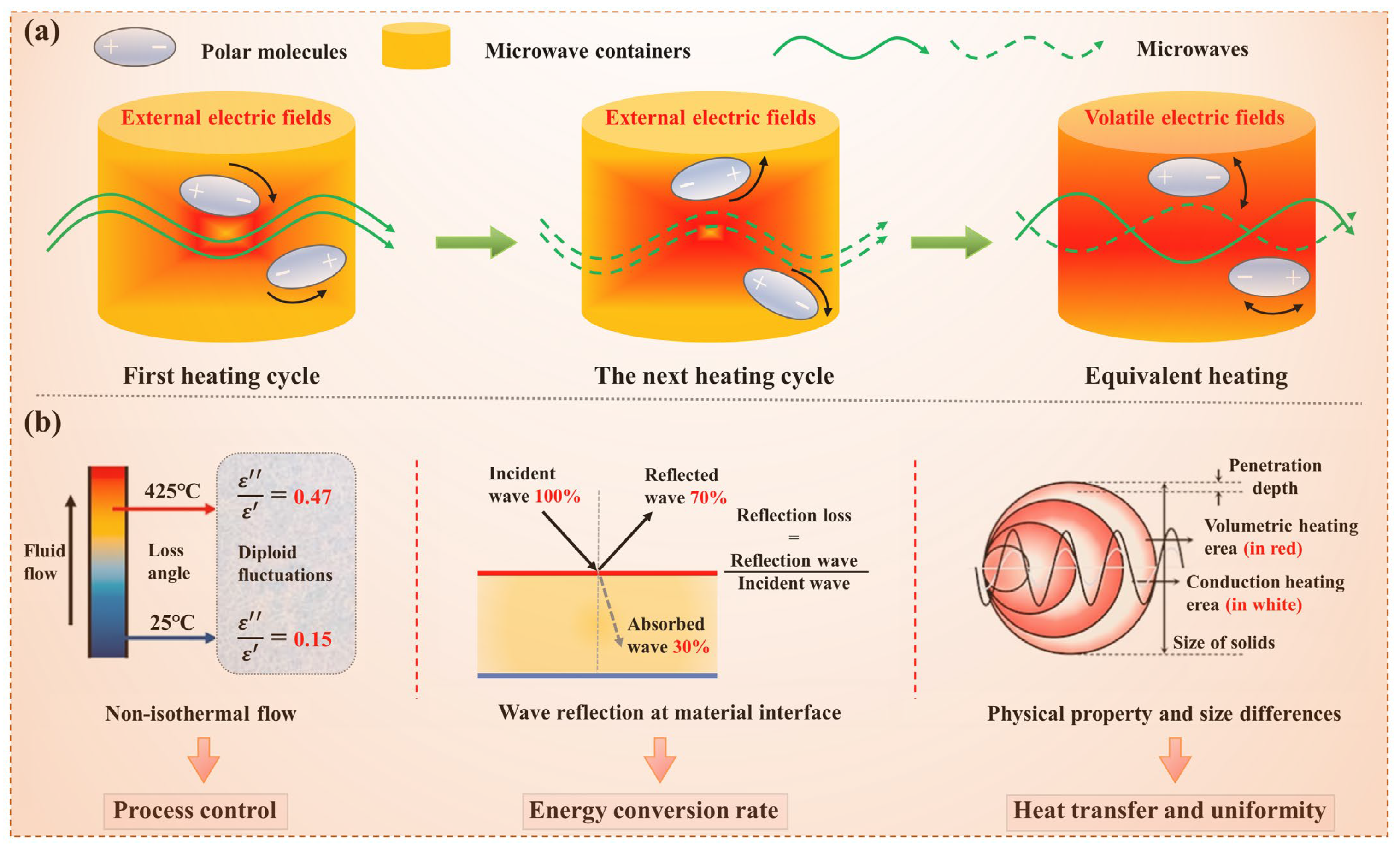

3.2.3. Dielectric Loss Mechanism of TM

3.3. Influencing Factors in MD of TM

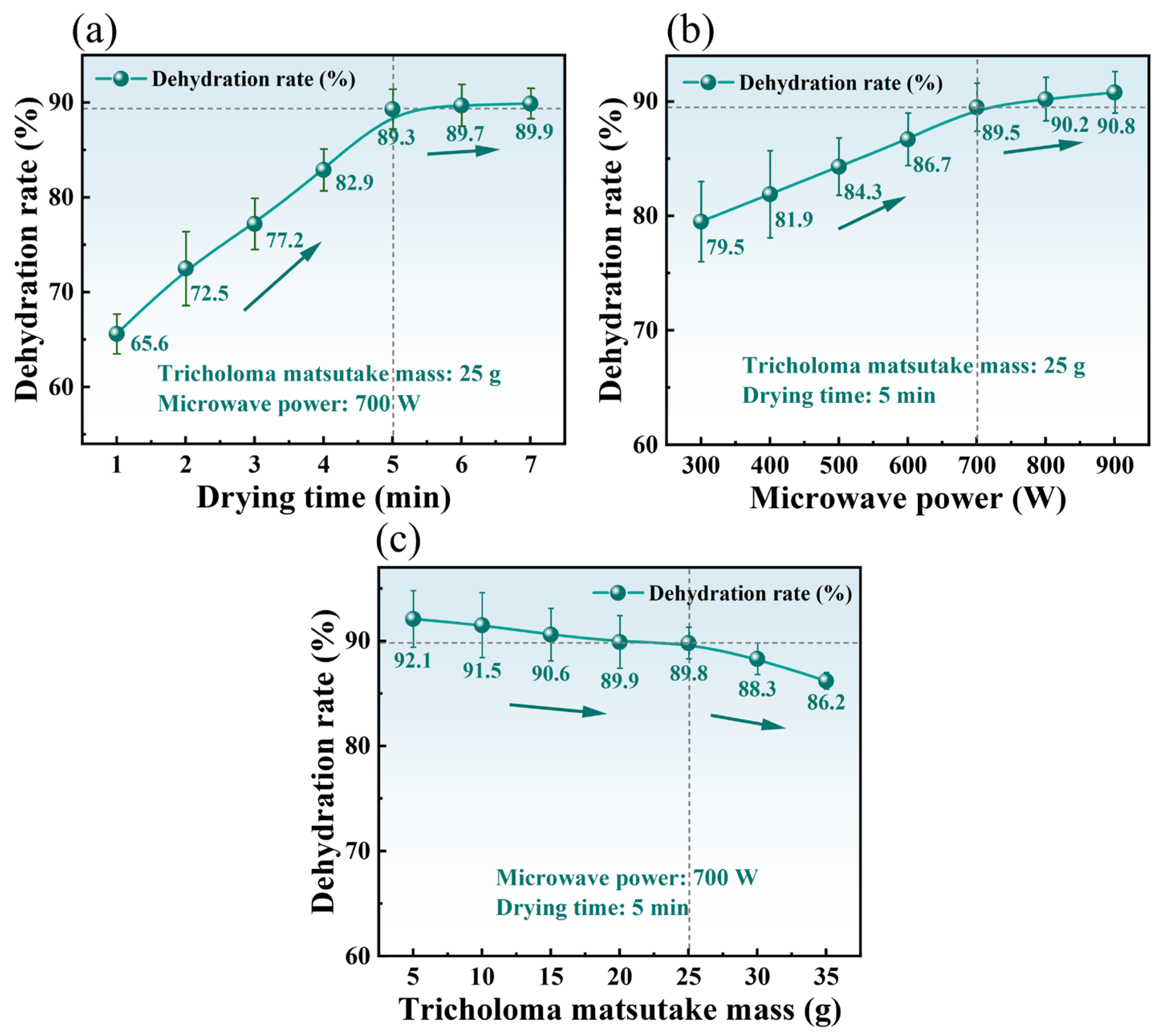

3.3.1. Effect of Drying Time on DR

3.3.2. Effect of Microwave Power on DR

3.3.3. Effect of Sample Mass on DR

3.4. RSM for Optimizing MD of Fresh TM

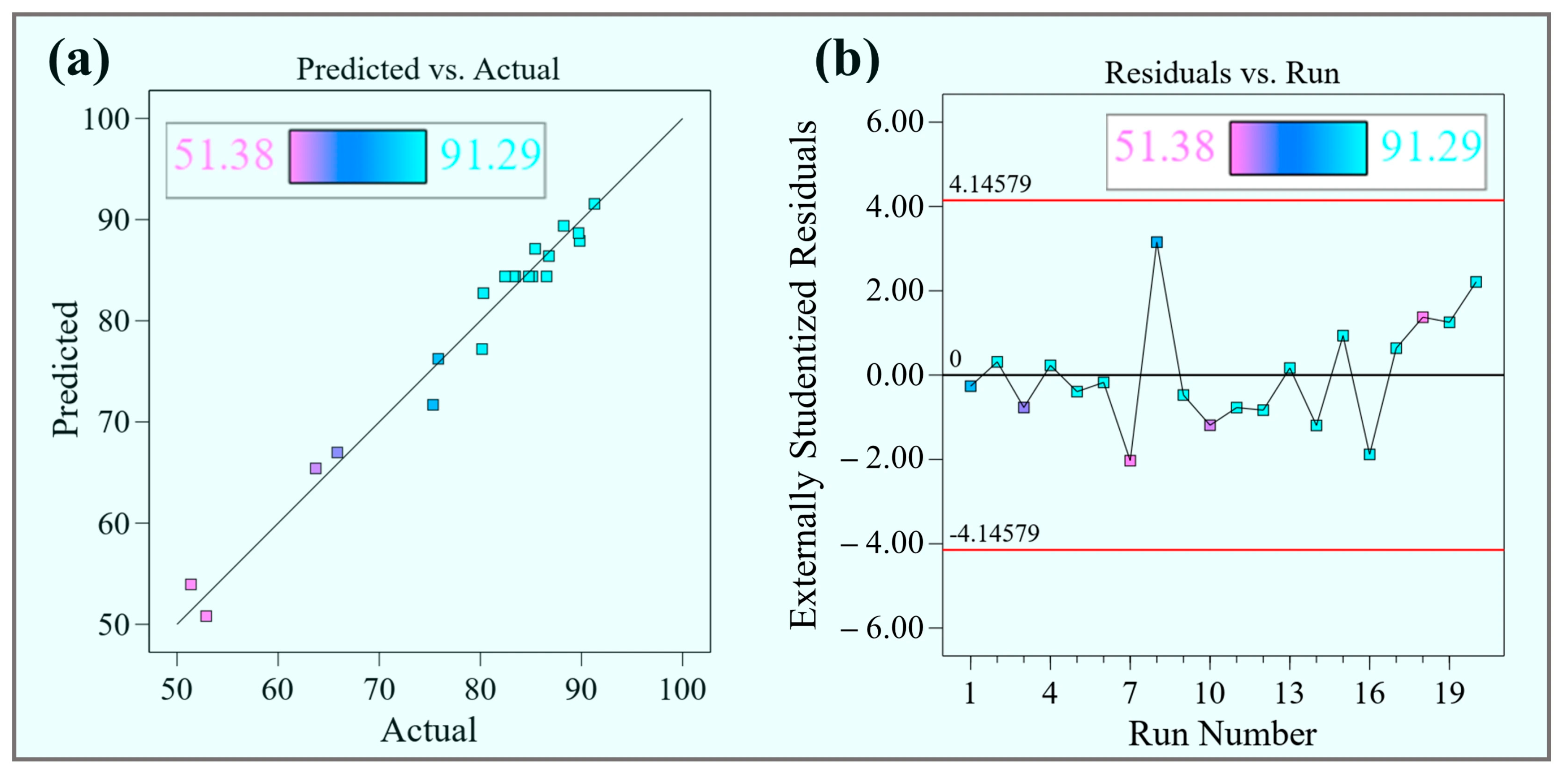

3.4.1. Model Construction and Regression Analysis

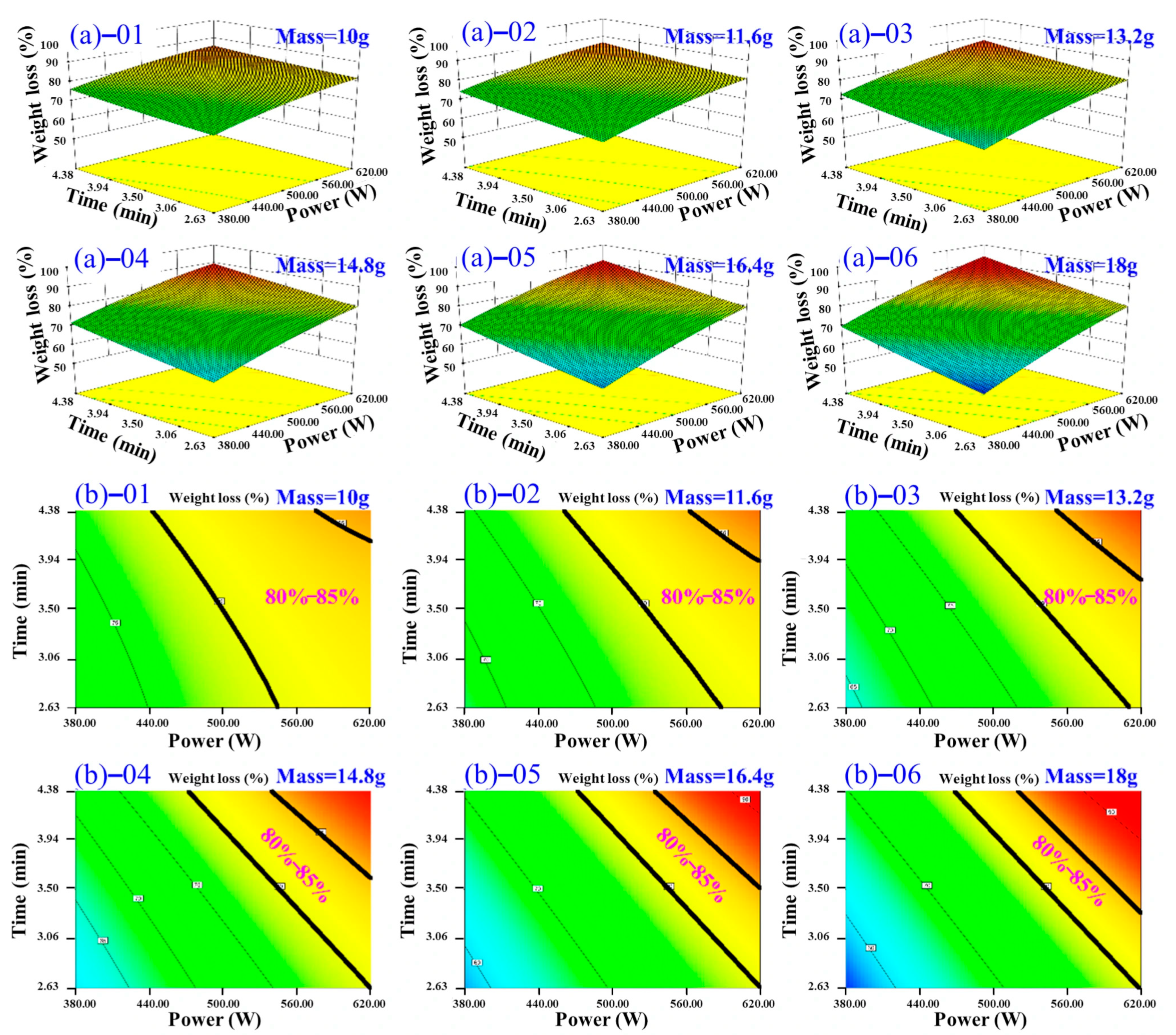

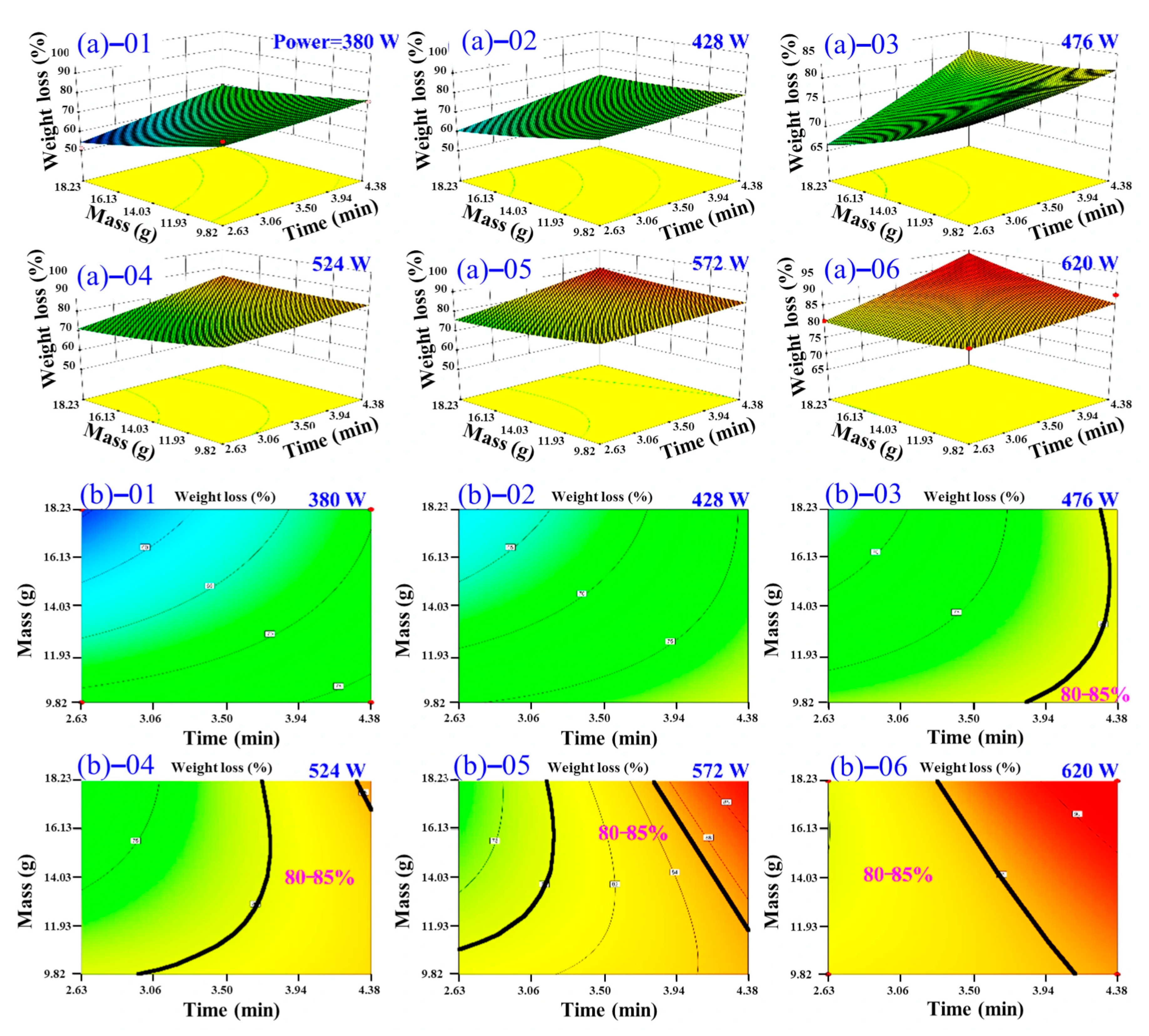

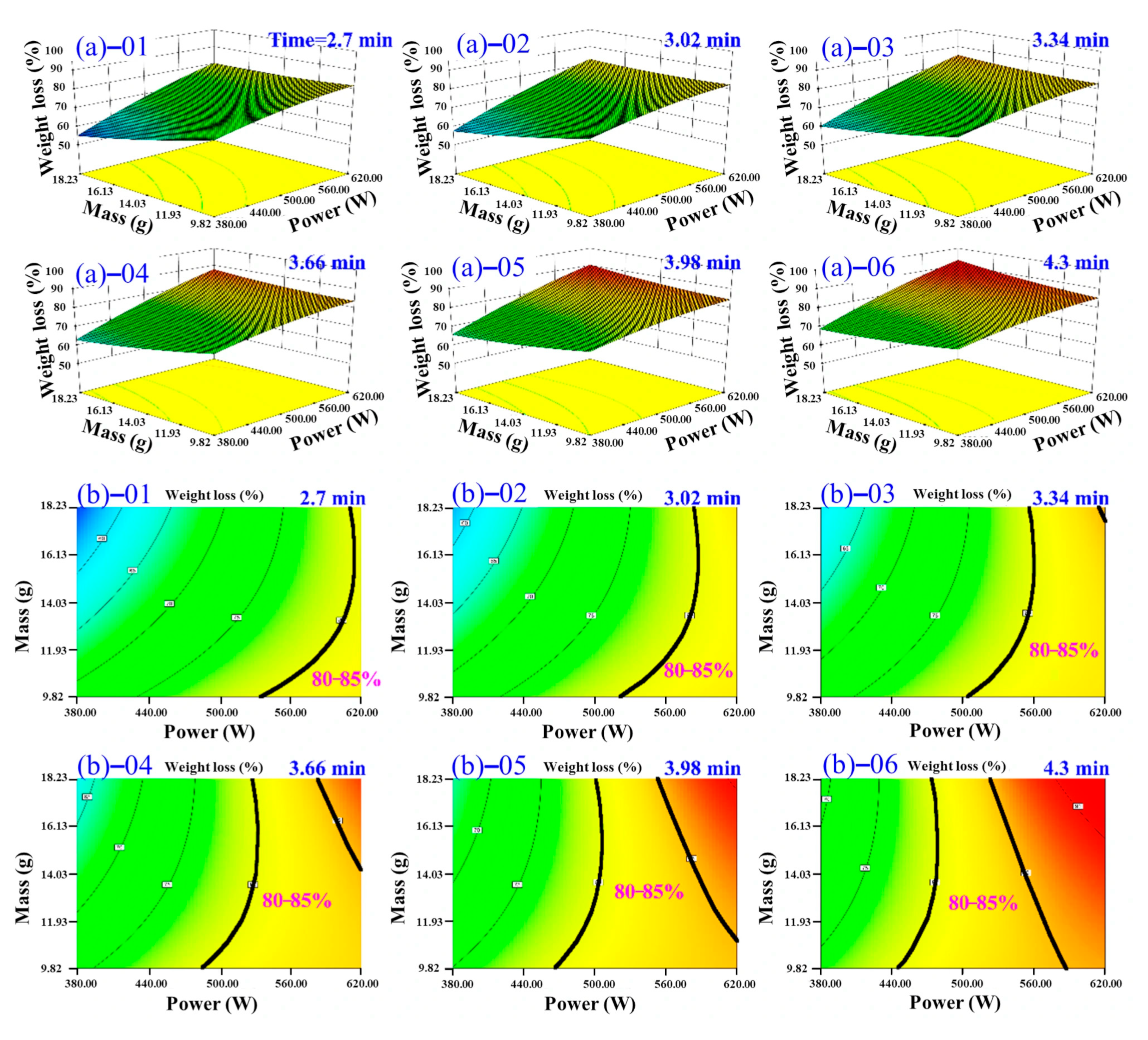

3.4.2. Response Surface Analysis and Process Optimization

3.4.3. Verification Experiments of the Optimization Model

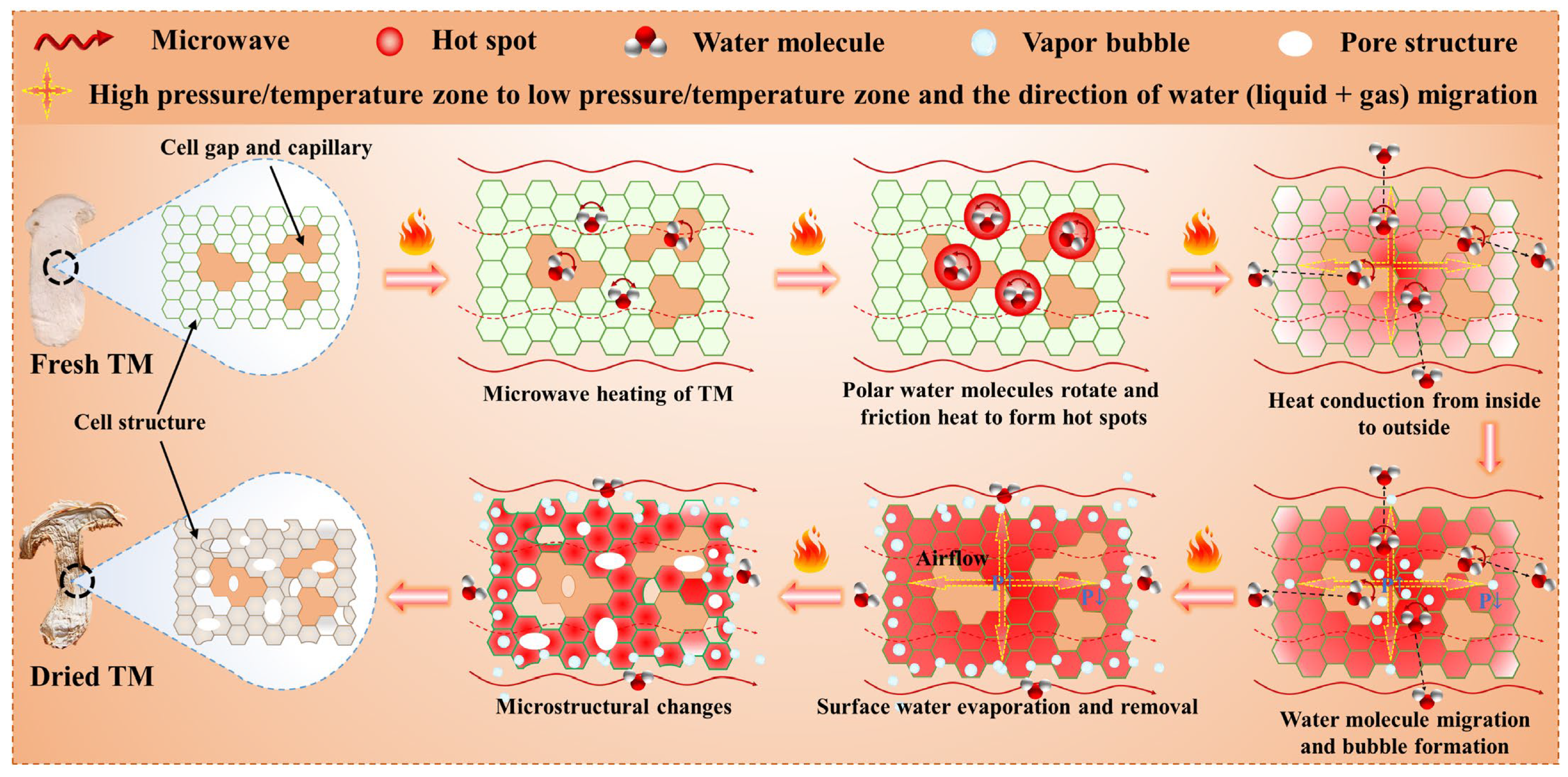

3.4.4. Enhanced Dehydration Mechanism of Microwave-Dried TM

3.4.5. Economic Benefit Analysis

3.5. Pilot-Scale MD Experiment of TM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TM | Tricholoma matsutake |

| MD | Microwave drying |

| RSM | Response surface methodology |

| DR | Dehydration rate |

| CCD | Central Composite Design |

| Relative permittivity | |

| Relative dielectric loss | |

| Loss tangent | |

| TG | Thermogravimetric |

| SEM | Scanning electron microscope |

| EDS | Energy-dispersive X-ray spectroscopy |

| DSC | Differential scanning calorimetry |

References

- Zhang, L.; Zhang, M.; Mujumdar, A.S. Development of flavor during drying and applications of edible mushrooms: A review. Dry. Technol. 2021, 39, 1685–1703. [Google Scholar] [CrossRef]

- Zhang, F.; Lu, B.; He, X.; Yu, F. Flavor Variations in Precious Tricholoma matsutake under Different Drying Processes as Detected with HS-SPME-GC-MS. Foods 2024, 13, 2123. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Zhang, X.; Cai, G.; An, S.; Wang, X.; Teng, L.; Wang, D. Tricholoma matsutake Aqueous Extract Induces Hepatocellular Carcinoma Cell Apoptosis via Caspase-Dependent Mitochondrial Pathway. BioMed Res. Int. 2016, 2016, 9014364. [Google Scholar] [CrossRef]

- Gavahian, M.; Sheu, F.-H.; Tsai, M.-J.; Chu, Y.-H. The effects of dielectric barrier discharge plasma gas and plasma-activated water on texture, color, and bacterial characteristics of shiitake mushroom. J. Food Process. Preserv. 2020, 44, e14316. [Google Scholar] [CrossRef]

- Wen, X.; Geng, F.; Xu, Y.; Li, X.; Liu, D.; Liu, Z.; Luo, Z.; Wang, J. Quantitative transcriptomic and metabolomic analyses reveal the changes in Tricholoma matsutake fruiting bodies during cold storage. Food Chem. 2022, 381, 132292. [Google Scholar] [CrossRef]

- Combet, E.; Eastwood, D.C.; Burton, K.S.; Combet, E.; Henderson, J.; Henderson, J.; Combet, E. Eight-carbon volatiles in mushrooms and fungi: Properties, analysis, and biosynthesis. Mycoscience 2006, 47, 317–326. [Google Scholar] [CrossRef]

- Deng, Y.; Luo, Y.; Wang, Y.; Zhao, Y. Effect of different drying methods on the myosin structure, amino acid composition, protein digestibility and volatile profile of squid fillets. Food Chem. 2015, 171, 168–176. [Google Scholar] [CrossRef] [PubMed]

- Pei, F.; Yang, W.; Ma, N.; Fang, Y.; Zhao, L.; An, X.; Xin, Z.; Hu, Q. Effect of the two drying approaches on the volatile profiles of button mushroom (Agaricus bisporus) by headspace GC–MS and electronic nose. LWT Food Sci. Technol. 2016, 72, 343–350. [Google Scholar] [CrossRef]

- Picardi, S.M.; Issenberg, P. Volatile constituents of mushrooms (Agaricus bisporus). Changes which occur during heating. J. Agric. Food Chem. 1973, 21, 959–962. [Google Scholar] [CrossRef]

- Lu, W. Application of microwave drying technology in tea processing: Mechanisms and implications. Agric. Mach. Agron. 2025, 56, 58–61. [Google Scholar]

- Yue, Y.; Zhang, Q.; Ma, G.; Wan, F.; Zang, Z.; Xu, Y.; Kang, F.; Huang, X. Quality Evaluation and Heat and Mass Transfer Mechanism of Microwave Vacuum Drying of Astragalus Roots. Foods 2024, 13, 3075. [Google Scholar] [CrossRef]

- Niu, Y.; Gong, S.; Peng, H.; Le, T.; Li, N.; Fang, S.; Ju, S.; Xu, L. Microwave-absorbing characteristics of secondary copper smelting fly ash: High-temperature dielectric properties, thermal behavior, and microwave heating mechanism. J. Phys. Chem. Solids 2024, 188, 111883. [Google Scholar] [CrossRef]

- Gong, S.; Li, G.; Liu, B.; Zhang, T.; Niu, Y.; Liu, P.; Dong, X. Basic research on the microwave dielectric properties of ammonium hexachlororuthenate (IV) via Ru doping. J. Magn. Magn. Mater. 2023, 565, 170182. [Google Scholar] [CrossRef]

- Taheri, S.; Brodie, G.; Gupta, D. Microwave fluidised bed drying of red lentil seeds: Drying kinetics and reduction of botrytis grey mold pathogen. Food Bioprod. Process. 2020, 119, 390–401. [Google Scholar] [CrossRef]

- Chojnacka, K.; Mikula, K.; Izydorczyk, G.; Skrzypczak, D.; Witek-Krowiak, A.; Moustakas, K.; Ludwig, W.; Kułażyński, M. Improvements in drying technologies—Efficient solutions for cleaner production with higher energy efficiency and reduced emission. J. Clean. Prod. 2021, 320, 128706. [Google Scholar] [CrossRef]

- Tang, Y.; Long, L.; Mao, L.; Huang, Q.; Wen, L.; Li, J.; Chi, Z. Effects of drying methods on polyphenol and antioxidant activities of waterlily tea. Food Res. Dev. 2020, 41, 59–65. [Google Scholar]

- Wang, H.; Yu, Z. Effects of different drying methods on physicochemical properties and antioxidant activity of dried cabbage. Sci. Technol. Food Ind. 2020, 41, 81–86. [Google Scholar]

- Lin, T.M.; Durance, T.D.; Scaman, C.H. Characterization of vacuum microwave, air and freeze dried carrot slices. Food Res. Int. 1998, 31, 111–117. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, S.; Li, J.; Diao, Y.; Yin, X.; Cheng, Y. Effect of hot air-microwave drying on the quality and flavor of mushroom. Sci. Technol. Food Ind. 2017, 38, 80–83. [Google Scholar]

- Fan, S.; Liu, G. Effects of different drying methods on the contents of hydroxysafflor Yellow A, Kaempferol and Safflor Yellow A in Carthamus Tinctorrius. China Pharm. 2020, 23, 1198–1200. [Google Scholar]

- Wang, Z.; Sheng, H.; Chen, S.; Xin, S.; Jiang, H. Effects of different drying methods on polyphenols, antioxidant activity and aroma components of artichoke powder. Food Ferment. Ind. 2019, 45, 149–156. [Google Scholar]

- Jiang, N.; Liu, C.; Li, D.; Zhou, Y. Effect of blanching on the dielectric properties and microwave vacuum drying behavior of Agaricus bisporus slices. Innov. Food Sci. Emerg. Technol. 2015, 30, 89–97. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, M.; Mujumdar, A.S.; Jiang, H. Effect of salt and sucrose content on dielectric properties and microwave freeze drying behavior of re-structured potato slices. J. Food Eng. 2011, 106, 290–297. [Google Scholar] [CrossRef]

- Yolmeh, M.; Jafari, S.M. Applications of Response Surface Methodology in the Food Industry Processes. Food Bioprocess Technol. 2017, 10, 413–433. [Google Scholar] [CrossRef]

- Laid, T.M.; Abdelhamid, K.; Eddine, L.S.; Abderrhmane, B. Optimizing the biosynthesis parameters of iron oxide nanoparticles using central composite design. J. Mol. Struct. 2021, 1229, 129497. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Yang, Y.; Wei, H.; Xue, L.; Zhao, M.; Cai, J. Optimization of combined microwave and hot air drying technology for purple cabbage by Response Surface Methodology (RSM). Food Sci. Nutr. 2021, 9, 4568–4577. [Google Scholar] [CrossRef] [PubMed]

- Tüfekçi, S.; Özkal, S.G. The Optimization of Hybrid (Microwave–Conventional) Drying of Sweet Potato Using Response Surface Methodology (RSM). Foods 2023, 12, 3003. [Google Scholar] [CrossRef]

- Haiming, Y.; Zhongbo, J.; Xuefeng, Z.; Chunlan, Q.; Haiyuan, L.; Hanyang, W. Research of the effect of microwave combined with hot air drying method on drying quality of tricholoma matsutake. J. Chin. Agric. Mech. 2020, 41, 72–78, 88. [Google Scholar]

- Peng, Z.; Hwang, J.-Y.; Kim, B.-G.; Mouris, J.; Hutcheon, R. Microwave Absorption Capability of High Volatile Bituminous Coal during Pyrolysis. Energy Fuels 2012, 26, 5146–5151. [Google Scholar] [CrossRef]

- Garcia-Baños, B.; Catalá-Civera, J.M.; Peñaranda-Foix, F.L.; Plaza-González, P.; Llorens-Vallés, G. In Situ Monitoring of Microwave Processing of Materials at High Temperatures through Dielectric Properties Measurement. Materials 2016, 9, 349. [Google Scholar] [CrossRef]

- Laybourn, A.; Katrib, J.; Palade, P.A.; Easun, T.L.; Champness, N.R.; Schröder, M.; Kingman, S.W. Understanding the electromagnetic interaction of metal organic framework reactants in aqueous solution at microwave frequencies. Phys. Chem. Chem. Phys. 2016, 18, 5419–5431. [Google Scholar] [CrossRef]

- Guemouni, S.; Mouhoubi, K.; Brahmi, F.; Dahmoune, F.; Belbahi, A.; Benyoub, C.; Adjeroud-Abdellatif, N.; Atmani, K.; Bakhouche, H.; Boulekbache-Makhlouf, L.; et al. Convective and microwave drying kinetics and modeling of tomato slices, energy consumption, and efficiency. J. Food Process Eng. 2022, 45, e14113. [Google Scholar] [CrossRef]

- Huang, M.; Li, H.; Zhang, M.; Liu, B.; Yang, X.; Liu, P. Optimization of microwave drying for amomum tsao-ko using response surface methodology. China Condiment 2018, 43, 13–17+31. [Google Scholar]

- Nisoa, M.; Wattanasit, K.; Tamman, A.; Sirisathitkul, Y.; Sirisathitkul, C. Microwave Drying for Production of Rehydrated Foods: A Case Study of Stink Bean (Parkia speciosa) Seed. Appl. Sci. 2021, 11, 2918. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, B.; Zhang, L.; Guo, S. Microwave-absorbing properties of cathode material during reduction roasting for spent lithium-ion battery recycling. J. Hazard. Mater. 2020, 384, 121487. [Google Scholar] [CrossRef]

- Qi, S.; Han, J.; Lagnika, C.; Jiang, N.; Qian, C.; Liu, C.; Li, D.; Tao, Y.; Yu, Z.; Wang, L.; et al. Dielectric properties of edible fungi powder related to radio-frequency and microwave drying. Food Prod. Process. Nutr. 2021, 3, 15. [Google Scholar] [CrossRef]

- Lombraña, J.I.; Rodríguez, R.; Ruiz, U. Microwave-drying of sliced mushroom. Analysis of temperature control and pressure. Innov. Food Sci. Emerg. Technol. 2010, 11, 652–660. [Google Scholar] [CrossRef]

- Meda, V.; Orsat, V.; Raghavan, V. 2—Microwave heating and the dielectric properties of foods. In The Microwave Processing of Foods, 2nd ed.; Regier, M., Knoerzer, K., Schubert, H., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 23–43. [Google Scholar]

- Beneroso, D.; Albero-Ortiz, A.; Monzó-Cabrera, J.; Díaz-Morcillo, A.; Arenillas, A.; Menéndez, J.A. Dielectric characterization of biodegradable wastes during pyrolysis. Fuel 2016, 172, 146–152. [Google Scholar] [CrossRef]

- Giri, S.K.; Prasad, S. Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J. Food Eng. 2007, 78, 512–521. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, X.; Pan, L. Heat and mass transfer behavior and energy consumption characteristics for microwave drying of Quercus acutissima Carruth wood. Biomass Chem. Eng. 2025, 59, 39–47. [Google Scholar]

- Funebo, T.; Ohlsson, T. Microwave-assisted air dehydration of apple and mushroom. J. Food Eng. 1998, 38, 353–367. [Google Scholar] [CrossRef]

- Li, L.; Xiaowei, J.; Xiaomin, Q.; Keshuo, Y.; Jian, C.; Tai, F.; Fumao, W.; Zhanlong, S.; Zhao, X. Experimental study and energy analysis on microwave-assisted lignite drying. Dry. Technol. 2019, 37, 962–975. [Google Scholar] [CrossRef]

- Zhang, M.; Tang, J.; Mujumdar, A.S.; Wang, S. Trends in microwave-related drying of fruits and vegetables. Trends Food Sci. Technol. 2006, 17, 524–534. [Google Scholar] [CrossRef]

- Yang, Y.; Ding, J.; Wu, X.; Wang, P.; Sun, D.; Yu, X.; Zhang, Z.; Li, D. Optimization of hot-air drying process parameters of Lentinus edodes based on response surface. J. Agric. Sci. Technol. 2023, 25, 154–164. [Google Scholar]

- Chen, W.-H.; Carrera Uribe, M.; Kwon, E.E.; Lin, K.-Y.A.; Park, Y.-K.; Ding, L.; Saw, L.H. A comprehensive review of thermoelectric generation optimization by statistical approach: Taguchi method, analysis of variance (ANOVA), and response surface methodology (RSM). Renew. Sustain. Energy Rev. 2022, 169, 112917. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Dinh, D.K.; Mok, Y.S.; Yoon, K.H.; Dao, V.D.; Hossain, M.M.; Saud, S.; Sosiawati, T. High-throughput volatile organic compounds removal in a sandwich-type honeycomb catalyst system combined with plasma. Appl. Catal. B Environ. 2022, 310, 121328. [Google Scholar] [CrossRef]

- Madadi, S.; Charbonneau, L.; Bergeron, J.-Y.; Kaliaguine, S. Aerobic epoxidation of limonene using cobalt substituted mesoporous SBA-16 Part 1: Optimization via Response Surface Methodology (RSM). Appl. Catal. B Environ. 2020, 260, 118049. [Google Scholar] [CrossRef]

- Niu, Y.; Gong, S.; Zheng, J.; Zhou, X.; Song, Z.; Ju, S.; Gu, Y. Catalytic performance of low loading palladium-carbon catalyst in rosin disproportionation: Characterization, process enhancement, and reaction pathway. Appl. Catal. A Gen. 2025, 691, 120077. [Google Scholar] [CrossRef]

- Teleken, J.T.; Porciúncula, B.D.A.; Teleken, J.G.; Carciofi, B.A.M. Drying of foods under intermittent supply of microwave energy: Proposal for a mathematical model. Acta Scientiarum. Technol. 2021, 43, e51037. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Liu, C.; Shen, L.; Zhao, X.; Xue, L. Research progress in the microwave technologies for foodstuffs and agricultural products. Trans. Chin. Soc. Agric. Eng. 2024, 40, 14–28. [Google Scholar]

- Lin, F.; Wei, Z.; Yang, M.; Li, C.; Li, L.; Wu, Z.; Liu, Z. Analysis on moisture changes and quality of Morchella Esculenta slices during microwave drying progress. Food Sci. 2025, 46, 313–321. [Google Scholar]

- Yang, M.; Chen, X.; Wang, L.; Ren, X.; Liu, W.; Li, L.; Ren, G.; Law, C.L.; Cao, W.; Zhang, M.; et al. Effect of moisture migration on texture and viscoelasticity of Chinese yam during multi-phase microwave drying (MMD)—Focusing on the evaporation-dehydration stage. Food Chem. X 2025, 26, 102314. [Google Scholar] [CrossRef]

- Vadivambal, R.; Jayas, D.S. Changes in quality of microwave-treated agricultural products—A review. Biosyst. Eng. 2007, 98, 1–16. [Google Scholar] [CrossRef]

- Radoiu, M. Microwave drying process scale-up. Chem. Eng. Process.-Process Intensif. 2020, 155, 108088. [Google Scholar] [CrossRef]

- Anyanwu, C.N.; Onyia, C.; Uchendu, A.J.; Aneke, N.N.; Ohagwu, J.C.; Ojike, O.; Kumar, A.; Kalu-Uka, A.; Ukadike, O.O. Solar photovoltaic (PV)-driven active crop drying system for plantain (MUSA SPP): Design, development, and performance evaluation. J. Food Process Eng. 2021, 44, e13892. [Google Scholar] [CrossRef]

| Method | Material | Key Findings | Source |

|---|---|---|---|

| MD, hot air, vacuum freeze drying | Lotus flower tea | 400 W MD demonstrated high efficiency with effective preservation of phenolic compounds in lotus flower tea, resulting in enhanced antioxidant activity. | [16] |

| Hot air, MD, hybrid hot air–MD | Cabbage | MD samples retained 67.3% vitamin C, 90.0% free phenols, and 86.6% total phenols, demonstrating stronger antioxidant activity. | [17] |

| Hot air, freeze, MD | Carrot | MD products exhibited optimal rehydration capacity and high α-carotene and vitamin C levels, with sensory attributes comparable to freeze-dried samples. | [18] |

| Vacuum freeze, MD, hybrid vacuum freeze–hot air | Shiitake mushroom slices | MD samples showed the lowest formaldehyde content. | [19] |

| Shade, sun, hot air, vacuum freeze, MD | Safflower | MD-treated samples contained higher hydroxysafflor yellow A, kaempferol, and total flavonoids. | |

| MD, freeze, hot air convection, vacuum drying | Red chili powder | MD required the shortest drying time, yielding products with brighter color, higher particle density, and lower porosity, enhancing storage stability. | [20] |

| Hot air, vacuum, vacuum freeze, MD | Artichoke powder | MD achieved the fastest drying rate, producing powders with maximum bulk density, optimal water/oil holding capacities, and highest crude fat content. | [21] |

| Sample Name | Trial 1 | Trial 2 | Trial 3 | Average Moisture Content |

|---|---|---|---|---|

| TM | 86.64% | 90.51% | 88.25% | 88.47% |

| Factors | Codes | Levels | ||||

|---|---|---|---|---|---|---|

| −1.682 | −1 | 0 | 1 | 1.682 | ||

| Power/W | A | 298.19 | 380.00 | 500.00 | 620.00 | 701.82 |

| Time/min | B | 2.03 | 2.63 | 3.51 | 4.38 | 4.98 |

| Mass/g | C | 6.95 | 9.82 | 14.03 | 18.23 | 21.09 |

| Run | Factor 1 | Factor 2 | Factor 3 | Response Value |

|---|---|---|---|---|

| A: Power /W | B: Time /min | C: Mass /g | DR /% | |

| 1 | 380.00 | 2.63 | 9.82 | 63.72 |

| 2 | 620.00 | 2.63 | 9.82 | 85.42 |

| 3 | 380.00 | 4.38 | 9.82 | 75.84 |

| 4 | 620.00 | 4.38 | 9.82 | 91.29 |

| 5 | 380.00 | 2.63 | 18.23 | 51.38 |

| 6 | 620.00 | 2.63 | 18.23 | 80.30 |

| 7 | 380.00 | 4.38 | 18.23 | 65.85 |

| 8 | 620.00 | 4.38 | 18.23 | 88.24 |

| 9 | 298.19 | 3.51 | 14.03 | 52.89 |

| 10 | 701.82 | 3.51 | 14.03 | 89.82 |

| 11 | 500.00 | 2.03 | 14.03 | 75.32 |

| 12 | 500.00 | 4.98 | 14.03 | 86.78 |

| 13 | 500.00 | 3.51 | 6.95 | 89.71 |

| 14 | 500.00 | 3.51 | 21.09 | 80.17 |

| 15 | 500.00 | 3.51 | 14.03 | 86.55 |

| 16 | 500.00 | 3.51 | 14.03 | 83.44 |

| 17 | 500.00 | 3.51 | 14.03 | 85.14 |

| 18 | 500.00 | 3.51 | 14.03 | 83.25 |

| 19 | 500.00 | 3.51 | 14.03 | 84.79 |

| 20 | 500.00 | 3.51 | 14.03 | 82.44 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value (Prob > F) | Significance |

|---|---|---|---|---|---|---|

| Model | 2561.46 | 9 | 284.61 | 44.73 | <0.0001 | Significant |

| A–Power | 1660.04 | 1 | 1660.04 | 260.90 | <0.0001 | |

| B–Time | 260.74 | 1 | 260.74 | 40.98 | <0.0001 | |

| C–Mass | 158.63 | 1 | 158.63 | 24.93 | 0.0005 | |

| AB | 20.42 | 1 | 20.42 | 3.21 | 0.1035 | |

| AC | 25.06 | 1 | 25.06 | 3.94 | 0.0752 | |

| BC | 2.44 | 1 | 2.44 | 0.38 | 0.5494 | |

| A2 | 406.98 | 1 | 406.98 | 63.96 | 0.00001 | |

| B2 | 51.28 | 1 | 51.28 | 8.06 | 0.0175 | |

| C2 | 3.76 | 1 | 3.76 | 0.59 | 0.4595 | |

| Residual | 63.63 | 10 | 6.36 | |||

| Lack of fit | 52.32 | 5 | 10.46 | 4.63 | 0.0590 | Not significant |

| Pure error | 11.30 | 5 | 2.26 | |||

| Cor total | 2625.09 | 19 |

| Power/W | Time/min | Mass/g | Predicted DR/% | Measured DR/% | Absolute Deviation/% |

|---|---|---|---|---|---|

| 620.00 | 0.00 | 13.20 | 0.00 | 0.00 | 0.00 |

| 620.00 | 2.70 | 13.20 | 83.50–85.50 | 85.41 | 1.50 |

| 620.00 | 3.66 | 13.20 | 85.50–87.50 | 86.90 | 1.50 |

| 620.00 | 4.30 | 13.20 | 88.00–89.50 | 89.15 | 1.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, S.; Niu, Y.; Yuwen, C.; Liu, B. Microwave Drying of Tricholoma Matsutake: Dielectric Properties, Mechanism, and Process Optimization. Foods 2025, 14, 3054. https://doi.org/10.3390/foods14173054

Gong S, Niu Y, Yuwen C, Liu B. Microwave Drying of Tricholoma Matsutake: Dielectric Properties, Mechanism, and Process Optimization. Foods. 2025; 14(17):3054. https://doi.org/10.3390/foods14173054

Chicago/Turabian StyleGong, Siyu, Yifan Niu, Chao Yuwen, and Bingguo Liu. 2025. "Microwave Drying of Tricholoma Matsutake: Dielectric Properties, Mechanism, and Process Optimization" Foods 14, no. 17: 3054. https://doi.org/10.3390/foods14173054

APA StyleGong, S., Niu, Y., Yuwen, C., & Liu, B. (2025). Microwave Drying of Tricholoma Matsutake: Dielectric Properties, Mechanism, and Process Optimization. Foods, 14(17), 3054. https://doi.org/10.3390/foods14173054