Advances in Resistant Starch Research from Agro-Industrial Waste: A Bibliometric Analysis of Scientific Trends

Abstract

1. Introduction

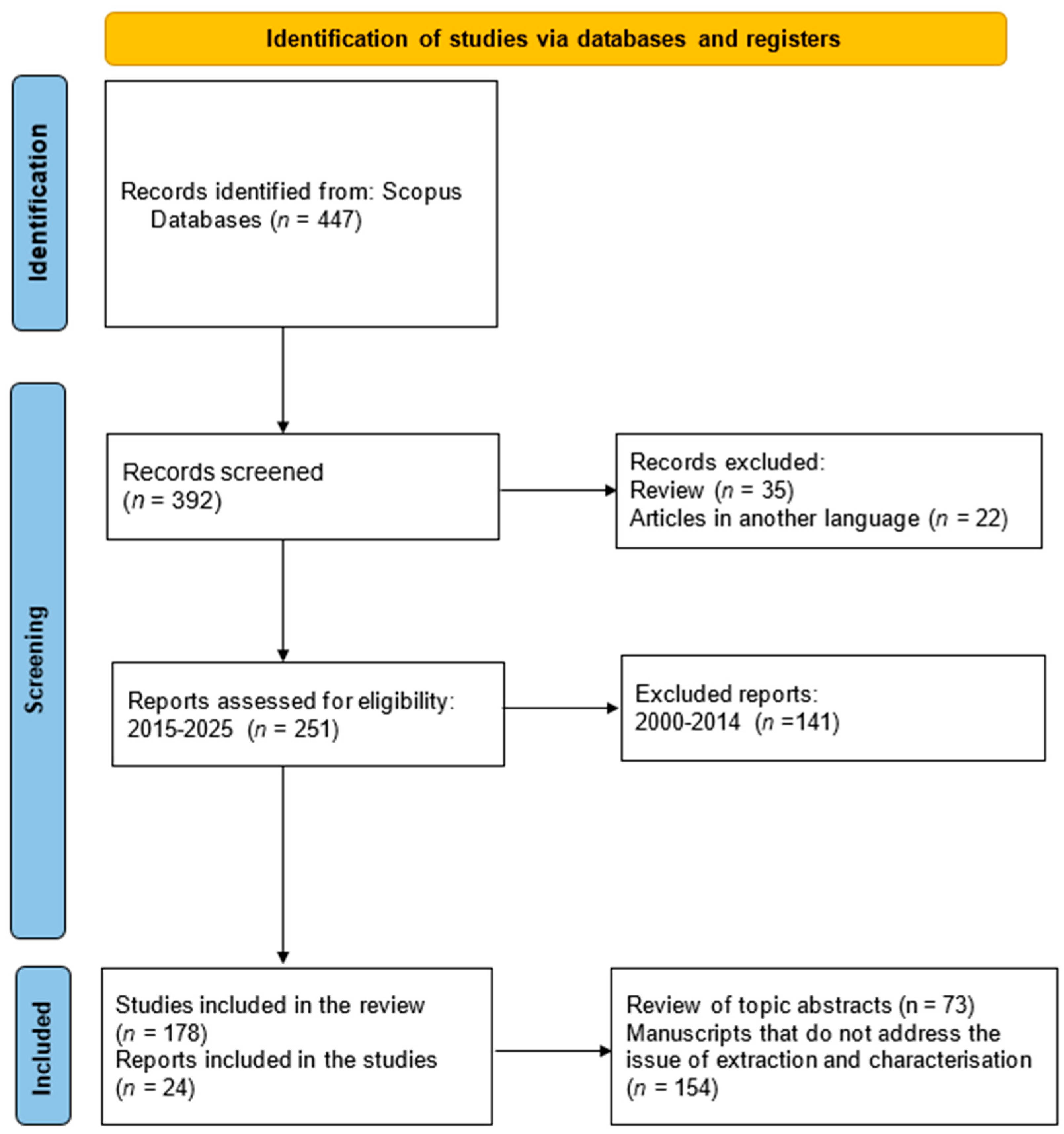

2. Materials and Methods

2.1. Literature Selection Criteria

2.2. Data Synthesis and Analysis

3. Bibliometric Analysis

3.1. Annual Scientific Production

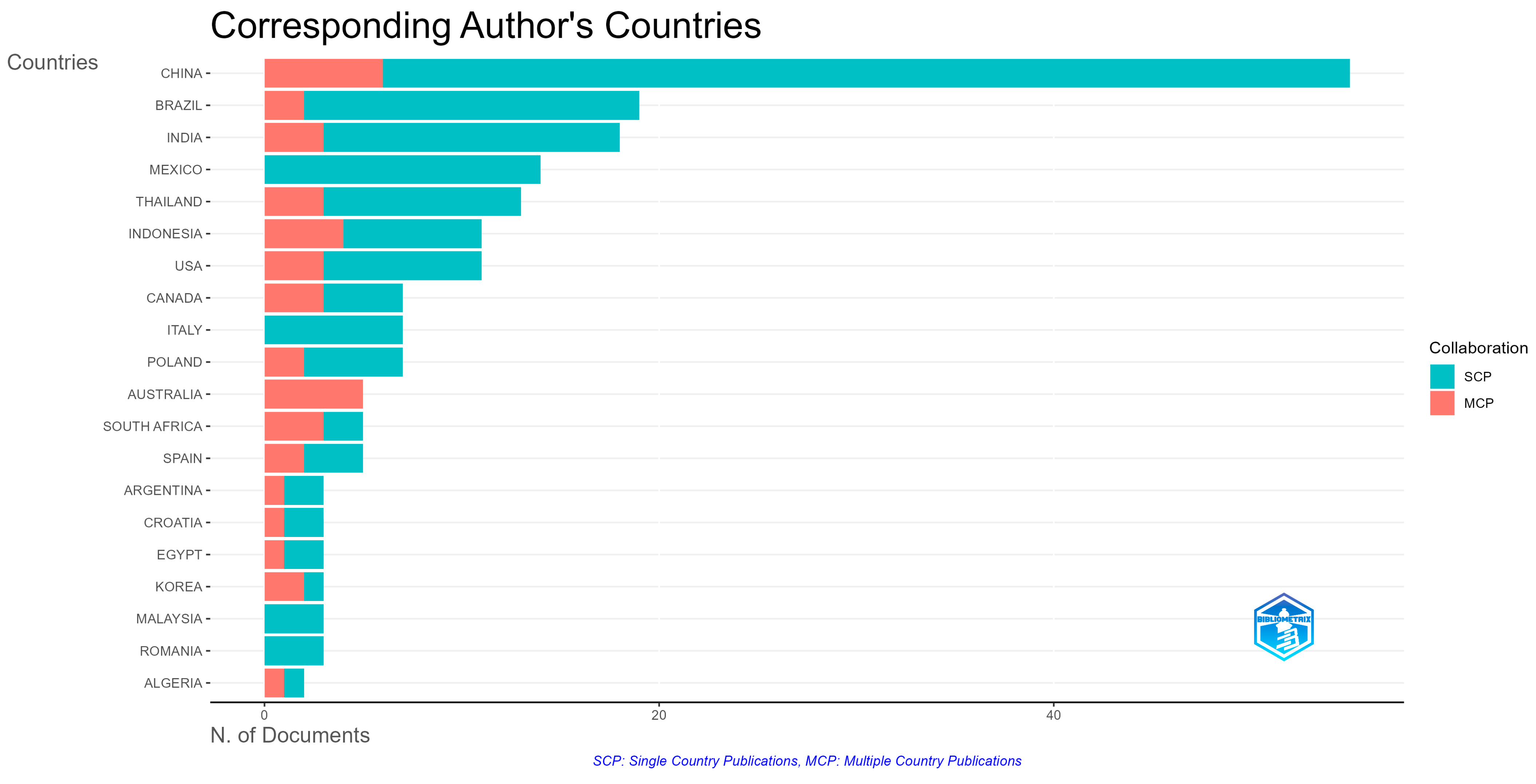

3.2. Production by Country

3.3. Author Contributions

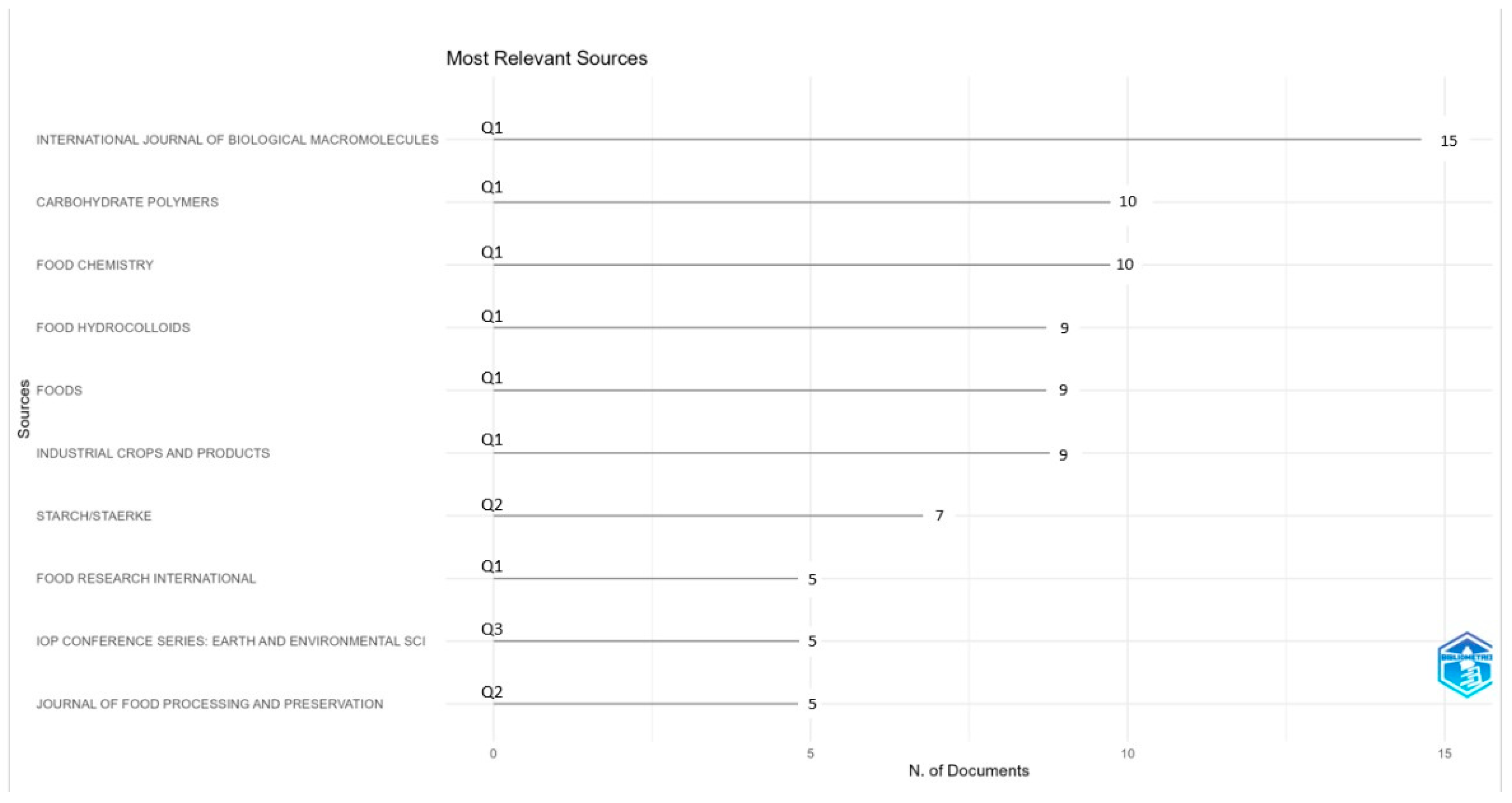

3.4. Contribution of Journals

3.5. Contribution of Affiliations

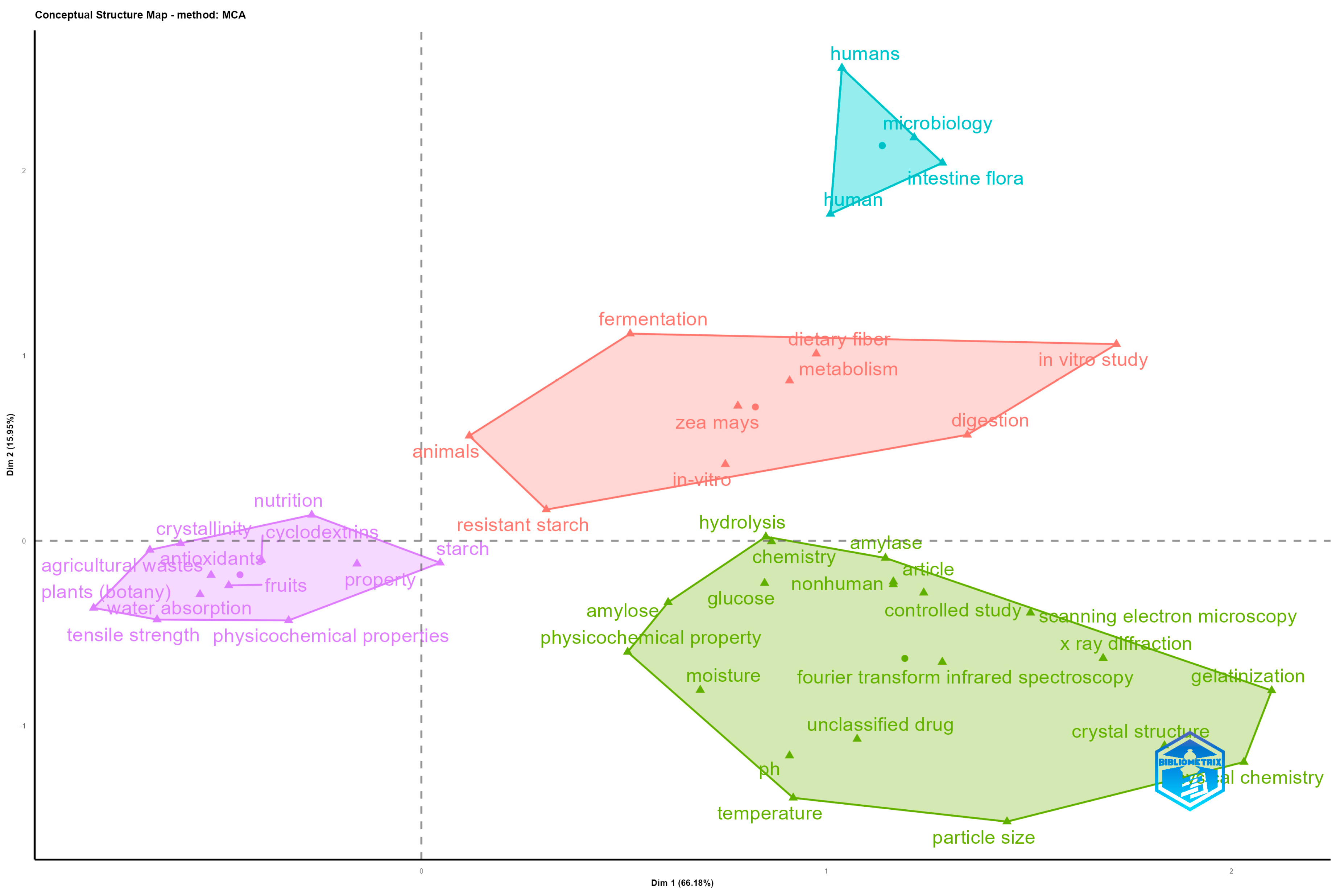

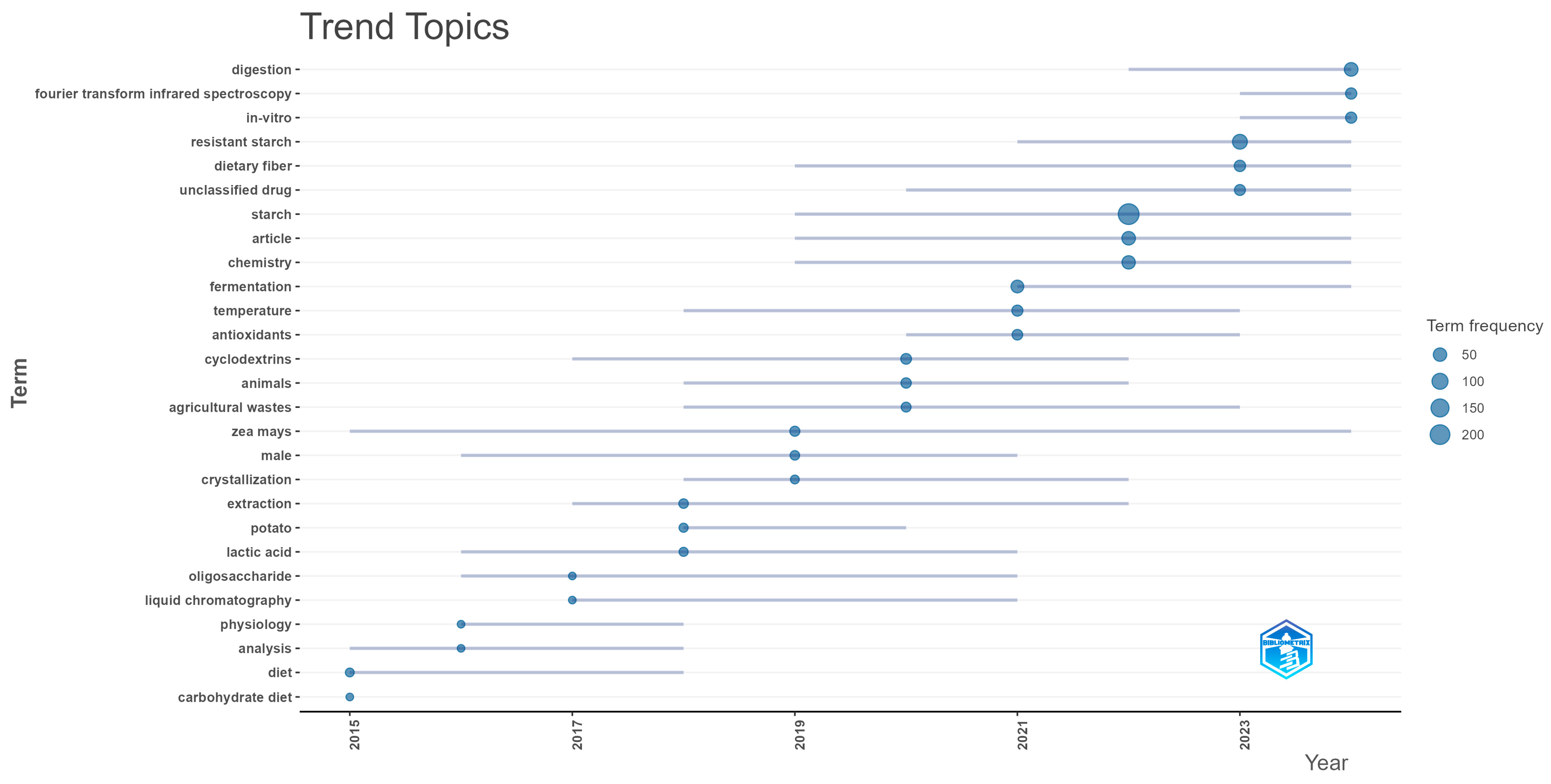

3.6. Keyword Analysis

4. Extraction and Characterisation of RSs from By-Products

4.1. Agro-Industrial By-Products as a Source of RS

4.2. Extraction Techniques Used for the Recovery of RSs

4.3. Characterisation of RSs

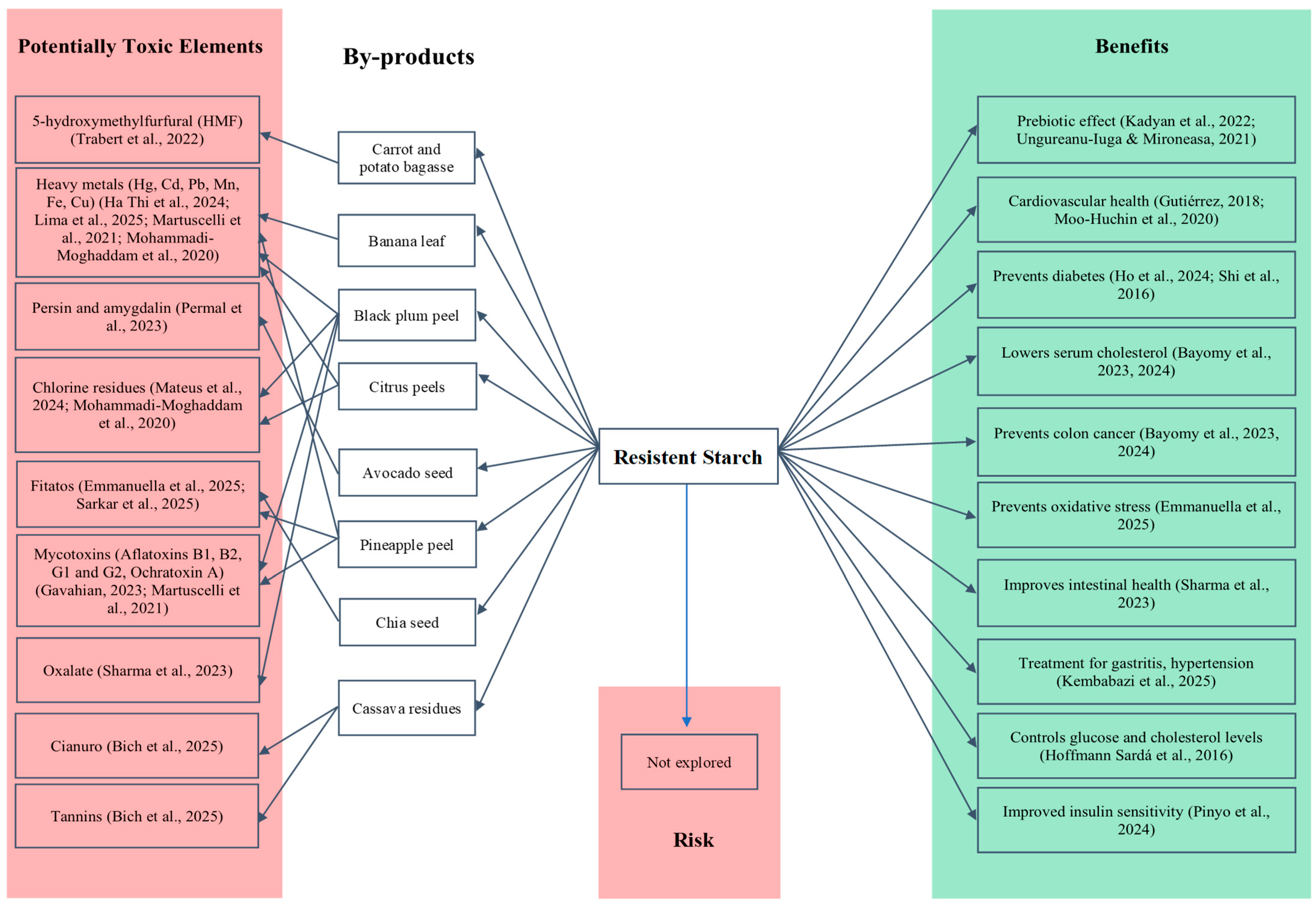

5. Health Benefits and Risks of RSs from By-Products

6. Trends and Suggestions for Future Research

- (a)

- Identify and quantify potentially toxic elements in starches extracted from agro-industrial by-products. Hazards in food are often present in very low concentrations, so analytical techniques could also be improved for rapid and accurate detection, especially to quantify emerging hazards.

- (b)

- Assess the sustainability of the reuse of agro-industrial by-products in the extraction of resistant starches and their application in the food industry.

- (c)

- Assess the toxicological risk of the extraction of resistant starches from agro-industrial by-products by investigating dose–response models based on epidemiological studies, exposure, weight, and age. In addition, use probabilistic models to address uncertainties and make informed risk decisions.

- (d)

- Integrate risk–benefit research to promote informed consumption, prevent hazards, and protect consumer health.

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Etchepare, M.d.A.; Raddatz, G.C.; Cichoski, A.J.; Flores, É.M.M.; Barin, J.S.; Queiroz Zepka, L.; Jacob-Lopes, E.; Grosso, C.R.F.; de Menezes, C.R. Effect of Resistant Starch (Hi-Maize) on the Survival of Lactobacillus Acidophilus Microencapsulated with Sodium Alginate. J. Funct. Foods 2016, 21, 321–329. [Google Scholar] [CrossRef]

- DeMartino, P.; Cockburn, D.W. Resistant Starch: Impact on the Gut Microbiome and Health. Curr. Opin. Biotechnol. 2020, 61, 66–71. [Google Scholar] [CrossRef] [PubMed]

- Neuhaus, A.; Cassanta, R.; Cappellari, F. Amido Resistente: Alternativa de Alimento Funcional Para a Homeostase Da Glicose, Redução Do Perfil Lipídico e Modulação Da Microbiota Intestinal. Saúde Desenvolv. Hum. 2020, 8, 109–120. [Google Scholar] [CrossRef]

- Olayo-Contreras, V.M.; Alemán-Castillo, S.J.; Rodríguez-Castillejos, G.; Castillo-Ruiz, O. Almidón Resistente Como Prebiótico y Sus Beneficios En El Organismo Humano. TIP Rev. Espec. Cienc. Químico-Biológicas 2022, 24. [Google Scholar] [CrossRef]

- Lu, J.; Ma, B.; Qiu, X.; Sun, Z.; Xiong, K. Effects of Resistant Starch Supplementation on Oxidative Stress and Inflammation Biomarkers: A Systematic Review and Meta-Analysis of Randomized Controlled Trials. Asia Pac. J. Clin. Nutr. 2021, 30, 614–623. [Google Scholar] [CrossRef]

- Montroy, J.; Berjawi, R.; Lalu, M.M.; Podolsky, E.; Peixoto, C.; Sahin, L.; Stintzi, A.; Mack, D.; Fergusson, D.A. The Effects of Resistant Starches on Inflammatory Bowel Disease in Preclinical and Clinical Settings: A Systematic Review and Meta-Analysis. BMC Gastroenterol. 2020, 20, 372. [Google Scholar] [CrossRef]

- Fuentes-Zaragoza, E.; Riquelme-Navarrete, M.J.; Sánchez-Zapata, E.; Pérez-Álvarez, J.A. Resistant Starch as Functional Ingredient: A Review. Food Res. Int. 2010, 43, 931–942. [Google Scholar] [CrossRef]

- Rodriguez-Garcia, M.E.; Hernandez-Landaverde, M.A.; Delgado, J.M.; Ramirez-Gutierrez, C.F.; Ramirez-Cardona, M.; Millan-Malo, B.M.; Londoño-Restrepo, S.M. Crystalline Structures of the Main Components of Starch. Curr. Opin. Food Sci. 2021, 37, 107–111. [Google Scholar] [CrossRef]

- Ho, L.H.; Segar, R.; Mathihalagan, F.S.; Zakaria, S.H.; Tuan Mazlam, S.A.H. Characterization of Resistant Starch (Type III) Produced from Banana (Musa Acuminata x Balbisiana CV Awak) Pseudostem. Canrea J. Food Technol. Nutr. Culin. J. 2024, 7, 162–179. [Google Scholar] [CrossRef]

- Bussolo de Souza, C.; Jonathan, M.; Isay Saad, S.M.; Schols, H.A.; Venema, K. Characterization and in Vitro Digestibility of By-Products from Brazilian Food Industry: Cassava Bagasse, Orange Bagasse and Passion Fruit Peel. Bioact. Carbohydr. Diet. Fibre 2018, 16, 90–99. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Herniou-Julien, C.; Álvarez, K.; Alvarez, V.A. Structural Properties and in Vitro Digestibility of Edible and PH-Sensitive Films Made from Guinea Arrowroot Starch and Wastes from Wine Manufacture. Carbohydr. Polym. 2018, 184, 135–143. [Google Scholar] [CrossRef]

- Saeaurng, K.; Kuakpetoon, D. A Comparative Study of Mango Seed Kernel Starches and Other Commercial Starches: The Contribution of Chemical Fine Structure to Granule Crystallinity, Gelatinization, Retrogradation, and Pasting Properties. J. Food Meas. Charact. 2018, 12, 2444–2452. [Google Scholar] [CrossRef]

- Corredor, Y.A.V.; Pérez, L.I.P. Aprovechamiento de Residuos Agroindustriales En El Mejoramiento de La Calidad Del Ambiente. Rev. Fac. Cienc. Básicas 2018, 14, 59–72. [Google Scholar] [CrossRef]

- Alzate, L.; Jimenez, C.; Londoño, J. Aprovechamiento de Residuos Agroindustriales Para Mejorar La Calidad Sensorial y Nutricional de Productos Avícolas. Prod. Limpia 2011, 6, 108–127. [Google Scholar]

- Singh, R.S.; Singh, T. Inulinase and Pullulanase Production from Agro-Industrial Residues; De Gruyter Berlin: Boston, MA, USA, 2019; ISBN 9783110563337. [Google Scholar]

- Hadidi, M.; Aghababaei, F.; Gonzalez-Serrano, D.J.; Goksen, G.; Trif, M.; McClements, D.J.; Moreno, A. Plant-Based Proteins from Agro-Industrial Waste and by-Products: Towards a More Circular Economy. Int. J. Biol. Macromol. 2024, 261, 129576. [Google Scholar] [CrossRef]

- Panesar, R.; Kaur, S.; Panesar, P.S. Production of Microbial Pigments Utilizing Agro-Industrial Waste: A Review. Curr. Opin. Food Sci. 2015, 1, 70–76. [Google Scholar] [CrossRef]

- Sharma, R. Agro-Industrial Waste to Energy—Sustainable Management. Sustain. Mater. Technol. 2024, 41, e01117. [Google Scholar] [CrossRef]

- Bellopede, R.; Zichella, L.; Gołębiewska, E.; Kalinowska, M.; Yildiz, G. Sustainable Use of Apple Pomace (AP) in Different Industrial Sectors. Materials 2022, 15, 1788. [Google Scholar] [CrossRef] [PubMed]

- Pack, E.D.; Meyerhoff, K.; Schmale, D.G. Tracking Zearalenone and Type-B Trichothecene Mycotoxins in the Commercial Production of Beer and Brewers’ Spent Grains. J. Am. Soc. Brew. Chem. 2022, 80, 180–189. [Google Scholar] [CrossRef]

- Rubenstein, E.; McLaughlin, T.; Winant, R.C.; Sanchez, A.; Eckart, M.; Krasinska, K.M.; Chien, A. Azetidine-2-Carboxylic Acid in the Food Chain. Phytochemistry 2009, 70, 100–104. [Google Scholar] [CrossRef]

- Muñoz, F.J. El Riesgo En Los Niños Del Consumo de Alimentos Transformados. Los Agentes Químicos En Los Alimentos. Isla Arriarán Rev. Cult. Científica 2008, 279–331. [Google Scholar]

- Salazar, N.J.; Enríquez, S.A.; Martínez, B.S.; Gonzáles, G.A. Residuos Agroindustriales Como Fuente de Nutrientes y Compuestos Fenólicos. Epistemus 2023, 17, 60–69. [Google Scholar] [CrossRef]

- Page, M.J.; Moher, D.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. PRISMA 2020 Explanation and Elaboration: Updated Guidance and Exemplars for Reporting Systematic Reviews. BMJ 2021, 372, n160. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Watson, M. Guidance on Conducting a Systematic Literature Review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- Flores-Iwasaki, M.; Guadalupe, G.A.; Pachas-Caycho, M.; Chapa-Gonza, S.; Mori-Zabarburú, R.C.; Guerrero-Abad, J.C. Internet of Things (IoT) Sensors for Water Quality Monitoring in Aquaculture Systems: A Systematic Review and Bibliometric Analysis. AgriEngineering 2025, 7, 78. [Google Scholar] [CrossRef]

- Guadalupe, G.A.; Grandez-Yoplac, D.E.; García, L.; Doménech, E. A Comprehensive Bibliometric Study in the Context of Chemical Hazards in Coffee. Toxics 2024, 12, 526. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-Tool for Comprehensive Science Mapping Analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Nakthong, N.; Wongsagonsup, R.; Amornsakchai, T. Characteristics and Potential Utilizations of Starch from Pineapple Stem Waste. Ind. Crops Prod. 2017, 105, 74–82. [Google Scholar] [CrossRef]

- Pinyo, J.; Wongsagonsup, R.; Boonsanong, N.; Hongsanyatham, S.; Somprasong, N.; Khunoad, P.; Suphantharika, M.; Smith, S.M.; Amornsakchai, T. Noodles Made from Blends of Rice Flour and Pineapple Stem Starch: Physical Properties, Cooking Qualities, in Vitro Starch Digestibility and Sensory Properties. Int. J. Food Sci. Technol. 2024, 59, 5105–5117. [Google Scholar] [CrossRef]

- Sriprablom, J.; Suphantharika, M.; Smith, S.M.; Amornsakchai, T.; Pinyo, J.; Wongsagonsup, R. Physicochemical, Rheological, In-Vitro Digestibility, and Emulsifying Properties of Starch Extracted from Pineapple Stem Agricultural Waste. Foods 2023, 12, 2028. [Google Scholar] [CrossRef]

- Li, L.; He, T.; Ling, Y.; Li, X.; Sui, C.; Cao, R.; Li, C. Preparation, Structure Characterization and Functional Properties of Pea Dregs Resistant Dextrin. Front. Sustain. Food Syst. 2023, 7, 1182642. [Google Scholar] [CrossRef]

- Anh Ngoc Le, T.; Jie Lin Lee, J.; Ning Chen, W. Stimulation of Lactic Acid Production and Lactobacillus Plantarum Growth in the Coculture with Bacillus Subtilis Using Jackfruit Seed Starch. J. Funct. Foods 2023, 104, 105535. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, M.; Zhu, K.; Wu, G.; Tan, L. Functional Properties and Utilization of Artocarpus Heterophyllus Lam Seed Starch from New Species in China. Int. J. Biol. Macromol. 2018, 107, 1395–1405. [Google Scholar] [CrossRef] [PubMed]

- Bayomy, H.M.; Alamri, E.S.; Albalawi, A.N.; Alharbi, R.; Al-Maris, S.; Rozan, M.A.; Shamsia, S.M. Formation of Resistant Starch and Cracker Products from Leftover Rice in Saudi Arabia. J. Agric. Food Res. 2023, 14, 100832. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, R.; Huang, Z.; Cai, M.; Lou, W.; Wang, Y.; Gharsallaoui, A.; Roubik, H.; Yang, K.; Sun, P. Preparation and Characterization of Octenyl Succinic Anhydride Nano Starch from Tiger Nut Meals. Food Qual. Saf. 2023, 7, fyad030. [Google Scholar] [CrossRef]

- Yang, W.; Han, X.; Huang, T.; Shen, Z.; Qin, F.; Wei, M.; Fu, Z. Physicochemical Properties and the Digestibility of Cassava Root and Stem Starches Associated with Genotypes. Starch/Staerke 2022, 74, 2100030. [Google Scholar] [CrossRef]

- Hadisoewignyo, L.; Kuncoro, F.; Tjandrawinata, R.R. Isolation and Characterization of Agung Banana Peel Starch from East Java Indonesia. Int. Food Res. J. 2017, 24, 1324–1330. [Google Scholar]

- Shini, V.S.; Billu, A.; Suvachan, A.; Nisha, P. Exploring the Nutritional, Physicochemical and Hypoglycemic Properties of Green Banana Flours from Unexploited Banana Cultivars of Southern India. Sustain. Food Technol. 2024, 2, 1113–1127. [Google Scholar] [CrossRef]

- Ling, C.X.; Chang, Y.P. Valorizing Guava (Psidium guajava L.) Seeds through Germination-Induced Carbohydrate Changes. J. Food Sci. Technol. 2017, 54, 2041–2049. [Google Scholar] [CrossRef]

- Soto-Maldonado, C.; Concha-Olmos, J.; Cáceres-Escobar, G.; Meneses-Gómez, P. Sensory Evaluation and Glycaemic Index of a Food Developed with Flour from Whole (Pulp and Peel) Overripe Banana (Musa cavendishii) Discards. LWT 2018, 92, 569–575. [Google Scholar] [CrossRef]

- Huang, J.; Lin, L.; Wang, J.; Wang, Z.; Liu, Q.; Wei, C. In Vitro Digestion Properties of Heterogeneous Starch Granules from High-Amylose Rice. Food Hydrocoll. 2016, 54, 10–22. [Google Scholar] [CrossRef]

- Bortolatto, R.; Bittencourt, P.R.S.; Yamashita, F. Biodegradable Starch/Polyvinyl Alcohol Composites Produced by Thermoplastic Injection Containing Cellulose Extracted from Soybean Hulls (Glycine max L.). Ind. Crops Prod. 2022, 176, 114383. [Google Scholar] [CrossRef]

- Jozinović, A.; Panak Balentić, J.; Ačkar, Đ.; Babić, J.; Pajin, B.; Miličević, B.; Guberac, S.; Vrdoljak, A.; Šubarić, D. Cocoa Husk Application in the Enrichment of Extruded Snack Products. J. Food Process. Preserv. 2019, 43, e13866. [Google Scholar] [CrossRef]

- Moo-Huchin, V.M.; Ac-Chim, D.M.; Chim-Chi, Y.A.; Ríos-Soberanis, C.R.; Ramos, G.; Yee-Madeira, H.T.; Ortiz-Fernández, A.; Estrada-León, R.J.; Pérez-Pacheco, E. Huaya (Melicoccus bijugatus) Seed Flour as a New Source of Starch: Physicochemical, Morphological, Thermal and Functional Characterization. J. Food Meas. Charact. 2020, 14, 3299–3309. [Google Scholar] [CrossRef]

- Ong, Y.Q.; Harith, S.; Shahril, M.R.; Shahidan, N.; Hapidin, H. Organoleptic, Hypoglycaemic, and in Vitro Starch Digestion Effects of Formulated Melon Manis Terengganu Peel Powder. Int. Food Res. J. 2022, 29, 1293–1303. [Google Scholar] [CrossRef]

- Maniglia, B.C.; Silveira, T.M.G.; Tapia-Blácido, D.R. Starch Isolation from Turmeric Dye Extraction Residue and Its Application in Active Film Production. Int. J. Biol. Macromol. 2022, 202, 508–519. [Google Scholar] [CrossRef]

- Ungureanu-Iuga, M.; Mironeasa, S. Advance on the Capitalization of Grape Peels By-Product in Common Wheat Pasta. Appl. Sci. 2021, 11, 11129. [Google Scholar] [CrossRef]

- Gutiérrez, T.J. Plantain Flours as Potential Raw Materials for the Development of Gluten-Free Functional Foods. Carbohydr. Polym. 2018, 202, 265–279. [Google Scholar] [CrossRef]

- Ververis, E.; Ackerl, R.; Azzollini, D.; Colombo, P.A.; de Sesmaisons, A.; Dumas, C.; Fernandez-Dumont, A.; Ferreira da Costa, L.; Germini, A.; Goumperis, T.; et al. Novel Foods in the European Union: Scientific Requirements and Challenges of the Risk Assessment Process by the European Food Safety Authority. Food Res. Int. 2020, 137, 109515. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Xu, Q.; Kong, Q.; Li, F.; Lu, L.; Xu, Y.; Wei, Y. Synthesis and Functions of Resistant Starch. Adv. Nutr. 2023, 14, 1131–1144. [Google Scholar] [CrossRef] [PubMed]

- Birt, D.F.; Boylston, T.; Hendrich, S.; Jane, J.L.; Hollis, J.; Li, L.; McClelland, J.; Moore, S.; Phillips, G.J.; Rowling, M.; et al. Resistant Starch: Promise for Improving Human Health. Adv. Nutr. 2013, 4, 587–601. [Google Scholar] [CrossRef] [PubMed]

- Bindels, L.B.; Delzenne, N.M.; Cani, P.D.; Walter, J. Opinion: Towards a More Comprehensive Concept for Prebiotics. Nat. Rev. Gastroenterol. Hepatol. 2015, 12, 303–310. [Google Scholar] [CrossRef] [PubMed]

- Nugent, A.P. Health Properties of Resistant Starch. Nutr. Bull. 2005, 30, 27–54. [Google Scholar] [CrossRef]

- Ma, Z.; Boye, J.I. Research Advances on Structural Characterization of Resistant Starch and Its Structure-Physiological Function Relationship: A Review. Crit. Rev. Food Sci. Nutr. 2018, 58, 1059–1083. [Google Scholar] [CrossRef]

- Nilsson, A.C.; Östman, E.M.; Holst, J.J.; Björck, I.M.E. Including Indigestible Carbohydrates in the Evening Meal of Healthy Subjects Improves Glucose Tolerance, Lowers Inflammatory Markers, and Increases Satiety after a Subsequent Standardized Breakfast. J. Nutr. 2008, 138, 732–739. [Google Scholar] [CrossRef]

- Chen, Z.; Liang, N.; Zhang, H.; Li, H.; Guo, J.; Zhang, Y.; Chen, Y.; Wang, Y.; Shi, N. Resistant Starch and the Gut Microbiome: Exploring Beneficial Interactions and Dietary Impacts. Food Chem. X 2024, 21, 101118. [Google Scholar] [CrossRef]

- Robertson, M.D.; Bickerton, A.S.; Dennis, A.L.; Vidal, H.; Frayn, K.N. Insulin-Sensitizing Effects of Dietary Resistant Starch and Effects on Skeletal Muscle and Adipose Tissue Metabolism. Am. J. Clin. Nutr. 2005, 82, 559–567. [Google Scholar] [CrossRef][Green Version]

- Bojarczuk, A.; Skąpska, S.; Mousavi Khaneghah, A.; Marszałek, K. Health Benefits of Resistant Starch: A Review of the Literature. J. Funct. Foods 2022, 93, 105094. [Google Scholar] [CrossRef]

- Kadyan, S.; Sharma, A.; Arjmandi, B.H.; Singh, P.; Nagpal, R. Prebiotic Potential of Dietary Beans and Pulses and Their Resistant Starch for Aging-Associated Gut and Metabolic Health. Nutrients 2022, 14, 1726. [Google Scholar] [CrossRef]

- Shi, M.; Wang, K.; Yu, S.; Gilbert, R.G.; Gao, Q. Structural Characterizations and in Vitro Digestibility of Acid-treated Wrinkled and Smooth Pea Starch (Pisum Sativum L.). Starch Stärke 2016, 68, 762–770. [Google Scholar] [CrossRef]

- Emmanuella, B.; Ijeoma, N.; Sunday, A.; Ogo, O.; Ogbene, I. Nutritional Composition, Bioactive Compounds and Antioxidant Potential of Pineapple Rind Flour as Functional Food Ingredient. J. Food Biochem. 2025, 2025, 8832878. [Google Scholar] [CrossRef]

- Sharma, V.; Jahan, K.; Kumar, P.; Puri, A.; Sharma, V.K.; Mishra, A.; Bharatam, P.V.; Sharma, D.; Rishi, V.; Roy, J. Mechanistic Insights into Granule-Bound Starch Synthase I (GBSSI.L539P) Allele in High Amylose Starch Biosynthesis in Wheat (Triticum aestivum L.). Funct. Integr. Genom. 2023, 23, 20. [Google Scholar] [CrossRef]

- Ha Thi, D.; Cao Thi, H.; Tran, Y.D.T.; Mac, T.V. Bioactivity-Maximized Herbal Tea Formulation from Banana Leaf and Other Musa Acuminata AAA by-Products Using D-Optimal Mixture Design. Appl. Food Res. 2024, 4, 100593. [Google Scholar] [CrossRef]

- Lima, V.d.C.; Sampaio, R.F.; Correia, L.D.B.; Júnior, J.L.R.; Barretto, A.C.d.S.; Pereira, T.M.T. Mineral Concentration in Citrus Peel Flours. Comun. Sci. 2025, 16, e4275. [Google Scholar] [CrossRef]

- Martuscelli, M.; Esposito, L.; Di Mattia, C.D.; Ricci, A.; Mastrocola, D. Characterization of Coffee Silver Skin as Potential Food-Safe Ingredient. Foods 2021, 10, 1367. [Google Scholar] [CrossRef] [PubMed]

- Trabert, A.; Schmid, V.; Keller, J.; Emin, M.A.; Bunzel, M. Chemical Composition and Technofunctional Properties of Carrot (Daucus carota L.) Pomace and Potato (Solanum tuberosum L.) Pulp as Affected by Thermomechanical Treatment. Eur. Food Res. Technol. 2022, 248, 2451–2470. [Google Scholar] [CrossRef]

- Mohammadi-Moghaddam, T.; Firoozzare, A.; Kariminejad, M.; Sorahi, M.; Tavakoli, Z. Black Plum Peel as a Useful By-Product for the Production of New Foods: Chemical, Textural, and Sensory Characteristics of Halva Masghati. Int. J. Food Prop. 2020, 23, 2005–2019. [Google Scholar] [CrossRef]

- Mateus, A.R.S.; Mariño-Cortegoso, S.; Barros, S.C.; Sendón, R.; Barbosa, L.; Pena, A.; Sanches-Silva, A. Citrus By-Products: A Dual Assessment of Antioxidant Properties and Food Contaminants towards Circular Economy. Innov. Food Sci. Emerg. Technol. 2024, 95, 103737. [Google Scholar] [CrossRef]

- Gavahian, M. Valorized Pineapple Waste by Conventional and Energy-Saving Ohmic Extraction: Potentially Toxic Elements and Mycotoxin Contamination. Qual. Assur. Saf. Crop. Foods 2023, 15, 11–21. [Google Scholar] [CrossRef]

- Sarkar, A.; Miah, M.S.; Masum, M.; Amin, M.S.A.; Alam, M. Fortification of Wheat Biscuits with Chia Seed Fiber and Flower Waste: Nutritional, Antinutritional, Functional, and Storage Properties. Appl. Food Res. 2025, 5, 100864. [Google Scholar] [CrossRef]

- Bich, H.N.T.; Doan, C.C.; Phan, U.N.K.; Le, K.T.V.; Bui, T.D.; Tanaka, M.; Van Vo, M. Sustainable Improvement of Nutrition Quality and Biological Activity from Cassava Residue and Okara through Solid-State Fermentation by Pleurotus Citrinopileatus Mycelium. J. Appl. Biol. Biotechnol. 2025, 13, 44–54. [Google Scholar] [CrossRef]

- Permal, R.; Chia, T.; Arena, G.; Fleming, C.; Chen, J.; Chen, T.; Chang, W.L.; Seale, B.; Hamid, N.; Kam, R. Converting Avocado Seeds into a Ready to Eat Snack and Analysing for Persin and Amygdalin. Food Chem. 2023, 399, 134011. [Google Scholar] [CrossRef] [PubMed]

- Kourkopoulos, A.; Sijm, D.T.H.M.; Mircheva, A.; Bastos, V.C.; Vrolijk, M.F. In Vitro Hazard Characterization of Contaminants Migrating from Recycled Paper Food Contact Materials. Regul. Toxicol. Pharmacol. 2025, 159, 105816. [Google Scholar] [CrossRef]

- Li, J.; Sobańtka, A. A Systematic Analysis of the Effect of Extraction Solvents on the Chemical Composition of Extraction Solutions and the Analytical Implications in Extractables and Leachables Studies. J. Pharm. Biomed. Anal. 2023, 222, 115081. [Google Scholar] [CrossRef]

- Doménech, E.; Martorell, S. Assessment of Safety Margins of Exposure to Non-Genotoxic Chemical Substances in Food. Food Control 2017, 79, 1–9. [Google Scholar] [CrossRef]

- Guadalupe, G.A.; García, L.; Chavez, S.G.; Doménech, E. Ecological and Health Risk Assessment of Metals in Organic and Conventional Peruvian Coffee from a Probabilistic Approach. Agronomy 2024, 14, 2817. [Google Scholar] [CrossRef]

- Guadalupe, G.A.; Grandez-Yoplac, D.E.; Arellanos, E.; Doménech, E. Probabilistic Risk Assessment of Metals, Acrylamide and Ochratoxin A in Instant Coffee from Brazil, Colombia, Mexico and Peru. Foods 2024, 13, 726. [Google Scholar] [CrossRef]

- Guadalupe, G.A.; García, L.; Quispe-Sánchez, L.; Doménech, E. The Fault Tree Analysis (FTA) to Support Management Decisions on Pesticide Control in the Reception of Peruvian Parchment Coffee. Food Control 2024, 166, 110729. [Google Scholar] [CrossRef]

- Guadalupe, G.A.; Chavez, S.G.; Arellanos, E.; Doménech, E. Probabilistic Risk Characterization of Heavy Metals in Peruvian Coffee: Implications of Variety, Region and Processing. Foods 2023, 12, 3254. [Google Scholar] [CrossRef]

- Doménech, E.; Martorell, S. Formulation and Application of the Probability of Exceedance Metric for Risk Characterization of Non-Threshold Chemical Hazards in Food. Food Control 2021, 124, 107910. [Google Scholar] [CrossRef]

- Doménech, E.; Martorell, S. Review of the Terminology, Approaches, and Formulations Used in the Guidelines on Quantitative Risk Assessment of Chemical Hazards in Food. Foods 2024, 13, 714. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Jiang, H.; Kim, H.J.; Yum, M.Y.; Campbell, M.R.; Jane, J.L.; White, P.J.; Hendrich, S. Increased Butyrate Production During Long-Term Fermentation of In Vitro-Digested High Amylose Cornstarch Residues with Human Feces. J. Food Sci. 2015, 80, 1997–2004. [Google Scholar] [CrossRef] [PubMed]

- Simões, J.; Moreira, A.S.P.; Da Costa, E.; Evtyugin, D.; Domingues, P.; Nunes, F.M.; Coimbra, M.A.; Domingues, M.R.M. Oxidation of Amylose and Amylopectin by Hydroxyl Radicals Assessed by Electrospray Ionisation Mass Spectrometry. Carbohydr. Polym. 2016, 148, 290–299. [Google Scholar] [CrossRef] [PubMed]

- Bunyameen, N.; Perin, A.; Donlao, N. Utilization of Banana Agricultural Waste -Effects of Processing Conditions on Properties of Unripe Banana (Musa cavendish) Pulp and Peel Flours-. Eng. Agric. Environ. Food 2020, 13, 129–138. [Google Scholar] [CrossRef]

- Gómez, J.A.; Pino-Hernández, E.; Abrunhosa, L.; Matallana, L.G.; Sánchez, O.J.; Teixeira, J.A.; Nobre, C. Valorisation of Rejected Unripe Plantain Fruits of Musa AAB Simmonds: From Nutritional Characterisation to the Conceptual Process Design for Prebiotic Production. Food Funct. 2021, 12, 3009–3021. [Google Scholar] [CrossRef]

- Kaur, B.; Venkatrao, K.B.; Panesar, P.S.; Chopra, H.K.; Anal, A.K. Optimization of Ultrasound-Assisted Enzymatic Extraction of Resistant Starch from Green Banana Peels and Its Structural Characterization. J. Food Sci. Technol. 2022, 59, 4663–4672. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Liang, Y.-C.; Huang, F.-L.; Chang, W.-C. Effect of Freeze–Thaw Cycles on Physicochemical and Functional Properties of Ginger Starch. Processes 2023, 11, 1828. [Google Scholar] [CrossRef]

- Yüce, B.; Güzel, B.; Canlı, O.; Olgun, E.Ö.; Kaya, D.; Aşçı, B.; Hocaoğlu, S.M. Comprehensive Research and Risk Assessment on the Pollution Profile of Organic Micropollutants (OMPs) in Different Types of Citrus Essential Oils Produced from Waste Citrus Peels in Türkiye. J. Food Compos. Anal. 2025, 142, 107463. [Google Scholar] [CrossRef]

| By-Product | Extraction | Characterisation | Characteristics Assessed | RS Type | Reference |

|---|---|---|---|---|---|

| Pineapple stalk | Mechanical | Physicochemical Morphological Thermal Structural | High amylose content (34.4%) High gelatinisation temperature High enthalpy of gelatinisation (19.4 J/g) Particle size (median of 9.69 µm) Type A crystalline structure | N.S. | [29] |

| Chemical | Functional Physicochemical Morphological Structural Thermal | High amylose content (30.56%) Higher proportion of slow-digesting starch and RS Larger granules than rice starch Crystalline structure of type A (in its pure form); in noodles, a mixture of types B and V due to retrogradation Higher thermal stability | N.S. | [30] | |

| Physical | Morphological Thermal Physicochemical | High amylose content (30.82%) High gelatinisation temperature High content of slowly digested starch (SDS) High RS content Low paste viscosity | N.S. | [31] | |

| Pea waste | Chemical | Morphological Physicochemical | Large and variable particle size Amorphous structure High RS content Slow digestion | N.S. | [32] |

| Jackfruit seeds (Artocarpus heterophyllu) | Mechanical/chemical | Physicochemical Structural Thermal | High percentage of RS Smooth, round, or bell-shaped granules (5–11 μm) High thermal stability | RS2 | [33] |

| Mechanical/chemical | Structural Morphological Thermal | Type A crystalline structure Variations in granule shape and size Variations in thermal properties (gelatinisation temperature and enthalpy) High amylose content (26.56–38.34%) | N.S. | [34] | |

| Cooked rice waste | Physical/chemical | Thermal Morphological Physicochemical Structural | Changes in gelatinisation temperatures (To, Tp, and Tc) and enthalpy (ΔH) by DSC Polyhedral granules with rough surfaces observed by SEM Changes in chemical structure detected by FTIR Starch, protein, and moisture contents | N.S. | [35] |

| Tiger nut flour oil (Cyperus esculentus) | Physical/chemical | Physicochemical Morphological Thermal | Higher amylose content than native starch Higher swelling power Lower gelatinisation temperature after modification with OSA Unique microstructure (thin fibres and oblate structure) after modification with OSA | N.S. | [36] |

| Banana pseudostem | Mechanical/physical | Morphological Structural Physicochemical | Native starch has irregular granules and a B-type crystalline structure | RS3 | [9] |

| Cassava by-products (root, stem, and cassava bagasse) | Physical/mechanical/chemical | Physicochemical Functional | Yield of 12% RS Water retention Functional properties (prebiotic effects) | RS1 | [10] |

| Physical/mechanical | Physicochemical Morphological Functional | RS content Amylose content Solubility Moisture Swelling Granule shape Digestibility Freeze–thaw stability | N.S. | [37] | |

| Orange bagasse | Chemical | Physicochemical Functional | Glucose, fructose, saccharose, and pectin Small amounts of starch Digestion Capacity for fibre supplementation | N.S. | [10] |

| Maracuyá shell | Chemical | Physicochemical Functional | Pectin and hemicellulose Starch content Fibre supplementation Digestion Low level of methylesterification | N.S. | [10] |

| Plantain mask | Physical/mechanical/chemical | Morphological Physicochemical Thermal Functional | Single or separate granules; elongated, cylindrical shape Starch source pH varies between 4 and 7 Moisture content of 6.06 ± 0.83% Gelatinisation temperature of 59.75 °C (DSC) Gelatinised starch Amylose and amylopectin contents High viscosity | N.S. | [38] |

| Chemical | Physicochemical Functional | Source of RS Total starch content Water absorption Low glycaemic index | N.S. | [39] | |

| Guava seeds | Chemical | Physicochemical | Amylose and amylopectin contents RS content Digestible starch content | N.S. | [40] |

| Grape residue meal | Physical/mechanical | Physicochemical | Anthocyanins Fibre | N.S. | [11] |

| Guinea arrowroot (Calathea allouia) | Physical/chemical | Physicochemical Structural | Amylose content RS content Crystallinity | RS3 RS4 | [11] |

| Mango seeds | Physical/chemical | Physicochemical Morphological Structural Thermal | Amylose and amylopectin contents RS content Granular form High crystallinity Higher gelatinisation temperature (78.13–82.39 °C) Enthalpy (17.32–19.45 J/g) | RS2 | [12] |

| Under-ripe banana pulp and peel | Physical/chemical | Physicochemical | Low starch content High dietary fibre RS content | N.S. | [41] |

| Rice endosperm | Physical | Physicochemical Morphological Structural | Amylose content Polygonal, elongated starch Crystallinity | N.S. | [42] |

| Soya husk (Glycine max L.) | Physical/chemical | Physicochemical | Cellulose | N.S. | [43] |

| Cacao husk | Physical/chemical | Physicochemical Functional | RS content Antioxidant capacity | N.S. | [44] |

| Huaya seed (Melicoccus bijugatu) | Physical/chemical | Physicochemical Thermal Structural Functional | Starch content RS content Low swelling capacity Amylose content Gelatinisation temperature (81.45 ± 0.15 °C) Crystallinity High viscosity (thickening property) | N.S. | [45] |

| Melon mask | Physical/chemical | Physicochemical Functional | RS content Dietary fibre Glycaemic effect Starch digestibility | N.S. | [46] |

| Curcuma root | Chemical/mechanical | Physicochemical Morphological Structural Functional | Amylose content Starch content Swelling power Solubility Crystallinity Phenols Antioxidant activity | N.S. | [47] |

| Grape mask | Physical/mechanical | Physicochemical | Dietary fibre Phenolic compounds | N.S. | [48] |

| Parameter | Description | Reference | ||

|---|---|---|---|---|

| EDI | Estimated daily intake | C · IR/Bw | mg/kgBw/day | [77] |

| C | Concentration | Potentially toxic element | mg/kg | |

| IR | Ingestion rate | kg/day | ||

| Bw | Body weight | kgBw | ||

| HQ | Hazard quotient | EDI/RV | [78] | |

| RV | Reference value | RfD; potentially toxic element | mg/kgBw/day | |

| HI | Hazard index | [79] | ||

| MOE | Margin of exposure | BMDL%/EDI | [80] | |

| BMDL% | Benchmark dose | BMDL%; potentially toxic element | ||

| POE | Probability of exceedance | |||

| CR | Cancer risk | EDI · SF | [78] | |

| SF | Slope factor | SF; potentially toxic element | (mg/kgBw/day)−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saavedra-Cordova, M.A.; Mosilot-Acosta, V.S.; Grandez-Yoplac, D.E.; Chavez, S.G.; Guadalupe, G.A. Advances in Resistant Starch Research from Agro-Industrial Waste: A Bibliometric Analysis of Scientific Trends. Foods 2025, 14, 2815. https://doi.org/10.3390/foods14162815

Saavedra-Cordova MA, Mosilot-Acosta VS, Grandez-Yoplac DE, Chavez SG, Guadalupe GA. Advances in Resistant Starch Research from Agro-Industrial Waste: A Bibliometric Analysis of Scientific Trends. Foods. 2025; 14(16):2815. https://doi.org/10.3390/foods14162815

Chicago/Turabian StyleSaavedra-Cordova, Milena A., Valeri S. Mosilot-Acosta, Dorila E. Grandez-Yoplac, Segundo G. Chavez, and Grobert A. Guadalupe. 2025. "Advances in Resistant Starch Research from Agro-Industrial Waste: A Bibliometric Analysis of Scientific Trends" Foods 14, no. 16: 2815. https://doi.org/10.3390/foods14162815

APA StyleSaavedra-Cordova, M. A., Mosilot-Acosta, V. S., Grandez-Yoplac, D. E., Chavez, S. G., & Guadalupe, G. A. (2025). Advances in Resistant Starch Research from Agro-Industrial Waste: A Bibliometric Analysis of Scientific Trends. Foods, 14(16), 2815. https://doi.org/10.3390/foods14162815