Sustainable Incorporation of Chlamydomonas reinhardtii Powder into Flour-Based Systems: Investigating Its Influence on Flour Pasting Properties, Dough Physical Properties, and Baked Product Quality

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pasting Properties

2.3. The Physical Properties of Dough

2.3.1. Farinographic Properties

2.3.2. Extensographic Properties

2.4. Baking Procedure of Soda Crackers and Cookies

2.5. The Quality Properties of Soda Crackers and Cookies

2.5.1. Expansion Ratio Analysis

2.5.2. Colorimetric Analysis

2.5.3. The Texture of Soda Crackers and Cookies

2.6. Statistical Analysis

3. Results and Discussion

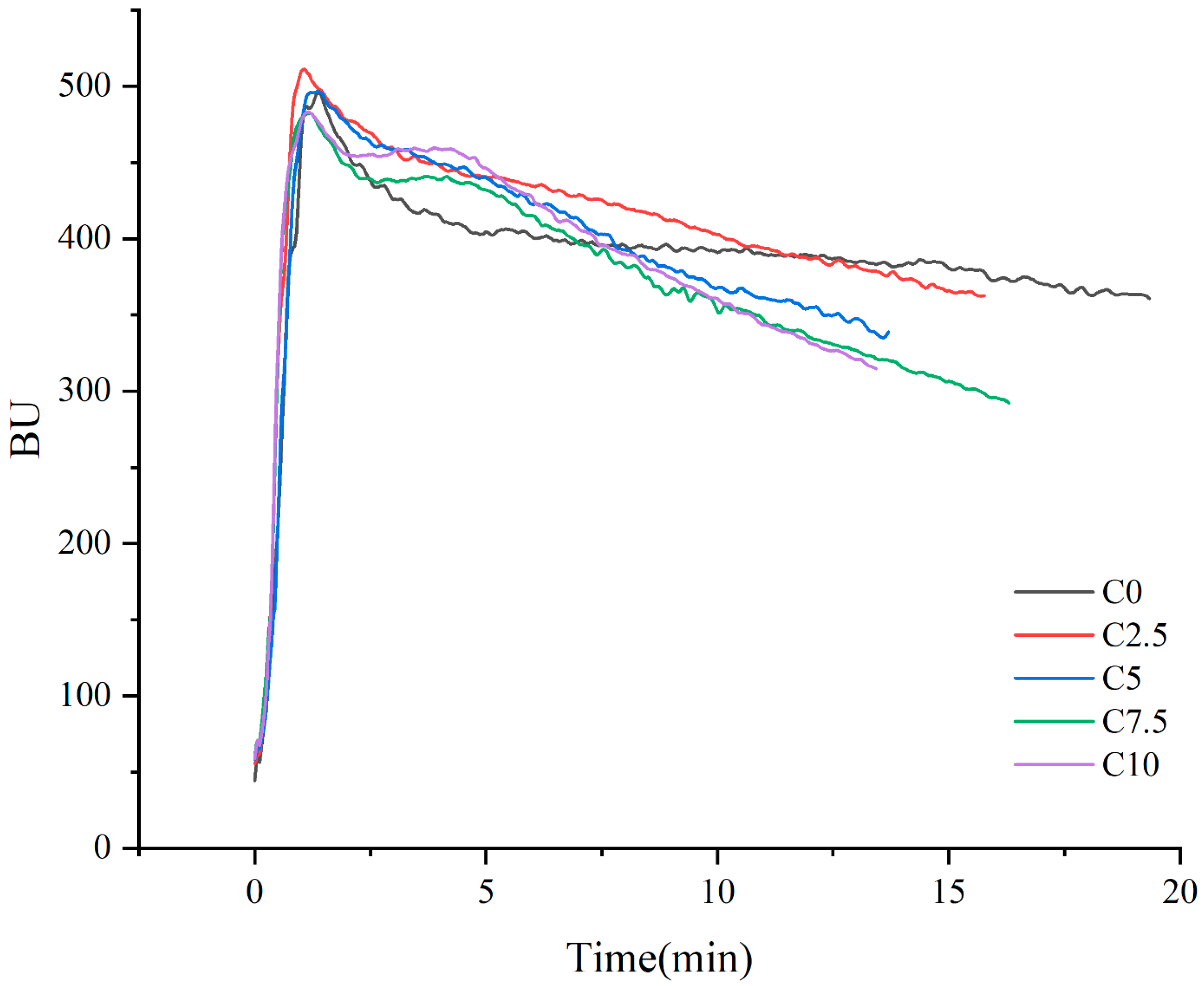

3.1. Pasting Properties

3.2. The Physical Properties of Dough

3.2.1. Farinograph Properties

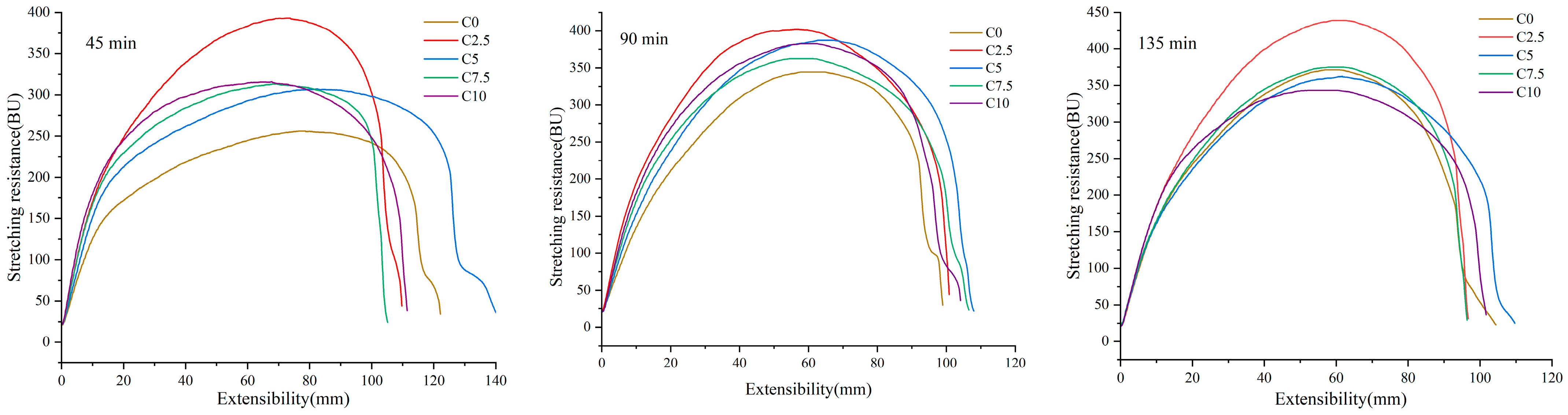

3.2.2. Extensograph Properties

3.3. The Quality Properties of Soda Crackers and Cookies

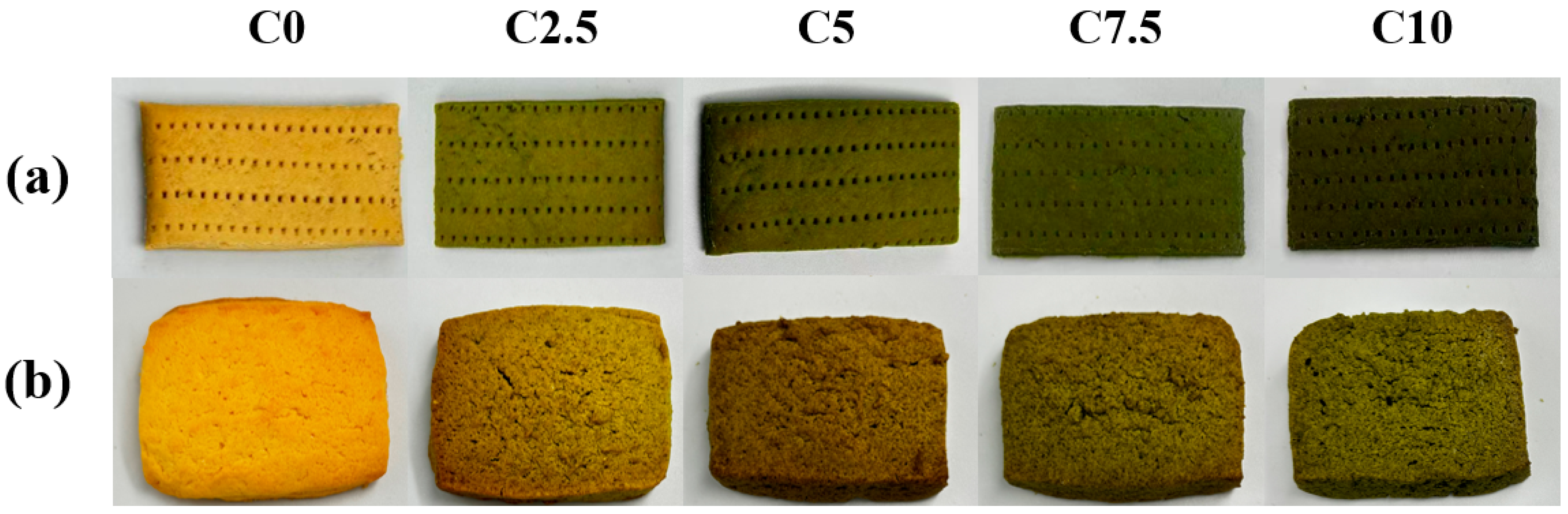

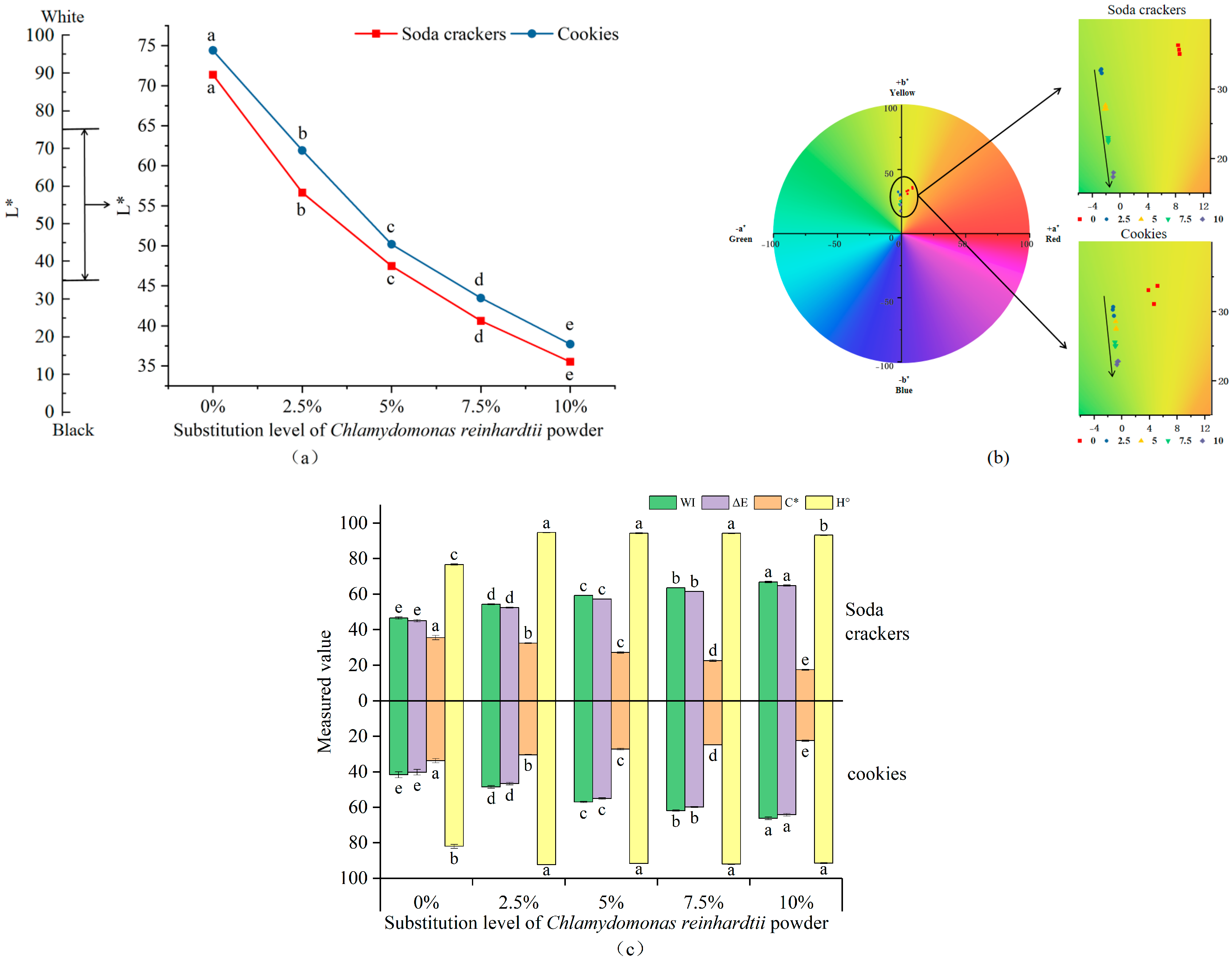

3.3.1. Colorimetric Analysis

3.3.2. Expansion Ratio Analysis and the Texture of Soda Crackers and Cookies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nakov, G.; Stamatovska, V.; Necinova, L.I.N.; Damyanova, S. Sensor analysis of functional biscuits. Ukr. Food J. 2016, 5, 56–62. [Google Scholar]

- Boobier, W.J.; Baker, J.S.; Davies, B. Development of a healthy biscuit: An alternative approach to biscuit manufacture. Nutr. J. 2006, 5, 7. [Google Scholar] [CrossRef]

- Pereira, A.M.; Lisboa, C.R.; Costa, J.A.V. High protein ingredients of microalgal origin: Obtainment and functional properties. Innov. Food Sci. Emerg. Technol. 2018, 47, 187–194. [Google Scholar] [CrossRef]

- Caporgno, M.P.; Mathys, A. Trends in Microalgae Incorporation Into Innovative Food Products With Potential Health Benefits. Front. Nutr. 2018, 5, 58–68. [Google Scholar] [CrossRef]

- da Silva, S.P.; Ferreira do Valle, A.; Perrone, D. Microencapsulated Spirulina maxima biomass as an ingredient for the production of nutritionally enriched and sensorially well-accepted vegan biscuits. Lwt 2021, 142, 110997. [Google Scholar] [CrossRef]

- Hussein, A.M.S.; Mostafa, S.; Ata, S.M.; Hegazy, N.A.; Abu-Reidah, I.M.; Zaky, A.A. Effect of Spirulina Microalgae Powder in Gluten-Free Biscuits and Snacks Formulated with Quinoa Flour. Processes 2025, 13, 625. [Google Scholar] [CrossRef]

- Becker, E.W.J.B.A. Micro-algae as a source of protein. Biotechnol. Adv. 2007, 25, 207–210. [Google Scholar] [CrossRef]

- Darwish, R.M.; Magee, K.J.; Gedi, M.A.; Farmanfarmaian, A.; Zaky, A.S.; Young, I.; Gray, D.A. Evaluation of Chlamydomonas reinhardtii Microalgae as a Sustainable Feed Supplement and Fishmeal Substitute in Aquaculture with a Positive Impact on Human Nutrition. Fermentation 2023, 9, 682. [Google Scholar] [CrossRef]

- Jin, Z.; Gu, Y.; Zhang, W. Lactic acid bacteria-fermented Chlamydomonas reinhardtii as an innovative ingredient to produce microalgae-enriched steamed bread. Cereal Chem. 2024, 101, 1327–1344. [Google Scholar] [CrossRef]

- Khemiri, S.; Khelifi, N.; Nunes, M.C.; Ferreira, A.; Gouveia, L.; Smaali, I.; Raymundo, A. Microalgae biomass as an additional ingredient of gluten-free bread: Dough rheology, texture quality and nutritional properties. Algal Res. 2020, 50, 101998. [Google Scholar] [CrossRef]

- Zhao, Y.; Bai, M.; Qiu, D.; Zhang, J.; Zhao, N.; Feng, G.; Wu, H.; Zeng, M.; Obadina, A.O. Comparative evaluation of sensory and instrumental flavor profiles of four edible microalgae: Spirulina platensis, Chlorella pyrenoidosa, Chlamydomonas reinhardtii, and Haematococcus pluvialis. Algal Res. 2024, 82, 103628. [Google Scholar] [CrossRef]

- Sahni, P.; Sharma, S.; Singh, B. Evaluation and quality assessment of defatted microalgae meal of Chlorella as an alternative food ingredient in cookies. Nutr. Food Sci. 2019, 49, 221–231. [Google Scholar] [CrossRef]

- Batista, A.P.; Niccolai, A.; Fradinho, P.; Fragoso, S.; Bursic, I.; Rodolfi, L.; Biondi, N.; Tredici, M.R.; Sousa, I.; Raymundo, A. Microalgae biomass as an alternative ingredient in cookies: Sensory, physical and chemical properties, antioxidant activity and in vitro digestibility. Algal Res. 2017, 26, 161–171. [Google Scholar] [CrossRef]

- Lu, L.; He, C.; Liu, B.; Wen, Q.; Xia, S. Incorporation of chickpea flour into biscuits improves the physicochemical properties and in vitro starch digestibility. Food Sci. Technol. Res. 2022, 159, 113222. [Google Scholar] [CrossRef]

- Xie, X.; Yuan, Z.; Fu, K.; An, J.; Deng, L. Effect of Partial Substitution of Flour with Mealworm (Tenebrio molitor L.) Powder Dough Biscuit Properties. Foods 2022, 11, 2156. [Google Scholar] [CrossRef]

- Cui, R.; Fei, Y.; Zhu, F. Physicochemical, structural and nutritional properties of steamed bread fortified with red beetroot powder and their changes during breadmaking process. Food Chem. 2022, 383, 132547. [Google Scholar] [CrossRef]

- Mamat, H.; Abu Hardan, M.O.; Hill, S.E. Physicochemical properties of commercial semi-sweet biscuit. Food Chem. 2010, 121, 1029–1038. [Google Scholar] [CrossRef]

- Otegbayo, B.; Aina, J.; Asiedu, R.; Bokanga, M. Pasting characteristics of fresh yams (Dioscorea spp.) as indicators of textural quality in a major food product—‘pounded yam’. Food Chem. 2006, 99, 663–669. [Google Scholar] [CrossRef]

- Chen, L.; Ren, F.; Yu, X.; Zhang, Z.; Xu, D.; Tong, Q. Pasting investigation, SEM observation and the possible interaction study on rice starch-pullulan combination. Int. J. Biol. Macromol. 2015, 73, 45–48. [Google Scholar] [CrossRef] [PubMed]

- Ould Eleya, M.M.; Ko, S.; Gunasekaran, S. Scaling and fractal analysis of viscoelastic properties of heat-induced protein gels. Food Hydrocoll. 2004, 18, 315–323. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Wang, H.; Ai, L.; Xiong, W. Insight into protein-starch ratio on the gelatinization and retrogradation characteristics of reconstituted rice flour. Int. J. Biol. Macromol. 2020, 146, 524–529. [Google Scholar] [CrossRef]

- Peressini, D.; Peighambardoust, S.H.; Hamer, R.J.; Sensidoni, A.; van der Goot, A.J. Effect of shear rate on microstructure and rheological properties of sheared wheat doughs. J. Cereal Sci. 2008, 48, 426–438. [Google Scholar] [CrossRef]

- Whitney, K.; Simsek, S. Potato flour as a functional ingredient in bread: Evaluation of bread quality and starch characteristics. Int. J. Food Sci. Technol. 2020, 55, 3639–3649. [Google Scholar] [CrossRef]

- Graça, C.; Fradinho, P.; Sousa, I.; Raymundo, A. Impact of Chlorella vulgaris on the rheology of wheat flour dough and bread texture. Food Sci. Technol. Res. 2018, 89, 466–474. [Google Scholar] [CrossRef]

- Dervas, G.; Doxastakis, G.; Hadjisavva-Zinoviadi, S.; Triantafyllakos, N. Lupin flour addition to wheat flour doughs and effect on rheological properties. Food Chem. 1998, 66, 67–73. [Google Scholar] [CrossRef]

- Doxastakis, G.; Zafiriadis, I.; Irakli, M.; Marlani, H.; Tananaki, C. Lupin, soya and triticale addition to wheat flour doughs and their effect on rheological properties. Food Chem. 2001, 77, 219–227. [Google Scholar] [CrossRef]

- Yoon, S.; Yang, G.; Kwon, H.; Lee, S. Effects of wheat flour supplemented with soy protein concentrate on the rheology, microstructure and water mobility of protein-fortified precooked noodles. Int. J. Food Sci. Technol. 2022, 57, 4107–4118. [Google Scholar] [CrossRef]

- Jia, S.; Cao, J.; Dai, Y.; Hou, H.; Wang, W.; Ding, X.; Zhang, H. Effect of potassium carbonate on rheological properties of dough and its mechanism. Food Sci. Technol. Res. 2021, 152, 112335. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Dough rheology and bread quality of wheat–chickpea flour blends. Ind. Crops Prod. 2012, 36, 196–202. [Google Scholar] [CrossRef]

- Tian, S.; Wang, F.; Luo, M.; Yan, F.; Ke, D.; Chen, H.; Gao, S. Effect of Chlorella pyrenoidosa powder on rheological properties and fermentation characteristics of dough. J. Food Process. Preserv. 2022, 46, e16446. [Google Scholar] [CrossRef]

- Přihoda, J.; Hrušková, M. Mlynářská technologie svazek 1 Hodnocení kvality. Praha Nakl. 5P Svaz Průmyslových Mlýnu České Repub. 2007, 187, 181–188. [Google Scholar]

- Miś, A.; Dziki, D. Extensograph curve profile model used for characterising the impact of dietary fibre on wheat dough. J. Cereal Sci. 2013, 57, 471–479. [Google Scholar] [CrossRef]

- Wade, P. Biscuits, Cookies, and Crackers. Volume 1: The Principles of the Cratf; Elsevier Applied Science: Amsterdam, The Netherlands, 1988. [Google Scholar]

- Zhu, F.; Sakulnak, R.; Wang, S. Effect of black tea on antioxidant, textural, and sensory properties of Chinese steamed bread. Food Chem. 2016, 194, 1217–1223. [Google Scholar] [CrossRef]

- Bourne, M.C. Basic principles of food texture measurement. In Dough Rheology and Baked Product Texture; Springer: Berlin/Heidelberg, Germany, 1990; pp. 331–341. [Google Scholar]

- Singh, P.; Singh, R.; Jha, A.; Rasane, P.; Gautam, A.K. Optimization of a process for high fibre and high protein biscuit. J. Food Sci. Technol. 2015, 52, 1394–1403. [Google Scholar] [CrossRef] [PubMed]

- Dufour, M.; Chaunier, L.; Lourdin, D.; Réguerre, A.L.; Hugon, F.; Dugué, A.; Kansou, K.; Saulnier, L.; Della Valle, G. Unravelling the relationships between wheat dough extensional properties, gluten network and water distribution. Food Hydrocoll. 2024, 146, 109214. [Google Scholar] [CrossRef]

- Kim, E.H.J.; Corrigan, V.K.; Wilson, A.J.; Waters, I.R.; Hedderley, D.I.; Morgenstern, M.P. Fundamental Fracture Properties Associated with Sensory Hardness of Brittle Solid Foods. J. Texture Stud. 2011, 43, 49–62. [Google Scholar] [CrossRef]

- Levine, L.S.a.H. Structure-Function Relationships ofCookie and Cracker Ingredients. Sci. Cookie Cracker Prod. 1994, 9, 23–141. [Google Scholar]

- Srikanlaya, C.; Therdthai, N.; Ritthiruangdej, P.; Zhou, W. Effect of butter content and baking condition on characteristics of the gluten—free dough and bread. Int. J. Food Sci. Technol. 2017, 52, 1904–1913. [Google Scholar] [CrossRef]

| CRP (%) | LWF (%) | Protein (g/100 g) | Fat (g/100 g) | Carbohydrate (g/100 g) | Moisture (g/100 g) | Ash (g/100 g) |

|---|---|---|---|---|---|---|

| 0 | 100 | 8.50 | 1.10 | 76.40 | 13.00 | 0.45 |

| 2.5 | 97.5 | 9.38 | 1.19 | 75.52 | 12.75 | 0.62 |

| 5 | 95 | 10.26 | 1.28 | 74.66 | 12.50 | 0.78 |

| 7.5 | 92.5 | 11.13 | 1.37 | 73.79 | 12.24 | 0.95 |

| 10 | 90 | 12.01 | 1.46 | 72.93 | 11.99 | 1.12 |

| Soda Crackers | Cookies | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C0 | C2.5 | C5 | C7.5 | C10 | C0 | C2.5 | C5 | C7.5 | C10 | ||

| Formulation | CRP (g) | 0 | 3.75 | 7.5 | 11.25 | 15 | 0 | 3.75 | 7.5 | 11.25 | 15 |

| Flour (g) | 150 | 146.25 | 142.5 | 138.75 | 135 | 150 | 146.25 | 142.5 | 138.75 | 135 | |

| Salt (g) | 2 | 1 | |||||||||

| Butter (g) | 30 | 100 | |||||||||

| Sugar (g) | - | 60 | |||||||||

| Yeast (g) | 3 | - | |||||||||

| Milk (g) | 60 | - | |||||||||

| Egg | - | 1 | |||||||||

| Baking soda (g) | 1 | - | |||||||||

| Key Process Parameters | Fermentation | 25 °C, 75% humidity, 30 min | - | ||||||||

| Refrigeration time (min) | - | 40 | |||||||||

| Baking Parameters | Top: 175 °C, Bottom: 155 °C, 20 min | Top: 175 °C, Bottom: 155 °C, 20 min | |||||||||

| Pasting Temperature (°C) | Peak Viscosity (rvu) | Peak Time (min) | Trough (rvu) | Final Viscosity (rvu) | Breakdown (rvu) | Setback (rvu) | |

|---|---|---|---|---|---|---|---|

| C0 | 80.63 ± 1.34 a | 376.46 ± 1.20 a | 7.20 ± 0.00 a | 359.95 ± 0.56 a | 429.25 ± 0.72 b | 16.51 ± 0.64 c | 69.31 ± 1.28 c |

| C2.5 | 80.80 ± 1.94 a | 361.49 ± 2.55 b | 7.20 ± 0.00 a | 349.83 ± 3.19 a | 411.39 ± 1.71 c | 11.67 ± 0.64 d | 61.57 ± 1.48 d |

| C5 | 77.68 ± 2.52 a | 355.09 ± 3.62 b | 7.12 ± 0.10 ab | 334.39 ± 3.74 b | 410.35 ± 3.51 c | 20.71 ± 0.12 b | 75.96 ± 0.23 b |

| C7.5 | 75.51 ± 2.07 a | 337.07 ± 2.87 c | 6.92 ± 0.18 b | 309.46 ± 1.12 c | 449.46 ± 0.68 a | 27.61 ± 1.75 a | 140.00 ± 0.44 a |

| C10 | 80.15 ± 3.22 a | 319.89 ± 2.00 d | 7.15 ± 0.09 ab | 305.13 ± 2.96 c | 444.59 ± 4.19 a | 14.77 ± 0.95 cd | 139.45 ± 1.22 a |

| Water Absorption (%) | Dough Development Time (min) | Stability Time (min) | Degree of Softening (FU) | Farinograph Quality Number | |

|---|---|---|---|---|---|

| C0 | 57.20 ± 0.10 d | 1.27 ± 0.12 a | 1.17 ± 0.06 b | 114.67 ± 7.64 b | 18.33 ± 0.58 b |

| C2.5 | 59.10 ± 0.30 c | 1.10 ± 0.10 a | 1.47 ± 0.15 a | 124.00 ± 5.57 b | 21.33 ± 3.21 b |

| C5 | 61.17 ± 0.21 b | 1.13 ± 0.15 a | 1.17 ± 0.12 b | 157.33 ± 4.51 a | 21.00 ± 2.00 b |

| C7.5 | 61.93 ± 0.25 b | 1.07 ± 0.15 a | 0.83 ± 0.06 c | 159.00 ± 1.00 a | 17.67 ± 0.58 b |

| C10 | 63.93 ± 0.71 a | 1.07 ± 0.15 a | 0.73 ± 0.06 c | 166.67 ± 5.51 a | 44.00 ± 3.46 a |

| Proofing Time (min) | Sample | Stretching Energy (cm2) | Extensibility (mm) | Stretching Resistance (BU) | Stretch Ratio |

|---|---|---|---|---|---|

| 45 | C0 | 43.00 ± 3.00 c | 121.67 ± 3.21 a | 265.00 ± 5.57 c | 2.17 ± 0.06 c |

| C2.5 | 59.33 ± 1.53 a | 111.00 ± 1.73 a | 390.33 ± 10.26 a | 3.50 ± 0.10 a | |

| C5 | 53.33 ± 4.93 ab | 129.67 ± 13.05 a | 304.00 ± 14.73 b | 2.37 ± 0.29 bc | |

| C7.5 | 48.33 ± 1.53 bc | 114.00 ± 11.36 a | 311.67 ± 9.07 b | 2.77 ± 0.32 b | |

| C10 | 50.33 ± 3.06 bc | 114.00 ± 2.00 a | 316.00 ± 17.00 b | 2.77 ± 0.15 b | |

| 90 | C0 | 46.67 ± 2.08 a | 107.33 ± 6.66 a | 334.33 ± 9.07 c | 3.13 ± 0.25 b |

| C2.5 | 53.67 ± 2.31 a | 99.00 ± 3.61 a | 410.33 ± 20.50 a | 4.13 ± 0.25 a | |

| C5 | 53.33 ± 2.52 a | 105.67 ± 6.66 a | 380.33 ± 11.55 ab | 3.60 ± 0.30 ab | |

| C7.5 | 51.33 ± 3.06 a | 104.67 ± 4.93 a | 361.33 ± 11.59 bc | 3.43 ± 0.06 ab | |

| C10 | 53.67 ± 3.06 a | 103.00 ± 5.29 a | 390.00 ± 11.27 ab | 3.80 ± 0.35 ab | |

| 135 | C0 | 49.33 ± 3.21 ab | 110.00 ± 4.36 a | 369.33 ± 25.54 ab | 3.37 ± 0.23 b |

| C2.5 | 57.33 ± 3.06 a | 98.67 ± 2.08 b | 413.67 ± 21.94 a | 4.40 ± 0.36 a | |

| C5 | 51.67 ± 2.52 ab | 104.33 ± 4.93 ab | 371.33 ± 20.65 ab | 3.57 ± 0.31 b | |

| C7.5 | 49.67 ± 5.03 ab | 99.67 ± 5.51 ab | 370.00 ± 18.03 ab | 3.70 ± 0.17 b | |

| C10 | 48.33 ± 2.08 b | 100.33 ± 2.89 ab | 350.33 ± 12.70 b | 3.50 ± 0.10 b |

| Sample | Expansion Ratio (%) | Peak Force (N) | Peak Distance (mm) | |

|---|---|---|---|---|

| Soda crackers | C0 | 1.89 ± 0.10 a | 24.38 ± 0.59 b | 39.11 ± 0.01 ab |

| C2.5 | 1.74 ± 0.02 ab | 25.47 ± 2.35 b | 38.38 ± 1.25 b | |

| C5 | 1.65 ± 0.02 b | 31.50 ± 0.78 a | 40.32 ± 0.34 a | |

| C7.5 | 1.49 ± 0.09 c | 32.97 ± 2.26 a | 39.54 ± 0.14 ab | |

| C10 | 1.41 ± 0.01 c | 31.70 ± 0.32 a | 40.46 ± 0.38 a | |

| Cookies | C0 | 1.26 ± 0.01 a | 3.70 ± 0.27 b | 11.69 ± 0.33 a |

| C2.5 | 1.21 ± 0.03 ab | 3.60 ± 0.04 b | 11.31 ± 0.98 ab | |

| C5 | 1.16 ± 0.05 bc | 4.25 ± 0.52 b | 10.21 ± 0.15 bc | |

| C7.5 | 1.13 ± 0.00 c | 4.40 ± 0.09 b | 10.19 ± 0.24 bc | |

| C10 | 1.09 ± 0.02 c | 5.38 ± 0.35 a | 9.47 ± 0.07 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Z.; Wang, J.; Ma, S.; An, J.; Shang, L.; Tao, Y.; Tian, C.; Deng, L. Sustainable Incorporation of Chlamydomonas reinhardtii Powder into Flour-Based Systems: Investigating Its Influence on Flour Pasting Properties, Dough Physical Properties, and Baked Product Quality. Foods 2025, 14, 3621. https://doi.org/10.3390/foods14213621

Yuan Z, Wang J, Ma S, An J, Shang L, Tao Y, Tian C, Deng L. Sustainable Incorporation of Chlamydomonas reinhardtii Powder into Flour-Based Systems: Investigating Its Influence on Flour Pasting Properties, Dough Physical Properties, and Baked Product Quality. Foods. 2025; 14(21):3621. https://doi.org/10.3390/foods14213621

Chicago/Turabian StyleYuan, Zhihe, Jiaojiao Wang, Shangyan Ma, Jianhui An, Longchen Shang, Yexing Tao, Cheng Tian, and Lingli Deng. 2025. "Sustainable Incorporation of Chlamydomonas reinhardtii Powder into Flour-Based Systems: Investigating Its Influence on Flour Pasting Properties, Dough Physical Properties, and Baked Product Quality" Foods 14, no. 21: 3621. https://doi.org/10.3390/foods14213621

APA StyleYuan, Z., Wang, J., Ma, S., An, J., Shang, L., Tao, Y., Tian, C., & Deng, L. (2025). Sustainable Incorporation of Chlamydomonas reinhardtii Powder into Flour-Based Systems: Investigating Its Influence on Flour Pasting Properties, Dough Physical Properties, and Baked Product Quality. Foods, 14(21), 3621. https://doi.org/10.3390/foods14213621