Prediction of Storage Quality and Multi-Objective Optimization of Storage Conditions for Fresh Lycium barbarum L. Based on Optimized Latin Hypercube Sampling

Abstract

1. Introduction

- (i)

- To study the effect patterns of storage time, storage temperature, and fruit initial maturity on the hardness, SSC, TA, and Vc of fresh Lycium barbarum L. Miller during storage.

- (ii)

- Using Latin hypercube sampling to develop neural networks, models based on radial basis function neural networks (RBFNNs) and Elman neural networks (ELMANs) were established to predict the quality characteristics of fresh Lycium barbarum L. based on storage environments. During the training of the neural networks, Latin hypercube sampling was employed to automatically identify the optimal hyperparameters of the neural networks, allowing for the analysis and comparison of the predictive accuracy of each model.

- (iii)

- Based on the constructed predictive model, the contribution values of storage temperature parameters, storage time parameters, and fruit initial maturity parameters to hardness, soluble solid content (SSC), titratable acidity (TA), and vitamin C (Vc) content were analyzed.

- (iv)

- Using the Particle Swarm Optimization (PSO) algorithm, the constructed predictive model was optimized for the values of hardness, soluble solid content (SSC), titratable acidity (TA), and vitamin C (Vc), as well as the storage condition parameters. This resulted in the determination of the optimal storage temperature and initial maturity parameter values suitable for the specified storage duration.

2. Materials and Methods

2.1. Materials

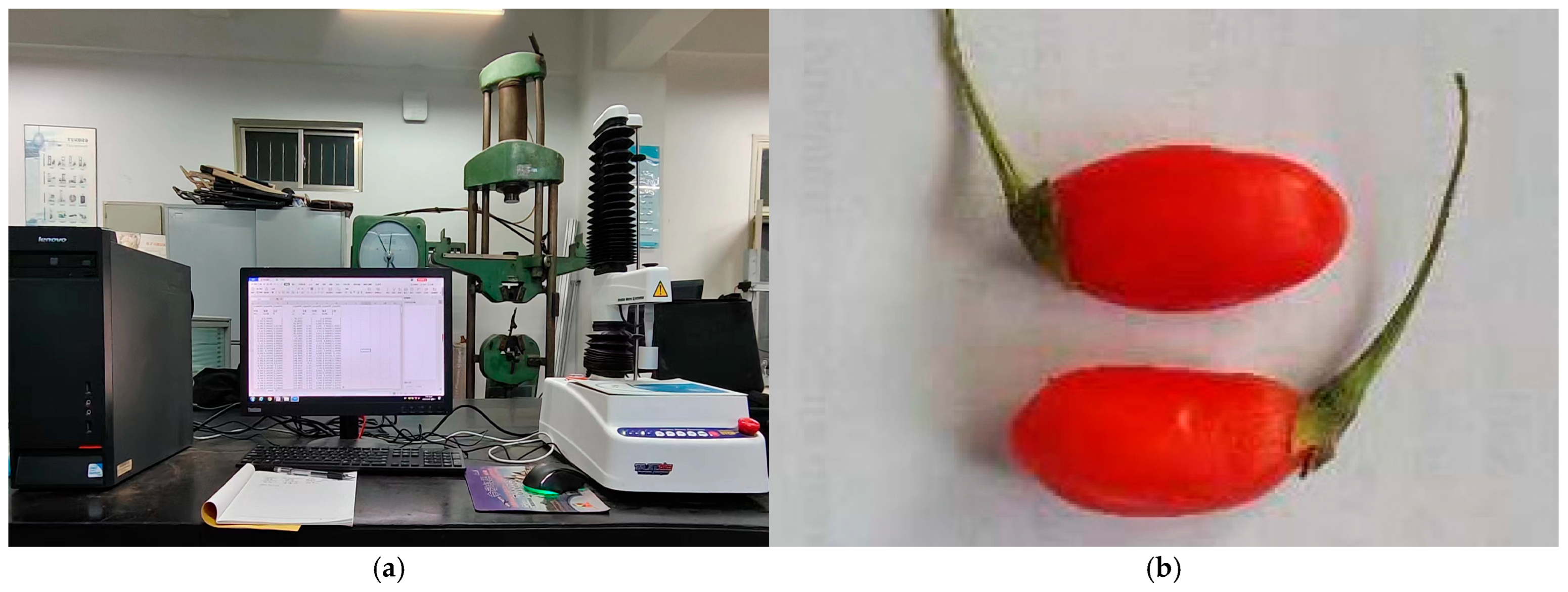

2.1.1. Sample Selection and Determination of Initial Indicators

2.1.2. Determination of Goji Berry Initial Maturity

2.2. Methods

2.2.1. Determination of Hardness

2.2.2. Determination of SSC

2.2.3. Determination of TA

2.2.4. Determination of Vc

2.2.5. Statistical Analysis

2.3. Model Method

2.3.1. Design of Optimized Latin Hypercube Experimental Scheme (OLHS)

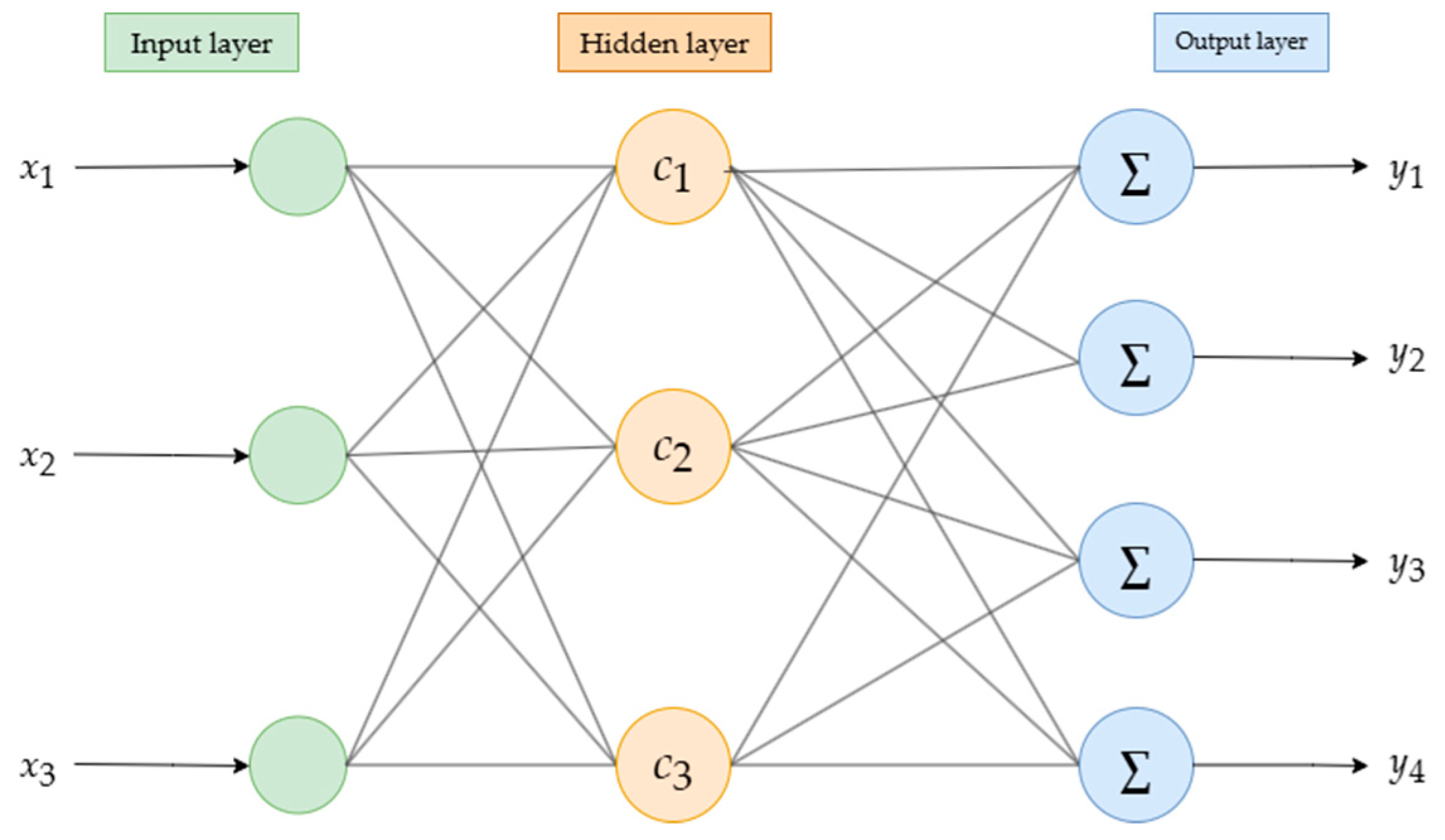

2.3.2. RBF Neural Network (RBFNN)

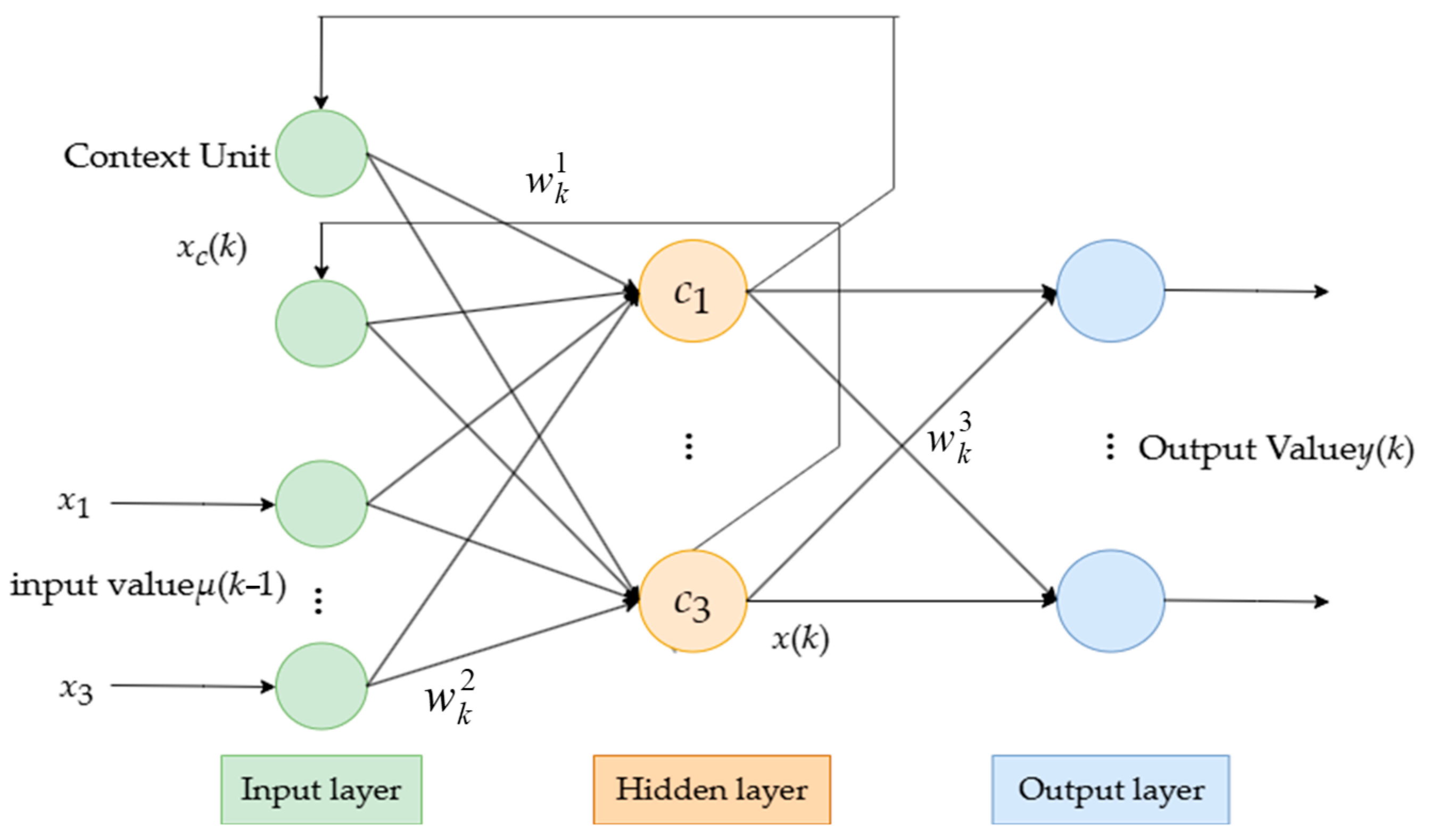

2.3.3. Elman Neural Network (ELMAN)

2.3.4. Determination of the Optimal Prediction Model

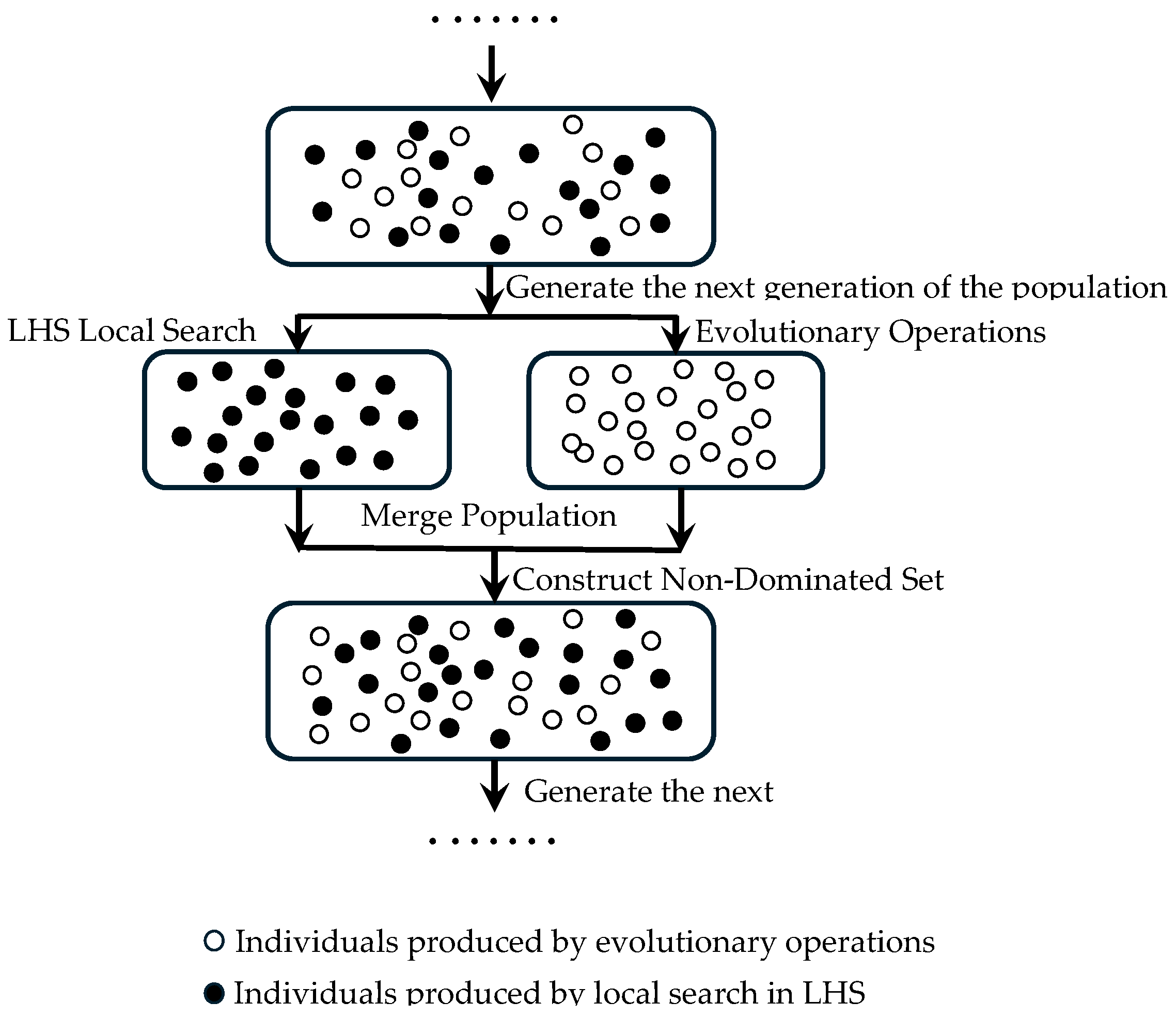

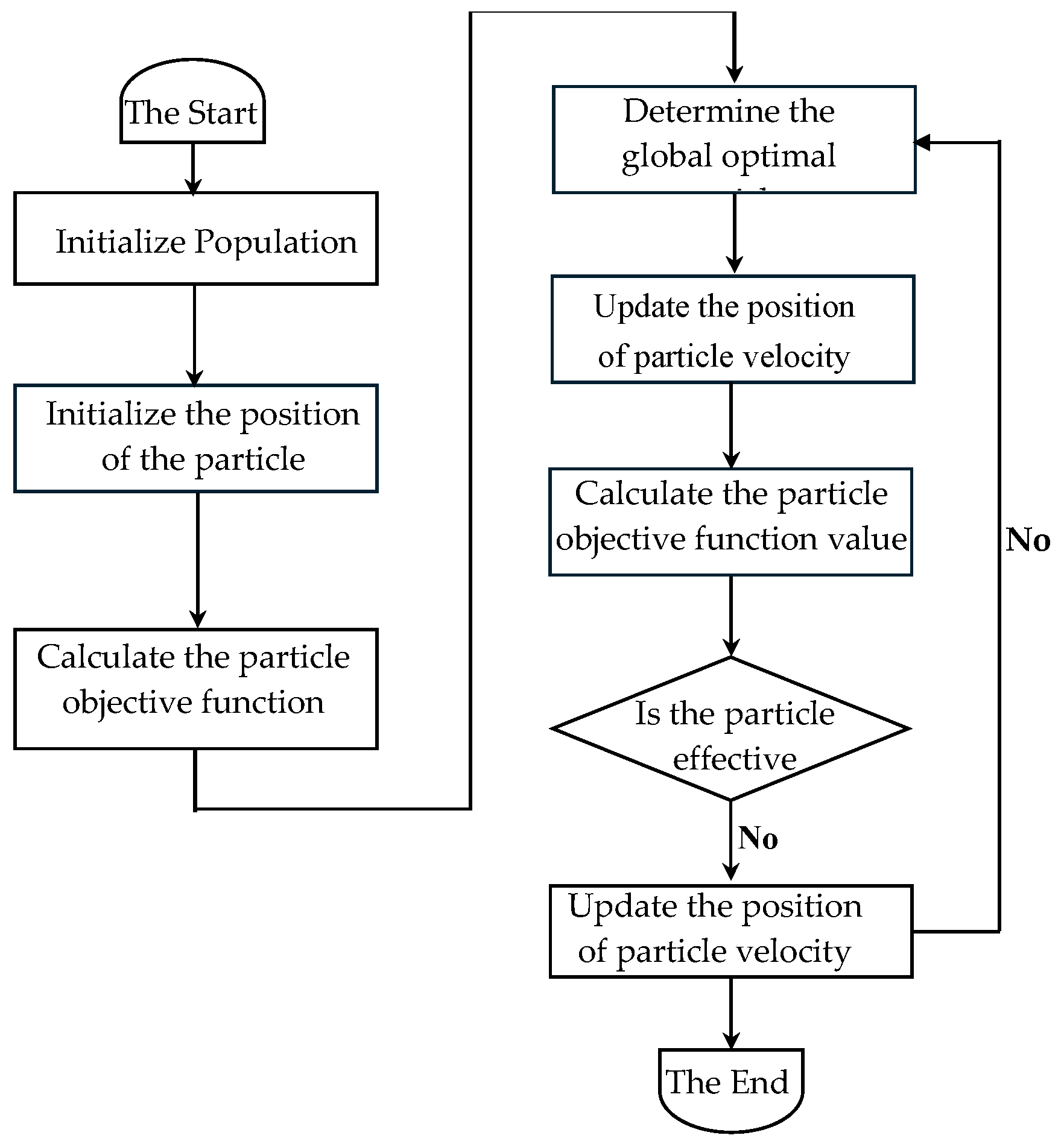

2.3.5. Particle Swarm Optimization

3. Results

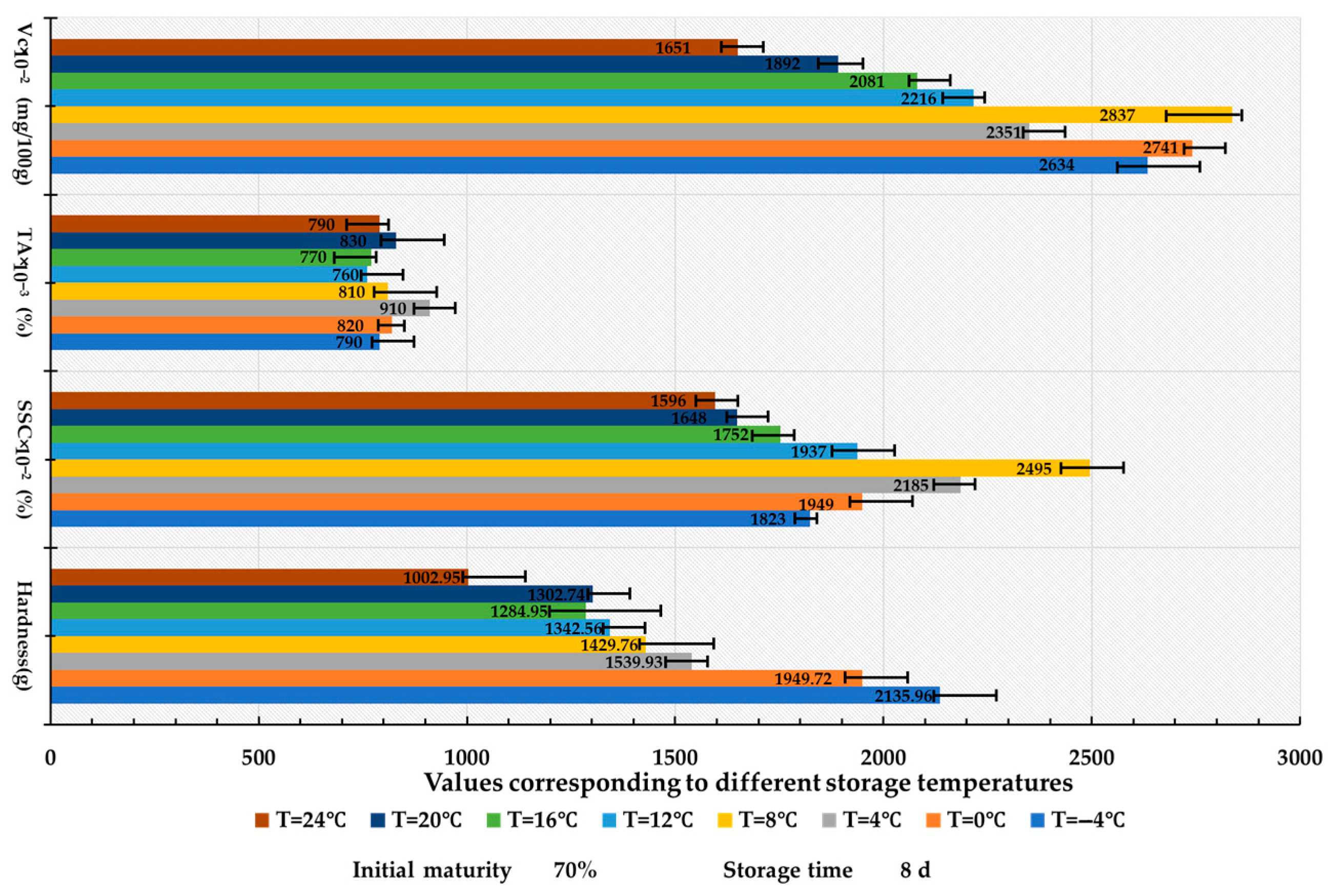

3.1. The Effect of Different Storage Temperatures on the Quality Characteristics of Lycium barbarum L.

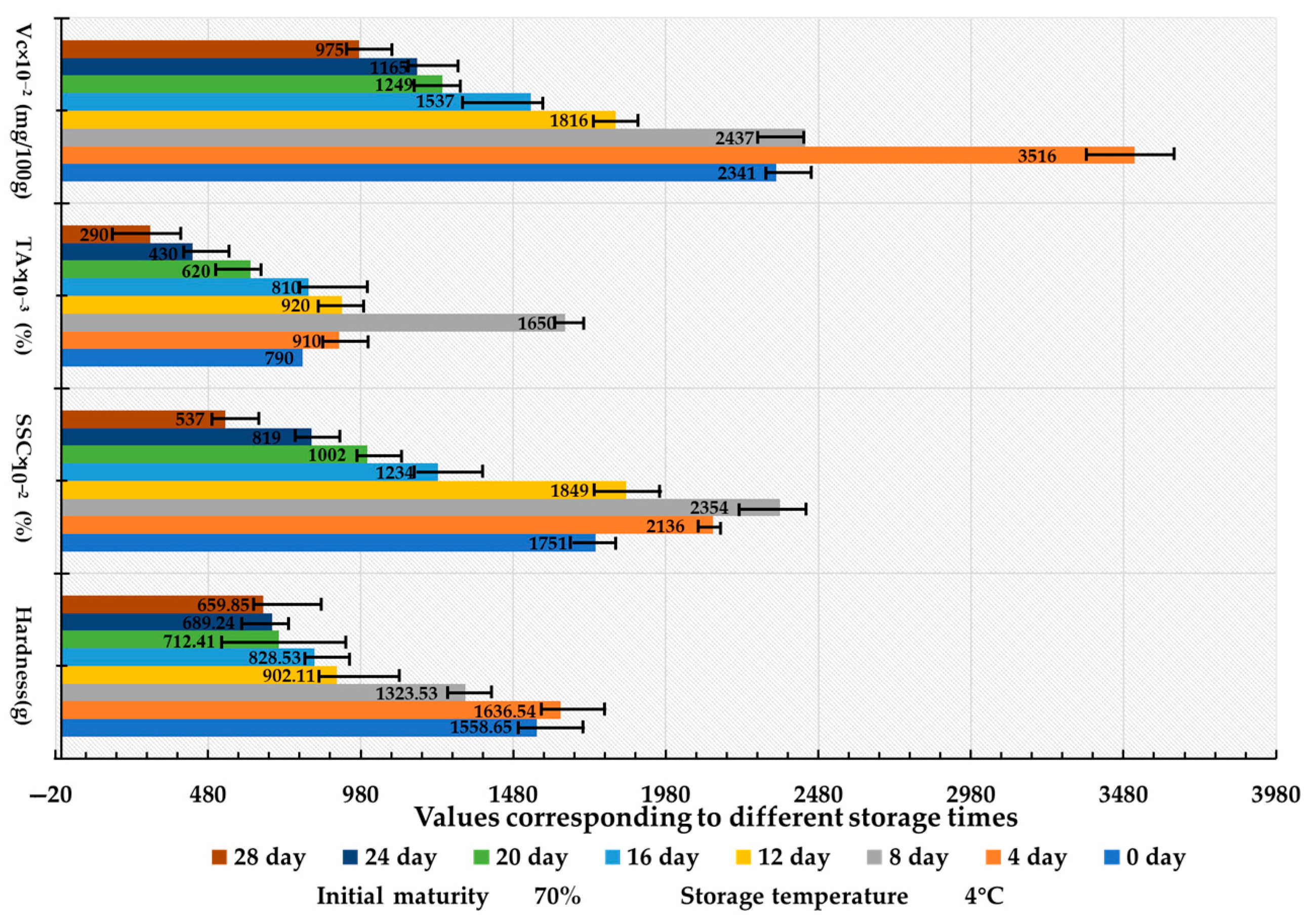

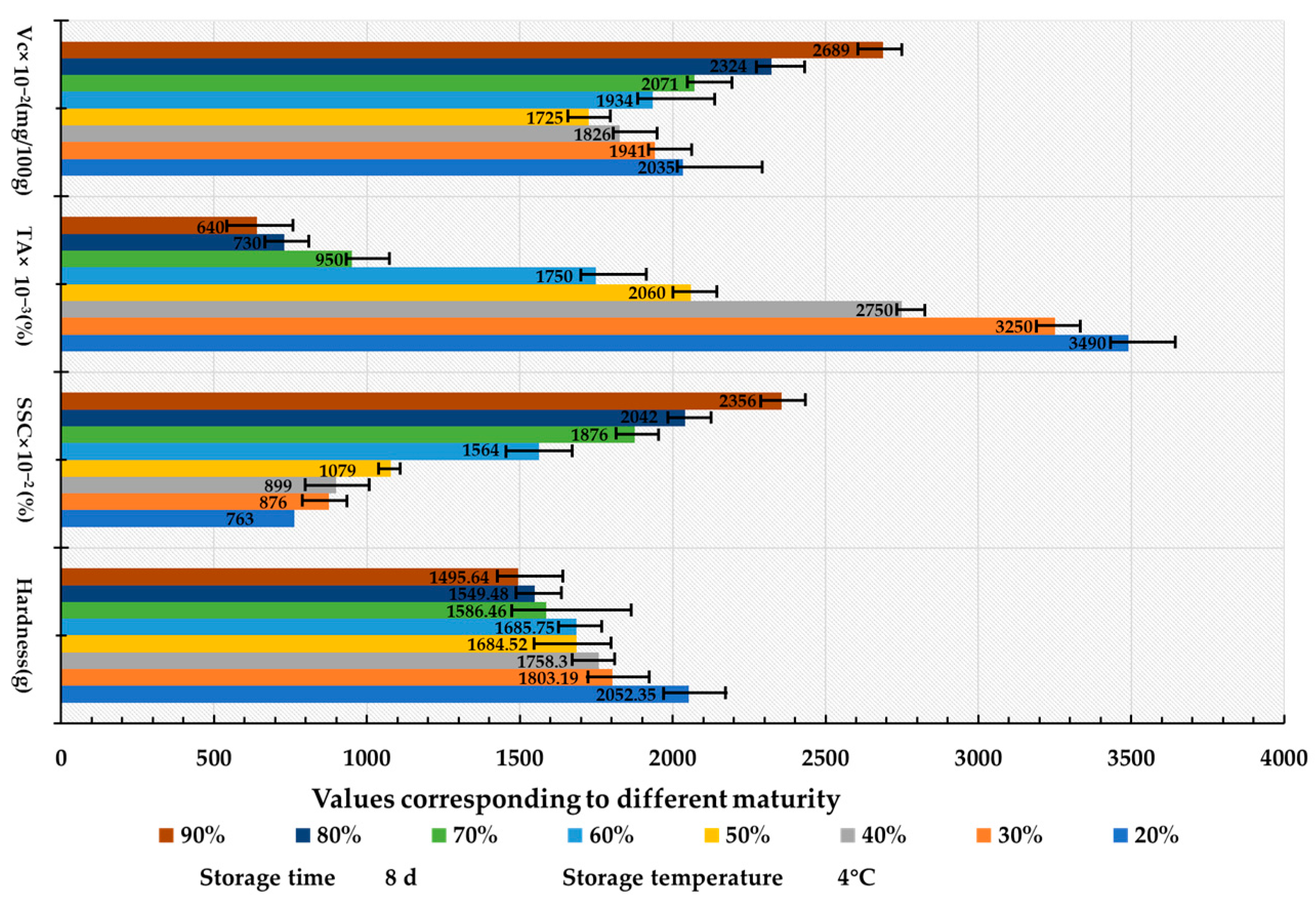

3.2. The Effect of Different Storage Durations on the Quality Characteristics of Lycium barbarum L.

3.3. The Effect of Different Initial Maturity on the Quality Characteristics of Lycium barbarum L.

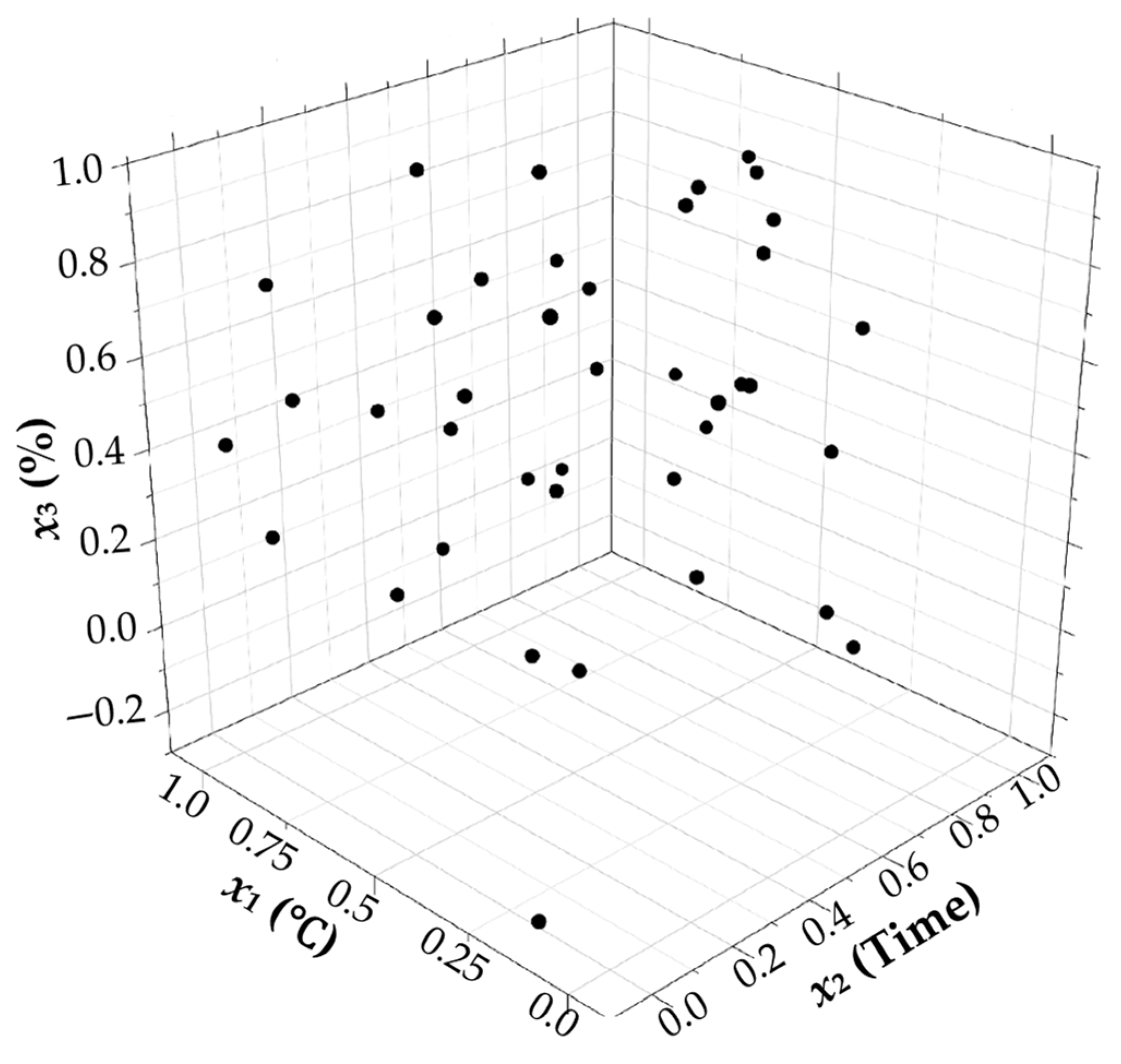

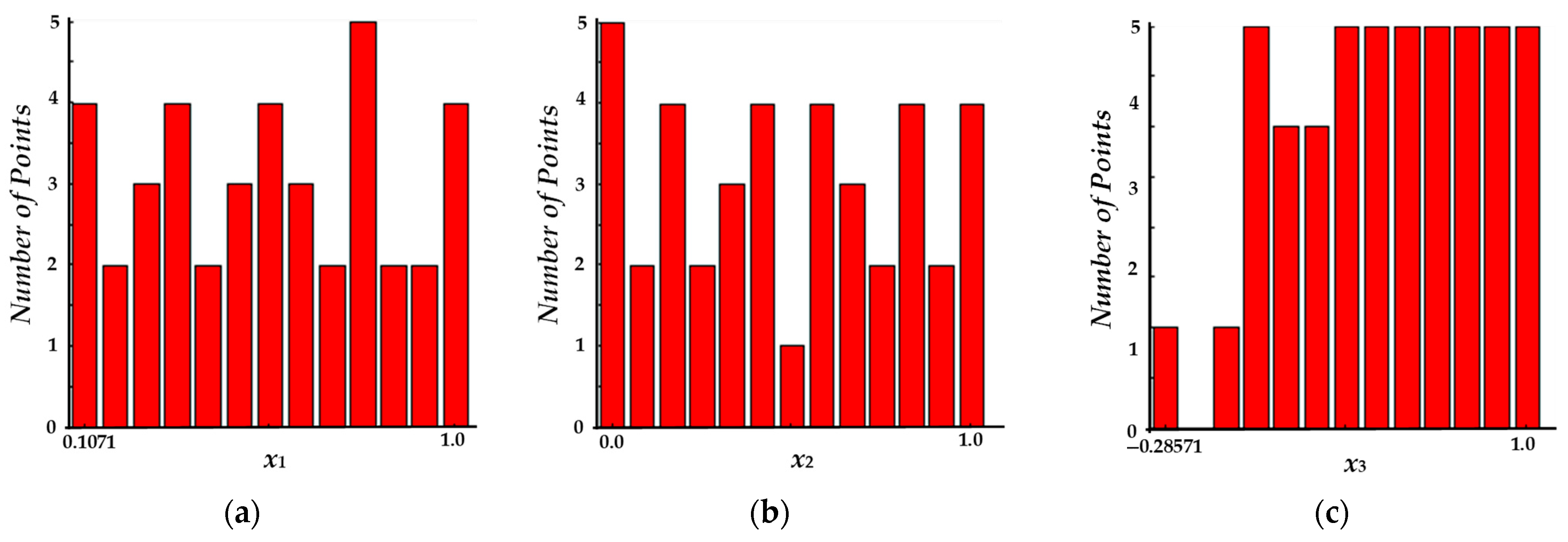

3.4. Optimized Latin Hypercube Sampling Experimental Design (OLHS)

3.4.1. Uniformity of Latin Hypercube Sampling

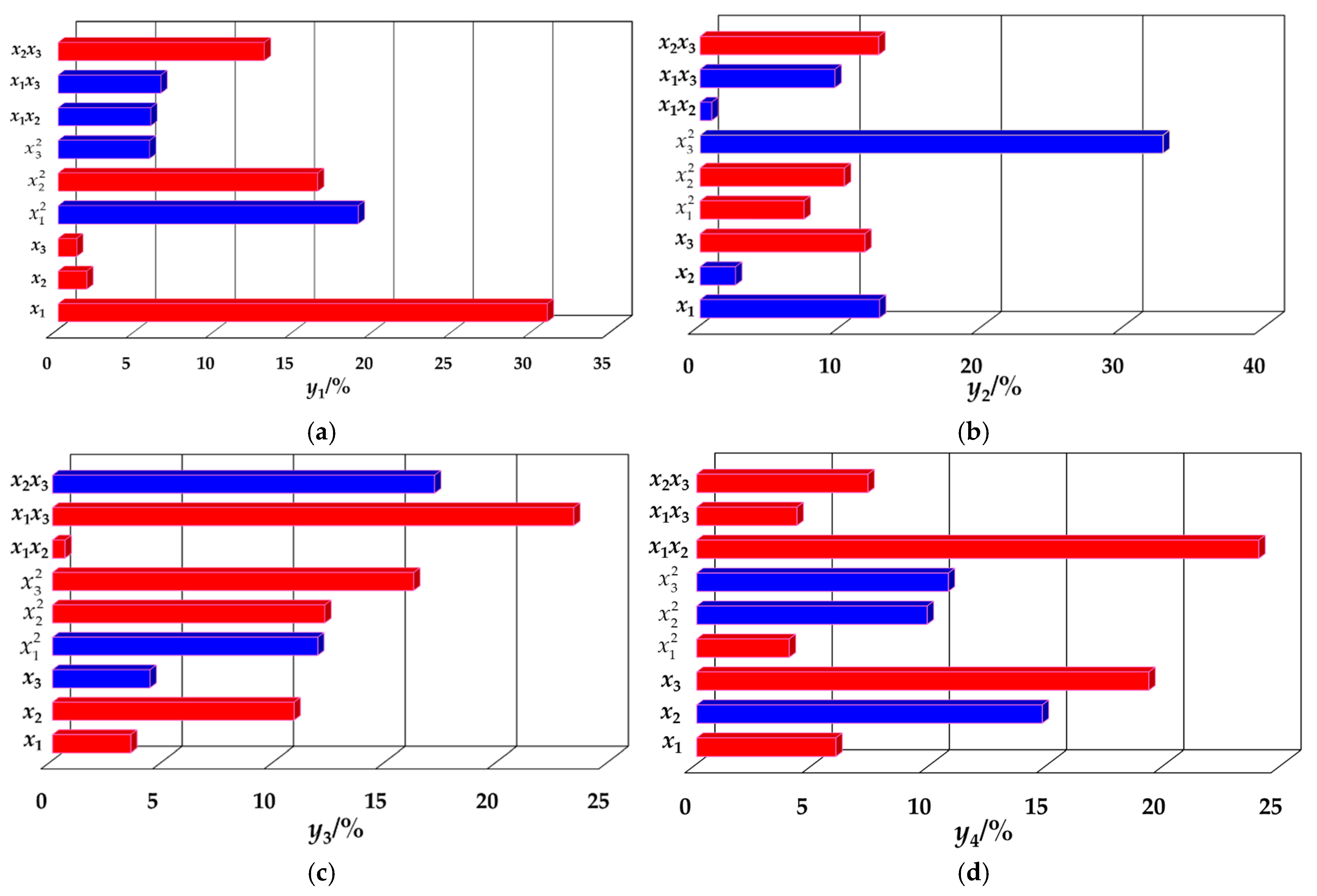

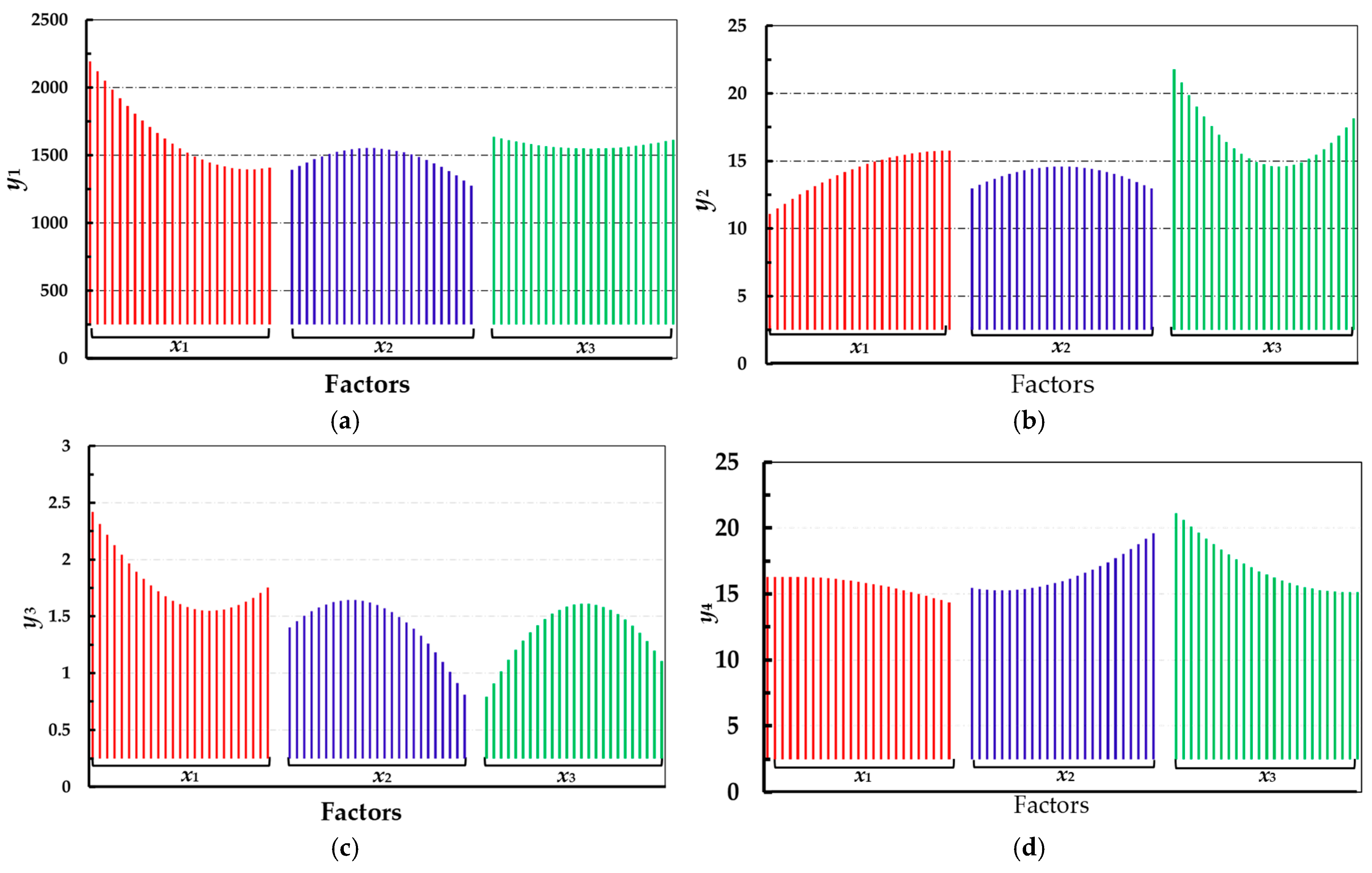

3.4.2. The Influence of Various Factors on Quality Indicators

3.4.3. The Correlation Between Storage Environment and the Quality Characteristics of Lycium barbarum L.

3.5. Goji Berry Quality Indicator Prediction Model

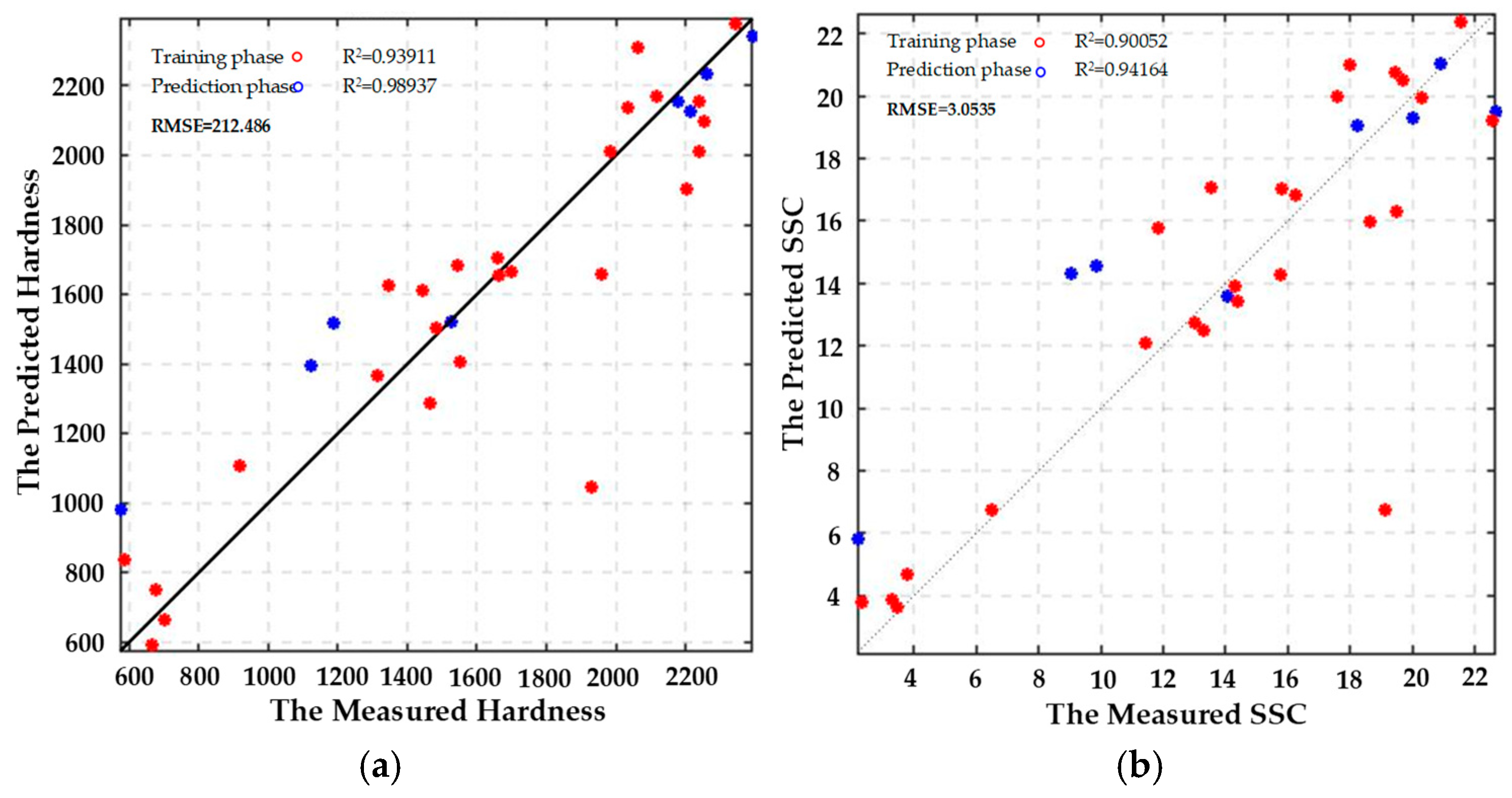

3.5.1. Prediction of Goji Berry Quality Characteristics Based on the RBFNN Regression Prediction Model

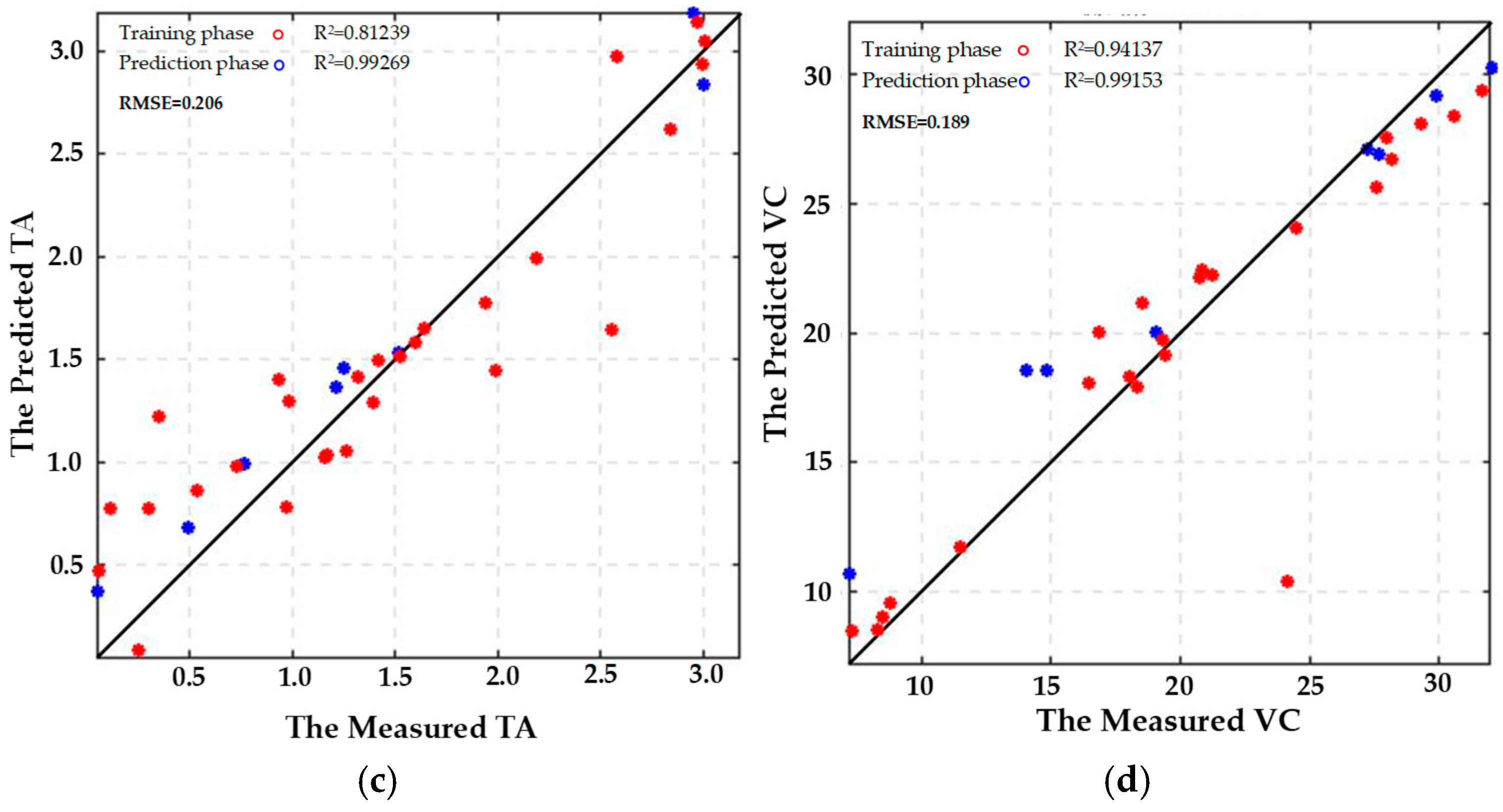

3.5.2. Prediction of Goji Berry Quality Characteristics Based on the ELMAN Regression Prediction Model

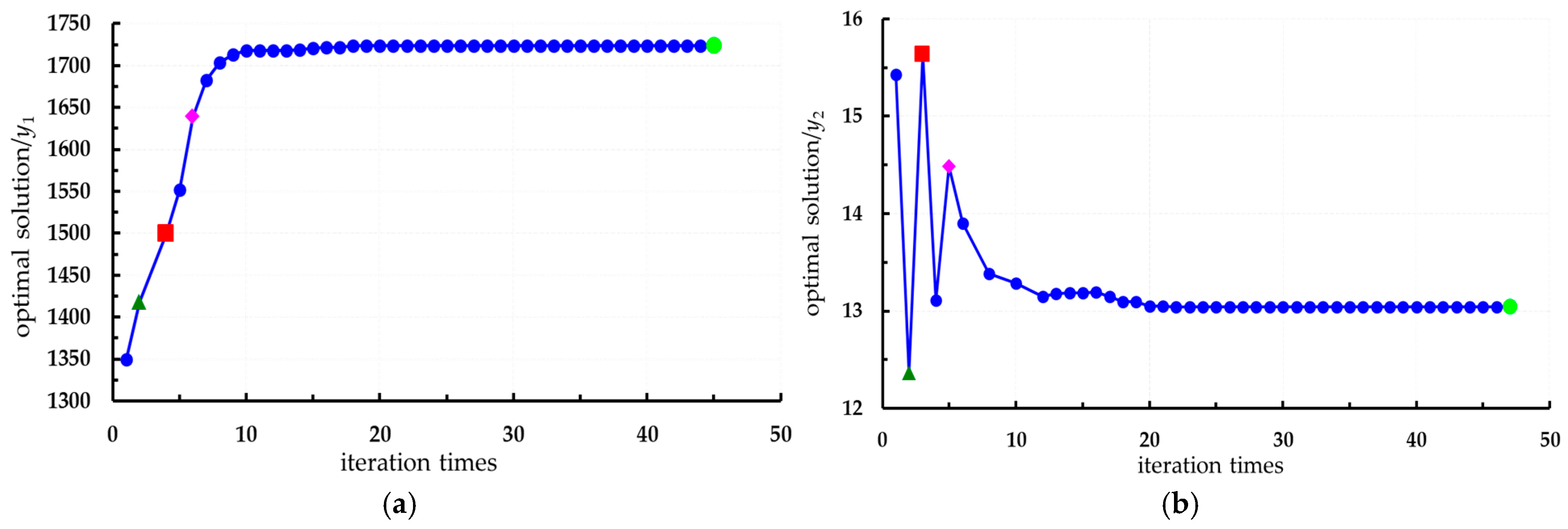

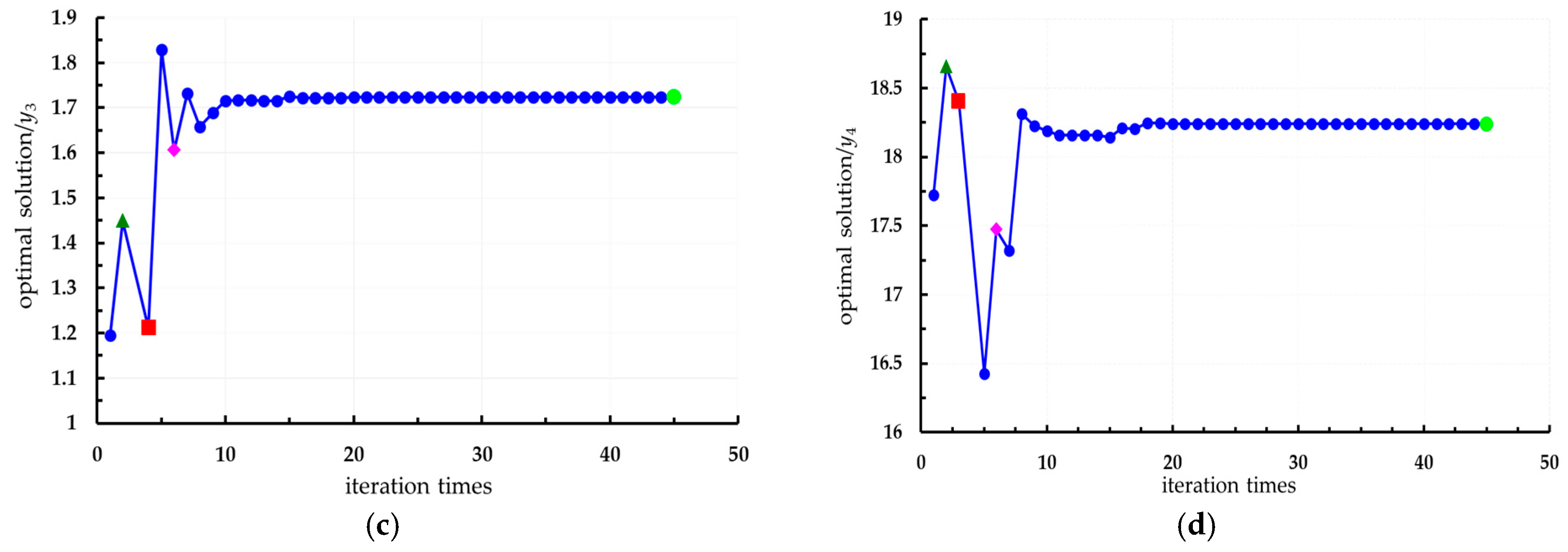

4. Multi-Objective Optimization and Experimental Verification

4.1. Construction and Solution of the Objective Function

4.2. Experimental Verification

5. Conclusions

- (1)

- This study systematically elucidates the differential effects of temperature, duration, and initial maturity on the storage quality of fresh Lycium barbarum L. The findings indicated that storage temperature significantly influenced fruit hardness (contributing up to 30.8%), (SSC), and Vc content, while exerting a comparatively minor effect on TA. Additionally, storage duration exhibited a characteristic trend of initially increasing and then decreasing SSC, TA, and Vc contents, whereas hardness consistently decreased with extended storage time. Notably, harvest initial maturity exerted the most significant regulatory effect on TA and SSC contents, contributing 19.28%, while its effects on hardness and Vc contents were relatively limited.

- (2)

- This study established a comprehensive analytical framework. An optimal Latin hypercube experimental design was employed to ensure uniform distribution of sampling points within the multidimensional parameter space. Utilizing the Pareto analysis method, we quantified, for the first time, the contribution of each storage condition to the quality indices, revealing that x1 had the most significant impact on hardness, while x3 contributed the most to Vc. Additionally, we innovatively developed a radial basis RBFNN prediction model, which demonstrated a marked improvement in prediction accuracy compared to ELMAN, achieving a 35% reduction in error, particularly in hardness prediction.

- (3)

- Through the application of the PSO algorithm for multi-objective optimization, the optimal combination of storage parameters was determined: a storage temperature of 10 °C, a storage time of 20 days, and a harvest initial maturity of ≥60%. Under these optimized conditions, the quality indices of fresh Lycium barbarum L. reached an optimal balance: hardness was measured at 15.01 N, SSC was 17.5%, TA was 1.22%, and Vc content was 18.5 mg/100 g.

- (4)

- The whole-chain analysis framework of “experimental design-machine learning-intelligent optimization” established in this study not only offers a scientific decision-making method for the preservation of fresh Lycium barbarum L., but also provides a technical pathway for quality control research of other distinctive agricultural products. Nonetheless, the analytical process is limited by challenges such as product homogenization, extreme storage conditions (e.g., temperatures exceeding 12 °C or initial maturity levels surpassing 80%), and insufficient integration of biological mechanisms. To enhance the model’s accuracy, we will incorporate mechanistic models (e.g., the Michaelis–Menten equation) to develop a hybrid model, broaden the variety of samples, and increase the volume of real-time monitoring data from near-infrared spectroscopy in future research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chinese Pharmacopocia Commissiom. Chinese Pharmacopocia, Beijing, China; Medical Science and Technology Press: Hong Kong, China, 2015; Volume 67. [Google Scholar]

- Sun, W.; Shahrajabian, M.H.; Cheng, Q. Health benefits of wolfberry (Gou Qi Zi, Fructus barbarum L.) on the basis of ancient Chineseherbalism and Western modern medicine. Avicenna J. Phytomed 2021, 11, 109–119. [Google Scholar]

- Emamgholizadeh, S.; Parsaeian, M.; Baradaran, M. Seed yield prediction of sesame using artificial neural network. Eur. J. Agron. 2015, 68, 89–96. [Google Scholar] [CrossRef]

- Torkashvand, A.M.; Ahmadi, A.; Nikravesh, N.L. Prediction of kiwifruit firmness using fruit mineral nutrient concentration by artificial neural network (ANN) and multiple linear regressions (MLR). J. Integr. Agric. 2017, 16, 1634–1644. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, C.; Wu, C.; Kou, X.; Xue, Z. Storage quality prediction of winter jujube based on particle swarm optimization-backpropagation-artificial neural network (PSO-BP-ANN). Sci. Hortic. 2024, 331, 112789. [Google Scholar] [CrossRef]

- Xing, W.; Liu, W.; Li, H.; Zeng, X.; Fan, X.; Xing, S.; Gong, H. Development of predictive models for shelf-life of sweet cherry under different storage temperatures. LWT 2025, 215, 117442. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, D.; Ren, X.; Shen, Y.; Cao, X.; Liu, H.; Li, J. Quality changes and shelf-life prediction model of postharvest apples using partial least squares and artificial neural network analysis. Food Chem. 2022, 394, 133526. [Google Scholar] [CrossRef]

- Niazian, M.; Sadat-Noori, S.A.; Abdipour, M. Modeling the seed yield of Ajowan (Trachyspermum ammi L.) using artificial neural network and multiple linear regression models. Ind. Crop. Prod. 2018, 117, 224–234. [Google Scholar] [CrossRef]

- Mohammed, M.; Munir, M.; Aljabr, A. Prediction of Date Fruit Quality Attributes during Cold Storage Based on Their Electrical Properties Using Artificial Neural Networks Models. Foods 2022, 11, 1666. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Chen, T.; Zhou, P.; Huang, X.; Liu, D.; Jin, W.; Zhang, H.; Zhou, J.; Wang, Z.; Gao, Z. Prediction and optimization of fruit quality of peach based on artificial neural network. J. Food Compos. Anal. 2022, 11, 104604. [Google Scholar] [CrossRef]

- Tracey, J.; Zhu, J.; Crooks, K.R. Modeling and inference of animal movement using artificial neural networks. Environ. Ecol. Stat. 2011, 18, 393–410. [Google Scholar] [CrossRef]

- Lan, H.; Wang, Z.; Niu, H.; Zhang, H.; Zhang, Y.; Tang, Y.; Liu, Y. A nondestructive testing method for soluble solid content in Korla fragrant pears based on electrical properties and artificial neural network. Food Sci. Nutr. 2020, 8, 5172–5181. [Google Scholar] [CrossRef]

- Sanad Alsbu, R.A.; Yarlagadda, P.; Karim, A. An Empirical Model for Predicting the Fresh Food Quality Changes during Storage. Foods 2023, 12, 2113. [Google Scholar] [CrossRef] [PubMed]

- Bajd, F.; Škrlep, M.; Čandek-Potokar, M.; Serša, I. MRI-aided texture analyses of compressed meat products. J. Food Eng. 2017, 207, 108–118. [Google Scholar] [CrossRef]

- Owoyemi, A.; Balaklav, M.; Kochanek, B.; Porat, R.; Koenigstein, N.; Salzer, Y.; Lichter, A. Deviations from optimal storage temperature and its impact on postharvest quality of table grape cv. Scarlotta Seedless. Postharvest Biol. Technol. 2024, 215, 113013. [Google Scholar] [CrossRef]

- Lin, F.; Chen, D.; Liu, C.; He, J. Non-Destructive Detection of Golden Passion Fruit Quality Based on Dielectric Characteristics. J. Appl. Sci. 2024, 14, 2200. [Google Scholar] [CrossRef]

- Jakhar, V.; Baswal, A.K.; Gupta, A.; Gill, K.S.; Ozturk, B. Impact of Post-harvest Application of Methyl Salicylate and Salicylic Acid on Storage Life and Quality of ‘Kinnow’ Mandarin (Citrus nobilis Lour × C. deliciosa Tenora) Fruit Under Ambient Storage Conditions. Erwerbs-Obstbau 2023, 65, 2517–2526. [Google Scholar] [CrossRef]

- Andrea, C.G.S.; Angel, G.; Mari, I.G. Comparative study of six pear cultivars in terms of their phenolic and vitamin C contents and antioxidant capacity. J. Sci. Food Agric. 2003, 83, 995–1003. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, W.; Jiang, Y.; Bao, A.; Tong, W.; Wang, B. Effects of different harvesting periods on the storage quality and senescence of apple at room temperature. Trans. CSAE 2020, 36, 300–306. [Google Scholar]

- GB 5009.86-2016; National Food Safety Standard—Determination of ascorbic acid in foods. Standards Press of China: Beijing, China, 2016.

- Zeng, X.; Zhen, Z.; He, J.; Han, L. A feature selection approach based on sensitivity of RBFNNs. Neurocomputing 2018, 275, 2200–2208. [Google Scholar] [CrossRef]

- Hu, Y.; You, J.; Liu, J.; He, T. An eigenvector based center selection for fast training scheme of RBFNN. Inf. Sci. 2018, 428, 62–75. [Google Scholar] [CrossRef]

- Moore, J.; Chapman, R. Application of Particle Swarm to Multiobjective Optimization; Technical Report; Departament of Computer Science and Software Engineering, Auburn University: Auburn, AL, USA, 1999. [Google Scholar]

- Coello Coello, C.A.; Lecsuga, M.S. MOPSO: A proposal for multiple objective particle swarm optimization. In Proceedings of the IEEE Congress on Evolutionary Computation, Honolulu, HI, USA, 12–17 May 2002; pp. 1051–1056. [Google Scholar]

- Dai, C.; Wang, Y.; Ye, M. A new multi-objective particle swarm optimization algorithm based on decomposition. Inf. Sci. 2015, 325, 541–557. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, X.; Cheng, R.; Qiu, J.; Jin, Y. A competitive mechanism based multi-objective particle swarm optimizer with fast convergence. Inf. Sci. 2018, 427, 63–76. [Google Scholar] [CrossRef]

- He, C.; Li, M.; Zhang, C.; Chen, H.; Li, X.; Li, J. A competitive swarm optimizer with probabilistic criteria for many-objective optimization problems. Complex Intell. Syst. 2022, 8, 4697–4725. [Google Scholar] [CrossRef]

- Durillo, J.J.; García-Nieto, J.; Nebro, A.J.; Coello, C.A.C.; Luna, F.; Alba, E. Multi-objective particle swarm optimizers: An experimental comparison. In Proceedings of the 5th International Conference on Evolutionary MultiCriterion Optimization, Nantes, France, 7–10 April 2009; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Nebro, A.J.; Durillo, J.J.; Garcia Nieto, J.; Coello Coello, C.A.; Luna, F.; Alba, E. SMPSO: A new PSO-based metaheuristic for multiobjective optimization. In Proceedings of the IEEE Symposium on Computational Intelligence in Miulti-Criteria Decision-Making, Nashville, TN, USA, 30 March–2 April 2009; pp. 66–73. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Zitzler, E.; Laumanns, M.; Thiele, L. SPEA2: Improving the Strength Pareto Evolutionary Algorithm; TIK-Report No. 103; ETH Zurich: Zurich, Switzerland, 2001. [Google Scholar]

- Nebro, A.J.; Durillo, J.J.; Luna, F.; Dorronsoro, B.; Alba, E. Design issues in a multiobjective cellular genetic algorithm. In Proceedings of the Evolutionary Multi-Criterion Optimization, 4th International Conference, EMO 2007, Matsushima, Japan, 5–8 March 2007; Lecture Notes in Computer Science. Obayashi, S., Deb, K., Poloni, C., Hiroyasu, T., Murata, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; Volume 4403, pp. 126–140. [Google Scholar]

- Reyes Sierra, M.; Coello Coello, C.A. Improving PSO-Based Multi-Objective Optimization Using Crowding, Mutation and ε-Dominance. In Proceedings of the Evolutionary Multi-Criterion Optimization: Third International Conference, EMO 2005, Guanajuato, Mexico, 9–11 March 2005; Coello Coello, C.A., Hernández Aguirre, A., Zitzler, E., Eds.; Lecture Notes in Computer Science, Vol. 3410. Springer: Berlin/Heidelberg, Germany, 2005; pp. 505–519. [Google Scholar] [CrossRef]

- Zolfaghari, M.; Sahari, M.A.; Barzegar, M.; Samadloiy, H. Physicochemical and enzymatic properties of five kiwifruit cultivars during cold storage. Food Bioprocess Technol. 2008, 3, 239–246. [Google Scholar] [CrossRef]

- Da, Y.; Li, D.; Xu, W.; Fu, W.; Liao, R.; Shi, J.; Wang, J. Effects of packaging design with dual function films on quality of wax apples stored at ambient temperatures. Food Bioprocess Technol. 2018, 11, 1904–1910. [Google Scholar] [CrossRef]

- Davey, M.W.; Van Montagu, M.; Inze, D.; Sanmartin, M.; Kanellis, A.K.; Smirnoff, N.; Benzie, J.; Strain, J.; Favell, D.; Fletcher, J.M. Plant L-ascorbic acid: Chemistry, function, metabolism, bioavailability and effects of processing. J. Sci. Food Agric. 2020, 80, 825–860. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Li, M.; Chen, Y.; Li, W.; Zhou, L.; Sun, X.; Wang, C.; Chen, X. Dynamics of Organic Acids in Goji Berry (Lycium barbarum L.) During Postharvest Storage. Food Chem. 2022, 396, 133215. [Google Scholar]

- Zhang, R.; Liu, Y.; Zhao, X.; Zhang, Y.; Zhou, X.; Sun, X.; Wang, C.; Chen, X. Starch degradation enzymes in relation to soluble sugars accumulation during goji berry ripening. Postharvest Biol. Technol. 2023, 201, 112345. [Google Scholar]

- Wang, Y.; Zhao, X.; Liu, Y.; Zhang, W.; Zhang, R.; Hu, P.; Wang, W.; Li, Y.; Zhang, R. Anthocyanin accumulation and molecular analysis of correlated genes in Lycium ruthenicum Murray. Acta Physiol. Plant. 2018, 40, 359. [Google Scholar]

- Zang, Z.; Huang, X.; He, C.; Zhang, Q.; Jiang, C.; Wan, F. Improving Drying Characteristics and Physicochemical Quality of Angelica sinensis by Novel Tray Rotation Microwave Vacuum Drying. Foods 2023, 12, 1202. [Google Scholar] [CrossRef] [PubMed]

- Zang, Z.; Huang, X.; Ma, G.; Zhang, Q.; Jiang, C. Evaluation of drying characteristics and physicochemical properties of Angelicae sinensis Radix under different drying methods based on combination entropy weight and variable coefficient method. Chin. Tradit. Herb. Drugs 2022, 53, 7403–7413. [Google Scholar]

- Zang, Z.; Wan, F.; Ma, G.; Xu, Y.; Wu, B.; Huang, X. Effect of ultrasound combined with chemical pretreatment as an innovative non-thermal technology on the drying process, quality properties and texture of cherry subjected to radio frequency vacuum drying. Ultrason. Sonochemistry 2024, 108, 106980. [Google Scholar] [CrossRef] [PubMed]

| Input Factors | Storage Temperature (°C) | Storage Time (Days) | Initial Maturity (%) |

|---|---|---|---|

| Value range | −4 to 24 | 0 to 28 | 20 to 90 |

| Serial Number | Influencing Factors | Quality Indicators | |||||

|---|---|---|---|---|---|---|---|

| x1 | x2 | x3 | y1 | y2 | y3 | y4 | |

| Hardness (N) | SSC (%) | TA (%) | Vc (mg/100 g) | ||||

| 1 | 0.66 | 0.51 | 0.18 | 14.08 | 6.25 | 1.76 | 22.23 |

| 2 | 0.68 | 0.62 | 0.49 | 12.56 | 10.36 | 2.34 | 15.34 |

| 3 | 0.27 | 0.13 | 0.15 | 19.76 | 9.12 | 4.12 | 17.36 |

| 4 | 0.91 | 0.85 | 0.36 | 13.30 | 8.45 | 2.19 | 16.28 |

| 5 | 0.77 | 0.03 | 0.23 | 22.15 | 16.59 | 0.82 | 18.25 |

| 6 | 0.31 | 0.28 | 0.97 | 11.13 | 20.16 | 0.98 | 22.16 |

| 7 | 0.63 | 0.69 | 0.82 | 9.67 | 19.26 | 0.71 | 17.52 |

| 8 | 0.50 | 1.00 | 0.85 | 9.84 | 6.15 | 0.75 | 12.35 |

| 9 | 0.20 | 0.92 | 0.77 | 14.28 | 14.61 | 0.49 | 26.42 |

| 10 | 0.79 | 0.77 | 0.05 | 18.33 | 12.34 | 0.95 | 14.65 |

| 11 | 0.29 | 0.97 | 0.31 | 20.94 | 5.36 | 1.03 | 21.35 |

| 12 | 0.70 | 0.95 | 0.59 | 15.06 | 10.57 | 1.26 | 18.46 |

| 13 | 0.95 | 0.64 | 0.64 | 12.12 | 14.46 | 1.09 | 14.52 |

| 14 | 0.22 | 0.08 | 0.74 | 18.59 | 15.26 | 0.42 | 16.79 |

| 15 | 0.11 | 0.44 | 0.26 | 24.21 | 5.43 | 3.43 | 9.36 |

| 16 | 0.75 | 0.36 | 0.69 | 14.31 | 11.52 | 1.12 | 12.52 |

| 17 | 0.13 | 0.41 | 0.72 | 22.03 | 16.85 | 0.36 | 19.56 |

| 18 | 0.47 | 0.77 | 0.00 | 16.26 | 14.36 | 2.42 | 11.54 |

| 19 | 0.84 | 0.33 | 0.38 | 15.53 | 13.42 | 1.34 | 17.56 |

| 20 | 0.24 | 0.23 | 0.46 | 18.40 | 12.46 | 0.97 | 17.42 |

| 21 | 0.79 | 0.10 | 0.90 | 14.02 | 21.35 | 1.52 | 21.52 |

| 22 | 0.98 | 0.56 | 0.21 | 11.30 | 17.42 | 1.03 | 13.26 |

| 23 | 0.43 | 0.82 | 0.56 | 17.60 | 19.54 | 1.52 | 16.52 |

| 24 | 0.38 | 0.59 | 0.33 | 18.00 | 11.26 | 1.95 | 14.26 |

| 25 | 0.15 | 0.72 | 0.51 | 19.46 | 15.62 | 2.75 | 21.36 |

| 26 | 0.40 | 0.49 | 0.67 | 17.31 | 18.43 | 0.46 | 18.42 |

| 27 | 0.57 | 0.21 | 0.10 | 15.65 | 17.26 | 0.95 | 8.79 |

| 28 | 0.61 | 0.38 | 1.00 | 12.60 | 21.03 | 0.25 | 28.42 |

| 29 | 0.59 | 0.87 | 0.28 | 9.63 | 19.42 | 2.15 | 7.69 |

| 30 | 0.52 | 0.15 | 0.77 | 11.14 | 17.03 | 1.26 | 18.79 |

| 31 | 0.86 | 0.90 | 0.87 | 8.01 | 18.06 | 0.85 | 21.52 |

| 32 | 0.73 | 0.05 | 0.54 | 12.27 | 20.71 | 3.41 | 12.89 |

| 33 | 0.54 | 0.31 | 0.44 | 16.25 | 12.36 | 0.95 | 19.52 |

| 34 | 1.00 | 0.18 | 0.62 | 11.14 | 21.59 | 1.09 | 18.42 |

| 35 | 0.45 | 0.00 | 0.41 | 16.53 | 15.62 | 0.56 | 15.49 |

| 36 | 0.34 | 0.67 | 0.92 | 17.57 | 13.52 | 0.26 | 11.03 |

| 37 | 0.93 | 0.26 | 0.08 | 14.11 | 11.34 | 1.96 | 16.85 |

| 38 | 0.36 | 0.46 | 0.03 | 20.25 | 21.52 | 2.63 | 18.42 |

| 39 | 0.89 | 0.54 | 0.95 | 8.97 | 19.53 | 1.65 | 12.85 |

| 40 | 0.18 | 0.74 | 0.13 | 19.61 | 15.85 | 2.09 | 18.04 |

| Model | Phase | Indicators of Predictive Accuracy | Hardness | SSC | TA | Vc |

|---|---|---|---|---|---|---|

| RBFNN | Training | R2 | 0.99 | 0.97 | 0.99 | 0.99 |

| RMSE | 185.21 | 2.10 | 0.18 | 0.16 | ||

| Prediction | R2 | 0.98 | 0.94 | 0.99 | 0.99 | |

| RMSE | 212.49 | 3.05 | 0.21 | 0.19 | ||

| ELMAN | Training | R2 | 0.85 | 0.98 | 0.99 | 0.99 |

| RMSE | 310.75 | 1.85 | 0.20 | 0.18 | ||

| Prediction | R2 | 0.69 | 0.96 | 0.98 | 0.98 | |

| RMSE | 385.78 | 2.611 | 0.23407 | 0.2141 |

| Indicators of Predictive Accuracy | Hardness (%) | SSC (%) | TA (%) | Vc (mg/100 g) |

|---|---|---|---|---|

| MAPE | 6.2 | 4.8 | 7.5 | 5.9 |

| NRMSE | 0.18 | 0.15 | 0.21 | 0.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mou, X.; Huang, X.; Ma, G.; Luo, Q.; Yang, X.; Xin, S.; Wan, F. Prediction of Storage Quality and Multi-Objective Optimization of Storage Conditions for Fresh Lycium barbarum L. Based on Optimized Latin Hypercube Sampling. Foods 2025, 14, 2807. https://doi.org/10.3390/foods14162807

Mou X, Huang X, Ma G, Luo Q, Yang X, Xin S, Wan F. Prediction of Storage Quality and Multi-Objective Optimization of Storage Conditions for Fresh Lycium barbarum L. Based on Optimized Latin Hypercube Sampling. Foods. 2025; 14(16):2807. https://doi.org/10.3390/foods14162807

Chicago/Turabian StyleMou, Xiaobin, Xiaopeng Huang, Guojun Ma, Qi Luo, Xiaoping Yang, Shanglong Xin, and Fangxin Wan. 2025. "Prediction of Storage Quality and Multi-Objective Optimization of Storage Conditions for Fresh Lycium barbarum L. Based on Optimized Latin Hypercube Sampling" Foods 14, no. 16: 2807. https://doi.org/10.3390/foods14162807

APA StyleMou, X., Huang, X., Ma, G., Luo, Q., Yang, X., Xin, S., & Wan, F. (2025). Prediction of Storage Quality and Multi-Objective Optimization of Storage Conditions for Fresh Lycium barbarum L. Based on Optimized Latin Hypercube Sampling. Foods, 14(16), 2807. https://doi.org/10.3390/foods14162807