Oil Extraction Systems Influence the Techno-Functional and Nutritional Properties of Pistachio Processing By-Products

Abstract

1. Introduction

2. Methods

2.1. Natural Pistachios

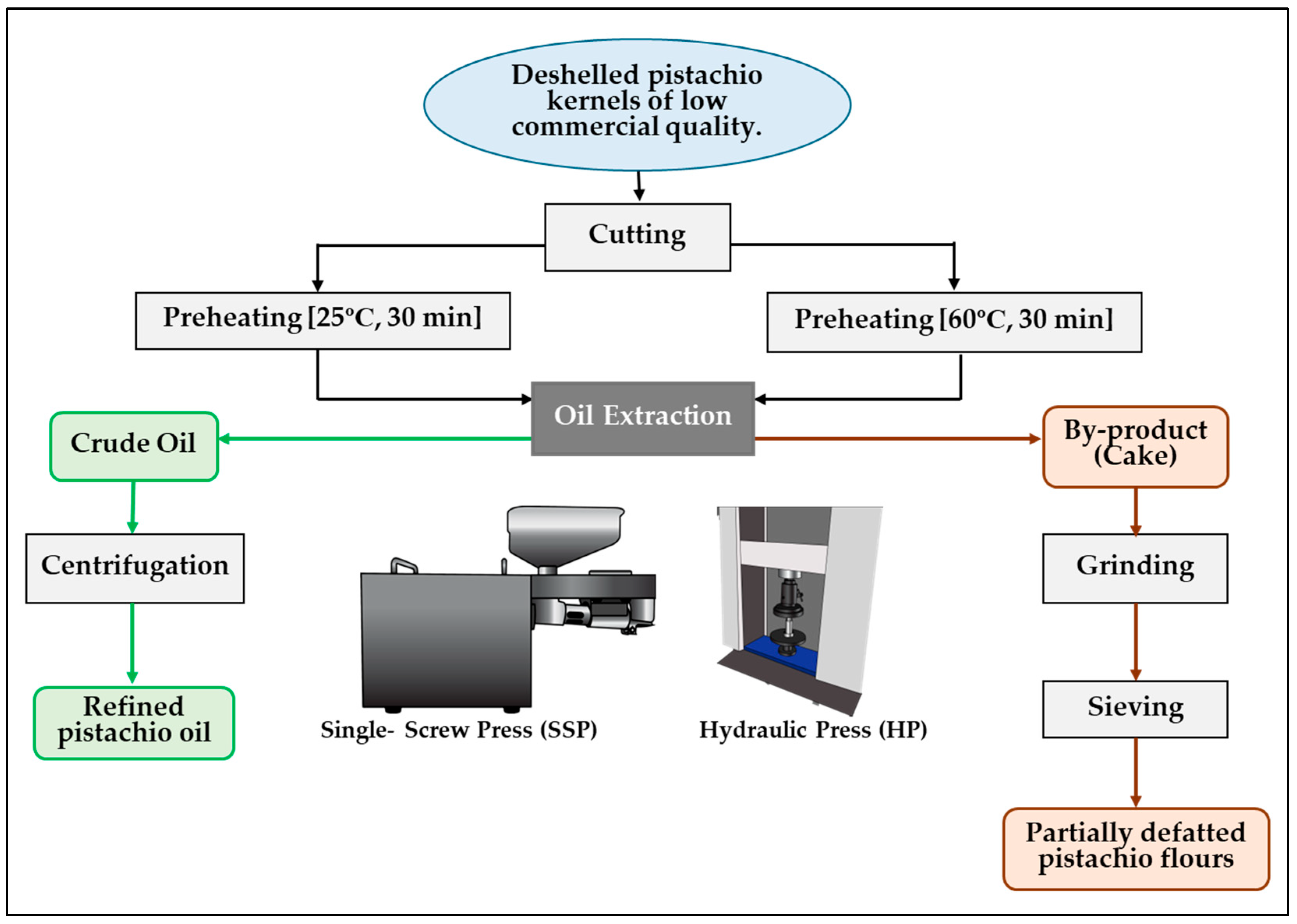

2.2. Oil Extraction Process

2.2.1. Thermal Pretreatment of Pistachios

2.2.2. Single-Screw Press (SSP)

2.2.3. Hydraulic Press (HP)

2.2.4. Oil and By-Product Processing

2.3. Determination of Extraction Yields

2.4. Characterisation of Oil

2.5. Nutritional Composition and Colour of Flours

2.6. Techno-Functional Properties of Flours

2.7. Statistical Analysis

3. Results and Discussion

3.1. Extraction Yields

3.2. Characteristics of Extracted Pistachio Oils

3.3. Nutritional Composition and Colour of Flours

3.3.1. Proximal and Mineral Compositions

3.3.2. Tocopherol Content

3.3.3. Colour

3.4. Techno-Functional Properties of Flours

3.4.1. Hydration Properties

3.4.2. Emulsifying Properties

3.4.3. Foaming Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rabadán, A.; Álvarez-Ortí, M.; Gómez, R.; Pardo-Giménez, A.; Pardo, J.E. Characterization of Pistachio Oils and Defatted Flours Regarding Cultivar and Geographic Origin. J. Food Compos. Anal. 2018, 71, 56–64. [Google Scholar] [CrossRef]

- Martínez, M.L.; Fabani, M.P.; Baroni, M.V.; Magrini Huaman, R.N.; Ighani, M.; Maestri, D.M.; Wunderlin, D.; Tapia, A.; Feresin, G.E. Argentinian Pistachio Oil and Flour: A Potential Novel Approach of Pistachio Nut Utilization. J. Food Sci. Technol. 2016, 53, 2260–2269. [Google Scholar] [CrossRef] [PubMed]

- FAOSTAT Data Production. Available online: https://www.fao.org/faostat/es/#data/QCL (accessed on 6 June 2025).

- Salinas, M.V.; Guardianelli, L.M.; Sciammaro, L.; Picariello, G.; Mamone, G.; Puppo, M.C. Nutritional Ingredient By-Product of the Pistachio Oil Industry: Physicochemical Characterization. J. Food Sci. Technol. 2021, 58, 921–930. [Google Scholar] [CrossRef] [PubMed]

- Mateos, R.; Salvador, M.D.; Fregapane, G.; Goya, L. Why Should Pistachio Be a Regular Food in Our Diet? Nutrients 2022, 14, 3207. [Google Scholar] [CrossRef] [PubMed]

- Sena-Moreno, E.; Pardo, J.E.; Catalán, L.; Gómez, R.; Pardo-Giménez, A.; Alvarez-Ortí, M. Drying Temperature and Extraction Method Influence Physicochemical and Sensory Characteristics of Pistachio Oils. Eur. J. Lipid Sci. Technol. 2015, 117, 684–691. [Google Scholar] [CrossRef]

- Dreher, M.L. Pistachio Nuts: Composition and Potential Health Benefits. Nutr. Rev. 2012, 70, 234–240. [Google Scholar] [CrossRef]

- Catalán, L.; Alvarez-Ortí, M.; Pardo-Giménez, A.; Gómez, R.; Rabadán, A.; Pardo, J.E. Pistachio Oil: A Review on Its Chemical Composition, Extraction Systems, and Uses. Eur. J. Lipid Sci. Technol. 2017, 119, 1600126. [Google Scholar] [CrossRef]

- Roncero, J.M.; Álvarez-Ortí, M.; Pardo-Giménez, A.; Rabadán, A.; Pardo, J.E.; Señoráns, F.J. Influence of Pressure Extraction Systems on the Performance, Quality and Composition of Virgin Almond Oil and Defatted Flours. Foods 2021, 10, 1049. [Google Scholar] [CrossRef]

- Sena-Moreno, E.; Pardo, J.E.; Pardo-Giménez, A.; Gómez, R.; Alvarez-Ortí, M.; Alvarez, M. Differences in Oils from Nuts Extracted by Means of Two Pressure Systems. Int. J. Food Prop. 2016, 19, 2750–2760. [Google Scholar] [CrossRef][Green Version]

- Rabadán, A.; Álvarez-Ortí, M.; Gómez, R.; Alvarruiz, A.; Pardo, J.E. Optimization of Pistachio Oil Extraction Regarding Processing Parameters of Screw and Hydraulic Presses. LWT—Food Sci. Technol. 2017, 83, 79–85. [Google Scholar] [CrossRef]

- Pardo-Giménez, A.; Catalán, L.; Carrasco, J.; Álvarez-Ortí, M.; Zied, D.; Pardo, J. Effect of Supplementing Crop Substrate with Defatted Pistachio Meal on Agaricus bisporus and Pleurotus ostreatus Production. J. Sci. Food Agric. 2015, 96, 3838–3845. [Google Scholar] [CrossRef]

- Guardianelli, L.; Puppo, M.C.; Salinas, M.V. Influence of Pistachio By-Product from Edible Oil Industry on Rheological, Hydration, and Thermal Properties of Wheat Dough. LWT 2021, 150, 111917. [Google Scholar] [CrossRef]

- Sanchiz, A.; Pedrosa, M.M.; Guillamón, E.; Arribas, C.; Cabellos, B.; Linacero, R.; Cuadrado, C. Influence of Boiling and Autoclave Processing on the Phenolic Content, Antioxidant Activity and Functional Properties of Pistachio, Cashew and Chestnut Flours. LWT 2019, 105, 250–256. [Google Scholar] [CrossRef]

- Santos, J.; Alvarez-Ortí, M.; Sena-Moreno, E.; Rabadán, A.; Pardo, J.E.; Beatriz, M.; Oliveira, P.P. Effect of Roasting Conditions on the Composition and Antioxidant Properties of Defatted Walnut Flour. J. Sci. Food Agric. 2017, 98, 1813–1820. [Google Scholar] [CrossRef]

- Ling, B.; Zhang, B.; Li, R.; Wang, S. Nutritional Quality, Functional Properties, Bioactivity, and Microstructure of Defatted Pistachio Kernel Flour. J. Am. Oil Chem. Soc. 2016, 93, 689–699. [Google Scholar] [CrossRef]

- Santos, O.V.; Corrêa, N.C.F.; Carvalho, R.N.; Costa, C.E.F.; França, L.F.F.; Lannes, S.C.S. Comparative Parameters of the Nutritional Contribution and Functional Claims of Brazil Nut Kernels, Oil and Defatted Cake. Food Res. Int. 2013, 51, 841–847. [Google Scholar] [CrossRef]

- Burbano, J.J.; Cabezas, D.M.; Correa, M.J. Characterization and Techno-Functional Properties of High Protein Walnut Flour from an Oil By-Product. Plant Foods Hum. Nutr. 2024, 79, 810–818. [Google Scholar] [CrossRef] [PubMed]

- Mendoza-Pérez, R.J.; Náthia-Neves, G.; Blanco, B.; Vela, A.J.; Caballero, P.A.; Ronda, F. Physicochemical Characterisation of Seeds, Oil and Defatted Cake of Three Hempseed Varieties Cultivated in Spain. Foods 2024, 13, 531. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.M.; Peng, Q.; Zhong, J.Z.; Liu, W.; Zhong, Y.J.; Wang, F. Molecular and Functional Properties of Protein Fractions and Isolate from Cashew Nut (Anacardium occidentale L.). Molecules 2018, 23, 393. [Google Scholar] [CrossRef] [PubMed]

- Fernández-López, J.; Lucas-González, R.; Viuda-Martos, M.; Sayas-Barberá, E.; Angel Pérez-Alvarez, J. Chia Oil Extraction Coproduct as a Potential New Ingredient for the Food Industry: Chemical, Physicochemical, Techno-Functional and Antioxidant Properties. Plant Foods Hum. Nutr. 2018, 73, 130–136. [Google Scholar] [CrossRef]

- Iyenagbe, D.O.; Malomo, S.A.; Idowu, A.O.; Badejo, A.A.; Fagbemi, T.N. Effects of Thermal Processing on the Nutritional and Functional Properties of Defatted Conophor Nut (Tetracarpidium conophorum) Flour and Protein Isolates. Food Sci. Nutr. 2017, 5, 1170–1178. [Google Scholar] [CrossRef]

- Gbadamosi, S.O.; Abiose, S.H.; Aluko, R.E. Amino Acid Profile, Protein Digestibility, Thermal and Functional Properties of Conophor Nut (Tetracarpidium conophorum) Defatted Flour, Protein Concentrate and Isolates. Int. J. Food Sci. Technol. 2012, 47, 731–739. [Google Scholar] [CrossRef]

- AACC. Approved Methods of Analysis, 11th ed.; Cereals & Grains Association: St. Paul, MN, USA, 2010. [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International, 22nd ed.; Latimer, G.W., Ed.; Oxford University Press: New York, NY, USA, 2023. [Google Scholar]

- Commission Delegated Regulation (EU) 2022/2104 of 29 July 2022 Supplementing Regulation (EU) No 1308/2013 of the European Parliament and of the Council as Regards Marketing Standards for Olive Oil and Repealing Commission Regulation (EEC) No 2568/91 and Commission Implementing Regulation (EU) No 29/2012; L283. 2022. Available online: http://data.europa.eu/eli/reg_del/2022/2104/oj (accessed on 15 June 2025).

- CIE Colorimetry. International Commission on Illumination; Commission Internationale de l’Eclairage: Washington, DC, USA, 2004; p. 72. ISBN 3901906339. Available online: https://cielab.xyz/pdf/cie.15.2004%20colorimetry.pdf (accessed on 15 June 2025).

- Abebe, W.; Collar, C.; Ronda, F. Impact of Variety Type and Particle Size Distribution on Starch Enzymatic Hydrolysis and Functional Properties of Tef Flours. Carbohydr. Polym. 2015, 115, 260–268. [Google Scholar] [CrossRef]

- Ronda, F.; Abebe, W.; Pérez-Quirce, S.; Collar, C. Suitability of Tef Varieties in Mixed Wheat Flour Bread Matrices: A Physico-Chemical and Nutritional Approach. J. Cereal Sci. 2015, 64, 139–146. [Google Scholar] [CrossRef]

- Rebolleda, S.; Rubio, N.; Beltrán, S.; Sanz, M.T.; González-Sanjosé, M.L. Supercritical Fluid Extraction of Corn Germ Oil: Study of the Influence of Process Parameters on the Extraction Yield and Oil Quality. J. Supercrit. Fluids 2012, 72, 270–277. [Google Scholar] [CrossRef]

- Calix-Rivera, C.S.; Villanueva, M.; Náthia-Neves, G.; Ronda, F. Changes on Techno-Functional, Thermal, Rheological, and Microstructural Properties of Tef Flours Induced by Microwave Radiation—Development of New Improved Gluten-Free Ingredients. Foods 2023, 12, 1345. [Google Scholar] [CrossRef] [PubMed]

- Vicente, A.; Villanueva, M.; Caballero, P.A.; Muñoz, J.M.; Ronda, F. Buckwheat Grains Treated with Microwave Radiation: Impact on the Techno-Functional, Thermal, Structural, and Rheological Properties of Flour. Food Hydrocoll. 2023, 137, 108328. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Torbati, M.; Azadmard-Damirchi, S.; Savage, G.P. Effect of Roasting and Microwave Pre-Treatments of Nigella sativa L. Seeds on Lipase Activity and the Quality of the Oil. Food Chem. 2019, 274, 480–486. [Google Scholar] [CrossRef] [PubMed]

- Álvarez-Ortí, M.; Quintanilla, C.; Sena, E.; Alvarruiz, A.; Pardo, J.E. The Effects of a Pressure Extraction System on Quality the Parameters of Different Virgin Pistachio (Pistacia vera L. Var. Larnaka) Oils. Grasas y Aceites 2012, 63, 260–266. [Google Scholar] [CrossRef]

- Gaber, M.A.F.M.; Tujillo, F.J.; Mansour, M.P.; Juliano, P. Improving Oil Extraction from Canola Seeds by Conventional and Advanced Methods. Food Eng. Rev. 2018, 10, 198–210. [Google Scholar] [CrossRef]

- Ling, B.; Yang, X.; Li, R.; Wang, S. Physicochemical Properties, Volatile Compounds, and Oxidative Stability of Cold Pressed Kernel Oils from Raw and Roasted Pistachio (Pistacia vera L. Var Kerman). Eur. J. Lipid Sci. Technol. 2016, 118, 1368–1379. [Google Scholar] [CrossRef]

- Gazor, H.R.; Minaei, S. Influence of Temperature and Air Velocity on Drying Time and Quality Parameters of Pistachio (Pistacia vera L.). Dry. Technol. 2005, 23, 2463–2475. [Google Scholar] [CrossRef]

- Rabadán, A.; Gallardo-Guerrero, L.; Gandul-Rojas, B.; Álvarez-Ortí, M.; Pardo, J.E. Effect of Roasting Conditions on Pigment Composition and Some Quality Parameters of Pistachio Oil. Food Chem. 2018, 264, 49–57. [Google Scholar] [CrossRef]

- Mavlanov, U.; Czaja, T.P.; Nuriddinov, S.; Dalimova, D.; Dragsted, L.O.; Engelsen, S.B.; Khakimov, B. The Effects of Industrial Processing and Home Cooking Practices on Trans-Fatty Acid Profiles of Vegetable Oils. Food Chem. 2025, 469, 142571. [Google Scholar] [CrossRef]

- Rabadán, A.; Pardo, J.E.; Gómez, R.; Alvarruiz, A.; Álvarez-Ortí, M. Usefulness of Physical Parameters for Pistachio Cultivar Differentiation. Sci. Hortic. 2017, 222, 7–11. [Google Scholar] [CrossRef]

- Burbano, J.J.; Correa, M.J. Composition and Physicochemical Characterization of Walnut Flour, a By-Product of Oil Extraction. Plant Foods Hum. Nutr. 2021, 76, 233–239. [Google Scholar] [CrossRef] [PubMed]

- Mandalari, G.; Barreca, D.; Gervasi, T.; Roussell, M.A.; Klein, B.; Feeney, M.J.; Carughi, A. Pistachio Nuts (Pistacia vera L.): Production, Nutrients, Bioactives and Novel Health Effects. Plants 2021, 11, 18. [Google Scholar] [CrossRef] [PubMed]

- An, J.; Adelina, N.M.; Zhang, L.; Zhao, Y. Effect of Roasting Pre-treatment of Two Grafted Pine Nuts (Pinus koraiensis) on Yield, Color, Chemical Compositions, Antioxidant Activity, and Oxidative Stability of the Oil. J. Food Process. Preserv. 2021, 46, e16145. [Google Scholar] [CrossRef]

- Al Juhaimi, F.; Özcan, M.M.; Ghafoor, K.; Babiker, E.E.; Hussain, S. Comparison of Cold-Pressing and Soxhlet Extraction Systems for Bioactive Compounds, Antioxidant Properties, Polyphenols, Fatty Acids and Tocopherols in Eight Nut Oils. J. Food Sci. Technol. 2018, 55, 3163–3173. [Google Scholar] [CrossRef]

- Sarkis, J.R.; Côrrea, A.P.F.; Michel, I.; Brandeli, A.; Tessaro, I.C.; Marczak, L.D.F. Evaluation of the Phenolic Content and Antioxidant Activity of Different Seed and Nut Cakes from the Edible Oil Industry. J. Am. Oil Chem. Soc. 2014, 91, 1773–1782. [Google Scholar] [CrossRef]

- Minh, N.P.; Pham, V.T.; Da, V.T.; Vinh, T.Q.; Thuan, L.Q. Effect of Drying, Roasting and Preservation on Antioxidant of Cashew (Anacardium occidentale) Nut. J. Pharm. Sci. Res. 2019, 9, 930–934. [Google Scholar]

- Labuckas, D.; Maestri, D.; Lamarque, A. Effect of Different Oil Extraction Methods on Proximate Composition and Protein Characteristics of Walnut (Juglans regia L.) Flour. LWT—Food Sci. Technol. 2014, 59, 794–799. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, N. Studies on Functional, Thermal and Pasting Properties of Flours from Different Chickpea (Cicer arietinum L.) Cultivars. Food Chem. 2005, 91, 403–411. [Google Scholar] [CrossRef]

- Jitngarmkusol, S.; Hongsuwankul, J.; Tananuwong, K. Chemical Compositions, Functional Properties, and Microstructure of Defatted Macadamia Flours. Food Chem. 2008, 110, 23–30. [Google Scholar] [CrossRef]

- Ma, X.; Zheng, C.; Zhou, Q.; Huang, C.; Wang, W.; Huang, Y.; Liu, C. Comparison Evaluation Pretreatments on the Quality Characteristics, Oxidative Stability, and Volatile Flavor of Walnut Oil. Food Chem. 2024, 448, 139124. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Samples | p-Values | ||||||

|---|---|---|---|---|---|---|---|---|

| PO-SSP25 | PO-SSP60 | PO-HP25 | PO-HP60 | SE | F1 | F2 | F1 × F2 | |

| Extraction yield (g/100 g) | ||||||||

| Oil | 40.1 b | 39.7 b | 23.4 a | 25.1 a | 0.9 | *** | ns | ns |

| Cake | 59 a | 60 a | 76 b | 75 b | 1 | *** | ns | ns |

| Colour | ||||||||

| L* | 38 b | 33 a | 45 c | 45 c | 1 | ** | ns | * |

| a* | −6.4 b | −5.4 c | −9.3 a | −4.1 d | 0.1 | ns | ** | *** |

| b* | 91 b | 81 a | 99 c | 99 c | 2 | ** | ns | * |

| C* | 91 b | 82 a | 99 c | 100 c | 2 | ** | ns | * |

| h | 94.0 b | 93.8 b | 95.4 c | 92.4 a | 0.3 | ns | * | ** |

| Free acidity (% oleic acid) | 0.6 a | 0.6 a | 0.6 a | 0.7 a | 0.1 | ns | ns | ns |

| PO-SSP25 | PO-HP25 | SE | p-Value | |

|---|---|---|---|---|

| Palmitic, C16:0 | 14 a | 14 a | 1 | ns |

| Stearic, C18:0 | 0.9 a | 0.9 a | 0.2 | ns |

| Arachidic, C20:0 | 0.11 a | 0.11 a | 0.02 | ns |

| Behenic, C22:0 | 0.11 a | 0.11 a | 0.02 | ns |

| Lignoceric, C24:0 | 0.05 a | 0.06 a | 0.01 | ns |

| Palmitoleic, C16:1 | 1.5 a | 1.5 a | 0.3 | ns |

| Vaccenic, C18:1n7 | 2.6 a | 2.8 a | 0.5 | ns |

| Oleic, C18:1n9 | 49 a | 47 a | 4 | ns |

| Gondoic, C20:1n9 | 0.3 a | 0.3 a | 0.1 | ns |

| Linoleic, C18:2n6 | 30 a | 31 a | 2 | ns |

| α-Linolenic, C18:3n3 | 0.8 a | 0.9 a | 0.2 | ns |

| SFA | 15.1 a | 15.6 a | 0.9 | ns |

| MUFA | 54 a | 51 a | 5 | ns |

| PUFA | 31 a | 32 a | 4 | ns |

| TFA | 0.20 a | 0.07 b | 0.02 | * |

| ω-3 | 0.8 a | 0.9 a | 0.1 | ns |

| ω-6 | 30 a | 31 a | 4 | ns |

| ω-9 | 49 a | 48 a | 4 | ns |

| Parameters | Samples | p-Values | ||||||

|---|---|---|---|---|---|---|---|---|

| PF-SSP25 | PF-SSP60 | PF-HP25 | PF-HP60 | SE | F1 | F2 | F1 × F2 | |

| Proximal composition (g/100 g) | ||||||||

| Moisture | 3.9 b | 3.4 a | 4.8 d | 4.6 c | 0.1 | *** | *** | *** |

| Carbohydrates | 17 a | 16 a | 16 a | 15 a | 2 | ns | ns | ns |

| Fat | 17.4 a | 18.3 a | 28.5 b | 28.1 b | 0.8 | *** | ns | * |

| Protein | 44 b | 44 b | 38 a | 39 a | 3 | ** | ns | ns |

| Fibre | 12 b | 12 b | 8 a | 8 a | 2 | ** | ns | ns |

| Ash | 5.6 b | 5.8 b | 4.9 a | 4.8 a | 0.2 | ** | ns | ns |

| Mineral composition (mg/100 g) | ||||||||

| Potassium (K) | 1714 b | 1691 b | 1495 a | 1499 a | 21 | *** | ns | ns |

| Phosphorus (P) | 1020 b | 993 b | 885 a | 941 ab | 25 | * | ns | ns |

| Magnesium (Mg) | 213 c | 201 bc | 181 a | 194 b | 5 | ** | ns | * |

| Calcium (Ca) | 186 c | 179 c | 160 a | 174 b | 4 | ** | ns | * |

| Iron (Fe) | 5.3 a | 5.1 a | 4.8 a | 4.6 a | 0.7 | ns | ns | ns |

| Zinc (Zn) | 3.1 c | 2.9 b | 2.6 a | 2.9 b | 0.1 | ** | ns | * |

| Tocopherols (mg/kg): | ||||||||

| γ-tocopherol | 103 a | 103 a | 143 b | 146 b | 10 | ** | ns | ns |

| α-tocopherol | 5.9 a | 6.0 a | 8.2 b | 8.7 b | 0.6 | ** | ns | ns |

| δ-tocopherol | 2.3 b | 2.2 b | 3.1 a | 3.4 a | 0.2 | ** | ns | ns |

| Total tocopherols | 111 a | 111 a | 154 b | 158 b | 10 | ** | ns | ns |

| Colour | ||||||||

| L* | 56.4 a | 57.8 b | 75.0 c | 78.2 d | 0.1 | *** | *** | *** |

| a* | 16.1 d | 15.2 c | 8.3 b | 7.2 a | 0.1 | *** | *** | ns |

| b* | 39.1 d | 37.6 c | 31.1 b | 29.6 a | 0.1 | *** | *** | ns |

| C* | 42.3 d | 40.5 c | 32.1 b | 30.4 a | 0.1 | *** | *** | ns |

| h | 67.6 a | 68.0 b | 75.0 c | 76.3 d | 0.1 | *** | *** | *** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mendoza-Pérez, R.J.; Álvarez-Olmedo, E.; Vicente, A.; Ronda, F.; Caballero, P.A. Oil Extraction Systems Influence the Techno-Functional and Nutritional Properties of Pistachio Processing By-Products. Foods 2025, 14, 2722. https://doi.org/10.3390/foods14152722

Mendoza-Pérez RJ, Álvarez-Olmedo E, Vicente A, Ronda F, Caballero PA. Oil Extraction Systems Influence the Techno-Functional and Nutritional Properties of Pistachio Processing By-Products. Foods. 2025; 14(15):2722. https://doi.org/10.3390/foods14152722

Chicago/Turabian StyleMendoza-Pérez, Rito J., Elena Álvarez-Olmedo, Ainhoa Vicente, Felicidad Ronda, and Pedro A. Caballero. 2025. "Oil Extraction Systems Influence the Techno-Functional and Nutritional Properties of Pistachio Processing By-Products" Foods 14, no. 15: 2722. https://doi.org/10.3390/foods14152722

APA StyleMendoza-Pérez, R. J., Álvarez-Olmedo, E., Vicente, A., Ronda, F., & Caballero, P. A. (2025). Oil Extraction Systems Influence the Techno-Functional and Nutritional Properties of Pistachio Processing By-Products. Foods, 14(15), 2722. https://doi.org/10.3390/foods14152722