Advances in Food Quality Management Driven by Industry 4.0: A Systematic Review-Based Framework

Abstract

1. Introduction

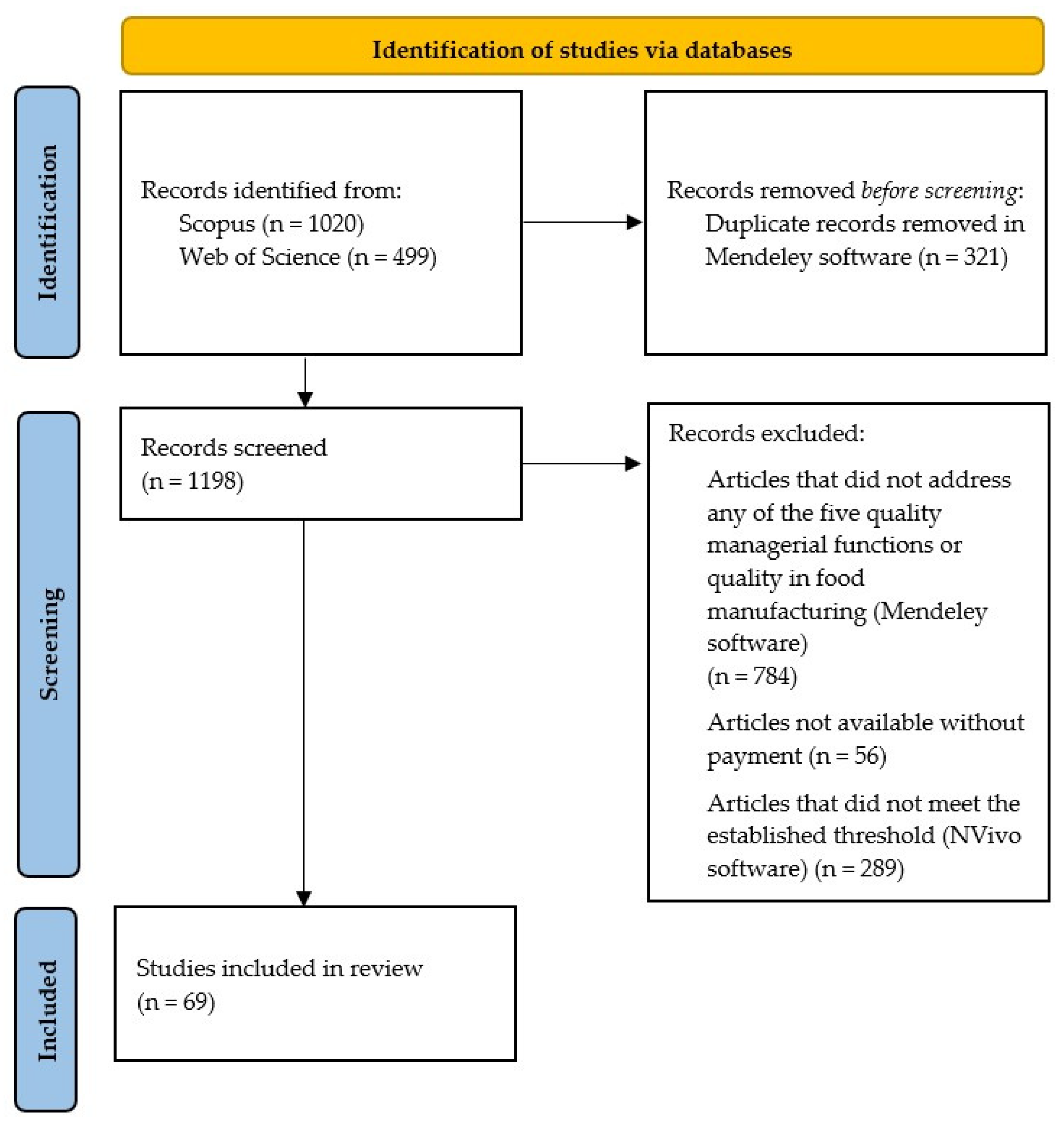

2. Materials and Methods

2.1. Study Design and Systematic Review Protocol

2.2. Search Strategy

2.3. Study Selection

2.4. Data Extraction

2.5. Data Synthesis and Data Analysis

2.6. Framework Development and Validation

3. Results

3.1. Search and Characteristics of Studies

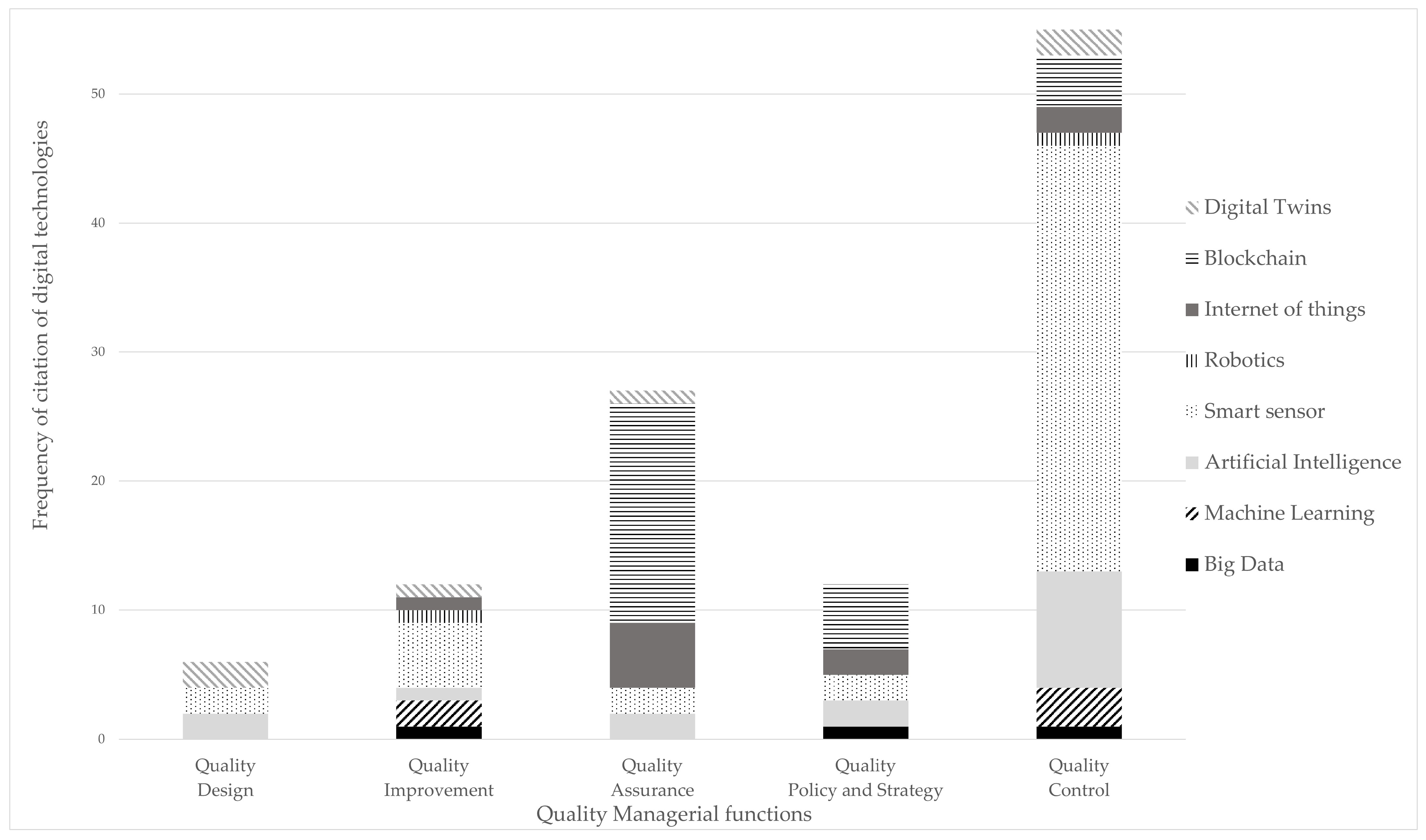

3.2. Quality Managerial Functions Supported by Industry 4.0 Technologies

3.2.1. Quality Design

3.2.2. Quality Control

3.2.3. Quality Improvement

3.2.4. Quality Assurance

3.2.5. Quality Policy and Strategy

4. Discussion

4.1. Maturity of Quality Managerial Functions in Adoption of Digital Technologies

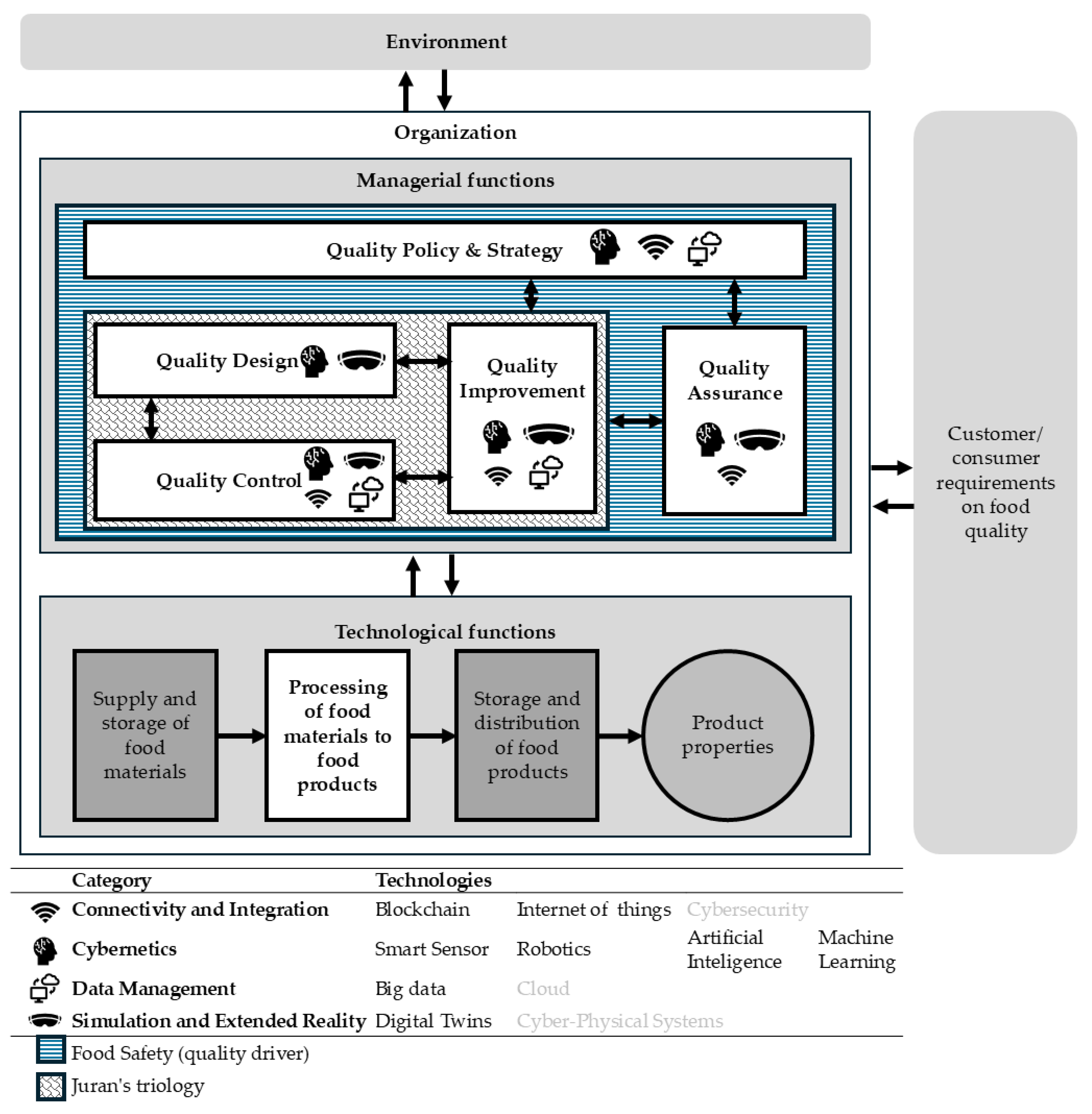

4.2. Food Quality Management 4.0 Framework Proposition

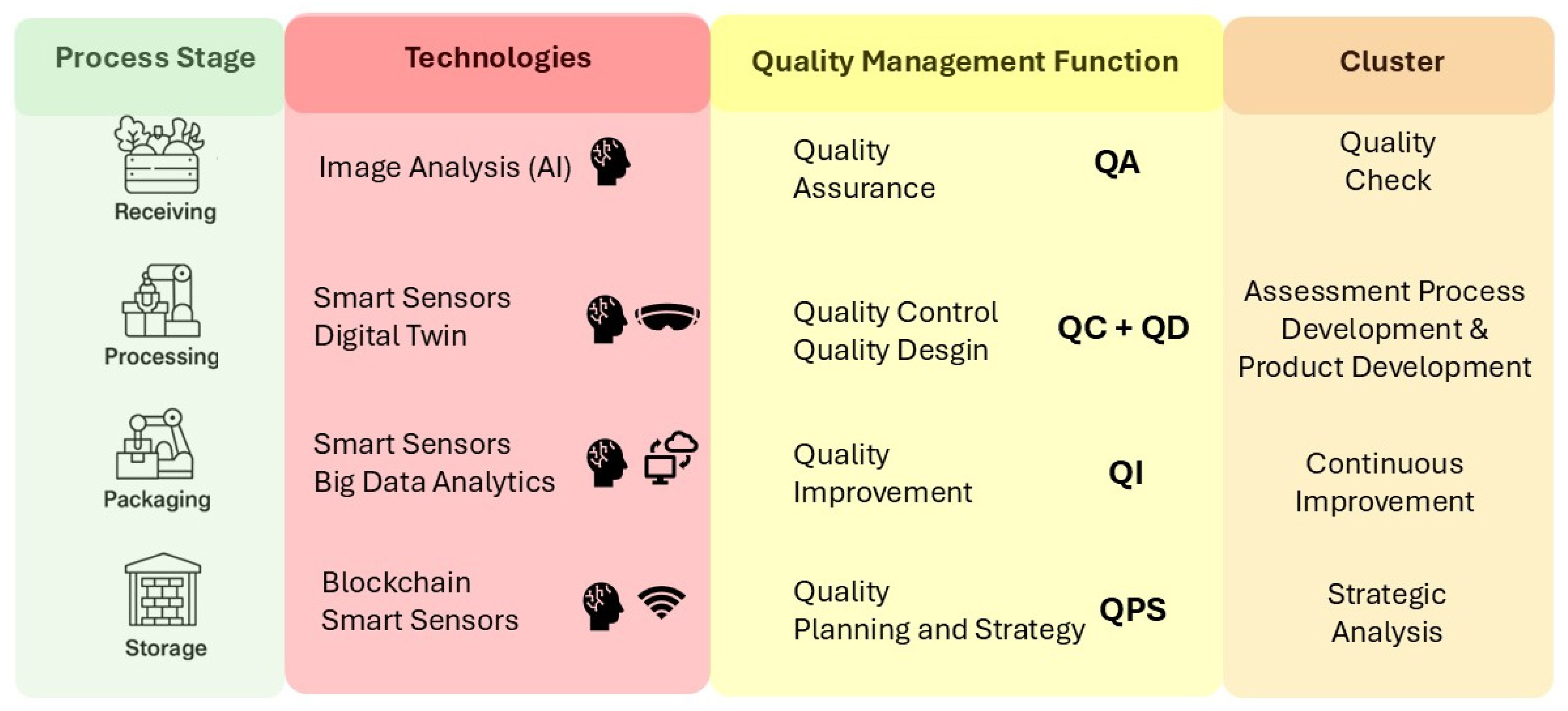

Practical Application: A Cocoa Manufacturing Illustrative Example

4.3. FQM 4.0 Framework Validation in the Food Industry

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FQM | Food Quality Management |

| QD | Quality Design |

| QC | Quality Control |

| QI | Quality Improvement |

| QA | Quality Assurance |

| QPS | Quality Policy and Strategy |

| AI | Artificial Intelligence |

| ML | Machine Learning |

| IoT | Internet of Things |

| BD | Big Data Analysis |

| DT | Digital Twin |

| QFD | Quality Function Deployment |

| DoE | Design of Experiments |

| HACCP | Hazard Analysis and Critical Control Points |

References

- Lim, S.A.H.; Antony, J. Statistical Process Control Readiness in the Food Industry: Development of a Self-Assessment Tool. Trends Food Sci. Technol. 2016, 58, 133–139. [Google Scholar] [CrossRef]

- Dora, M.; Kumar, M.; Van Goubergen, D.; Molnar, A.; Gellynck, X. Food Quality Management System: Reviewing Assessment Strategies and a Feasibility Study for European Food Small and Medium-Sized Enterprises. Food Control 2013, 31, 607–616. [Google Scholar] [CrossRef]

- Dias, A.M.; Carvalho, A.M.; Sampaio, P. Quality 4.0: Literature Review Analysis, Definition and Impacts of the Digital Transformation Process on Quality. Int. J. Qual. Reliab. Manag. 2022, 39, 1312–1335. [Google Scholar] [CrossRef]

- Luning, P.A.; Marcelis, W.J. A Conceptual Model of Food Quality Management Functions Based on a Techno-Managerial Approach. Trends Food Sci. Technol. 2007, 18, 159–166. [Google Scholar] [CrossRef]

- Kondakci, T.; Zhou, W. Recent Applications of Advanced Control Techniques in Food Industry. Food Bioprocess Tech. 2017, 10, 522–542. [Google Scholar] [CrossRef]

- Hassoun, A.; Aït-Kaddour, A.; Abu-Mahfouz, A.M.; Rathod, N.B.; Bader, F.; Barba, F.J.; Biancolillo, A.; Cropotova, J.; Galanakis, C.M.; Jambrak, A.R.; et al. The Fourth Industrial Revolution in the Food Industry—Part I: Industry 4.0 Technologies. Crit. Rev. Food Sci. Nutr. 2023, 63, 6547–6563. [Google Scholar] [CrossRef] [PubMed]

- Ilyukhin, S.V.; Haley, T.A.; Singh, R.K. A Survey of Control System Validation Practices in the Food Industry. Food Control 2001, 12, 297–304. [Google Scholar] [CrossRef]

- Schuh, G.; Anderl, R.; Gausemeier, J.; ten Hompel, M.; Wahlster, W. (Eds.) Industrie 4.0 Maturity Index: Managing the Digital Transformation of Companies; Acatech Study; Herbert Utz Verlag: Munich, Germany, 2020; Volume 64. [Google Scholar]

- Hassoun, A.; Jagtap, S.; Garcia-Garcia, G.; Trollman, H.; Pateiro, M.; Lorenzo, J.M.; Trif, M.; Rusu, A.V.; Aadil, R.M.; Šimat, V.; et al. Food Quality 4.0: From Traditional Approaches to Digitalized Automated Analysis. J. Food Eng. 2023, 337, 111216. [Google Scholar] [CrossRef]

- Hassoun, A.; Kamiloglu, S.; Garcia-Garcia, G.; Parra-López, C.; Trollman, H.; Jagtap, S.; Aadil, R.M.; Esatbeyoglu, T. Implementation of Relevant Fourth Industrial Revolution Innovations across the Supply Chain of Fruits and Vegetables: A Short Update on Traceability 4.0. Food Chem. 2023, 409, 135303. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, 71. [Google Scholar]

- Guruswamy, S.; Pojić, M.; Subramanian, J.; Mastilović, J.; Sarang, S.; Subbanagounder, A.; Stojanović, G.; Jeoti, V. Toward Better Food Security Using Concepts from Industry 5.0. Sensors 2022, 22, 8377. [Google Scholar] [CrossRef] [PubMed]

- FAO Sustainable Food Systems—Concept and Framework. In Sustainable Food Systems—Concept and Framework; FAO: Rome, Italy, 2018; pp. 1–8.

- Defraeye, T.; Shrivastava, C.; Berry, T.; Verboven, P.; Onwude, D.; Schudel, S.; Bühlmann, A.; Cronje, P.; Rossi, R.M. Digital Twins Are Coming: Will We Need Them in Supply Chains of Fresh Horticultural Produce? Trends Food Sci. Technol. 2021, 109, 245–258. [Google Scholar] [CrossRef]

- Alahi, M.E.E.; Mukhopadhyay, S.C. Detection Methodologies for Pathogen and Toxins: A Review. Sensors 2017, 17, 1885. [Google Scholar] [CrossRef] [PubMed]

- Hassoun, A.; Jagtap, S.; Trollman, H.; Garcia-Garcia, G.; Abdullah, N.A.; Goksen, G.; Bader, F.; Ozogul, F.; Barba, F.J.; Cropotova, J.; et al. Food Processing 4.0: Current and Future Developments Spurred by the Fourth Industrial Revolution. Food Control 2023, 145, 109507. [Google Scholar] [CrossRef]

- Taneja, A.; Nair, G.; Joshi, M.; Sharma, S.; Sharma, S.; Jambrak, A.R.; Roselló-Soto, E.; Barba, F.J.; Castagnini, J.M.; Leksawasdi, N.; et al. Artificial Intelligence: Implications for the Agri-Food Sector. Agronomy 2023, 13, 1397. [Google Scholar] [CrossRef]

- Mavani, N.R.; Ali, J.M.; Othman, S.; Hussain, M.A.; Hashim, H.; Rahman, N.A. Application of Artificial Intelligence in Food Industry—A Guideline. Food Eng. Rev. 2022, 14, 134–175. [Google Scholar] [CrossRef]

- Misra, N.N.; Dixit, Y.; Al-Mallahi, A.; Bhullar, M.S.; Upadhyay, R.; Martynenko, A. IoT, Big Data, and Artificial Intelligence in Agriculture and Food Industry. IEEE Internet Things J. 2022, 9, 6305–6324. [Google Scholar] [CrossRef]

- Addanki, M.; Patra, P.; Kandra, P. Recent Advances and Applications of Artificial Intelligence and Related Technologies in the Food Industry. Appl. Food Res. 2022, 2, 100126. [Google Scholar] [CrossRef]

- Kang, Z.; Zhao, Y.; Chen, L.; Guo, Y.; Mu, Q.; Wang, S. Advances in Machine Learning and Hyperspectral Imaging in the Food Supply Chain. Food Eng. Rev. 2022, 14, 596–616. [Google Scholar] [CrossRef]

- Saha, D.; Manickavasagan, A. Machine Learning Techniques for Analysis of Hyperspectral Images to Determine Quality of Food Products: A Review. Curr. Res. Food Sci. 2021, 4, 28–44. [Google Scholar] [CrossRef]

- Ropodi, A.I.; Panagou, E.Z.; Nychas, G.-J.E. Data Mining Derived from Food Analyses Using Non-Invasive/Non-Destructive Analytical Techniques; Determination of Food Authenticity, Quality & Safety in Tandem with Computer Science Disciplines. Trends Food Sci. Technol. 2016, 50, 11–25. [Google Scholar] [CrossRef]

- Ishwarappa; Anuradha, J. A Brief Introduction on Big Data 5Vs Characteristics and Hadoop Technology. Procedia Comput. Sci. 2015, 48, 319–324. [Google Scholar] [CrossRef]

- Onwude, D.I.; Chen, G.; Eke-Emezie, N.; Kabutey, A.; Khaled, A.Y.; Sturm, B. Recent Advances in Reducing Food Losses in the Supply Chain of Fresh Agricultural Produce. Processes 2020, 8, 1431. [Google Scholar] [CrossRef]

- Feng, H.H.; Wang, X.; Duan, Y.Q.; Zhang, J.; Zhang, X.S. Applying Blockchain Technology to Improve Agri-Food Traceability: A Review of Development Methods, Benefits and Challenges. J. Clean. Prod. 2020, 260, 121031. [Google Scholar] [CrossRef]

- Tanwar, S.; Parmar, A.; Kumari, A.; Jadav, N.K.; Hong, W.C.; Sharma, R. Blockchain Adoption to Secure the Food Industry: Opportunities and Challenges. Sustainability 2022, 14, 7036. [Google Scholar] [CrossRef]

- Henrichs, E.; Noack, T.; Piedrahita, A.M.P.; Salem, M.A.; Stolz, J.; Krupitzer, C. Can a Byte Improve Our Bite? An Analysis of Digital Twins in the Food Industry. Sensors 2022, 22, 115. [Google Scholar] [CrossRef]

- Tinoco, E.; Lima, R.M.; Mesquita, D.; Souza, M.C. Using Scenarios for the Development of Personal Communication Competence in Project Management. Int. J. Proj. Organ. Manag. 2023, 15, 307–331. [Google Scholar] [CrossRef]

- Matindoust, S.; Baghaei-Nejad, M.; Abadi, M.H.S.; Zou, Z.; Zheng, L.R. Food Quality and Safety Monitoring Using Gas Sensor Array in Intelligent Packaging. Sens. Rev. 2016, 36, 169–183. [Google Scholar] [CrossRef]

- Peres, F.A.P.; Peres, T.N.; Fogliatto, F.S.; Anzanello, M.J. Strategies for Synchronizing Chocolate Conching Batch Process Data Using Dynamic Time Warping. J. Food Sci. Technol. 2020, 57, 122–133. [Google Scholar]

- Ahmadihaji, A.; Izquierdo, R.; Shih, A. From Chip-Based to Chipless RFID Sensors: A Review. IEEE Sens. J. 2023, 23, 11356–11373. [Google Scholar] [CrossRef]

- Kim, C.; Lee, K.K.; Kang, M.S.; Shin, D.M.; Oh, J.W.; Lee, C.S.; Han, D.W. Artificial Olfactory Sensor Technology That Mimics the Olfactory Mechanism: A Comprehensive Review. Biomater. Res. 2022, 26. [Google Scholar] [CrossRef]

- Bandal, A.; Thirugnanam, M. Quality Measurements of Fruits and Vegetables Using Sensor Network. In Proceedings of the 3rd International Symposium on Big Data and Cloud Computing, ISBCC 2016, Vellore, India, 10–11 March 2016; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; Volume 49, pp. 121–130. [Google Scholar]

- Saravanan, P.; Sathish Kumar, S. Sensor Grid Middleware Architecture for Food Quality Control Units. Res. J. Pharm. Biol. Chem. Sci. 2013, 4, 1020–1029. [Google Scholar]

- Feng, H.; Wang, W.; Chen, B.; Zhang, X. Evaluation on Frozen Shellfish Quality by Blockchain Based Multi-Sensors Monitoring and SVM Algorithm during Cold Storage. IEEE Access 2020, 8, 54361–54370. [Google Scholar] [CrossRef]

- Hameed, H.; Zafar, N.A.; Alkhammash, E.H.; Hadjouni, M. Blockchain-Based Formal Model for Food Supply Chain Management System Using VDM-SL. Sustainability 2022, 14, 14202. [Google Scholar] [CrossRef]

- Peres, F.A.P.; Peres, T.N.; Fogliatto, F.S.; Anzanello, M.J. Fault Detection in Batch Processes through Variable Selection Integrated to Multiway Principal Component Analysis. J. Process Control 2019, 80, 223–234. [Google Scholar] [CrossRef]

- Reig, C.; Avila-Navarro, E. Printed Antennas for Sensor Applications: A Review. IEEE Sens. J. 2014, 14, 2406–2418. [Google Scholar] [CrossRef]

- Zhu, P.H.; Wang, Y.C.; Ma, P.; Li, S.S.; Fan, F.Q.; Cui, K.; Ge, S.G.; Zhang, Y.; Yu, J.H. Low-Power and High-Performance Trimethylamine Gas Sensor Based on n-n Heterojunction Microbelts of Perylene Diimide/CdS. Anal. Chem. 2019, 91, 5591–5598. [Google Scholar] [CrossRef] [PubMed]

- Anisimov, D.S.; Abramov, A.A.; Gaidarzhi, V.P.; Kaplun, D.S.; Agina, E.V.; Ponomarenko, S.A. Food Freshness Measurements and Product Distinguishing by a Portable Electronic Nose Based on Organic Field-Effect Transistors. ACS Omega 2023. [Google Scholar] [CrossRef]

- Abbatangelo, M.; Núñez-Carmona, E.; Sberveglieri, V. Novel Equipment for Food Quality Control: An IoT Nanowire Gas Sensors Array. Chem. Eng. Trans. 2019, 75, 25–30. [Google Scholar] [CrossRef]

- Wang, D.Y.; Zhang, M.; Mujumdar, A.S.; Yu, D.X. Advanced Detection Techniques Using Artificial Intelligence in Processing of Berries. Food Eng. Rev. 2022, 14, 176–199. [Google Scholar] [CrossRef]

- Othman, S.; Mavani, N.R.; Hussain, M.A.; Abd Rahman, N.; Ali, J.M. Artificial Intelligence-Based Techniques for Adulteration and Defect Detections in Food and Agricultural Industry: A Review. J. Agric. Food Res. 2023, 12, 100590. [Google Scholar] [CrossRef]

- Ordoñez-Araque, R.; Rodríguez-Villacres, J.; Urresto-Villegas, J. Electronic Nose, Tongue and Eye: Their Usefulness for the Food Industry. Vitae 2020, 27, 1–13. [Google Scholar] [CrossRef]

- Mahmood, L.; Ghommem, M.; Bahroun, Z. Smart Gas Sensors: Materials, Technologies, Practical Applications, and Use of Machine Learning—A Review. J. Appl. Comput. Mech. 2023, 9, 775–803. [Google Scholar] [CrossRef]

- Anwar, H.; Anwar, T.; Murtaza, S. Review on Food Quality Assessment Using Machine Learning and Electronic Nose System. Biosens. Bioelectron. X 2023, 14, 100365. [Google Scholar] [CrossRef]

- Galvan, D.; Aquino, A.; Effting, L.; Mantovani, A.C.G.; Bona, E.; Conte, C.A. E-Sensing and Nanoscale-Sensing Devices Associated with Data Processing Algorithms Applied to Food Quality Control: A Systematic Review. Crit. Rev. Food Sci. Nutr. 2021, 62, 6605–6645. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Zhu, Y.; Zou, L.; Zhu, H.; Cao, R.; Zhao, G. Combination of Machine Learning and Intelligent Sensors in Real-Time Quality Control of Alcoholic Beverages. Food Sci. Technol. 2022, 42, e54622. [Google Scholar] [CrossRef]

- Rodríguez, S.D.; Barletta, D.A.; Wilderjans, T.F.; Bernik, D.L. Fast and Efficient Food Quality Control Using Electronic Noses: Adulteration Detection Achieved by Unfolded Cluster Analysis Coupled with Time-Window Selection. Food Anal. Methods 2014, 7, 2042–2050. [Google Scholar] [CrossRef]

- Menon, S.; Jain, K. Blockchain Technology for Transparency in Agri-Food Supply Chain: Use Cases, Limitations, and Future Directions. IEEE Trans. Eng. Manag. 2021, 71, 106–120. [Google Scholar] [CrossRef]

- Song, C.Y.; Wu, Z.P.; Gray, J.; Meng, Z.Z. An RFID-Powered Multisensing Fusion Industrial IoT System for Food Quality Assessment and Sensing. IEEE Trans. Ind. Inf. 2024, 20, 337–348. [Google Scholar] [CrossRef]

- Yu, B.; Zhan, P.; Lei, M.; Zhou, F.; Wang, P. Food Quality Monitoring System Based on Smart Contracts and Evaluation Models. IEEE Access 2020, 8, 12479–12490. [Google Scholar] [CrossRef]

- Akhtaruzzaman Khan, M.; Emran Hossain, M.; Shahaab, A.; Khan, I. ShrimpChain: A Blockchain-Based Transparent and Traceable Framework to Enhance the Export Potentiality of Bangladeshi Shrimp. Smart Agric. Technol. 2022, 2, 100041. [Google Scholar] [CrossRef]

- Oates, M.J.; Gonzalez-Teruel, J.D.; Ruiz-Abellon, M.C.; Guillamon-Frutos, A.; Ramos, J.A.; Torres-Sanchez, R. Using a Low-Cost Components e-Nose for Basic Detection of Different Foodstuffs. IEEE Sens. J. 2022, 22, 13872–13881. [Google Scholar] [CrossRef]

- Karakaya, D.; Ulucan, O.; Turkan, M. Electronic Nose and Its Applications: A Survey. Int. J. Autom. Comput. 2020, 17, 179–209. [Google Scholar] [CrossRef]

- Coombs, C.E.O.; Allman, B.E.; Morton, E.J.; Gimeno, M.; Horadagoda, N.; Tarr, G.; González, L.A. Differentiation of Livestock Internal Organs Using Visible and Short-Wave Infrared Hyperspectral Imaging Sensors. Sensors 2022, 22, 3347. [Google Scholar] [CrossRef] [PubMed]

- Lam, M.B.; Nguyen, T.H.; Chung, W.Y. Deep Learning-Based Food Quality Estimation Using Radio Frequency-Powered Sensor Mote. IEEE Access 2020, 8, 88360–88371. [Google Scholar] [CrossRef]

- Siddiqui, J.; Taheri, M.; Ul Alam, A.; Deen, M.J. Nanomaterials in Smart Packaging Applications: A Review. Small 2022, 18, 2101171. [Google Scholar] [CrossRef]

- Huang, W.T.; Wang, X.P.; Xia, J.; Li, Y.L.; Zhang, L.W.; Feng, H.H.; Zhang, X.S. Flexible Sensing Enabled Agri-Food Cold Chain Quality Control: A Review of Mechanism Analysis, Emerging Applications, and System Integration. Trends Food Sci. Technol. 2023, 133, 189–204. [Google Scholar] [CrossRef]

- Chung, W.Y.; Le, G.T.; Tran, T.V.; Nguyen, N.H. Novel Proximal Fish Freshness Monitoring Using Batteryless Smart Sensor Tag. Sens. Actuators B-Chem. 2017, 248, 910–916. [Google Scholar] [CrossRef]

- Ahari, H.; Akbari-Adreghani, B.; Razavilar, V.; Motallebi, A.; Moradi, S.; Anvar, A.A. The Staphylococcus Aureus Exotoxin Recognition Using a Sensor Designed by Nanosilica and SEA Genotyping by Multiplex PCR. Appl. Food Biotechnol. 2014, 1, 37–44. [Google Scholar] [CrossRef]

- Deepa, S.N.; Jayalakshmi, N.Y. An Intelligent Neural Network Algorithm for Uncertainty Handling in Sensor Failure Scenario of Food Quality Assurance Model. Comput. Assist. Methods Eng. Sci. 2022, 29, 105–123. [Google Scholar] [CrossRef]

- Kaya, A.; Keçeli, A.S.; Catal, C.; Tekinerdogan, B. Sensor Failure Tolerable Machine Learning-Based Food Quality Prediction Model. Sensors 2020, 20, 3173. [Google Scholar] [CrossRef] [PubMed]

- Wijaya, D.R.; Sarno, R.; Zulaika, E. Noise Filtering Framework for Electronic Nose Signals: An Application for Beef Quality Monitoring. Comput. Electron. Agric. 2019, 157, 305–321. [Google Scholar] [CrossRef]

- Barandun, G.; Gonzalez-Macia, L.; Lee, H.S.; Dincer, C.; Güder, F. Challenges and Opportunities for Printed Electrical Gas Sensors. ACS Sens. 2022, 7, 2804–2822. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, S.; Wang, X.; Huang, J.; Pan, W.; Zhang, J.; Meteku, B.E.; Zeng, J. UV Illumination-Enhanced Ultrasensitive Ammonia Gas Sensor Based on (001)TiO2/MXene Heterostructure for Food Spoilage Detection. J. Hazard. Mater. 2022, 423, 127160. [Google Scholar] [CrossRef]

- Mohammed, M.; Riad, K.; Alqahtani, N. Design of a Smart IoT-Based Control System for Remotely Managing Cold Storage Facilities. Sensors 2022, 22, 4680. [Google Scholar] [CrossRef]

- Kittichotsatsawat, Y.; Jangkrajarng, V.; Tippayawong, K.Y. Enhancing Coffee Supply Chain towards Sustainable Growth with Big Data and Modern Agricultural Technologies. Sustainability 2021, 13, 4593. [Google Scholar] [CrossRef]

- Zhu, G.N.; Zeng, Y.; Teoh, Y.S.; Toh, E.; Wong, C.Y.; Chen, I.M. A Bin-Picking Benchmark for Systematic Evaluation of Robotic-Assisted Food Handling for Line Production. IEEE/ASME Trans. Mechatron. 2023, 28, 1778–1788. [Google Scholar] [CrossRef]

- Yu, Z.L.; Jung, D.Y.; Park, S.; Hu, Y.X.; Huang, K.; Rasco, B.A.; Wang, S.; Ronholm, J.; Lu, X.N.; Chen, J.H. Smart Traceability for Food Safety. Crit. Rev. Food Sci. Nutr. 2020, 62, 905–916. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, K.; Singh, A.; Neha. A Blockchain-Enabled Security Framework for Smart Agriculture. Comput. Electr. Eng. 2023, 106, 108594. [Google Scholar] [CrossRef]

- Ehsan, I.; Khalid, M.I.; Ricci, L.; Iqbal, J.; Alabrah, A.; Ullah, S.S.; Alfakih, T.M. A Conceptual Model for Blockchain-Based Agriculture Food Supply Chain System. Sci. Program. 2022, 2022, 108594. [Google Scholar] [CrossRef]

- van Hilten, M.; Ongena, G.; Ravesteijn, P. Blockchain for Organic Food Traceability: Case Studies on Drivers and Challenges. Front. Blockchain 2020, 3, 567175. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, P.C.; Xu, J.P.; Wang, X.Y.; Yu, J.B.; Zhao, Z.Y.; Dong, Y.F. Blockchain-Based Safety Management System for the Grain Supply Chain. IEEE Access 2020, 8, 36398–36410. [Google Scholar] [CrossRef]

- Nurgazina, J.; Pakdeetrakulwong, U.; Moser, T.; Reiner, G. Distributed Ledger Technology Applications in Food Supply Chains: A Review of Challenges and Future Research Directions. Sustainability 2021, 13, 4206. [Google Scholar] [CrossRef]

- Lin, W.; Huang, X.; Fang, H.; Wang, V.; Hua, Y.; Wang, J.; Yin, H.; Yi, D.; Yau, L. Blockchain Technology in Current Agricultural Systems: From Techniques to Applications. IEEE Access 2016, 8, 143920–143937. [Google Scholar] [CrossRef]

- Jing, R.; Li, P. Quality Control System of Red Jujube by Hybrid Model: Development of an Efficient Framework. Front. Plant Sci. 2022, 13, 888978. [Google Scholar] [CrossRef]

- Creydt, M.; Fischer, M. Blockchain and More—Algorithm Driven Food Traceability. Food Control 2019, 105, 45–51. [Google Scholar] [CrossRef]

- Prashar, D.; Jha, N.; Jha, S.; Lee, Y.; Joshi, G.P. Blockchain-Based Traceability and Visibility for Agricultural Products: A Decentralizedway of Ensuring Food Safety in India. Sustainability 2020, 12, 3497. [Google Scholar] [CrossRef]

- Pandey, V.; Pant, M.; Snasel, V. Blockchain Technology in Food Supply Chains: Review and Bibliometric Analysis. Technol. Soc. 2022, 69, 101954. [Google Scholar] [CrossRef]

- Peng, X.; Zhang, X.; Wang, X.; Li, H.; Xu, J.; Zhao, Z. Multi-Chain Collaboration-Based Information Management and Control for the Rice Supply Chain. Agriculture 2022, 12, 689. [Google Scholar] [CrossRef]

- Qian, J.; Yu, Q.; Jiang, L.; Yang, H.; Wu, W. Food Cold Chain Management Improvement: A Conjoint Analysis on COVID-19 and Food Cold Chain Systems. Food Control 2022, 137, 108940. [Google Scholar] [CrossRef]

- da Silva, F.T.; Baierle, I.C.; Correa, R.G.d.F.; Sellitto, M.A.; Peres, F.A.P.; Kipper, L.M. Open Innovation in Agribusiness: Barriers and Challenges in the Transition to Agriculture 4.0. Sustainability 2023, 15, 8562. [Google Scholar] [CrossRef]

- Rao, S.; Chen, F.; Hu, W.; Gao, F.; Huang, J.; Yi, H. Consumers’ Valuations of Tea Traceability and Certification: Evidence from a Blockchain Knowledge Experiment in Six Megacities of China. Food Control 2023, 151, 109827. [Google Scholar] [CrossRef]

- Heinonen, K. Characterizing Ex Situ Value: A Customer-Dominant Perspective on Value. J. Travel. Res. 2023, 62, 1707–1721. [Google Scholar] [CrossRef]

- Fadilasari, D.P.; Roy Ghatak, R.; Garza-Reyes, J.A.; Joshi, R.; Kandasamy, J. Adopting Quality Management Practices in the Industry 4.0 Era: An Investigation into the Challenges. Total Qual. Manag. Bus. Excell. 2024, 35, 1098–1123. [Google Scholar] [CrossRef]

- Yfanti, S.; Sakkas, N. Technology Readiness Levels (TRLs) in the Era of Co-Creation. Appl. Syst. Innov. 2024, 7, 32. [Google Scholar] [CrossRef]

- Duong, L.N.K.; Al-Fadhli, M.; Jagtap, S.; Bader, F.; Martindale, W.; Swainson, M.; Paoli, A. A Review of Robotics and Autonomous Systems in the Food Industry: From the Supply Chains Perspective. Trends Food Sci. Technol. 2020, 106, 355–364. [Google Scholar] [CrossRef]

- Deng, W.; Alias, S.N.; Md Rami, A.A.; Ismail, I.A. Antecedents of Resistance to Organizational Change: A Systematic Literature Review. Int. J. Acad. Res. Bus. Soc. Sci. 2023, 13, 1210–1236. [Google Scholar] [CrossRef]

- Pittri, H.; Godawatte, G.A.G.R.; Esangbedo, O.P.; Antwi-Afari, P.; Bao, Z. Exploring Barriers to the Adoption of Digital Technologies for Circular Economy Practices in the Construction Industry in Developing Countries: A Case of Ghana. Buildings 2025, 15, 1090. [Google Scholar] [CrossRef]

| Quality Managerial Function | Aims | Keywords or Related Terms |

|---|---|---|

| Quality Design | Aims to incorporate quality into activities related to developing processes, products, or materials. These activities must be related to customers’ interests regarding a safer and higher quality product. | Process development Product development New material development Quality Function Deployment (QFD) Failure Mode and Effects Analysis (FMEA) Design of Experiments (DoE) Customer satisfaction Customer expectation Customer dissatisfaction |

| Quality Control | Aims to ensure that the variation in products and processes remains within a certain tolerance that is considered acceptable. Thus, compliance with specifications is assessed, and, where appropriate, interventions are made. | Statistical process control Acceptance sampling Visual inspection New analysis method New sensor proposal Inspection Classification Fraud Prediction Monitoring Assessment Detection |

| Quality Improvement | Aims to improve the quality system with a focus on causes and solutions through the change of people, processes, and resources to bring them to a higher level of quality, working with the reduction in tolerance in the production process. | Waste reduction Continuous improvement Lean Manufacturing Process variability reduction Six Sigma Lean sigma Metrics dashboards Performance enhancement sensor |

| Quality Assurance | Aims to control the quality system, its methods, and evaluations and to assure consumers and customers that the quality requirements have been met. | Quality management programs Hazard Analysis and Critical Control Points (HACCP) International Organization for Standardization (ISO) British Retail Consortium (BRC) International Featured Standards (IFS) Quality check Quality system Traceability Quality Audit Contract compliance Safety hazards Certification |

| Quality Policy and Strategy | Aims to define long-term food quality objectives and targets and how to achieve them through the quality system. | Total quality management Customer focus Strategic analysis Strategic partnership Food safety strategy Organizational culture Quality cost analysis Quality Strategy Development Quality policy |

| Category | Industry 4.0 Technologies | Definition |

|---|---|---|

| Cybernetics | Smart Sensor | Sensors are transducers that measure physical and chemical quantities and convert them into electrical signals. They are the gateway to enabling Industry 4.0, ensuring better food quality and safety through low-cost, fast, reliable, and cost-effective detection methods [6,15]. Smart sensors can be classified into physical sensors, which measure temperature, humidity, and pressure in the food or vibration during transportation; chemical sensors that measure changes in pH and variations in gas concentrations (such as oxygen and carbon dioxide); and biological sensors that mimic the senses of the human body such as smell, sight, and taste [6,15,16]. |

| Cybernetics | Artificial Intelligence or AI | AI technology is often associated with sensors. AI involves the development of algorithms and computer models that allow machines to process and analyze a large volume of data, identify patterns and relationships, and make predictions or decisions based on these analyses [17]. This technology is thus said to simulate human thinking and intelligence, learning ability, and knowledge storage [10,18,19], allowing answers to complex questions to be discovered [20]. |

| Cybernetics | Machine Learning or ML | ML is a subcategory of AI [18,20,21,22]. This technology relates to developing and applying algorithms that can learn the patterns present in data and convert empirical data, using it to make classifications and predictions [21,22,23]. Examples of ML algorithms include artificial neural network (ANN), k-nearest neighbor (k-NN), support vector machine (SVM), decision trees (DTr), random forest (RF), and genetic algorithms. Deep learning is a subdivision of ML used for pattern recognition and decision-making [6,18,20]. |

| Cybernetics | Robotics | Robotics is considered another sub-area of AI [20]. Autonomous robots have been reported to provide skilled labor and reduce production costs [6]. |

| Data Management | Big Data | Decision-making based on analyzing a massive amount of data generated by operations, which undergo the digitization and automation of their processes, is related to big data technology [6,24]. |

| Data Management | Cloud | Cloud is understood as a digital infrastructure used to store large amounts of data generated, whether personal or corporate [6]. |

| Connectivity and Integration | Internet of Things or IoT | IoT, considered an essential dimension of Industry 4.0 [3], allows humans, objects, and things to connect and communicate at any time and anywhere. IoT systems consist of a network of physical objects with embedded technology to detect, communicate, and interact with their internal states or the external environment [25]. In the manufacturing environment, it enables data transfer between interconnected computer devices and industrial machinery [6]. |

| Connectivity and Integration | Blockchain | Blockchain is an inviolable, transparent, decentralized, and, therefore, reliable technology that stores each environ transaction using cryptographic hashes [26,27]. |

| Connectivity and Integration | Cybersecurity | Cybersecurity is the process and technology that support protecting information and technology systems [6]. |

| Simulation and Extended Reality | Digital Twins or DT | DT technology is a virtual product, process, or device representation. A twin connects to the real world via sensors and provides real-time data to the virtual twin [6,14,28]. |

| Simulation and Extended Reality | Cyber-physical systems | Cyber-physical systems have a strong relationship with DT, IoT, and robotics, as they integrates the physical and virtual worlds [6]. |

| TRL | % Proposals | Quality Function Most Mentioned |

|---|---|---|

| 1–2 | 30 | QC (48%) |

| 3–4 | 54 | QC (63%) |

| 5–6 | 13 | QA (75% |

| 7–8 | 3 | QA (100%) |

| 9 | 0 |

| Managerial Quality Functions Supported by Industry 4.0 Category | % |

|---|---|

| QC and Cybernetics | 72 |

| QI and Cybernetics | 6 |

| QA and Connectivity and Integration | 5 |

| QA and Simulation and Extended Reality | 3 |

| QD and Cybernetics | 3 |

| QI and Data Management | 3 |

| QA and Cybernetics | 1 |

| Other | 1 |

| None | 6 |

| Total | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peres, F.A.P.; Bondarczuk, B.A.; Gomes, L.d.C.; Jardim, L.d.C.; Corrêa, R.G.d.F.; Baierle, I.C. Advances in Food Quality Management Driven by Industry 4.0: A Systematic Review-Based Framework. Foods 2025, 14, 2429. https://doi.org/10.3390/foods14142429

Peres FAP, Bondarczuk BA, Gomes LdC, Jardim LdC, Corrêa RGdF, Baierle IC. Advances in Food Quality Management Driven by Industry 4.0: A Systematic Review-Based Framework. Foods. 2025; 14(14):2429. https://doi.org/10.3390/foods14142429

Chicago/Turabian StylePeres, Fernanda Araujo Pimentel, Beniamin Achilles Bondarczuk, Leonardo de Carvalho Gomes, Laurence de Castro Jardim, Ricardo Gonçalves de Faria Corrêa, and Ismael Cristofer Baierle. 2025. "Advances in Food Quality Management Driven by Industry 4.0: A Systematic Review-Based Framework" Foods 14, no. 14: 2429. https://doi.org/10.3390/foods14142429

APA StylePeres, F. A. P., Bondarczuk, B. A., Gomes, L. d. C., Jardim, L. d. C., Corrêa, R. G. d. F., & Baierle, I. C. (2025). Advances in Food Quality Management Driven by Industry 4.0: A Systematic Review-Based Framework. Foods, 14(14), 2429. https://doi.org/10.3390/foods14142429