Optimization of the Rheological Properties of Fat Replacers Based on Inulin at Different Degrees of Polymerization and Their Application in Beef Burgers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Design and Inulin-Based Gels Preparation

2.3. Rheological Determination

2.4. Selection of the Optimal Formulation of Inulin-Based Gels

2.5. Preparation of Beef Burgers Containing Optimal Formulation of Inulin-Based Gels

2.6. Cooking Parameters of Beef Burgers

2.7. Statistical Analysis

3. Results and Discussion

3.1. Models Evaluation

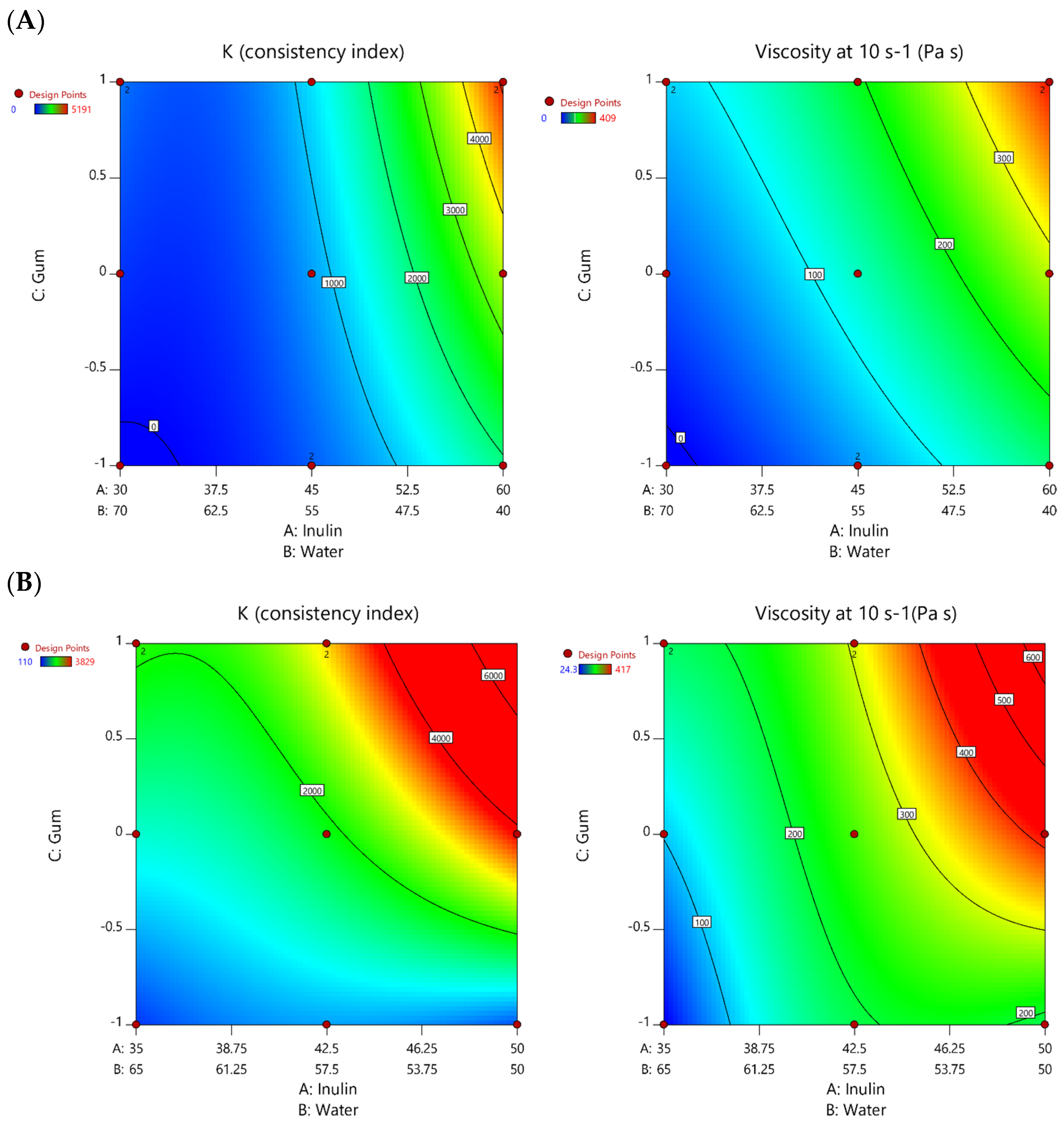

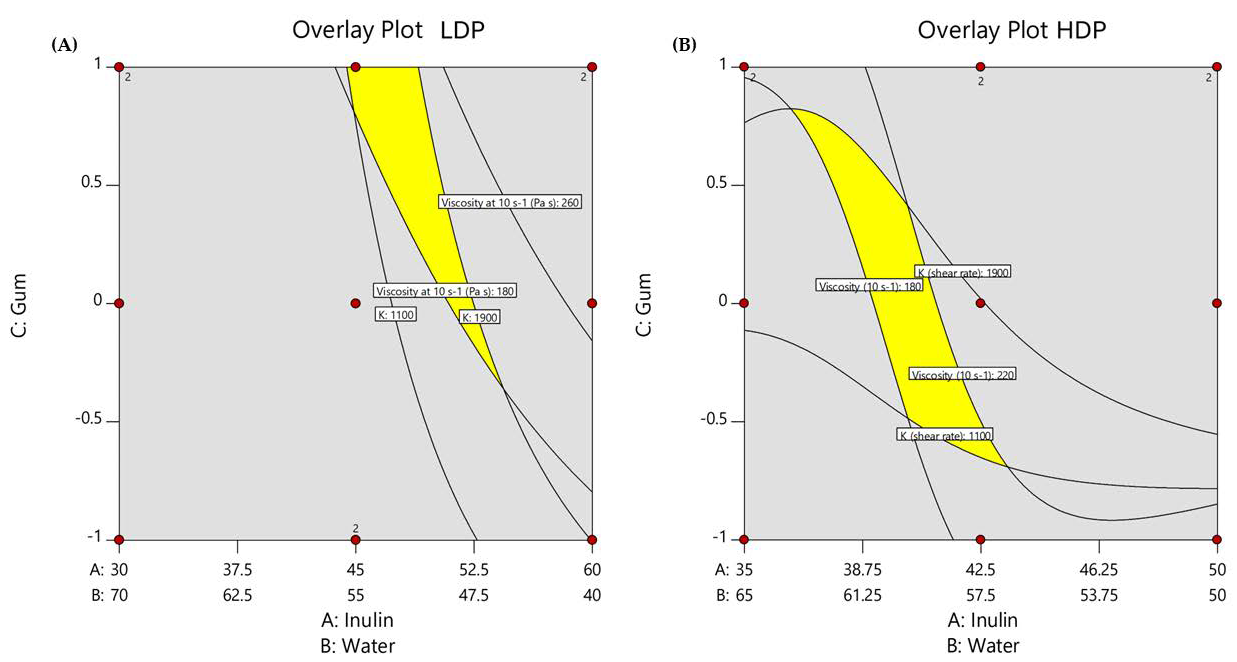

3.2. Rheological Properties of Inulin-Based Gels and Back Fat and Optimization of Formulations

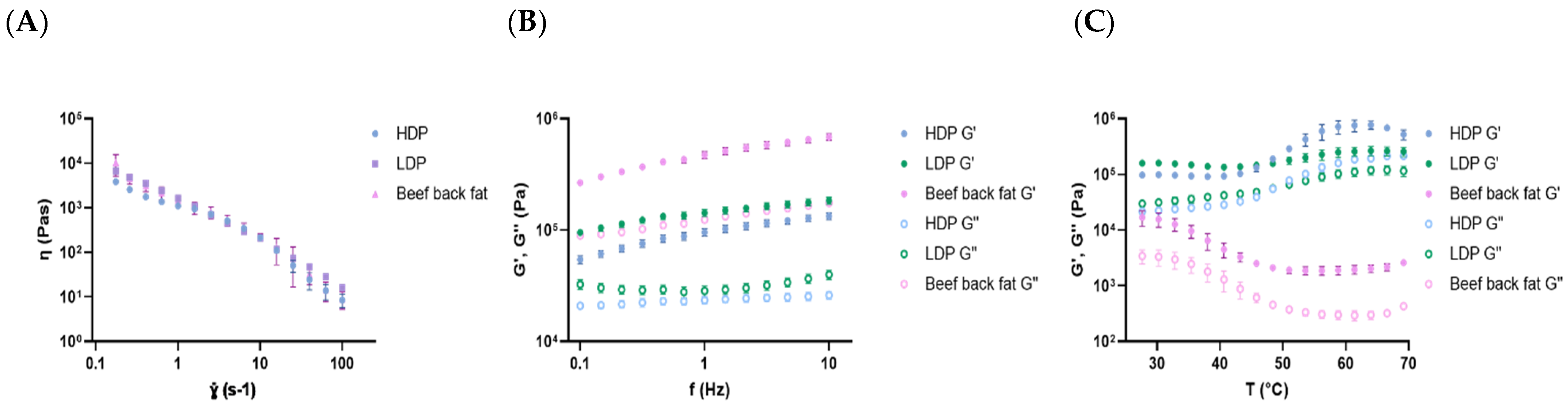

3.3. Rheological Properties of the Optimized Formulations and Comparison with the Beef Back Fat

3.4. Cooking Properties of Cooked Beef Burgers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LDP | Low Degree of Polymerization |

| HDP | High Degree of Polymerization |

| CTR | Control burger |

| LDP-B | Low-fat beef burger formulated with inulin LDP |

| HDP-B | Low-fat beef burger formulated with inulin HDP |

| DP | Degree of Polymerization |

References

- Lombardi, S.J.; Nazzaro, F.; Grazia, L.; Coppola, R.; Fratianni, F.; Pellegrini, M.; Iarusso, I.; Tremonte, P.; Coppola, F. Use of Inulin and Pumpkin Oil in the Manufacture of High-Quality Mortadella-Style Sausage from Buffalo Meat. Foods 2025, 14, 1427. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, M.; Khorshidian, N.; Hosseini, H. An overview of the functionality of inulin in meat and poultry products. Nutr. Food Sci. 2018, 48, 819–835. [Google Scholar] [CrossRef]

- Prates, J.A. The Role of Meat Lipids in Nutrition and Health: Balancing Benefits and Risks. Nutrients 2025, 17, 350. [Google Scholar] [CrossRef]

- Berizi, E.; Shekarforoush, S.; Mohammadinezhad, S.; Hosseinzadeh, S.; Farahnaki, A. The use of inulin as fat replacer and its effect on texture and sensory properties of emulsion type sausages. Iran. J. Vet. Res. 2017, 18, 253–257. [Google Scholar]

- Piñero, M.P.; Parra, K.; Huerta-Leidenz, N.; De Moreno, L.A.; Ferrer, M.; Araujo, S.; Barboza, Y. Effect of oat’s soluble fibre (β-glucan) as a fat replacer on physical, chemical, microbiological and sensory properties of low-fat beef patties. Meat Sci. 2008, 80, 675–680. [Google Scholar] [CrossRef]

- Luo, D.; Li, Y.; Xu, B.; Ren, G.; Li, P.; Li, X.; Han, S.; Liu, J. Effects of inulin with different degree of polymerization on gelatinization and retrogradation of wheat starch. Food Chem. 2017, 229, 35–43. [Google Scholar] [CrossRef] [PubMed]

- Bis-Souza, C.V.; Henck, J.M.M.; Barretto, A.C.D.S. Performance of low-fat beef burger with added soluble and insoluble dietary fibers. Food Sci. Technol. 2018, 38, 522–529. [Google Scholar] [CrossRef]

- Illippangama, A.U.; Jayasena, D.D.; Jo, C.; Mudannayake, D.C. Inulin as a functional ingredient and their applications in meat products. Carbohydr. Polym. 2022, 275, 118706. [Google Scholar] [CrossRef]

- Wang, R.; Wan, J.; Liu, C.; Xia, X.; Ding, Y. Pasting, thermal, and rheological properties of rice starch partially replaced by inulin with different degrees of polymerization. Food Hydrocoll. 2019, 92, 228–232. [Google Scholar] [CrossRef]

- El-Zeny, T.; Essa, R.Y.; Bisar, B.A.; Metwalli, S.M. Effect of using chicory roots powder as a fat replacer on beef burger quality. Slov. Vet. Res. 2019, 56 (Suppl. S22), 509–514. [Google Scholar] [CrossRef]

- Keenan, D.F.; Auty, M.A.; Doran, L.; Kerry, J.P.; Hamill, R.M. Investigating the influence of inulin as a fat substitute in comminuted products using rheology, calorimetric and microscopy techniques. Food Struct. 2014, 2, 1–13. [Google Scholar] [CrossRef]

- dos Santos Silva, R.; dos Santos Lima, A.; da Silva, L.P.; do Nascimento Silva, R.; Pereira, E.M.; de Oliveira, F.L.N.; Azerêdo, G.A. Addition of essential oils and inulin for production of reduced salt and fat ham. Aust. J. Crop Sci. 2019, 13, 1031–1036. [Google Scholar] [CrossRef]

- Guedes-Oliveira, J.M.; Costa-Lima, B.R.; Oliveira, D.; Neto, A.; Deliza, R.; Conte-Junior, C.A.; Guimarães, C.F.M. Mixture design approach for the development of reduced fat lamb patties with carboxymethyl cellulose and inulin. Food Sci. Nutr. 2019, 7, 1328–1336. [Google Scholar] [CrossRef]

- Keenan, D.F.; Resconi, V.C.; Kerry, J.P.; Hamill, R.M. Modelling the influence of inulin as a fat substitute in comminuted meat products on their physico-chemical characteristics and eating quality using a mixture design approach. Meat Sci. 2014, 96, 1384–1394. [Google Scholar] [CrossRef]

- Felisberto, M.H.F.; Galvão, M.T.E.L.; Picone, C.S.F.; Cunha, R.L.; Pollonio, M.A.R. Effect of prebiotic ingredients on the rheological properties and microstructure of reduced-sodium and low-fat meat emulsions. LWT-Food Sci. Technol. 2015, 60, 148–155. [Google Scholar] [CrossRef]

- Afshari, R.; Hosseini, H.; Khaksar, R.; Mohammadifar, M.A.; Amiri, Z.; Komeili, R.; Khaneghah, A.M. Investigation of the effects of inulin and β-glucan on the physical and sensory properties of low-fat beef burgers containing vegetable oils: Optimisation of the formulation using D-optimal mixture design. Food Technol. Biotechnol. 2015, 53, 436–445. [Google Scholar] [CrossRef]

- Eriksson, L.; Johansson, E.; Wikström, C. Mixture design—Design generation, PLS analysis, and model usage. Chemom. Intell. Lab. Syst. 1998, 43, 1–24. [Google Scholar] [CrossRef]

- Xu, J.; Kenar, J.A. Rheological and micro-rheological properties of chicory inulin gels. Gels 2024, 10, 171. [Google Scholar] [CrossRef] [PubMed]

- De Angelis, D.; Vurro, F.; Santamaria, M.; Garzon, R.; Rosell, C.M.; Summo, C.; Pasqualone, A. Effect of dry-fractionated pea protein on the physicochemical properties and the nutritional features of gluten-free focaccia flat bread. LWT-Food Sci. Technol. 2023, 182, 114873. [Google Scholar] [CrossRef]

- de Souza Paglarini, C.; de Figueiredo Furtado, G.; Honorio, A.R.; Mokarzel, L.; da Silva Vidal, V.A.; Ribeiro, A.P.B.; Pollonio, M.A.R. Functional emulsion gels as pork back fat replacers in Bologna sausage. Food Struct. 2019, 20, 100105. [Google Scholar] [CrossRef]

- De Angelis, D.; Latrofa, V.; Squeo, G.; Pasqualone, A.; Summo, C. Dry-fractionated protein concentrate as egg replacer in sponge cake: How the rheological properties of the batters affect the physical and structural quality of the products. J. Sci. Food Agric. 2024, 104, 1190–1199. [Google Scholar] [CrossRef] [PubMed]

- Krystyjan, M.; Ciesielski, W.; Khachatryan, G.; Sikora, M.; Tomasik, P. Structure, rheological, textural and thermal properties of potato starch–Inulin gels. LWT-Food Sci. Technol. 2015, 60, 131–136. [Google Scholar] [CrossRef]

- Hu, X.; Zhou, H.; McClements, D.J. Utilization of emulsion technology to create plant-based adipose tissue analogs: Soy-based high internal phase emulsions. Food Struct. 2022, 33, 100290. [Google Scholar] [CrossRef]

- Choe, J.H.; Kim, H.Y.; Lee, J.M.; Kim, Y.J.; Kim, C.J. Quality of frankfurter-type sausages with added pig skin and wheat fiber mixture as fat replacers. Meat Sci. 2013, 93, 849–854. [Google Scholar] [CrossRef]

- Tabarestani, H.S.; Mahoonak, A.S.; Ghorbani, M. Formulating low-fat beef burger with fenugreek seed gum: Impact on texture, chemistry, and sensory characteristics. Food Humanit. 2024, 2, 100260. [Google Scholar] [CrossRef]

- Berry, B.W. Low fat level effects on sensory, shear, cooking, and chemical properties of ground beef patties. J. Food Sci. 1992, 57, 537. [Google Scholar] [CrossRef]

- American Meat Science Association. American Meat Science Association Research Guidelines for Cookery Sensory Evaluation Instrumental Tenderness Measurements of Meat; AMSA: Savoy, IL, USA, 2015; pp. 1–106. [Google Scholar]

- Heydari, F.; Varidi, M.J.; Varidi, M.; Mohebbi, M. Study on quality characteristics of camel burger and evaluating its stability during frozen storage. J. Food Meas. Charact. 2016, 10, 148–155. [Google Scholar] [CrossRef]

- Barnes, H.A. A Handbook of Elementary Rheology; University of Wales, Institute of Non-Newtonian Fluid Mechanics: Wales, UK, 2000. [Google Scholar]

- Gurt, A.; Khonsari, M. A review of the rheological consistency of materials. Lubricants 2024, 12, 236. [Google Scholar] [CrossRef]

- Bchir, B.; Sadin, N.; Ronkart, S.N.; Blecker, C. Effect of powder properties on the physicochemical and rheological characteristics of gelation inulin–water systems. Colloid. Polym. Sci. 2019, 297, 849–860. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, X.; Wang, Y.; Guo, T.; Guan, P.; Hou, J.; Chen, Z. Effects of inulin with different polymerization degrees on the structural and gelation properties of potato protein. Food Chem. X 2024, 22, 101405. [Google Scholar] [CrossRef]

- Torres, M.D.; Hallmark, B.; Wilson, D.I. Effect of concentration on shear and extensional rheology of guar gum solutions. Food Hydrocoll. 2014, 40, 85–95. [Google Scholar] [CrossRef]

- Alaei, F.; Hojjatoleslamy, M.; Hashemi Dehkordi, S.M. The effect of inulin as a fat substitute on the physicochemical and sensory properties of chicken sausages. Food Sci. Nutr. 2018, 6, 512–519. [Google Scholar] [CrossRef] [PubMed]

- Montoya, L.; Quintero, N.; Ortiz, S.; Lopera, J.; Millán, P.; Rodríguez-Stouvenel, A. Inulin as a fat-reduction ingredient in pork and chicken meatballs: Its effects on physicochemical characteristics and consumer perceptions. Foods 2022, 11, 1066. [Google Scholar] [CrossRef]

- Franco, D.; Martins, A.J.; López-Pedrouso, M.; Cerqueira, M.A.; Purriños, L.; Pastrana, L.M.; Vicente, A.A.; Zapata, C.; Lorenzo, J.M. Evaluation of linseed oil oleogels to partially replace pork backfat in fermented sausages. J. Sci. Food Agric. 2020, 100, 218–224. [Google Scholar] [CrossRef]

- Santos, D.; Monteiro, M.J.; Voss, H.P.; Komora, N.; Teixeira, P.; Pintado, M. The most important attributes of beef sensory quality and production variables that can affect it: A review. Livest. Sci. 2021, 250, 104573. [Google Scholar] [CrossRef]

- Kidane, S.W. Application of Response Surface Methodology in Food Process Modeling and Optimization. In Response Surface Methodology in Engineering Science; Kayaroganam, P., Ed.; IntechOpen: Rijeka, Croatia, 2021. [Google Scholar]

- Squeo, G.; De Angelis, D.; Leardi, R.; Summo, C.; Caponio, F. Background, applications and issues of the experimental designs for mixture in the food sector. Foods 2021, 10, 1128. [Google Scholar] [CrossRef]

- Joyner, H.S. Explaining food texture through rheology. Curr. Opin. Food Sci. 2018, 21, 7–14. [Google Scholar] [CrossRef]

- Ji, X.; Yin, M.; Hao, L.; Shi, M.; Liu, H.; Liu, Y. Effect of inulin on pasting, thermal, rheological properties and in vitro digestibility of pea starch gel. Int. J. Biol. Macromol. 2021, 193, 1669–1675. [Google Scholar] [CrossRef]

- Hernández-Cruz, M.C.; Meza-Gordillo, R.; Torrestiana-Sánchez, B.; Rosales-Quintero, A.; Ventura-Canseco, L.M.C.; Castañón-Gonzáles, J.H. Chicken fat and biodiesel viscosity modification with additives for the formulation of biolubricants. Fuel 2017, 198, 42–48. [Google Scholar] [CrossRef]

- Goodrum, J.W.; Geller, D.P.; Adams, T.T. Rheological characterization of yellow grease and poultry fat. J. Am. Oil Chem. Soc. 2002, 79, 961–964. [Google Scholar] [CrossRef]

- Li, Y.; Ma, X.; Liu, X. Physicochemical and rheological properties of cross-linked inulin with different degree of polymerization. Food Hydrocoll. 2019, 95, 318–325. [Google Scholar] [CrossRef]

- Gomes, A.; Costa, A.L.R.; Fasolin, L.H.; Silva, E.K. Rheological properties, microstructure, and encapsulation efficiency of inulin-type dietary fiber-based gelled emulsions at different concentrations. Carbohydr. Polym. 2025, 347, 122742. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Zhu, Y.; Wang, X.; Peng, H.; Wang, Z.; Yue, C.; Wang, L.; Bai, Z.; Li, P.; Luo, D. Study of the structural characterization, physicochemical properties and antioxidant activities of phosphorylated long-chain inulin with different degrees of substitution. Int. J. Biol. Macromol. 2024, 263, 130139. [Google Scholar] [CrossRef]

- Wang, L.; Liu, H.M.; Zhu, C.Y.; Xie, A.J.; Ma, B.J.; Zhang, P.Z. Chinese quince seed gum: Flow behaviour, thixotropy and viscoelasticity. Carbohydr. Polym. 2019, 209, 230–238. [Google Scholar] [CrossRef] [PubMed]

- Berger, L.M.; Witte, F.; Tomasevic, I.; Heinz, V.; Weiss, J.; Gibis, M.; Terjung, N. A review on the relation between grinding process and quality of ground meat. Meat Sci. 2023, 205, 109320. [Google Scholar] [CrossRef]

- Ahmed, J.; Ptaszek, P.; Basu, S. Food rheology: Scientific development and importance to food industry. In Advances in Food Rheology; Ahmed, J., Ptaszek, P., Basu, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–4. ISBN 9780081004319. [Google Scholar]

- Zhang, Y.; Wang, Y.; Yang, B.; Han, X.; He, Y.; Wang, T.; Zhao, J. Effects of zucchini polysaccharide on pasting, rheology, structural properties and in vitro digestibility of potato starch. Int. J. Biol. Macromol. 2023, 253, 127077. [Google Scholar] [CrossRef]

- Difonzo, G.; Noviello, M.; De Angelis, D.; Porfido, C.; Terzano, R.; Caponio, F. Emulsion filled gels based on inulin and dry-fractionated pulse proteins to produce low-fat baked goods. LWT-Food Sci. Technol. 2024, 207, 116620. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, X.; Xu, B. Differences in physicochemical, rheological, and prebiotic properties of inulin isolated from five botanical sources and their potential applications. Food Res. Int. 2024, 180, 114048. [Google Scholar] [CrossRef] [PubMed]

- Adewale, P.; Dumont, M.J.; Ngadi, M. Rheological, thermal, and physicochemical characterization of animal fat wastes for use in biodiesel production. Energy Technol. 2014, 2, 634–642. [Google Scholar] [CrossRef]

- Jiménez-Colmenero, F.; Cofrades, S.; Herrero, A.M.; Fernández-Martín, F.; Rodríguez-Salas, L.; Ruiz-Capillas, C. Konjac gel fat analogue for use in meat products: Comparison with pork fats. Food Hydrocoll. 2012, 26, 63–72. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X.; Li, S.; Sun, J.; Liu, X. Effect of inulin on the pasting, textural, and rheological properties of sweet potato starch. CyTA-J. Food 2019, 17, 733–743. [Google Scholar] [CrossRef]

- Liu, M.; Chen, G.; Zhang, H.; Yu, Q.; Mei, X.; Kan, J. Heat-induced inulin-gluten gel: Insights into the influences of inulin molecular weight on the rheological and structural properties of gluten gel to molecular and physicochemical characteristics. Food Hydrocoll. 2021, 111, 106397. [Google Scholar] [CrossRef]

- Hesarinejad, M.A.; Koocheki, A.; Razavi, S.M.A. Dynamic rheological properties of Lepidium perfoliatum seed gum: Effect of concentration, temperature and heating/cooling rate. Food Hydrocoll. 2014, 35, 583–589. [Google Scholar] [CrossRef]

- Singh, M.; Rani, H.; Chopra, H.K. Extraction, optimization, purification and characterization of inulin from chicory roots using conventional and greener extraction techniques. Int. J. Biol. Macromol. 2025, 306, 141385. [Google Scholar] [CrossRef] [PubMed]

- Barbera, S.; Tassone, S. Meat cooking shrinkage: Measurement of a new meat quality parameter. Meat Sci. 2006, 73, 467–474. [Google Scholar] [CrossRef]

- Vu, G.; Zhou, H.; McClements, D.J. Impact of cooking method on properties of beef and plant-based burgers: Appearance, texture, thermal properties, and shrinkage. J. Agric. Food Res. 2022, 9, 100355. [Google Scholar] [CrossRef]

- Leyva-Porras, C.; Saavedra–Leos, M.Z.; López-Pablos, A.L.; Soto-Guerrero, J.J.; Toxqui-Terán, A.; Fozado-Quiroz, R.E. Chemical, thermal and physical characterization of inulin for its technological application based on the degree of polymerization. J. Food Process Eng. 2017, 40, e12333. [Google Scholar] [CrossRef]

- Purslow, P.P.; Oiseth, S.; Hughes, J.; Warner, R.D. The structural basis of cooking loss in beef: Variations with temperature and ageing. Food Res. Int. 2016, 89, 739–748. [Google Scholar] [CrossRef]

| Trial | Inulin (X1) (g/100 g) | Water (X2) (g/100 g) | Guar Gum (X3) (g/100 g) | Trial | Inulin (X1) (g/100 g) | Water (X2) (g/100 g) | Guar Gum (X3) (g/100 g) |

|---|---|---|---|---|---|---|---|

| LDP Gel | HDP Gel | ||||||

| 1 | 30 | 70 | 0.5 | 1 | 35 | 65 | 0.5 |

| 2 | 30 | 70 | 1.5 | 2 | 35 | 65 | 1.5 |

| 3 | 30 | 70 | 3.5 | 3 | 35 | 65 | 3.5 |

| 3 * | 30 | 70 | 3.5 | 3 * | 35 | 65 | 3.5 |

| 4 | 45 | 55 | 0.5 | 4 | 42.5 | 57.5 | 0.5 |

| 4 * | 45 | 55 | 0.5 | 5 | 42.5 | 57.5 | 1.5 |

| 5 | 45 | 55 | 1.5 | 6 | 42.5 | 57.5 | 3.5 |

| 6 | 45 | 55 | 3.5 | 6 * | 42.5 | 57.5 | 3.5 |

| 7 | 60 | 40 | 0.5 | 7 | 50 | 50 | 0.5 |

| 8 | 60 | 40 | 1.5 | 8 | 50 | 50 | 1.5 |

| 9 | 60 | 40 | 3.5 | 9 | 50 | 50 | 3.5 |

| 9 * | 60 | 40 | 3.5 | 9 * | 50 | 50 | 3.5 |

| Sample | Lean Meat (g/100 g) | Beef Back Fat (g/100 g) | LDP Gel (g/100 g) | HDP Gel (g/100 g) |

|---|---|---|---|---|

| CTR | 88 | 12 | - | - |

| LDP-B | 88 | 5 | 7 | - |

| HDP-B | 88 | 5 | - | 7 |

| Response | A (Inulin) | B (Water) | AB (Inulin–Water) | AC (Inulin–Gum) | BC (Water–Gum) | ABC | R2 | R2 adj | p-Value |

|---|---|---|---|---|---|---|---|---|---|

| LDP gel | |||||||||

| K (Pa sn−1) | 3510 | 251 | −4208 | 1600 | 325 | −2428 | 0.998 | 0.996 | <0.001 |

| η (Pa s at ɣ̇ 10 s−1) | 280 | 37 | −124 | 125 | 47 | −81 | 0.986 | 0.974 | <0.001 |

| HDP gel | |||||||||

| K (Pa sn−1) | 3830 | 1202 | −2559 | 3491 | 911 | −4035 | 0.965 | 0.913 | 0.006 |

| η (Pa s at ɣ̇ 10 s−1) | 417 | 102 | −41 | 232 | 81 | −393 | 0.930a | 0.982 | 0.020 |

| Trial | K (Pa sn−1) | η (Pa s at ɣ̇ 10 s−1) |

|---|---|---|

| LDP 1 | 0 ± 0 | 0 ± 0 |

| LDP 2 | 102.49 ± 3.83 | 17.09 ± 0.52 |

| LDP 3 | 629.07 ± 28.98 | 90.71 ± 7.21 |

| LDP 4 | 519.15 ± 37.72 | 73.75 ± 7.35 |

| LDP 5 | 718.15 ± 76.86 | 85.27 ± 16.51 |

| LDP 6 | 1239 ± 27.57 | 214.75 ± 0.77 * |

| LDP 7 | 1868.5 ± 96.87 * | 153.9 ± 9.47 |

| LDP 8 | 3594.5 ± 388.2 | 281.1 ± 56.28 * |

| LDP 9 | 5191 ± 43.84 | 409.3 ± 127.56 |

| HDP 1 | 109 ± 0.30 | 24.28 ± 0.40 |

| HDP 2 | 1565 ± 51.10 * | 95.45 ± 8.05 |

| HDP 3 | 1973 ± 231 * | 181 ± 0.50 * |

| HDP 4 | 922 ± 22.90 * | 190 ± 0.45 * |

| HDP 5 | 1398 ± 555 * | 151 ± 17.5 |

| HDP 6 | 3046 ± 825 | 327 ± 44 |

| HDP 7 | 338.3 ± 57.2 | 185 ± 7.3 * |

| HDP 8 | 3830 ± 455 | 417 ± 91 |

| HDP 9 | n.d. | n.d. |

| Beef back fat | 1525.33 ± 475.84 | 220.77 ± 40.43 |

| Sample | Inulin (%) | Water (%) | Guar Gum (%) | K (Pa sn−1) | η (Pa s at ɣ̇ 10 s−1) |

|---|---|---|---|---|---|

| LDP gel | 51.52 | 48.48 | 1.50 | 1506.67 ± 15.28 a (1735 ± 115) | 211.10 ± 21.55 a (186 ± 23) |

| HDP gel | 39.12 | 60.88 | 1.50 | 1218.67 ± 101.52 a (1414 ± 368) | 215.13 ± 28.29 a (180 ± 46) |

| Beef fat | 1525.33 ± 475.84 a | 220.77 ± 40.44 a |

| Sample | Cooking Loss (%) | Cooking Yield (%) | Diameter Reduction (%) | Thickness Increases (%) | Shrinkage (%) |

|---|---|---|---|---|---|

| CTR | 26.67 ± 1.25 a | 73.33 ± 1.25 c | 21.00 ± 0.25 a | 7.50 ± 2.50 a | 18.49 ± 0.45 a |

| LDP-B | 24.09 ± 0.65 b | 75.09 ± 0.65 b | 17.50 ± 0.30 b | 4.00 ± 1.73 ab | 15.63 ± 0.54 ab |

| HDP-B | 21.36 ± 0.91 c | 78.63 ± 0.91 a | 16.30 ± 1.70 b | 3.00 ± 1.00 b | 14.54 ± 1.63 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Totaro, M.P.; Miccolis, M.; De Angelis, D.; Natrella, G.; Caponio, F.; Summo, C.; Faccia, M. Optimization of the Rheological Properties of Fat Replacers Based on Inulin at Different Degrees of Polymerization and Their Application in Beef Burgers. Foods 2025, 14, 2127. https://doi.org/10.3390/foods14122127

Totaro MP, Miccolis M, De Angelis D, Natrella G, Caponio F, Summo C, Faccia M. Optimization of the Rheological Properties of Fat Replacers Based on Inulin at Different Degrees of Polymerization and Their Application in Beef Burgers. Foods. 2025; 14(12):2127. https://doi.org/10.3390/foods14122127

Chicago/Turabian StyleTotaro, Michela Pia, Mariana Miccolis, Davide De Angelis, Giuseppe Natrella, Francesco Caponio, Carmine Summo, and Michele Faccia. 2025. "Optimization of the Rheological Properties of Fat Replacers Based on Inulin at Different Degrees of Polymerization and Their Application in Beef Burgers" Foods 14, no. 12: 2127. https://doi.org/10.3390/foods14122127

APA StyleTotaro, M. P., Miccolis, M., De Angelis, D., Natrella, G., Caponio, F., Summo, C., & Faccia, M. (2025). Optimization of the Rheological Properties of Fat Replacers Based on Inulin at Different Degrees of Polymerization and Their Application in Beef Burgers. Foods, 14(12), 2127. https://doi.org/10.3390/foods14122127