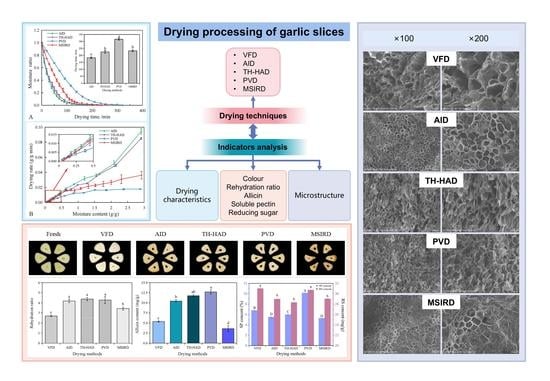

Comparative Study on the Influence of Various Drying Techniques on Drying Characteristics and Physicochemical Quality of Garlic Slices

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Drying Experiments

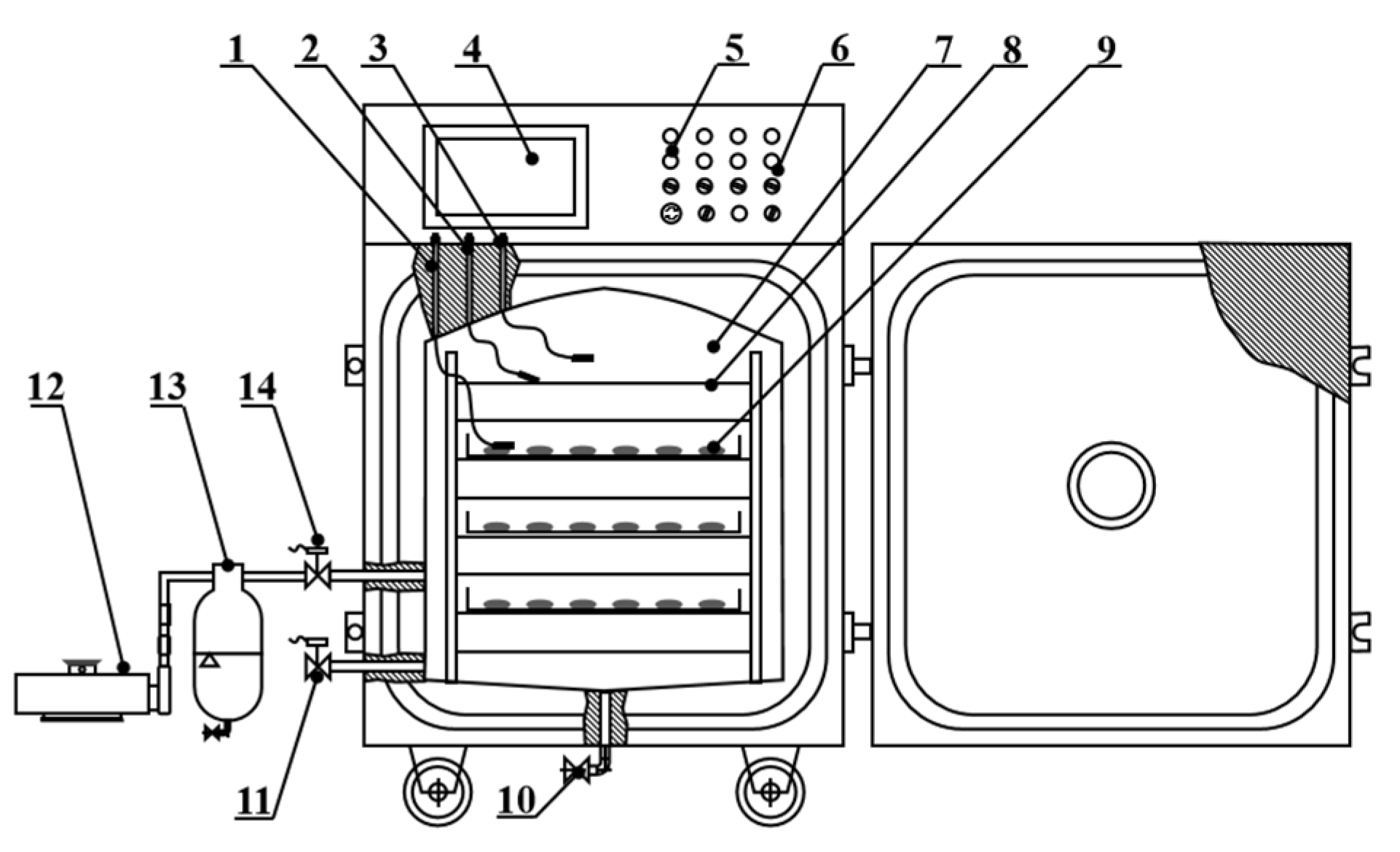

2.2.1. Vacuum Freeze Drying (VFD)

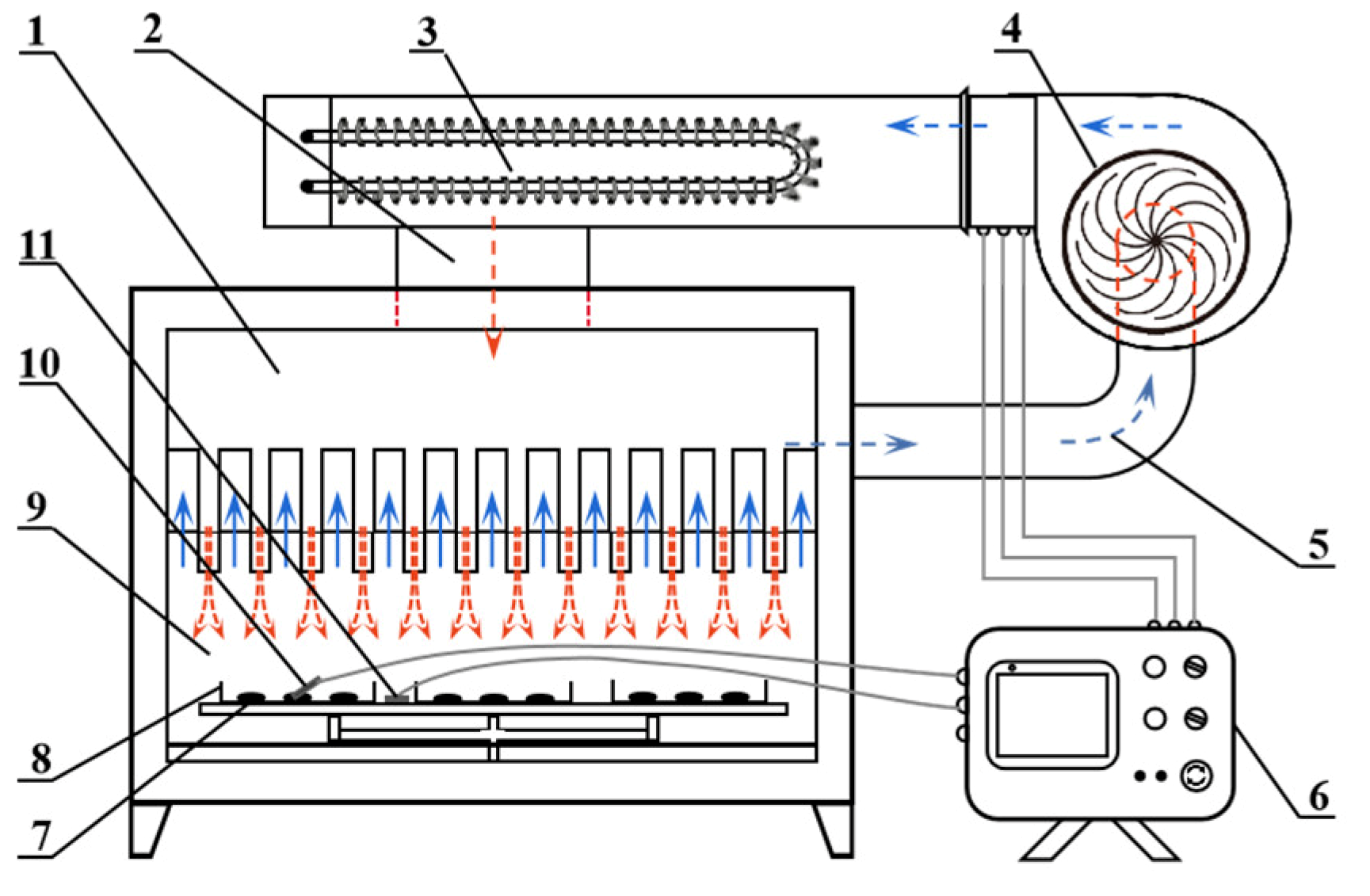

2.2.2. Air Impingement Drying (AID)

2.2.3. Hot Air Drying Based on Temperature and Humidity Control (TH-HAD)

2.2.4. Pulsed Vacuum Drying (PVD)

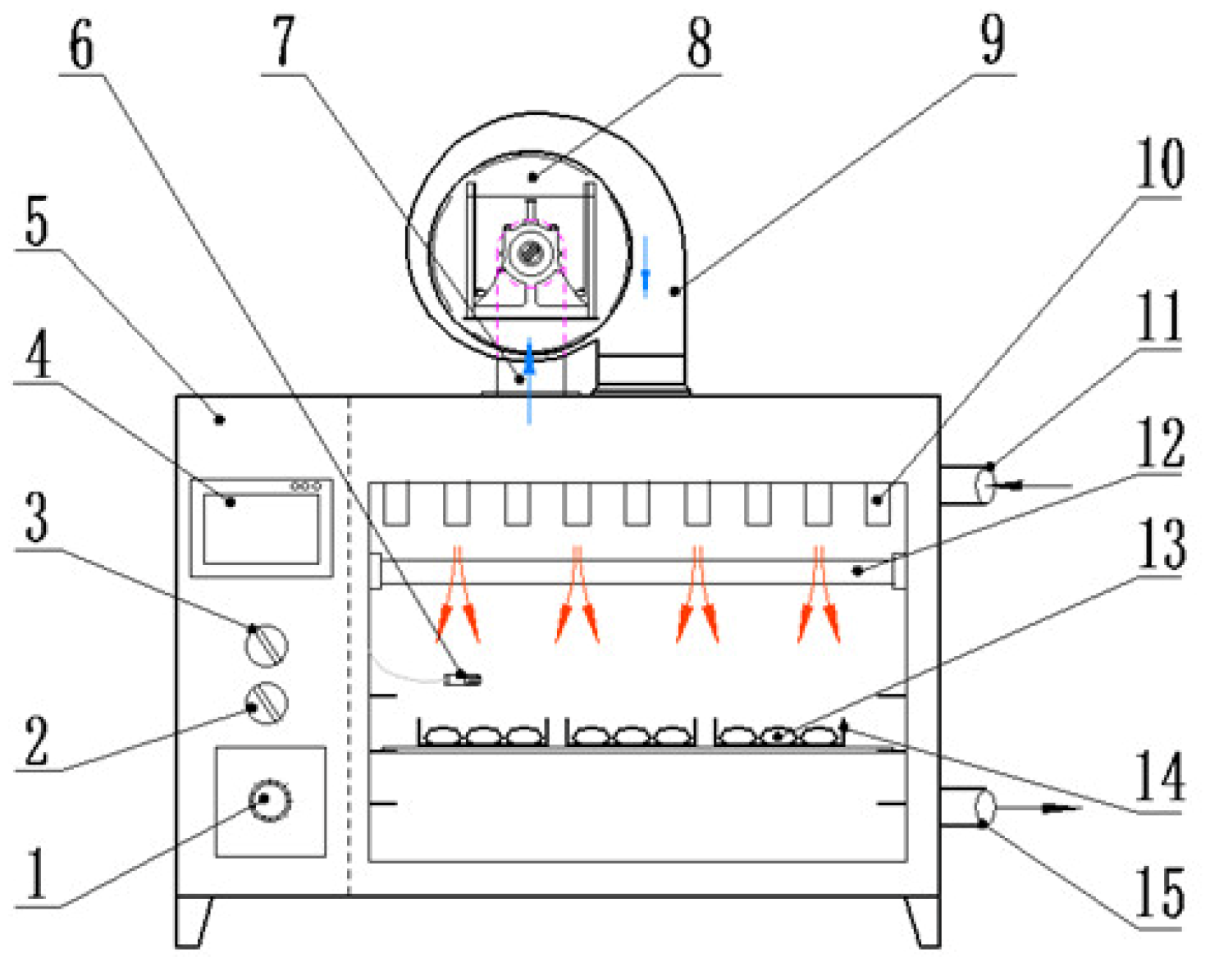

2.2.5. Medium- and Short-Wave Infrared Radiation Drying (MSIRD)

2.3. Drying Characteristics

2.3.1. Drying Kinetics

2.3.2. Modeling of Drying Curves

2.4. Rehydration Ratio (RR)

2.5. Microstructure Measurement

2.6. Color

2.7. Allicin Content

2.8. Soluble Pectin Content

2.9. Reducing Sugar Content

2.10. Statistical Data Analysis

3. Results and Discussion

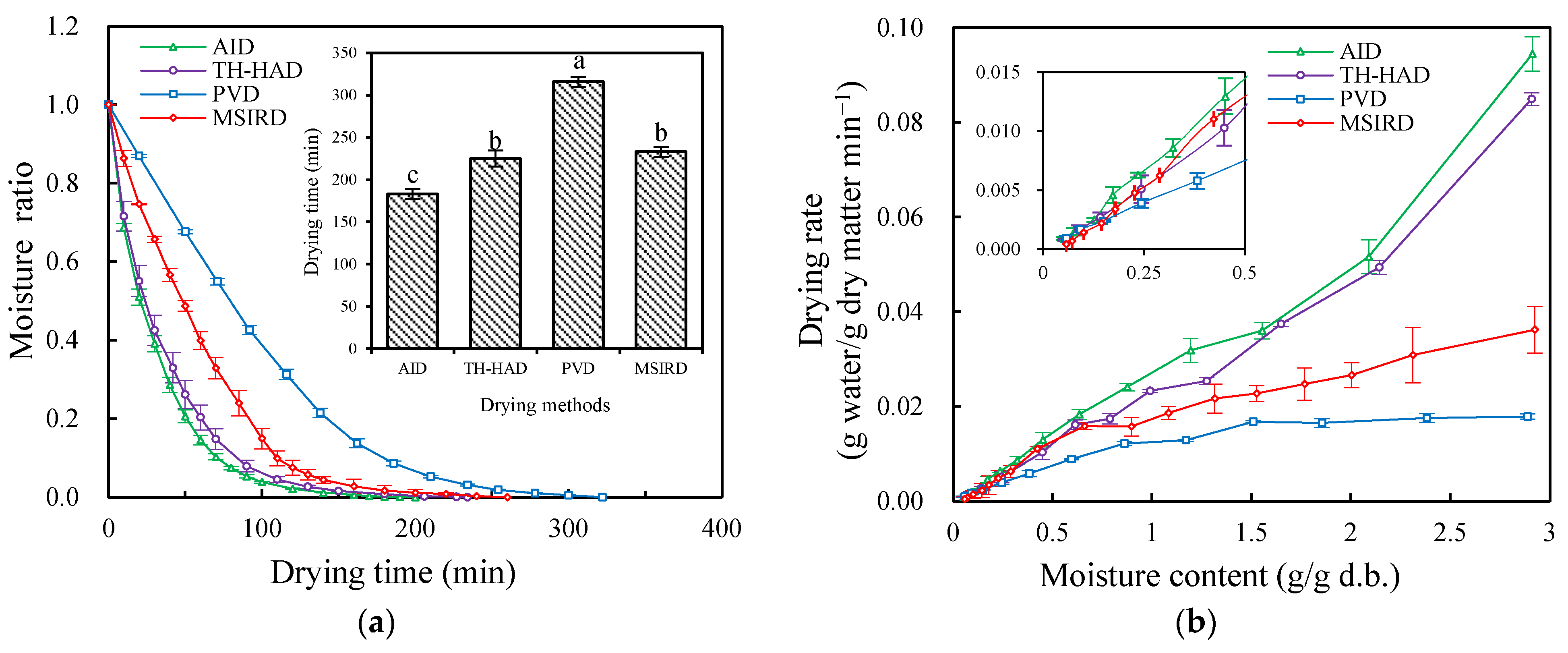

3.1. Drying Characteristics Analysis

3.1.1. Drying Kinetics Curves

3.1.2. Modeling of Drying Curves

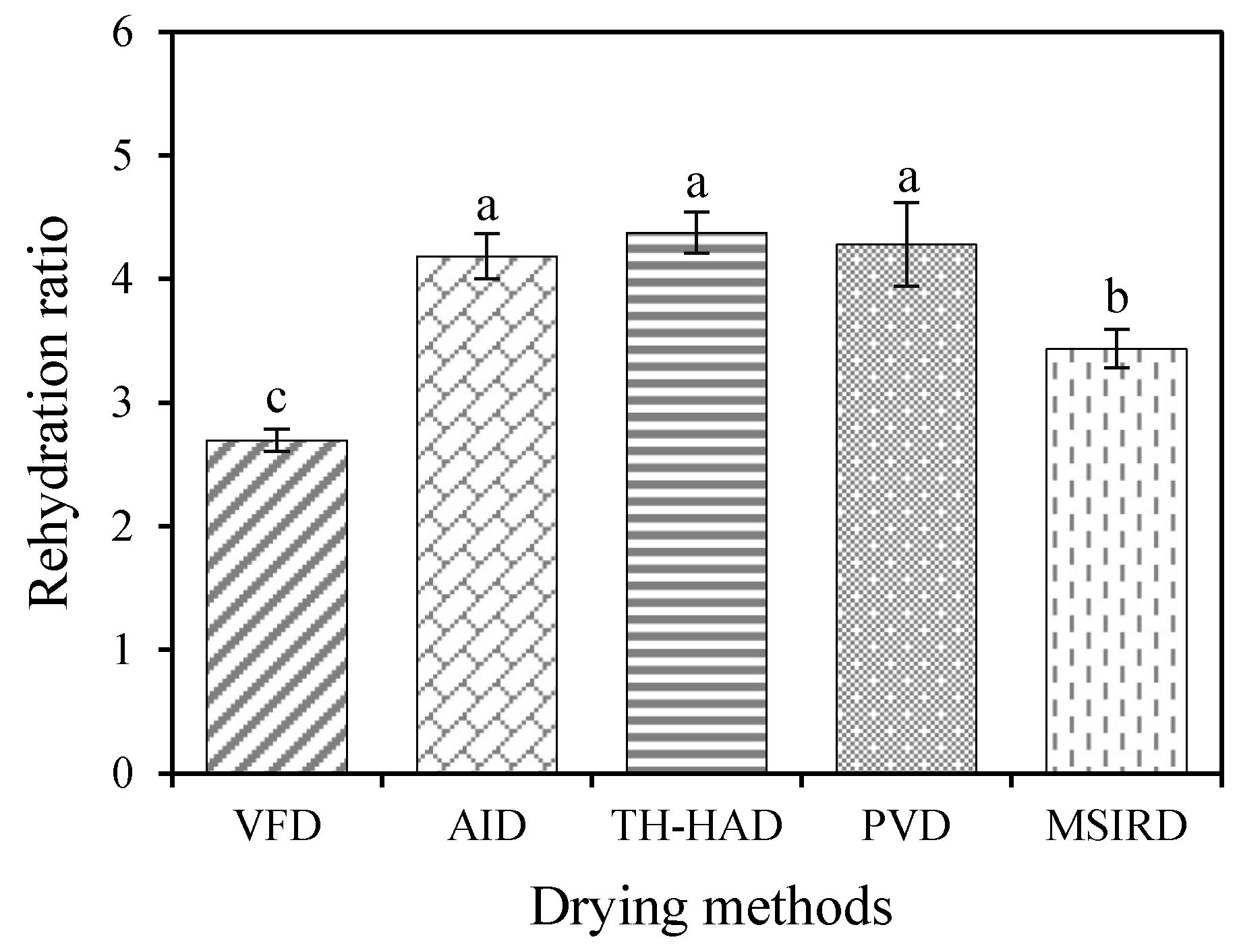

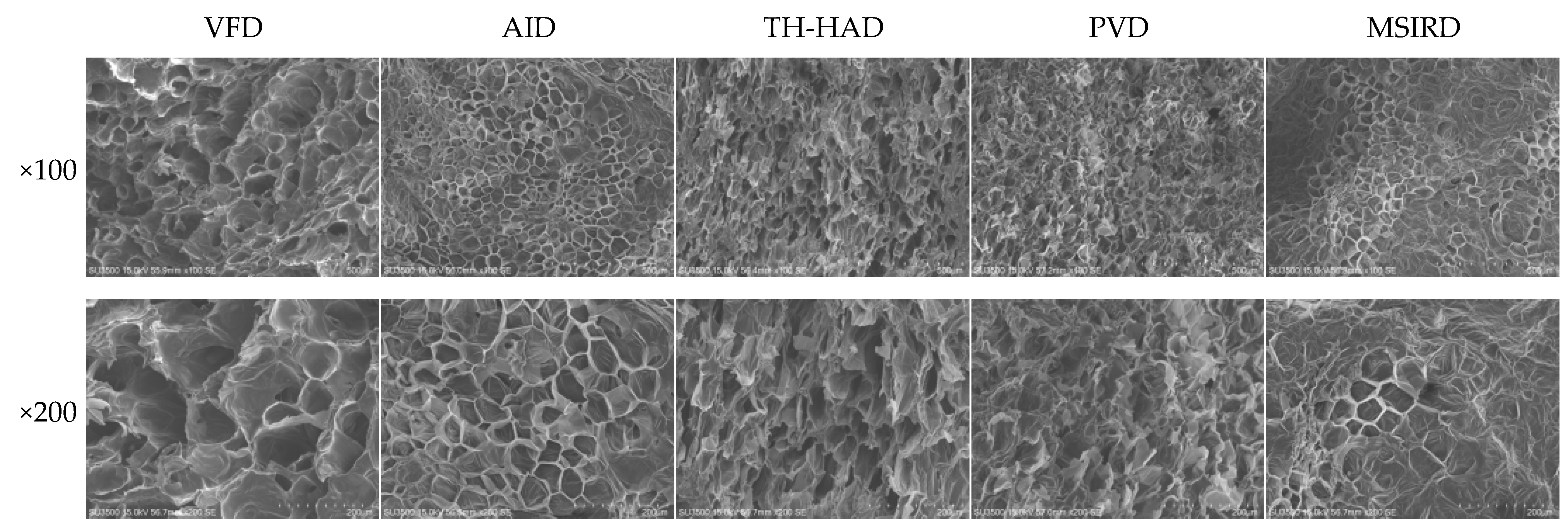

3.2. Rehydration Ratio and Microstructure

3.3. Color and Form

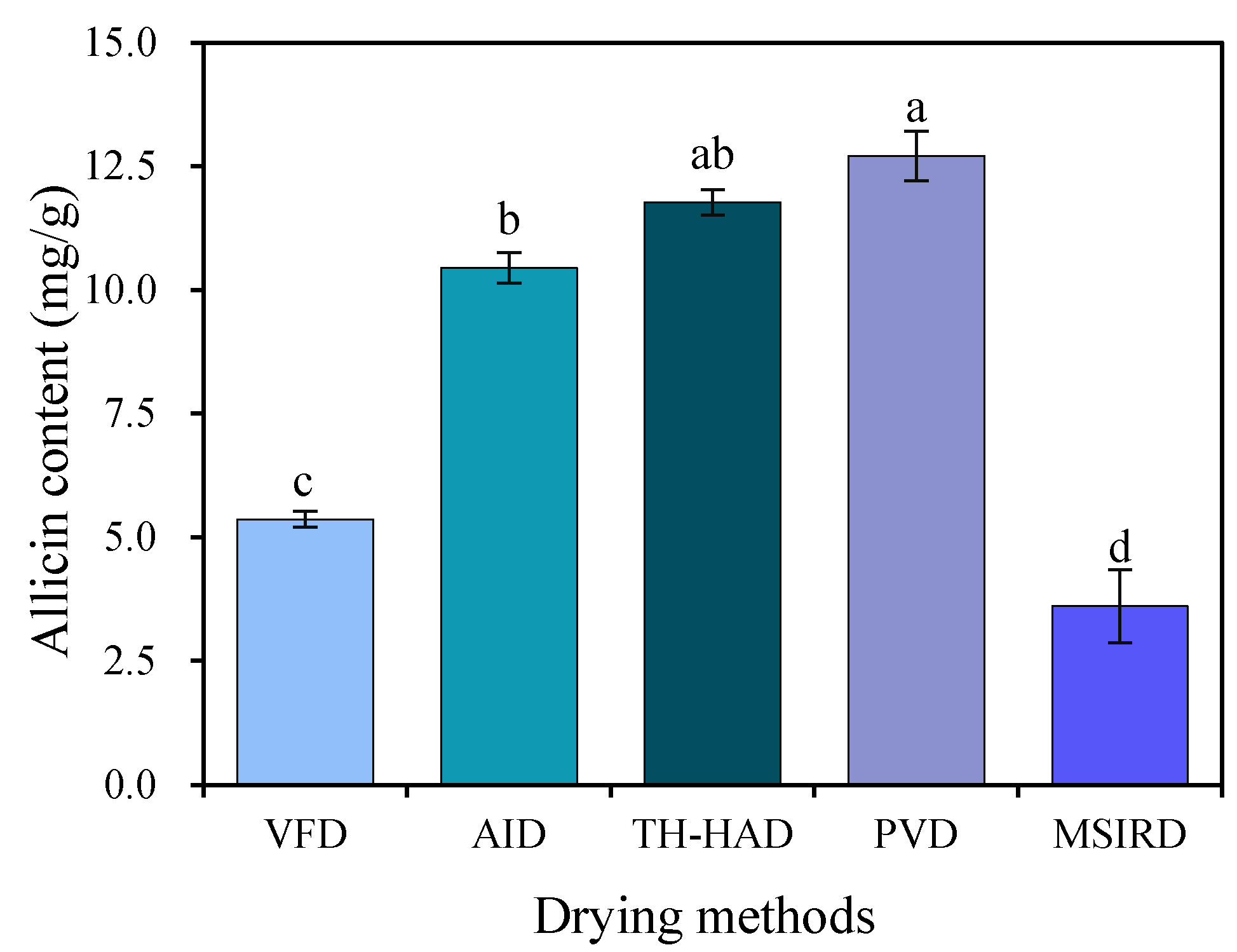

3.4. Allicin Content

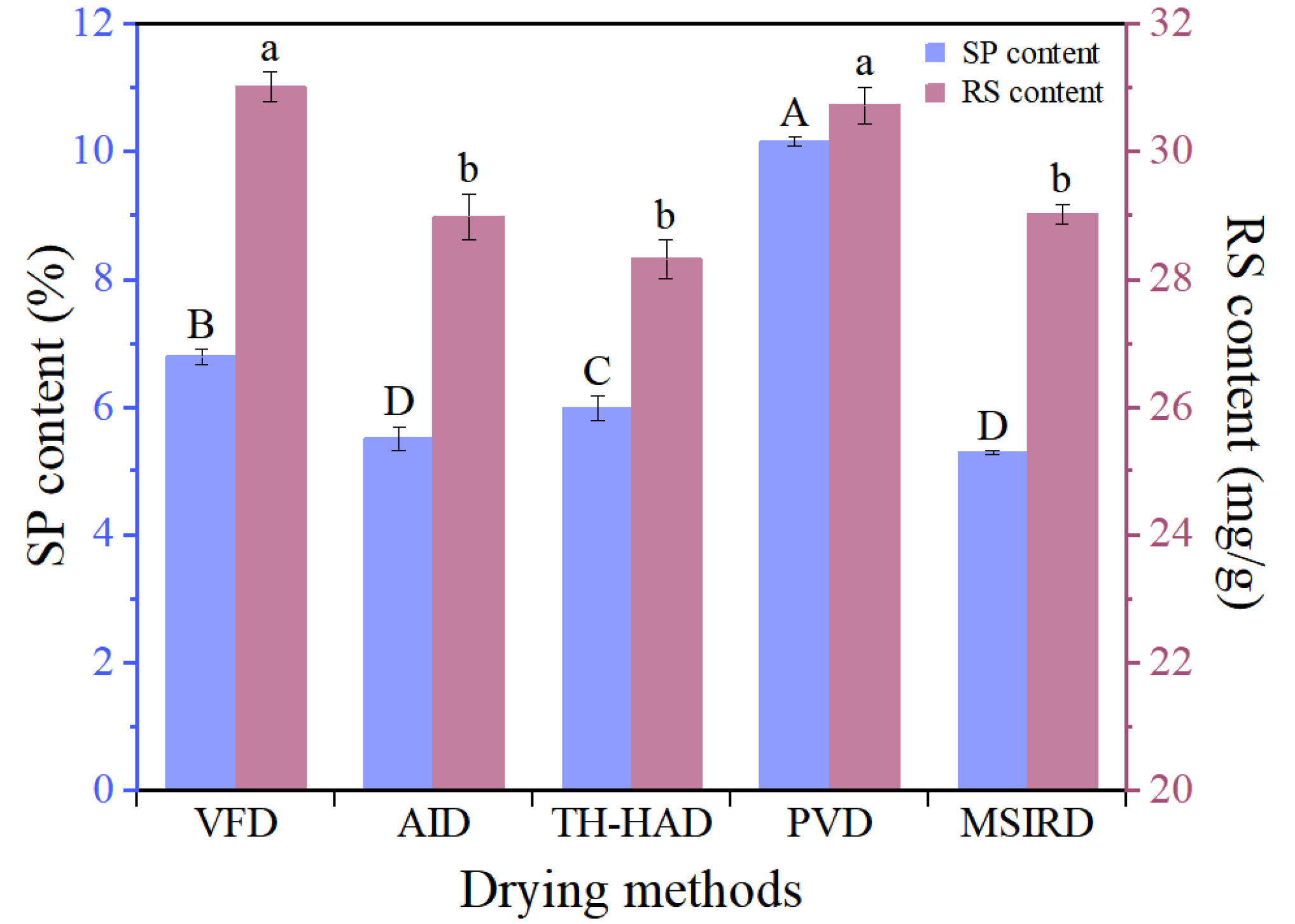

3.5. Soluble Pectin (SP) and Reducing Sugar (RS) Content

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mondal, A.; Banerjee, S.; Bose, S.; Mazumder, S.; Haber, R.A.; Farzaei, M.H.; Bishayee, A. Garlic constituents for cancer prevention and therapy: From phytochemistry to novel formulations. Pharmacol. Res. 2022, 175, 105–837. [Google Scholar] [CrossRef] [PubMed]

- FAO Stat Database. Available online: http://faostat.fao.org (accessed on 25 February 2023).

- Gebreyohannes, G.; Gebreyohannes, M. Medicinal values of garlic: A review. Int. J. Med. Med. Sci. 2013, 5, 401–408. [Google Scholar] [CrossRef]

- Kaur, R.; Tiwari, A.; Manish, M.; Maurya, I.K.; Bhatnagar, R.; Singh, S. Common garlic (Allium sativum L.) has potent Anti-Bacillus anthracis activity. J. Ethnopharmacol. 2021, 264, 113230. [Google Scholar] [CrossRef] [PubMed]

- Tedeschi, P.; Nigro, M.; Travagli, A.; Catani, M.; Cavazzini, A.; Merighi, S.; Gessi, S. Therapeutic potential of allicin and aged garlic extract in Alzheimer's disease. Int. J. Mol. Sci. 2022, 23, 6950. [Google Scholar] [CrossRef]

- Antony, S.; Kumar, K.K.; Menon, J.S. Assessment of phyto-constituents by GC-MS and anti-tumour activity of garlic grown in different altitude: A comparative study. Pharmacogn. J. 2019, 11, 350–354. [Google Scholar] [CrossRef]

- Yan, J.K.; Wang, C.; Yu, Y.B.; Wu, L.X.; Chen, T.T.; Wang, Z.W. Physicochemical characteristics and in vitro biological activities of polysaccharides derived from raw garlic (Allium sativum L.) bulbs via three-phase partitioning combined with gradient ethanol precipitation method. Food Chem. 2021, 339, 128081. [Google Scholar] [CrossRef]

- Torun, M.; Ozdemir, F. Milk protein and zein coatings over peeled garlic cloves to extend their shelf life. Sci. Hortic. 2022, 291, 110571. [Google Scholar] [CrossRef]

- Ludlow, R.A.; Pacenza, M.; Chiappetta, A.; Christofides, S.R.; Evans, G.; Graz, M.; Marti, G.; Rogers, H.J.; Muller, C.T. Storage time and temperature affects volatile organic compound profile, alliinase activity and postharvest quality of garlic. Postharvest Biol. Technol. 2021, 177, 111533. [Google Scholar] [CrossRef]

- Sharma, G.P.; Prasad, S. Drying of garlic (Allium sativum) cloves by microwave-hot air combination. J. Food Eng. 2001, 50, 99–105. [Google Scholar] [CrossRef]

- Bassey, E.J.; Cheng, J.H.; Sun, D.W. Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends Food Sci. Technol. 2021, 112, 137–148. [Google Scholar] [CrossRef]

- Liu, Z.L.; Xie, L.; Zielinska, M.; Pan, Z.; Deng, L.Z.; Zhang, J.S.; Gao, L.; Wang, S.Y.; Zheng, Z.A.; Xiao, H.W. Improvement of drying efficiency and quality attributes of blueberries using innovative far-infrared radiation heating assisted pulsed vacuum drying (FIR-PVD). Innov. Food Sci. Emerg. Technol. 2022, 77, 102948. [Google Scholar] [CrossRef]

- Chen, Y.N.; Li, M.; Dharmasiri, T.S.K.; Song, X.Y.; Liu, F.; Wang, X. Novel ultrasonic-assisted vacuum drying technique for dehydrating garlic slices and predicting the quality properties by low field nuclear magnetic resonance. Food Chem. 2020, 306, 125625. [Google Scholar] [CrossRef]

- Thuwapanichayanan, R.; Prachayawarakorn, S.; Kunwisawa, J.; Soponronnarit, S. Determination of effective moisture diffusivity and assessment of quality attributes of banana slices during drying. LWT-Food Sci. Technol. 2011, 44, 1502–1510. [Google Scholar] [CrossRef]

- Le, X.; Hu, S.; Zheng, J.; Cui, E.; Zhu, Y.; Zhu, M. The influence of different drying methods on bioactive components of Eucommia ulmoides Oliver male flower and the comprehensive assessment for industrial application. Ind. Crop. Prod. 2022, 177, 114469. [Google Scholar] [CrossRef]

- Le Loeuff, J.; Boy, V.; Morancais, P.; Colinart, T.; Bourgougnon, N.; Lanoiselle, J.L. Mathematical modeling of air impingement drying of the brown algae Sargassum muticum (Fucales). Chem. Eng. Technol. 2021, 44, 2073–2081. [Google Scholar] [CrossRef]

- Boy, V.; Ben Khalifa, W.; Drevillon, L.; Lemee, Y.; Lendormi, T.; Lanoiselle, J.L. Air impingement and intermittent drying: Application to apple and to mango. Can. J. Chem. Eng. 2021, 99, 120–134. [Google Scholar] [CrossRef]

- Liu, Z.L.; Bai, J.W.; Wang, S.X.; Meng, J.S.; Wang, H.; Yu, X.L.; Gao, Z.J.; Xiao, H.W. Prediction of energy and exergy of mushroom slices drying in hot air impingement dryer by artificial neural network. Dry. Technol. 2020, 38, 1959–1970. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.L.; Vidyarthi, S.K.; Wang, Q.H.; Gao, L.; Li, B.R.; Wei, Q.; Liu, Y.H.; Xiao, H.W. Effects of different drying methods on drying kinetics, physicochemical properties, microstructure, and energy consumption of potato (Solanum tuberosum L.) cubes. Dry. Technol. 2021, 39, 418–431. [Google Scholar] [CrossRef]

- Li, W.; Gou, G.; He, Y.; Tan, S. Innovative air-impingement jet drying of red cabbage: Kinetic description and prediction of the degradation of cyanidin-3-diglucoside-5-glucoside and cyanidin. Food Chem. X 2022, 15, 100422. [Google Scholar] [CrossRef]

- Dai, J.W.; Rao, J.Q.; Wang, D.; Xie, L.; Xiao, H.W.; Liu, Y.H.; Gao, Z.J. Process-Based drying temperature and humidity integration control enhances drying kinetics of apricot halves. Dry. Technol. 2015, 33, 365–376. [Google Scholar] [CrossRef]

- Reyer, S.; Awiszus, S.; Meissner, K.; Müller, J. High precision laboratory dryer for thin layer and bulk drying with adjustable temperature, relative humidity and velocity of the drying air. HardwareX 2020, 8, e00133. [Google Scholar] [CrossRef] [PubMed]

- Garcia-llobodanin, L.; Billiris, A. Effect of the drying air conditions on the drying rate and milling quality of a long-grain rice variety. Food Sci. Technol. 2023, 43, e65722. [Google Scholar] [CrossRef]

- Ju, H.Y.; Zhao, S.H.; Mujumdar, A.S.; Fang, X.M.; Gao, Z.J.; Zheng, Z.A.; Xiao, H.W. Energy efficient improvements in hot air drying by controlling relative humidity based on Weibull and Bi-Di models. Food Bioprod. Process. 2018, 111, 20–29. [Google Scholar] [CrossRef]

- Li, X.Y.; Liu, Y.H.; Gao, Z.J.; Xie, Y.K.; Wang, H. Computer vision online measurement of shiitake mushroom (Lentinus edodes) surface wrinkling and shrinkage during hot air drying with humidity control. J. Food Eng. 2021, 292, 110253. [Google Scholar] [CrossRef]

- Xie, Y.; Gao, Z.; Liu, Y.; Xiao, H. Pulsed Vacuum Drying of Rhizoma Dioscoreae Slices. LWT-Food Sci. Technol. 2017, 80, 237–249. [Google Scholar] [CrossRef]

- Link, J.V.; Tribuzi, G.; Laurindo, J.B. Conductive multi-flash drying of mango slices: Vacuum pulse conditions on drying rate and product properties. J. Food Process Preserv. 2018, 42, e13440. [Google Scholar] [CrossRef]

- Boateng, I.D.; Soetanto, D.A.; Yang, X.M.; Zhou, C.S.; Saalia, F.K.; Li, F.N. Effect of pulsed-vacuum, hot-air, infrared, and freeze-drying on drying kinetics, energy efficiency, and physicochemical properties of Ginkgo biloba L. seed. J. Food Process Eng. 2021, 44, e13655. [Google Scholar] [CrossRef]

- Wang, J.; Bai, T.Y.; Wang, D.; Fang, X.M.; Xue, L.Y.; Zheng, Z.A.; Gao, Z.J.; Xiao, H.W. Pulsed vacuum drying of Chinese ginger (Zingiber officinale Roscoe) slices: Effects on drying characteristics, rehydration ratio, water holding capacity, and microstructure. Dry. Technol. 2019, 37, 301–311. [Google Scholar] [CrossRef]

- Nowak, D.; Lewicki, P.P. Infrared drying of apple slices. Innov. Food Sci. Emerg. Technol. 2004, 5, 353–360. [Google Scholar] [CrossRef]

- Ai, Z.P.; Ren, H.F.; Lin, Y.W.; Sun, W.L.; Yang, Z.L.; Zhang, Y.; Zhang, H.; Yang, Z.Y.; Pandiselvam, R.; Liu, Y.H. Improving drying efficiency and product quality of Stevia rebaudiana leaves using innovative medium-and short-wave infrared drying (MSWID). Innov. Food Sci. Emerg. Technol. 2022, 81, 103154. [Google Scholar] [CrossRef]

- Tangkhawanit, E.; Meeso, N.; Siriamornpun, S. Changes in bioactive components, biological activities and starch digestibility of soymilk residues as affected by far-infrared radiation combined with hot-air and hot-air drying. Dry. Technol. 2022, 40, 3357–3370. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, G.; Li, X.; Zhao, Y.; Lei, D.; Ding, G.; Ambrose, K.; Liu, Y. Combined medium- and short-wave infrared and hot air impingement drying of sponge gourd (Luffa cylindrical) slices. J. Food Eng. 2020, 284, 110043. [Google Scholar] [CrossRef]

- Xu, M.; Tian, G.; Zhao, C.; Ahmad, A.; Zhang, H.; Bi, J.; Xiao, H.; Zheng, J. Infrared drying as a quick preparation method for dried tangerine peel. Int. J. Anal. Chem. 2017, 2017, 6254793. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists. Official Methods of Analysis, 15th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Wang, J.; Mu, W.S.; Fang, X.M.; Mujumdar, A.S.; Yang, X.H.; Xue, L.Y.; Xie, L.; Xiao, H.W.; Gao, Z.J.; Zhang, Q. Pulsed vacuum drying of Thompson seedless grape: Effects of berry ripeness on physicochemical properties and drying characteristic. Food Bioprod. Process. 2017, 106, 117–126. [Google Scholar] [CrossRef]

- Liu, Z.L.; Xie, L.; Zielinska, M.; Pan, Z.L.; Wang, J.; Deng, L.Z.; Wang, H.; Xiao, H.W. Pulsed vacuum drying enhances drying of blueberry by altering micro-, ultrastructure and water status and distribution. LWT-Food Sci. Technol. 2021, 142, 111013. [Google Scholar] [CrossRef]

- Uribe, E.; Vega-Galvez, A.; Di Scala, K.; Oyanadel, R.; Torrico, J.S.; Miranda, M. Characteristics of convective drying of pepino fruit (Solanum muricatum Ait.): Application of Weibull distribution. Food Bioprocess Technol. 2011, 4, 1349–1356. [Google Scholar] [CrossRef]

- Cunha, L.M.; Oliveira, F.A.R.; Oliveira, J.C. Optimal experimental design for estimating the kinetic parameters of processes described by the Weibull probability distribution function. J. Food Eng. 1998, 37, 175–191. [Google Scholar] [CrossRef]

- Wang, C.Y.; Singh, R.P. A single layer drying equation for rough rice. ASAE Pap. 1978, 78, 3001–3006. [Google Scholar]

- Tao, Y.; Li, D.D.; Chai, W.S.; Show, P.L.; Yang, X.H.; Manickam, S.; Xie, G.J.; Han, Y.B. Comparison between airborne ultrasound and contact ultrasound to intensify air drying of blackberry: Heat and mass transfer simulation, energy consumption and quality evaluation. Ultrason. Sonochem. 2021, 72, 105410. [Google Scholar] [CrossRef]

- Yang, K.W.; Wang, D.; Vidyarthi, S.K.; Li, S.B.; Liu, Z.L.; Wang, H.; Chen, X.J.; Xiao, H.W. Pulsed vacuum drying of persimmon slices: Drying kinetics, physicochemical properties, microstructure and antioxidant capacity. Plants 2022, 11, 2500. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Pei, Y.P.; Sutar, P.P.; Liu, D.H.; Deng, L.Z.; Duan, X.; Liu, Z.L.; Xiao, H.W. Pulsed vacuum drying of banana: Effects of ripeness on drying kinetics and physicochemical properties and related mechanism. LWT-Food Sci. Technol. 2022, 161, 113362. [Google Scholar] [CrossRef]

- Qiao, H.; Gao, Z.; Wang, J.; Zheng, Z.; Wei, Q.; Li, G. Optimization of vacuum pulsed drying process of garlic. Trans. Chin. Soc. Agric. Eng. 2018, 34, 256–263. [Google Scholar] [CrossRef]

- Polat, A.; Izli, N. Drying characteristics and quality evaluation of ‘Ankara’ pear dried by electrohydrodynamic-hot air (EHD) method. Food Control 2022, 134, 108774. [Google Scholar] [CrossRef]

- Cao, J.; Jiang, W.; Zhao, Y. Experiment Guidance of Postharvest Physiology and Biochemistry of Fruits and Vegetables, 1st ed.; China Light Industry Press: Beijing, China, 2007; pp. 59–92. [Google Scholar]

- Moreira, R.G. Impingement drying of foods using hot air and superheated steam. J. Food Eng. 2001, 49, 291–295. [Google Scholar] [CrossRef]

- Anderson, B.A.; Singh, R.P. Modeling the thawing of frozen foods using air impingement technology. Int. J. Refrig. 2006, 29, 294–304. [Google Scholar] [CrossRef]

- Lou, Z.Q.; Mujumdar, A.S.; Yap, C. Effects of geometric parameters on confined impinging jet heat transfer. Appl. Therm. Eng. 2005, 25, 2687–2697. [Google Scholar] [CrossRef]

- Deng, L.Z.; Yang, X.H.; Mujumdar, A.S.; Zhao, J.H.; Wang, D.; Zhang, Q.; Wang, J.; Gao, Z.J.; Xiao, H.W. Red pepper (Capsicum annuum L.) drying: Effects of different drying methods on drying kinetics, physicochemical properties, antioxidant capacity, and microstructure. Dry. Technol. 2018, 36, 893–907. [Google Scholar] [CrossRef]

- Meng, J.S.; Jiang, J.C.; Zheng, Z.A.; Deng, L.Z.; Wang, J.; Xue, L.Y.; Han, Z.L.; Wang, H.; Xiao, H.W. Effects of three drying technologies on drying kinetics and quality attributes of yam slices. Chin. Tradit. Herb. Drugs 2019, 50, 2575–2582. [Google Scholar] [CrossRef]

- Yang, X.H.; Deng, L.Z.; Mujumdar, A.S.; Xiao, H.W.; Zhang, Q.; Kan, Z. Evolution and modeling of colour changes of red pepper (Capsicum annuum L.) during hot air drying. J. Food Eng. 2018, 231, 101–108. [Google Scholar] [CrossRef]

- Marques, L.G.; Prado, M.M.; Freire, J.T. Rehydration characteristics of freeze-dried tropical fruits. LWT-Food Sci. Technol. 2009, 42, 1232–1237. [Google Scholar] [CrossRef]

- Feng, Y.B.; Xu, B.G.; Yagoub, A.E.A.; Ma, H.L.; Sun, Y.H.; Xu, X.; Yu, X.J.; Zhou, C.S. Role of drying techniques on physical, rehydration, flavor, bioactive compounds and antioxidant characteristics of garlic. Food Chem. 2021, 343, 128404. [Google Scholar] [CrossRef]

- Markowski, M.; Bondaruk, J.; Błaszczak, W. Rehydration behavior of vacuum-microwave-dried potato cubes. Dry. Technol. 2009, 27, 296–305. [Google Scholar] [CrossRef]

- Xiao, H.W.; Law, C.L.; Sun, D.W.; Gao, Z.J. Color change kinetics of American ginseng (Panax quinquefolium) slices during air impingement drying. Dry. Technol. 2014, 32, 418–427. [Google Scholar] [CrossRef]

- Wang, H.; Fang, X.M.; Sutar, P.P.; Meng, J.S.; Wang, J.; Yu, X.L.; Xiao, H.W. Effects of vacuum-steam pulsed blanching on drying kinetics, colour, phytochemical contents, antioxidant capacity of carrot and the mechanism of carrot quality changes revealed by texture, microstructure and ultrastructure. Food Chem. 2021, 338, 127799. [Google Scholar] [CrossRef]

- Doganturk, M.; Demiray, E.; Gursoy, O.; Yilmaz, Y. Kinetics of allicin potential loss in garlic slices during convective drying. Qual. Assur. Saf. Crop. Foods 2019, 11, 211–220. [Google Scholar] [CrossRef]

- Jones, M.G.; Hughes, J.; Tregova, A.; Milne, J.; Tomsett, A.B.; Collin, H.A. Biosynthesis of the flavour precursors of onion and garlic. J. Exp. Bot. 2004, 55, 1903–1918. [Google Scholar] [CrossRef]

- Aware, R.S.; Thorat, B.N. Garlic under various drying study and its impact on allicin retention. Dry. Technol. 2011, 29, 1510–1518. [Google Scholar] [CrossRef]

- Ratti, C.; Araya-Farias, M.; Mendez-Lagunas, L.; Makhlouf, J. Drying of garlic (Alliumsativum) and its effect on allicin retention. Dry. Technol. 2007, 25, 349–356. [Google Scholar] [CrossRef]

- Zhu, R.; Shen, J.; Law, C.L.; Ma, X.; Li, D.; Han, Y.; Kiani, H.; Manickam, S.; Tao, Y. Combined calcium pretreatment and ultrasonic/microwave drying to dehydrate black chokeberry: Novel mass transfer modeling and metabolic pathways of polyphenols. Innov. Food Sci. Emerg. Technol. 2023, 83, 103215. [Google Scholar] [CrossRef]

- Niu, Y.B.; Wei, S.Y.; Liu, H.; Zang, Y.Z.; Cao, Y.X.; Zhu, R.G.; Zheng, X.; Yao, X.D. The kinetics of nutritional quality changes during winter jujube slices drying process. Qual. Assur. Saf. Crop. Foods 2021, 13, 73–82. [Google Scholar] [CrossRef]

| Drying Methods | Weibull | Wang and Singh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| α (min) | β | χ2 | RSS | R2 | a | b | χ2 | RSS | R2 | |

| AID | 30.4653 | 0.95 | 7.20 × 10−5 | 0.001 | 0.999 | −0.0167 | 6.19 × 10−5 | 0.0128 | 0.204 | 0.850 |

| TH-HAD | 35.3494 | 0.92 | 1.00 × 10−4 | 0.001 | 0.999 | −0.0145 | 4.58 × 10−5 | 0.0159 | 0.223 | 0.833 |

| PVD | 100.7441 | 1.39 | 1.54 × 10−4 | 0.002 | 0.999 | −0.0074 | 1.37 × 10−5 | 0.0003 | 0.003 | 0.998 |

| MSIRD | 61.2684 | 1.25 | 3.80 × 10−4 | 0.007 | 0.997 | −0.0112 | 2.95 × 10−5 | 0.0019 | 0.034 | 0.983 |

| Fresh | VFD | AID | TH-HAD | PVD | MSIRD | |

|---|---|---|---|---|---|---|

| Image |  |  |  |  |  |  |

| L* | 79.36 ± 0.68 d | 91.57 ± 0.41 a | 82.93 ± 0.17 c | 83.52 ± 0.28 c | 87.98 ± 0.03 b | 74.97 ± 0.51 e |

| a* | −5.86 ± 0.81 e | −2.35 ± 0.51 d | 2.57 ± 0.32 b | 2.47 ± 0.06 b | −1.03 ± 0.14 c | 4.67 ± 0.21 a |

| b* | 7.98 ± 0.27 c | 3.34 ± 0.18 d | 24.22 ± 0.43 a | 23.93 ± 0.36 a | 13.28 ± 0.20 b | 24.18 ± 0.40 a |

| ΔE | — | 13.53 ± 0.44 c | 18.64 ± 0.50 b | 18.47 ± 0.27 b | 11.21 ± 0.17 d | 19.82 ± 0.31 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Z.-A.; Wang, S.-Y.; Wang, H.; Xiao, H.; Liu, Z.-L.; Pan, Y.-H.; Gao, L. Comparative Study on the Influence of Various Drying Techniques on Drying Characteristics and Physicochemical Quality of Garlic Slices. Foods 2023, 12, 1314. https://doi.org/10.3390/foods12061314

Zheng Z-A, Wang S-Y, Wang H, Xiao H, Liu Z-L, Pan Y-H, Gao L. Comparative Study on the Influence of Various Drying Techniques on Drying Characteristics and Physicochemical Quality of Garlic Slices. Foods. 2023; 12(6):1314. https://doi.org/10.3390/foods12061314

Chicago/Turabian StyleZheng, Zhi-An, Shan-Yu Wang, Hui Wang, Hongmei Xiao, Zi-Liang Liu, Ya-Hui Pan, and Lei Gao. 2023. "Comparative Study on the Influence of Various Drying Techniques on Drying Characteristics and Physicochemical Quality of Garlic Slices" Foods 12, no. 6: 1314. https://doi.org/10.3390/foods12061314

APA StyleZheng, Z.-A., Wang, S.-Y., Wang, H., Xiao, H., Liu, Z.-L., Pan, Y.-H., & Gao, L. (2023). Comparative Study on the Influence of Various Drying Techniques on Drying Characteristics and Physicochemical Quality of Garlic Slices. Foods, 12(6), 1314. https://doi.org/10.3390/foods12061314