Dough Rheological Behavior and Bread Quality as Affected by Addition of Soybean Flour in a Germinated Form

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

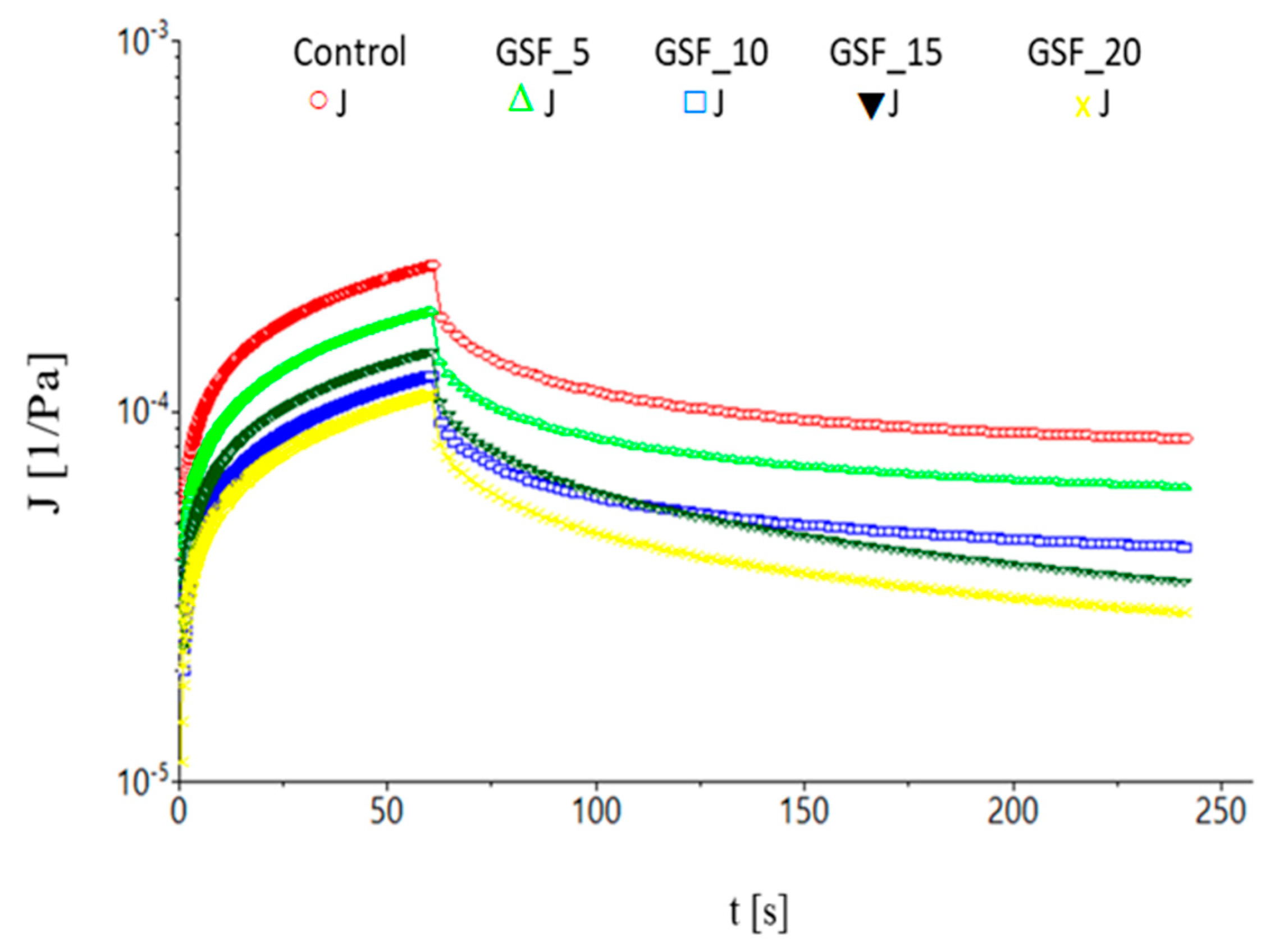

2.2. Dough Fundamental Rheological Properties

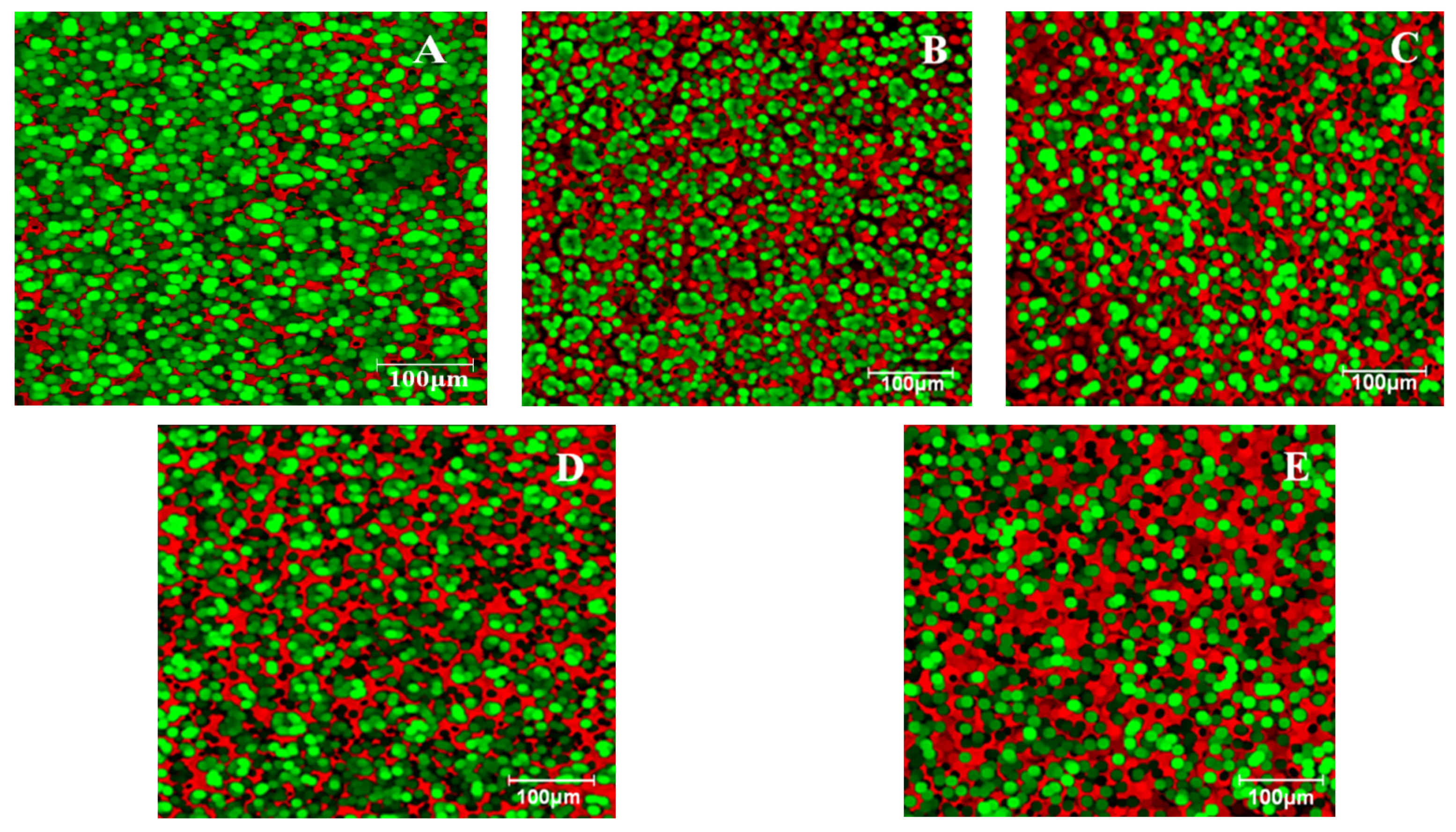

2.3. Dough Microstructure

2.4. Bread Making

2.5. Bread Quality Evaluation

2.5.1. Bread Physical Characteristics

2.5.2. Color Parameters

2.5.3. Texture Profile Analysis

2.5.4. Crumb Structure

2.5.5. Sensory Analysis

2.6. Statistical Analysis

3. Results

3.1. Flour Characteristics

3.2. Dough Fundamental Rheological Properties

3.3. Dough Microstructure

3.4. Bread Quality Evaluation

3.4.1. Bread Physical Characteristics

3.4.2. Color Parameters of Bread Samples

3.4.3. Texture Profile Analysis of Bread Samples

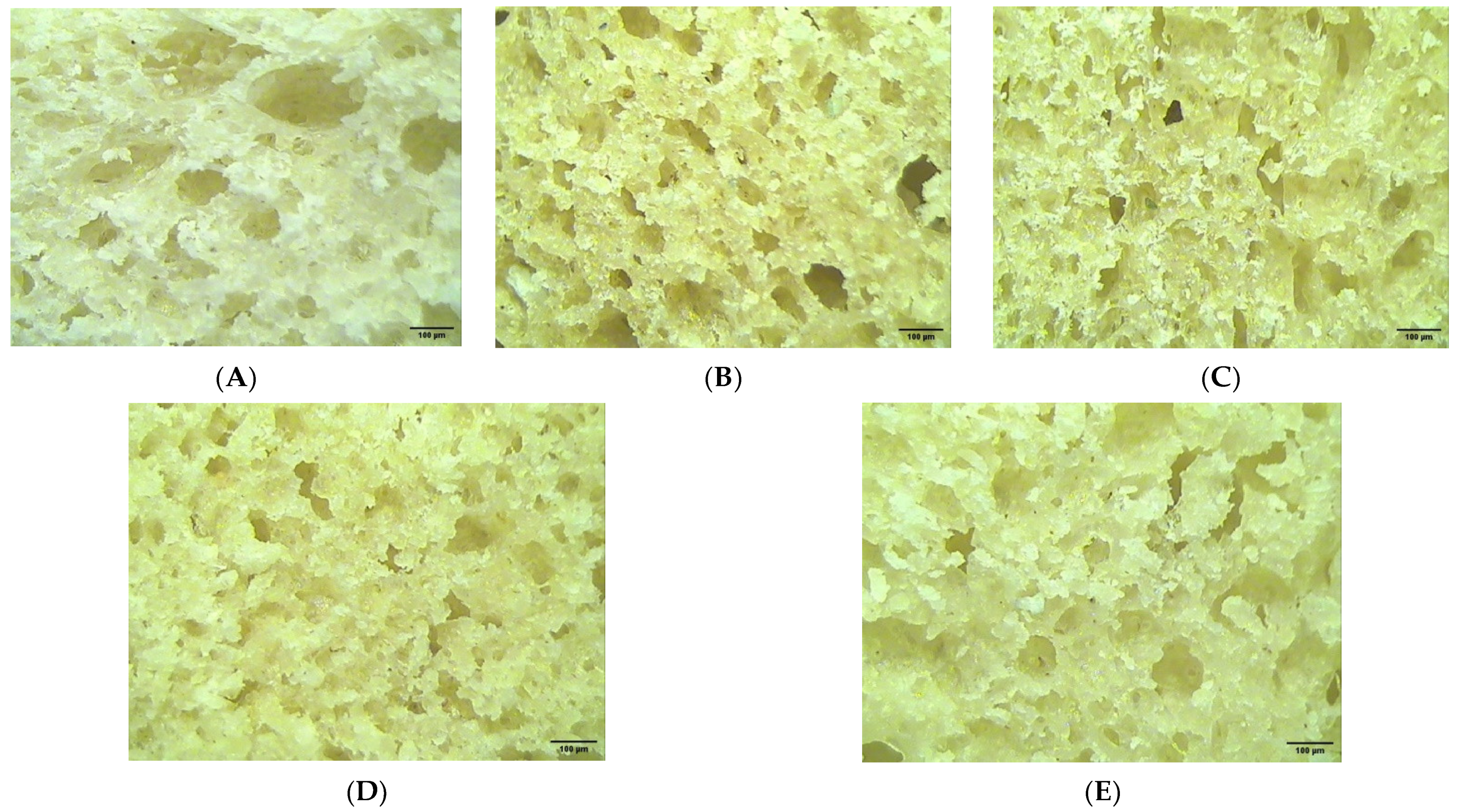

3.4.4. Crumb Structure of Breads Samples

3.4.5. Sensory Analysis of Bread Samples

3.4.6. Effect of GSF Addition on Bread Compositional Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- van der Vossen-Wijmenga, W.P.; Zwietering, M.H.; Boer, E.P.J.; Velema, E.; den Besten, H.M.W. Perception of food-related risks: Difference between consumers and experts and changes over time. Food Control 2022, 141, 109142. [Google Scholar] [CrossRef]

- Talwar, S.; Kaur, P.; Kumar, S.; Hossain, M.; Dhir, A. What determines a positive attitude towards natural food products? An expectancy theory approach. J. Clean. Prod. 2021, 327, 129204. [Google Scholar] [CrossRef]

- Semba, R.D.; Ramsing, R.; Rahman, N.; Kraemer, K.; Bloem, M.W. Legumes as a sustainable source of protein in human diets. Glob. Food Sec. 2021, 28, 100520. [Google Scholar] [CrossRef]

- Miyahira, R.F.; Costa Antunes, A.E. Bacteriological safety of sprouts: A brief review. Int. J. Food Microbiol. 2021, 352, 109266. [Google Scholar] [CrossRef] [PubMed]

- Jimenez, M.D.; Lobo, M.; Sammán, N. 12th IFDC 2017 Special Issue—Influence of germination of quinoa (Chenopodium quinoa) and amaranth (Amaranthus) grains on nutritional and techno-functional properties of their flours. J. Food Compos. Anal. 2019, 84, 103290. [Google Scholar] [CrossRef]

- Sokrab, A.M.; Mohamed Ahmed, I.A.; Babiker, E.E. Effect of germination on antinutritional factors, total, and extractable minerals of high and low phytate corn (Zea mays L.) genotypes. J. Saudi Soc. Agric. Sci. 2012, 11, 123–128. [Google Scholar] [CrossRef]

- Rodríguez-Espana, M.; Figueroa-Hernández, C.Y.; Figueroa-Cardenas, J.D.; Rayas-Duarte, P.; Hernández-Estrada, Z.J. Effects of germination and lactic acid fermentation on nutritional and rheological properties of sorghum: A graphical review. Curr. Res. Food Sci. 2022, 5, 807–812. [Google Scholar] [CrossRef]

- Ávila do Nascimento, L.; Abhilasha, A.; Singh, J.; Elias, M.C. Colussi, Rice Germination and Its Impact on Technological and Nutritional Properties: A Review. Rice Sci. 2022, 29, 201–215. [Google Scholar] [CrossRef]

- Sibiya, H.; Bhagwat, P.; Amobonye, A.; Pillai, S. Effects of flaxseed and soybean supplementation on the nutritional and antioxidant properties of mahewu—A South African beverage. S. Afr. J. Bot. 2022, 150, 275–284. [Google Scholar] [CrossRef]

- Yu, X.; Meenu, M.; Xu, B.; Yu, H. Impact of processing technologies on isoflavones, phenolic acids, and antioxidant capacities of soymilk prepared from 15 soybean varieties. Food Chem. 2021, 345, 128612. [Google Scholar] [CrossRef]

- Sacks, F.M.; Lichtenstein, A.; Van Horn, L.; Harris, W.; Kris-Etherton, P.; Winston, M. Soy protein, isoflavones and cardiovascular health: An American Heart Association Science Advisory for professionals from the nutrition committee. Circulation 2006, 113, 1034–1044. [Google Scholar] [CrossRef]

- de Oliveira Silva, F.; Miranda, T.G.; Justo, T.; da Silva Frasão, B.; Conte-Junior, C.A.; Monteiro, M.; Perrone, D. Soybean meal and fermented soybean meal as functional ingredients for the production of low-carb, high-protein, high-fiber and high isoflavones biscuits. LWT-Food Sci. Technol. 2018, 90, 224–231. [Google Scholar] [CrossRef]

- Xu, D.; Peng, Y.; Wu, F.; Jin, Y.; Yang, N.; Xu, X. Effect of fermented cream with partial substitution of soy protein isolate on bread quality and volatile compounds. Food Biosci. 2022, 50, 102142. [Google Scholar] [CrossRef]

- Li, W.; Cao, W.; Wang, P.; Li, J.; Zhang, Q.; Yan, Y. Selectively hydrolyzed soy protein as an efficient quality improver for steamed bread and its influence on dough components. Food Chem. 2021, 359, 129926. [Google Scholar] [CrossRef]

- Nilufer-Erdil, D.; Serventi, L.; Boyacioglu, D.; Vodovotz, Y. Effect of soy milk powder addition on staling of soy bread. Food Chem. 2012, 131, 1132–1139. [Google Scholar] [CrossRef]

- Jimenez-Maroto, L.A.; Sato, T.; Rankin, S.A. Saltiness potentiation in white bread by substituting sodium chloride with a fermented soy ingredient. J. Cereal Sci. 2013, 58, 313–317. [Google Scholar] [CrossRef]

- Hong, T.; Wang, L.; Xu, Y.; Jin, Y.; Xu, D.; Wu, F.; Xu, X. Comparative study of soluble soybean polysaccharides on bread staling under acidic conditions. Food Chem. 2023, 400, 133950. [Google Scholar] [CrossRef] [PubMed]

- Naumenko, N.; Potoroko, I.; Kalinina, I. Stimulation of antioxidant activity and γ-aminobutyric acid synthesis in germinated wheat grain Triticum aestivum L. by ultrasound: Increasing the nutritional value of the product. Ultrason. Sonochem. 2022, 86, 106000. [Google Scholar] [CrossRef] [PubMed]

- Dhingra, S.; Jood, S. Organoleptic and nutritional evaluation of wheat breads supplemented with soybean and barley flour. Food Chem. 2002, 77, 479–488. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Dough rheology and bread quality of wheat–chickpea flour blends. Ind. Crops Prod. 2012, 36, 196–202. [Google Scholar] [CrossRef]

- Ungureanu-Iuga, M.; Atudorei, D.; Codină, G.G. Rheological Approaches of Wheat Flour Dough Enriched with Germinated Soybean and Lentil. Appl. Sci. 2021, 11, 11706. [Google Scholar] [CrossRef]

- Atudorei, D.; Stroe, S.G.; Codină, G.G. Physical, Physiological and Minerals Changes of Different Legumes Types during the Germination Process. Ukr. Food J. 2020, 9, 844–863. [Google Scholar] [CrossRef]

- ICC. Standard Methods of the International Association for Cereal Chemistry: Methods 104/1, 110/1, 136, 105/2, 171, 121, 107/1; International Association for Cereal Chemistry: Vienna, Austria, 2010. [Google Scholar]

- Atudorei, D.; Ungureanu-Iuga, M.; Codină, G.G.; Mironeasa, S. Germinated Chickpea and Lupin as Promising Ingredients for Breadmaking—Rheological Features. Agronomy 2021, 11, 2588. [Google Scholar] [CrossRef]

- Mironeasa, S.; Codină, G.G. Dough rheological behavior and microstructure characterization of composite dough with wheat and tomato seed flours. Foods 2019, 8, 626. [Google Scholar] [CrossRef]

- Atudorei, D.; Mironeasa, S.; Codină, G.G. Effects of Germinated Lentil Flour on Dough Rheological Behavior and Bread Quality. Foods 2022, 11, 2982. [Google Scholar] [CrossRef]

- AACC (American Association of Cereal Chemists). AACC Official Method. In Approved Methods of American Association of Cereal Chemists, 10th ed.; AACC (American Association of Cereal Chemists): St. Paul, MN, USA, 2000; pp. 14–50. [Google Scholar]

- SR 91:2007; Romanian Standards Catalog for Cereal and Milling Products Analysis. ASRO: Bucharest, Romania, 2008.

- Atudorei, D.; Ropciuc, S.; Codină, G.G. Possibilities to Use Germinated Lupine Flour as an Ingredient in Breadmaking to Improve the Final Product Quality. Agronomy 2022, 12, 667. [Google Scholar] [CrossRef]

- Iuga, M.; Boestean, O.; Ghendov-Mosanu, A.; Mironeasa, S. Impact of dairy ingredients on wheat flour dough rheology and bread properties. Foods 2020, 9, 828. [Google Scholar] [CrossRef]

- Archunan, G. Microbiology; Sarup and Sons: New Delhi, India, 2004. [Google Scholar]

- Codină, G.G.; Mironeasa, S.; Mironeasa, C. Variability and relationship among Mixolab and Falling Number evaluation based on influence of fungal α-amylase addition. J. Sci. Food Agric. 2012, 92, 2162–2170. [Google Scholar] [CrossRef] [PubMed]

- Atudorei, D.; Stroe, S.-G.; Codină, G.G. Impact of Germination on the Microstructural and Physicochemical Properties of Different Legume Types. Plants 2021, 10, 592. [Google Scholar] [CrossRef]

- Roman-Gutierrez, A.D.; Guilbert, S.; Cuq, B. Description of microstructural changes in wheat flour and flour components during hydration by using environmental scanning electron microscopy. LWT 2002, 35, 730–740. [Google Scholar] [CrossRef]

- Peighambardoust, S.H.; Dadpour, M.R.; Dokouhaki, M. Application of epifluorescence light microscopy (EFLM) to study the microstructure of wheat dough: A comparison with confocal scanning laser microscopy (CSLM) technique. J. Cereal Sci. 2010, 51, 21–27. [Google Scholar] [CrossRef]

- van de Velde, F.; Weinbreck, F.; Edelman, M.W.; Van der Linden, E.; Tromp, R.H. Visualisation of biopolymer mixtures using confocal scanning laser microscopy (CSLM) and covalent labelling techniques. Colloids Surf. B. 2003, 31, 159–168. [Google Scholar] [CrossRef]

- Stevensona, D.H.; Doorenbos, R.K.; Jane, J.; Inglett, G.E. Structures and Functional Properties of Starch From Seeds of Three Soybean (Glycine max (L.) Merr.) Varieties. Starch 2006, 58, 509–519. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.-J.; Li, D.; Xue, J.; Mao, Z.-H. Effects of drying methods on rheological properties of flaxseed gum. Carbohydr. Polym. 2009, 78, 213–219. [Google Scholar] [CrossRef]

- Kotsiou, K.; Sacharidis, D.-D.; Matsakidou, A.; Biliaderis, C.G.; Lazaridou, A. Physicochemical and functional aspects of composite wheat-roasted chickpea flours in relation to dough rheology, bread quality and staling phenomena. Food Hydrocoll. 2022, 124, 107322. [Google Scholar] [CrossRef]

- Selaković, A.; Nikolić, I.; Dokić, L.; Šoronja-Simović, D.; Šimurina, O.; Zahorec, J.; Šereš, Z. Enhancing rheological performance of laminated dough with whole wheat flour by vital gluten addition. LWT 2021, 138, 110604. [Google Scholar] [CrossRef]

- Villanueva, M.; Harasym, J.; Muñoz, J.M.; Ronda, F. Rice flour physically modified by microwave radiation improves viscoelastic behavior of doughs and its bread-making performance. Food Hydrocoll. 2019, 90, 472–481. [Google Scholar] [CrossRef]

- Struck, S.; Straube, D.; Zahn, S.; Rohm, H. Interaction of wheat macromolecules and berry pomace in model dough: Rheology and microstructure. J. Food Eng. 2018, 223, 109–115. [Google Scholar] [CrossRef]

- Zhang, D.; Mu, T.; Sun, H.; He, J. Effects of different high hydrostatic pressure-treated potato starch on the processing performance of dough-like model systems. Food Res. Int. 2019, 120, 456–463. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Y.; Li, W.; Qin, F.; Chen, J. Effects of oligosaccharides and soy soluble polysaccharide on the rheological and textural properties of calcium sulfateinduced soy protein gels. Food Bioprocess Technol. 2017, 10, 556–567. [Google Scholar] [CrossRef]

- Xue, F.; Xie, Y.; Li, C.; Wang, S.; Liu, X. Prevention of frozen-dough from deterioration with incorporation of glutenin-polyphenols conjugates prepared by ultrasound. LWT 2021, 151, 112141. [Google Scholar] [CrossRef]

- Melese, A.D.; Keyata, E.O. Effects of blending ratios and baking temperature on physicochemical properties and sensory acceptability of biscuits prepared from pumpkin, common bean, and wheat composite flour. Heliyon 2022, 8, e10848. [Google Scholar] [CrossRef]

- Carboni, A.D.; Salinas, M.V.; Puppo, M.C. Production of legume-wheat dough of optimum quality for breadmaking: Essential analyses required. Curr. Opin. Food Sci. 2023, 49, 100970. [Google Scholar]

- Luo, X.; Li, D.; Tao, Y.; Wang, P.; Yang, R.; Han, Y. Effect of static magnetic field treatment on the germination of brown rice: Changes in α-amylase activity and structural and functional properties in starch. Food Chem. 2022, 383, 132392. [Google Scholar] [CrossRef]

- Wang, H.; Xiao, N.; Ding, J.; Zhang, Y.; Liu, X.; Zhang, H. Effect of germination temperature on hierarchical structures of starch from brown rice and their relation to pasting properties. Int. J. Biol. Macromol. 2020, 147, 965972. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Zhang, H.; Guo, X.; Qian, H. The impact of germination on the characteristics of brown rice flour and starch. J. Sci. Food Agric. 2012, 92, 380–387. [Google Scholar] [CrossRef] [PubMed]

- Heberle, T.; Ávila, B.P.; Ávila do Nascimento, L.; Gularte, M.A. Consumer perception of breads made with germinated rice flour and its nutritional and technological properties. Appl. Food Res. 2022, 2, 100142. [Google Scholar] [CrossRef]

- Shin, D.J.; Kim, W.; Kim, Y. Physicochemical and sensory properties of soy bread made with germinated, steamed, and roasted soy flour. Food Chem. 2013, 141, 517–523. [Google Scholar] [CrossRef]

- Mostafa, M.M.; Rahma, E.H.; Rady, A.H. Chemical and nutritional changes in soybean during germination. Food Chem. 1987, 23, 257–275. [Google Scholar] [CrossRef]

- Garrido-Galand, S.; Asensio-Grau, A.; Calvo-Lerma, J.; Heredia, A.; Andrés, A. The potential of fermentation on nutritional and technological improvement of cereal and legume flours: A review. Food Res. Int. 2021, 145, 110398. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Childs, M.; Loos, M.; Taylor, A.; Smart, L.B.; Abbaspourrad, A. The effects of germination on the composition and functional properties of hemp seed protein isolate. Food Hydrocoll. 2023, 134, 108085. [Google Scholar] [CrossRef]

- Xin, T.; Tang, S.; Su, T.; Huang, Z.; Huang, F.; Zhang, R.; Dong, L.; Shen, Y.; Su, D. Impact of replacing wheat flour with lychee juice by-products on bread quality characteristics and microstructure. LWT 2022, 165, 113696. [Google Scholar] [CrossRef]

- Cardone, G.; Grassi, S.; Scipioni, A.; Marti, A. Bread-making performance of durum wheat as affected by sprouting. LWT 2020, 134, 110021. [Google Scholar] [CrossRef]

- Marti, A.; Cardone, G.; Pagani, M.A.; Casiraghi, M.C. Flour from sprouted wheat as a new ingredient in bread-making. LWT-Food Sci. Technol. 2018, 89, 237–243. [Google Scholar] [CrossRef]

- Amiri, A.; Shahedi, M.; Kadivar, M. Evaluation of physicochemical properties of gluten modified by Glucose oxidase and Xylanase. J. Cereal Sci. 2016, 71, 37–42. [Google Scholar] [CrossRef]

- Gómez, A.V.; Ferrer, E.G.; Anón, M.C.; Puppo, M.C. Changes in secondary structure of gluten proteins due to emulsifiers. J. Mol. Struct. 2013, 1033, 51–58. [Google Scholar] [CrossRef]

- Sheikholeslami, Z.; Mahfouzi, M.; Karimi, M.; Ghiafehdavoodi, M. Modification of dough characteristics and baking quality based on whole wheat flour by enzymes and emulsifiers supplementation. LWT 2021, 139, 110794. [Google Scholar] [CrossRef]

- Troadec, R.; Nestora, S.; Niquet-Léridon, C.; Marier, D.; Jacolot, P.; Sarron, E.; Regnault, S.; Anton, P.M.; Jouquand, C. Effect of leavening agent on Maillard reaction and the bifidogenic effect of traditional French bread. Food Chem. 2022, 393, 133387. [Google Scholar] [CrossRef]

- Millar, K.A.; Barry-Ryan, C.; Burke, R.; McCarthy, S.; Gallagher, E. Dough properties and baking characteristics of white bread, as affected by addition of raw, germinated and toasted pea flour. Innov. Food Sci. Emerg. Technol. 2019, 56, 102189. [Google Scholar] [CrossRef]

- Millar, K.A.; Barry-Ryan, C.; Burke, R.; Hussey, K.; McCarthy, S.; Gallagher, E. Effect of pulse flours on the physiochemical characteristics and sensory acceptance of baked crackers. Int. J. Food Sci. Technol. 2017, 52, 1155–1163. [Google Scholar] [CrossRef]

- Barber, S.; Baguena, R.; Barber, C.B.; Martinez-Anaya, M.A. Evolution of biochemical and rheological characteristics and breadmaking quality during a multistage wheat sour dough process. Zeitschrift Fur Lebensmittel-Untersuchung Und Forschung 1991, 192, 46–52. [Google Scholar] [CrossRef]

- Borrelli, R.C.; Fogliano, V. Bread crust melanoidins as potential prebiotic ingredients. Mol. Nutr. Food Res. 2005, 49, 673–678. [Google Scholar] [CrossRef]

- Helou, C.; Denis, S.; Spatz, M.; Marier, D.; Rame, V.; Alric, M.; Tessier, F.J.; Gadonna Widehem, P. Insights into bread melanoidins: Fate in the upper digestive tract and impact on the gut microbiota using in vitro systems. Food Funct. 2015, 6, 3737–3745. [Google Scholar] [CrossRef] [PubMed]

- Rufián-Henares, J.A.; Morales, F.J. Functional properties of melanoidins: In vitro antioxidant, antimicrobial and antihypertensive activities. Food Res. Int. 2007, 40, 995–1002. [Google Scholar] [CrossRef]

- Yang, M.; Ding, L.; Wang, P.; Wu, Y.; Areeprasert, C.; Wang, M.; Chen, X.; Wang, F.; Yu, G. Formation of melanoidins and development of characterization techniques during thermal pretreatment of organic solid waste: A critical review. Fuel 2023, 334, 126790. [Google Scholar] [CrossRef]

- Mao, S.; Kaur, L.; Mu, T.H.; Singh, J. Development and characterisation of plant and dairy-based high protein Chinese steamed breads (mantou): Physico-chemical and textural characteristics. Food Hydrocoll. 2022, 2, 100102. [Google Scholar] [CrossRef]

- Özcan, M.M. The effect of ginger (Zingiber officinale) powders at different concentrations on bioactive compounds, antioxidant activity, phenolic constituents, nutrients and sensory characteristics of wheat bread. Int. J. Gastron. Food Sci. 2022, 28, 100532. [Google Scholar] [CrossRef]

- Xu, J.; Wang, W.; Li, Y. Dough properties, bread quality, and associated interactions with added phenolic compounds: A review. J. Funct. Foods 2019, 52, 629–639. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, Y.; Qin, L. The cause of germination increase the phenolic compound contents of Tartary buckwheat (Fagapyrum tataricum). J. Future Foods 2022, 2–4, 372–379. [Google Scholar] [CrossRef]

- Ma, K.K.; Grossmann, L.; Nolden, A.A.; McClements, D.J. Functional and physical properties of commercial pulse proteins compared to soy derived protein. Future Foods 2022, 6, 100155. [Google Scholar] [CrossRef]

- Lv, Y.; Tang, T.; Xu, L.; Wang, J.; Su, Y.; Li, J.; Gu, L.; Zhang, M.; Yang, Y.; Zhang, C. Influence of soybean dietary fiber with varying particle sizes and transglutaminase on soy protein isolate gel. Food Res. Int. 2022, 161, 111876. [Google Scholar] [CrossRef] [PubMed]

- Fang, H.; Li, J.; Huo, T.; Niu, Y.; Yu, L. Novel double cross-linked gels of soybean protein isolates and soluble dietary fiber from soybean coats with their functionalities. Food Hydrocoll. 2021, 113, 106474. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S.; Khatkar, B.S. Optimization of bread firmness, specific loaf volume and sensory acceptability of bread with soluble fiber and different water levels. J. Cereal Sci. 2016, 70, 186–191. [Google Scholar] [CrossRef]

- Sun, X.; Ma, L.; Zhong, X.; Liang, J. Potential of raw and fermented maize gluten feed in bread making: Assess of dough rheological properties and bread quality. LWT 2022, 162, 113482. [Google Scholar] [CrossRef]

- Özkaya, B.; Baumgartner, B.; Özkaya, H. Effects of concentrated and dephytinized wheat bran and rice bran addition on bread properties. J. Texture Stud. 2018, 49, 84–93. [Google Scholar] [CrossRef]

- Comettant-Rabanal, R.; Carvalho, C.W.P.; Ascheri, J.L.R.; Chávez, D.W.H.; Germani, R. Extruded whole grain flours and sprout millet as functional ingredients for gluten-free bread. LWT-Food Sci. Technol. 2021, 150, 112042. [Google Scholar] [CrossRef]

- Müller, D.C.; Nguyen, H.; Li, Q.; Schönlechner, R.; Schwenninger, S.M.; Wismer, W.; Gänzle, M. Enzymatic and microbial conversions to achieve sugar reduction in bread. Food Res. Int. 2021, 143, 110296. [Google Scholar] [CrossRef]

- Pongjaruvat, W.; Methacanon, P.; Seetapan, N.; Fuongfuchat, A.; Gamonpilas, C. Influence of pregelatinised tapioca starch and transglutaminase on dough rheology and quality of gluten-free jasmine rice breads. Food Hydrocoll. 2014, 36, 143–150. [Google Scholar] [CrossRef]

- Tebben, L.; Shen, Y.; Li, Y. Improvers and functional ingredients in whole wheat bread: A review of their effects on dough properties and bread quality. Trends Food Sci. Technol. 2018, 81, 10–24. [Google Scholar] [CrossRef]

- Pico, J.; Bernal, J.; Gómez, M. Wheat bread aroma compounds in crumb and crust: A review. Food Res. Int. 2015, 75, 200–215. [Google Scholar] [CrossRef]

- Rizzello, C.G.; Calasso, M.; Campanella, D.; De Angelis, M.; Gobbetti, M. Use of sourdough fermentation and mixture of wheat, chickpea, lentil and bean flours for enhancing the nutritional, texture and sensory characteristics of white bread. Int. J. Food Microbiol. 2014, 180, 7887. [Google Scholar] [CrossRef] [PubMed]

- Atudorei, D.; Atudorei, O.; Codină, G.G. Dough Rheological Properties, Microstructure and Bread Quality of Wheat-Germinated Bean Composite Flour. Foods 2021, 10, 1542. [Google Scholar] [CrossRef] [PubMed]

| Sample | Protein (%) | Fat (%) | Ash (%) | Moisture (%) | Carbohydrate (%) |

|---|---|---|---|---|---|

| Control | 12.30 ± 0.01 e | 1.12 ± 0.00 e | 0.65 ± 0.00 e | 14.60 ± 0.01 a | 71.32 ± 0.01 a |

| GSF_5 | 13.69 ± 0.00 d | 1.96 ± 0.00 d | 0.87 ± 0.01 d | 14.39 ± 0.01 b | 69.08 ± 0.00 b |

| GSF_10 | 15.09 ± 0.01 c | 2.79 ± 0.01 c | 1.08 ± 0.02 c | 14.18 ± 0.01 c | 66.82 ± 0.01 c |

| GSF_15 | 16.48 ± 0.01 b | 3.63 ± 0.01 b | 1.30 ± 0.03 b | 13.97 ± 0.02 d | 64.57 ± 0.01 d |

| GSF_20 | 17.87 ± 0.01 a | 4.47 ± 0.01 a | 1.51 ± 0.04 a | 13.76 ± 0.03 f | 62.31 ± 0.01 e |

| Samples | Creep Phase | Recovery Phase | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| JCo × 105 (Pa−1) | JCm × 105 (Pa−1) | λC (s) | μCo × 10−6 (Pa·s) | Jmax × 105 (Pa−1) | JRo × 105 (Pa−1) | JRm × 105 (Pa−1) | λR (s) | Jr × 105 (Pa−1) | Jr/Jmax (%) | |

| Control | 6.93 e (0.02) | 20.00 c (0.01) | 34.99 a (0.05) ab | 0.57 c (0.00) | 24.76 e (0.02) | 8.66 e (0.04) | 8.32 e (0.00) | 34.36 a (0.00) | 16.98 e (0.04) | 68.57 b (0.14) |

| GSF_5 | 5.18 d (0.01) | 20.00 c (0.00) | 35.60 ab (0.08) | 0.12 a (0.01) | 18.64 d (0.02) | 6.47 d (0.02) | 6.32 d (0.00) | 34.84 b (0.00) | 12.79 d (0.02) | 68.61 b (0.03) |

| GSF_10 | 3.33 b (0.03) | 10.01 b (0.01) | 35.97 bc (0.00) | 0.13 a (0.02) | 12.51 b (0.02) | 4.47 c (0.03) | 4.30 a (0.00) | 36.63 c (0.00) | 8.77 b (0.03) | 70.08 c (0.09) |

| GSF_15 | 3.98 c (0.07) | 10.00 b (0.00) | 36.50 cd (0.58) | 0.18 b (0.00) | 14.52 c (0.02) | 3.62 b (0.02) | 6.13 c (0.00) | 44.84 e (0.00) | 9.75 c (0.02) | 67.13 a (0.02) |

| GSF_20 | 3.02 a (0.03) | 9.73 a (0.21) | 36.94 c (0.08) | 0.16 b (0.01) | 11.15 a (0.02) | 3.01 a (0.02) | 4.49 b (0.00) | 42.55 d (0.00) | 7.50 a (0.02) | 67.27 a (0.06) |

| Bread Samples | Specific Volume (cm3/100 g) | Porosity (%) | Elasticity (%) |

|---|---|---|---|

| Control | 331.5 ± 0.74 b | 67.4 ± 0.86 b | 91.3 ± 0.57 b |

| GSF_5 | 339.1 ± 0.73 c | 70.6 ± 0.47 c | 91.9 ± 0.24 bc |

| GSF_10 | 349.1 ± 0.82 d | 72.3 ± 0.30 d | 93.0 ± 0.06 cd |

| GSF_15 | 357.2 ± 1.49 e | 73.7 ± 0.46 d | 94.4 ± 0.44 d |

| GSF_20 | 327.6 ± 0.55 a | 65.4 ± 0.50 a | 88.6 ± 0.81 a |

| Bread Samples | Crust Color | Crumb Color | ||||

|---|---|---|---|---|---|---|

| L* | a* | b* | L | a* | b* | |

| Control | 76.25 ± 0.94 d | 3.44 ± 0.27 a | 3.14 ± 0.43 a | 66.37 ± 0.88 d | −4.62 ± 0.32 e | 1.69 ± 0.22 a |

| GSF_5 | 75.55 ± 0.43 d | 4.93 ± 0.07 b | 8.96 ± 0.14 b | 64.11 ± 0.12 b | −3.63 ± 0.27 d | 4.59 ± 0.31 b |

| GSF_10 | 71.74 ± 0.98 c | 6.36 ± 0.33 c | 10.36 ± 0.44 b | 61.03 ± 0.59 b | −2.86 ± 0.14 c | 6.93 ± 0.08 c |

| GSF_15 | 68.27 ± 0.84 b | 9.37 ± 0.22 d | 12.18 ± 0.20 c | 57.63 ± 0.41 a | −1.80 ± 0.14 b | 9.14 ± 0.15 d |

| GSF_20 | 59.46 ± 0.50 a | 13.33 ± 0.40 e | 15.93 ± 0.78 d | 57.21 ± 0.31 a | −0.78 ± 0.15 a | 11.04 ± 0.15 e |

| Bread Samples | Firmness (N) | Gumminess (N) | Cohesiveness (Adimensional) | Resilience (Adimensional) |

|---|---|---|---|---|

| Control | 9.01 ± 3.06 a | 7.23 ± 1.73 b | 0.82 ± 0.03 c | 1.72 ± 0.04 d |

| GSF_5 | 12.78 ± 0.48 ab | 6.10 ± 0.72 ab | 0.50 ± 0.02 a | 1.67 ± 0.02 d |

| GSF_10 | 16.38 ± 0.68 bc | 5.56 ± 0.42 ab | 0.70 ± 0.02 b | 1.58 ± 0.03 c |

| GSF_15 | 18.70 ± 0.28 c | 4.37 ± 0.54 a | 0.57 ± 0.02 a | 1.42 ± 0.02 b |

| GSF_20 | 20.34 ± 1.04 c | 6.70 ± 0.30 ab | 0.54 ± 0.03 a | 1.30 ± 0.01 a |

| Sample | Pores Density (1/cm2) | Mean Cell Size (mm2) | Pore Circularity (Adimensional) | Cell Area Fraction (%) |

|---|---|---|---|---|

| Control | 14.13 ± 0.82 e | 0.14 ± 0.02 c | 0.90 ± 0.08 a | 0.68 ± 0.09 a |

| GSF_5 | 10.65 ± 0.64 b | 0.10 ± 0.01 ab | 0.89 ± 0.07 a | 0.76 ± 0.08 b |

| GSF_10 | 12.99 ± 0.78 d | 0.12 ± 0.02 bc | 0.88 ± 0.03 a | 1.49 ± 0.15 d |

| GSF_15 | 9.24 ± 0.59 a | 0.09 ± 0.01 a | 0.89 ± 0.05 a | 0.68 ± 0.07 a |

| GSF_20 | 11.61 ± 0.64 c | 0.11± 0.01 abc | 0.89 ± 0.09 a | 1.11 ± 0.18 c |

| Bread Samples | Moisture (%) | Protein (%) | Fat (%) | Ash (%) | Carbohydrates (%) | Energy (kcal/100 g) |

|---|---|---|---|---|---|---|

| Control | 44.72 ± 0.02 ab | 8.80 ± 0.01 a | 0.81 ± 0.01 a | 0.51 ± 0.01 a | 45.14 ± 0.04 e | 223.13 ± 0.14 a |

| SGF_5 | 44.81 ± 0.01 c | 9.73 ± 0.02 b | 1.38 ± 0.01 b | 0.61 ± 0.01 b | 43.46 ± 0.01 d | 225.18 ± 0.03 b |

| SGF_10 | 44.75 ± 0.02 b | 10.81 ± 0.01 c | 2.04 ± 0.02 c | 0.76 ± 0.01 c | 41.64 ± 0.01 c | 228.16 ± 0.04 c |

| SGF_15 | 44.69 ± 0.03 a | 11.64 ± 0.03 d | 2.62 ± 0.02 d | 0.92 ± 0.01 d | 40.12 ± 0.03 b | 230.66 ± 0.09 d |

| SGF_20 | 44.83 ± 0.03 c | 12.65 ± 0.03 e | 3.33 ± 0.02 e | 1.06 ± 0.01 e | 38.13 ± 0.05 a | 233.09 ± 0.06 e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atudorei, D.; Mironeasa, S.; Codină, G.G. Dough Rheological Behavior and Bread Quality as Affected by Addition of Soybean Flour in a Germinated Form. Foods 2023, 12, 1316. https://doi.org/10.3390/foods12061316

Atudorei D, Mironeasa S, Codină GG. Dough Rheological Behavior and Bread Quality as Affected by Addition of Soybean Flour in a Germinated Form. Foods. 2023; 12(6):1316. https://doi.org/10.3390/foods12061316

Chicago/Turabian StyleAtudorei, Denisa, Silvia Mironeasa, and Georgiana Gabriela Codină. 2023. "Dough Rheological Behavior and Bread Quality as Affected by Addition of Soybean Flour in a Germinated Form" Foods 12, no. 6: 1316. https://doi.org/10.3390/foods12061316

APA StyleAtudorei, D., Mironeasa, S., & Codină, G. G. (2023). Dough Rheological Behavior and Bread Quality as Affected by Addition of Soybean Flour in a Germinated Form. Foods, 12(6), 1316. https://doi.org/10.3390/foods12061316