Compositional Traits of Grains and Groats of Barley, Oat and Spelt Grown at Organic and Conventional Fields

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials

2.2. Processing of Harvested Grain

2.3. Compositional Characteristics and Caloric Value

2.4. Statistical Analysis

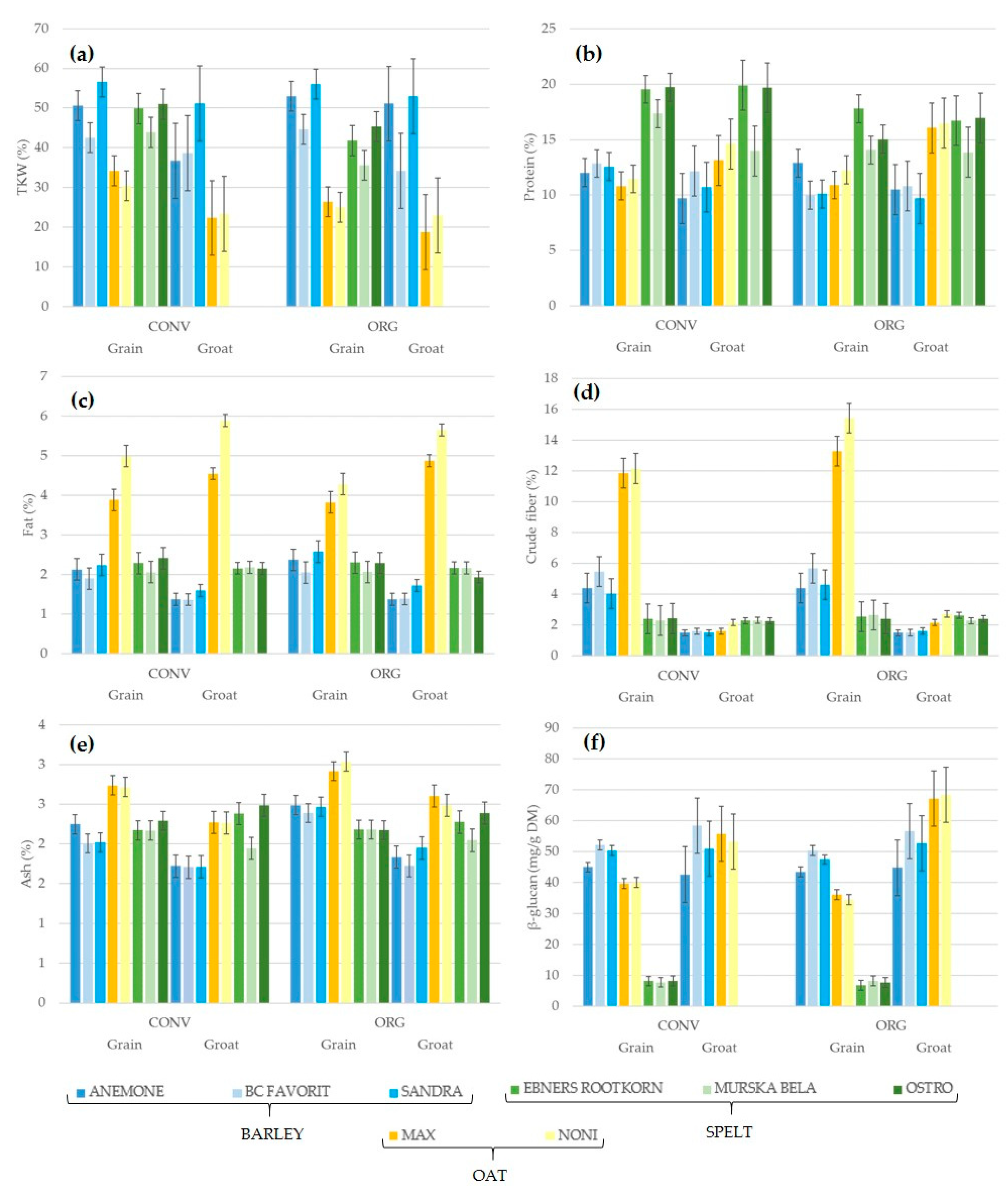

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Chatzidimitriou, E.; Wood, L.; Hasanalieva, G.; Markellou, E.; Iversen, P.O.; Seal, C.; Baranski, M.; Vigar, V.; Ernst, L.; et al. Effect of wheat species (Triticum aestivum vs. T. spelta), farming system (organic vs. conventional) and flour type (wholegrain vs. white) on composition of wheat flour—Results of a retail survey in the UK and Germany—2. Antioxidant activity, and phenolic and mineral content. Food Chem. X 2020, 6, 100091. [Google Scholar] [CrossRef]

- Poutanen, K.S.; Kårlund, A.O.; Gómez-Gallego, C.; Johansson, D.P.; Scheers, N.M.; Marklinder, I.M.; Eriksen, A.K.; Silventoinen, P.C.; Nordlund, E.; Sozer, N.; et al. Grains—A major source of sustainable protein for health. Nutr. Rev. 2022, 80, 1648–1663. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Wu, H.; Sajid, A.; Li, Z. Whole grain cereals: The potential roles of functional components in human health. Crit. Rev. Food Sci. Nutr. 2021, 62, 8388–8402. [Google Scholar] [CrossRef] [PubMed]

- Biel, W.; Kazimierska, K.; Bashutska, U. Nutritional value of wheat, triticale, barley and oat grains. Acta Sci. Pol. Zootech. 2020, 19, 19–28. [Google Scholar] [CrossRef]

- Rahman, S.M.E.; Mele, M.A.; Lee, Y.T.; Islam, M.Z. Consumer preference, quality, and safety of organic and conventional fresh fruits, vegetables, and cereals. Foods 2021, 10, 105. [Google Scholar] [CrossRef] [PubMed]

- Escarnot, E.; Dornez, E.; Verspreet, J.; Agneessens, R.; Courtin, C.M. Quantification and visualization of dietary fibre components in spelt and wheat kernels. J. Cereal Sci. 2015, 62, 124–133. [Google Scholar] [CrossRef]

- Farag, M.A.; Xiao, J.; Abdallah, H.M. Nutritional value of barley cereal and better opportunities for its processing as a value-added food: A comprehensive review. Crit. Rev. Food Sci. Nutr. 2022, 62, 1092–1104. [Google Scholar] [CrossRef]

- Sharma, P.; Kotari, S.L. Barley: Impact of processing on physicochemical and thermal properties—A review. Food Rev. Int. 2017, 33, 359–381. [Google Scholar] [CrossRef]

- Punia, S.; Sandhu, K.S.; Dhull, S.B.; Siroha, A.K.; Purewal, S.S.; Kaur, M.; Kidwai, M.K. Oat starch: Physico-chemical, morphological, rheological characteristics and its applications—A review. Int. J. Biol. Macromol. 2020, 154, 493–498. [Google Scholar] [CrossRef]

- Wang, J.; Baranski, M.; Korkut, R.; Kalee, H.A.; Wood, L.; Bilsborrow, P.; Janovska, D.; Leifert, A.; Winter, S.; Willson, A.; et al. Performance of modern and traditional spelt wheat (Triticum spelta) varieties in rain-fed and irrigated, organic and conventional production systems in a semi-arid environment; results from exploratory field experiments in Crete, Greece. Agronomy 2021, 11, 890. [Google Scholar] [CrossRef]

- Dolijanović, Ž.; Nikolić, S.R.; Subić, J.; Jovović, Z.; Oljača, J.; Bačić, J. Organic spelt production systems: Productive and financial performance in three orographic regions. Ital. J. Agron. 2022, 17, 2025. [Google Scholar] [CrossRef]

- Anders, A.; Kolankowska, E.; Choszcz, D.J.; Konopka, S.; Kaliniewicz, Z. The effect of selected parameters on spelt dehulling in a wire mesh cylinder. Sustainability 2020, 12, 43. [Google Scholar] [CrossRef]

- Călinoiu, L.F.; Vodnar, D.C. Whole grains and phenolic acids: A review on bioactivity, functionality, health benefits and bioavailability. Nutrients 2018, 10, 1615. [Google Scholar] [CrossRef]

- Tieri, M.; Ghelfi, F.; Vitale, M.; Vetrani, C.; Marventano, S.; Lafranconi, A.; Godos, J.; Titta, L.; Gambera, A.; Alonzo, E.; et al. Whole grain consumption and human health: An umbrella review of observational studies. Int. J. Food Sci. Nutr. 2020, 71, 668–677. [Google Scholar] [CrossRef] [PubMed]

- Kulathunga, J.; Reuhs, B.L.; Zwinger, S.; Simsek, S. Comparative study on kernel quality and chemical composition of ancient and modern wheat species: Einkorn, emmer, spelt and hard red spring wheat. Foods 2021, 10, 761. [Google Scholar] [CrossRef]

- Tiwari, U.; Cummins, E. Factors influencing β-glucan levels and molecular weight in cereal-based products. Cereal Chem. 2009, 86, 290–301. [Google Scholar] [CrossRef]

- Schmidt, M. Cereal beta-glucans: An underutilized health endorsing food ingredient. Crit. Rev. Food Sci. Nutr. 2022, 62, 3281–3300. [Google Scholar] [CrossRef]

- Kumar, D.; Kalita, P. Reducing postharvest losses during storage of grain crops to strengthen food security in developing countries. Foods 2017, 6, 8. [Google Scholar] [CrossRef]

- Dziadek, K.; Kopeć, A.; Pastucha, E.; Piątkowska, E.; Leszczyńska, T.; Pisulewska, E.; Witkowicz, R.; Francik, R. Basic chemical composition and bioactive compounds content in selected cultivars of buckwheat whole seeds, dehulled seeds and hulls. J. Cereal Sci. 2016, 69, 1–8. [Google Scholar] [CrossRef]

- Labban, L.; Thallaj, N.; Al Masri, M. Nutritional value of traditional syrian sweets and their calorie density. J. Adv. Res. Food Sci. Nutr. 2020, 3, 34–41. [Google Scholar] [CrossRef]

- Allai, F.M.; Azad, Z.R.A.A.; Gul, K.; Dar, B.N. Wholegrains: A review on the amino acid profile, mineral content, physicochemical, bioactive composition and health benefits. Int. J. Food Sci. Technol. 2022, 57, 1849–1865. [Google Scholar] [CrossRef]

- Frølich, W.; Åman, P.; Tetens, I. Whole grain foods and health—A Scandinavian perspective. Food Nutr. Res. 2013, 57, 18503. [Google Scholar] [CrossRef] [PubMed]

- Tóth, V.; Láng, L.; Vida, G.; Mikó, P.; Rakszegi, M. Characterization of the protein and carbohydrate related quality traits of a large set of spelt wheat genotypes. Foods 2022, 11, 2061. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Zhou, L.; Chen, J.; Qiu, Z.; He, Y. GainTKW: A measurement system of thousand kernel weight based on the android platform. Agronomy 2018, 8, 178. [Google Scholar] [CrossRef]

- Hejcman, M.; Hlísnikovský, L.; Hejcmanová, P.; Šálková, T.; Beneš, J. Kernel weights of Triticum, Hordeum, Avena, Secale and Panicum species can be used for better estimation of importance of different cereal species in archaeobotanical assemblages. Interdiscip. Archaeol. 2016, 7, 189–196. Available online: http://www.iansa.eu (accessed on 6 January 2023). [CrossRef]

- Lahouar, L.; el Arem, A.; Achour, L. Bioactive compounds in whole grain barley: Nutraceutical properties and health benefits. J. Bioresour. Valorization 2016, 1, 5–15. Available online: http://www.biolival.com/index.php/revue/archives-jvb (accessed on 6 January 2023).

- Tosh, S.M.; Bordenave, N. Emerging science on benefits of whole grain oat and barley and their soluble dietary fibers for heart health, glycemic response, and gut microbiota. Nutr. Rev. 2020, 78, 13–20. [Google Scholar] [CrossRef]

- EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). Scientific Opinion on the substantiation of health claims related to beta-glucans from oats and barley and maintenance of normal blood LDL-cholesterol concentrations (ID 1236, 1299), increase in satiety leading to a reduction in energy intake (ID 851, 852), reduction of post-prandial glycaemic responses (ID 821, 824), and “digestive function”(ID 850) pursuant to Article 13(1) of Regulation (EC) No 1924/2006. EFSA J. 2011, 9, 2207. [Google Scholar] [CrossRef]

- Menkovska, M.; Damjanovski, D.; Levkov, V.; Gjorgovska, N.; Knezevic, D.; Nikolova, N.; Stanoev, V. Content of B-glucan in cereals grown by organic and conventional farming. Banats J. Biotechnol. 2017, 8, 39–47. [Google Scholar] [CrossRef]

- Muhammad, H.S.; Muhammad, F.S.; Muhammad, S.; Niaz, A.Q.; Safia, M. The importance of cereals (Poaceae: Gramineae) nutrition in human health: A review. J. Cereal. Oilseeds 2013, 4, 32–35. [Google Scholar] [CrossRef]

- Beloshapka, A.N.; Buff, P.R.; Fahey Jr, G.C.; Swanson, K.S. Compositional analysis of whole grains, processed grains, grain co-products, and other carbohydrate sources with applicability to pet animal nutrition. Foods 2016, 5, 23. [Google Scholar] [CrossRef] [PubMed]

| Species | Latin Name | Type | Variety Name | Field Management | Technological Procedures Applied to Harvested Grain |

|---|---|---|---|---|---|

| Barley | Hordeum vulgare L. | Winter | Anemone | CONV | (i) Cleaning with a grain winnowing machine; (ii) Brushing/polishing (3×) of the cleaned raw grains by centrifugal force with an adapted traditional stone mill. |

| ORG | |||||

| BC Favorit | CONV | ||||

| ORG | |||||

| Sandra | CONV | ||||

| ORG | |||||

| Oat | Avena sativa L. | Spring | Max | CONV | (i) Cleaning with a grain winnowing machine; (ii) Brushing/polishing (7×) of the cleaned raw grains by centrifugal force with an adapted traditional stone mill. |

| ORG | |||||

| Noni | CONV | ||||

| ORG | |||||

| Spelt | Triticum spelta L. | Winter | Ebners Rotkorn | CONV | (i) Threshing with a Wintersteiger LD359 machine; (ii) Cleaning of the hulled raw grains with Haldrup DC-20; (iii) Brushing/polishing (1×) of the cleaned raw grains by centrifugal force with an adapted traditional stone mill. |

| ORG | |||||

| Murska bela | CONV | ||||

| ORG | |||||

| Ostro | CONV | ||||

| ORG |

| Parameter | Unit | Statistical Parameter | n | Barley | n | Oat | n | Spelt | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grains | Groats | Grains | Groats | Grains | Groats | ||||||

| TKW | g | Min-Max | 6 | 42.57-56.59 | 34.22-52.99 | 4 | 25.03-34.22 | 18.79-23.40 | 6 | 35.58-50.98 | / |

| Mean | 50.58 | 44.14 | 29.04 | 21.87 | 44.58 | / | |||||

| SD | 5.34 | 7.75 | 3.60 | 1.82 | 5.14 | / | |||||

| CV (%) | 10.56 | 17.56 | 12.41 | 8.32 | 11.53 | / | |||||

| Protein | % | Min-Max | 6 | 10.00–12.87 | 9.70–12.17 | 4 | 10.83–12.27 | 13.13–16.48 | 6 | 14.07–19.73 | 13.86–19.81 |

| Mean | 11.73 | 10.60 | 11.37 | 15.07 | 17.26 | 16.85 | |||||

| SD | 1.23 | 0.83 | 0.57 | 1.31 | 2.11 | 2.40 | |||||

| CV (%) | 10.45 | 7.84 | 5.06 | 8.72 | 12.23 | 14.27 | |||||

| Crude fibre | % | Min-Max | 6 | 4.04–5.68 | 1.49–1.61 | 4 | 11.86–15.43 | 1.59–2.71 | 6 | 2.29–2.64 | 2.26–2.62 |

| Mean | 4.76 | 1.53 | 13.18 | 2.15 | 2.45 | 2.35 | |||||

| SD | 0.60 | 0.05 | 1.40 | 0.40 | 0.11 | 0.13 | |||||

| CV (%) | 12.63 | 3.39 | 10.65 | 18.44 | 4.58 | 5.42 | |||||

| Fat | % | Min-Max | 6 | 1.90–2.58 | 1.37–1.72 | 4 | 3.82–4.99 | 4.55–5.89 | 6 | 2.06–2.41 | 1.94–2.18 |

| Mean | 2.21 | 1.47 | 4.24 | 5.24 | 2.24 | 2.12 | |||||

| SD | 0.22 | 0.14 | 0.47 | 0.55 | 0.13 | 0.08 | |||||

| CV (%) | 9.97 | 9.45 | 10.99 | 10.47 | 5.78 | 3.97 | |||||

| Ash | % | Min-Max | 6 | 2.01–2.49 | 1.71–1.95 | 4 | 2.72–3.04 | 2.26–2.61 | 6 | 2.17–2.30 | 1.95–2.49 |

| Mean | 2.27 | 1.78 | 2.86 | 2.41 | 2.20 | 2.26 | |||||

| SD | 0.20 | 0.09 | 0.13 | 0.15 | 0.04 | 0.19 | |||||

| CV (%) | 8.68 | 5.04 | 4.63 | 6.06 | 2.01 | 8.64 | |||||

| β-glucan | mg/g DM | Min–Max | 6 | 43.39–52.18 | 42.62–58.43 | 4 | 34.50–40.07 | 53.20–68.40 | 6 | 6.74–8.22 | / |

| Mean | 48.14 | 51.02 | 37.58 | 61.13 | 7.78 | / | |||||

| SD | 3.15 | 5.77 | 2.35 | 6.76 | 0.52 | / | |||||

| CV (%) | 6.55 | 11.31 | 6.24 | 11.05 | 6.62 | / | |||||

| LSD Statistic | TKW | Protein | Crude Fibre | Fat | Ash | β-glucan | |

|---|---|---|---|---|---|---|---|

| Grains | Species/variety | 3.79 | 1.26 | 0.97 | 0.27 | 0.12 | 1.57 |

| Field management | 13.76 | 4.57 | 3.51 | 0.97 | 0.43 | 5.71 | |

| Species/variety | *** | n.s. | *** | *** | *** | *** | |

| Field management | * | n.s. | n.s. | n.s. | *** | * | |

| Groats | Species/variety | 9.44 | 2.25 | 0.20 | 0.15 | 0.14 | 8.95 |

| Field management | 23.08 | 8.16 | 0.71 | 0.54 | 0.50 | 21.89 | |

| Species/variety | * | n.s. | n.s. | *** | n.s. | n.s. | |

| Field management | n.s. | n.s. | * | n.s. | n.s. | n.s. | |

| CONV | Species/variety | 5.33 | 1.88 | 3.53 | 0.51 | 0.24 | 9.82 |

| Fraction | 13.04 | 6.84 | 12.79 | 1.84 | 0.88 | 24.02 | |

| Species/variety | ** | ** | n.s. | *** | n.s. | n.s. | |

| Fraction | * | n.s. | * | n.s. | n.s. | n.s. | |

| ORG | Species/variety | 4.75 | 2.18 | 4.18 | 0.73 | 0.29 | 19.38 |

| Fraction | 11.61 | 7.91 | 15.16 | 2.64 | 1.04 | 47.41 | |

| Species/variety | *** | * | n.s. | ** | n.s. | n.s. | |

| Fraction | * | n.s. | * | n.s. | * | n.s. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sinkovič, L.; Rakszegi, M.; Pipan, B.; Meglič, V. Compositional Traits of Grains and Groats of Barley, Oat and Spelt Grown at Organic and Conventional Fields. Foods 2023, 12, 1054. https://doi.org/10.3390/foods12051054

Sinkovič L, Rakszegi M, Pipan B, Meglič V. Compositional Traits of Grains and Groats of Barley, Oat and Spelt Grown at Organic and Conventional Fields. Foods. 2023; 12(5):1054. https://doi.org/10.3390/foods12051054

Chicago/Turabian StyleSinkovič, Lovro, Marianna Rakszegi, Barbara Pipan, and Vladimir Meglič. 2023. "Compositional Traits of Grains and Groats of Barley, Oat and Spelt Grown at Organic and Conventional Fields" Foods 12, no. 5: 1054. https://doi.org/10.3390/foods12051054

APA StyleSinkovič, L., Rakszegi, M., Pipan, B., & Meglič, V. (2023). Compositional Traits of Grains and Groats of Barley, Oat and Spelt Grown at Organic and Conventional Fields. Foods, 12(5), 1054. https://doi.org/10.3390/foods12051054