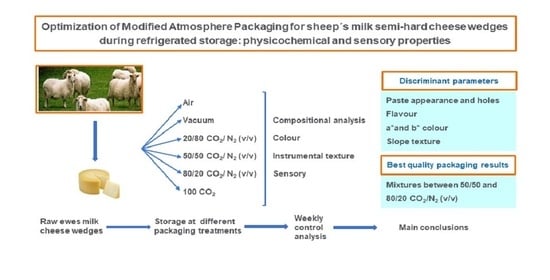

Optimization of Modified Atmosphere Packaging for Sheep’s Milk Semi-Hard Cheese Wedges during Refrigerated Storage: Physicochemical and Sensory Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Cheese Collection, Packaging, and Sampling

2.2. Headspace Gas Composition of Packed Cheese Wedges

2.3. Physicochemical Analysis of Cheese

2.4. Cheese Colour Measurement

2.5. Texture Profile Analysis of Cheese

2.6. Cheese Sensory Analysis

2.7. Data Treatment and Statistical Analysis

3. Results and Discussion

3.1. Headspace Gas Composition

3.1.1. O2 Concentration

3.1.2. CO2 Concentration

3.2. Physicochemical Analysis of Cheeses

3.3. Instrumental Colour Parameters

3.4. Texture Profile Analysis

3.5. Sensory Properties of Cheeses

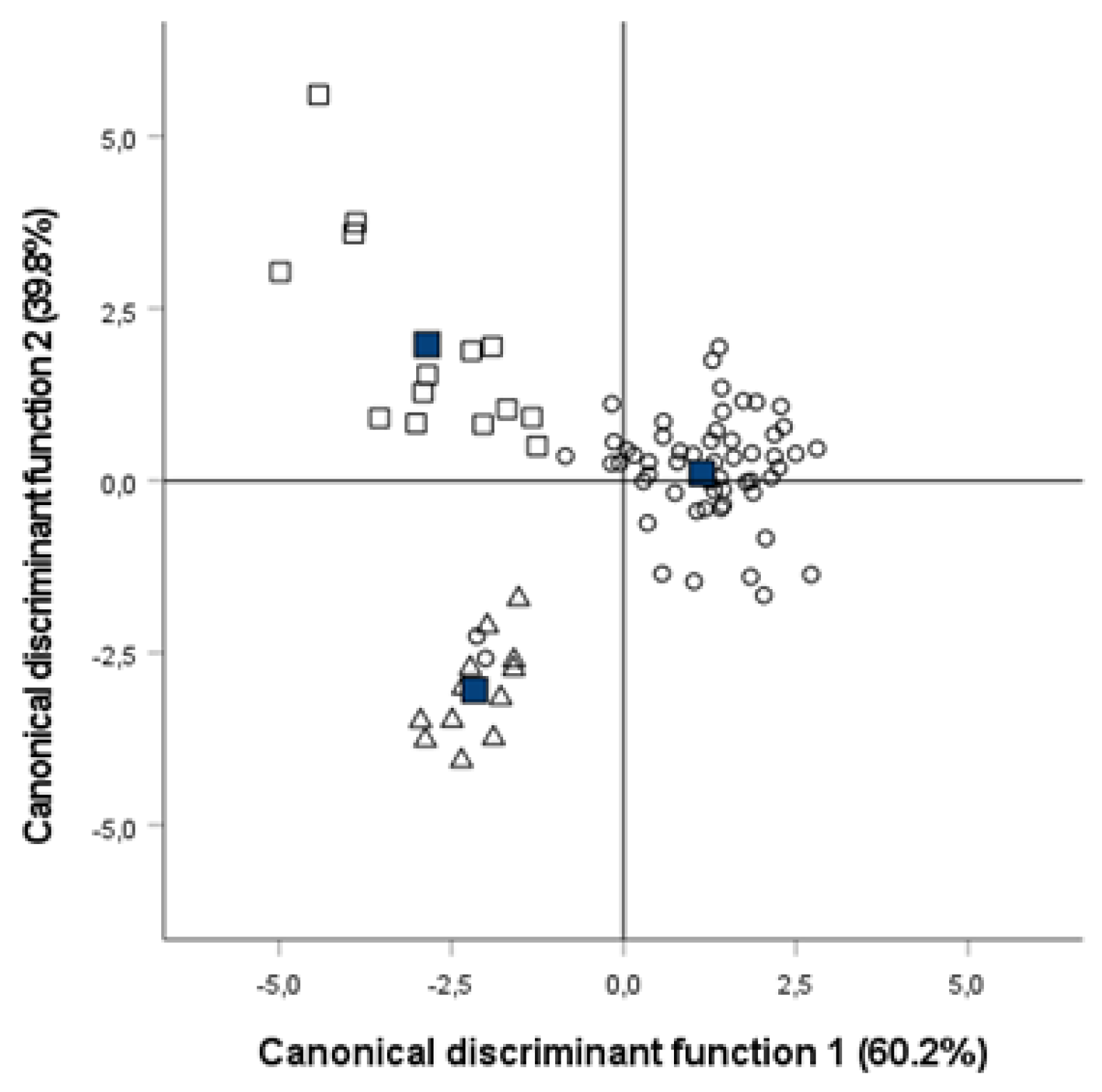

3.6. Discriminant Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stadista. Produccion Anual de Queso a Nivel Mundial de 2015 a 2022. Available online: https://es.statista.com/estadisticas/1311313/produccion-de-queso-en-el-mundo/ (accessed on 24 January 2023).

- Eurostat. Milk and Milk Products Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Milk_and_milk_product_statistics#Milk_products. (accessed on 18 January 2023).

- Ministerio de Agricultura, Pesca y Alimentacion (MAPA). Estadisticas Agrarias de 2021. Available online: https://www.mapa.gob.es/es/estadistica/temas/estadisticas-agrarias/cuadro_b_2021 (accessed on 19 January 2023).

- Figueroa Sanchez, A.; Perea Muñoz, J.; Caballero-Villalobos, J.; Arias Sanchez, R.; Garzon, A.; Angon Sanchez de Pedro, E. Coagulation process in Manchega sheep milk from Spain: A path analysis approach. J. Dairy Sci. 2021, 104, 7544–7554. [Google Scholar] [CrossRef] [PubMed]

- Idiazabal PDO Cheese. Available online: https://www.quesoidiazabal.eus (accessed on 2 November 2022).

- Zabaleta, L.; Albisu, M.; Ojeda, M.; Gil, P.F.; Etaio, I.; Perez-Elortondo, F.J.; de Renobales, M.; Barron, L. Occurrence of sensory defects in semi-hard ewe’s raw milk cheeses. Dairy Sci. Technol. 2016, 96, 53–65. [Google Scholar] [CrossRef]

- Poças, M.F.; Pintado, M. Packaging and Shelf Life of Cheese. In Food Packaging and Shelf Life; Robertson, G.L., Ed.; CRC Press, Taylor and Francis Group: Boca Ratón, FL, USA, 2009; pp. 103–125. [Google Scholar]

- Ciccullo, F.; Cagliano, R.; Bartezzaghi, G.; Perego, A. Implementing the circular economy paradigm in the agri-food supply chain: The role of food waste prevention technologies. Resour. Conserv. Recycl. 2021, 164, 105114. [Google Scholar] [CrossRef]

- Najera, A.I.; Nieto, S.; Barron, L.J.R.; Albisu, M. A review of the preservation of hard and semi-hard cheeses: Quality and safety. Int. J. Environ. Res. Public Health 2021, 18, 9789. [Google Scholar] [CrossRef] [PubMed]

- Juric, M.; Bertelsen, G.; Mortensen, G.; Petersen, M.A. Light-induced colour and aroma changes in sliced, modified atmosphere packaged semi-hard cheeses. Int. Dairy J. 2003, 13, 239–249. [Google Scholar] [CrossRef]

- Trobetas, A.; Badeka, A.; Kontominas, M.G. Light-induced changes in grated Graviera hard cheese packaged under modified atmospheres. Int. Dairy J. 2008, 18, 1133–1139. [Google Scholar] [CrossRef]

- Garabal, J.I.; Rodriguez-Alonso, P.; Franco, D.; Centeno, J.A. Chemical and biochemical study of industrially produced San Simón da Costa smoked semi-hard cow’s milk cheeses: Effects of storage under vacuum and different modified atmospheres. J. Dairy Sci. 2010, 93, 1868–1881. [Google Scholar] [CrossRef]

- Romani, S.; Sacchetti, G.; Pittia, P.; Pinnavaia, G.G.; Dalla Rosa, M. Physical, Chemical, Textural and Sensorial Changes of Portioned Parmigiano Reggiano Cheese Packed under Different Conditions. Food Sci. Technol. Int. 2002, 8, 203–211. [Google Scholar] [CrossRef]

- Piscopo, A.; Zappia, A.; de Bruno, A.; Poiana, M. Qualitative variations on Calabrian Provola cheeses stored under different packaging conditions. J. Dairy Res. 2015, 82, 499–505. [Google Scholar] [CrossRef]

- Hocking, A.D.; Faedo, M. Fungi causing thread mould spoilage of vacuum packaged Cheddar cheese during maturation. Int. J. Food Microbiol. 1992, 16, 123–130. [Google Scholar] [CrossRef]

- Bellio, A.; Astegiano, S.; Traversa, A.; Bianchi, D.M.; Gallina, S.; Vitale, N.; Zuccon, F.; Decastelli, L. Behaviour of Listeria monocytogenes and Staphylococcus aureus in sliced, vacuum-packaged raw milk cheese stored at two different temperatures and time periods. Int. Dairy J. 2016, 57, 15–19. [Google Scholar] [CrossRef]

- Favati, F.; Galgano, F.; Pace, A.M. Shelf-life evaluation of portioned Provolone cheese packaged in protective atmosphere. LWT Food Sci. Technol. 2007, 40, 480–488. [Google Scholar] [CrossRef]

- Tansman, G.F.; Kindstedt, P.S.; Hughes, J.M. Crystal fingerprinting: Elucidating the crystals of Cheddar, Parmigiano-Reggiano, Gouda, and soft washed-rind cheeses using powder x-ray diffractometry. Dairy Sci. Technol. 2015, 95, 651–664. [Google Scholar] [CrossRef] [PubMed]

- Esmer, O.K.; Balkir, P.; Seckin, A.K.; Irkin, R. The Effect of Modified Atmosphere and Vacuum Packaging on the Physicochemical, Microbiological, Sensory and Textural Properties of Crottin de Chavignol Cheese. Food Sci. Technol. Res. 2009, 15, 367–376. [Google Scholar] [CrossRef]

- Rodriguez-Aguilera, R.; Oliveira, J.C.; Montanez, J.C.; Mahajan, P.V. Effect of modified atmosphere packaging on quality factors and shelf-life of mould surface-ripened cheese: Part II varying storage temperature. LWT Food Sci. Technol. 2011, 44, 337–342. [Google Scholar] [CrossRef]

- Todaro, M.; Palmeri, M.; Cardamone, C.; Settanni, L.; Mancuso, I.; Mazza, F.; Scatassa, M.L.; Corona, O. Impact of packaging on the microbiological, physicochemical and sensory characteristics of a “pasta filata” cheese. Food Package Shelf Life 2018, 17, 85–90. [Google Scholar] [CrossRef]

- Gonzalez-Fandos, E.; Sanz, S.; Olarte, C. Microbiological, physicochemical and sensory characteristics of Cameros cheese packaged under modified atmospheres. Food Microbiol. 2000, 17, 407–414. [Google Scholar] [CrossRef]

- Cosentino, C.; Paolino, R.; Valentini, V.; Musto, M.; Ricciardi, A.; Adduci, F.; D’Adamo, C.; Pecora, G.; Freschi, P. Effect of jenny milk addition on the inhibition of late blowing in semihard cheese. J. Dairy Sci. 2015, 98, 5133–5142. [Google Scholar] [CrossRef]

- Colchin, L.M.; Owens, S.L.; Lyubachevskaya, G.; Boyle-Roden, E.; Russek-Cohen, E.; Rankin, S.A. Modified Atmosphere Packaged Cheddar Cheese Shreds: Influence of Fluorescent Light Exposure and Gas Type on Color and Production of Volatile Compounds. J. Agric. Food Chem. 2001, 49, 2277–2282. [Google Scholar] [CrossRef]

- ISO/TS 11869; Fermented Milks—Determination of Titratable Acidity—Potentiometric Method. International Organization for Standardization: Geneva, Switzerland, 2012.

- AOAC. Acidity of Milk, Titrimetric Method AOAC Official Method 920.124; Association of Official Agricultural Chemists: Rockville, MD, USA, 2005. [Google Scholar]

- Rohm, H.; Jaros, D. Colour of hard cheese. Z. Für Lebensm.-Unters. Und Forsch. 1996, 203, 241–244. [Google Scholar] [CrossRef]

- Frau, M.; Simal, S.; Femenia, A.; Sanjuan, E.; Rossello, C. Use of principal component analysis to evaluate the physical properties of Mahon cheese. Eur. Food Res. Technol. 1999, 210, 73–76. [Google Scholar] [CrossRef]

- del Caro, A.; Fadda, C.; Sanguinetti, A.M.; Carboni, M.G.; Pinna, G.; Naes, T.; Menichelli, E.; Piga, A. Influence of Technology and Ripening on Textural and Sensory Properties of Vacuum Packaged Ewe’s Cheese. Czech J. Food Sci. 2016, 34, 456–462. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Bourne, M.C. Texture profile analysis. Food Technol. 1978, 32, 62–66. [Google Scholar]

- Wee, M.S.M.; Goh, A.T.; Stieger, M.; Forde, C.G. Correlation of instrumental texture properties from textural profile analysis (TPA) with eating behaviours and macronutrient composition for a wide range of solid foods. Food Funct. 2018, 9, 5301–5312. [Google Scholar] [CrossRef] [PubMed]

- Ojeda, M.; Etaio, I.; Fernandez-Gil, M.P.; Albisu, M.; Salmeron, J.; Perez-Elortondo, F.J. Sensory quality control of cheese: Going beyond the absence of defects. Food Control 2015, 51, 371–380. [Google Scholar] [CrossRef]

- Valdivielso, I.; Albisu, M.; de Renobales, M.; Barron, L.J.R. Changes in the volatile composition and sensory properties of cheeses made with milk from commercial sheep flocks managed indoors, part-time grazing in valley, and extensive mountain grazing. Int. Dairy J. 2016, 53, 29–36. [Google Scholar] [CrossRef]

- ISO 8589:2007/Amd 1:2014; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneve, Switzerland, 2014.

- Khoshgozaran, S.; Azizi, M.H.; Bagheripoor-Fallah, N. Evaluating the effect of modified atmosphere packaging on cheese characteristics: A review. Dairy Sci. Technol. 2011, 92, 1–24. [Google Scholar] [CrossRef]

- Costa, C.; Lucera, A.; Lacivita, V.; Saccotelli, M.A.; Conte, A.; Del Nobile, M.A. Packaging optimisation for portioned Canestrato di Moliterno cheese. Int. J. Dairy Technol. 2016, 69, 401–409. [Google Scholar] [CrossRef]

- Atallah, A.A.; El-Deeb, A.M.; Mohamed, E.N. Shelf-life of Domiati cheese under modified atmosphere packaging. J. Dairy Sci. 2021, 104, 8568–8581. [Google Scholar] [CrossRef]

- O’ Callaghan, K.A.M.; Papkovsky, D.B.; Kerry, J.P. An Assessment of the Influence of the Industry Distribution Chain on the Oxygen Levels in Commercial Modified Atmosphere Packaged Cheddar Cheese Using Non-Destructive Oxygen Sensor Technology. Sensors 2016, 16, 916. [Google Scholar] [CrossRef] [PubMed]

- Kristensen, D.; Orlien, V.; Mortensen, G.; Brockhoff, P.; Skibsted, L.H. Light-induced oxidation in sliced Havarti cheese packaged in modified atmosphere. Int. Dairy J. 2000, 10, 95–103. [Google Scholar] [CrossRef]

- Kirkin, C.; Gunes, G.; Kilic-Akyilmaz, M. Preservation of precut white cheese by modified atmosphere packaging. Int. J. Dairy Technol. 2013, 66, 576–586. [Google Scholar] [CrossRef]

- Solomakos, N.; Govari, M.; Botsoglou, E.; Pexara, A. Effect of modified atmosphere packaging on physicochemical and microbiological characteristics of Graviera Agraphon cheese during refrigerated storage. J. Dairy Res. 2019, 86, 483–489. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Alonso, P.; Centeno, J.A.; Garabal, J.I. Biochemical study of industrially produced Arzúa-Ulloa semi-soft cows’ milk cheese: Effects of storage under vacuum and modified atmospheres with high-nitrogen contents. Int. Dairy J. 2011, 21, 261–271. [Google Scholar] [CrossRef]

- Dermiki, M.; Ntzimani, A.; Badeka, A.; Savvaidis, I.N.; Kontominas, M.G. Shelf-life extension and quality attributes of the whey cheese “Myzithra Kalathaki” using modified atmosphere packaging. LWT Food Sci. Technol. 2008, 41, 284–294. [Google Scholar] [CrossRef]

- Pintado, M.E.; Malcata, F.X. Optimization of modified atmosphere packaging with respect to physicochemical characteristics of Requeijao. Food Res. Int. 2000, 33, 821–832. [Google Scholar] [CrossRef]

- Alves, R.M.V.; Sarantopoulos, C.; Van Dender, A.; Faria, J.d.A. Stability of sliced mozzarella cheese in modified-atmosphere packaging. J. Food Prot. 1996, 59, 838–844. [Google Scholar] [CrossRef]

- Diezhandino, I.; Fernandez, D.; Sacristan, N.; Combarros-Fuertes, P.; Prieto, B.; Fresno, J.M. Rheological, textural, colour and sensory characteristics of a Spanish blue cheese (Valdeon cheese). LWT Food Sci. Technol. 2016, 65, 1118–1125. [Google Scholar] [CrossRef]

- Di Marzo, S.; Di Monaco, R.; Iaccarino, T.; Cavella, S.; Masi, P. Determinazione della shelf life del Canestrato Pugliese in fette confezionato in film biodegradabili, Ricerche ed Innovazioni nell’Industria Alimentare. In 6° Congresso Italiano di Scienza degli Alimenti; Chiriotti Editori: Pinerolo, Italy, 2004; pp. 414–419. [Google Scholar]

- Martin, B.; Fedele, V.; Ferlay, A.; Grolier, P.; Rock, E.; Gruffat, D.; Chilliard, Y. Effects of grass-based diets on the content of micronutrients and fatty acids in bovine and caprine dairy products. Land use systems in grassland dominated regions. In Proceedings of the 20th General Meeting of the European Grassland Federation, Luzern, Switzerland, 21–24 June 2004; pp. 876–886. [Google Scholar]

- Romani, S.; Sacchetti, G.; Vannini, L.; Pinnavaia, G.G.; Dalla Rosa, M.; Corradini, C. Storage stability of portioned packed Parmigiano Reggiano cheese [Emilia-Romagna]. Sci. Tec. Latt. Casearia 1999, 50, 273–290. [Google Scholar]

- Avila, M.; Garde, S.; Nuñez, M. The influence of some manufacturing and ripening parameters on the colour of ewes’ milk cheese. Milchwissenschaft 2008, 63, 160–164. [Google Scholar]

- Singh, P.; Wani, A.A.; Karim, A.A.; Langowski, H.C. The use of carbon dioxide in the processing and packaging of milk and dairy products: A review. Int. J. Dairy Technol. 2012, 65, 161–177. [Google Scholar] [CrossRef]

- Temiz, H. Effect of modified atmosphere packaging on characteristics of sliced kashar cheese. J. Food Process. Preserv. 2010, 34, 926–943. [Google Scholar] [CrossRef]

- Agarwal, S.; Costello, M.; Clark, S. Gas-Flushed Packaging Contributes to Calcium Lactate Crystals in Cheddar Cheese. J. Dairy Sci. 2005, 88, 3773–3783. [Google Scholar] [CrossRef] [PubMed]

- Hotchkiss, J.H.; Werner, B.G.; Lee, E.Y.C. Addition of Carbon Dioxide to Dairy Products to Improve Quality: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2006, 5, 158–168. [Google Scholar] [CrossRef]

- Dybing, S.T.; Wiegand, J.A.; Brudvig, S.A.; Huang, E.A.; Chandan, R.C. Effect of processing variables on the formation of calcium lactate crystals on Cheddar cheese. J. Dairy Sci. 1988, 71, 1701–1710. [Google Scholar] [CrossRef]

| Day | Air | MAP1 | MAP2 | MAP3 | MAP4 |

|---|---|---|---|---|---|

| 0 | 2.45 ± 0.78 d | 23.98 ± 0.67 a | 52.90 ± 0.78 a | 83.80 ± 0.35 a | 100.08 ± 0.04 a |

| 14 | 7.20 ± 1.56 cd | 19.20 ± 0.99 ab | 44.75 ± 0.78 ab | 76.80 ± 0.99 ab | 100.00 ± 0.00 a |

| 21 | 7.25 ± 0.78 cd | 17.70 ± 0.57 b | 40.60 ± 1.41 bc | 73.65 ± 2.62 ab | 99.95 ± 0.07 a |

| 28 | 10.49 ± 0.69 bc | 18.30 ± 1.56 ab | 40.50 ± 1.98 bc | 70.40 ± 6.36 ab | 97.95 ± 2.90 a |

| 35 | 13.35 ± 4.03 abc | 17.05 ± 0.21 b | 37.53 ± 2.02 bcd | 64.20 ± 8.34 ab | 94.65 ± 7.42 a |

| 42 | 17.00 ± 0.57 a | 17.95 ± 2.05 ab | 38.35 ± 4.45 bcd | 66.00 ± 9.90 ab | 93.80 ± 8.77 a |

| 49 | 14.25 ± 0.49 ab | 17.15 ± 1.34 b | 33.90 ± 2.40 cd | 59.80 ± 14.85 ab | 99.10 ± 0.00 a |

| 56 | 13.80 ± 0.57 ab | 16.70 ± 2.97 b | 29.50 ± 4.38 d | 47.65 ± 14.07 b | - |

| L* | a* | b* | Yi | Zi | |

|---|---|---|---|---|---|

| Packaging treatment | ns | ** | ** | ** | ns |

| Storage time | ns | ns | ns | ns | ns |

| Interaction | ns | ns | ns | ns | ns |

| x ± SD | 81.27 ± 2.22 | −2.80 ± 0.47 | 12.27 ± 0.93 | 21.54 ± 1.56 | 47.04 ± 3.37 |

| Texture | ||||||

|---|---|---|---|---|---|---|

| Day | Air | Vacuum | MAP1 | MAP2 | MAP3 | MAP4 |

| 0 | 5.36 ± 0.63 a1 | 5.36 ± 0.63 a1 | 5.36 ± 0.63 a1 | 5.36 ± 0.63 a1 | 5.36 ± 0.63 a1 | 5.36 ± 0.63 a1 |

| 14 | 5.07 ± 0.92 a12 | 5.29 ± 0.9 a12 | 5.14 ± 0.86 a12 | 5.18 ± 0.77 a1 | 5.07 ± 0.83 a1 | 4.75 ± 0.75 a12 |

| 21 | 4.84 ± 0.89 a12 | 5.00 ± 0.68 a12 | 5.07 ± 1.00 a12 | 4.79 ± 0.98 a1 | 4.43 ± 0.51 a1 | 4.71 ± 0.83 a12 |

| 28 | 4.50 ± 0.76 a12 | 4.79 ± 0.80 a12 | 4.71 ± 0.73 a12 | 4.86 ± 0.77 a1 | 5.00 ± 0.88 a1 | 4.64 ± 0.74 a12 |

| 35 | 4.21 ± 0.43 a2 | 4.64 ± 0.74 a12 | 4.50 ± 0.65 a12 | 4.77 ± 0.70 a1 | 4.86 ± 0.86 a1 | 4.14 ± 0.66 a2 |

| 42 | 4.50 ± 0.52 a12 | 4.92 ± 0.83 a12 | 4.79 ± 0.58 a12 | 4.93 ± 0.88 a1 | 5.14 ± 0.77 a1 | 4.50 ± 0.66 a12 |

| 49 | - | 4.79 ± 0.80 a12 | 4.50 ± 0.85 a12 | 5.21 ± 0.89 a1 | 4.79 ± 0.56 a1 | 4.21 ± 0.43 a12 |

| 56 | - | 4.36 ± 0.50 a2 | 4.43 ± 0.51 ab2 | 4.64 ± 0.74 ab1 | 4.86 ± 0.66 a1 | 3.86 ± 0.77 b2 |

| Flavour | ||||||

| 0 | 5.50 ± 0.52 a1 | 5.50 ± 0.5 a1 | 5.50 ± 0.52 a1 | 5.50 ± 0.52 a1 | 5.50 ± 0.52 a1 | 5.50 ± 0.52 a1 |

| 14 | 5.07 ± 0.83 a12 | 5.14 ± 0.66 a12 | 5.07 ± 0.83 a1 | 5.21 ± 0.58 a1 | 5.07 ± 0.73 a1 | 5.04 ± 0.80 a12 |

| 21 | 4.43 ± 0.65 a234 | 4.93 ± 0.9 a23 | 4.93 ± 0.73 a1 | 5.00 ± 0.78 a1 | 4.86 ± 0.86 a1 | 4.29 ± 0.73 a23 |

| 28 | 4.23 ± 0.73 a234 | 4.29 ± 0.61 a3 | 4.64 ± 0.84 a123 | 4.86 ± 0.77 a1 | 4.79 ± 0.89 a1 | 4.43 ± 0.76 a23 |

| 35 | 3.93 ± 0.47 bc34 | 4.50 ± 0.6 ab23 | 4.50 ±0.85 ab123 | 4.57 ± 0.7 ab1 | 4.71 ± 0.73 ab1 | 4.14 ± 0.6 bc23 |

| 42 | 3.36 ± 1.00 c4 | 5.21 ± 0.70 ab12 | 4.86 ± 0.86 ab12 | 4.93 ± 0.83 ab1 | 5.36 ± 0.63 a1 | 4.29 ± 0.92 bc23 |

| 49 | - | 4.79 ± 0.80 a12 | 4.50 ± 0.85 a12 | 5.21 ± 0.89 a1 | 4.79 ± 0.56 a1 | 4.21 ± 0.43 a12 |

| 56 | - | 4.50 ± 0.94 ab23 | 3.71 ± 0.71 b3 | 4.57 ± 0.76 a1 | 4.79 ± 0.43 a1 | 3.71 ± 0.91 ab3 |

| Paste Appearance | ||||||

|---|---|---|---|---|---|---|

| Day | Air | Vacuum | MAP1 | MAP2 | MAP3 | MAP4 |

| 0 | 5.43 ± 0.65 a1 | 5.43 ± 0.65 a1 | 5.43 ± 0.65 a1 | 5.43 ± 0.65 a1 | 5.43 ± 0.65 a1 | 5.43 ± 0.65 a1 |

| 14 | 4.71 ± 1.07 ab12 | 3.86 ± 0.66 b12 | 5.14 ± 0.66 a12 | 5.21 ± 0.89 a12 | 4.64 ± 0.63 ab1 | 5.27 ± 0.83 a12 |

| 21 | 4.21 ± 0.70 ab12 | 3.36 ± 0.74 b2 | 4.36 ± 1.01 ab2 | 4.64 ± 0.84 a123 | 4.50 ± 1.02 a1 | 3.93 ± 0.73 ab23 |

| 28 | 3.71 ± 0.73 bc23 | 3.14 ± 0.36 c23 | 4.43 ± 0.85 ab12 | 4.36 ± 0.74 ab23 | 4.93 ± 0.83 a1 | 4.21 ± 0.98 ab12 |

| 35 | 3.36 ± 0.50 b234 | 3.21 ± 0.58 b23 | 4.36 ± 0.84 a2 | 4.21 ± 0.70 a23 | 4.79 ± 0.80 a1 | 4.00 ± 0.78 ab23 |

| 42 | 1.79 ± 1.05 b4 | 2.78 ± 0.43 b234 | 4.71 ± 0.91 a12 | 4.57 ± 0.75 a123 | 5.29 ± 0.73 a1 | 4.29 ± 0.73 a12 |

| 49 | 2.14 ± 0.66 b34 | 2.21 ± 0.43 b34 | 4.86 ± 0.53 a12 | 4.50 ± 0.52 a123 | 4.93 ± 0.73 a1 | 2.86 ± 0.53 b3 |

| 56 | 1.64 ± 0.74 b4 | 1.64 ± 0.63 b4 | 4.29 ± 0.61 a2 | 4.00 ± 0.78 a3 | 4.50 ± 0.65 a1 | 4.22 ± 0.80 a12 |

| Holes | ||||||

| 0 | 5.64 ± 0.50 a1 | 5.64 ± 0.50 a1 | 5.64 ± 0.50 a1 | 5.64 ± 0.50 a1 | 5.64 ± 0.50 a1 | 5.64 ± 0.50 a1 |

| 14 | 4.36 ± 1.08 ab2 | 4.00 ± 0.78 b12 | 5.21 ± 1.31 ab12 | 5.36 ± 0.74 ab1 | 5.36 ± 0.50 ab12 | 5.79 ± 0.70 a1 |

| 21 | 4.14 ± 0.36 ab2 | 3.35 ± 0.63 b23 | 4.14 ± 0.66 ab3 | 4.43 ± 0.51 a3 | 4.71 ± 0.47 a2 | 4.21 ± 0.43 a2 |

| 28 | 4.29 ± 0.72 bc2 | 3.50 ± 0.65 c23 | 4.64 ±0.84 ab123 | 5.50 ± 0.52 a1 | 5.5 ± 0.52 a1 | 4.86 ± 0.77 ab12 |

| 35 | 4.00 ± 0.55 bc2 | 3.28 ± 0.61 c23 | 4.64 ±0.84 ab123 | 5.21 ± 0.70 a123 | 5.21 ± 0.80 a12 | 4.50 ± 0.52 ab2 |

| 42 | 3.93 ± 1.54 bc23 | 2.71 ± 0.47 bc34 | 5.43 ± 0.76 a1 | 5.50 ± 0.52 a1 | 5.64 ± 0.63 a1 | 4.64 ± 0.75 ab2 |

| 49 | 2.29 ± 0.47 c3 | 2.70 ± 0.83 bc34 | 4.36 ± 0.50 ab23 | 4.50 ± 0.52 a23 | 5.14 ± 0.66 a12 | 4.07 ± 0.73 ab2 |

| 56 | 4.14 ± 1.02 b2 | 1.00 ± 0.00 c4 | 5.14 ± 0.66 ab12 | 5.36 ± 0.50 a12 | 5.00 ± 0.55 ab12 | 4.64 ± 0.63 ab2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albisu, M.; Nieto, S.; Martínez, O.; Bustamante, M.Á.; Barron, L.J.R.; Nájera, A.I. Optimization of Modified Atmosphere Packaging for Sheep’s Milk Semi-Hard Cheese Wedges during Refrigerated Storage: Physicochemical and Sensory Properties. Foods 2023, 12, 849. https://doi.org/10.3390/foods12040849

Albisu M, Nieto S, Martínez O, Bustamante MÁ, Barron LJR, Nájera AI. Optimization of Modified Atmosphere Packaging for Sheep’s Milk Semi-Hard Cheese Wedges during Refrigerated Storage: Physicochemical and Sensory Properties. Foods. 2023; 12(4):849. https://doi.org/10.3390/foods12040849

Chicago/Turabian StyleAlbisu, Marta, Sonia Nieto, Olaia Martínez, María Ángeles Bustamante, Luis Javier R. Barron, and Ana Isabel Nájera. 2023. "Optimization of Modified Atmosphere Packaging for Sheep’s Milk Semi-Hard Cheese Wedges during Refrigerated Storage: Physicochemical and Sensory Properties" Foods 12, no. 4: 849. https://doi.org/10.3390/foods12040849

APA StyleAlbisu, M., Nieto, S., Martínez, O., Bustamante, M. Á., Barron, L. J. R., & Nájera, A. I. (2023). Optimization of Modified Atmosphere Packaging for Sheep’s Milk Semi-Hard Cheese Wedges during Refrigerated Storage: Physicochemical and Sensory Properties. Foods, 12(4), 849. https://doi.org/10.3390/foods12040849