Effect of Moisture and Oil Content in the Supercritical CO2 Defatting of Hermetia illucens Larvae

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples and Reagents

2.2. Determination of Moisture Content

2.3. Determination of Fat Content by Hexane Solvent Extraction

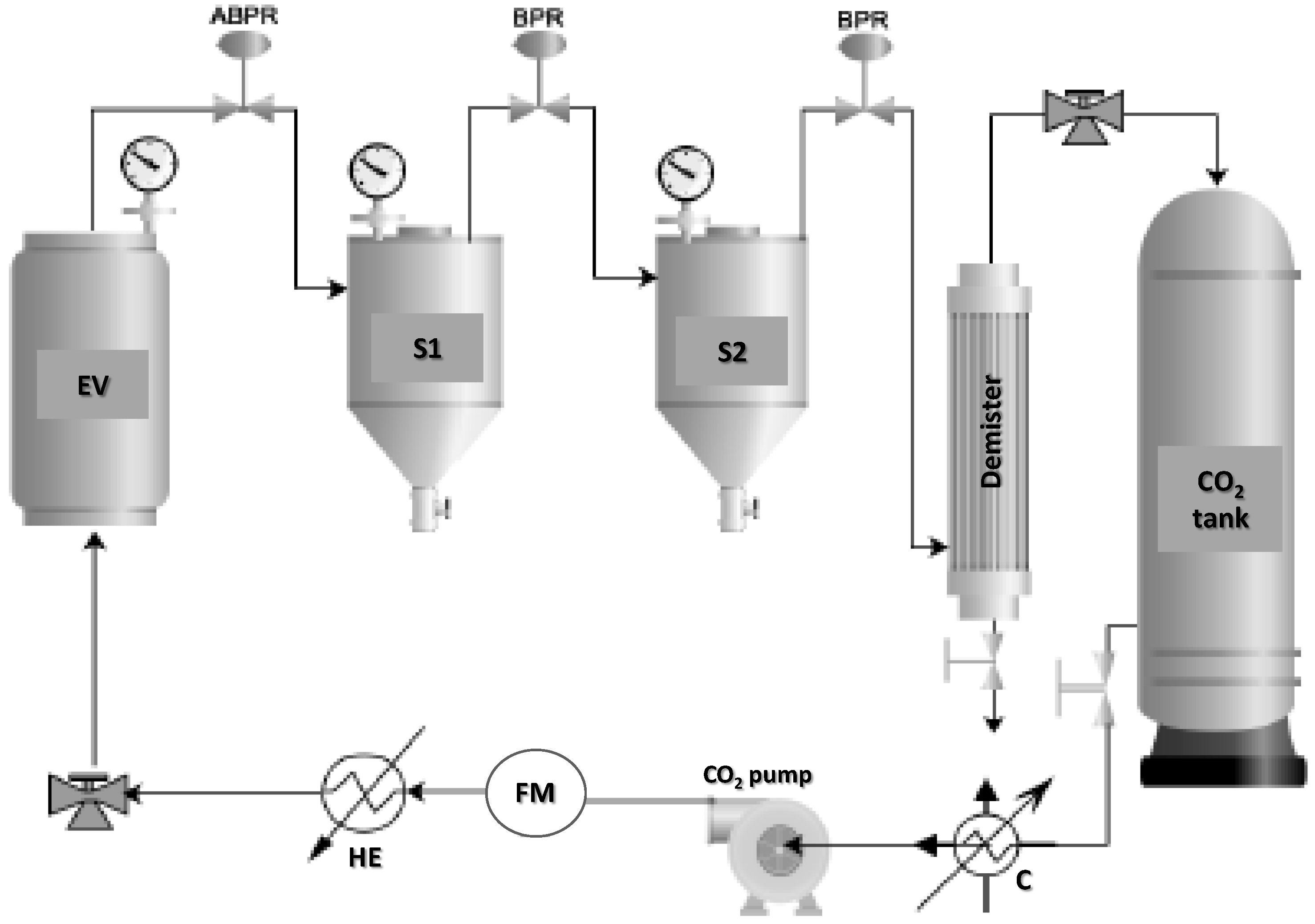

2.4. Defatting of H. illucens Flour by Supercritical CO2

2.4.1. Kinetic Study and Process Scale Up

2.4.2. Supercritical Extraction of Different H. illucens Larvae Batches

2.5. Analysis of the Extracted Oil

3. Results

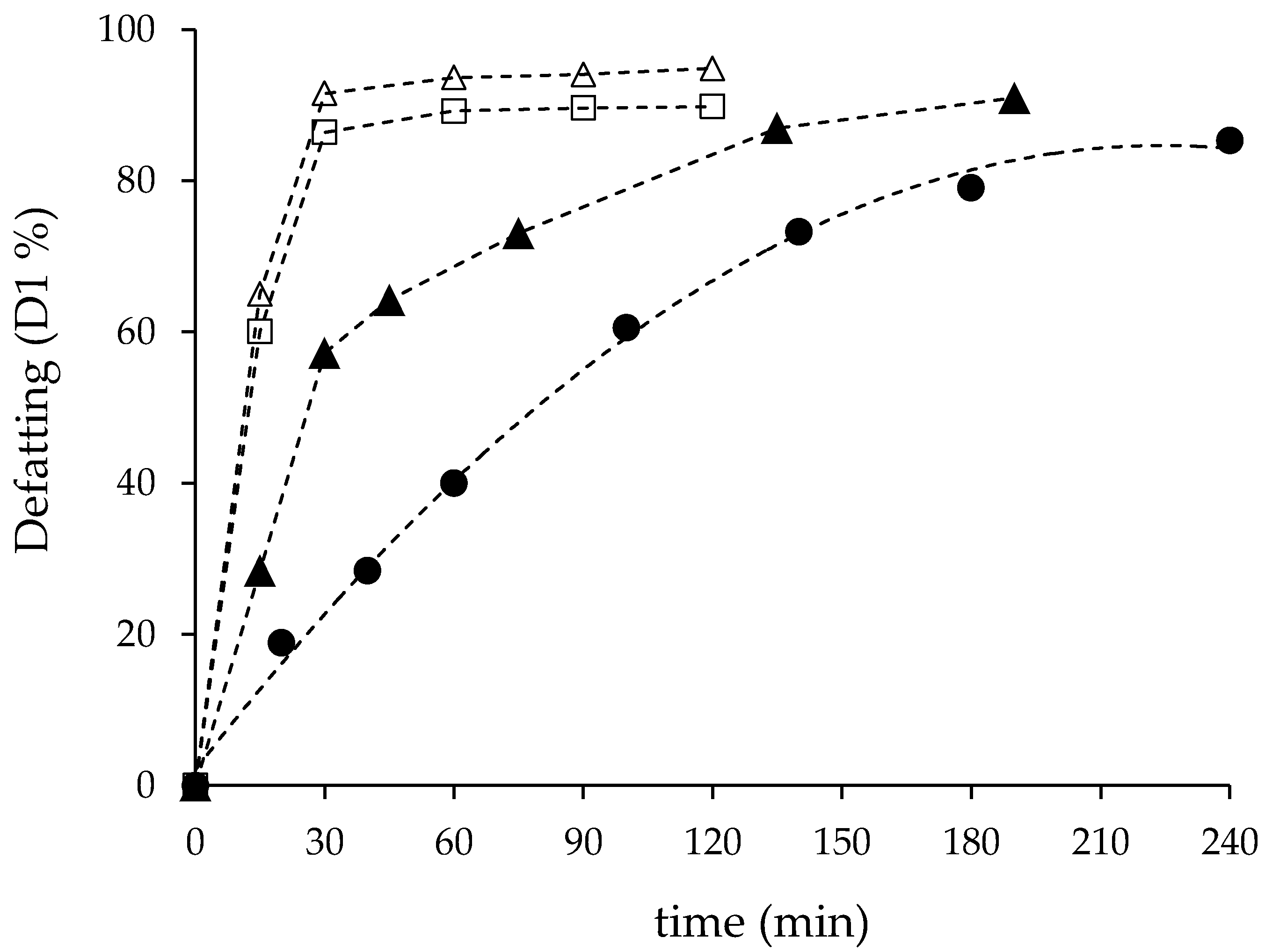

3.1. Kinetic Study and Process Scale-Up

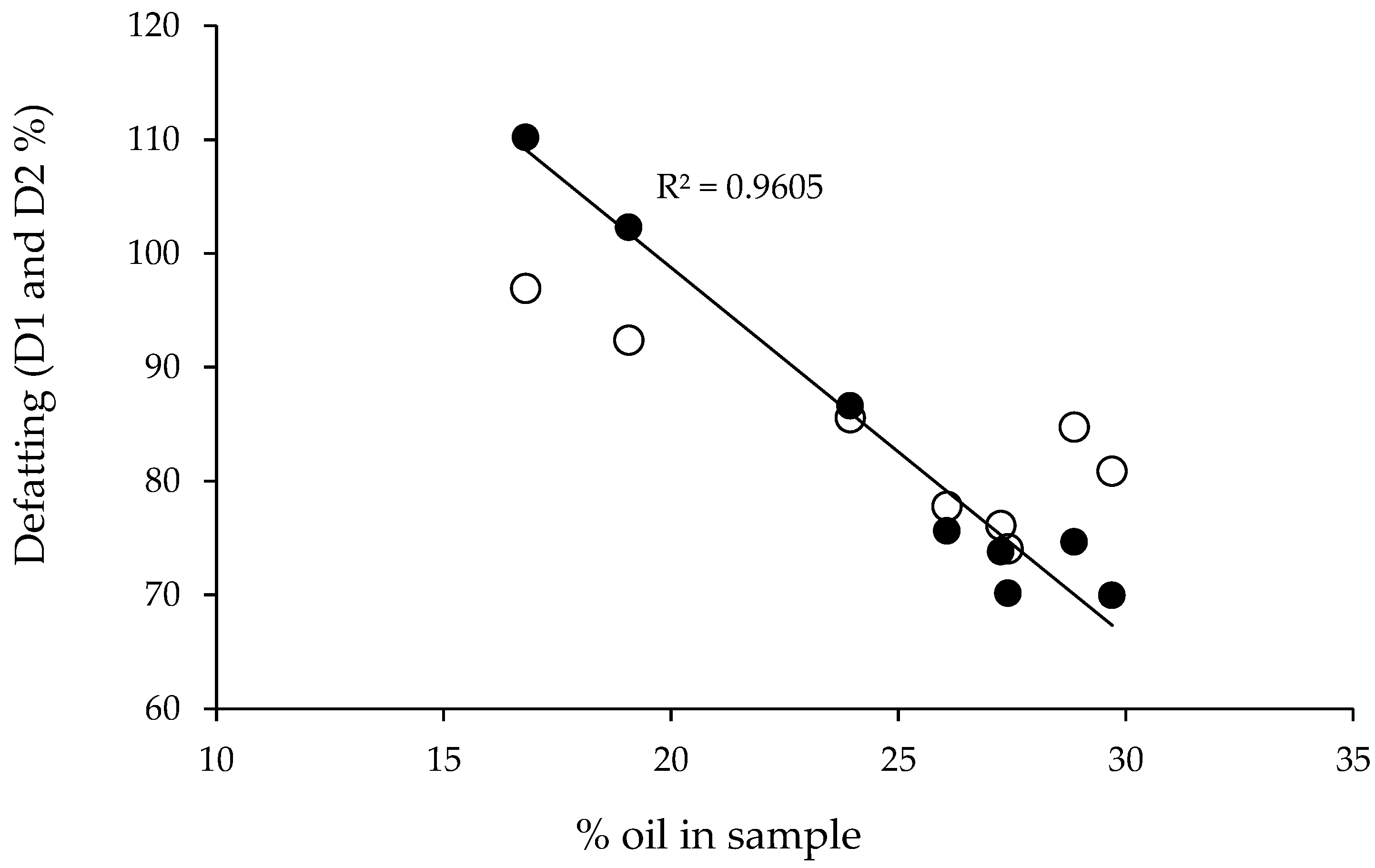

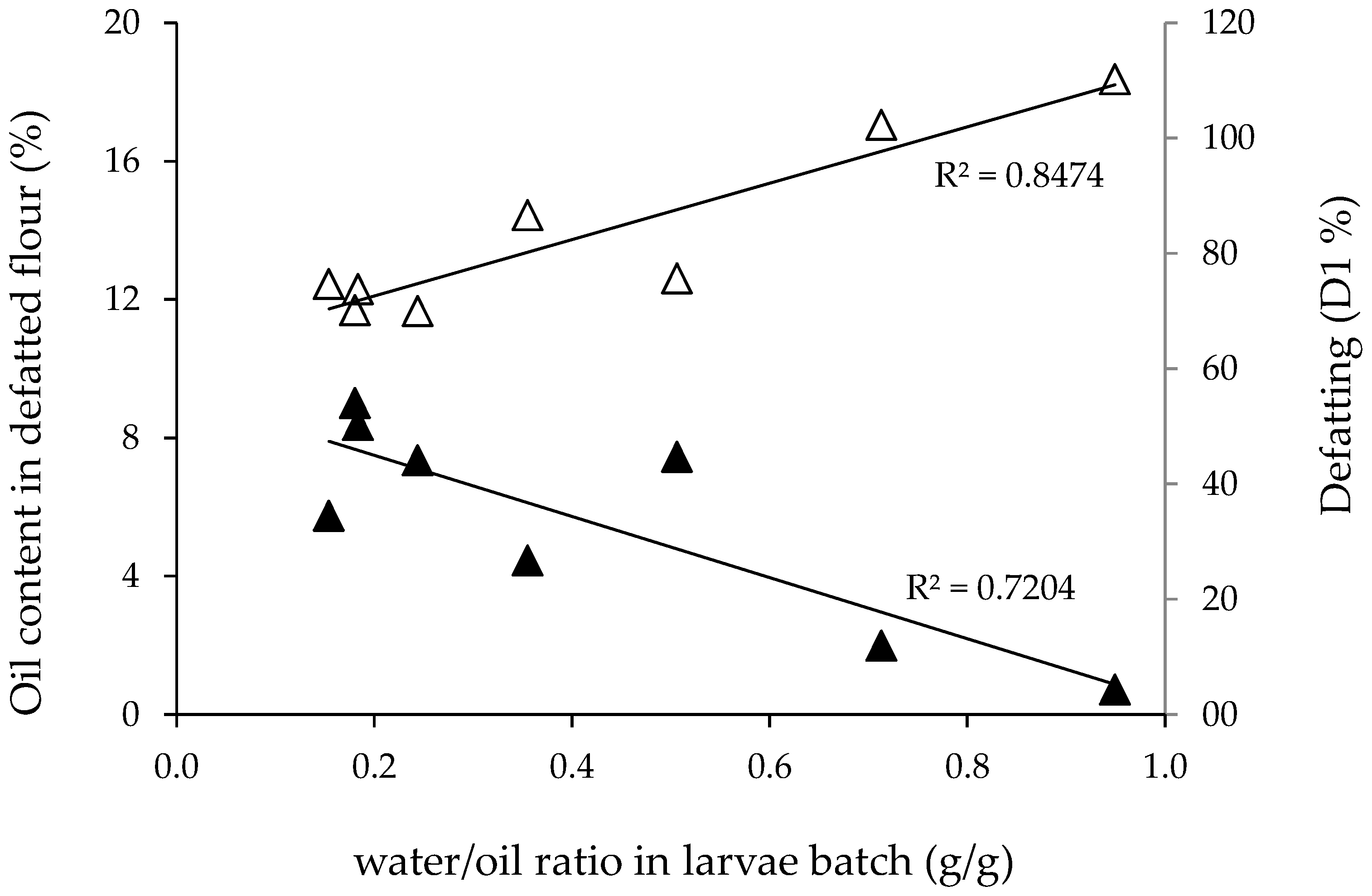

3.2. Extraction Yield and oil Recovery

3.3. Oil Composition, Moisture, and Peroxide Value

3.3.1. Fatty Acid Profile

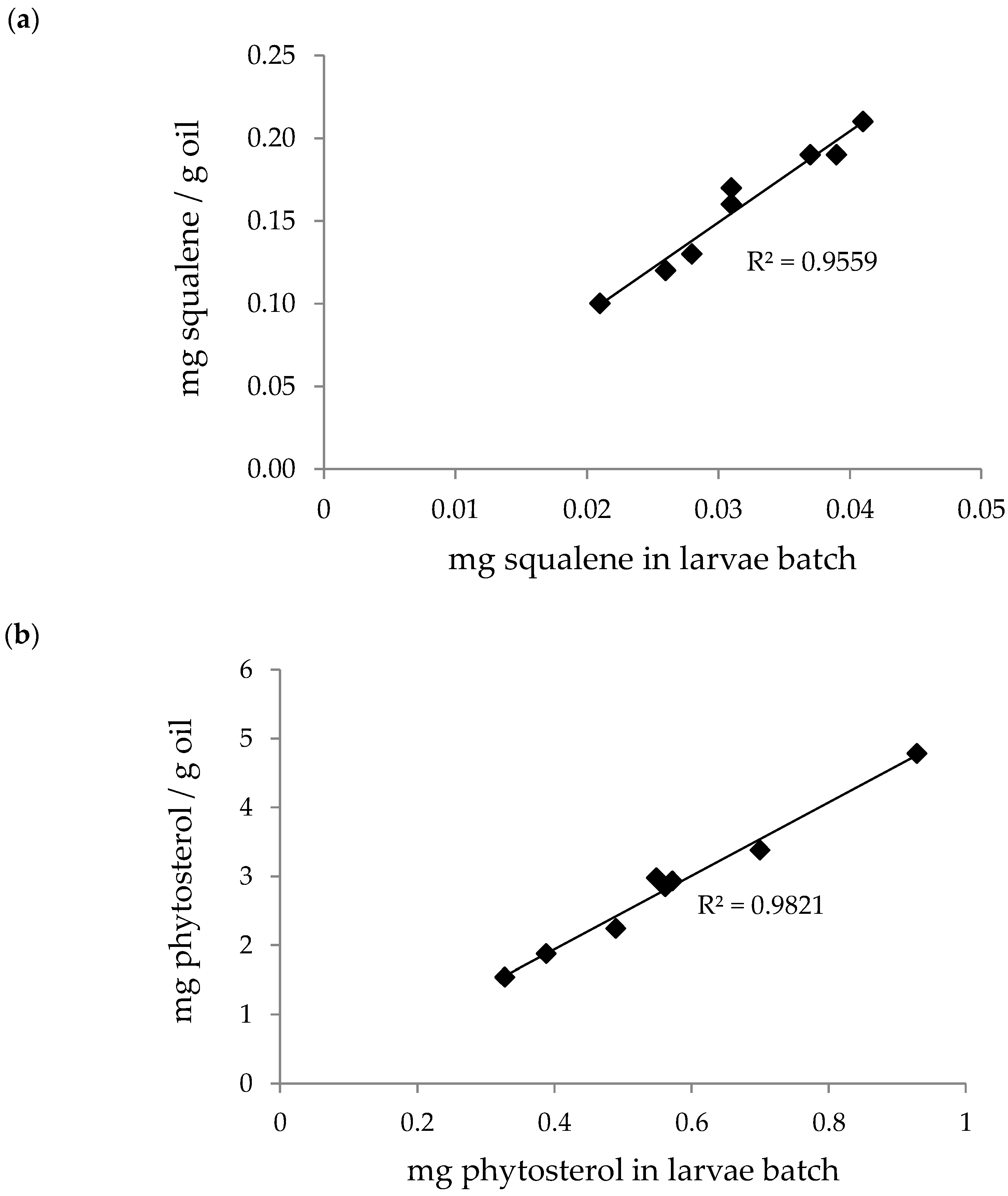

3.3.2. Minor Lipid Compounds

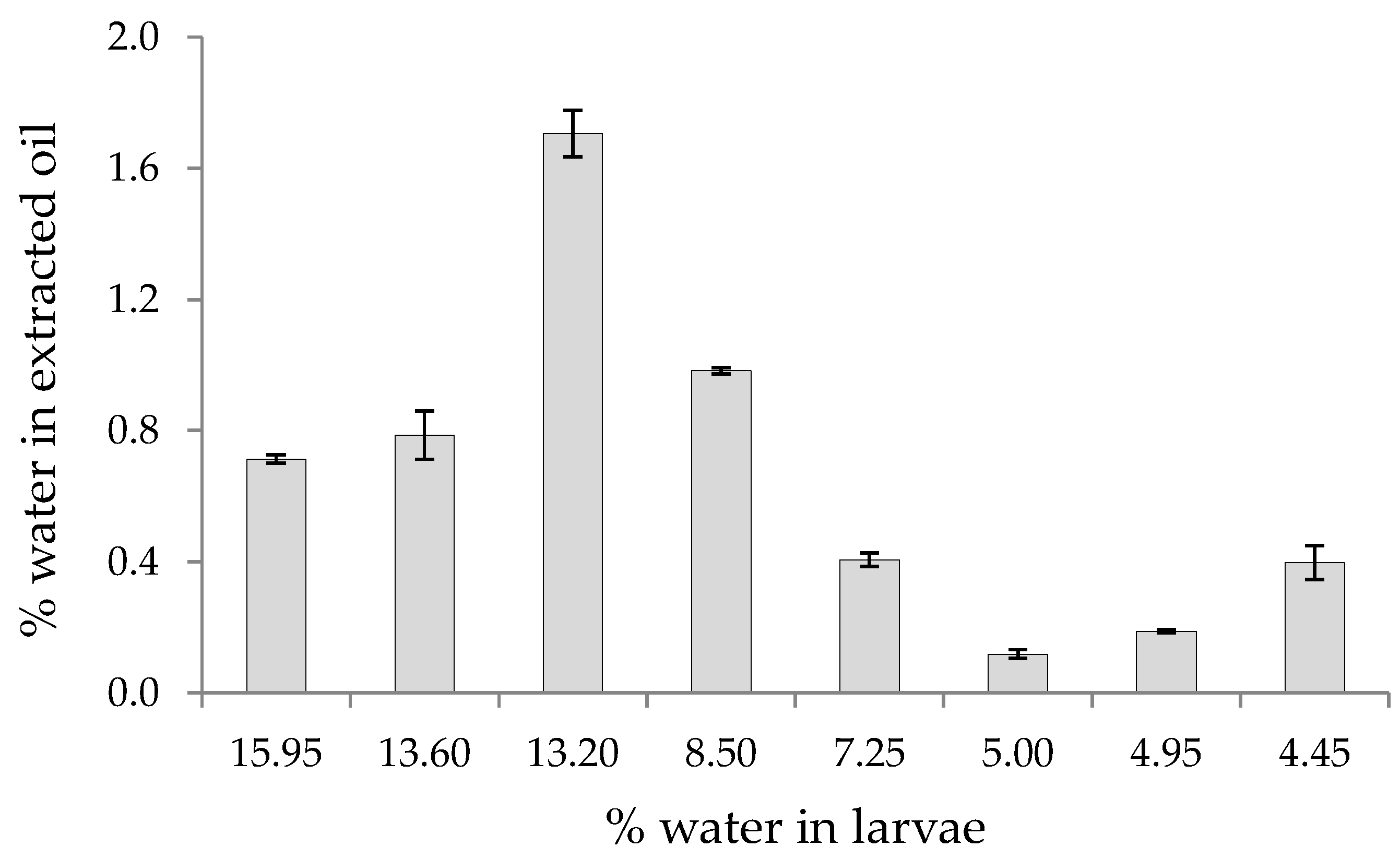

3.3.3. Moisture Content of Oils

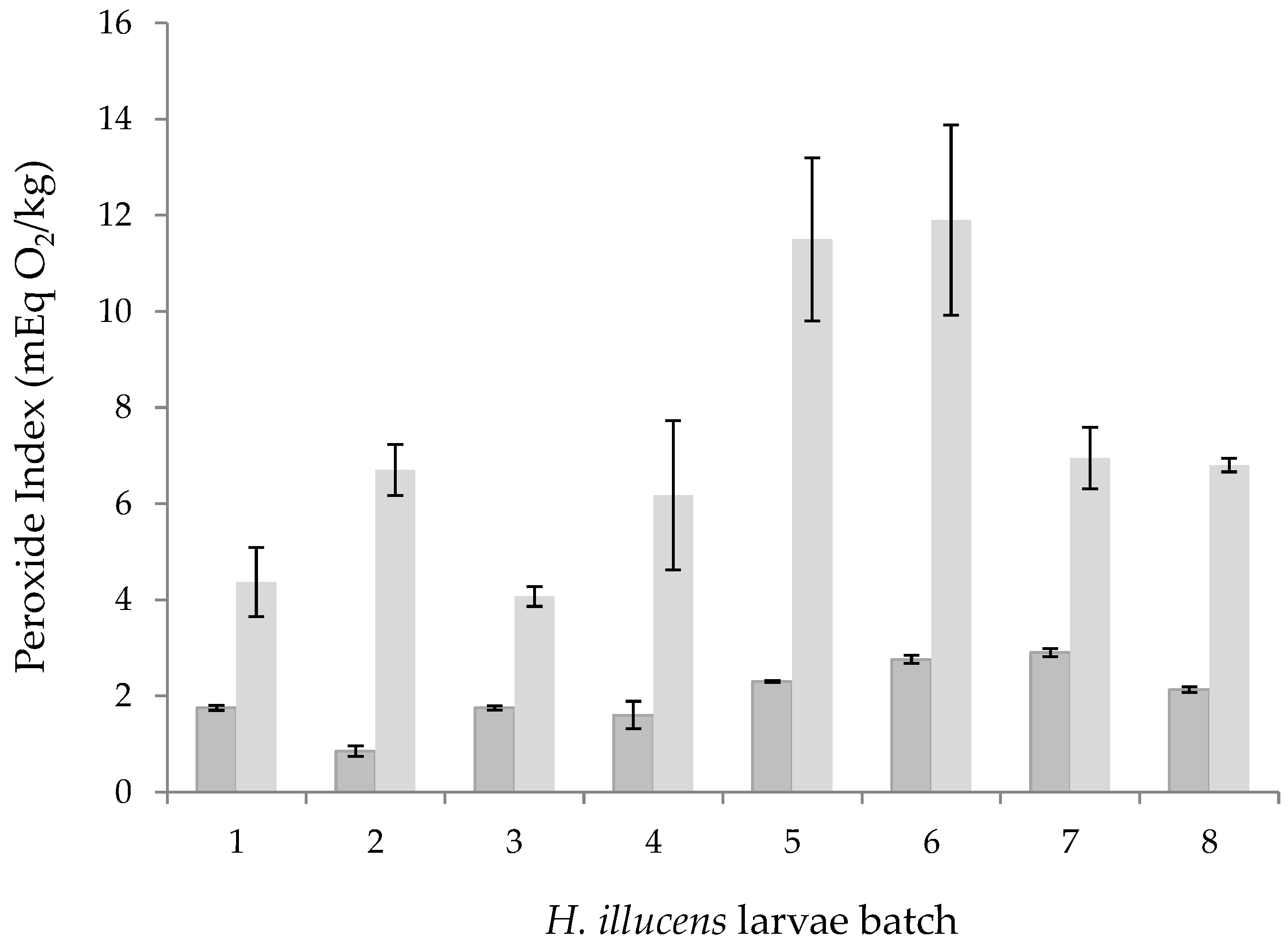

3.3.4. Peroxide Index of Extracted Oils

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Huis, A.; Van Itterbeeck, J.; Klunder, H.; Mertens, E.; Halloran, A.; Muir, G.; Vantomme, P. Edible Insects: Future Prospects for Food and Feed Security; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013; ISBN 9789251075968. [Google Scholar]

- European Union. Regulation (EU) 2015/2283 of the European Parliament and of the Council of 25 November 2015 on novel foods, amending Regulation (EU) No 1169/2011 of the European Parliament and of the Council and repealing Regulation (EC) No 258/97 of the European Parliament and of the Council and Commission Regulation (EC) No 1852/2001. J. Eur. Union 2015, L 327, 1–22. [Google Scholar]

- Turck, D.; Castenmiller, J.; De Henauw, S.; Hirsch-Ernst, K.I.; Kearney, J.; Maciuk, A.; Mangelsdorf, I.; McArdle, H.; Naska, A.; Knutsen, H.K.; et al. Safety of frozen and dried formulations from migratory locust (Locusta migratoria) as a Novel food pursuant to Regulation (EU) 2015/2283. EFSA J. 2021, 19, e06667. [Google Scholar] [PubMed]

- Turck, D.; Bohn, T.; Castenmiller, J.; De Henauw, S.; Hirsch-Ernst, K.I.; Maciuk, A.; Mangelsdorf, I.; McArdle, H.J.; Naska, A.; Knutsen, H.K. Safety of frozen and dried formulations from whole house crickets (Acheta domesticus) as a Novel food pursuant to Regulation (EU) 2015/2283. EFSA J. 2021, 19, e06779. [Google Scholar] [PubMed]

- Turck, D.; Bohn, T.; Castenmiller, J.; De Henauw, S.; Hirsch-Ernst, K.I.; Maciuk, A.; Mangelsdorf, I.; McArdle, H.J.; Naska, A.; Knutsen, H.K. Safety of frozen and freeze-dried formulations of the lesser mealworm (Alphitobius diaperinus larva) as a Novel food pursuant to Regulation (EU) 2015/2283. EFSA J. 2022, 20, e07325. [Google Scholar] [PubMed]

- Megido, R.C.; Gierts, C.; Blecker, C.; Brostaux, Y.; Haubruge, E.; Alabi, T.; Francis, F. Consumer acceptance of insect-based alternative meat products in Western countries. Food Qual. Prefer. 2016, 52, 237–243. [Google Scholar] [CrossRef]

- Wang, Y.-S.; Shelomi, M. Review of black soldier fly (Hermetia illucens) as animal feed and human food. Foods 2017, 6, 91. [Google Scholar] [CrossRef]

- Caligiani, A.; Marseglia, A.; Leni, G.; Baldassarre, S.; Maistrello, L.; Dossena, A.; Sforza, S. Composition of black soldier fly prepupae and systematic approaches for extraction and fractionation of proteins, lipids and chitin. Food Res. Int. 2018, 105, 812–820. [Google Scholar] [CrossRef]

- IPIFF. An Overview of the European Market of Insects as Feed; IPIFF: Brussels, Belgium, 2021. [Google Scholar]

- Müller, A.; Wolf, D.; Gutzeit, H.O. The black soldier fly, Hermetia illucens—A promising source for sustainable production of proteins, lipids and bioactive substances. Z. Naturforsch. C. J. Biosci. 2017, 72, 351–363. [Google Scholar] [CrossRef]

- Zhu, D.; Huang, X.; Tu, F.; Wang, C.; Yang, F. Preparation, antioxidant activity evaluation, and identification of antioxidant peptide from black soldier fly (Hermetia illucens L.) larvae. J. Food Biochem. 2020, 44, e13186. [Google Scholar] [CrossRef]

- Navarro del Hierro, J.; Cantero-Bahillo, E.; Fornari, T.; Martin, D. Effect of defatting and extraction solvent on the antioxidant and pancreatic lipase inhibitory activities of extracts from Hermetia illucens and Tenebrio molitor. Insects 2021, 12, 789. [Google Scholar] [CrossRef]

- Franco, A.; Scieuzo, C.; Salvia, R.; Petrone, A.M.; Tafi, E.; Moretta, A.; Schmitt, E.; Falabella, P. Lipids from Hermetia illucens, an innovative and sustainable source. Sustainability 2021, 13, 10198. [Google Scholar] [CrossRef]

- Kim, Y.B.; Kim, D.; Jeong, S.; Lee, J.; Kim, T.; Lee, H.; Lee, K. Black soldier fly larvae oil as an alternative fat source in broiler nutrition. Poult. Sci. 2020, 99, 3133–3143. [Google Scholar] [CrossRef] [PubMed]

- Laroche, M.; Perreault, V.; Marciniak, A.; Gravel, A.; Chamberland, J.; Doyen, A. Comparison of conventional and sustainable lipid extraction methods for the production of oil and protein isolate from edible insect meal. Foods 2019, 8, 572. [Google Scholar] [CrossRef]

- Botella-Martínez, C.; Lucas-González, R.; Pérez-Álvarez, J.A.; Fernández-López, J.; Viuda-Martos, M. Assessment of chemical composition and antioxidant properties of defatted flours obtained from several edible insects. Food Sci. Technol. Int. 2020, 27, 383–391. [Google Scholar] [CrossRef] [PubMed]

- Van Huis, A.; Oonincx, D.G.A.B. The environmental sustainability of insects as food and feed. A review. Agron. Sustain. Dev. 2017, 37, 43. [Google Scholar] [CrossRef]

- Van Huis, A. Insects as food and feed, a new emerging agricultural sector: A review. J. Insects Food Feed 2020, 6, 27–44. [Google Scholar] [CrossRef]

- Dhara, O.; Rani, K.N.P.; Chakrabarti, P.P. Supercritical carbon dioxide extraction of vegetable oils: Retrospective and prospects. Eur. J. Lipid Sci. Technol. 2022, 124, 2200006. [Google Scholar] [CrossRef]

- Kim, S.W.; Jung, T.S.; Ha, Y.J.; Gal, S.W.; Noh, C.W.; Kim, I.S.; Lee, J.H.; Yoo, J.H. Removal of fat from crushed black soldier fly larvae by carbon dioxide supercritical extraction. J. Anim. Feed Sci. 2019, 8, 83–88. [Google Scholar] [CrossRef]

- Cantero-Bahillo, E.; Navarro del Hierro, J.; Hernández, D.M.; Fernández-Felipe, M.T.; Fornari, T.; Martin, D. Supercritical-CO2 for defatting and production of bioactive extracts from black soldier fly (Hermetia illucens) larvae. J. Insects Food Feed 2022, 8, 1441–1453. [Google Scholar] [CrossRef]

- Laurent, S.; Jury, V.; de Lamballerie, M.; Fayolle, F. Effect of two defatting processes on the physicochemical and flow properties of Hermetia illucens and Tenebrio molitor larvae powders. J. Food Process. Preserv. 2022, 46, e16853. [Google Scholar] [CrossRef]

- Purschke, B.; Stegmann, T.; Schreiner, M.; Jäger, H. Pilotscale supercritical CO2 extraction of edible insect oil from Tenebrio molitor L. larvae—Influence of extraction conditions on kinetics, defatting performance and compositional properties. Eur. J. Lipid Sci. Technol. 2017, 119, 1600134. [Google Scholar] [CrossRef]

- Fornari, T.; Stateva, R.P. High Pressure Fluid Technology for Green Food Processing. In Food Engineering Series; Springer International Publishing: Cham, Switzerland, 2015; ISBN 978-3-319-10610-6. [Google Scholar] [CrossRef]

- ISO 662; Animal and Vegetable Fats and Oils—Determination of Moisture and Volatile Matter Content, 5th ed. International Organization for Standardization: Geneva, Switzerland, 2016.

- Villanueva-Bermejo, D.; Zahran, F.; García-Risco, M.R.; Reglero, G.; Fornari, T. Supercritical fluid extraction of Bulgarian Achillea millefolium. J. Supercrit. Fluids 2017, 119, 283–288. [Google Scholar] [CrossRef]

- Vázquez, L.; Prados, I.M.; Reglero, G.; Torres, C.F. Identification and quantification of ethyl carbamate occurring in urea complexation processes commonly utilized for polyunsaturated fatty acid concentration. Food Chem. 2017, 229, 28–34. [Google Scholar] [CrossRef] [PubMed]

- Herrera, T.; Navarro del Hierro, J.; Fornari, T.; Reglero, G.; Martin, D. Acid hydrolysis of saponin-rich extracts of quinoa, lentil, fenugreek and soybean to yield sapogenin-rich extracts and other bioactive compounds. J. Sci. Food Agric. 2019, 99, 3157–3167. [Google Scholar] [CrossRef] [PubMed]

- Martin, D.; Terrón, A.; Fornari, T.; Reglero, G.; Torres, C.F. Oxidative stabilization of ultra-high omega-3 concentrates as ethyl esters or triacylglycerols. Food Res. Int. 2012, 45, 336–341. [Google Scholar] [CrossRef]

- López-Padilla, A.; Ruiz-Rodriguez, A.; Restrepo Flórez, C.A.; Rivero Barrios, D.M.; Reglero, G.; Fornari, T. Vaccinium meridionale Swartz supercritical CO2 extraction: Effect of process conditions and scaling up. Materials 2016, 9, 519. [Google Scholar] [CrossRef]

- López-Padilla, A.; Ruiz-Rodriguez, A.; Reglero, G.; Fornari, T. Supercritical carbon dioxide extraction of Calendula officinalis: Kinetic modeling and scaling up study. J. Supercrit. Fluids 2017, 130, 292–300. [Google Scholar] [CrossRef]

- Noh, M.J.; Kim, T.G.; Hong, I.K.; Yoo, K. Measurements and correlation of effect of cosolvents on the solubilities of complex molecules in supercritical carbon dioxide. Korean J. Chem. Eng. 1995, 12, 48–55. [Google Scholar] [CrossRef]

- Beltrán, G.; Bucheli, M.E.; Aguilera, M.P.; Belaj, A.; Jimenez, A. Squalene in virgin olive oil: Screening of variability in olive cultivars. Eur. J. Lipid Sci. Technol. 2016, 118, 1250–1253. [Google Scholar] [CrossRef]

- Matthäus, B.; Piofczyk, T.; Katz, H.; Pudel, F. Renewable resources from insects: Exploitation, properties, and refining of fat obtained by cold-pressing from Hermetia illucens (Black Soldier Fly) larvae. Eur. J. Lipid Sci. Technol. 2019, 121, 1800376. [Google Scholar] [CrossRef]

- Boukid, F.; Riudavets, J.; Del Arco, L.; Castellari, M. Impact of diets including agro-industrial by-products on the fatty acid and sterol profiles of larvae biomass from Ephestia kuehniella, Tenebrio molitor and Hermetia illucens. Insects 2021, 12, 672. [Google Scholar] [CrossRef] [PubMed]

- Verleyen, T.; Forcades, M.; Verhe, R.; Dewettinck, K.; Huyghebaert, A.; De Greyt, W. Analysis of free and esterified sterols in vegetable oils. J. Am. Oil Chem. Soc. 2002, 79, 117–122. [Google Scholar] [CrossRef]

- CXS 19-1981; CODEX Alimentarius. International Food Standards. Standard for Edible Fats and Oils not Covered by Individual Standards. FAO: Roma, Italy, 2021.

- Codex Stand 329-2017; CODEX Alimentarius. International Food Standards. Standard for Fish Oils. IFFO: London, UK, 2017.

) and the oils extracted using hexane (

) and the oils extracted using hexane ( ).

).

| SS (270 cm3) | LS (1350 cm3) Calculated | LS (1350 cm3) Experimental | |

|---|---|---|---|

| F = larvae mass (g) | 100 | 450 | 450 |

| D (cm) | 4.3 | 6.7 | 6.7 |

| L (cm) | 18.8 | 38.3 | 38.3 |

| A = vessel cross-flow area (cm2) | 14.5 | 35.3 | 35.3 |

| Q (g/min) | 60.0 | 270.0 | 130.0 |

| v (cm/min) = Q/(A·ρ) | 4.48 | 8.29 | 4.00 |

| tR (min) = F/Q | 1.67 | 1.67 | 3.46 |

| Sample | % Oil in Sample | % Moisture in Sample | Mass Recovered in S1 (g) | Mass Recovered in S2 (g) | Defatted Sample (g) | Yield (%) | Oil Recovery (D1%) | % Oil in Defatted Sample | Defatting (D2%) | % Moisture in Oil Recovered |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 16.80 | 15.95 | 83.3 | 12.8 | 326.6 | 18.5 | 110.2 | 0.71 | 96.9 | 0.713 |

| 2 | 19.07 | 13.60 | 87.8 | 15.9 | 330.0 | 19.5 | 102.3 | 1.98 | 92.4 | 0.786 |

| 3 | 23.94 | 8.50 | 93.3 | 4.1 | 349.4 | 20.7 | 86.6 | 4.45 | 85.6 | 0.983 |

| 4 | 26.07 | 13.20 | 88.7 | 4.8 | 350.0 | 19.7 | 75.6 | 7.45 | 77.8 | 1.706 |

| 5 | 27.41 | 4.95 | 86.5 | 2.5 | 355.5 | 19.2 | 70.1 | 9.00 | 74.1 | 0.188 |

| 6 | 27.25 | 5.00 | 90.5 | 2.0 | 350.2 | 20.1 | 73.8 | 8.37 | 76.1 | 0.118 |

| 7 | 28.87 | 4.45 | 97.0 | 2.9 | 345.4 | 21.6 | 74.7 | 5.74 | 84.7 | 0.397 |

| 8 | 29.07 | 7.25 | 93.5 | 2.7 | 348.2 | 20.8 | 70.0 | 7.35 | 80.9 | 0.406 |

| Sample | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| C10:0 | 0.7 | 0.8 | 1.1 | 1.0 | 1.2 | 1.1 | 0.9 | 0.9 |

| C12:0 | 49.8 | 48.7 | 51.0 | 50.3 | 51.5 | 51.5 | 49.5 | 50.3 |

| C14:0 | 10.8 | 10.5 | 10.1 | 10.1 | 10.0 | 9.9 | 10.0 | 10.2 |

| C14:1 | 0.4 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| C16:0 | 14.7 | 14.4 | 12.8 | 13.0 | 12.8 | 12.7 | 13.5 | 13.2 |

| C16:1 | 2.3 | 2.3 | 2.4 | 2.4 | 2.3 | 2.4 | 2.5 | 2.4 |

| C17:0 | 0.4 | 0.5 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| C17:1 | 0.3 | 0.3 | 0.2 | 0.3 | 0.2 | 0.4 | 0.3 | 0.3 |

| C18:0 | 2.8 | 2.7 | 2.2 | 2.3 | 2.3 | 2.3 | 2.4 | 2.3 |

| C18:1 | 8.7 | 9.1 | 8.5 | 8.6 | 8.3 | 8.2 | 8.9 | 8.7 |

| C18:2 | 5.8 | 6.6 | 7.3 | 7.5 | 7.3 | 7.2 | 7.6 | 7.4 |

| C18:3 n-6 | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.2 | 0.1 | 0.1 |

| C18:3 n-3 | 2.9 | 3.2 | 3.3 | 3.4 | 3.2 | 3.2 | 3.3 | 3.2 |

| C20:1 | 0.3 | 0.3 | 0.2 | 0.2 | 0.1 | 0.2 | 0.1 | 0.1 |

| Total SFA | 79.2 | 77.6 | 77.6 | 77.1 | 78.1 | 77.8 | 76.7 | 77.3 |

| Total MUFA | 12.0 | 12.4 | 11.7 | 11.9 | 11.3 | 11.6 | 12.2 | 11.9 |

| Total PUFA | 8.9 | 10.1 | 10.8 | 11.1 | 10.6 | 10.6 | 11.0 | 10.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fornari, T.; Vázquez, L.; Villanueva-Bermejo, D.; Hurtado-Ribeira, R.; Martín Hernández, D.; Martin, D. Effect of Moisture and Oil Content in the Supercritical CO2 Defatting of Hermetia illucens Larvae. Foods 2023, 12, 490. https://doi.org/10.3390/foods12030490

Fornari T, Vázquez L, Villanueva-Bermejo D, Hurtado-Ribeira R, Martín Hernández D, Martin D. Effect of Moisture and Oil Content in the Supercritical CO2 Defatting of Hermetia illucens Larvae. Foods. 2023; 12(3):490. https://doi.org/10.3390/foods12030490

Chicago/Turabian StyleFornari, Tiziana, Luis Vázquez, David Villanueva-Bermejo, Raúl Hurtado-Ribeira, Diego Martín Hernández, and Diana Martin. 2023. "Effect of Moisture and Oil Content in the Supercritical CO2 Defatting of Hermetia illucens Larvae" Foods 12, no. 3: 490. https://doi.org/10.3390/foods12030490

APA StyleFornari, T., Vázquez, L., Villanueva-Bermejo, D., Hurtado-Ribeira, R., Martín Hernández, D., & Martin, D. (2023). Effect of Moisture and Oil Content in the Supercritical CO2 Defatting of Hermetia illucens Larvae. Foods, 12(3), 490. https://doi.org/10.3390/foods12030490