A Decade of Evidence of Sorghum Potential in the Development of Novel Food Products: Insights from a Bibliometric Analysis

Abstract

:1. Introduction

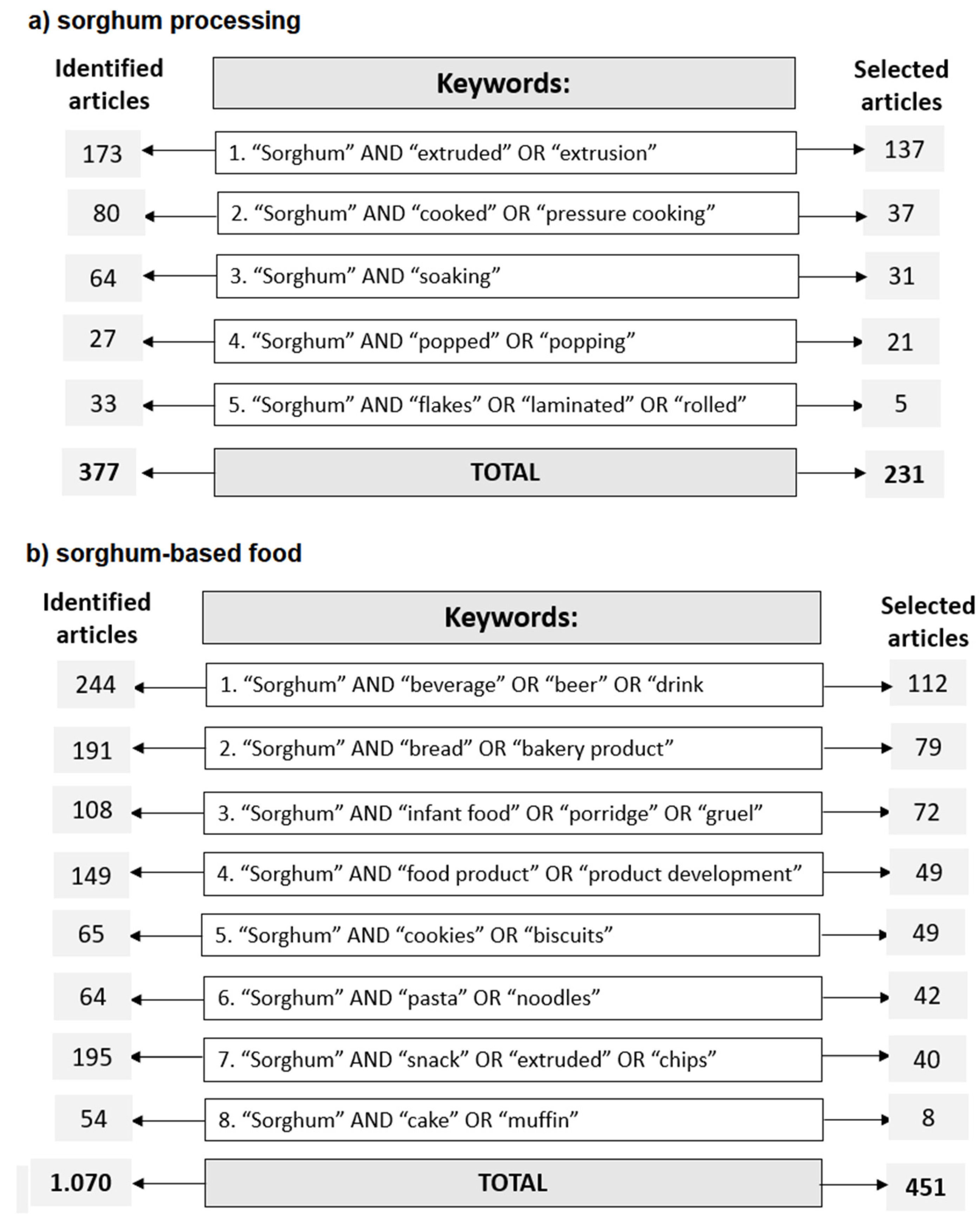

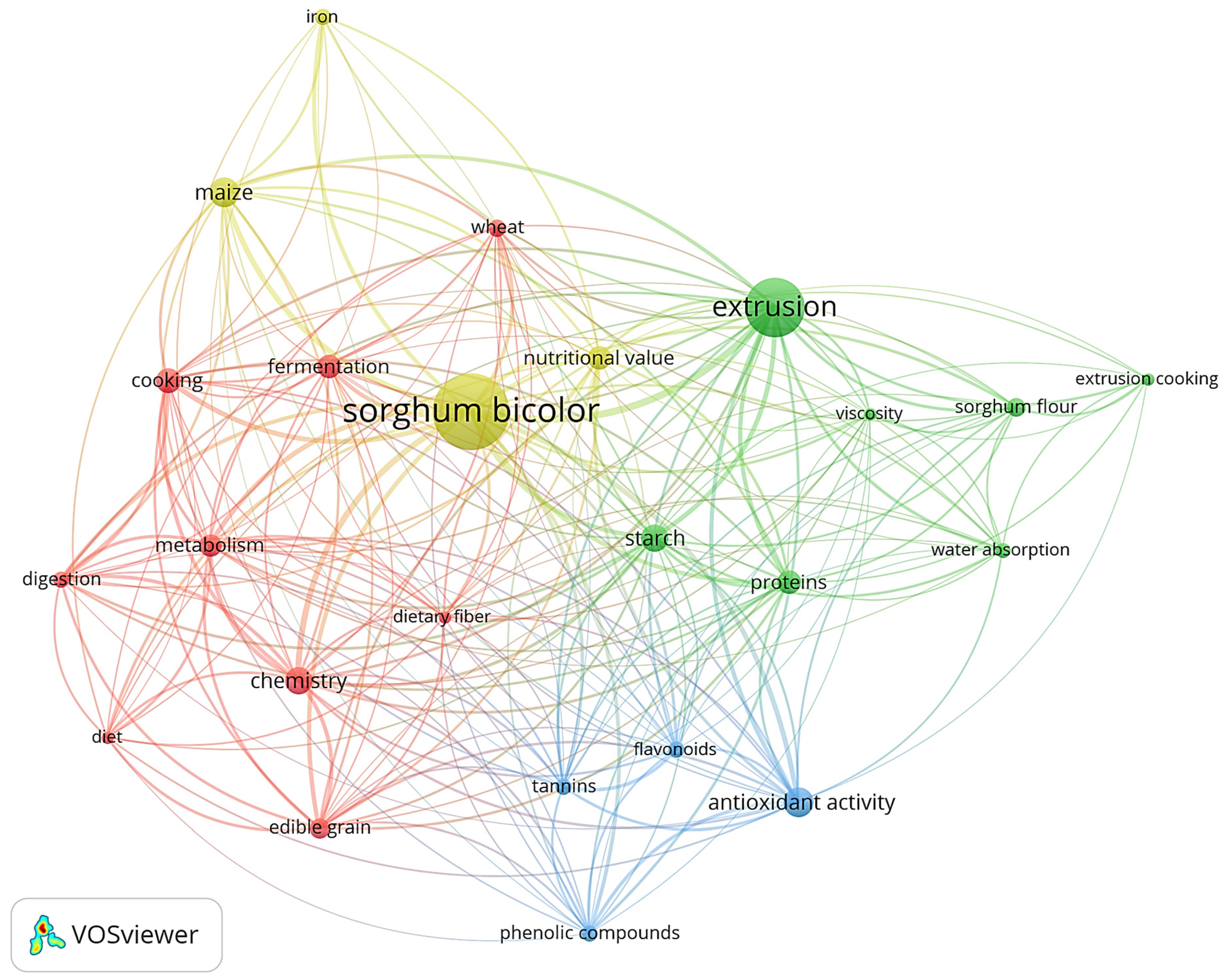

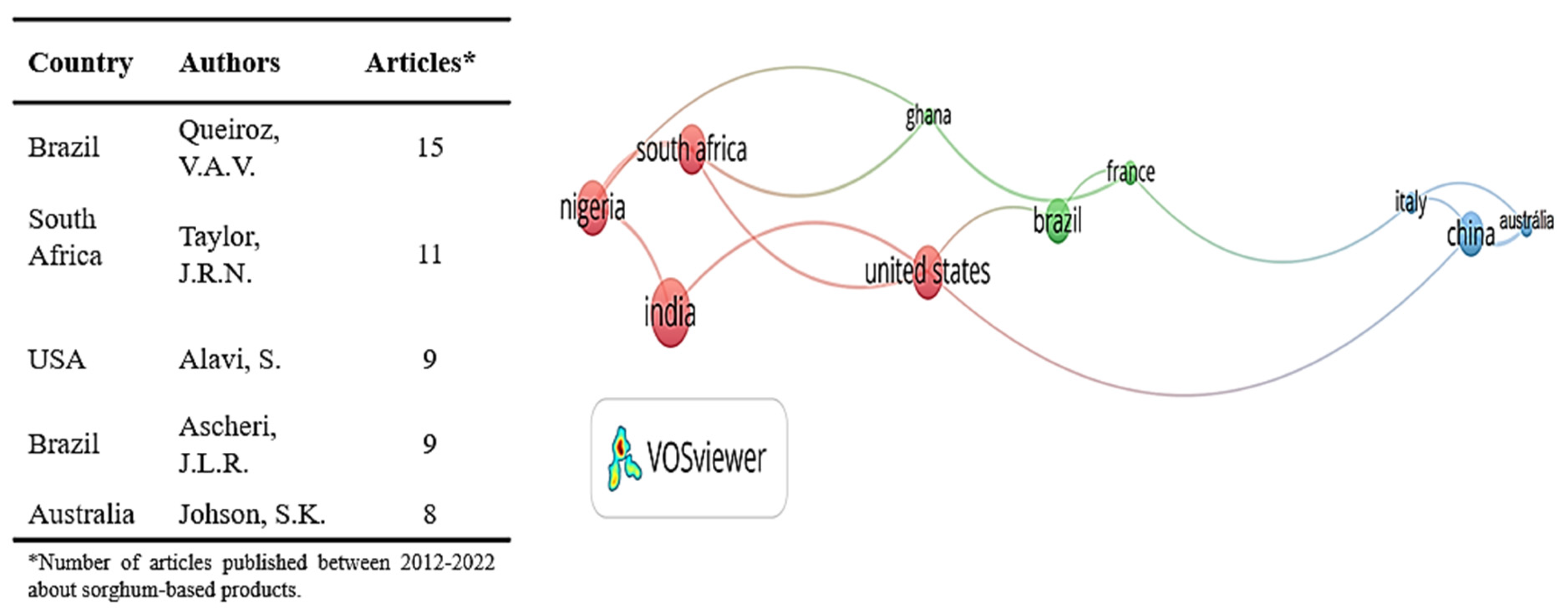

2. Research Methodology

3. Main Findings

3.1. Sorghum Processing

3.1.1. Soaking

3.1.2. Wet Cooking: Common and Pressure Method

3.1.3. Popping

3.1.4. Lamination

3.1.5. Extrusion

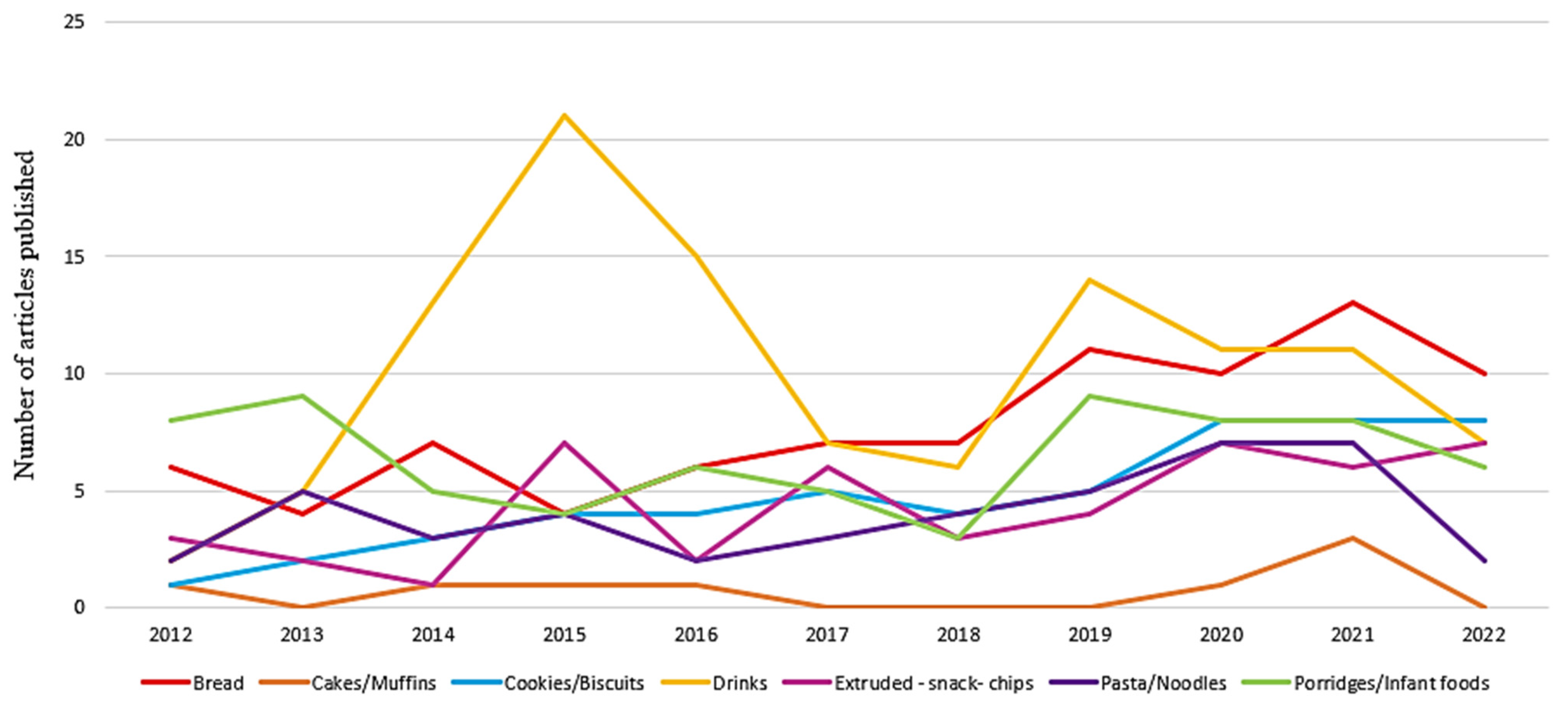

3.2. Sorghum-Based Food Products

3.2.1. Beverages and Syrup

3.2.2. Porridge

3.2.3. Bakery Products

3.2.4. Pasta Products

3.2.5. Sorghum-Based Ingredients

4. Conclusions and Future Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- USDA. United States of Agriculture. Market and Trade Data. Search USA Import Data|USA Trade Data Online (exportgenius.in). Available online: https://www.exportgenius.in/import-data/usa (accessed on 17 August 2023).

- FAOSTAT. Food and Agriculture Organization of the United States. Crops and Livestock Products. 2023. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 17 August 2023).

- Birhanu, S. Potential Benefits of Sorghum [Sorghum bicolor L. Moench] on Human Health: A Review. Int. J. Food Eng. Technol. 2021, 5, 8–18. [Google Scholar] [CrossRef]

- Guo, H.; Wu, H.; Sajid, A.; Li, Z. Whole Grain Cereals: The Potential Roles of Functional Components in Human Health. Crit. Rev. Food Sci. Nutr. 2022, 62, 8388–8402. [Google Scholar] [CrossRef] [PubMed]

- Anunciação, P.C.; Cardoso, L.M.; Queiroz, V.A.V.; de Menezes, C.B.; de Carvalho, C.W.P.; Pinheiro-Sant’Ana, H.M.; Alfenas, R.C.G. Consumption of a Drink Containing Extruded Sorghum Reduces Glycaemic Response of the Subsequent Meal. Eur. J. Nutr. 2018, 57, 251–257. [Google Scholar] [CrossRef] [PubMed]

- de Morais Cardoso, L.; Pinheiro, S.S.; Martino, H.S.D.; Pinheiro-Sant’Ana, H.M. Sorghum (Sorghum bicolor L.): Nutrients, Bioactive Compounds, and Potential Impact on Human Health. Crit. Rev. Food Sci. Nutr. 2017, 57, 372–390. [Google Scholar] [CrossRef]

- Gamage, H.K.A.H.; Tetu, S.G.; Chong, R.W.W.; Ashton, J.; Packer, N.H.; Paulsen, I.T. Cereal Products Derived from Wheat, Sorghum, Rice and Oats Alter the Infant Gut Microbiota In Vitro. Sci. Rep. 2017, 7, 14312. [Google Scholar] [CrossRef] [PubMed]

- Palavecino, P.M.; Ribotta, P.D.; León, A.E.; Bustos, M.C. Gluten-Free Sorghum Pasta: Starch Digestibility and Antioxidant Capacity Compared with Commercial Products. J. Sci. Food Agric. 2019, 99, 1351–1357. [Google Scholar] [CrossRef] [PubMed]

- Bianco-Gomes, A.C.; Nogueira, L.D.S.; Bono-Lopes, N.V.M.; Gouvêa-Souza, C.P.; Boldrini-França, J.; Gomes, V.M.; Cherene, M.B.; Alves, N.E.G.; Vasconcelos, C.M. Dry Heat and Pressure Favor Bioactive Compounds Preservation and Peptides Formation in Sorghum [Sorghum bicolor (L.) Moench]. Curr. Res. Food Sci. 2022, 5, 117–124. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Wang, W.; Zhao, Y. Phenolic Compounds in Whole Grain Sorghum and Their Health Benefits. Foods 2021, 10, 1921. [Google Scholar] [CrossRef]

- Khoddami, A.; Messina, V.; Vadabalija Venkata, K.; Farahnaky, A.; Blanchard, C.L.; Roberts, T.H. Sorghum in Foods: Functionality and Potential in Innovative Products. Crit. Rev. Food Sci. Nutr. 2021, 63, 1170–1186. [Google Scholar] [CrossRef]

- Taylor, J.R.N.; Duodu, K.G. Resistant-Type Starch in Sorghum Foods—Factors Involved and Health Implications. Starch 2022, 75, 2100296. [Google Scholar] [CrossRef]

- Apostol, L.; Belc, N.; Gaceu, L.; Oprea, O.B.; Popa, M.E. Sorghum Flour: A Valuable Ingredient for Bakery Industry? Appl. Sci. 2020, 10, 8597. [Google Scholar] [CrossRef]

- Centeno, A.C.L.; Aguiar, E.; Santos, F.; Queiroz, V.; Conti-Silva, A.; Krupa-Kozak, U.; Capriles, V. Defining Whole Grain Sorghum Flour and Water Levels to Improve Sensory and Nutritional Quality of Gluten-Free Bread—A Factorial Design Approach. Appl. Sci. 2021, 11, 8186. [Google Scholar] [CrossRef]

- Rashwan, A.K.; Yones, H.A.; Karim, N.; Taha, E.M.; Chen, W. Potential Processing Technologies for Developing Sorghum-Based Food Products: An Update and Comprehensive Review. Trends Food Sci. Technol. 2021, 110, 168–182. [Google Scholar] [CrossRef]

- Capriles, V.D.; Santos, F.G.; Aguiar, E.V. Innovative Gluten-Free Breadmaking. In Trends in Wheat and Bread Making; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 371–404. [Google Scholar]

- Aguiar, E.V.; Santos, F.G.; Krupa-Kozak, U.; Capriles, V.D. Nutritional facts regarding commercially available gluten-free bread worldwide: Recent advances and future challenges. Crit. Rev. Food Sci. Nutr. 2023, 63, 693–705. [Google Scholar] [CrossRef] [PubMed]

- Queiroz, V.A.V.; Aguiar, A.S.; de Menezes, C.B.; de Carvalho, C.W.P.; Paiva, C.L.; Fonseca, P.C.; da Conceição, R.R.P. A Low Calorie and Nutritive Sorghum Powdered Drink Mix: Influence of Tannin on the Sensorial and Functional Properties. J. Cereal Sci. 2018, 79, 43–49. [Google Scholar] [CrossRef]

- Moraes, É.A.; de Oliveira, F.C.E.; Queiroz, V.A.V.; Schaffert, R.E.; Cecon, P.R.; Moreira, A.V.; Ribeiro, S.M.R.; Martino, H.S.D. Domestic Processing Effects on Antioxidant Capacity, Total Phenols and Phytate Content of Sorghum. Curr. Nutr. Food Sci. 2019, 16, 501–507. [Google Scholar] [CrossRef]

- Chen, S.; Wang, L.; Ni, D.; Lin, L.; Wang, H.; Xu, Y. Characterization of Aroma Compounds in Cooked Sorghum Using Comprehensive Two-Dimensional Gas Chromatography-Time-of-Flight Mass Spectrometry and Gas Chromatography-Olfactometry-Mass Spectrometry. Molecules 2021, 26, 4796. [Google Scholar] [CrossRef] [PubMed]

- Abbas, Y.; Ahmad, A. Impact of processing on nutritional and antinutritional factors of legumes: A review. Food Sci. Technol. 2018, 19, 199–215. [Google Scholar]

- Davana, T.V.; Revanna, M.L. Development of Beer from Malted Sorghum (Sorghum bicolor). Int. J. Chem. Stud. 2021, 9, 330–334. [Google Scholar] [CrossRef]

- Aguerre, M.; Cajarville, C.; Repetto, J.L. Impact of Water Addition, Germination, Ensiling and Their Association on Sorghum Grain Nutritive Value. Anim. Feed Sci. Technol. 2015, 205, 75–81. [Google Scholar] [CrossRef]

- Afify, A.E.M.M.R.; El-Beltagi, H.S.; El-Salam, S.M.A.; Omran, A.A. Bioavailability of Iron, Zinc, Phytate and Phytase Activity during Soaking and Germination of White Sorghum Varieties. PLoS ONE 2011, 6, e25512. [Google Scholar] [CrossRef] [PubMed]

- Afify, A.E.M.M.R.; El-Beltagi, H.S.; El-Salam, S.M.A.; Omran, A.A. Biochemical Changes in Phenols, Flavonoids, Tannins, Vitamin E, β-Carotene and Antioxidant Activity during Soaking of Three White Sorghum Varieties. Asian Pac. J. Trop. Biomed. 2012, 2, 203–209. [Google Scholar] [CrossRef]

- Keyata, E.O.; Tola, Y.B.; Bultosa, G.; Forsido, S.F. Premilling Treatments Effects on Nutritional Composition, Antinutritional Factors, and in Vitro Mineral Bioavailability of the Improved Assosa I Sorghum Variety (Sorghum bicolor L.). Food Sci. Nutr. 2021, 9, 1929–1938. [Google Scholar] [CrossRef]

- Kruger, J.; Oelofse, A.; Taylor, J.R.N. Effects of Aqueous Soaking on the Phytate and Mineral Contents and Phytate: Mineral Ratios of Wholegrain Normal Sorghum and Maize and Low Phytate Sorghum. Int. J. Food Sci. Nutr. 2014, 65, 539–546. [Google Scholar] [CrossRef] [PubMed]

- Venkatasubbaiah, R.; Rajesh, S.K. Food processing and fermentation studies on reduction of phytic acid in Triticum aestivum and Sorghum bicolor (L.). J. Microbiol. Biotechnol. Food Sci. 2020, 10, 166–169. [Google Scholar] [CrossRef]

- Chao, S.; Mitchell, J.; Prakash, S.; Bhandari, B.; Fukai, S. Effects of Variety, Early Harvest, and Germination on Pasting Properties and Cooked Grain Texture of Brown Rice. J. Texture Stud. 2022, 53, 503–516. [Google Scholar] [CrossRef]

- Hithamani, G.; Srinivasan, K. Bioaccessibility of Polyphenols from Wheat (Triticum aestivum), Sorghum (Sorghum bicolor), Green Gram (Vigna radiata), and Chickpea (Cicer arietinum) as Influenced by Domestic Food Processing. J. Agric. Food Chem. 2014, 62, 11170–11179. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.; Chambers, E. Development of a Model System for Tasting Grain Varieties. Foods 2020, 9, 510. [Google Scholar] [CrossRef] [PubMed]

- Hicks-Roof, K.K.; Arikawa, A.; Schwam, M.; Osorio, D.; Walker, K. College Students Approve: Using Sorghum to Increase Whole-Grain Exposure in University Foodservice. J. Foodserv. Bus. Res. 2021, 24, 62–73. [Google Scholar] [CrossRef]

- Hoseney, R.C.; Zeleznak, K.; Abdelrahman, A. Mechanism of Popcorn Popping. J. Cereal Sci. 1983, 1, 43–52. [Google Scholar] [CrossRef]

- HameedaBanu, N.I.; Baragi, V.R.S.R.; Padmanabhan, A.J.; Vasudeva, S. Functional and Antioxidant Properties of Ready-to-Eat Flakes from Various Cereals Including Sorghum and Millets. Qual. Assur. Saf. Crops Foods 2012, 4, 126–133. [Google Scholar] [CrossRef]

- Mkandawire, N.L.; Weier, S.A.; Weller, C.L.; Jackson, D.S.; Rose, D.J. Composition, In Vitro Digestibility, and Sensory Evaluation of Extruded Whole Grain Sorghum Breakfast Cereals. LWT-Food Sci. Technol. 2015, 62, 662–667. [Google Scholar] [CrossRef]

- Aljobair, M.O. Characteristics of Cereal Flakes Manufactured Using Date Syrup in Place of Sugar. Nutr. Food Sci. 2018, 48, 899–910. [Google Scholar] [CrossRef]

- Okafor, C.A.; Falade, K.O. Nutritional, Physicochemical, and Sensory Characteristics of Extruded Bambara Groundnut (Vigna subterranea)-based Ready-to-eat Breakfast Cereal. J. Food Process. Preserv. 2021, 45, e15347. [Google Scholar] [CrossRef]

- Espinosa-Ramírez, J.; Rodríguez, A.; De la Rosa-Millán, J.; Heredia-Olea, E.; Pérez-Carrillo, E.; Serna-Saldívar, S.O. Shear-Induced Enhancement of Technofunctional Properties of Whole Grain Flours through Extrusion. Food Hydrocoll. 2021, 111, 106400. [Google Scholar] [CrossRef]

- Toledo, V.C.S.; Carvalho, C.W.P.; Vargas-Solórzano, J.W.; Ascheri, J.L.R.; Comettant-Rabanal, R. Extrusion Cooking of Gluten-free Whole Grain Flour Blends. J. Food Process. Eng. 2020, 43, e13303. [Google Scholar] [CrossRef]

- Taylor, J.R.N.; Schober, T.J.; Bean, S.R. Novel Food and Non-Food Uses for Sorghum and Millets. J. Cereal Sci. 2006, 44, 252–271. [Google Scholar] [CrossRef]

- Sharma, M.; Sangwan, R.S.; Khatkar, B.S.; Singh, S.P. Development of a Prebiotic Oligosaccharide Rich Functional Beverage from Sweet Sorghum Stalk Biomass. Waste Biomass Valorization 2021, 12, 2001–2012. [Google Scholar] [CrossRef]

- Makame, J.; Cronje, T.; Emmambux, N.M.; Kock, H. Dynamic Oral Texture Properties of Selected Indigenous Complementary Porridges Used in African Communities. Foods 2019, 8, 221. [Google Scholar] [CrossRef]

- Adebowale, O.J.; Taylor, J.R.N.; Kock, H.L. Stabilization of Wholegrain Sorghum Flour and Consequent Potential Improvement of Food Product Sensory Quality by Microwave Treatment of the Kernels. LWT 2020, 132, 109827. [Google Scholar] [CrossRef]

- Olojede, A.O.; Sanni, A.I.; Banwo, K.; Michael, T. Improvement of Texture, Nutritional Qualities, and Consumers’ Perceptions of Sorghum-Based Sourdough Bread Made with Pediococcus Pentosaceus and Weissella Confusa Strains. Fermentation 2022, 8, 32. [Google Scholar] [CrossRef]

- Ari Akin, P.; Miller, R.; Jaffe, T.; Koppel, K.; Ehmke, L. Sensory Profile and Quality of Chemically Leavened Gluten-Free Sorghum Bread Containing Different Starches and Hydrocolloids. J. Sci. Food Agric. 2019, 99, 4391–4396. [Google Scholar] [CrossRef] [PubMed]

- Nespeca, L.S.; Paulino, H.F.S.; Silva, T.B.V.; Bona, E.; Leimann, F.V.; Marques, L.L.M.; Cardoso, F.A.R.; Droval, A.A.; Fuchs, R.H.B. How Does the Replacement of Rice Flour with Flours of Higher Nutritional Quality Impact the Texture and Sensory Profile and Acceptance of Gluten-Free Chocolate Cakes? Int. J. Food Sci. Technol. 2021, 56, 2019–2029. [Google Scholar] [CrossRef]

- Moreno, M.M.C.; Barreto-Palacios, V.; Gonzalez-Carrascosa, R.; Iborra-Bernad, C.; Andres-Bello, A.; Martínez-Monzó, J.; García-Segovia, P. Evaluation of Textural and Sensory Properties on Typical Spanish Small Cakes Designed Using Alternative Flours. J. Culin. Sci. Technol. 2015, 13, 19–28. [Google Scholar] [CrossRef]

- Da Silva Fonte Boa, G.; Da Silva, B.P.; De Souza Dantas, M.I.; Duarte, F.L.M.; Martino, H.S.D.; Binoti, M.L. Sorghum, Germinated Millet and Chia Cookies: Development, Chemical Composition and Sensory Analysis. Arch. Latinoam. Nutr. 2021, 71, 218–227. [Google Scholar] [CrossRef]

- Shahzad, S.A.; Hussain, S.; Mohamed, A.A.; Alamri, M.S.; Qasem, A.A.A.; Ibraheem, M.A.; Almaiman, S.A.M.; El-Din, M.F.S. Gluten-Free Cookies from Sorghum and Turkish Beans; Effect of Some Non-Conventional and Commercial Hydrocolloids on Their Technological and Sensory Attributes. Food Sci. Technol. 2021, 41, 15–24. [Google Scholar] [CrossRef]

- Oliveira, L.L.; de Orlandin, L.C.; Aguiar, L.A.; Queiroz, V.A.V.; Zandonadi, R.P.; Botelho, R.B.A.; Alencar Figueiredo, L.F. Gluten-Free Sorghum Pasta: Composition and Sensory Evaluation with Different Sorghum Hybrids. Foods 2022, 11, 3124. [Google Scholar] [CrossRef]

- Xu, F.; Dube, N.M.; Han; Zhao, R.; Wang, Y.; Chen, J. The Effect of Zimbabwean Tannin-Free Sorghum Flour Substitution on Fine Dried Noodles Quality Characteristics. J. Cereal Sci. 2021, 102, 103320. [Google Scholar] [CrossRef]

- Chávez, D.W.H.; Ascheri, J.L.R.; Carvalho, C.W.P.; Bernardo, C.O.; Deliza, R.; Freitas-Sá, D.D.G.C.; Teles, A.S.C.; Queiroz, V.A.V. Physicochemical Properties, Characteristics, and Consumer Acceptance of Whole Grain Sorghum Expanded Extrudates. J. Food Process. Preserv. 2021, 45, e15837. [Google Scholar] [CrossRef]

- Correia, V.T.V.; D’Angelis, D.F.; Santos, A.N.; Roncheti, E.F.S.; Queiroz, V.A.V.; Figueiredo, J.E.F.; Silva, W.A.; Ferreira, A.A.; Fante, C.A. Tannin-Sorghum Flours in Cream Cheese: Physicochemical, Antioxidant and Sensory Characterization. LWT 2022, 154, 112672. [Google Scholar] [CrossRef]

- Cséfalvay, E.; Bakacsi, Z. Chemical-Free Processing of Sweet Sorghum Juice of Cultivar Sucrosorgho 506. Period. Polytech. Chem. Eng. 2019, 63, 36–50. [Google Scholar] [CrossRef]

- Mazumdar, D.; Rao, S.; Reddy, R. Innovative Use of Sweet Sorghum Juice in the Beverage Industry. Int. Food Res. J. 2012, 19, 1361–1366. [Google Scholar]

- De Oliveira, L.L.; Oliveira, G.T.; Alencar, E.R.; Queiroz, V.A.V.; Alencar Figueiredo, L.F. Physical, Chemical, and Antioxidant Analysis of Sorghum Grain and Flour from Five Hybrids to Determine the Drivers of Liking of Gluten-Free Sorghum Breads. LWT 2022, 153, 112407. [Google Scholar] [CrossRef]

- Yu, M.; Zhu, K.; Wang, X.; Lu, M.; Zhang, L.; Fu, X.; Wang, Y.; Xiao, Z.; Yang, Q. Comparison of Nutritional Quality and Sensory Acceptability of Biscuits Obtained from Wheat, Native, or Extruded Sorghum Flour. Cereal Chem. 2020, 97, 1244–1253. [Google Scholar] [CrossRef]

- Johnson, S.K.; Kaur, G.; Luitel, S.; Hoang, L.A.P.; Bhattarai, R.R. Replacement of Buckwheat by Black Sorghum Flour on Soba-Type Noodles. Int. J. Food Sci. Technol. 2021, 56, 5861–5870. [Google Scholar] [CrossRef]

- Cayres, C.A.; Ramírez Ascheri, J.L.; Peixoto Gimenes Couto, M.A.; Almeida, E.L.; Melo, L. Consumers’ Acceptance of Optimized Gluten-Free Sorghum-Based Cakes and Their Drivers of Liking and Disliking. J. Cereal Sci. 2020, 93, 102938. [Google Scholar] [CrossRef]

- Cervini, M.; Frustace, A.; Garrido, G.D.; Rocchetti, G.; Giuberti, G. Nutritional, Physical and Sensory Characteristics of Gluten-Free Biscuits Incorporated with a Novel Resistant Starch Ingredient. Heliyon 2021, 7, e06562. [Google Scholar] [CrossRef]

- Alencar, N.M.M.; Araújo, V.A.; Faggian, L.; Araújo, M.B.S.; Capriles, V.D. What about gluten-free products? An insight on celiac consumers’ opinions and expectations. J. Sens. Stud. 2021, 36, e12664. [Google Scholar] [CrossRef]

- Jafari, M.; Koocheki, A.; Milani, E. Physicochemical and Sensory Properties of Extruded Sorghum–Wheat Composite Bread. J. Food Meas. Charact. 2018, 12, 370–377. [Google Scholar] [CrossRef]

- Lopes, R.C.S.O.; Lima, S.L.S.; Silva, B.P.; Toledo, R.C.L.; Moreira, M.E.C.; Anunciação, P.C.; Walter, E.H.M.; Carvalho, C.W.P.; Queiroz, V.A.V.; Ribeiro, A.Q.; et al. Evaluation of the Health Benefits of Consumption of Extruded Tannin Sorghum with Unfermented Probiotic Milk in Individuals with Chronic Kidney Disease. Food Res. Int. 2018, 107, 629–638. [Google Scholar] [CrossRef] [PubMed]

| Sorghum-Based Product | Key Findings | Reference | |

|---|---|---|---|

| Beverages | Powdered drink mix using extruded tannin-sorghum flour and extruded tannin-free sorghum flour. |

| Queiroz et al. [18] |

| Sweet-sorghum juice treated with microbial and enzymatic bioprocessing. |

| Sharma et al. [41] | |

| Sorghum malted beer(40, 60 and 100% of SF). |

| Davana and Revanna [22] | |

| Porridges | Sorghum porridges containing 4, 8 and 10% of solids. |

| Makame et al. [42] |

| Microwave treatment of sorghum to improve porridges development. |

| Adebowale et al. [43] | |

| Bakery products | GFB developed SF (BRS501—white sorghum (WS) and BRS332—bronze sorghum (BS)) with potato starch. |

| Centeno et al. [14] |

| Sourdough GFB developed with SF with legume flour (cowpea and chickpea flour) |

| Olojede, Sanni and Banwo [44] | |

| GFB developed with SF combined with starch and hydrocolloids |

| Akin et al. [45] | |

| GF chocolate cakes developed with SF or Teff |

| Nespeca et al. [46] | |

| Madeleines (Spanish cake) |

| Moreno et al. [47] | |

| GF cookies developed with 100% SF or combined with chia (CF) (50% SF + 50% CF) |

| Bôa et al. [48] | |

| GF cookies prepared with 50% SF + 50% Turkish beans (TBF) |

| Shahzad et al. [49] | |

| Pasta products | GF pasta developed with brown, red and white SF |

| Oliveira et al. [50] |

| Dry white Chinese noodles |

| Xu et al. [51] | |

| Sorghum-based ingredients | Extruded ready-to-eat cereals |

| Mkandawire et al. [35] |

| Sorghum expanded extrudates |

| Chávez et al. [52] | |

| Cream cheese added with raw or extruded SF |

| Correia et al. [53] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguiar, E.V.; Santos, F.G.; Queiroz, V.A.V.; Capriles, V.D. A Decade of Evidence of Sorghum Potential in the Development of Novel Food Products: Insights from a Bibliometric Analysis. Foods 2023, 12, 3790. https://doi.org/10.3390/foods12203790

Aguiar EV, Santos FG, Queiroz VAV, Capriles VD. A Decade of Evidence of Sorghum Potential in the Development of Novel Food Products: Insights from a Bibliometric Analysis. Foods. 2023; 12(20):3790. https://doi.org/10.3390/foods12203790

Chicago/Turabian StyleAguiar, Etiene Valéria, Fernanda Garcia Santos, Valéria Aparecida Vieira Queiroz, and Vanessa Dias Capriles. 2023. "A Decade of Evidence of Sorghum Potential in the Development of Novel Food Products: Insights from a Bibliometric Analysis" Foods 12, no. 20: 3790. https://doi.org/10.3390/foods12203790

APA StyleAguiar, E. V., Santos, F. G., Queiroz, V. A. V., & Capriles, V. D. (2023). A Decade of Evidence of Sorghum Potential in the Development of Novel Food Products: Insights from a Bibliometric Analysis. Foods, 12(20), 3790. https://doi.org/10.3390/foods12203790