Formulation of Gluten-Free Cookies Utilizing Chickpea, Carob, and Hazelnut Flours through Mixture Design

Abstract

:1. Introduction

2. Materials and Methods

2.1. Contents of the Formulations

2.2. Measurement of Flour Characteristics

2.2.1. Chemical Composition

2.2.2. Physical Characteristics

2.3. Product Formulations

2.4. Measurement of Rheological Characteristics

2.5. Determination of Cookie Characteristics

2.5.1. Quality Characteristics

2.5.2. Measurement of Texture Characteristics of Cookies

2.5.3. In Vitro Digestion Test of Cookies

2.5.4. Sensory Evaluation

2.6. Statistical Analysis

3. Results and Discussion

3.1. Characteristics of the Flours

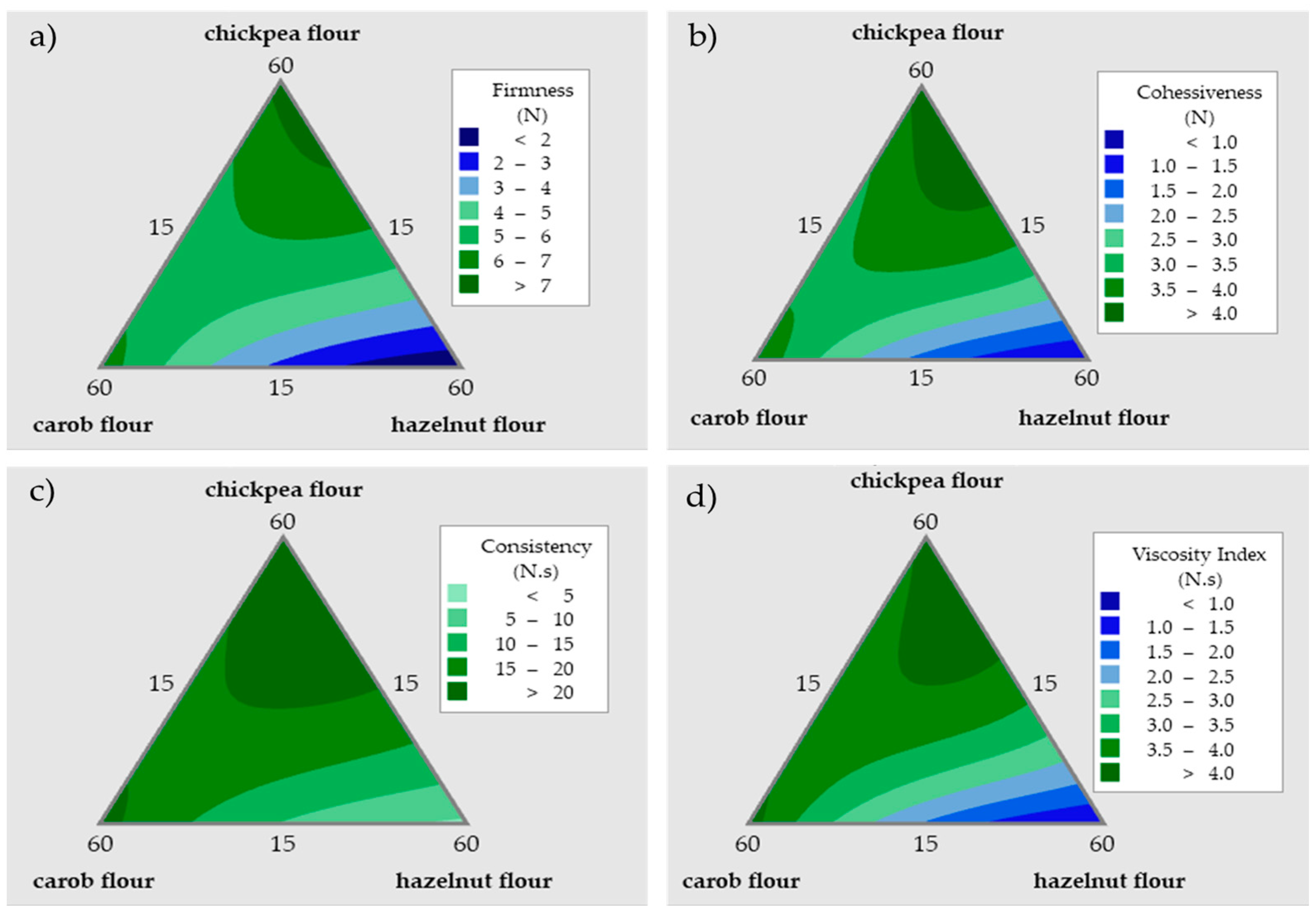

3.2. Rheological Characteristics of Cookie Doughs

3.3. Technological Attributes of the Baked Cookies

3.4. Sensory Properties of Baked Cookies

3.5. Nutritional Characteristics of the Baked Cookies

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gluten-Free Bakery Market Size & Share Report, 2022–2030. Available online: https://www.grandviewresearch.com/industry-analysis/gluten-free-bakery-market-report (accessed on 26 September 2023).

- Golley, S.; Corsini, N.; Topping, D.; Morell, M.; Mohr, P. Motivations for avoiding wheat consumption in Australia: Results from a population survey. Public Health Nutr. 2014, 18, 490–499. [Google Scholar] [CrossRef] [PubMed]

- Reilly, N.R. The gluten-free diet: Recognizing fact, fiction, and fad. J. Pediatr. 2016, 175, 206–210. [Google Scholar] [CrossRef] [PubMed]

- Catassi, C.; Bai, J.C.; Bonaz, B.; Bouma, G.; Calabrò, A.; Carroccio, A.; Castillejo, G.; Ciacci, C.; Cristofori, F.; Dolinsek, J.; et al. Non-Celiac Gluten Sensitivity: The New Frontier of Gluten Related Disorders. Nutrients 2013, 5, 3839–3853. [Google Scholar] [CrossRef] [PubMed]

- Du, S.K.; Jiang, H.; Yu, X.; Jane, J.L. Physicochemical and functional properties of whole legume flour. LWT 2014, 55, 308–313. [Google Scholar] [CrossRef]

- Maninder, K.; Sandhu, K.S.; Singh, N. Comparative study of the functional, thermal and pasting properties of flours from different field pea (Pisum sativum L.) and pigeon pea (Cajanus cajan L.) cultivars. Food Chem. 2007, 104, 259–267. [Google Scholar] [CrossRef]

- Mittal, R.; Nagi, H.P.S.; Sharma, P.; Sharma, S. Effect of processing on chemical composition and antinutritional factors in chickpea flour. J. Food Sci. Eng. 2012, 2, 180. [Google Scholar]

- Tsatsaragkou, K.; Yiannopoulos, S.; Kontogiorgi, A.; Poulli, E.; Krokida, M.; Mandala, I. Effect of carob flour addition on the rheological properties of gluten-free breads. Food Bioprocess Technol. 2014, 7, 868–876. [Google Scholar] [CrossRef]

- Yagcı, S.; Gogus, F. Selected physical properties of expanded extrudates from the blends of hazelnut flour-durum clear flour-rice. Int. J. Food Prop. 2009, 12, 405–413. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Bonaccorsi, G.; Lorini, C.; Cini, E. Assessment of the rheological properties and bread characteristics obtained by innovative protein sources (Cicer arietinum, Acheta domesticus, Tenebrio molitor): Novel food or potential improvers for wheat flour? LWT 2020, 118, 108867. [Google Scholar] [CrossRef]

- Demirkesen, I.; Ozkaya, B. Recent strategies for tackling the problems in gluten-free diet and products. Crit. Rev. Food Sci. 2022, 62, 571–597. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Wang, W.; Li, Y. Advanced properties of gluten-free cookies, cakes, and crackers: A review. Trends Food Sci. Technol. 2020, 103, 200–213. [Google Scholar] [CrossRef]

- Bravo-Núñez, N.; Gómez, M. Enrichment of cakes and cookies with pulse flours. A review. Food Rev. Int. 2021, 39, 2895–2913. [Google Scholar] [CrossRef]

- Yamsaengsung, R.; Berghofer, E.; Schoenlechner, R. Physical properties and sensory acceptability of cookies made from chickpea addition to white wheat or whole wheat flour compared to gluten-free amaranth or buckwheat flour. Int. J. Food Sci. Technol. 2012, 47, 2221–2227. [Google Scholar] [CrossRef]

- Torra, M.; Belorio, M.; Ayuso, M.; Carocho, M.; Ferreira, I.C.F.R.; Barros, L.; Gómez, M. Chickpea and chestnut flours as non-gluten alternatives in cookies. Foods 2021, 10, 911. [Google Scholar] [CrossRef]

- Byanju, B.; Hojilla-Evangelista, M.P.; Lamsal, B.P. Fermentation performance and nutritional assessment of physically processed lentil and green pea flour. J. Sci. Food Agric. 2021, 101, 5792–5806. [Google Scholar] [CrossRef]

- Narayana, K.; Rao, M.N. Effect of partial proteolysis on the functional properties of winged bean (Psophocarpus tetragonolobus) flour. J. Food Sci. 1984, 49, 944–947. [Google Scholar] [CrossRef]

- Turan, D.; Capanoglu, E.; Altay, F. Investigating the effect of roasting on functional properties of defatted hazelnut flour by response surface methodology (RSM). LWT 2015, 63, 758–765. [Google Scholar] [CrossRef]

- Dogruer, I.; Coban, B.; Baser, F.; Gulec, S.; Ozen, B. Techno-functional and in vitro digestibility properties of gluten-free cookies made from raw, pre-cooked, and germinated chickpea flours. Foods 2023, 12, 2829. [Google Scholar] [CrossRef]

- Encina-Zelada, C.R.; Cadavez, V.; Monteiro, F.; Teixeira, J.A.; Gonzales-Barron, U. Combined effect of xanthan gum and water content on physicochemical and textural properties of gluten-free batter and bread. Food Res. Int. 2018, 111, 544–555. [Google Scholar] [CrossRef]

- Inglett, G.; Chen, D.; Liu, S. Physical properties of gluten-free sugar cookies made from amaranth–oat composites. LWT 2015, 63, 214–220. [Google Scholar] [CrossRef]

- Chakraborty, S.K.; Singh, D.S.; Kumbhar, B.K.; Singh, D. Process parameter optimization for textural properties of ready-to-eat extruded snack food from millet and legume pieces blends. J. Texture Stud. 2009, 40, 710–726. [Google Scholar] [CrossRef]

- Englyst, K.N.; Hudson, G.J.; Englyst, H.N. Starch analysis in food. In Encyclopedia of Analytical Chemistry; Meyers, R.A., Ed.; Wiley: Hoboken, NJ, USA, 2000; pp. 4246–4262. [Google Scholar]

- Galvan, D.; Effting, L.; Cremasco, H.; Conte-Junior, C.A. Recent applications of mixture designs in beverages, foods, and pharmaceutical health: A systematic review and meta-analysis. Foods 2021, 10, 1941. [Google Scholar] [CrossRef] [PubMed]

- Sreerama, Y.N.; Sashikala, V.B.; Pratape, V.M.; Singh, V. Nutrients and antinutrients in cowpea and horse gram flours in comparison to chickpea flour: Evaluation of their flour functionality. Food Chem. 2012, 131, 462–468. [Google Scholar] [CrossRef]

- Román, L.; González, A.; Espina, T.; Gómez, M. Degree of roasting of carob flour affecting the properties of gluten-free cakes and cookies. J. Food Sci. Technol. 2017, 54, 2094–2103. [Google Scholar] [CrossRef] [PubMed]

- Ozdemir, F.; Akinci, I. Physical and nutritional properties of four major commercial Turkish hazelnut varieties. J. Food Eng. 2004, 63, 341–347. [Google Scholar] [CrossRef]

- Kirbaşlar, F.G.; Erkmen, G. Investigation of the effect of roasting temperature on the nutritive value of hazelnuts. Plant Food Human Nutr. 2003, 58, 1–10. [Google Scholar] [CrossRef]

- Özcan, M.; Arslan, D.; Gökçalik, H. Some compositional properties and mineral contents of carob (Ceratonia siliqua) fruit, flour and syrup. Int. J. Food Sci. Nutr. 2007, 58, 652–658. [Google Scholar] [CrossRef]

- Yurttas, H.C.; Schafer, H.W.; Warthesen, J.J. Antioxidant activity of nontocopherol hazelnut (Corylus spp.) phenolics. J. Food Sci. 2000, 65, 276–280. [Google Scholar] [CrossRef]

- Anil, M. Using of hazelnut testa as a source of dietary fiber in breadmaking. J. Food Eng. 2007, 80, 61–67. [Google Scholar] [CrossRef]

- Amarowicz, R.; Pegg, R.B. Legumes as a source of natural antioxidants. Eur. J. Lipid Sci. Technol. 2008, 110, 865–878. [Google Scholar] [CrossRef]

- Chandra, S.; Singh, S.; Kumari, D. Evaluation of functional properties of composite flours and sensorial attributes of composite flour biscuits. J. Food Sci. Technol. 2015, 52, 3681–3688. [Google Scholar] [CrossRef] [PubMed]

- Tagodoe, A.; Nip, W.K. Functional properties of raw and precooked taro (Colocasia esculenta) flours. Int. J. Food Sci. Technol. 2007, 29, 457–462. [Google Scholar] [CrossRef]

- Turfani, V.; Narducci, V.; Durazzo, A.; Galli, V.; Carcea, M. Technological, nutritional and functional properties of wheat bread enriched with lentil or carob flours. LWT 2017, 78, 361–366. [Google Scholar] [CrossRef]

- Ronda, F.; Pérez-Quirce, S.; Villanueva, M. Rheological properties of gluten-free bread doughs: Relationship with bread quality. In Advances in Food Rheology and Its Applications; Ahmed, J., Ed.; Woodhead Publ.: Sawston, UK, 2017; pp. 297–334. [Google Scholar] [CrossRef]

- Pycia, K.; Juszczak, L. The Effect of the addition of hazelnut or walnut flour on the rheological characteristics of wheat dough. Materials 2022, 15, 782. [Google Scholar] [CrossRef]

- Belorio, M.; Gómez, M. Gluten-free muffins versus gluten containing muffins: Ingredients and nutritional differences. Trends Food Sci. Technol. 2020, 102, 249–253. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S.; Khatkar, B. Cookie texture, spread ratio and sensory acceptability of cookies as a function of soluble dietary fiber, baking time and different water levels. LWT 2017, 80, 537–542. [Google Scholar] [CrossRef]

- Hoseney, R.C.; Rogers, D.E. Mechanism of sugar functionality in cookies. In The Science of Cookie and Cracker Production; Faridi, H., Ed.; Avi: New York, NY, USA, 1994; pp. 203–226. [Google Scholar]

- Miller, R.A.; Hoseney, R.C.; Morris, C.F. Effect of formula water content on the spread of sugar-snap cookies. Cereal Chem. 1997, 74, 669–671. [Google Scholar] [CrossRef]

- Skaltsi, A.; Marinopoulou, A.; Poriazi, A.; Petridis, D.; Papageorgiou, M. Development and optimization of gluten-free biscuits with carob flour and dry apple pomace. J. Food Proc. Preserv. 2022, 46, e15938. [Google Scholar] [CrossRef]

- Kotoki, D.; Deka, S.C. Baking loss of bread with special emphasis on increasing water holding capacity. J. Food Sci. Technol. 2010, 47, 128–131. [Google Scholar] [CrossRef]

| Ingredients (g) | Formulations | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| Chickpea flour | 60 | 37.5 | 37.5 | 15 | 15 | 15 | 30 | 30 | 30 |

| Carob flour | 15 | 37.5 | 15 | 60 | 37.5 | 15 | 30 | 30 | 30 |

| Hazelnut flour | 15 | 15 | 37.5 | 15 | 37.5 | 60 | 30 | 30 | 30 |

| Corn starch | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Brown sugar | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Margarine | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Egg | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Baking powder | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Properties | Pre-Cooked Chickpea | Carob | Hazelnut with Testa |

|---|---|---|---|

| Moisture (g/100 g) | 3.30 ± 0.20 a | 1.82 ± 0.26 b | 1.06 ± 0.18 b |

| Protein (g/100 g) | 20.71 ± 1.60 a | 3.66 ± 0.75 c | 15.65 ± 0.09 b |

| Fat (g/100 g) | 10.06 ± 1.27 b | 1.47 ± 1.11 c | 69.34 ± 0.86 a |

| Ash (g/100 g) | 1.95 ± 0.11 b | 3.36± 1.12 a | 1.98 ± 0.04 b |

| Fiber (g/100 g) | 1.96 ± 0.07 b | 1.09 ± 0.34 c | 22.59 ± 0.22 a |

| Total Phenolic Content (mg GAE/g flour) | 0.46 ± 0.08 c | 24.14 ± 5.72 a | 1.83 ± 0.00 b |

| Bulk Density (g/mL) | 0.70 ± 0.00 a | 0.78 ± 0.04 a | 0.48 ± 0.00 b |

| Water Retention Capacity (%) | 300.76 ± 12.84 a | 131.85 ± 6.30 b | - |

| Oil Absorption Capacity (g/g) | 1.38 ± 0.13 ab | 1.13 ± 0.10 b | 1.69 ± 0.21 a |

| Emulsion Activity (%) | 51.00 ± 1.41 a | 50.53 ± 3.68 a | 54.01 ± 4.23 a |

| Emulsion Stability (%) | 95.15 ± 4.03 a | 98.53 ± 2.08 a | 91.73 ± 6.03 a |

| Foaming Capacity (%) | 17.29 ± 3.83 a | 12.15 ± 5.15 b | 12.00 ± 0.00 b |

| Foaming Stability (%) | 8.17 ± 0.24 a | 6.87 ± 0.70 a | 2.83 ± 2.00 a |

| L* | 90.60 ± 1.01 a | 58.68 ± 1.38 c | 75.89 ± 0.58 b |

| a* | 0.91 ± 0.06 c | 12.29 ± 0.12 a | 5.92 ± 0.05 b |

| b* | 31.77 ± 0.23 a | 29.26 ± 0.56 b | 30.27 ± 0.13 ab |

| Formulation | Firmness (N) | Consistency (N × s) | Cohesiveness (N) | Viscosity Index (N × s) |

|---|---|---|---|---|

| 1 | 7.37 ± 0.48 a | 24.55 ± 1.37 a | 4.19 ± 0.23 a | 4.13 ± 0.06 a |

| 2 | 5.44 ± 0.23 c | 18.46 ± 0.26 b | 3.34 ± 0.04 b | 3.66 ± 0.17 a |

| 3 | 5.17 ± 1.40 b,c | 19.32 ± 2.11 a,b | 3.29 ± 1.05 a,b | 3.10 ± 1.28 a |

| 4 | 6.62 ± 0.74 a,b | 21.91 ± 3.7 a,b | 3.92 ± 0.47 a,b | 4.22 ± 0.47 a |

| 5 | 2.66 ± 0.14 d | 9.33 ± 0.82 c | 1.85 ± 0.12 b | 1.93 ± 0.13 b |

| 6 | 1.23 ± 0.03 e | 4.43 ± 0.09 c | 0.9 ± 0.0 d | 0.95 ± 0.04 c |

| 7 | 5.88 ± 0.19 b,c | 20.03 ± 1.22 a,b | 3.80 ± 0.19 a,b | 3.93 ± 0.21 a |

| 8 | 5.39 ± 0.31 c | 19.31 ± 1.39 b | 3.30 ± 0.25 b | 3.45 ± 0.31 a |

| 9 | 5.31 ± 0.24 c | 18.16 ± 1.61 b | 3.39 ± 0.22 b | 3.67 ± 0.3 a |

| Formulation | Moisture (%) | Baking Weight Loss (%) | Spread Factor | Hardness | L* | a* | b* |

|---|---|---|---|---|---|---|---|

| 1 | 7.16 ± 0.56 e | 13.05 ± 0.58 b,c | 3.77 ± 0.15 f | 3.92 ± 0.55 c,d | 41.42 ± 1.32 a | 9.06 ± 0.80 | 13.77 ± 0.67 a |

| 2 | 9.13 ± 0.23 a,b,c | 12.87 ± 0.80 b | 3.87 ± 0.17 f | 4.82 ± 0.58 b,c | 30.16 ± 1.74 c,d | 9.70 ± 0.40 a | 9.72 ± 0.56 a,b,c |

| 3 | 7.77 ± 0.30 d,e | 12.85 ± 1.13 d | 4.43 ± 0.30 c | 2.86 ± 0.53 d,e | 39.43 ± 1.72 a,b | 9.15± 0.72 a | 12.91 ± 1.01 a,b |

| 4 | 10.28 ± 0.13 a | 13.59 ± 0.75 b,c | 3.37 ± 0.14 e,f | 8.26 ± 1.21 a | 25.68 ± 1.51 c,d | 8.95 ± 0.35 a | 6.73 ± 0.74 c |

| 5 | 8.49 ± 0.25 c,d,e | 16.46 ± 0.87 a | 4.92 ± 0.32 b | 5.84 ± 0.82 b | 28.18 ± 0.76 c,d | 9.55 ± 0.24 a | 8.28 ± 0.86 b,c |

| 6 | 7.24 ± 0.17 e | 19.93 ± 1.10 a | 7.47 ± 0.38 a | 3.45 ± 0.89 d,e | 34.27 ± 1.53 a,b,c | 8.88 ± 0.57 a | 11.30 ± 1.27 a,b,c |

| 7 | 8.94 ± 0.19 b,c,d | 12.60 ± 0.92 d | 4.05 ± 0.20 d,e | 3.75 ± 0.70 d,e | 32.68 ± 1.23 b,c,d | 9.98 ± 0.31 a | 10.45 ± 0.51 a,b,c |

| 8 | 8.69 ± 0.35 c,d | 13.87 ± 1.10 b | 4.27 ± 0.15 c,d | 3.61 ± 0.63 d,e | 31.15 ± 1.50 c,d | 9.92 ± 0.43 a | 10.11 ± 0.65 a,b,c |

| 9 | 10.04 ± 0.37 a,b | 11.73 ± 0.65 c,d | 4.15 ± 0.20 d,e | 2.56 ± 0.26 e | 31.03 ± 1.09 c,d | 9.76 ± 0.62 a | 10.33 ± 0.98 a,b,c |

| Samples | Chickpea Flour | 30% Chickpea/30% Carob/30% Hazelnut Flours (Formulation 7) | 60% Chickpea/15% Carob/15% Hazelnut Flours (Formulation 1) |

|---|---|---|---|

| Color | 5.60 ± 1.15 a | 5.80 ± 1.36 a | 5.43 ± 1.28 a |

| Flavor | 4.50 ± 1.43 b | 5.40 ± 1.33 a | 5.33 ± 1.25 a |

| Texture | 5.48 ± 1.06 a | 5.43 ± 1.44 a | 5.50 ± 0.98 a |

| Taste | 4.55 ± 1.41 b | 5.55 ± 1.17 a | 5.43 ± 1.03 a |

| Overall acceptability | 4.78 ± 1.19 b | 5.63 ± 1.05 a | 5.28 ± 1.11 ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dogruer, I.; Baser, F.; Gulec, S.; Tokatli, F.; Ozen, B. Formulation of Gluten-Free Cookies Utilizing Chickpea, Carob, and Hazelnut Flours through Mixture Design. Foods 2023, 12, 3689. https://doi.org/10.3390/foods12193689

Dogruer I, Baser F, Gulec S, Tokatli F, Ozen B. Formulation of Gluten-Free Cookies Utilizing Chickpea, Carob, and Hazelnut Flours through Mixture Design. Foods. 2023; 12(19):3689. https://doi.org/10.3390/foods12193689

Chicago/Turabian StyleDogruer, Ilgin, Filiz Baser, Sukru Gulec, Figen Tokatli, and Banu Ozen. 2023. "Formulation of Gluten-Free Cookies Utilizing Chickpea, Carob, and Hazelnut Flours through Mixture Design" Foods 12, no. 19: 3689. https://doi.org/10.3390/foods12193689

APA StyleDogruer, I., Baser, F., Gulec, S., Tokatli, F., & Ozen, B. (2023). Formulation of Gluten-Free Cookies Utilizing Chickpea, Carob, and Hazelnut Flours through Mixture Design. Foods, 12(19), 3689. https://doi.org/10.3390/foods12193689