Evaluation of Hygiene Practice for Reducing Campylobacter Contamination on Cutting Boards and Risks Associated with Chicken Handling in Kitchen Environment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Web-Based Survey among Chefs in Eastern China

2.2. Sample Collection and Campylobacter Examination Method

2.3. Simulating the Handling of Contaminated Chicken in the Kitchen Environment

2.4. Simulating the Handling of Contaminated Chicken in a Kitchen Environment

2.5. Calculations and Statistics

3. Results

3.1. Chefs’ Self-Reported Handling Practices While Preparing Chicken

3.2. Campylobacter Contamination of Cutting Boards in Commercial Kitchens during Chicken Preparation

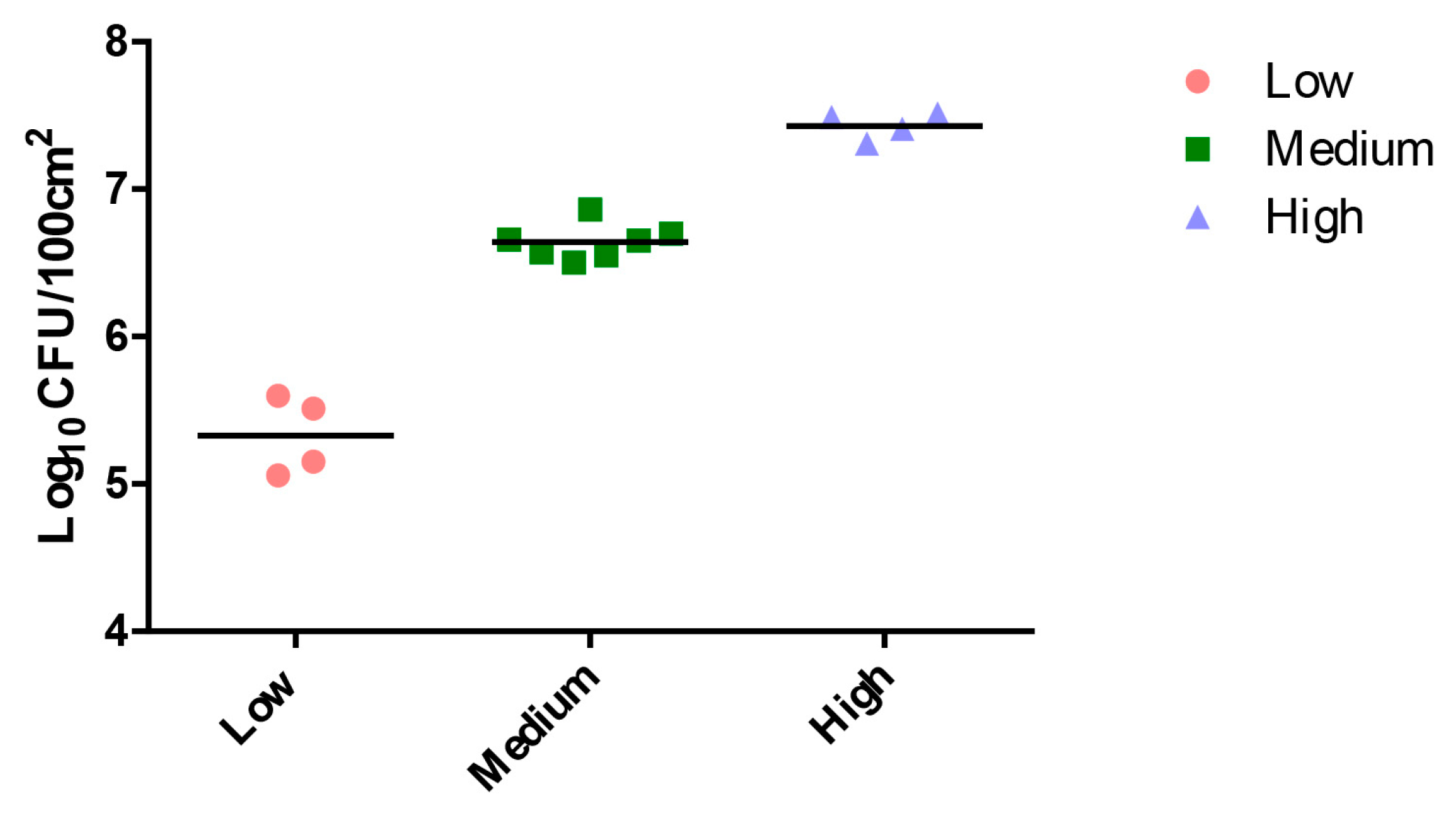

3.3. Risk Area of Campylobacter Spread during Simulated Chicken Preparation

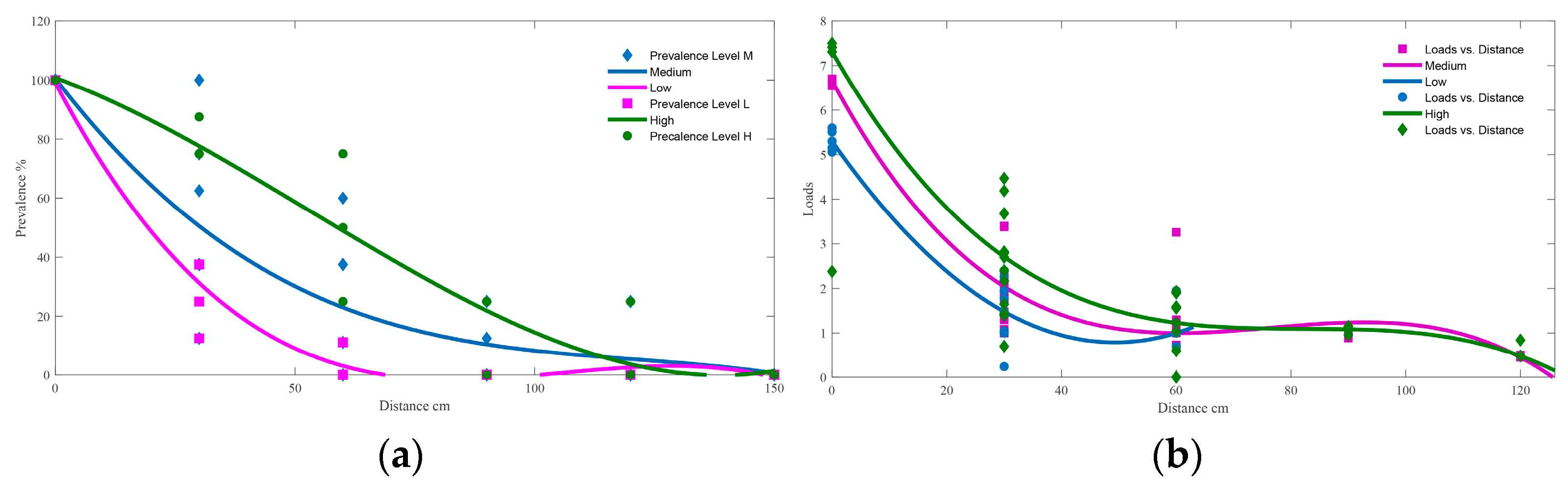

3.4. Risk Time of Campylobacter Survival on Different Surfaces

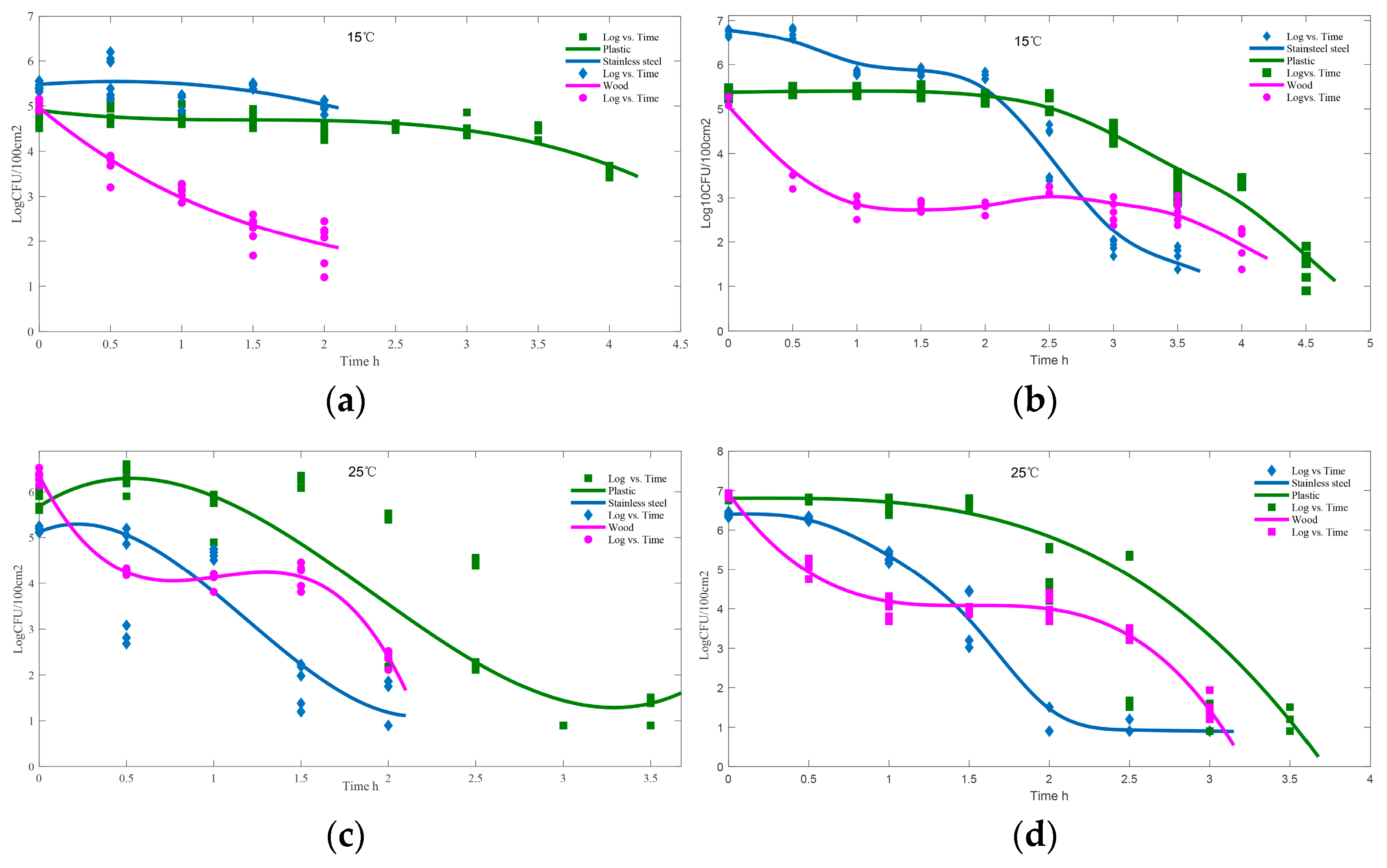

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EFSA. The European Union summary report on trends and sources of zoonoses, zoonotic agents and food-borne outbreaks in 2017. EFSA J. 2018, 16, e05500. [Google Scholar]

- EFSA. The European Union One Health 2020 Zoonoses Report. EFSA J. 2021, 19, 6971. [Google Scholar]

- Pogreba-Brown, K.; Barrett, E. Campylobacter and ethnicity-A Case-Case analysis to determine differences in disease presentation and risk factors. Foodborne Pathog. Dis. 2018, 15, 277–284. [Google Scholar] [CrossRef]

- Luber, P.; Brynestad, S.; Topsch, D.; Scherer, K.; Bartelt, E. Quantification of Campylobacter species cross-contamination during handling of contaminated fresh chicken parts in kitchens. Appl. Environ. Microb. 2006, 72, 66–70. [Google Scholar] [CrossRef]

- Eriksson, D.; Råhlén, E.; Bergenkvist, E.; Skarin, M.; Fernström, L.L.; Rydén, J.; Hansson, I. Survival of Campylobacter jejuni in frozen chicken meat and risks associated with handling contaminated chicken in the kitchen. Food Control 2023, 145, 109471. [Google Scholar] [CrossRef]

- Silva, J.; Leite, D.; Fernandes, M.; Mena, C.; Gibbs, P.A.; Teixeira, P. Campylobacter spp. as a Foodborne Pathogen: A Review. Front. Microbiol. 2011, 2, 200. [Google Scholar] [CrossRef]

- Facciolàr, A.; Riso, R.; Avventuroso, E.; Visalli, G.; Laganà, P. Campylobacter: From microbiology to prevention. J. Prev. Med. Hyg. 2017, 58, E79–E92. [Google Scholar]

- Cardoso, M.J.; Ferreir, V.; Truninger, M.; Mena, C.; Gibbs, P.A.; Teixeira, P. Cross-contamination events of Campylobacter spp. in domestic kitchens associated with consumer handling practices of raw poultry. Int. J. Food Microbiol. 2021, 338, 108984. [Google Scholar] [CrossRef]

- Møretrø, T.; Martens, L.; Teixeira, P.; Ferreira, V.B.; Maia, R.; Maugesten, T.; Langsrud, S. Is visual motivation for cleaning surfaces in the kitchen consistent with a hygienically clean environment? Food Control 2020, 111, 107077. [Google Scholar] [CrossRef]

- Takeoka, K.; Abe, H.; Koyama, K.; Koseki, S. Experimentally observed Campylobacter jejuni survival kinetics in chicken meat products during model gastric digestion tended to be lower than model predictions. Food Microbiol. 2022, 102, 103932. [Google Scholar] [CrossRef]

- Lai, H.; Tang, Y.; Ren, F.; Li, Z.; Li, F.; Cui, C.; Jiao, X.; Huang, J. An investigation into the critical factors influencing the spread of Campylobacter during chicken handling in commercial kitchens in China. Microorganisms 2021, 9, 1164. [Google Scholar] [CrossRef]

- Ngan, W.Y.; Rao, S.; Chan, L.C.; Sekoai, P.T.; Pu, Y.; Yao, Y.; Fung, A.H.Y.; Habimana, O. Impacts of wet market modernization levels and hygiene practices on the microbiome and microbial safety of wooden cutting boards in Hong Kong. Microorganisms 2020, 8, 1941. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Lin, X.; Zhu, J.; Cui, S.; Guo, L.; Yan, S.; Wang, W.; Xu, J.; Li, F. Quantification of cross-contamination of Campylobacter jejuni during food preparation in a model kitchen in China. J. Food Prot. 2021, 84, 850–856. [Google Scholar] [CrossRef]

- GB 14934-2016; National Food Safety Standards for Disinfection of Catering Utensils. National Health and Family Planning Commission: Beijing, China, 2017.

- Erkmen, O. Isolation and counting of Campylobacter jejuni. In Microbiological Analysis of Foods and Food Processing Environments; Erkmen, O., Ed.; Elsevier Inc.: London, UK, 2022; pp. 181–192. [Google Scholar]

- Birk, T.; Ingmer, H.; Andersen, M.T.; Jørgensen, K.; Brøndsted, L. Chicken juice, a food-based model system suitable to study survival of Campylobacter jejuni. Lett. Appl. Microbiol. 2004, 38, 66–71. [Google Scholar] [CrossRef]

- Redmond, E.C.; Griffith, C.J. Consumer food handling in the home: A review of food safety studies. J. Food Prot. 2003, 66, 130–161. [Google Scholar] [CrossRef]

- Evans, E.W.; Redmond, E.C. Behavioral Observation and Microbiological Analysis of Older Adult Consumers’ Cross-Contamination Practices in a Model Domestic Kitchen. J. Food Prot. 2018, 81, 569–581. [Google Scholar] [CrossRef]

- Allan, P.D.; Palmer, C.; Chan, F.; Lyons, R.; Nicholson, O.; Rose, M.; Hales, S.; Baker, M.G. Food safety labelling of chicken to prevent campylobacteriosis: Consumer expectations and current practices. BMC Public Health 2018, 18, 414. [Google Scholar] [CrossRef]

- Habib, I.; Harb, A.; Hansson, I.; Vågsholm, I.; Osama, W.; Adnan, S.; Anwar, M.; Agamy, N.; Boqvist, S. Challenges and opportunities towards the development of risk assessment at the consumer phase in developing countries-The case of Campylobacter cross-contamination during handling of raw chicken in two middle eastern countries. Pathogens 2020, 9, 62. [Google Scholar] [CrossRef]

- Møretrø, T.; Moen, B.; Almli, V.L.; Teixeira, P.; Ferreira, V.B.; Asli, A.W.; Nilsen, C.; Langsrud, S. Dishwashing sponges and brushes: Consumer practices and bacterial growth and survival. Int. J. Food Microbiol. 2021, 337, 108928. [Google Scholar] [CrossRef]

- Mattick, K. The survival of foodborne pathogens during domestic washing-up and subsequent transfer onto washing-up sponges, kitchen surfaces and food. Int. J. Food Microbiol. 2003, 85, 213–226. [Google Scholar] [CrossRef]

- Lai, H.; Tang, Y.; Wang, Z.; Ren, F.; Kong, L.; Jiao, X.; Huang, L. Handling practice as a critical point influencing the transmission route of campylobacter throughout a commercial restaurant kitchen in China. Food Control 2022, 139, 109056. [Google Scholar] [CrossRef]

- Mihalache, O.A.; Moretro, T.; Borda, D.; Dumitrascu, L.; Neagu, C.; Nguyen-The, C.; Maitre, I.; Didier, P.; Teixeira, P.; Lopes Junqueira, L.O.; et al. Kitchen layouts and consumers’ food hygiene practices: Ergonomics versus safety. Food Control 2022, 131, 108433. [Google Scholar] [CrossRef]

- Adetunji, V.O.; Isola, T.O. Crystal violet binding assay for assessment of biofilm formation by listeria monocytogenes and listeria spp. on wood, steel and glass surfaces. Glob. Vet. 2011, 6, 6–10. [Google Scholar]

- Bock, L.J.; Wand, M.E.; Sutton, J.M. Varying activity of chlorhexidine-based disinfectants against Klebsiella pneumoniae clinical isolates and adapted strains. J. Hosp. Infect. 2016, 93, 42–48. [Google Scholar] [CrossRef]

- Zhao, X.; Zhao, F.; Wang, J.; Zhong, N. Biofilm formation and control strategies of foodborne pathogens: Food safety perspectives. RSC Adv. 2017, 7, 36670–36683. [Google Scholar] [CrossRef]

- Guyard-Nicodème, M.; Tresse, O.; Houard, E.; Jugiau, F.; Courtillon, C.; EL Manaa, K.; Laisney, M.J.; Chemaly, M. Characterization of Campylobacter spp. transferred from naturally contaminated chicken legs to cooked chicken slices via a cutting board. Int. J. Food Microbiol. 2013, 164, 7–14. [Google Scholar] [CrossRef]

- Serov, D.A.; Baimler, I.V.; Burmistriv, D.E.; Baryshev, A.S.; Yanykin, D.V.; Astashev, M.E.; Simakin, A.V.; Gudkov, S.V. The development of new nanocomposite polytetrafluoroethylene/Fe(2)O(3) NPs to prevent bacterial contamination in meat industry. Polymers 2022, 14, 4880. [Google Scholar] [CrossRef]

- Kirchner, M.K. The Effect of Consumer Behaviors on Cross-Contamination While Preparing Meals in a Consumer Kitchen; North Carolina State University: Raleigh, NC, USA, 2020. [Google Scholar]

- DE Boer, E.; Hahne, M. Cross-contamination with Campylobacter jejuni and Salmonella spp. from Raw Chicken Products During Food Preparation. J. Food Prot. 1990, 53, 1067–1068. [Google Scholar] [CrossRef]

- Gorman, R.; Bloomfield, S.; Adley, C.C. A study of cross-contamination of food-borne pathogens in the domestic kitchen in the Republic of Ireland. Int. J. Food Microbiol. 2002, 76, 143–150. [Google Scholar] [CrossRef]

- Mylius, S.D.; Nauta, M.J.; Havelaar, A.H. Cross-contamination during food preparation: A mechanistic model applied to chicken-borne Campylobacter. Risk Anal. 2007, 27, 803–813. [Google Scholar] [CrossRef]

- Van Asselt, E.D.; de Jong, A.E.; de Jong, R.; Nauta, M.J. Cross-contamination in the kitchen: Estimation of transfer rates for cutting boards, hands and knives. J. Appl. Microbiol. 2008, 105, 1392–1401. [Google Scholar] [CrossRef] [PubMed]

- Hakeem, M.J.; Lu, X. Survival and control of Campylobacter in poultry production environment. Front. Cell Infect. Microbiol. 2020, 10, 615049. [Google Scholar] [CrossRef] [PubMed]

- Teh, K.H.; Flint, S.; French, N. Biofilm formation by Campylobacter jejuni in controlled mixed-microbial populations. Int. J. Food Microbiol. 2010, 143, 118–124. [Google Scholar] [CrossRef]

- Karki, A.B.; Ballard, K.; Harper, C.; Sheaff, R.J.; Fakhr, M.K. Staphylococcus aureus enhances biofilm formation, aerotolerance, and survival of Campylobacter strains isolated from retail meats. Sci. Rep. 2021, 11, 13837. [Google Scholar] [CrossRef]

| Total Sample (n = 154) | Jiangsu Province (n = 36) | Guangdong Province (n = 48) | Fujian Province (n = 33) | Guizhou Province (n = 17) | Hunan Province (n = 20) | |

|---|---|---|---|---|---|---|

| 1. Gender | ||||||

| Male | 70.78 | 69.44 | 79.17 | 72.73 | 64.71 | 55.00 |

| Female | 29.22 | 30.56 | 20.83 | 27.27 | 35.29 | 45.00 |

| 2. Age | ||||||

| 18–25 | 89.61 | 75.00 | 97.92 | 93.94 | 82.35 | 95.00 |

| 26–35 | 5.84 | 16.67 | 0.00 | 6.06 | 0.00 | 5.00 |

| 36–45 | 1.95 | 2.78 | 0.00 | 0.00 | 11.76 | 0.00 |

| 46–60 | 2.60 | 5.56 | 2.08 | 0.00 | 5.88 | 0.00 |

| 3. Education | ||||||

| Junior high school education | 3.25 | 0.00 | 8.33 | 0.00 | 5.88 | 0.00 |

| Senior high school education | 3.90 | 8.33 | 2.08 | 0.00 | 11.76 | 0.00 |

| Vocational education | 48.05 | 27.78 | 79.17 | 57.58 | 17.65 | 20.00 |

| College education | 39.61 | 50.00 | 8.33 | 36.36 | 64.71 | 80.00 |

| Graduate education | 5.19 | 13.89 | 2.08 | 6.06 | 0.00 | 0.00 |

| Items | Total Sample (n = 154) | Jiangsu Province (n = 36) | Guangdong Province (n = 48) | Fujian Province (n = 33) | Guizhou Province (n = 17) | Hunan Province (n = 20) |

|---|---|---|---|---|---|---|

| Type of catering service | ||||||

| Hotel | 58.44 | 50.00 | 72.92 | 72.73 | 17.65 | 50.00 |

| Restaurant | 35.71 | 44.44 | 20.83 | 24.24 | 70.59 | 45.00 |

| Fast food restaurant | 5.84 | 5.56 | 6.25 | 3.03 | 11.76 | 5.00 |

| Type of meat | ||||||

| Fresh chicken | 33.12 | 19.44 | 41.67 | 39.39 | 29.41 | 30.00 |

| Frozen chicken | 16.23 | 22.22 | 12.50 | 18.18 | 11.76 | 15.00 |

| Chicken slaughter in Wet market | 38.96 | 41.67 | 33.33 | 30.30 | 58.82 | 45.00 |

| Chicken breast or leg | 11.69 | 16.67 | 12.50 | 12.12 | 0.00 | 10.00 |

| Whether the whole chicken had been eviscerated or not | ||||||

| Yes | 87.01 | 94.44 | 83.33 | 81.82 | 88.24 | 90.00 |

| No | 12.99 | 5.56 | 16.67 | 18.18 | 11.76 | 10.00 |

| Before cutting, whether or not the chicken had been washed | ||||||

| Yes | 91.56 | 88.89 | 95.83 | 87.88 | 88.24 | 95.00 |

| No | 8.44 | 11.11 | 4.17 | 12.12 | 11.76 | 5.00 |

| Type of cutting board for chicken preparation | ||||||

| Plastic | 50.00 | 41.67 | 62.50 | 48.48 | 41.18 | 45.00 |

| Wood | 44.16 | 55.56 | 33.33 | 45.45 | 47.06 | 45.00 |

| Stainless steel | 1.95 | 2.78 | 0.00 | 6.06 | 0.00 | 0.00 |

| Other | 3.90 | 0.00 | 4.17 | 0.00 | 11.76 | 10.00 |

| Before chicken preparation, whether or not boards used for cutting other meat | ||||||

| Yes | 40.91 | 38.89 | 39.58 | 36.36 | 41.18 | 55.00 |

| No | 59.09 | 61.11 | 60.42 | 63.64 | 58.82 | 45.00 |

| After other meat preparation, method of cleaning boards | ||||||

| Washing with running tap water | 33.12 | 33.33 | 45.83 | 24.24 | 11.76 | 35.00 |

| Scrapping with knife | 31.17 | 19.44 | 25.00 | 42.42 | 41.18 | 40.00 |

| Washing with detergent | 35.71 | 47.22 | 29.17 | 33.33 | 47.06 | 25.00 |

| While preparing chicken, whether or not cloths used to clean cutting board | ||||||

| Yes | 48.05 | 61.11 | 41.67 | 45.45 | 41.18 | 50.00 |

| No | 51.95 | 38.89 | 58.33 | 54.55 | 58.82 | 50.00 |

| Cleaning method for cloths | ||||||

| Washing with running tap water | 17.53 | 19.44 | 18.75 | 21.21 | 5.88 | 15.00 |

| Washing with detergent | 51.95 | 50.00 | 56.25 | 42.42 | 64.71 | 50.00 |

| Boiling | 29.22 | 30.56 | 20.83 | 36.36 | 29.41 | 35.00 |

| No washing | 1.30 | 0.00 | 4.17 | 0.00 | 0.00 | 0.00 |

| After chicken preparation, method of cleaning boards | ||||||

| Washing with running tap water | 33.77 | 38.89 | 41.67 | 39.39 | 5.88 | 20.00 |

| Scrapping with knife | 24.03 | 19.44 | 16.67 | 18.18 | 41.18 | 45.00 |

| Washing with detergent | 41.56 | 41.67 | 39.58 | 42.42 | 52.94 | 35.00 |

| No washing | 0.65 | 0.00 | 2.08 | 0.00 | 0.00 | 0.00 |

| After touching the chicken, (usual) method of cleaning hands | ||||||

| No washing | 3.90 | 8.33 | 6.25 | 0.00 | 0.00 | 0.00 |

| Washing with running tap water | 41.56 | 27.78 | 39.58 | 51.52 | 41.18 | 55.00 |

| Washing with disinfectant | 54.55 | 63.89 | 54.17 | 48.48 | 58.82 | 45.00 |

| After chicken preparation, (usual) method of cleaning the knife | ||||||

| Washing with running tap water | 40.91 | 50.00 | 41.67 | 45.45 | 11.76 | 40.00 |

| Washing with detergent | 51.95 | 38.89 | 54.17 | 48.48 | 82.35 | 50.00 |

| Clean with cloth | 6.49 | 8.33 | 4.17 | 6.06 | 5.88 | 10.00 |

| No washing | 0.65 | 2.78 | 0.00 | 0.00 | 0.00 | 0.00 |

| Cleaning Method | Stage | Total | Positive | Detection Rate % | Average Loads (Log10CFU/100 cm2) |

|---|---|---|---|---|---|

| cleaning with a knife (n = 17) | chicken | 222 | 172 | 77.48 | 2.98 ± 0.93 |

| before cutting | 17 | 4 | 23.53 | 2.45 ± 0.68 a | |

| after cutting | 17 | 16 | 94.12 | 2.97 ± 0.94 b | |

| after cleaning process | 17 | 9 | 52.94 | 2.10 ± 0.56 a | |

| cleaning with running tap water (n = 5) | chicken | 67 | 58 | 86.57 | 3.25 ± 0.68 |

| before cutting | 5 | 0 | 0 | - | |

| after cutting | 5 | 5 | 100 | 3.44 ± 0.85 a | |

| after cleaning process | 5 | 3 | 60 | 2.85 ± 0.47 a | |

| cleaning with disinfectant (n = 1) | chicken | 12 | 12 | 100 | 4.03 ± 0.31 |

| before cutting | 1 | 0 | 0 | - | |

| after cutting | 1 | 1 | 100 | 3.76 ± 0.00 a | |

| After cleaning process | 1 | 1 | 100 | 1.6 ± 0.00 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, H.; Tang, Y.; Ren, F.; Jiao, X.-a.; Huang, J. Evaluation of Hygiene Practice for Reducing Campylobacter Contamination on Cutting Boards and Risks Associated with Chicken Handling in Kitchen Environment. Foods 2023, 12, 3245. https://doi.org/10.3390/foods12173245

Lai H, Tang Y, Ren F, Jiao X-a, Huang J. Evaluation of Hygiene Practice for Reducing Campylobacter Contamination on Cutting Boards and Risks Associated with Chicken Handling in Kitchen Environment. Foods. 2023; 12(17):3245. https://doi.org/10.3390/foods12173245

Chicago/Turabian StyleLai, Honggang, Yuanyue Tang, Fangzhe Ren, Xin-an Jiao, and Jinlin Huang. 2023. "Evaluation of Hygiene Practice for Reducing Campylobacter Contamination on Cutting Boards and Risks Associated with Chicken Handling in Kitchen Environment" Foods 12, no. 17: 3245. https://doi.org/10.3390/foods12173245

APA StyleLai, H., Tang, Y., Ren, F., Jiao, X.-a., & Huang, J. (2023). Evaluation of Hygiene Practice for Reducing Campylobacter Contamination on Cutting Boards and Risks Associated with Chicken Handling in Kitchen Environment. Foods, 12(17), 3245. https://doi.org/10.3390/foods12173245