Influence of Post-Heating Treatment on the Sensory and Textural Properties of Stirred Fermented Milk

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Processing

2.1.1. Stirred Fermented Milk

2.1.2. Post-Heating Treatments

2.2. Particle Size Distribution

2.3. Frequency Sweep, Strain Sweep, and Apparent Viscosity

2.3.1. Frequency Sweep

2.3.2. Strain Sweep

2.3.3. Apparent Viscosity

2.4. Thixotropic Properties

2.5. Texture Properties

2.6. Tribology

2.7. Sensory Analysis

2.8. Statistical Analysis

3. Results and Discussion

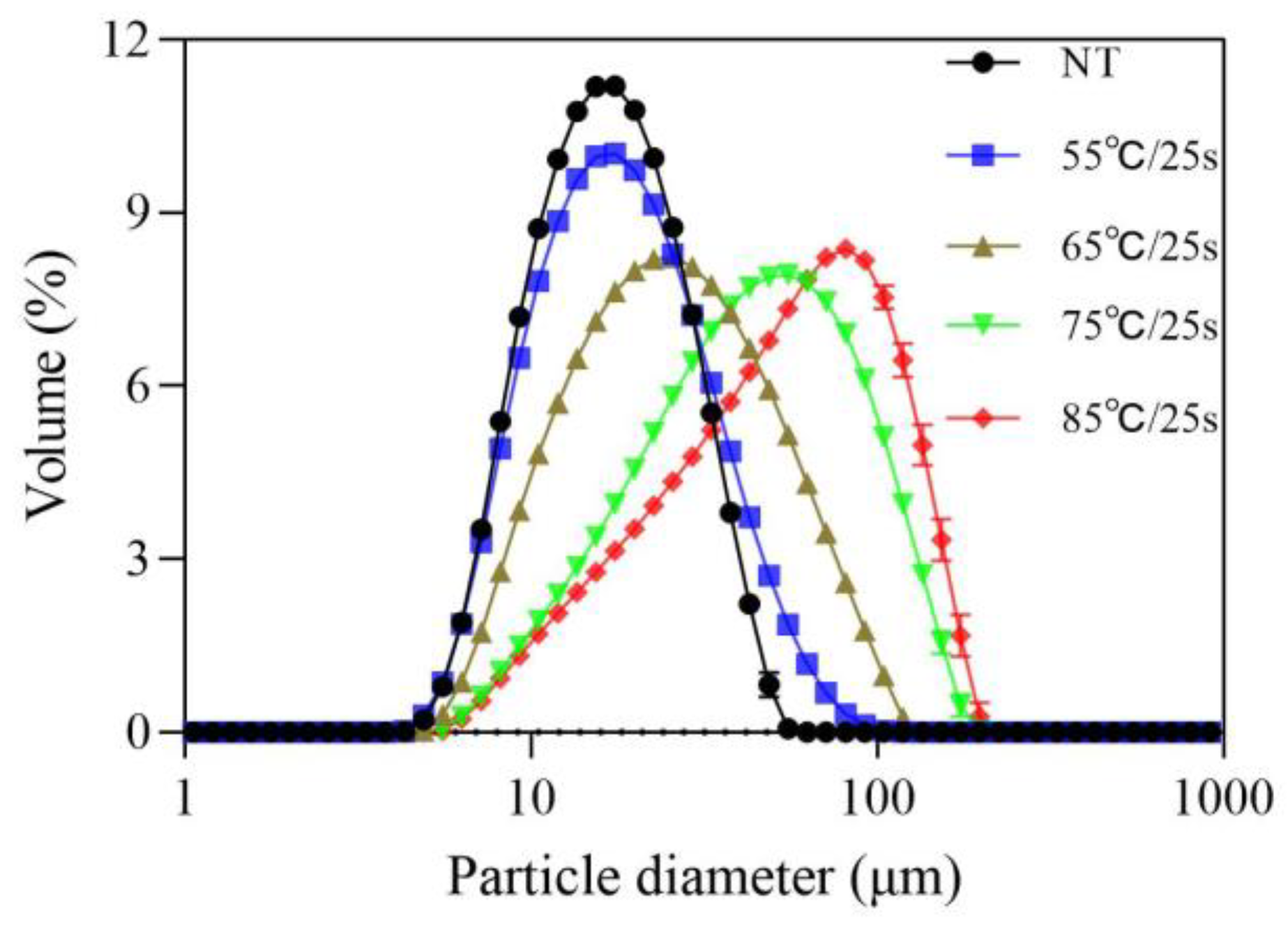

3.1. Particle Size Distribution of Post-Heating Fermented Milk

3.2. Flow Behavior and Textural Properties of Post-Heating Fermented Milk

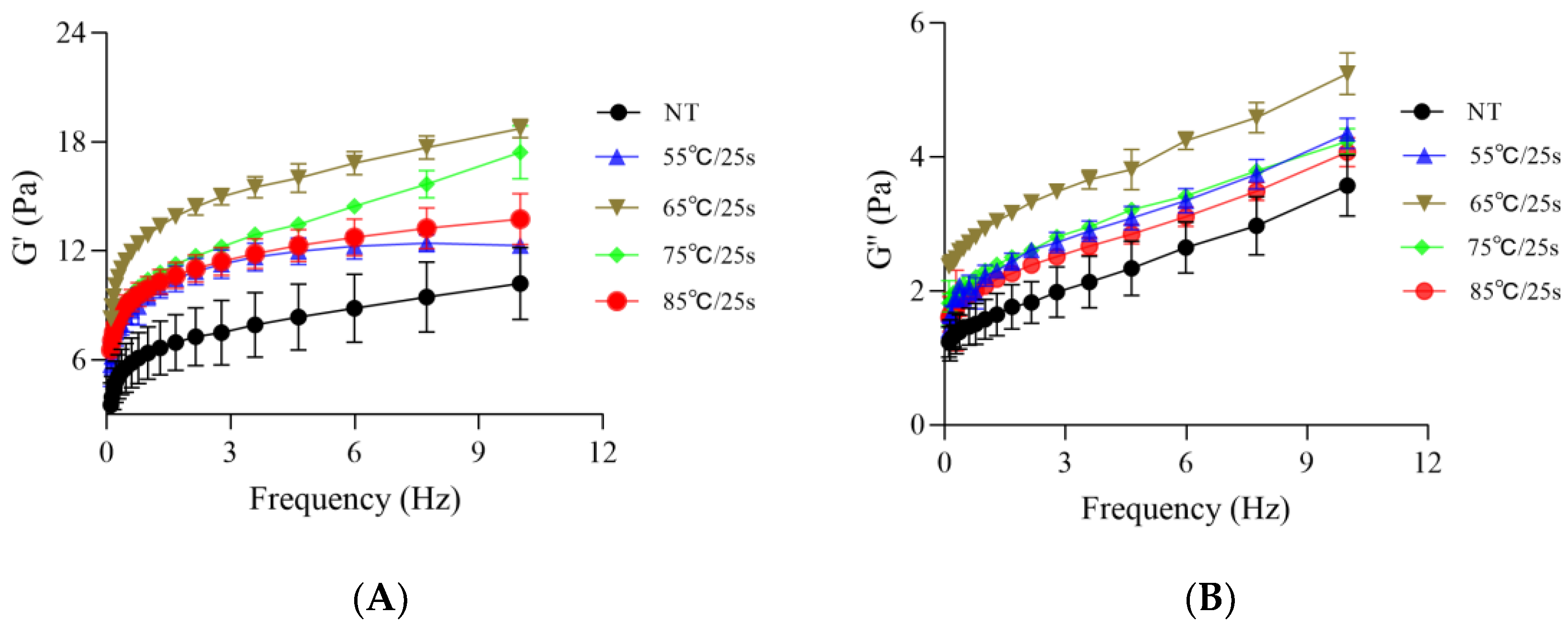

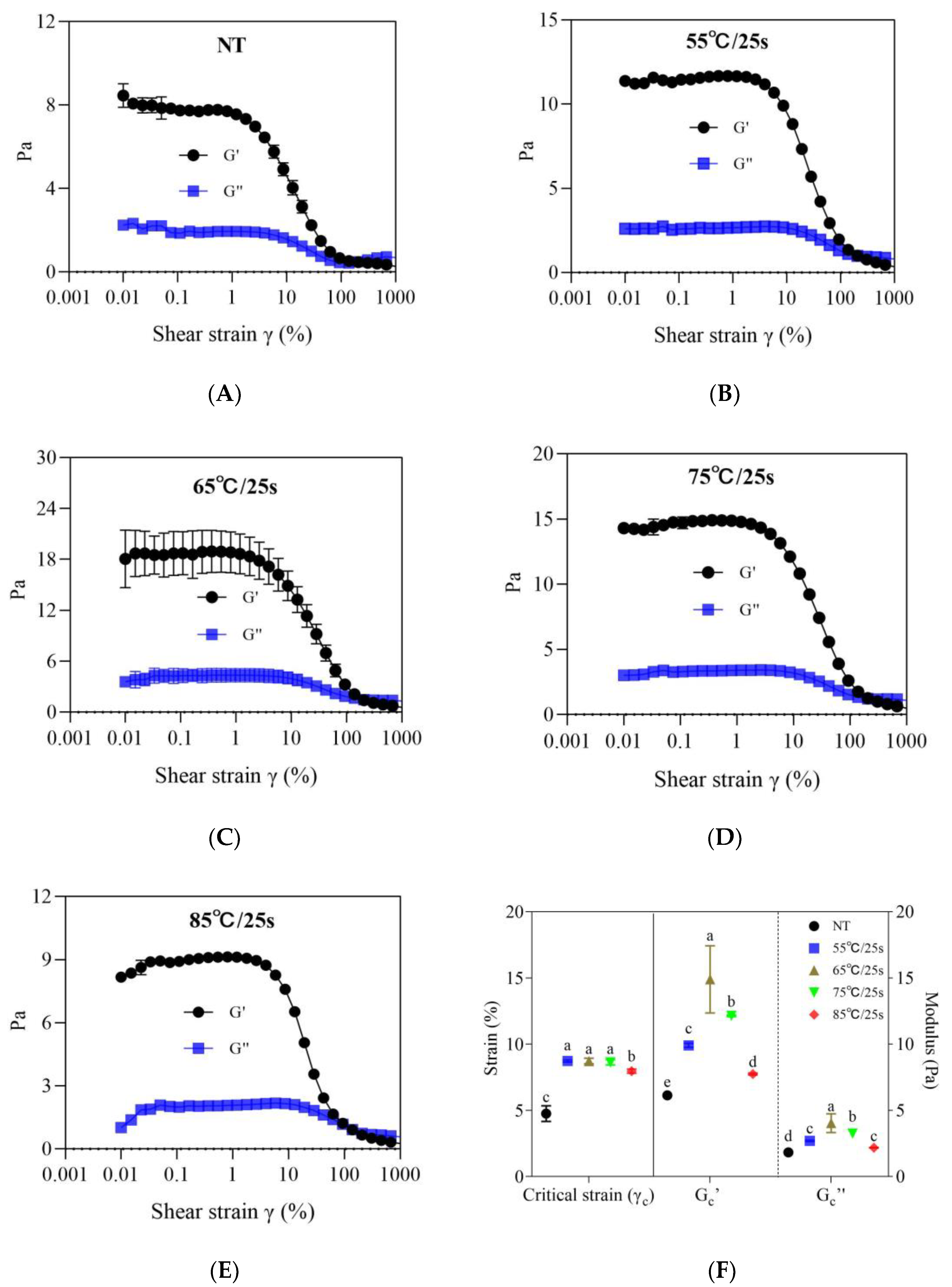

3.2.1. Frequency Sweep and Strain Sweep

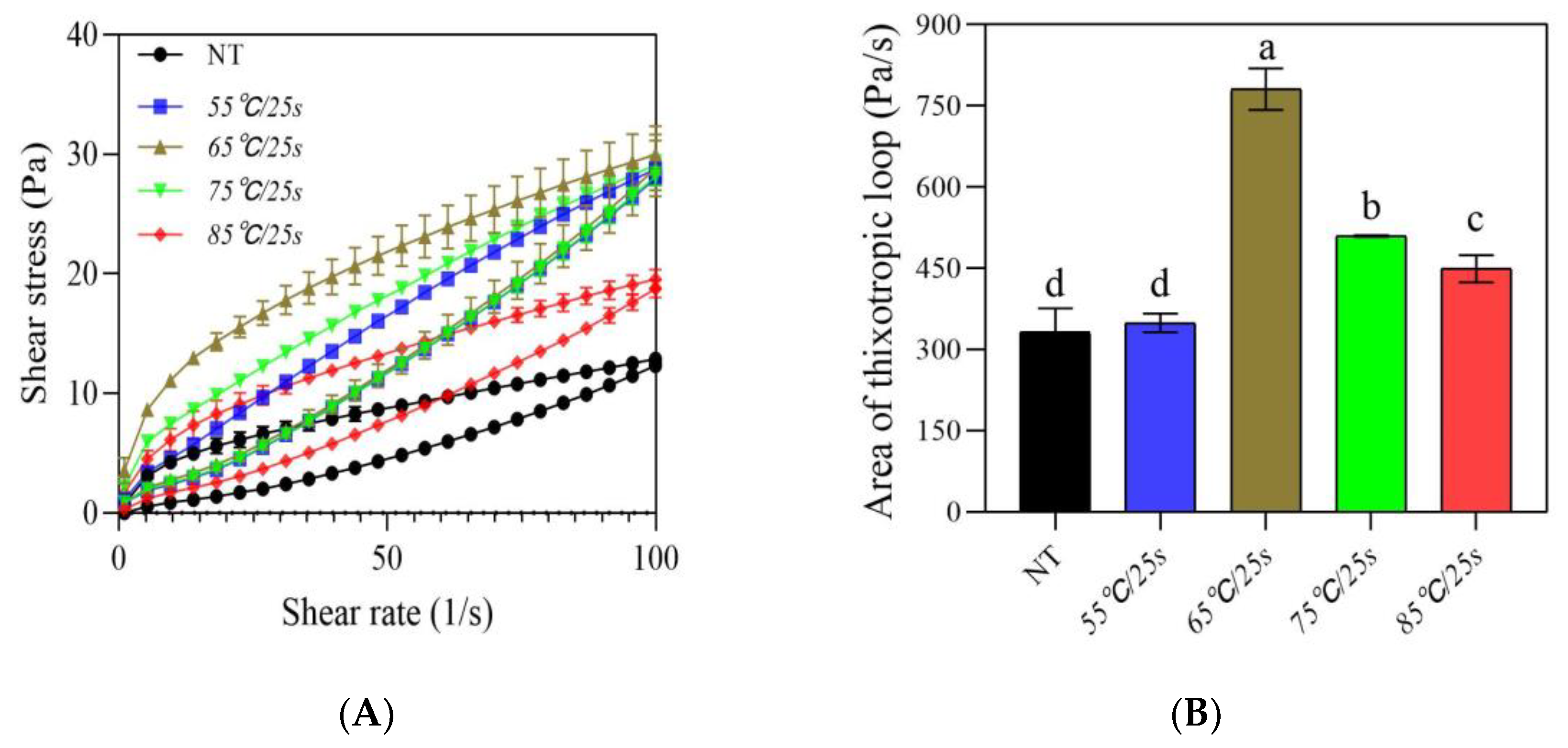

3.2.2. Thixotropic Properties

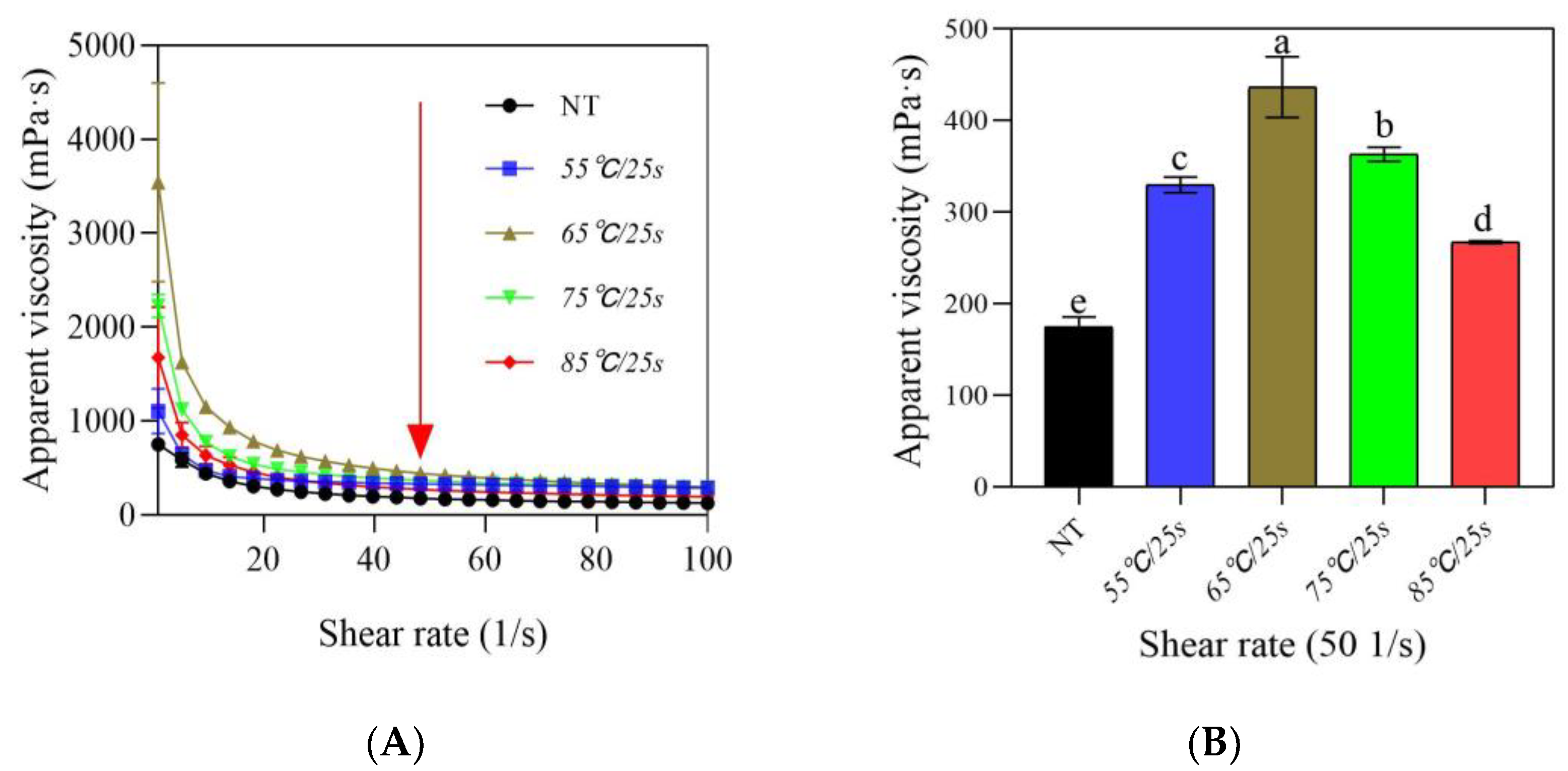

3.2.3. Apparent Viscosity

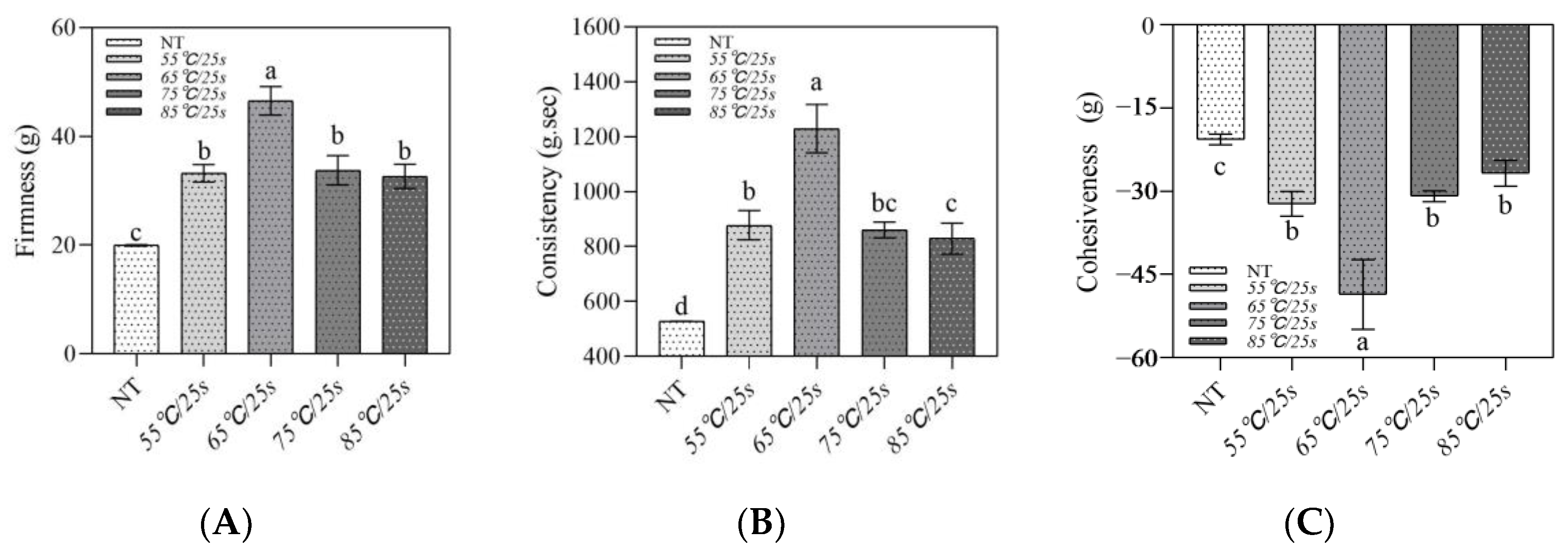

3.2.4. Texture Properties

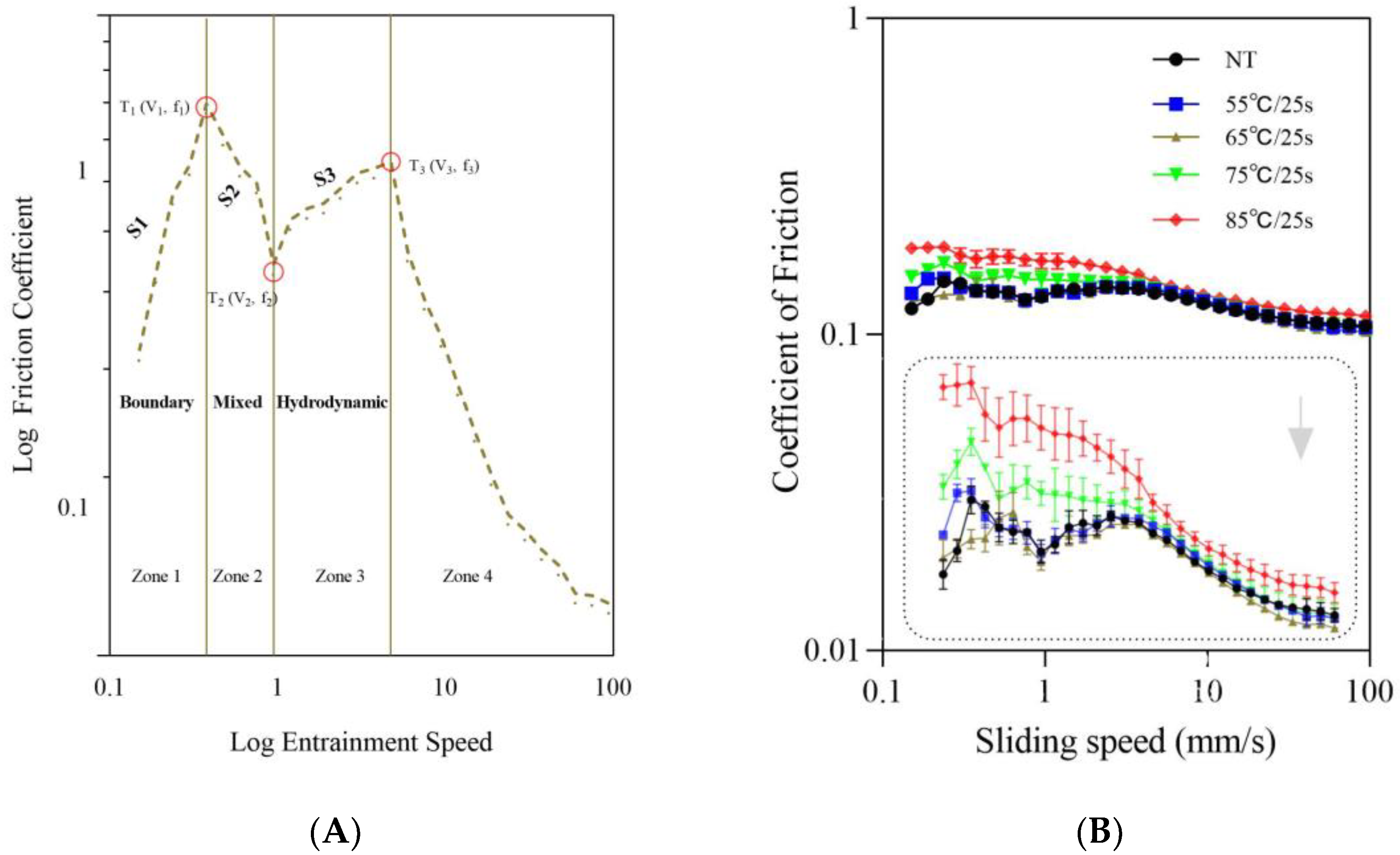

3.3. Tribology

3.4. Sensory Analysis

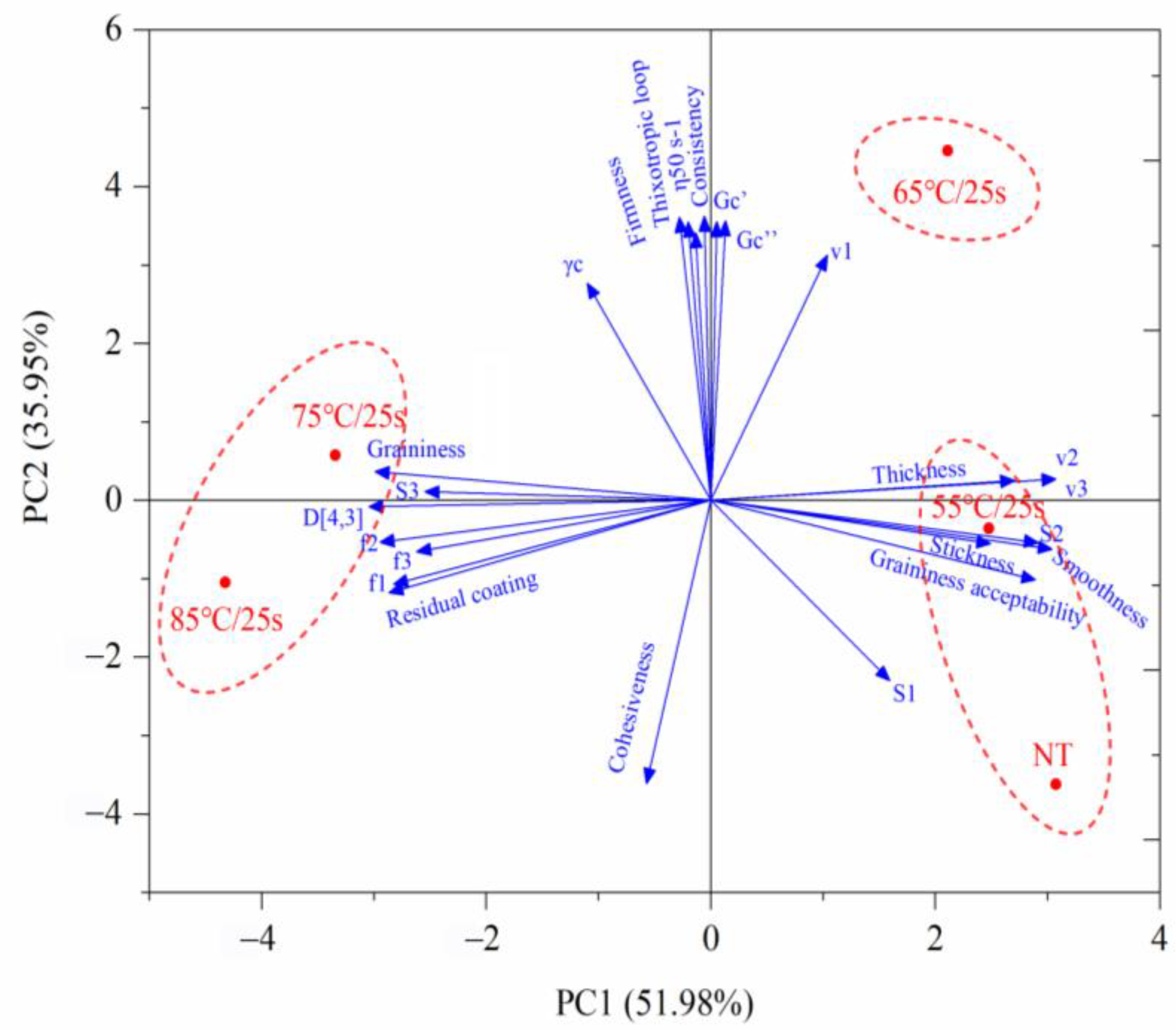

3.5. Correlation between the Instrumental Data and Sensory Properties of Post-Heating Stirred Fermented Milk

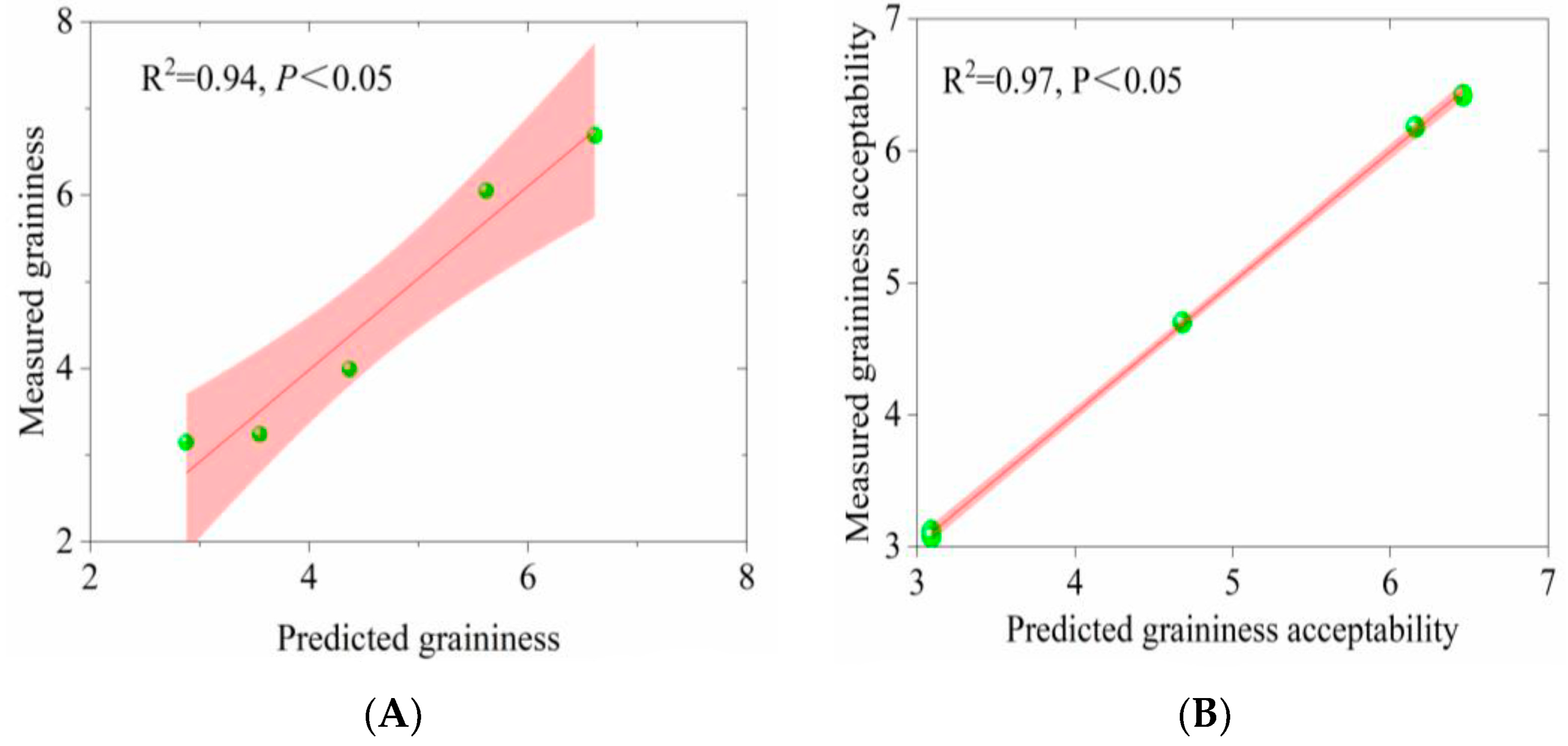

3.6. Regression Analysis of Graininess and Graininess Acceptability of Post-Heating Fermented Milk

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rohart, A.; Sieffermann, J.; Michon, C. Effect of micro-gel shape and concentration on sensory perception of micro-gels-enriched stirred yoghurts. Colloids Surf. 2015, 475, 94–102. [Google Scholar] [CrossRef]

- Xiangdong, L.; Jiaping, L.; Chengya, Q.; Lijuan, B. Post-sterilization technology to extended shelf-life in stirred yoghurt production. FFI 2008, 34, 146–151. [Google Scholar]

- Hahn, C.; Sramek, M.; Nöbel, S.; Hinrichs, J. Post-processing of concentrated fermented milk: Influence of temperature and holding time on the formation of particle clusters. Dairy Sci. Technol. 2012, 92, 91–107. [Google Scholar] [CrossRef]

- Hahn, C.; Wachter, T.; Nobel, S.; Weiss, J.; Eibel, H.; Hinrichs, J. Graininess in fresh cheese as affected by post-processing: Influence of tempering and mechanical treatment. Int. Dairy J. 2012, 26, 73–77. [Google Scholar] [CrossRef]

- Guénard-Lampron, V.; Bosc, V.; St-Gelais, D.; Villeneuve, S.; Turgeon, S.L. How do smoothing conditions and storage time change syneresis, rheological and microstructural properties of nonfat stirred acid milk gel? Int. Dairy J. 2020, 109, 104780. [Google Scholar] [CrossRef]

- Heck, A.J.; Schäfer, J.; Nöbel, S.; Hinrichs, J. Fat-free fermented concentrated milk products as milk protein-based microgel dispersions: Particle characteristics as key drivers of textural properties. Compr. Rev. Food Sci. Food Saf. 2021, 20, 6057–6088. [Google Scholar] [CrossRef]

- Schulz-Collins, D.; Senge, B. Acid-and acid/rennet-curd cheeses part A: Quark, cream cheese and related varieties. In Cheese: Chemistry, Physics and Microbiology, 3rd ed.; Fox, P., McSweeney, P., Cogan, T., Timothy, G., Eds.; Springer: Boston, MA, USA, 2004; pp. 301–328. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, X.; Pang, Z. Tribo-rheological properties of acid milk gels with different types of gelatin: Effect of concentration. J. Dairy Sci. 2019, 102, 7849–7862. [Google Scholar] [CrossRef]

- Bartoshuk, L.M.; Duffy, V.B.; Green, B.G.; Hoffman, H.J.; Ko, C.W.; Lucchina, L.A.; Marks, L.E.; Snyder, D.J.; Weiffenbach, J.M. Valid across-group comparisons with labeled scales: The gLMS versus magnitude matching. Physiol. Behav. 2004, 82, 109–114. [Google Scholar] [CrossRef]

- Mantilla, S.; Shewan, H.M.; Shingleton, R.; Stokes, J.R.; Smyth, H.E. Ability to detect and identify the presence of particles influences consumer acceptance of yoghurt. Food Qual. Prefer. 2020, 85, 103979. [Google Scholar] [CrossRef]

- Fidaleo, M.; Miele, N.A.; Mainardi, S.; Armini, V.; Nardi, R.; Cavella, S. Effect of refining degree on particle size, sensory and rheological characteristics of anhydrous paste for ice creams produced in industrial stirred ball mill. LWT-Food Sci. Technol. 2017, 79, 242–250. [Google Scholar] [CrossRef]

- Gilbert, A.; Rioux, L.; St-Gelais, D.; Turgeon, S.L. Smoothing temperature and ratio of casein to whey protein: Two tools to improve nonfat stirred yogurt properties. J. Dairy Sci. 2021, 104, 10485–10499. [Google Scholar] [CrossRef] [PubMed]

- Hahn, C.; Nobel, S.; Maisch, R.; Rosingh, W.; Weiss, J.; Hinrichs, J. Adjusting rheological properties of concentrated microgel suspensions by particle size distribution. Food Hydrocoll. 2015, 49, 183–191. [Google Scholar] [CrossRef]

- Gilbert, A.; Rioux, L.E.; St-Gelais, D.; Turgeon, S.L. Studying stirred yogurt microstructure using optical microscopy: How smoothing temperature and storage time affect microgel size related to syneresis. J. Dairy Sci. 2020, 103, 2139–2152. [Google Scholar] [CrossRef]

- Mokoonlall, A.; Nobel, S.; Hinrichs, J. Post-processing of fermented milk to stirred products: Reviewing the effects on gel structure. Trends Food Sci. Technol. 2016, 54, 26–36. [Google Scholar] [CrossRef]

- Guénard-Lampron, V.; Villeneuve, S.; St-Gelais, D.; Turgeon, S.L. Relationship between smoothing temperature, storage time, syneresis and rheological properties of stirred yogurt. Int. Dairy J. 2020, 109, 104–112. [Google Scholar] [CrossRef]

- Debon, J.; Prudêncio, E.S.; Petrus, J.C.C. Rheological and physico-chemical characterization of prebiotic microfiltered fermented milk. J. Food Eng. 2010, 99, 128–135. [Google Scholar] [CrossRef]

- Gregersen, S.B.; Glover, Z.J.; Wiking, L.; Simonsen, A.C.; Bertelsen, K.; Pedersen, B.; Poulsen, K.R.; Andersen, U.; Hammershøj, M. Microstructure and rheology of acid milk gels and stirred yoghurts-quantification of process-induced changes by auto- and cross correlation image analysis. Food Hydrocoll. 2021, 111, 106269. [Google Scholar] [CrossRef]

- Dibyakanta, S.; Niwas, M.H.; Chandra, D.S. Effect of hydrocolloids on the physico-chemical and rheological properties of reconstituted sweetened yoghurt powder. J. Sci. Food Agric. 2018, 98, 1696–1702. [Google Scholar] [CrossRef]

- Grasso, N.; Alonso-Miravalles, L.; O’Mahony, J.A. Composition, Physicochemical and Sensorial Properties of Commercial Plant-Based Yogurts. Foods 2020, 9, 252. [Google Scholar] [CrossRef]

- Magenis, R.B.; Prudêncio, E.S.; Amboni, R.D.M.C.; Júnior, N.G.C.; Oliveira, R.V.B.; Soldi, V.; Benedet, H.D. Compositional and physical properties of yogurts manufactured from milk and whey cheese concentrated by ultrafiltration. Int. J. Food Sci. Technol. 2006, 41, 560–568. [Google Scholar] [CrossRef]

- Miocinovic, J.; Miloradovic, Z.; Josipovic, M.; Nedeljkovic, A.; Radovanovic, M.; Pudja, P. Rheological and textural properties of goat and cow milk set type yoghurts. Int. Dairy J. 2016, 58, 43–45. [Google Scholar] [CrossRef]

- Huang, T.; Tu, Z.; Shangguan, X.; Wang, H.; Zhang, L.; Bansal, N. Characteristics of fish gelatin-anionic polysaccharide complexes and their applications in yoghurt: Rheology and tribology. Food Chem. 2021, 343, 128413. [Google Scholar] [CrossRef]

- Gilbert, A.; Turgeon, S.L. Studying stirred yogurt microstructure and its correlation to physical properties: A review. Food Hydrocoll. 2021, 121, 106970. [Google Scholar] [CrossRef]

- Saleh, A.; Mohamed, A.A.; Alamri, M.S.; Hussain, S.; Qasem, A.A.; Ibraheem, M.A. Effect of Different Starches on the Rheological, Sensory and Storage Attributes of Non-fat Set Yogurt. Foods 2020, 9, 61. [Google Scholar] [CrossRef] [PubMed]

- Divyang, M.; Prajapati; Shrigod, N.M. Textural and Rheological Properties of Yoghurt: A Review. Adv. Life Sci. 2016, 5, 5238–5254. [Google Scholar] [CrossRef]

- Nguyen, P.T.M.; Kravchuk, O.; Bhandari, B.; Prakash, S. Effect of different hydrocolloids on texture, rheology, tribology and sensory perception of texture and mouthfeel of low-fat pot-set yoghurt. Food Hydrocoll. 2017, 72, 90–104. [Google Scholar] [CrossRef]

- Skarlatos, L.; Marinopoulou, A.; Petridis, D.; Raphaelides, S. Texture assessment of set yoghurt using sensory and instrumental methods. Int. Dairy J. 2020, 104, 104644. [Google Scholar] [CrossRef]

- Krzeminski, A.; Tomaschunas, M.; Köhn, E.; Busch-Stockfisch, M.; Weiss, J.; Hinrichs, J. Relating Creamy Perception of Whey Protein Enriched Yogurt Systems to Instrumental Data by Means of Multivariate Data Analysis. J. Food Sci. 2013, 78, 314–319. [Google Scholar] [CrossRef]

- Nguyen, P.T.M.; Bhandari, B.; Prakash, S. Tribological method to measure lubricating properties of dairy products. J. Food Eng. 2016, 168, 27–34. [Google Scholar] [CrossRef]

| D[10] (μm) | D[50] (μm) | D[90] (μm) | D[4,3] (μm) | |

|---|---|---|---|---|

| NT | 7.30 ± 0.13 e | 13.63 ± 0.21 e | 24.98 ± 0.52 e | 15.02 ± 0.20 e |

| 55 °C/25 s | 8.83 ± 0.01 d | 17.72 ± 0.04 d | 38.65 ± 0.30 d | 21.27 ± 0.16 d |

| 65 °C/25 s | 10.52 ± 0.04 c | 25.04 ± 0.18 c | 61.20 ± 0.94 c | 31.08 ± 0.36 c |

| 75 °C/25 s | 14.73 ± 0.15 b | 41.05 ± 0.58 b | 87.30 ± 1.46 b | 46.60 ± 0.58 b |

| 85 °C/25 s | 16.40 ± 0.32 a | 55.87 ± 1.60 a | 122.17 ± 3.31 a | 63.23 ± 1.82 a |

| Tribological Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| v1 | f1 | v2 | f2 | v3 | f3 | S1 | S2 | S3 | |

| NT | 0.24 | 0.15 ± 0.01 | 0.75 | 0.13 ± 0.00 | 2.37 | 0.14 ± 0.00 | 0.31 ± 0.08 | −0.03 ± 0.01 | 0.01 ± 0.00 |

| 55 °C/25 s | 0.24 | 0.15 ± 0.01 | 0.75 | 0.13 ± 0.00 | 2.37 | 0.14 ± 0.00 | 0.17 ± 0.04 | −0.03 ± 0.01 | 0.01 ± 0.00 |

| 65 °C/25 s | 0.47 | 0.14 ± 0.00 | 0.75 | 0.13 ± 0.01 | 2.37 | 0.14 ± 0.00 | 0.07 ± 0.01 | −0.06 ± 0.02 | 0.01 ± 0.00 |

| 75 °C/25 s | 0.24 | 0.17 ± 0.00 | 0.38 | 0.15 ± 0.00 | 0.60 | 0.15 ± 0.00 | 0.18 ± 0.05 | −0.17 ± 0.03 | 0.06 ± 0.01 |

| 85 °C/25 s | 0.24 | 0.19 ± 0.01 | 0.38 | 0.17 ± 0.01 | 0.60 | 0.18 ± 0.01 | 0.03 ± 0.01 | −0.13 ± 0.03 | 0.03 ± 0.01 |

| Quantitative Descriptive Analysis (QDA) | Consumer Preference Analysis (CPA) | |||||

|---|---|---|---|---|---|---|

| Trained Panelists (n = 10) | Consumers (n = 50) | |||||

| Groups | Thickness | Smoothness | Graininess | Stickiness | Residual Coating | Graininess Acceptability |

| NT | 6.14 ± 0.17 a | 7.35 ± 0.71 a | 3.15 ± 0.58 d | 5.59 ± 0.18 a | 4.50 ± 0.33 b | 6.18 ± 1.39 a |

| 55 °C/25 s | 5.93 ± 0.22 ab | 7.03 ± 0.33 a | 3.24 ± 0.40 d | 5.87 ± 0.10 a | 4.69 ± 0.28 ab | 6.42 ± 1.43 a |

| 65 °C/25 s | 6.15 ± 0.23 a | 5.69 ± 0.58 b | 3.99 ± 0.45 c | 5.50 ± 0.13 a | 4.36 ± 0.29 b | 4.70 ± 1.48 b |

| 75 °C/25 s | 5.57 ± 0.33 b | 3.18 ± 0.32 c | 6.05 ± 0.31 b | 5.10 ± 0.54 b | 4.96 ± 0.29 a | 3.12 ± 1.56 c |

| 85 °C/25 s | 5.75 ± 0.31 ab | 2.39 ± 0.33 d | 6.69 ± 0.22 a | 5.33 ± 0.28 b | 5.15 ± 0.33 a | 3.08 ± 1.10 c |

| Attributes | Axis1 | Axis2 |

|---|---|---|

| Instrumental | ||

| Thixotropic loop | −0.07 | 0.96 |

| η50 s-1 | −0.04 | 0.93 |

| γc | −0.35 | 0.75 |

| Gc′ | 0.02 | 0.96 |

| Gc″ | 0.04 | 0.97 |

| Firmness | −0.09 | 0.98 |

| Consistency | −0.02 | 0.98 |

| Cohesiveness | −0.18 | −0.98 |

| D[4,3] | −0.98 | −0.02 |

| v1 | 0.33 | 0.85 |

| f1 | −0.91 | −0.29 |

| v2 | 0.99 | 0.07 |

| f2 | −0.95 | −0.15 |

| v3 | 0.99 | 0.07 |

| f3 | −0.84 | −0.18 |

| S1 | 0.51 | −0.62 |

| S2 | 0.94 | −0.15 |

| S3 | −0.82 | 0.03 |

| Sensory | ||

| Thickness | 0.87 | 0.07 |

| Smoothness | 0.98 | −0.17 |

| Graininess | −0.96 | 0.10 |

| Stickiness | 0.80 | −0.15 |

| Residual coating | −0.92 | −0.32 |

| Graininess acceptability | 0.93 | −0.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, F.; Li, D.; Li, H.; Chen, H.; Mao, X.; Wang, P. Influence of Post-Heating Treatment on the Sensory and Textural Properties of Stirred Fermented Milk. Foods 2023, 12, 3042. https://doi.org/10.3390/foods12163042

Gao F, Li D, Li H, Chen H, Mao X, Wang P. Influence of Post-Heating Treatment on the Sensory and Textural Properties of Stirred Fermented Milk. Foods. 2023; 12(16):3042. https://doi.org/10.3390/foods12163042

Chicago/Turabian StyleGao, Fei, Dongdong Li, Hongliang Li, Han Chen, Xueying Mao, and Pengjie Wang. 2023. "Influence of Post-Heating Treatment on the Sensory and Textural Properties of Stirred Fermented Milk" Foods 12, no. 16: 3042. https://doi.org/10.3390/foods12163042

APA StyleGao, F., Li, D., Li, H., Chen, H., Mao, X., & Wang, P. (2023). Influence of Post-Heating Treatment on the Sensory and Textural Properties of Stirred Fermented Milk. Foods, 12(16), 3042. https://doi.org/10.3390/foods12163042